Reactor capable of reducing back mixing for preparing alkenes by dehydrogenation of alkanes and preparation method

An alkane dehydrogenation and reactor technology, which is applied in the field of alkane dehydrogenation reaction devices and circulating fluidized bed alkane dehydrogenation reaction devices, can solve the problems of complex reaction regeneration system, avoid thermal reaction, reduce secondary conversion, The effect of increasing selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] The preparation method of alkane dehydrogenation to olefins by using the above-mentioned reaction device for alkane dehydrogenation to olefins includes the following steps, the raw material enters the reaction section from the feed distributor, the raw material and the catalyst flow upwards in parallel, and the two contact to carry out the catalytic reaction, Among them, at the section where the reaction section and the lower end of the reactor settling section are on the same horizontal plane, the average linear velocity of the gas is controlled at 0.3-10.0m / s, the reaction temperature is preferably controlled between 500-650°C, and the mass space time of the reaction is 0.1~15h.

[0066] On the other hand, in the reaction section, the average linear velocity of the gas at the outlet cross section of the catalyst riser is controlled at 0.01-3 m / s, preferably 0.2-0.7 m / s. In the reduced-diameter reaction section, the linear velocity of the gas in the reaction section wi...

Embodiment 1

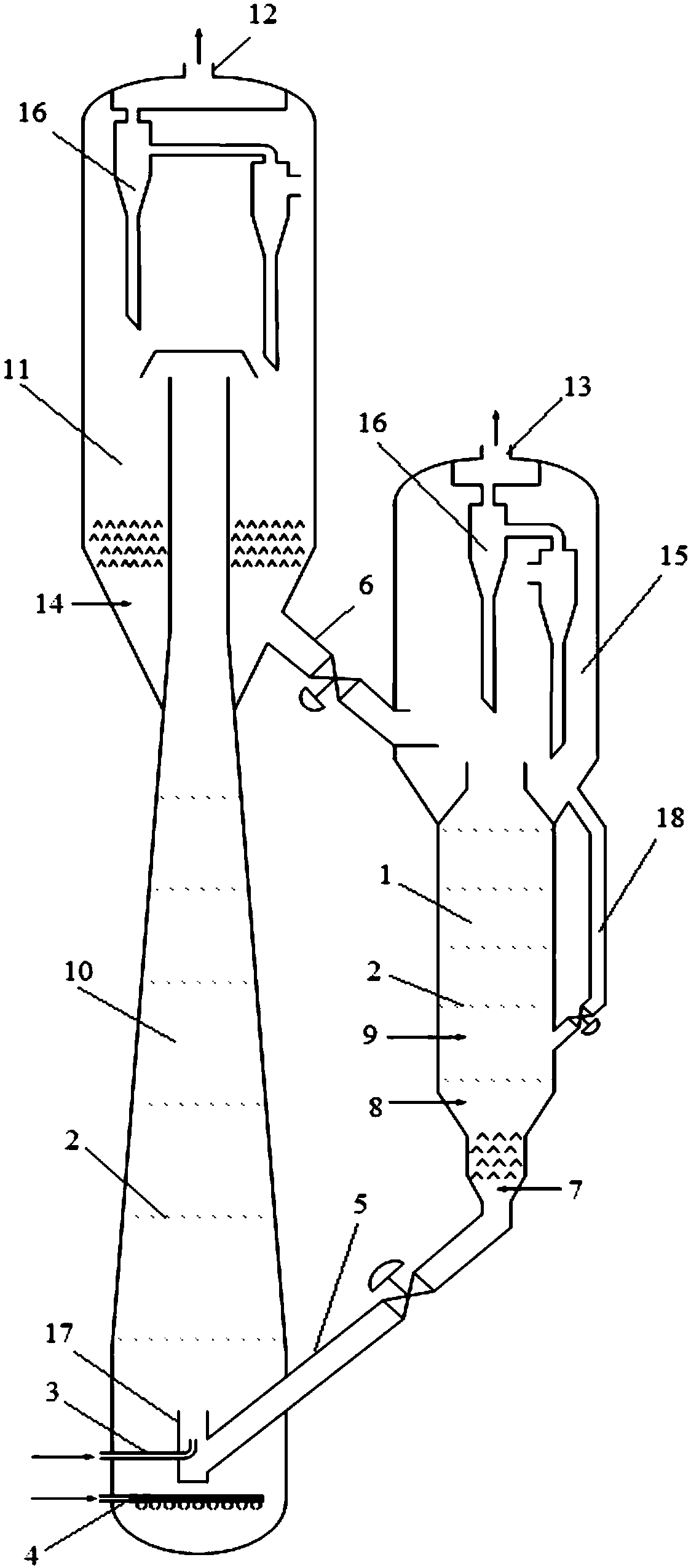

[0098] This embodiment refers to the attached figure 1 , 2 As shown, the reaction device for the catalytic dehydrogenation of alkanes provided in this application is used in combination with the catalyst regeneration device provided in this application. These two sets of devices can be used separately, and respectively used in combination with other reaction devices or catalyst regeneration devices in the prior art.

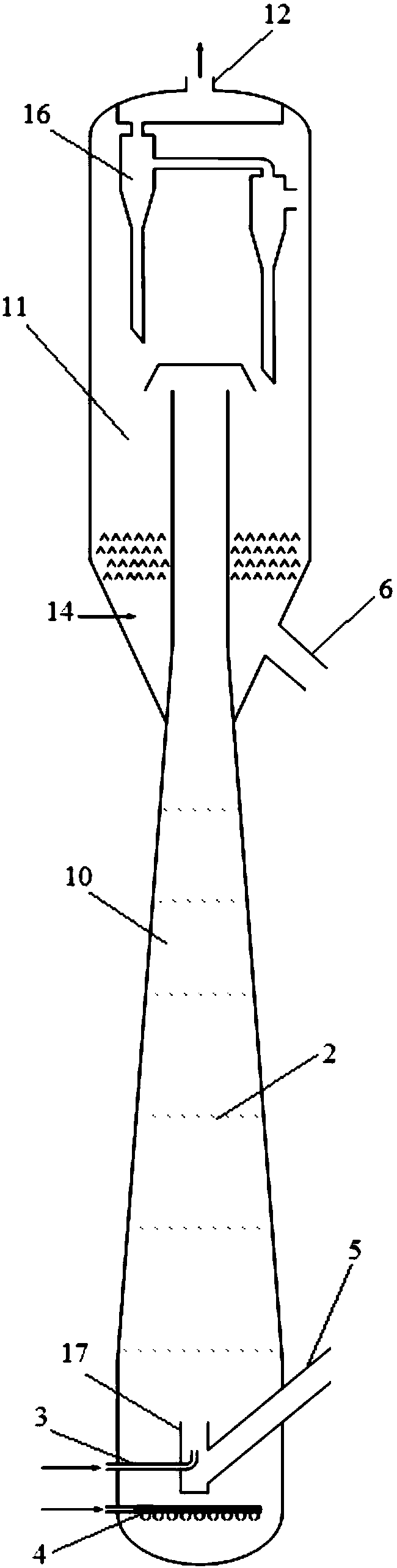

[0099] attached figure 1 The reaction device for the catalytic dehydrogenation of alkane comprises a reaction section 10 and a reactor settling section 11, the reactor settling section 11 is located at the top of the reaction section 10, and the diameter of the cross section of the reaction section 10 gradually decreases from bottom to top, and the catalyst is regenerated The inclined pipe 5 extends into the reaction section 10 , and the outlet end of the catalyst regeneration inclined pipe 5 is located at the lower part of the reaction section 10 . In this em...

