Patents

Literature

60results about How to "Reduce local high temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spliting arranging method for new three area burner of tangential circle boiler

InactiveCN1786564AEmission reductionBurnout has little effectCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCoal dustEngineering

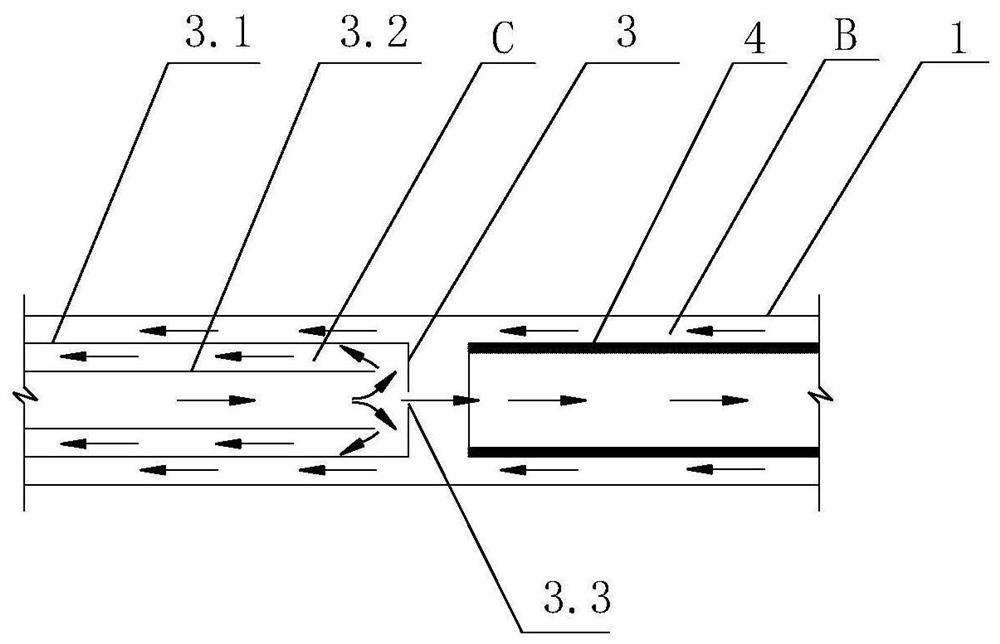

The invention discloses tangential firing boiler new three zones burner split arrangement type. The includes the following steps: dividing combustion process into three zones that stable combustion zone, combustion and reducing zone, and full combustion zone by gas coal type arrangement plus once wind centralizing arrangement plus fission OFA plus top OFA arrangement type; complementing combustion air in time by fission OFA arrangement; the deep hypoxia cryogenic combustion of the initial stage coal dust air flow and the deep fuel of the combustion and reducing zone are fractional combustion. This successfully solves the abuse that the current low NOx combustion technique denitrifying effect is bad. Secondary burn-out wind complementing type can greatly reduce the influence of the new three zones burner fission arrangement type on the combustion efficiency. Thus this can successfully solves the problem of taking account of the current NOx combustion technique and the combustion efficiency at the same time. It is the burner arrangement type with better denitrifying effect.

Owner:XIAN THERMAL POWER RES INST CO LTD

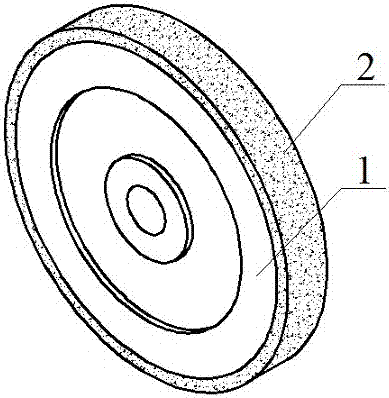

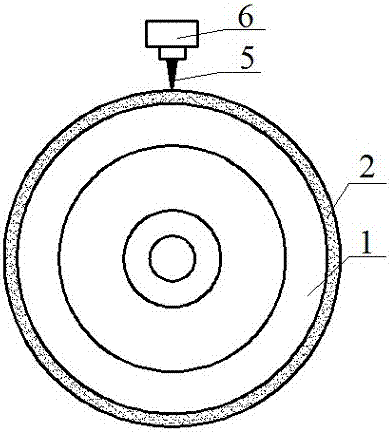

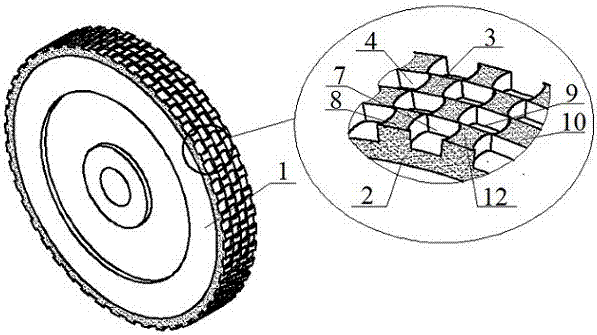

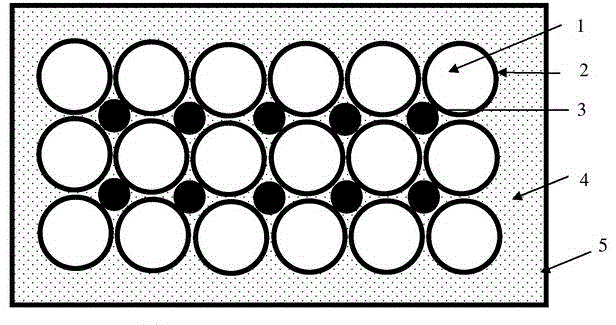

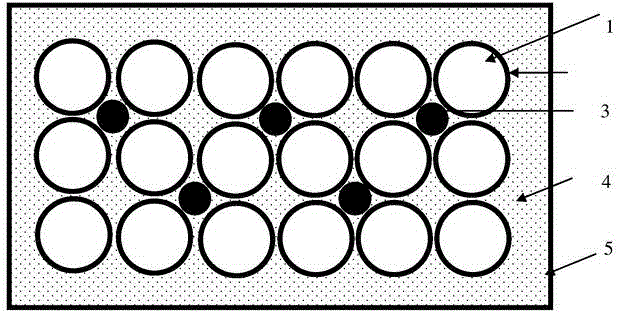

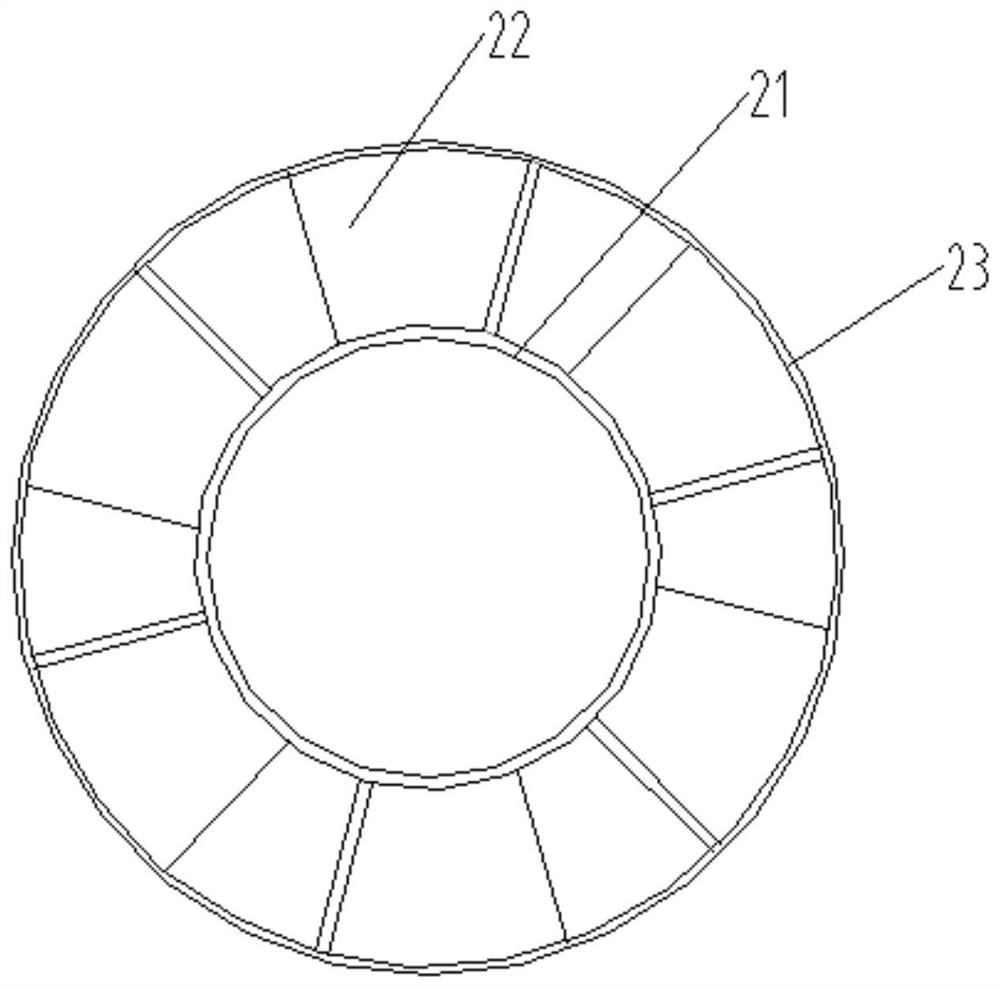

CVD diamond grinding wheel with ordered micro-structured surface and making method thereof

ActiveCN107962510AIncrease the number of effective sharpeningImprove surface qualityBonded abrasive wheelsGrinding devicesMaterial removalGas phase

The invention discloses a CVD diamond grinding wheel with an ordered micro-structured surface and a making method thereof. The grinding wheel is characterized in that a layer of diamond film is deposited on the outer circumferential face of a grinding wheel hub, a large number of staggered in-order micro grinding units are machined on the whole outer circumferential face of the diamond film, and the top ends of the grinding units are in kidney shapes. The making method is characterized in that through the chemical vapor deposition that is CVD, the diamond film is deposited on the outer circumference face of the grinding wheel hub, a pulse laser beam is adopted to machine the large number of micro grooves with the same geometric dimensioning in the outer circumference face of the whole diamond film, and the large number of micro grinding units are formed; the grinding units are arranged in a staggered and in-order manner, the top face of each grinding unit is in a kidney shape, according to the grinding wheel, the effective sharpening number of the grinding wheel during grinding can be improved, the chip formation efficiency and the surface material removal rate are improved, the cutting performance is improved, the surface machining quality and the cutting efficiency can be improved, the holding force of the grinding wheel hub to the grinding units can be increased, and the service life of the grinding wheel can be obviously prolonged.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

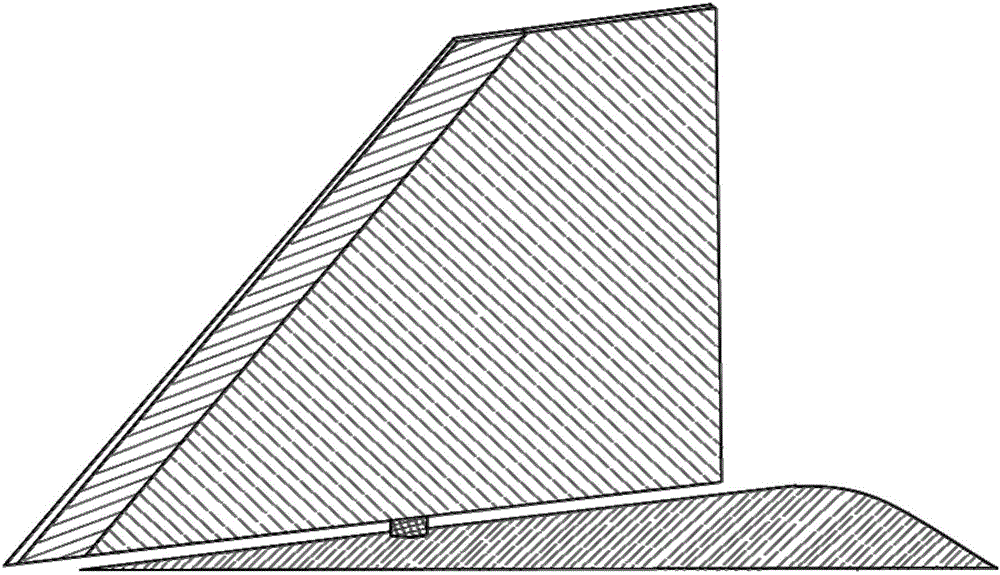

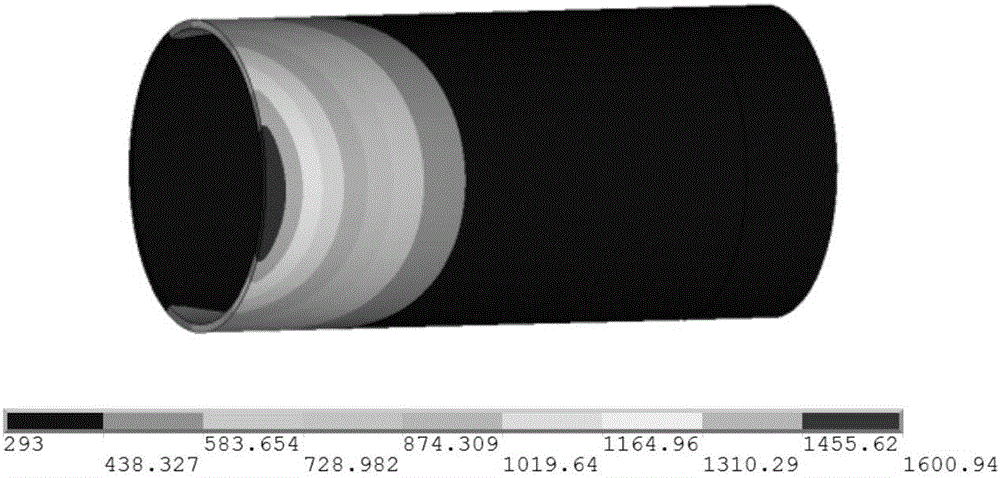

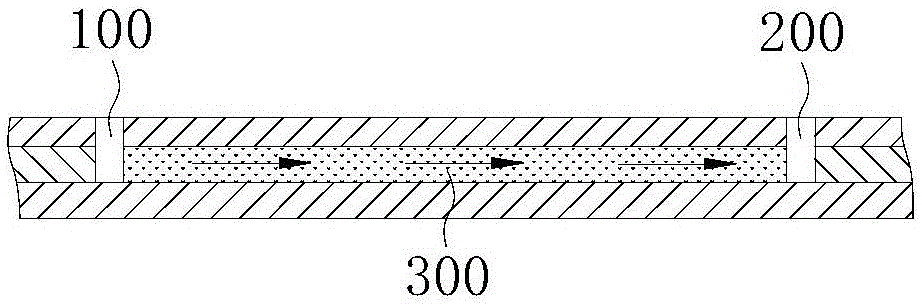

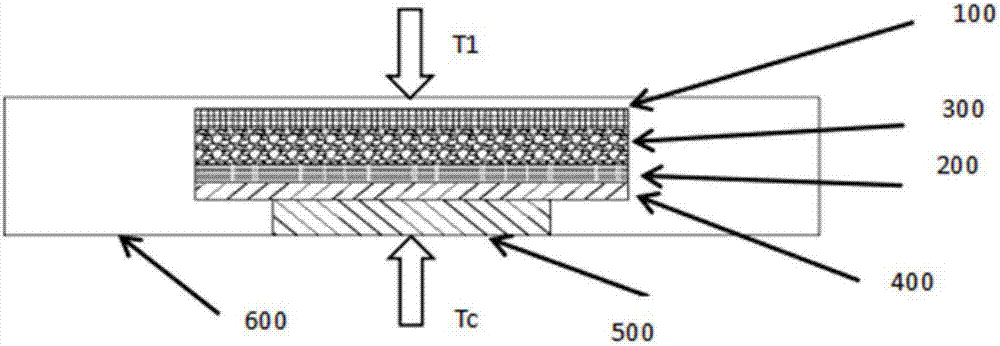

Hypersonic aircraft dredging-type rudderpost heat protection structure

ActiveCN106809375AIsothermalizationImprove thermal stress distributionAircraft controlGround installationsInsulation layerEngineering

The invention relates to a hypersonic aircraft dredging-type rudderpost heat protection structure. The rudderpost is designed as a hollow structure, the upper surface of the hollow cavity is positioned above the rudderpost mounting gap and is isolated from the control surface through a heat-insulation layer, and the lower surface is positioned inside the aircraft body and is isolated from the control actuator through a phase-change material or heat sink. The side wall of the hollow cavity is provided with a channel which is parallel to the rudderpost bus, a capillary core is welded with the surface of the channel, the hollow cavity is filled with a working medium, and the heat quantity of aerodynamic heating at the rudderpost gap is dredged to the inner wall of the whole hollow cavity through the phase change and dispersion of the working medium in the hollow cavity. The part of the rudderpost inside the aircraft body and the external surface of the control surface part are respectively provided with a heat-insulation layer.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

