Power battery thermal management method and system based on phase change material

A technology for power batteries and phase change materials, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of complex pipeline layout, difficult system maintenance, liquid leakage, etc., to achieve simple system structure, avoid local high temperature, meet the The effect of using conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

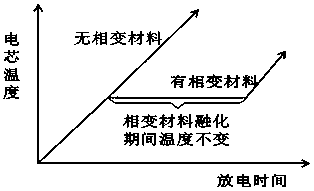

[0026] figure 1 It is a schematic diagram of battery temperature change with or without phase change material. With phase change material, the battery can maintain a constant temperature for a period of time, so that the temperature of the battery is in a linear and steady rise process, and the service life of the battery 4 is extended.

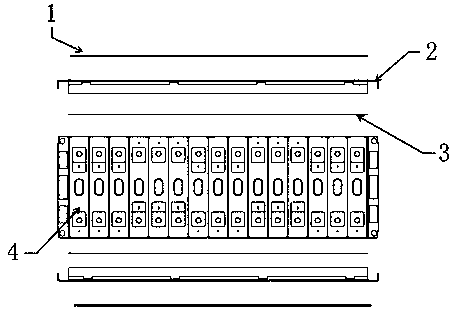

[0027] Such as figure 2 As shown, a power battery thermal management system based on phase change materials includes a heat-conducting fixing bracket 2, a PCM heat sink 3, and a PTC heating plate 1. The heat-conducting fixing bracket 2 is arranged outside the battery core 4, and the PCM heat sink 3 is surrounded by the battery core 4 and embedded inside the heat-conducting fixing bracket 2, and the PTC heating plate 1 is arranged outside the heat-conducting fixing bracket 2.

[0028] The PCM heat sink 3 is a graphite / paraffin composite PCM heat sink. The thermally conductive fixing bracket 2 is an aluminum bracket.

[0029] The entire power batter...

Embodiment 2

[0032] The system of the foregoing embodiment 1 can implement a phase change material-based power battery thermal management method, which is specifically as follows:

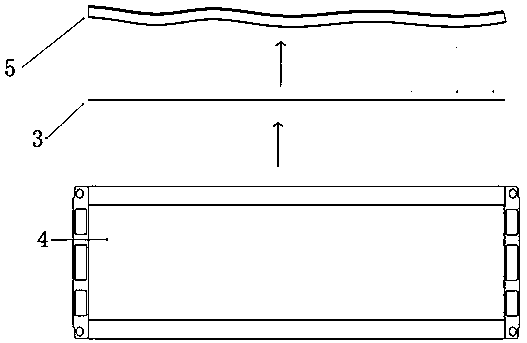

[0033] The cell 4 of the power battery is surrounded by the PCM heat sink 3. The thermal management method includes a heat dissipation phase and a heating phase. In the heat dissipation phase, when the temperature of the cell 4 reaches 35°C, the PCM heat sink 3 absorbs the heat generated when the cell 4 is discharged And change the form to reduce the temperature of the power battery;

[0034] During the heating phase, when the temperature of the cell 4 is lower than 35°C, the PCM heat sink 3 conducts the stored heat to the cell 4 to maintain the constant temperature state of the cell 4. The heating phase is as follows: Figure 4 Shown.

[0035] That is, when the temperature of the cell 4 is higher than 35°C, the phase change material absorbs the heat of the cell 4 for storage, and reduces the temperature of the cell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com