Photovoltaic module junction box with high heat dissipation performance

A technology of photovoltaic modules and heat dissipation performance, applied in the field of solar photovoltaic, can solve the problems of small allowable current, thermal deformation of junction box, affecting service life, etc., to achieve the effect of ensuring service life, avoiding local high temperature, and efficient heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

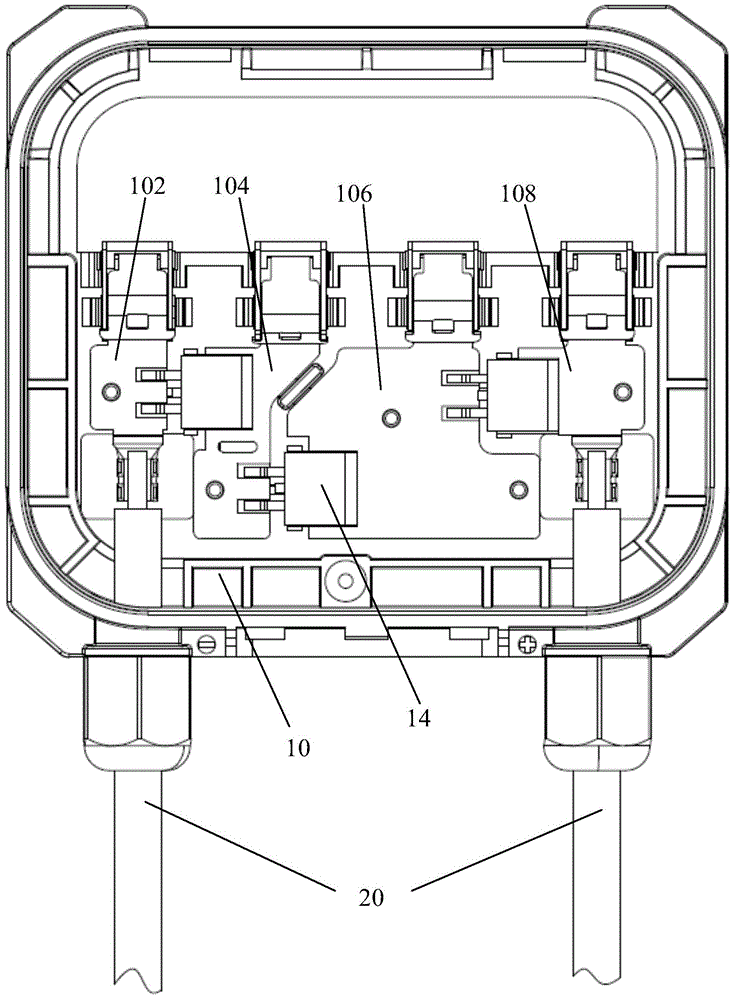

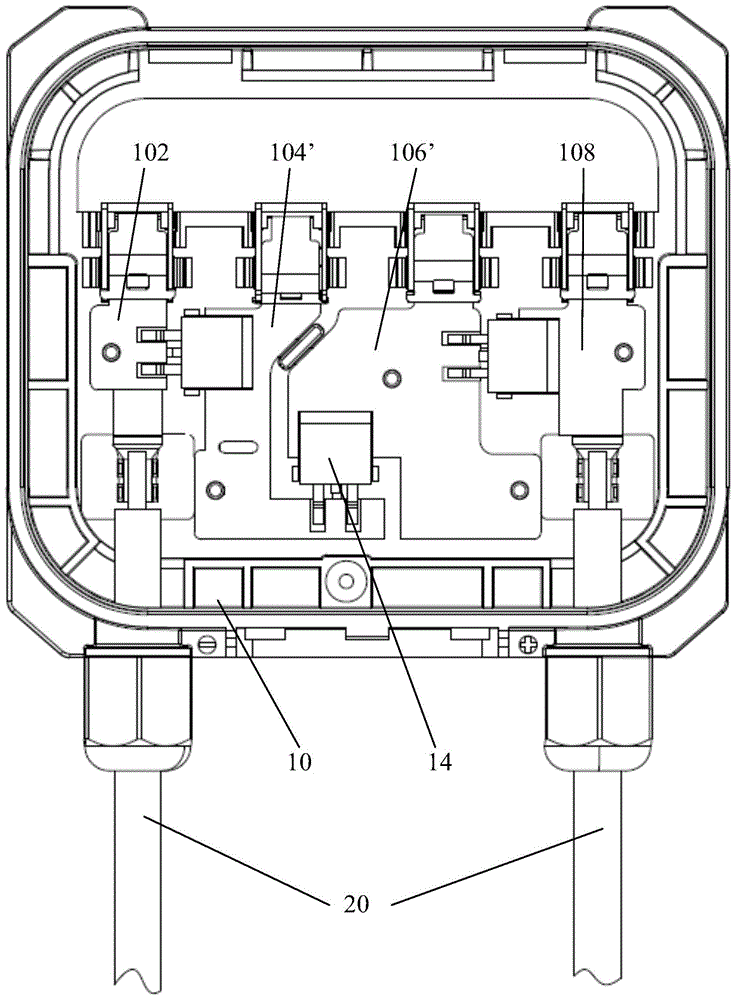

[0013] Feature and advantage of the present invention are described in detail as follows in conjunction with accompanying drawing:

[0014] like figure 1 Shown is a schematic structural diagram of a photovoltaic module junction box with efficient heat dissipation performance according to an embodiment of the present invention. A plurality of connecting terminals connected by strips, including a first connecting terminal 102, a second connecting terminal 104, a third connecting terminal 106 and a fourth connecting terminal 108, and stickers are arranged on the second connecting terminal 104 to the fourth connecting terminal 108. Chip diodes 14, the diodes 14 are respectively electrically connected to the adjacent connection terminals and maintain the same polarity after connection, wherein the plane area ratio of the second connection terminal 104 and the third connection terminal 106 arranged in the middle of the junction box is The plane area of the first connection termin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com