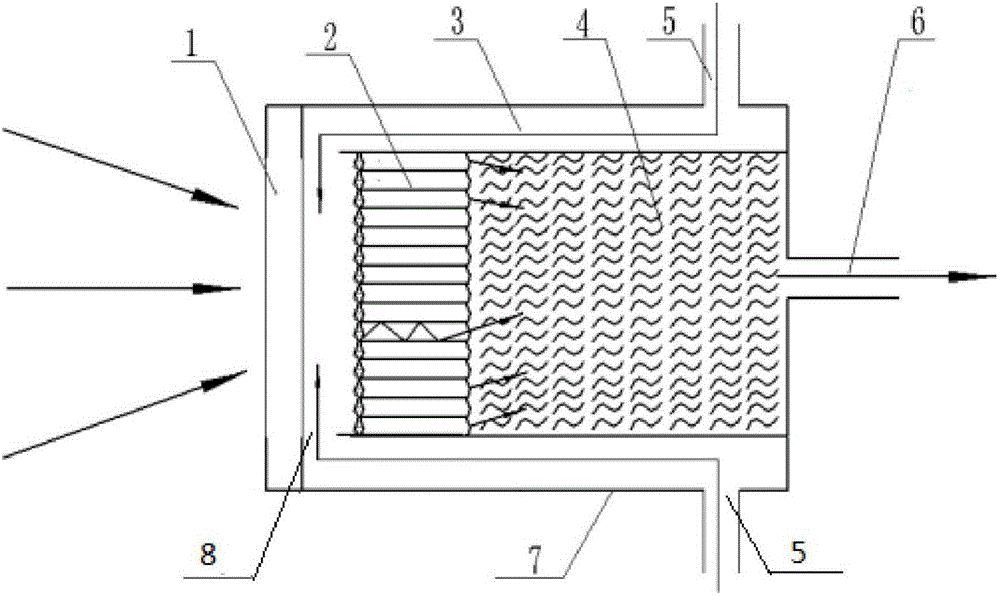

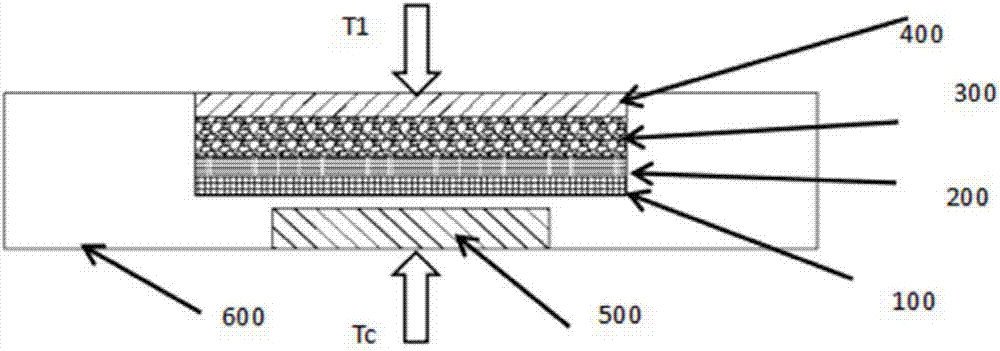

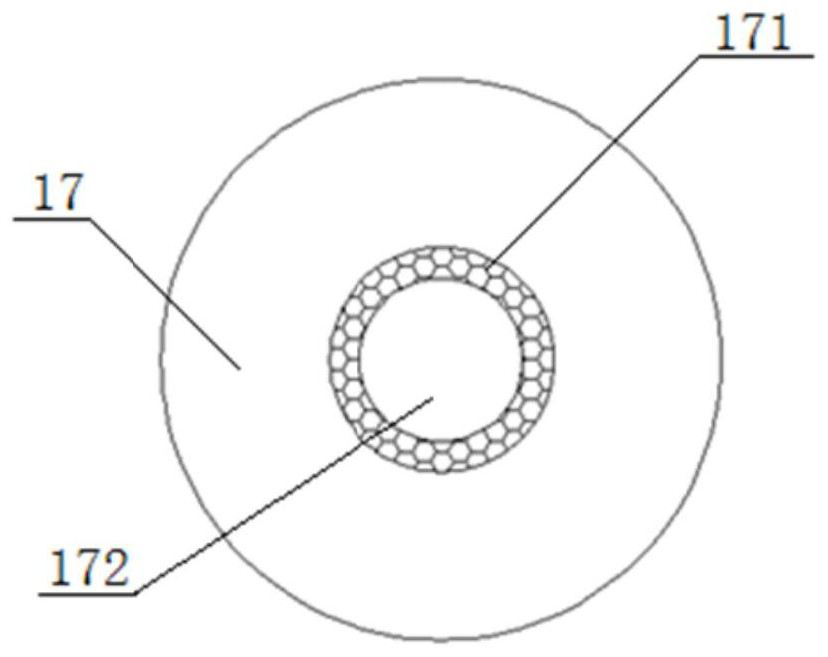

Glass tube bundle and porous medium composite structure solar absorber

InactiveCN106440418AEfficient Transmission ConversionIncrease the areaSolar heating energyHeat transfer optimizationPorous mediumSolar absorber

The invention discloses a glass tube bundle and porous medium composite structure solar absorber which comprises a solar absorber shell, wherein a quartz glass window is formed in one end of the solar absorber shell, and a medium outlet is formed in the other end of the solar absorber shell; the solar absorber shell and the quartz glass window are connected into a whole, and a cavity is formed between the solar absorber shell and the quartz glass window; glass tube bundles and porous media are sequentially arranged inside the cavity along the solar incident direction; a preheating channel is formed among the solar absorber shell, the glass tube bundles and the porous media; a first medium inlet is formed in one end of the preheating channel; and after preheated in the preheating channel, the media converge sunlight at the second medium inlet so as to enter the glass tube bundles. Because the glass tube bundles are small in solar absorption and small in external radiation energy, the thermal efficiency of the system is improved. Meanwhile, the incident sunlight is transmitted to the porous medium by the glass tube bundles, so that medium distribution is matched with sunlight flow density, while the porous medium is mainly capable of converting solar radiation energy into internal energy of working media; and therefore, the problem that the existing porous medium solar absorber is low in thermal efficiency and reliability is effectively solved.

Owner:FUJIAN UNIV OF TECH

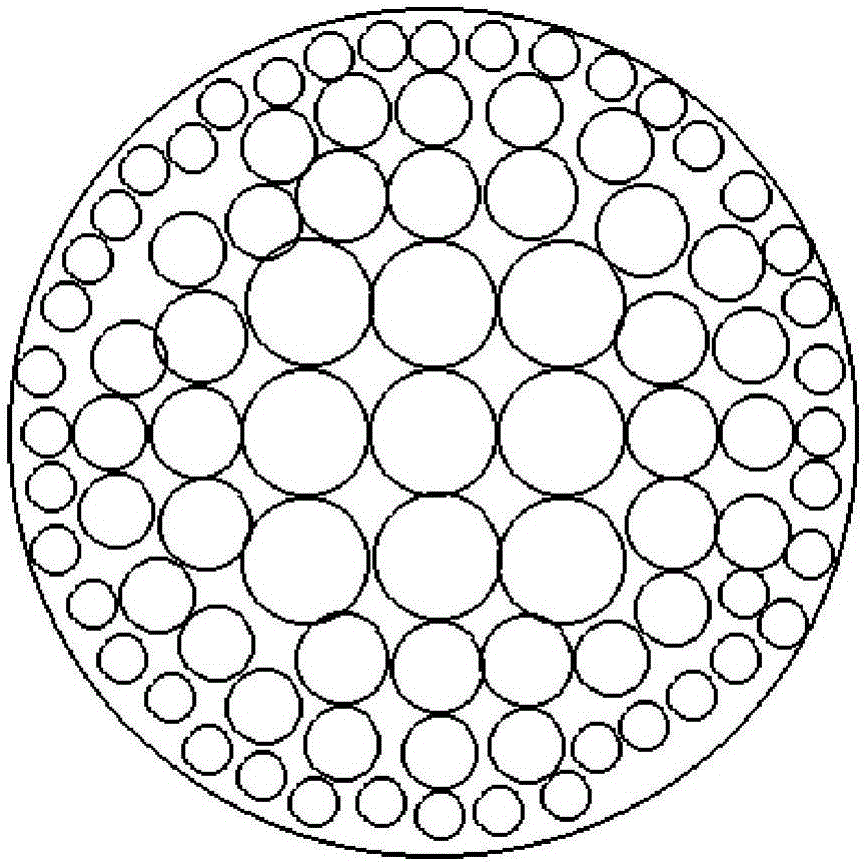

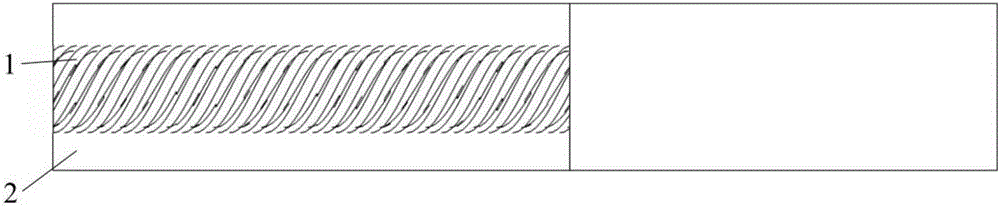

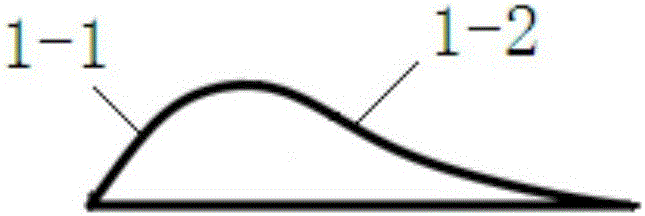

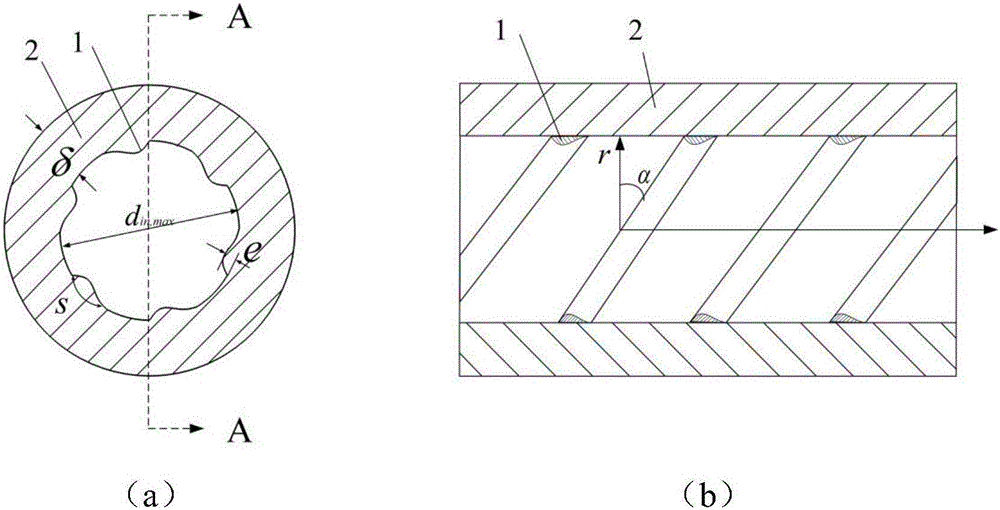

Boiler water-cooled wall inner threaded pipe with streamline-section inner ribs

ActiveCN105806127AImprove heat transfer performanceImprove heat transfer efficiencyCasings/liningsSteam boilersThreaded pipeEngineering

The invention discloses a boiler water-cooled wall inner threaded pipe with stream-line-section inner ribs. The boiler water-cooled wall inner threaded pipe comprises a pipe body and the ribs spirally arranged on the inner wall of the pipe body in the axial direction, wherein the cross sections of the ribs are in streamline shapes. The ribs which are spirally arranged are distributed at equal intervals, and the number of the ribs is 4 to 8. The included angle between the spiral direction of the ribs and a cross section is controlled within the range of 30 degrees to 60 degrees. The circumferential bottom width of the ribs of the boiler water-cooled wall inner threaded pipe is controlled within the range of 4 mm to 10 mm. The height of the highest point of the ribs of the boiler water-cooled wall inner threaded pipe is controlled within the range of 0.5 mm to 1.5 mm. The position of the highest point of the ribs is at the position of one third of the rib bottom width. By means of the novel boiler water-cooled wall inner threaded pipe, vortexes on the back flow sides of the ribs are avoided or reduced through the streamline inner ribs, so that the heat transfer capability of the inner wall face of the pipe is effectively improved, and the temperature level near rib roots on the back flow sides of the ribs is lowered. Therefore, the heat transfer performance of the boiler water-cooled wall inner threaded pipe can be further enhanced through the pipe shape.

Owner:XI AN JIAOTONG UNIV

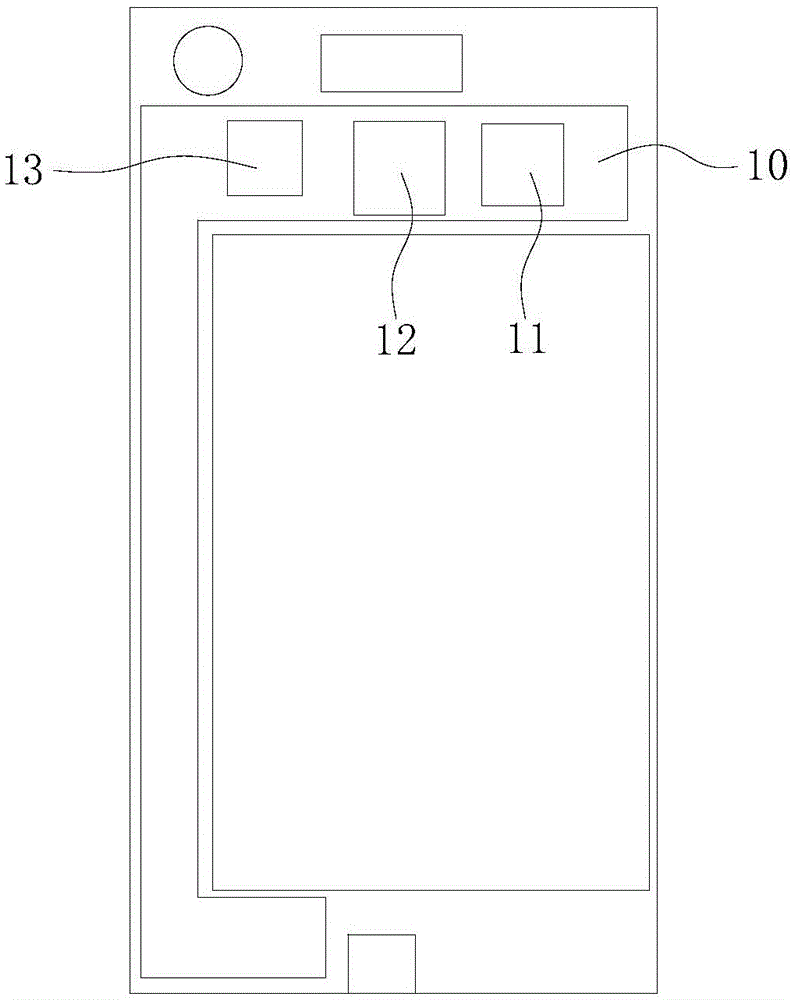

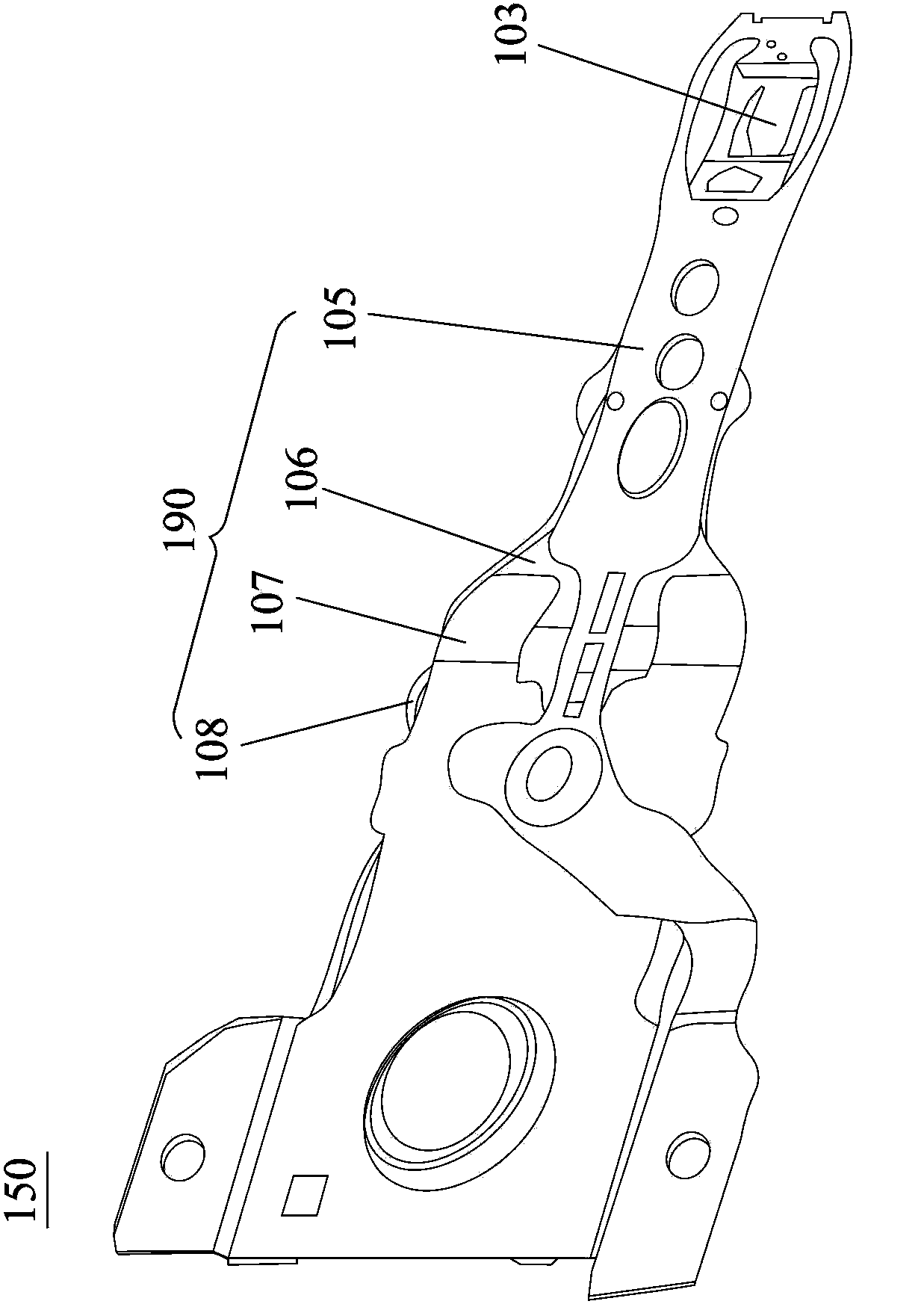

Heat radiation structure assembly of electronic device and electronic device

InactiveCN105050361AReduce local high temperatureEvenly distributedDigital data processing detailsCooling/ventilation/heating modificationsEngineeringMotherboard