Embodiment 2

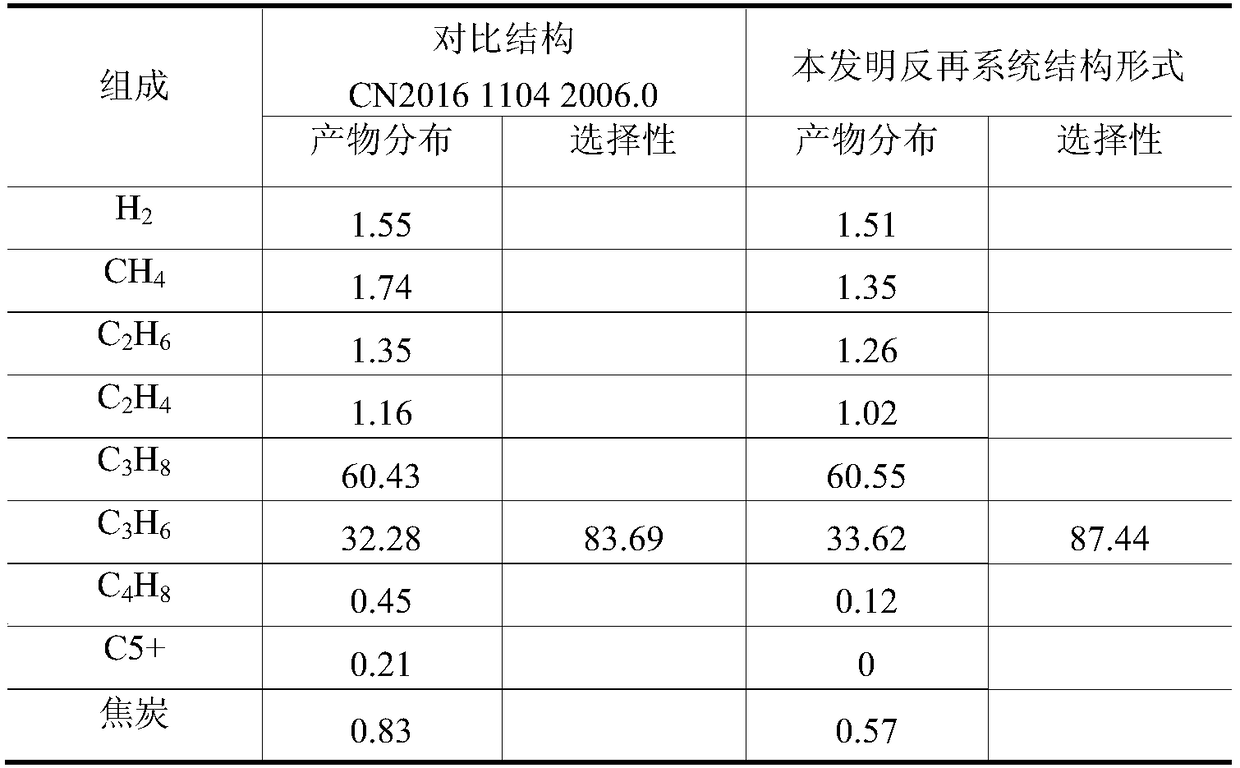

[0111] Propane dehydrogenation produces propylene, adopts the equipment of embodiment 1 of the present invention

[0112] Raw material: 99wt% propane, feed rate 0.6t / h

[0113] Catalyst: Environmentally friendly metal oxide catalyst ADHO-1 (ZL 201110123675.1)

[0114] Reaction conditions: set a layer of grids every 0.5m in the catalyst bed in the reaction section; the average temperature of the bed, 600°C; the pressure of the settler, 0.03MPa; the mass empty time, 3h; the average gas line of the outlet section of the riser in the reaction section Velocity, 0.5m / s; at the section where the bottom of the settling section of the reactor is connected to the reactor, the average linear velocity of the gas is 2m / s.

[0115] Regeneration conditions: a layer of grids can be set every 0.5m in the dense phase section of the regenerator; the temperature of the dense phase section of the regenerator is 700°C.

[0116] Structural form of the reaction-regeneration system: the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com