Stirling heat engine solar heat collector

A technology of solar heat collectors and heat engines, which is applied to solar heat collectors, solar heat collectors using working fluids, and solar thermal energy, etc., which can solve the problems of short service life, uneven heating on the surface of solar heat collectors, and inability to heat uniformly Stable transmission to heat exchange tubes and other issues, to achieve long service life, stable work, and reduce heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

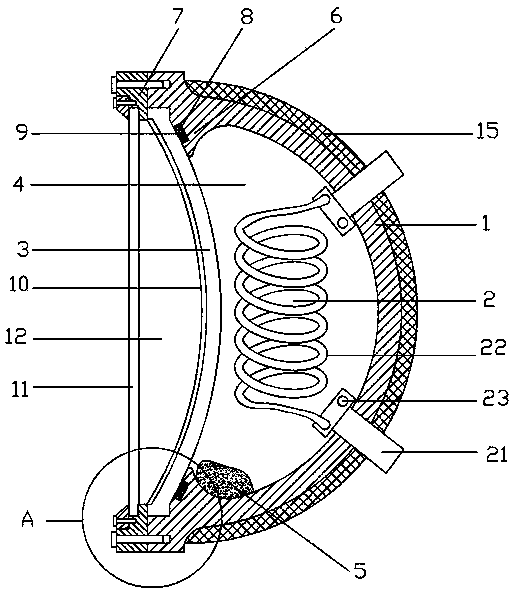

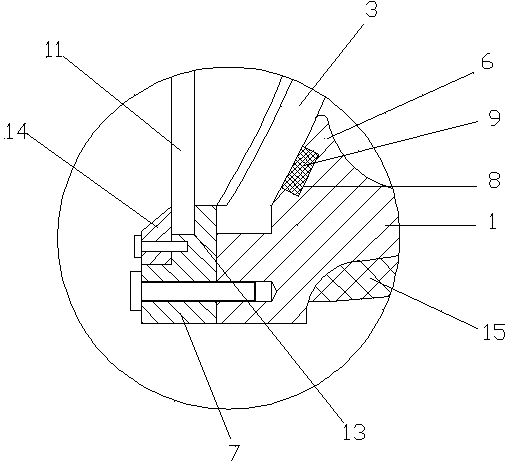

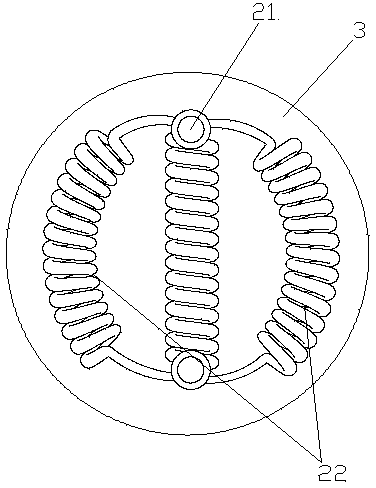

[0021] Such as figure 1 A Stirling heat engine solar collector shown includes a heat collecting cover 1 and a heat exchange tube 2 arranged in the heat collecting cover. In this embodiment, a heat collecting plate 3 is provided at the open end of the heat collecting cover. The heat collecting cover 1 is a hemisphere, the heat collecting plate 3 is a spherical plate, the heat collecting plate 3 is made of cermet, and its outer surface is provided with a high temperature resistant coating 10, the high temperature resistant coating is an alumina coating, and the heat collecting plate The outer convex surface of 3 faces the bottom of the heat collecting cover 1, and a closed heat collecting chamber 4 is formed between the heat collecting plate and the heat collecting cover. The heat collecting chamber 4 is provided with metal sodium 5, and the heat c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com