The invention discloses a heat radiation structure assembly of an electronic device. The heat radiation structure assembly comprises a mainboard and a mainboard supporting member, wherein the mainboard is used for installing a chip and comprises a relatively high-temperature first region and a relatively low-temperature second region, the heat radiation structure assembly also comprises a heat conduction part, and the heat conduction part is arranged on the mainboard and can be used for transferring heat to the second region from the first region. The heat conduction part is arranged on the mainboard with regard to different-temperature regions and is used for transferring heat of the relatively high-temperature first region on the mainboard to the relatively low-temperature second region, and thus, the heat on the mainboard is uniformly distributed. Moreover, the invention also discloses the electronic device. Through the introduction of the above heat radiation structure component into the electronic device, the heat of the relatively high-temperature region on the electronic device is automatically transferred to the relatively low-temperature region, local temperature of the electronic device is reduced, user application and system performance are prevented from being affected, and a user experience is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Method and device for smelting recycled copper in reverberator

InactiveCN102061396AReduce oxygen contentFacilitate control of burning rateReverberatory furnaceCombustorCombustion

The invention discloses a method and device for smelting recycled copper in a reverberator. With the method, partial high-temperature fumes of the reverberator are directly mixed with combustion-supporting air to form a combustion-supporting gas with high temperature and low oxygen concentration, thereby improving the uniformity of temperature distribution in the reverberator, reducing local high temperature and reducing the burning loss of metal. The horizontal section of a flue gate of the reverberator is connected with a fume backflow pipe, a high temperature fan and a bypass cool air pipe to transmit a part of high temperature fume exhausted from the reverberator to a burner so that high air temperature and low oxygen concentration combustion is implemented in the reverberator and the fume backflow content accounts for 30% to 50% of the total volume of the fume in the reverberator. The method provided by the invention has the advantages of high metal recovery rate and high heat efficiency, and the device has the advantages of simple structure and reliable performance.

Owner:CENT SOUTH UNIV

Aerogel heat insulating device for electronic product

InactiveCN107142037AReduce local high temperatureReduce temperature differenceFilm/foil adhesivesModifications by conduction heat transferTotal thicknessGraphene

The invention relates to an aerogel heat insulating device for an electronic product. The aerogel heat insulating device for the electronic product comprises a graphene sheet layer and an aerogel sheet layer located above the graphene sheet layer, wherein a high-molecular polymer insulating protection layer or an adhesive layer is arranged on the upper surface of the aerogel sheet layer; an adhesive layer or a high-molecular polymer insulating protection layer is arranged on the lower surface of the graphene sheet layer and is different from the layer arranged on the upper surface of the aerogel sheet layer; the total thickness of the aerogel heat insulating device is 0.2 to 5mm. According to the aerogel heat insulating device for the electronic product, disclosed by the invention, high-layer thermal property of the graphene layer is combined with a low heat conductivity coefficient of the aerogel layer, so that local high temperature is reduced, and temperature difference between a heat source position and a position away from a heat source is reduced; the aerogel heat insulating device easily realizes die cutting and forming, can be self-bonded and bent, and has higher flexibility.

Owner:QIHUA OPTRONICSKUNSHAN CO LTD

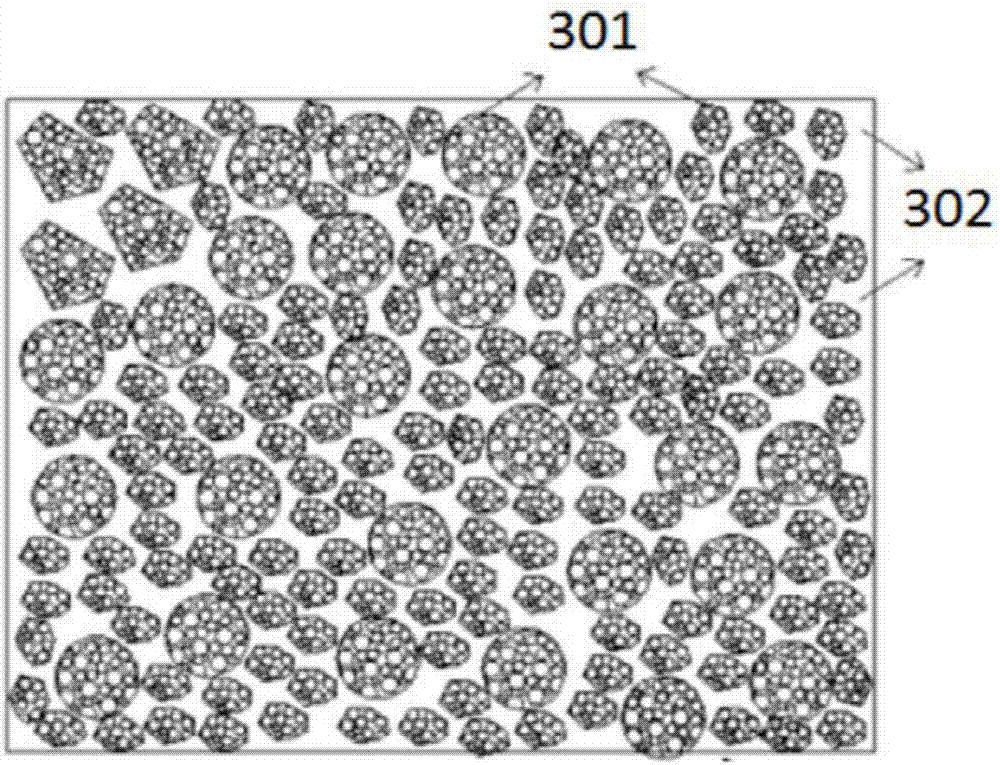

Method for preparing nanotube and PCM combined phase change temperature control component

InactiveCN109321212AHigh thermal conductivityImprove the equivalent thermal conductivityHeat-exchange elementsElectron beam welding apparatusElectrical conductorThermal insulation

The invention provides a method for preparing carbon nanotube and PCM-combined phase change temperature control component, which aims to provide a method for preparing a phase change temperature control component with high phase change latent heat and better heat conduction effect. The present invention is implemented as follows: casting pyrolytic graphite in the heat sink bottom and the verticalhot wall surface of a metal conductor packaging container; combining carbon nanotubes and phase change materials by ultrasonic vibration to form a carbon nanotube and phase change composite material,and charging the liquid carbon nanotube and phase change composite material in a heat conductive reinforcing skeleton by a vacuum co-fusion method; welding the heat conductive reinforcing skeleton ina phase change cavity to form a multilayer phase change latent heat self-control adjustment level that the pyrolytic graphite wrapping, in a U-shape, heat conductive reinforcing skeleton, and forminga thermal insulation buffer layer from the phase change cavity; and finally, welding a cover plate on the stepped opening of the metal conductor packaging container by electron beam welding, enclosingto form a closed phase change temperature control component, and processing to obtain the boundary dimension according to requirements.

Owner:10TH RES INST OF CETC

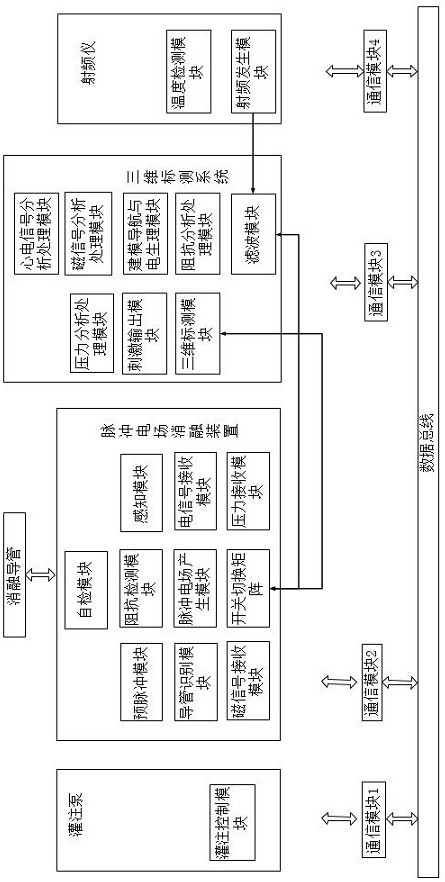

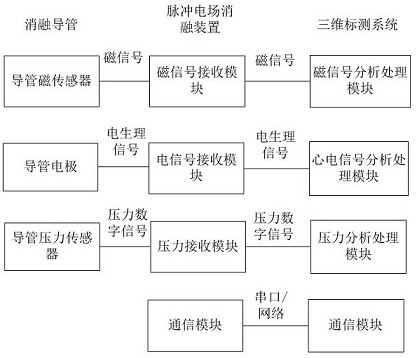

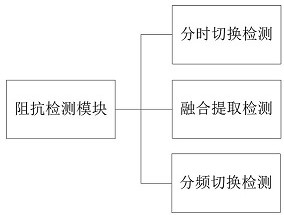

Integrated system for cardiac ablation

ActiveCN113768616AAchieve outputFlexible selectionSurgical navigation systemsDiagnostic recording/measuringRadio frequency energyRadio frequency signal

The invention relates to the technical field of cardiac ablation, in particular to an integrated system for cardiac ablation. The integrated system comprises a pulsed electric field ablation device, a three-dimensional marking system, a radio-frequency instrument and an ablation catheter, wherein the pulsed electric field ablation device comprises a magnetic signal receiving module, an electric signal receiving module, a pressure receiving module and an impedance detection module, and an electric signal, a magnetic signal, a pressure signal and an impedance signal of the catheter are separately transmitted to the three-dimensional marking system; and the three-dimensional marking system is used for carrying out analysis processing on the signals to obtain electrophysiological information on a patient, position information on the catheter and an attaching state of an operation position of the catheter. Under the control of the three-dimensional marking system, the system also realizes the switching of a pulse signal output by the pulsed electric field ablation device and a radio-frequency signal output by the radio-frequency instrument. The integrated system is more complete in design, pulsed electric field energy output, radio-frequency energy output and three-dimensional calibration can be achieved through one ablation catheter, and thus, the operation is simpler and more convenient.

Owner:四川锦江电子医疗器械科技股份有限公司

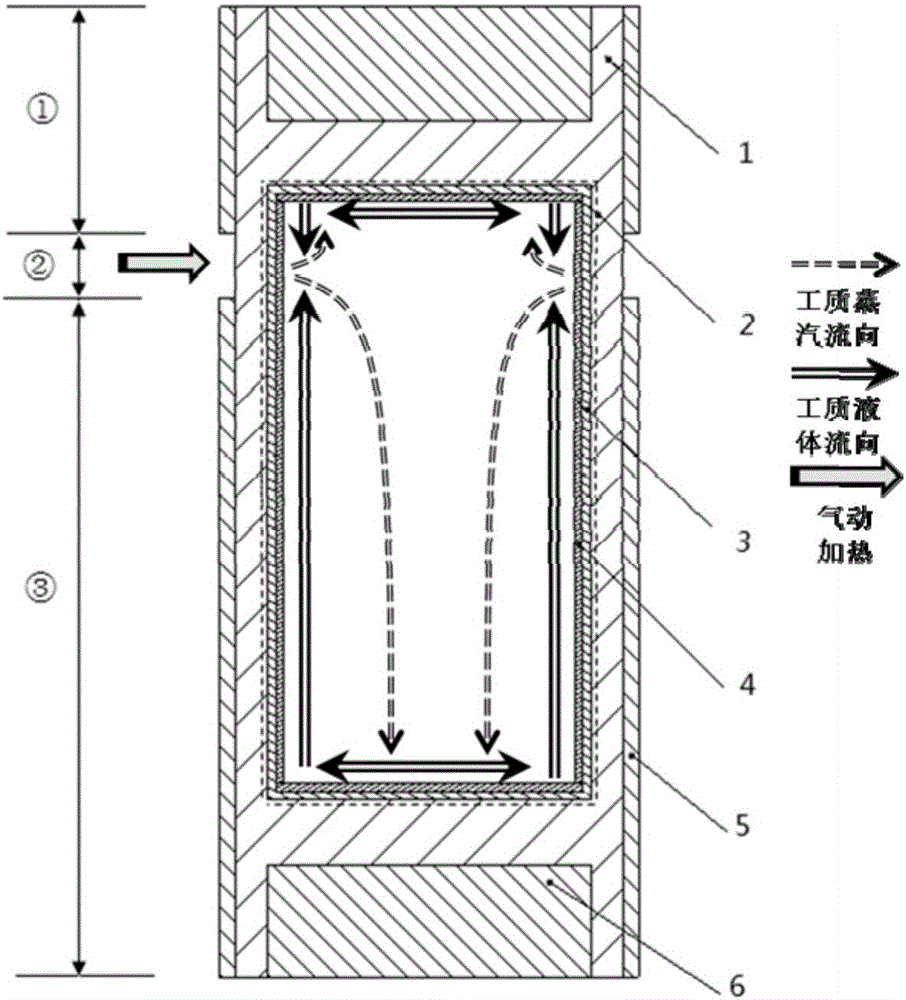

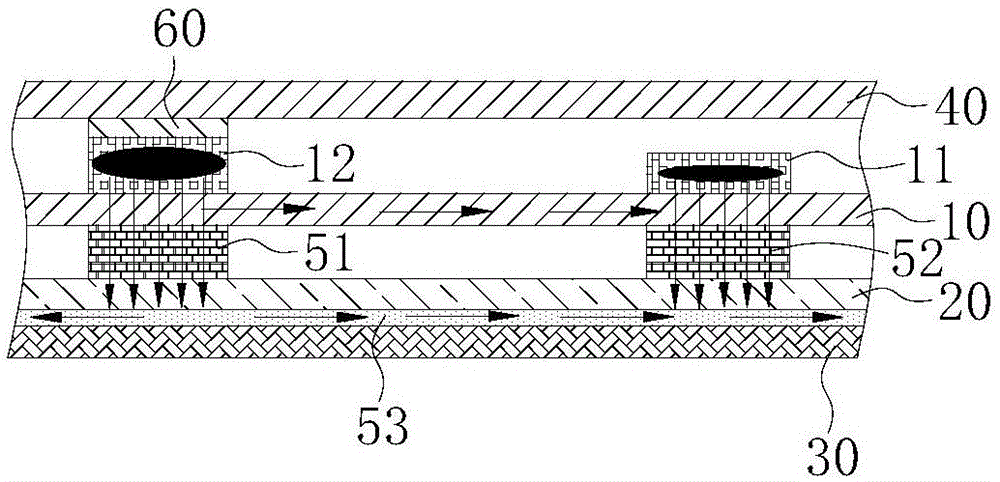

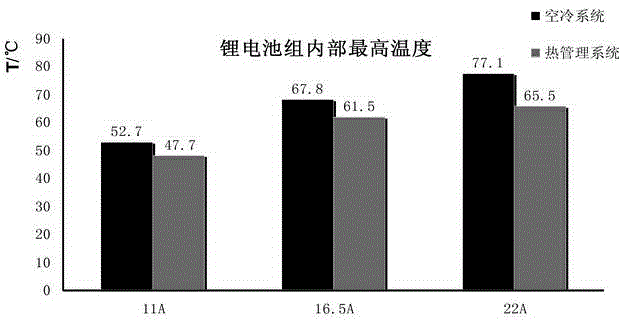

Temperature adjusting system for power lithium battery pack and power lithium battery pack

InactiveCN104538698AGive full play to heat absorptionMake up for thermal conductivityLi-accumulatorsThermodynamicsConductive coating

The invention relates to a temperature adjusting system for a power lithium battery pack and the power lithium battery pack. The system comprises a battery box, phase-change energy-storage capsules and a plurality of heat pipes, wherein a plurality of lithium battery units are arranged in the battery box; the surfaces of all the lithium battery units are coated with thermal conductive coatings; the phase-change energy-storage capsules are filled into the battery box among the lithium battery units; the plurality of heat pipes are inserted among the lithium battery units; the circumferential wall of each heat pipe is in contact with the phase-change energy-storage capsules; and the two ends of each heat pipe are in tight contact with an upper cover and a bottom plate of the battery box respectively. A phase-change energy-storage material which has high heat-storage density and high chemical stability is integrated with a heat pipe technology, so that the heat-absorbing performance of the phase-change material can be brought into full play; the defects of low heat conductivity coefficient and low energy-storage rate of the phase-change material can be overcome; rapid response is available under the condition of high-power and large-current discharge of the power lithium battery pack; and the lithium battery pack is controlled to work safely in an optimal temperature range.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

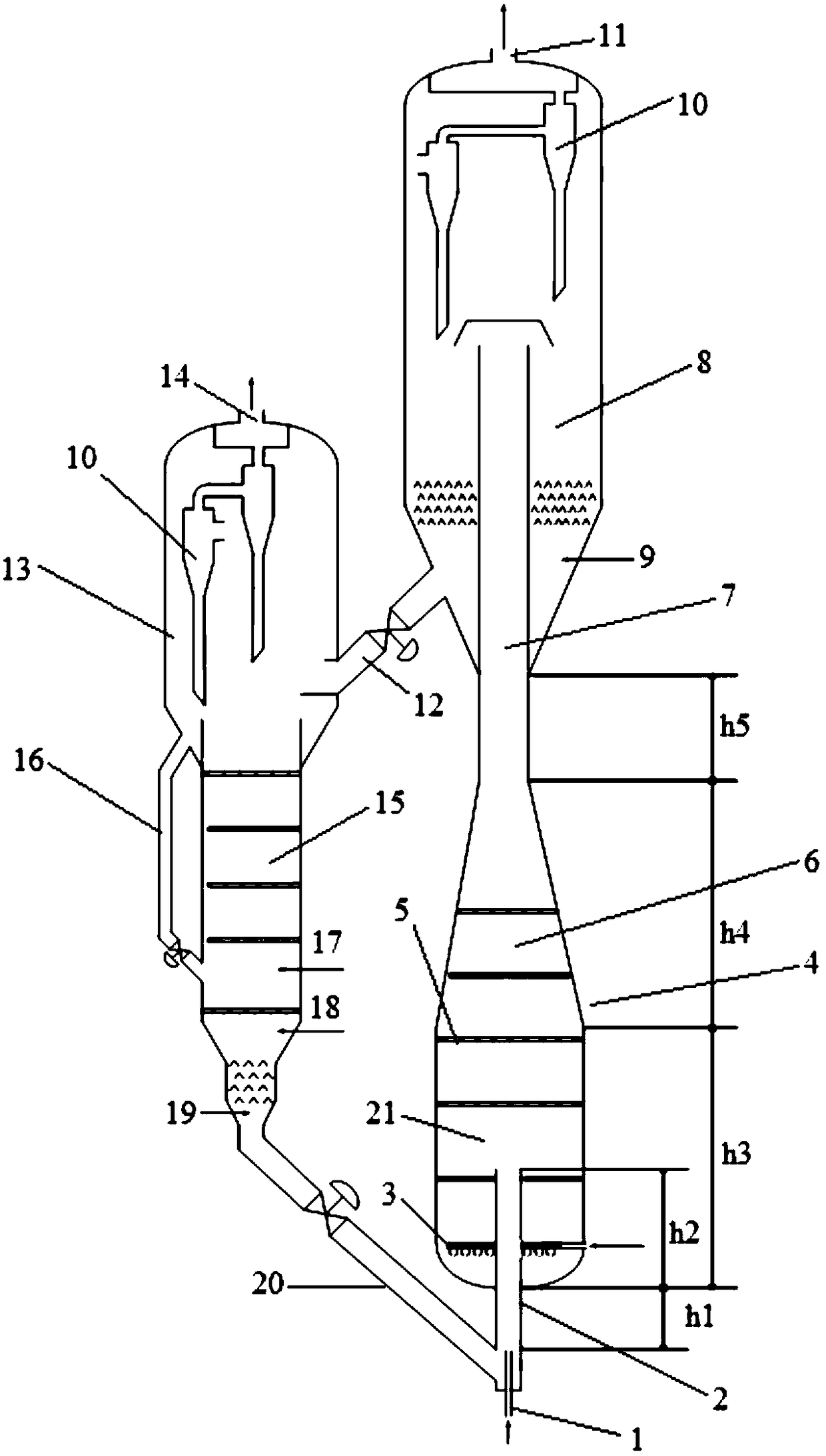

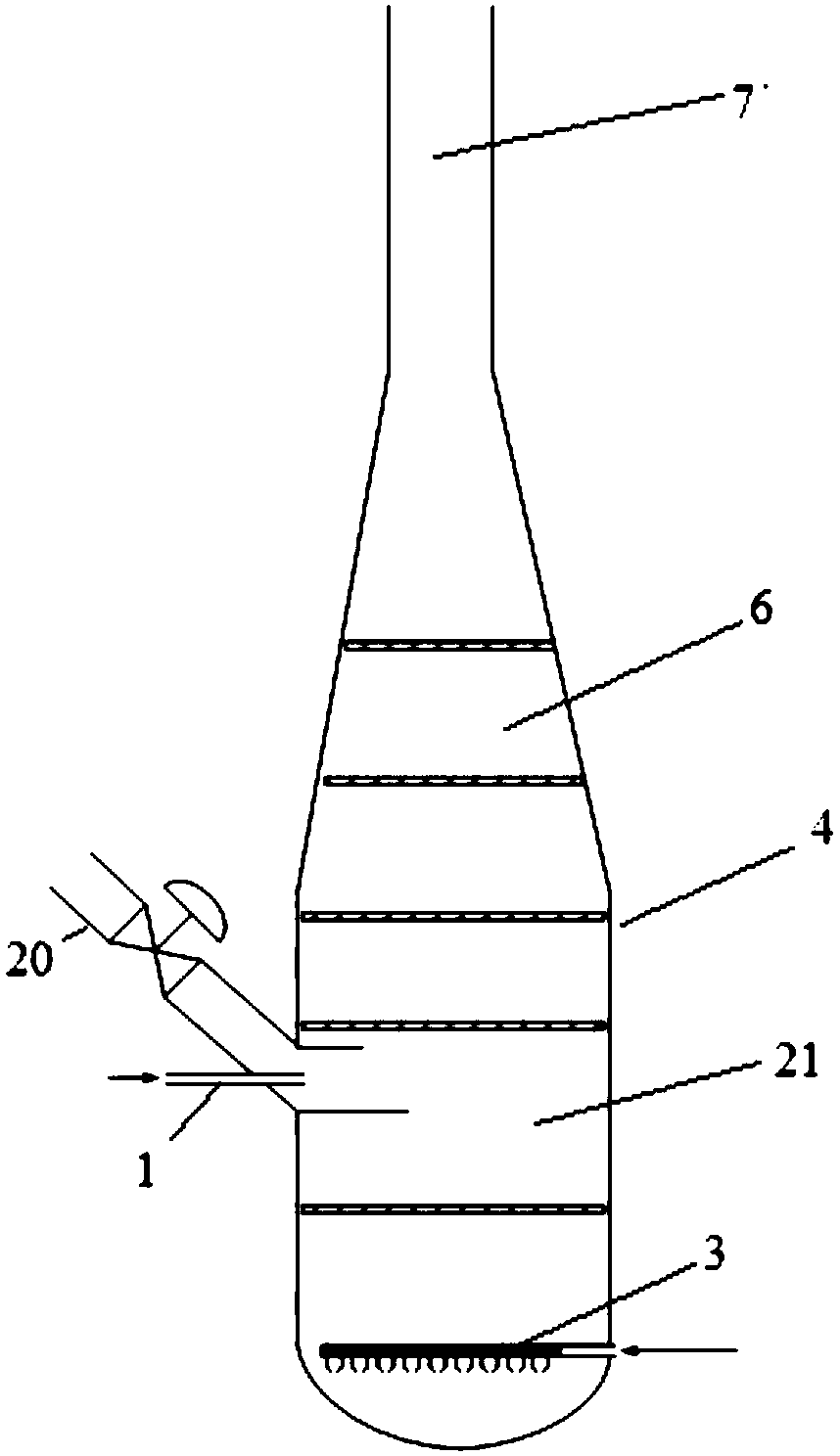

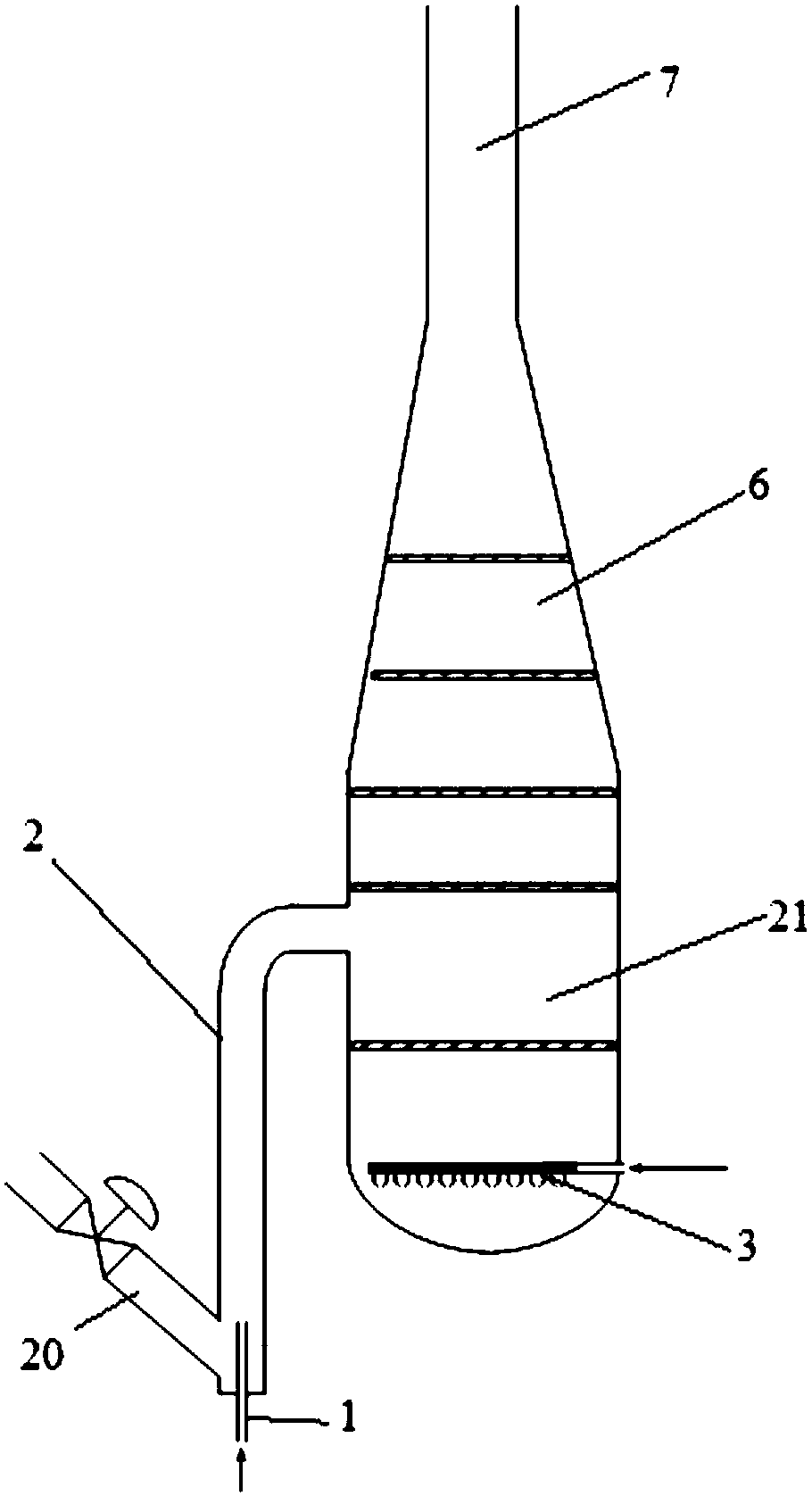

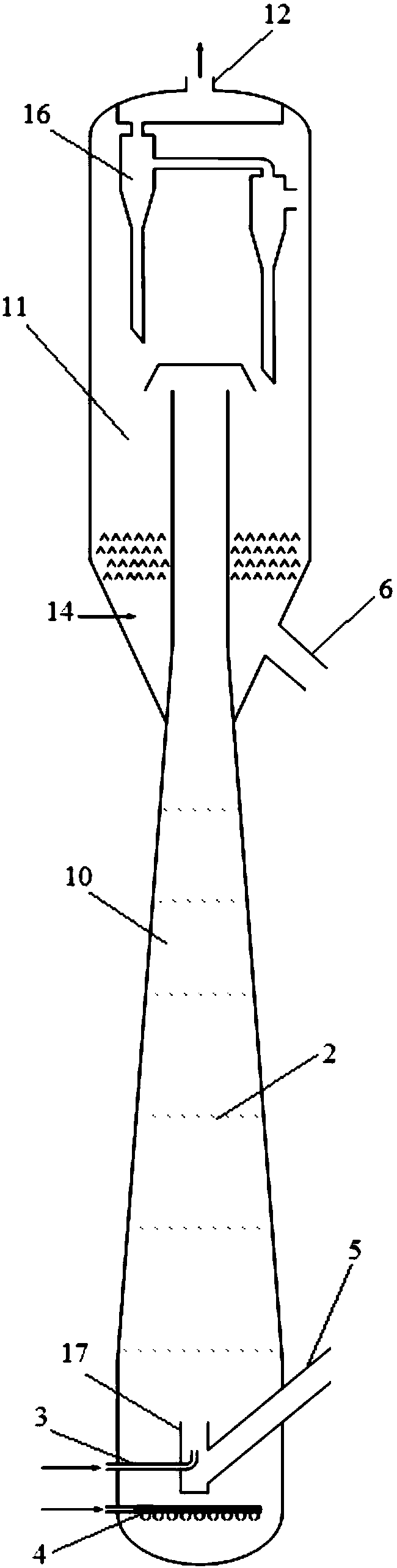

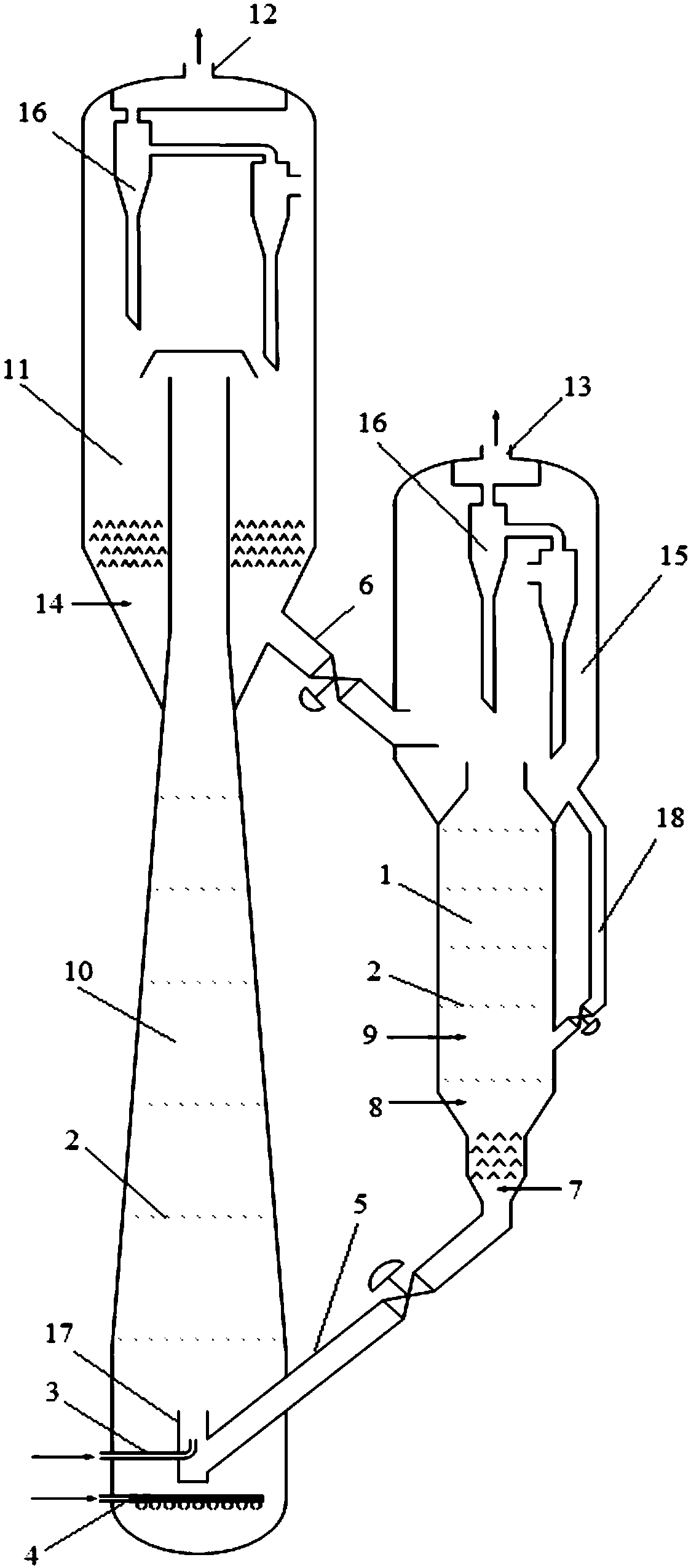

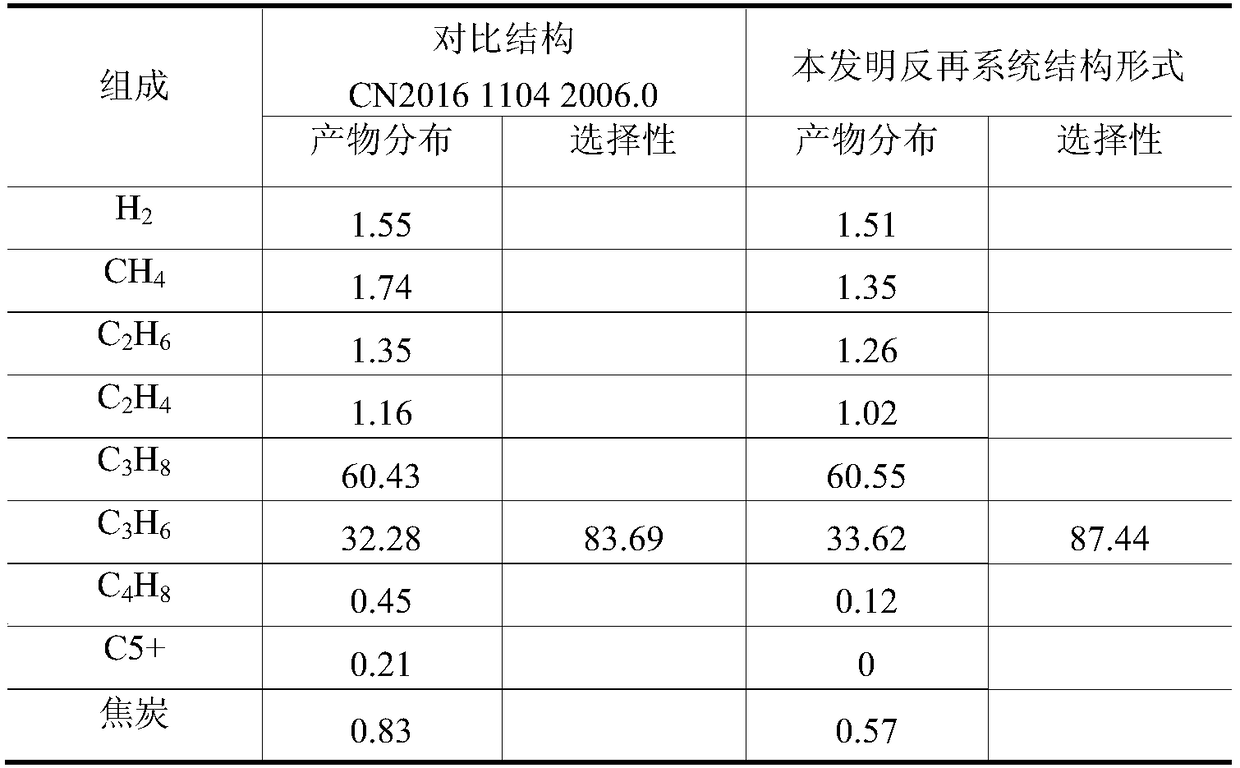

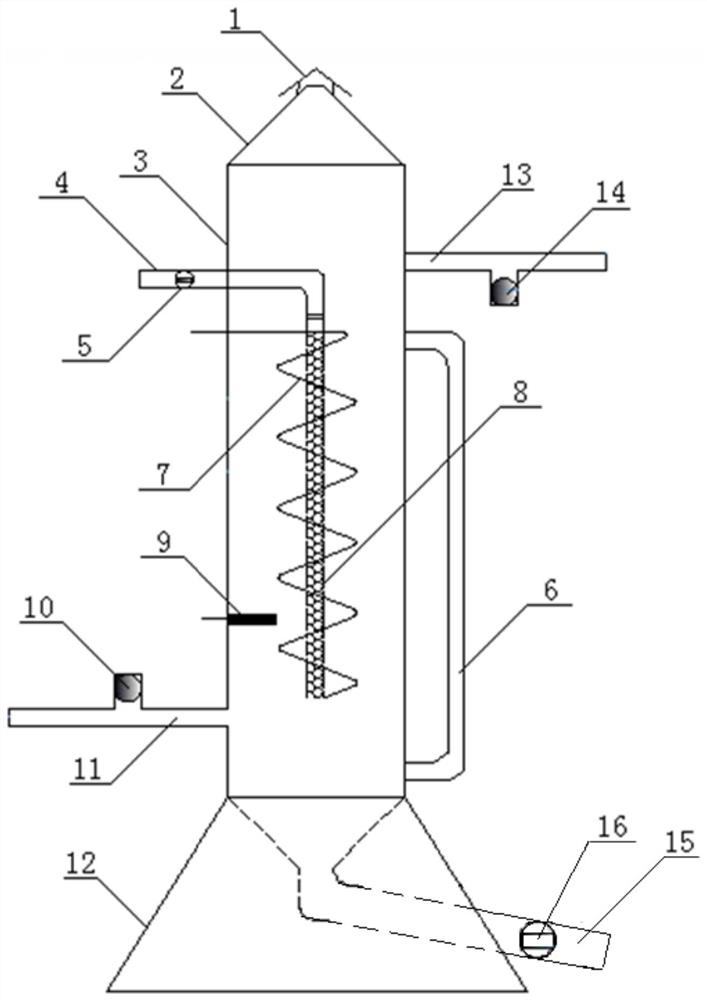

Circulating fluid bed reaction device for preparing olefin from alkane through catalytic dehydrogenation or catalytic cracking

ActiveCN109499486AReduce secondary conversionsTake advantage ofHydrocarbonsChemical recyclingAlkaneDehydrogenation

The invention provides a circulating fluid bed reaction device for preparing olefin from alkane through catalytic dehydrogenation or catalytic cracking. The device comprises a reactor and a reactor sedimentation section, wherein the reactor sedimentation section is positioned at the upper part of the reactor; the reactor comprises a diameter shrinkage section; the cross section diameter of the diameter shrinkage section is gradually decreased from bottom to top; a lifting pipe extends into the reactor from the lower part of the reactor; a catalyst regeneration inclined pipe is connected with the lifting pipe outside the reactor. The reaction device realizes the gradual diameter shrinkage along the fluid flowing direction; the secondary conversion of of olefin due to returning and mixing isreduced. Reactants and catalysts in the reactor realize the flow merging and upward flowing; the uniform distribution of temperature in the reactor can be effectively improved; the local high temperature is avoided.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Infant milk powder capable of improving immunity and protecting eyesight and preparation method thereof

InactiveCN105053251AHigh purityImprove absorption rateWhey manufactureDocosahexaenoic acidNucleotide

The invention relates to an infant milk powder capable of improving the immunity and protecting the eyesight and a preparation method thereof. The infant milk powder comprises the following raw materials in parts by weight: 600 to 800 parts of high-oil desalted whey powder, 100 to 200 parts of whole milk powder, 1 to 3 parts of whey protein powder, 2 to 5 parts of galactooligosaccharide, 1 to 3 parts of fructo-oligosaccharide, 1 to 3 parts of docosahexaenoic acid (DHA), 1 to 3 parts of eicosatetraenoic acid, 0.4 to 1 part of lactoferrin, 0.2 to 0.3 part of nucleotide, 0.05 to 0.07 part of bifidobacterium, 3 to 6 parts of lutein and composite vitamins, and 2 to 7 parts of composite mineral substances. The provided infant milk powder has the advantages that according to the components of breast milk, the components are optimized and configured so as to make the milk powder become more close to the breast milk; at the same time, the nutrients required by the infants are intensified, and through the optimized ratio, the components can react with each other to generate a synergetic effect to more effectively enhance the immunity of infants and protect the eyesight.

Owner:多加多乳业(天津)有限公司

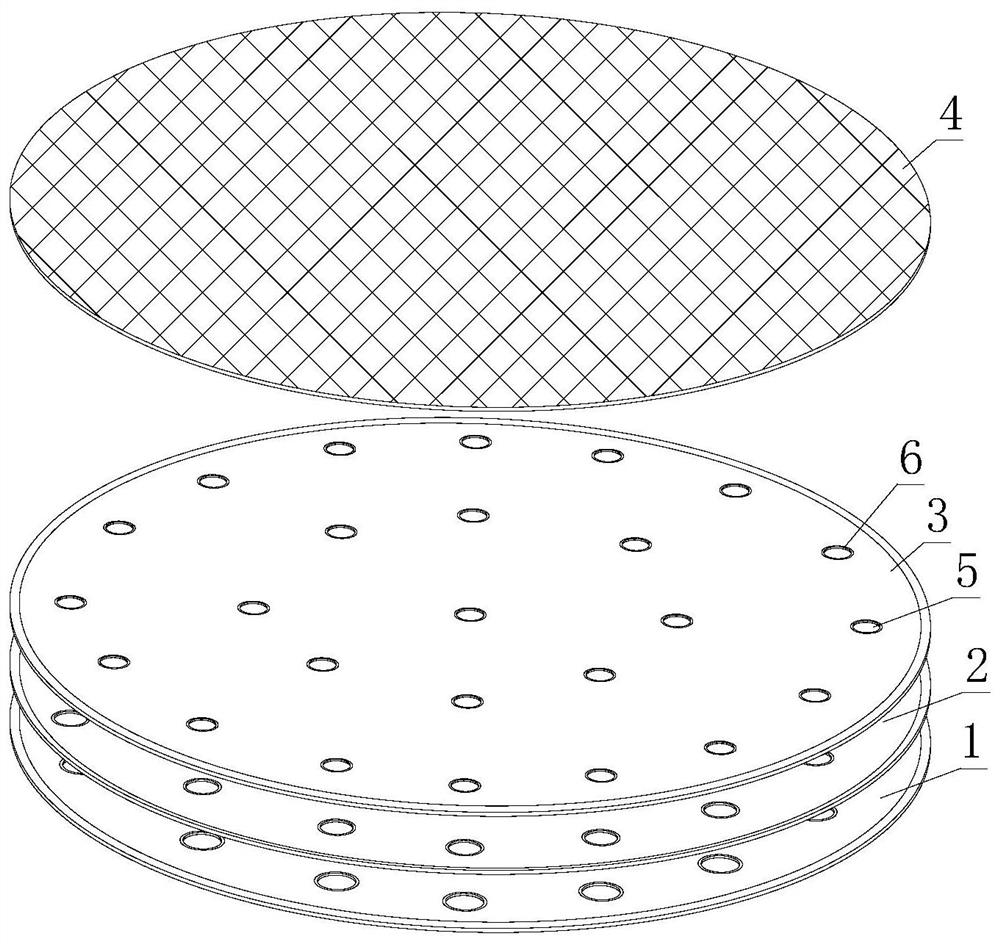

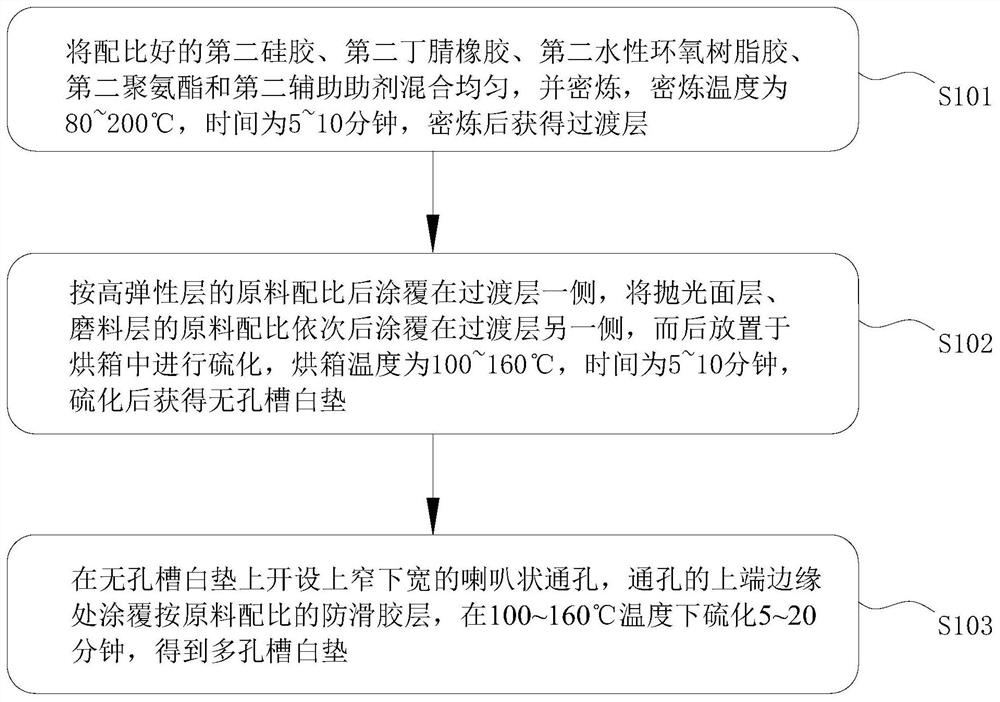

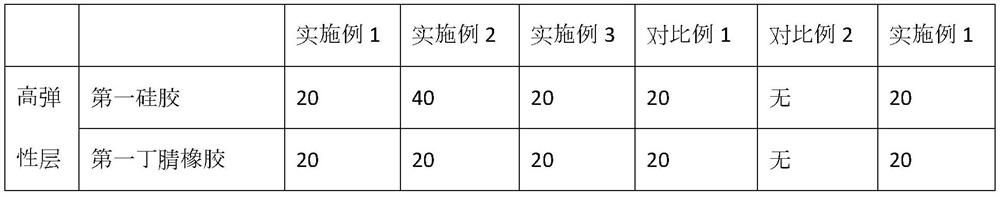

Porous groove white pad for polishing and grinding and production method

ActiveCN113510634AReduce high temperatureExtended service lifeAbrasion apparatusGrindingManufacturing engineering

The invention discloses a porous groove white pad for polishing and grinding and a production method, and belongs to the technical field of white pads. The porous groove white pad comprises a high-elasticity layer, a transition layer, a polishing surface layer and an abrasive material layer which are sequentially arranged from bottom to top, the high-elasticity layer, the transition layer, the polishing surface layer and the abrasive material layer are sequentially connected together in a composite mode, and a plurality of through holes with narrow tops and wide bottoms are formed after the high-elasticity layer, the transition layer and the polishing surface layer are overlapped with one another. Trumpet-shaped through holes with the narrow tops and the wide bottoms are formed in the white pad, the through holes are used for dissipating heat, local high temperature caused by friction is reduced, the service life of the white pad is prolonged, and the polishing quality is improved. The white pad is tightly attached to an object to be polished, the polishing surface layer and the abrasive material layer bend and deform towards one side of the abrasive material layer, the ports, facing the outer side, of the through holes are expanded, and the chip removal amount of the through holes is increased.

Owner:ANHUI HECHEN NEW MATERIAL CO LTD

Reactor capable of reducing back mixing for preparing alkenes by dehydrogenation of alkanes and preparation method

ActiveCN108654526ATake advantage ofHigh selectivityHydrocarbonsChemical recyclingDehydrogenationAlkene

The invention relates to reaction apparatus for catalytic dehydrogenation of alkanes. The reaction apparatus comprises a reaction section and a reactor sedimentation section; the reactor sedimentationsection is positioned on the upper part of the reaction section; the diameter of the reaction section is gradually decreased from top to bottom; a catalyst regeneration tube aslant stretches into thereaction section, and the outlet end of the catalyst regeneration slant tube is positioned at the lower part of the reaction section; and a feeding distribution device is positioned below the outletend of the catalyst regeneration slant tube in the reaction section. The reactants and the catalyst in the reactor flow concurrently upwards, so that the uniformity of the temperature distribution inthe reactor can be effectively improved, local high temperature can be avoided, and then the thermal reaction is reduced. In addition, the diameter of the reactor is gradually decreased along the flowing direction of the fluid, and the secondary conversion of the alkenes caused by back mixing is reduced, so that the yield and the selectivity of alkenes are improved. A high-temperature regeneratoris directly sprayed into the bottom of the dense-phase bed of the reactor, so that rapid mixing of the high-temperature catalyst with the catalyst in the reactor is facilitated, and local high temperature in the bed layer is avoided. The dense-phase fluidized catalyst is beneficial to the ending of the transmission of free radicals, so that the thermal reaction is reduced, and the selectivity of preparing alkenes by the dehydrogenation of alkanes is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

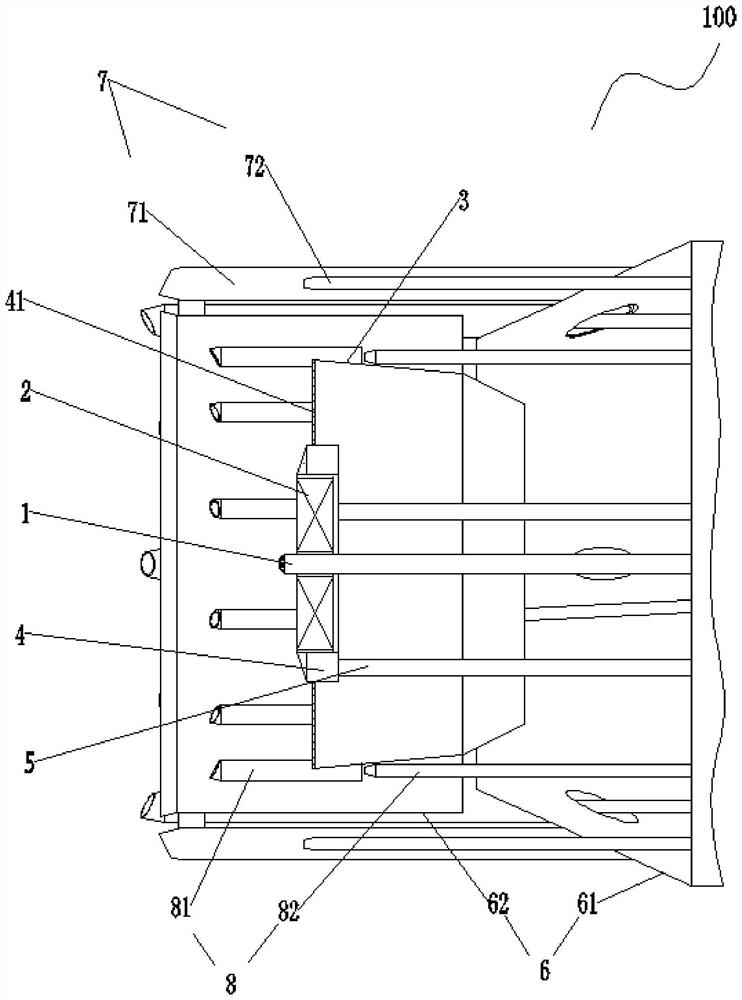

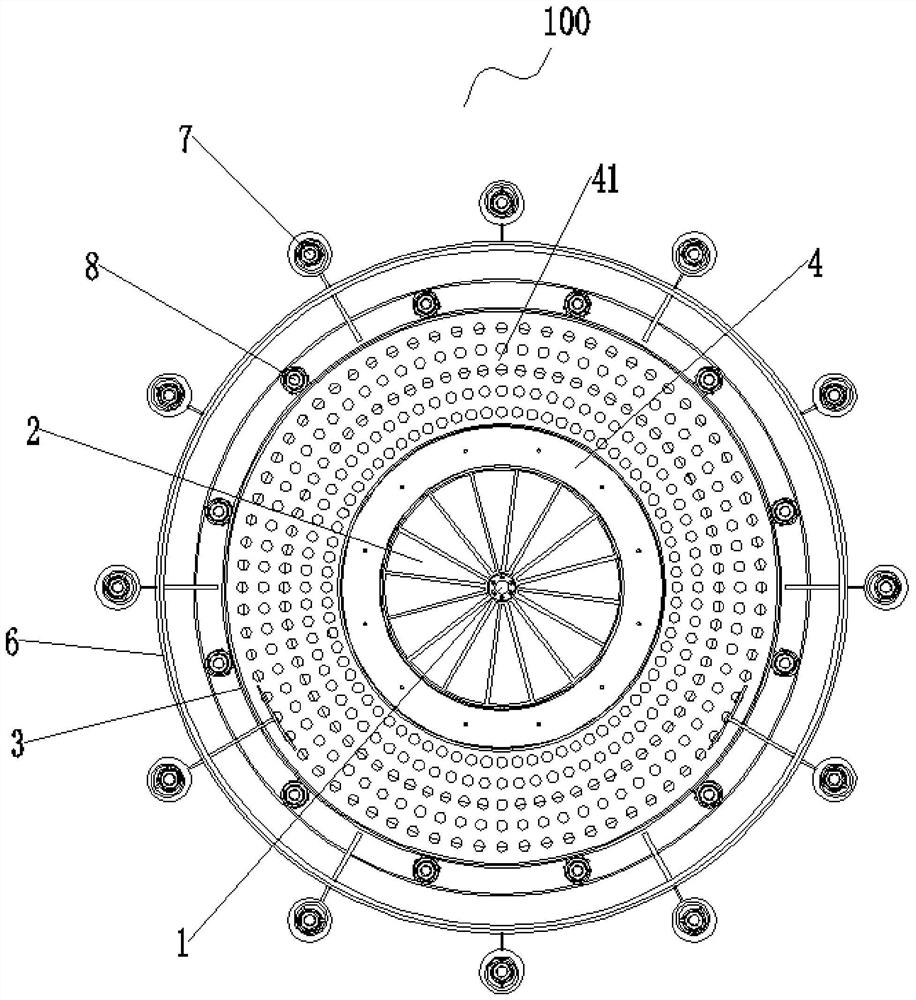

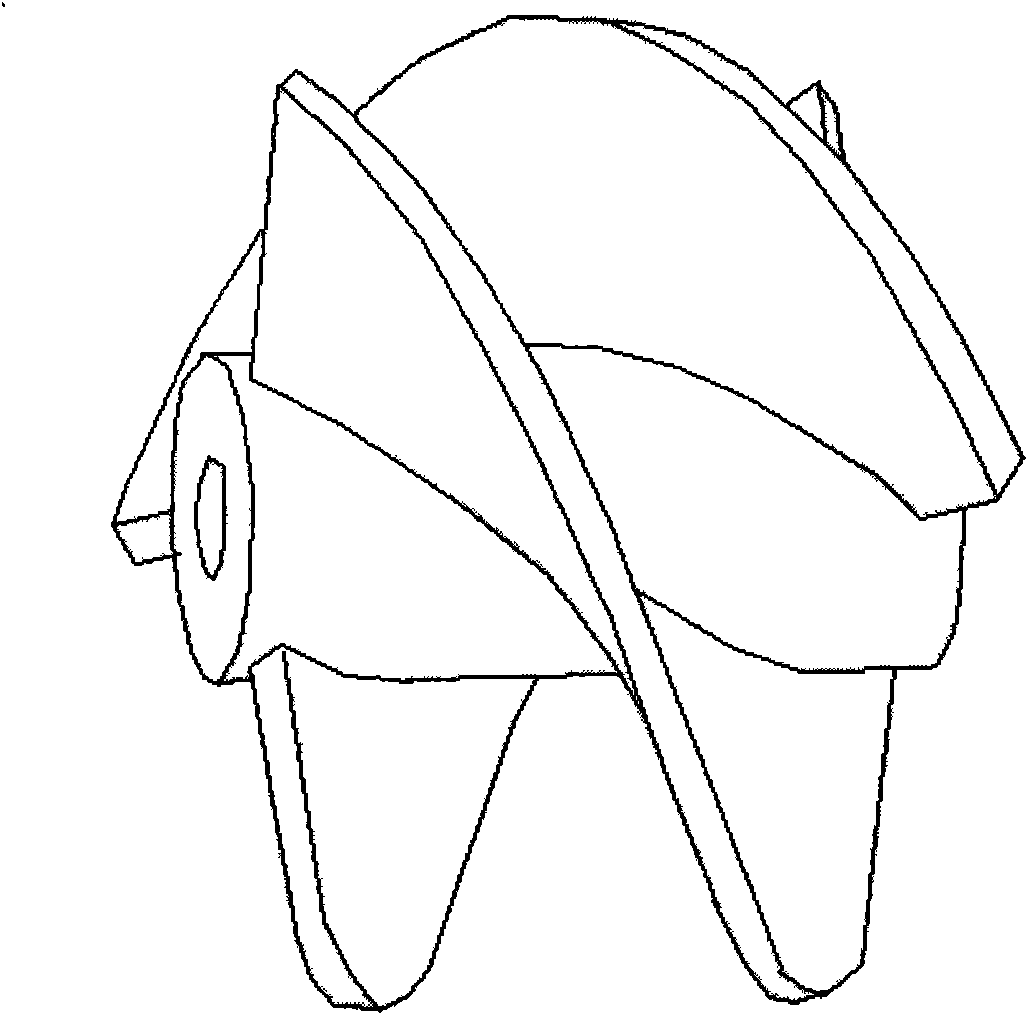

Internal circulation low nitrogen gas burner

ActiveCN112178626BReduce use costSolve the real problemFluegas recirculationGaseous fuel burnerThermodynamicsCombustion chamber

The invention relates to the field of burners, and discloses an internal circulation low-nitrogen gas burner. A swirler is sleeved on one end of a first gas pipe, and an annular gas head is sleeved on the outside of the swirler and has a gap with the swirler. Coordinated, the second gas pipe delivers gas to the annular gas head, the shunt pipe is sleeved on the outside of the annular gas head, and the flow partition is sleeved on the outside of the shunt pipe, and forms a flue gas channel with the shunt pipe. Multiple sets of inner ring gas components are located in the flue gas passage, and multiple sets of outer ring gas components are installed around the flow partition. The shunt pipe is used to divert the air to form the air for mixing smoke and the air for mixing combustion. When the air for mixing smoke flows through the flue gas channel, a negative pressure is generated at the smoke inlet, so that the smoke in the combustion chamber is sucked in and participates in combustion again. Due to the way of using the vacuum to directly recover the flue gas, not only the flue gas channel is omitted, the hidden danger of safety is eliminated, but also the use cost is reduced.

Owner:SHANGHAI NUOTE FEIBO COMBUSTION EQUIP CO LTD

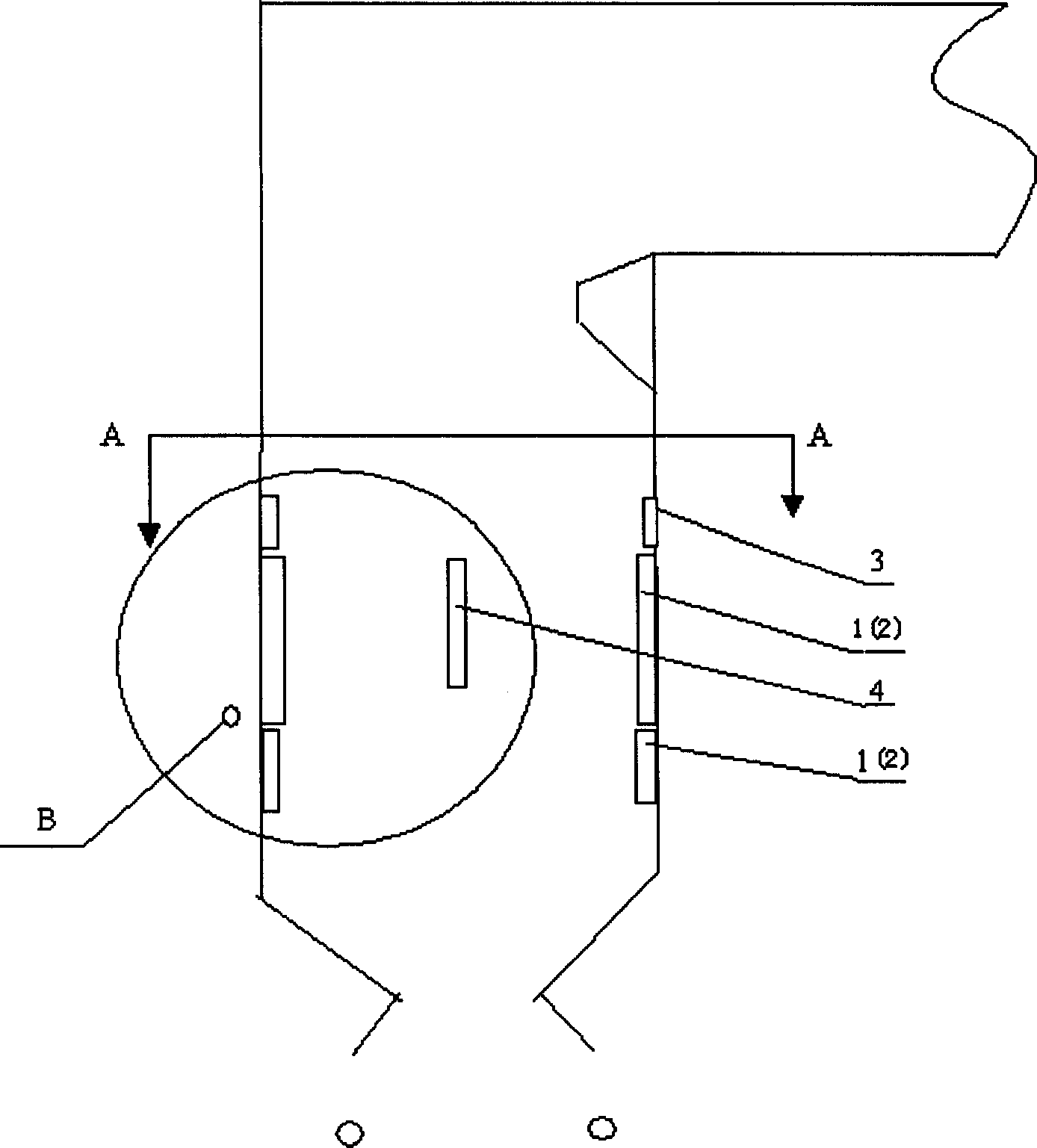

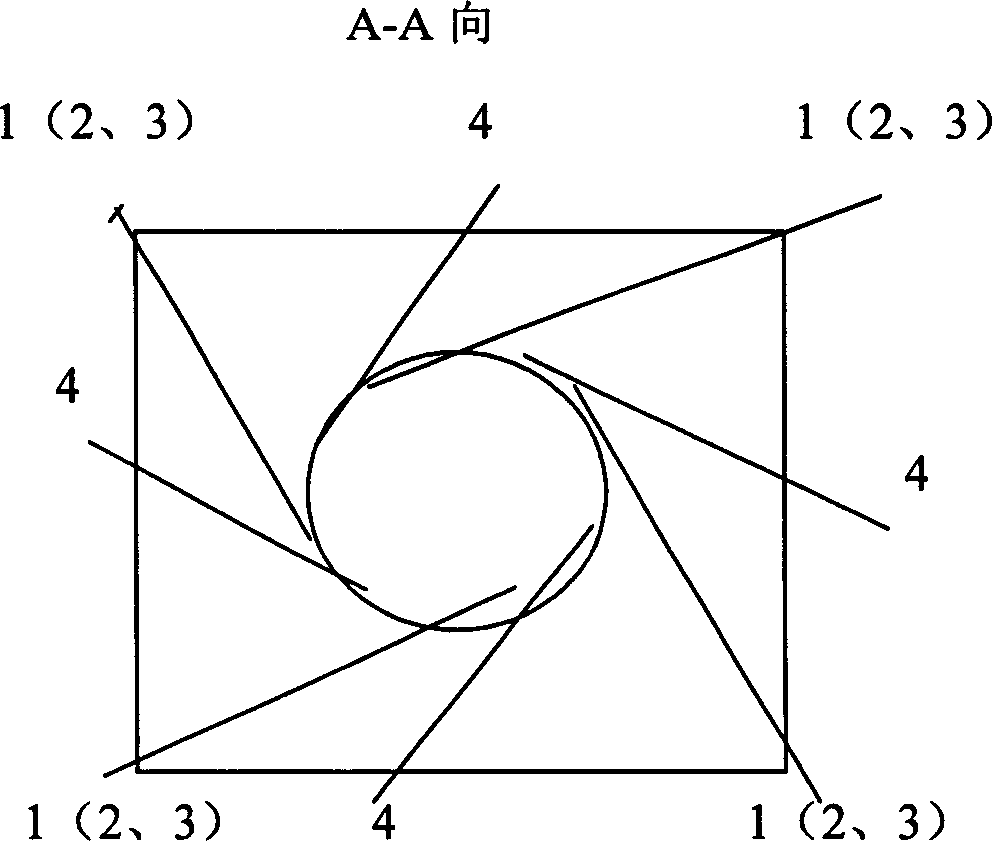

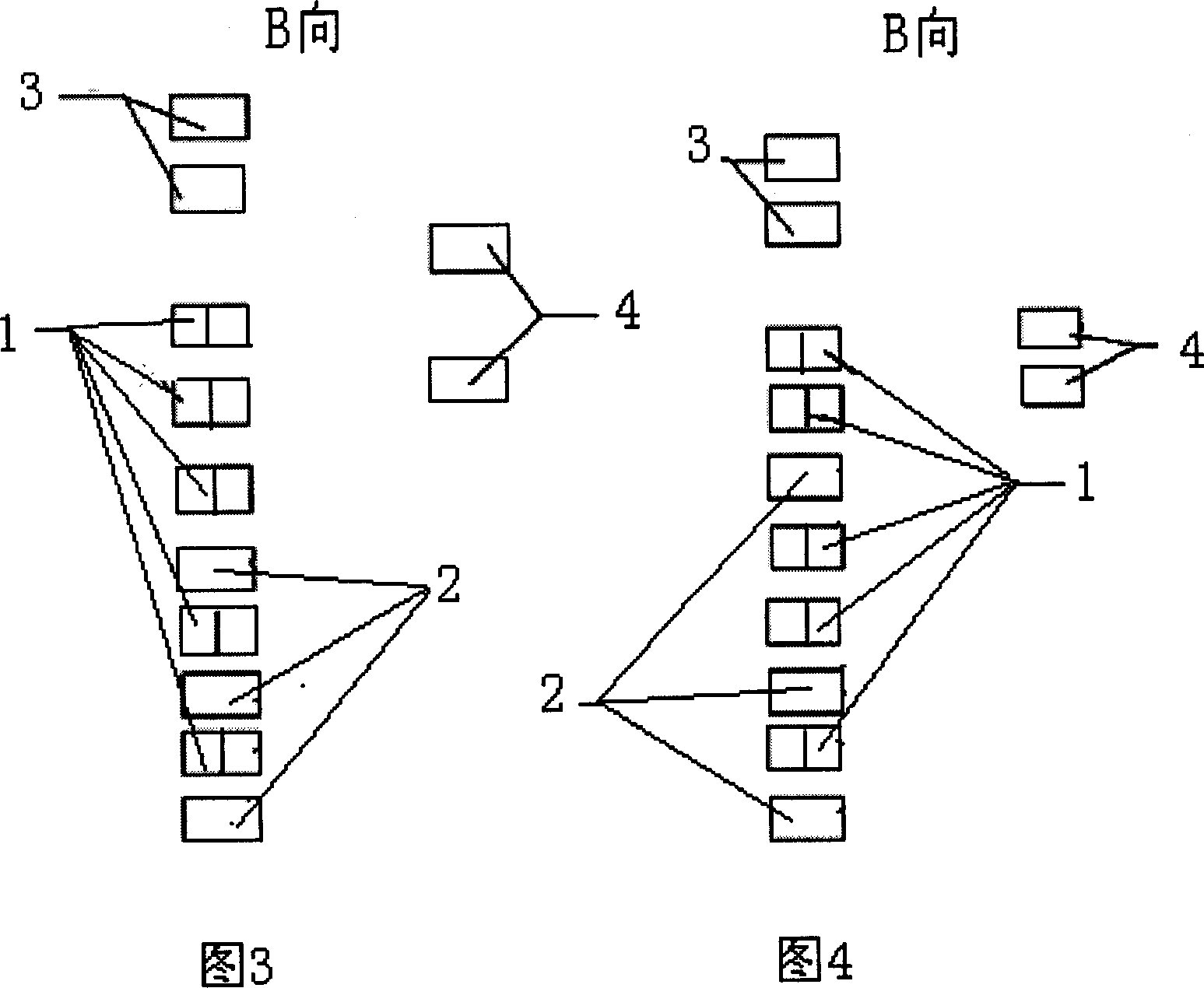

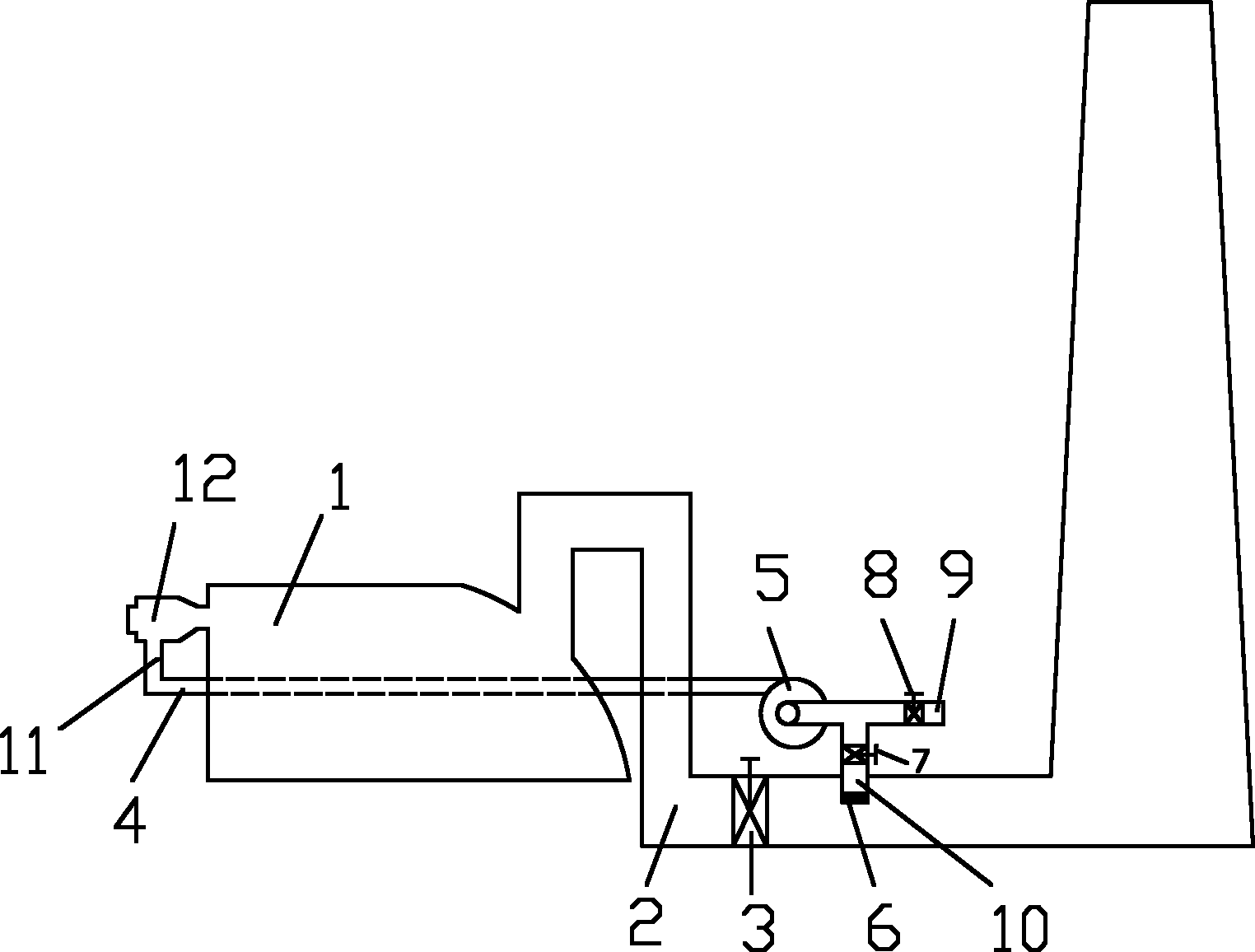

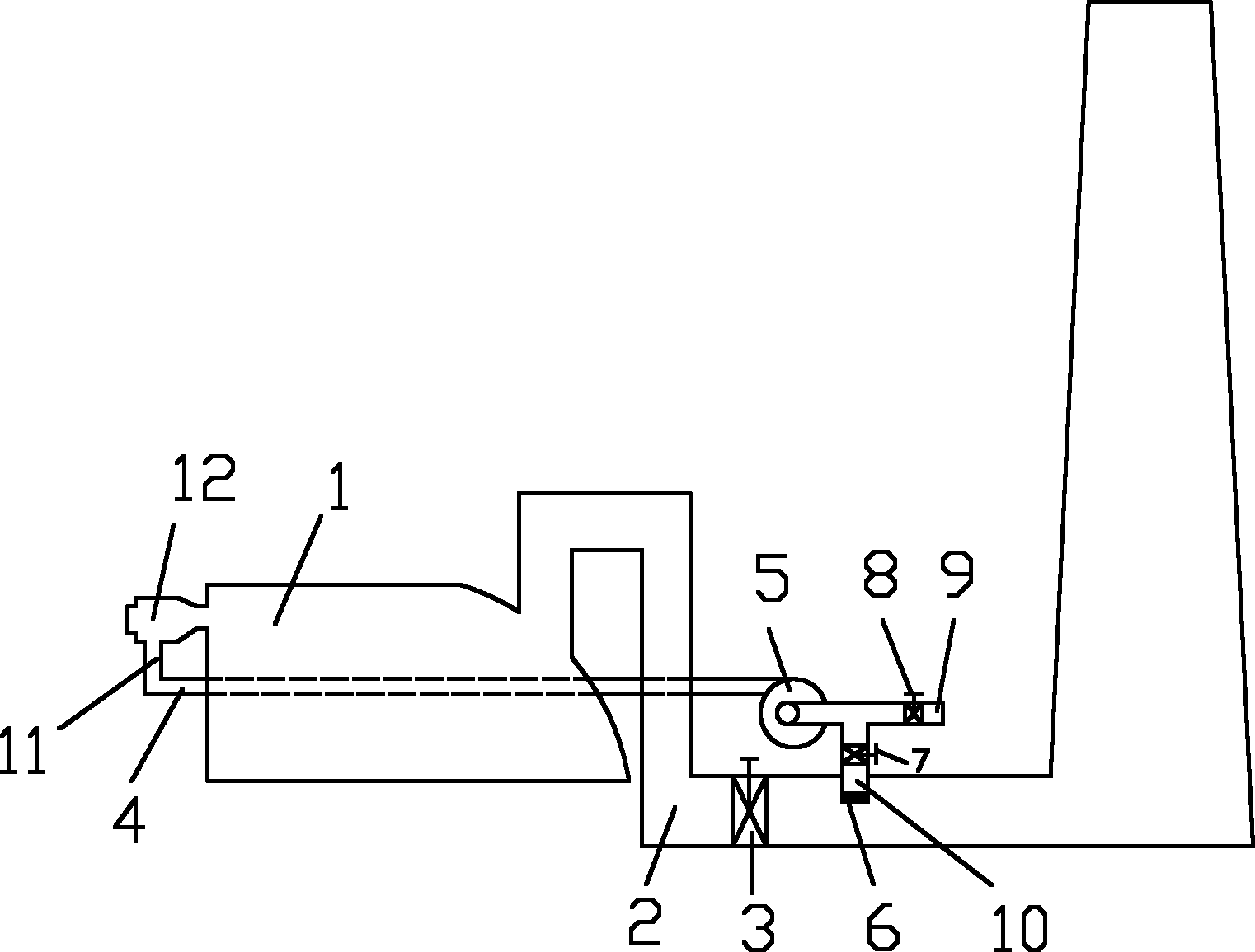

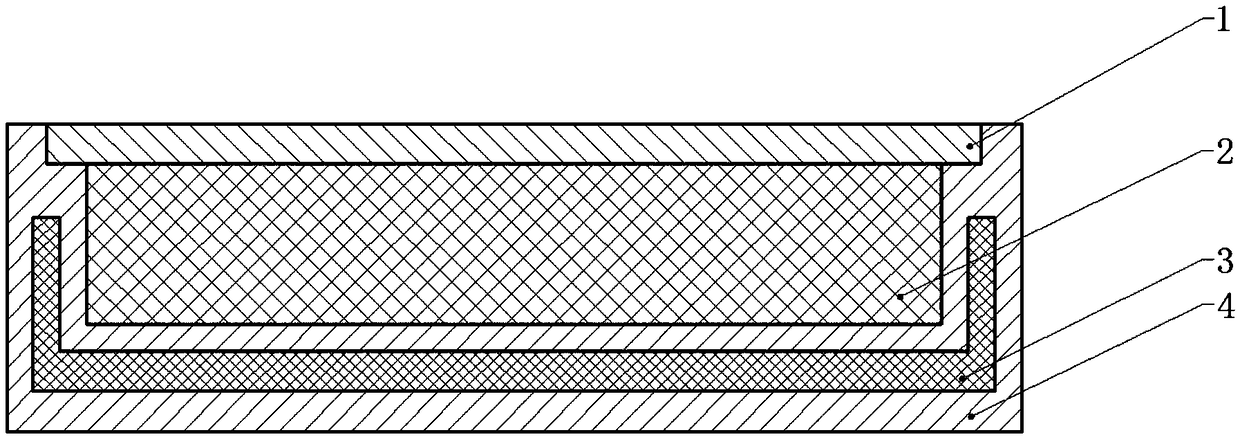

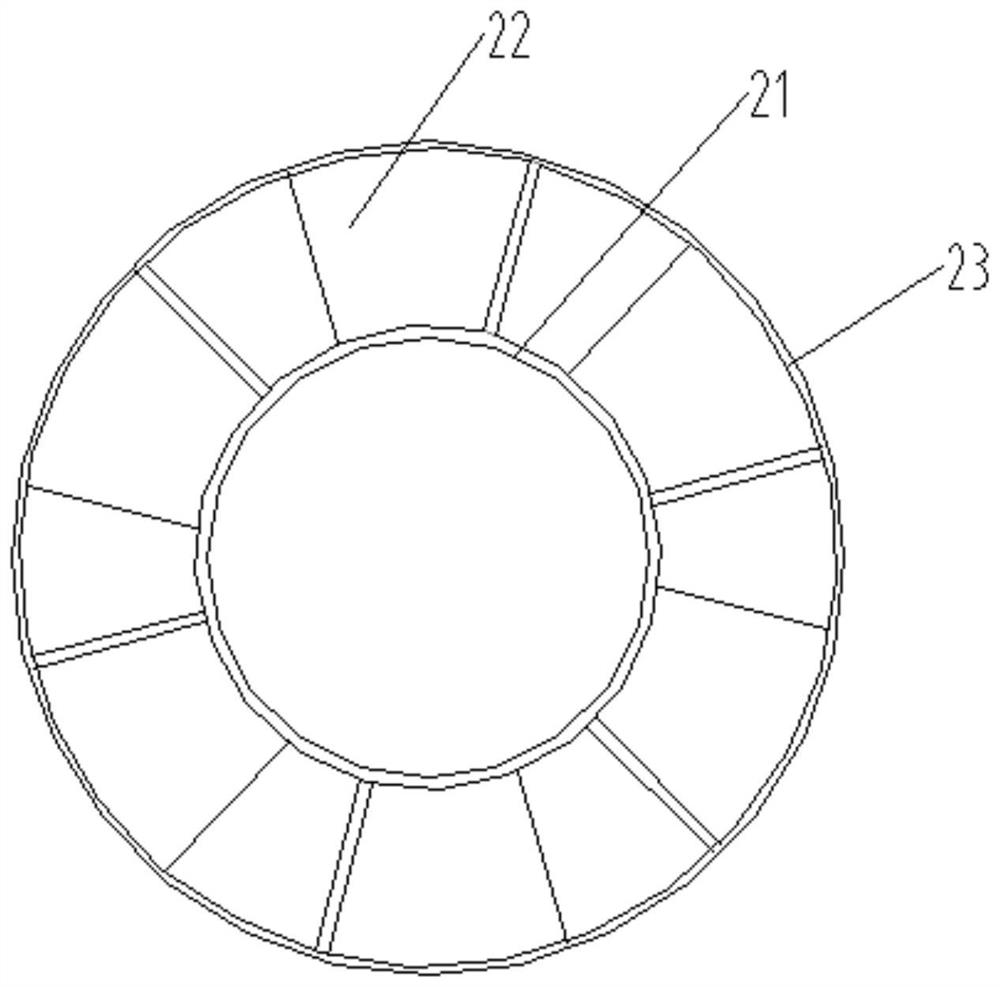

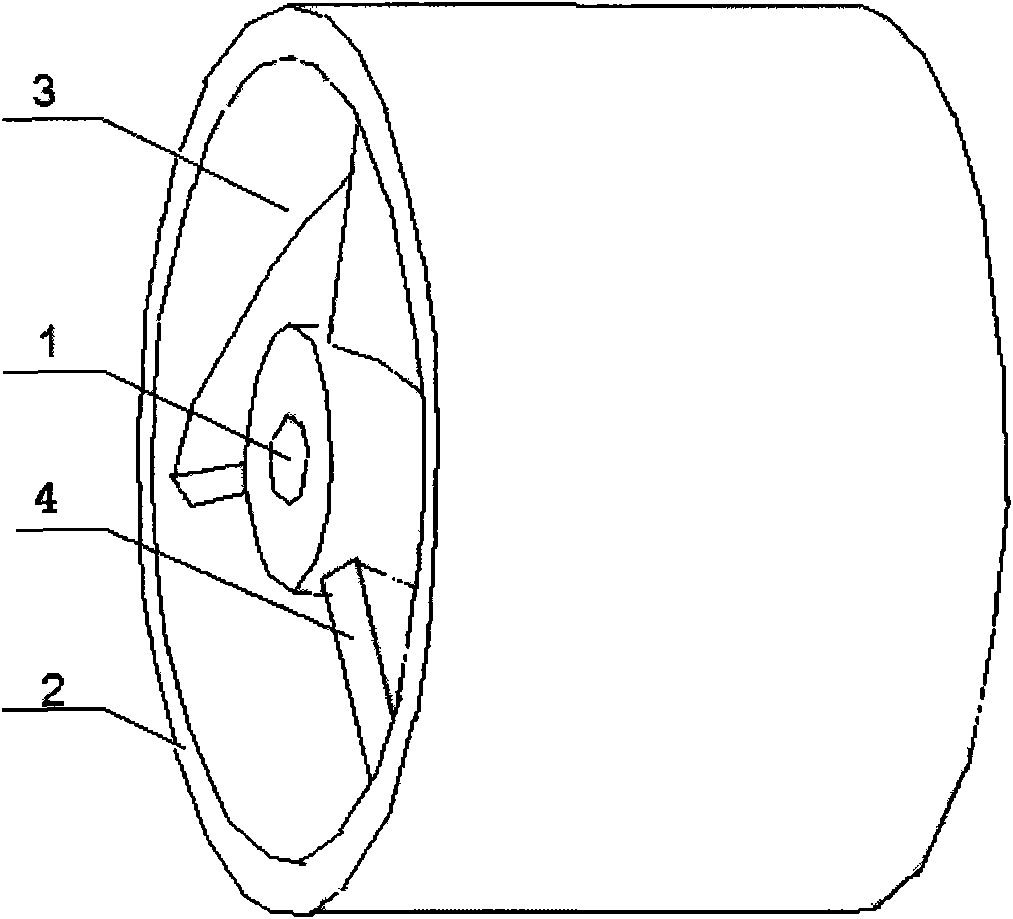

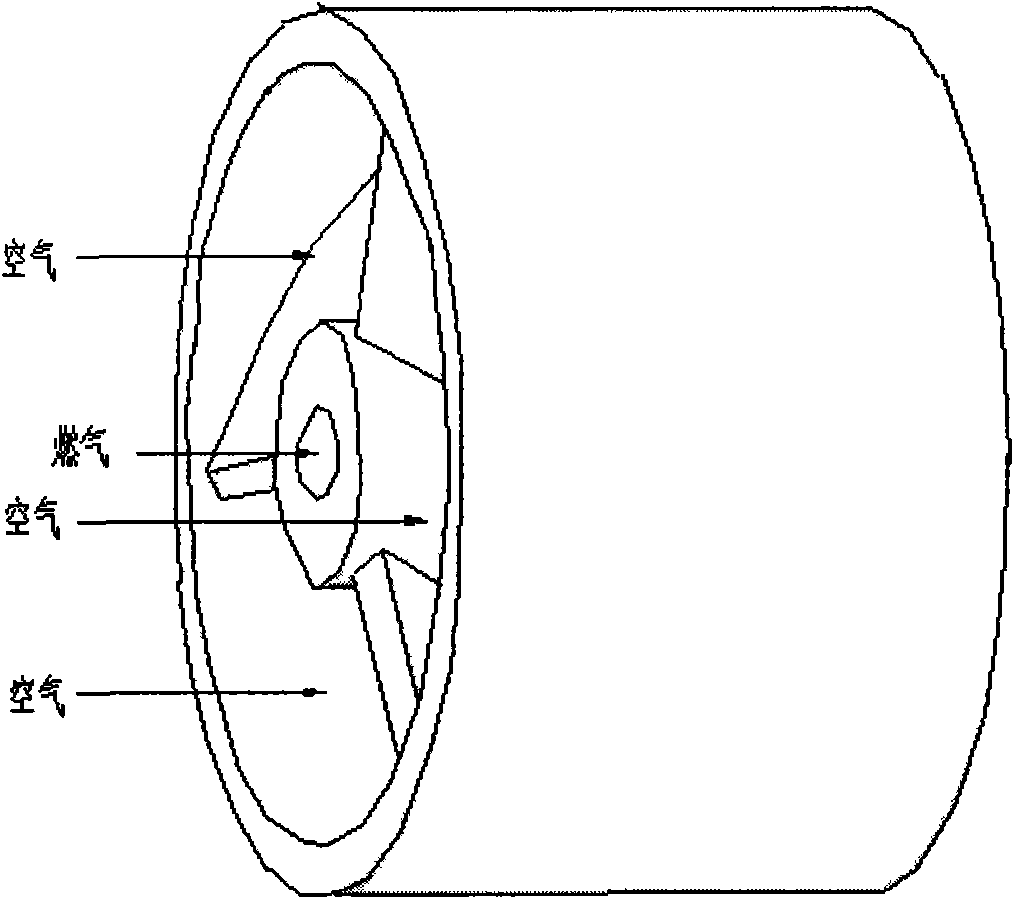

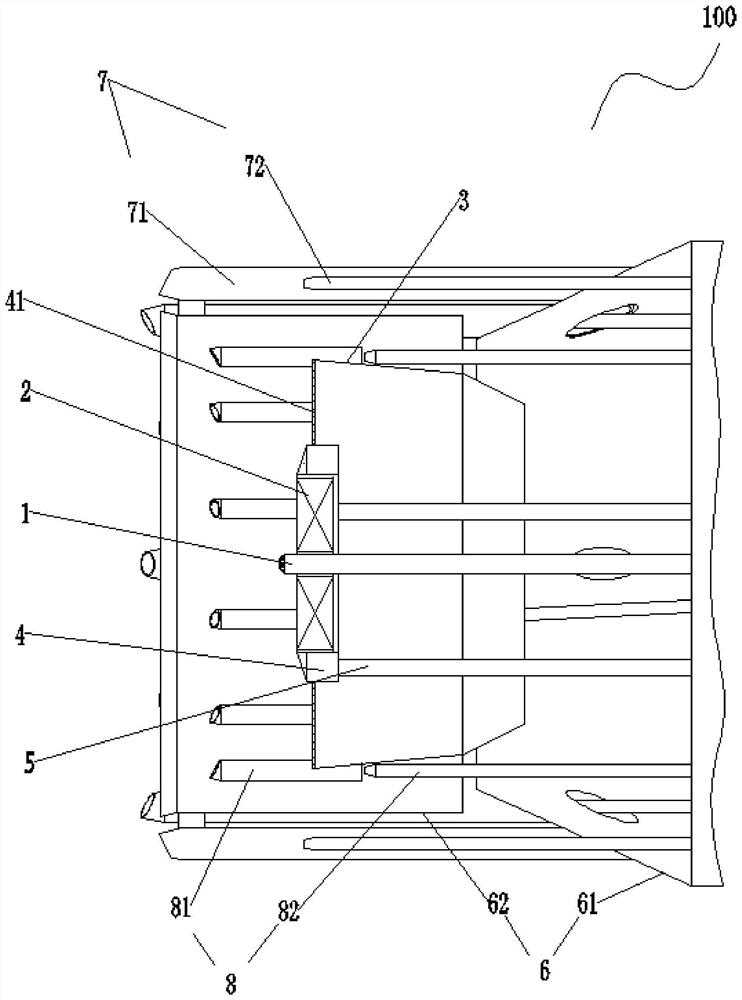

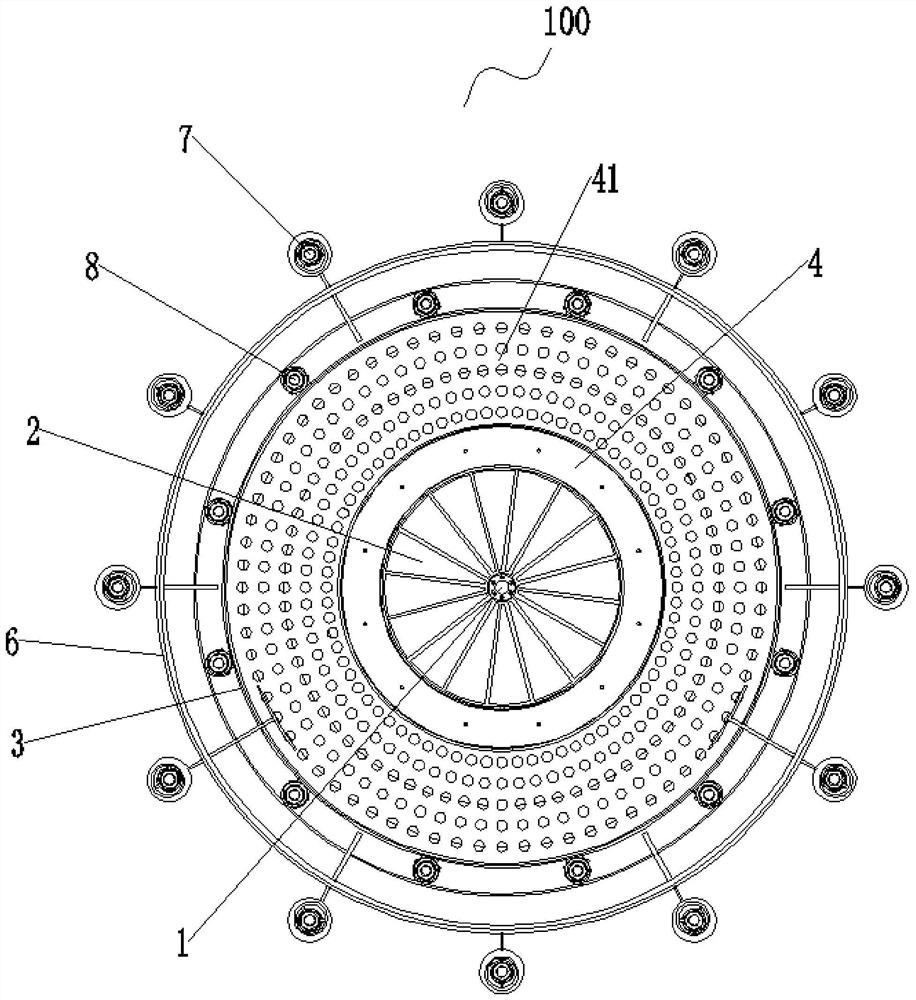

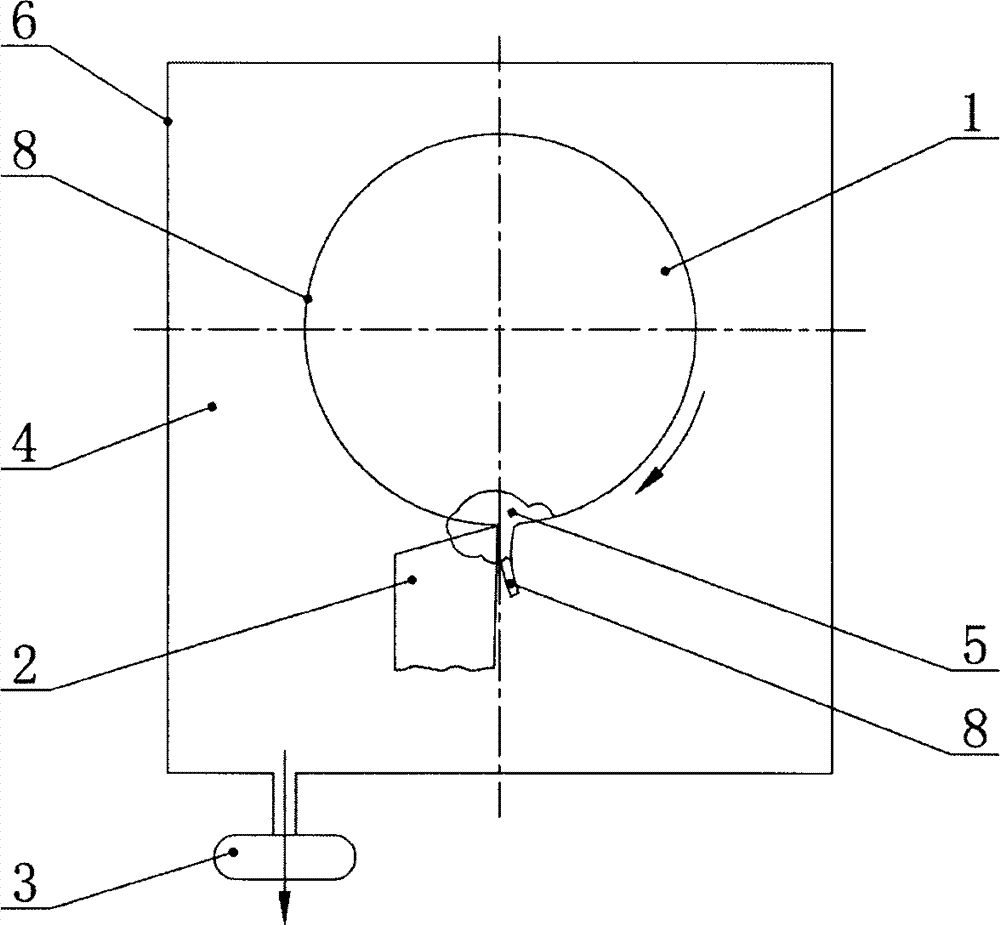

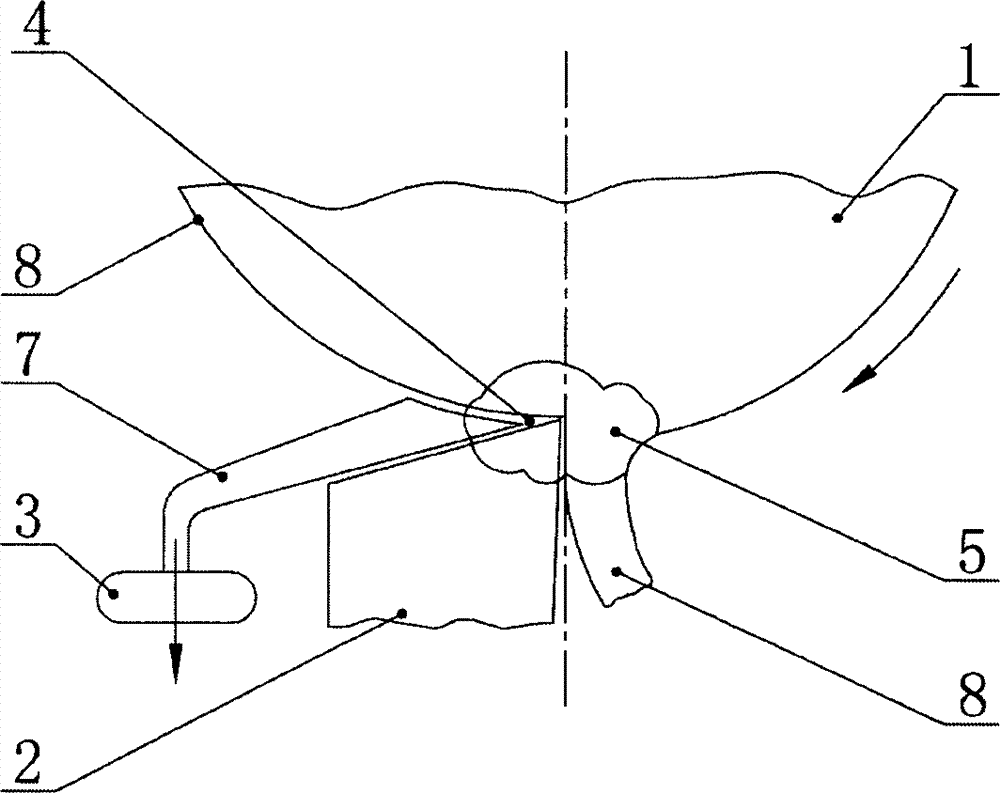

Cyclone burner for high-temperature air burning industrial furnace

InactiveCN101852434AUniform temperature distributionEmission reductionGaseous fuel burnerCycloneNitrogen oxides

The invention relates to a concentric axial cyclone burner of an industrial furnace high-temperature air burning technique. The concentric axial cyclone burner consists of a central round straight-through pipe (1), an outer layer casing pipe (2), a rotary channel (3) and a helical fin (4), wherein the central round straight-through pipe (1) is positioned at a coaxial position in the outer layer casing pipe (2). The concentric axial cyclone burner can strengthen the intensive mixing of a gas fuel and high-temperature air in a hearth of the industrial furnace so as to ensure that stable burning is realized at a lower inlet air oxygen concentration, the temperature distribution in the hearth is more uniform, the local temperature is reduced, and simultaneously the discharge of nitrogen oxides (NOX) is greatly reduced to fulfill the aims of energy saving and environmental protection.

Owner:DONGHUA UNIV

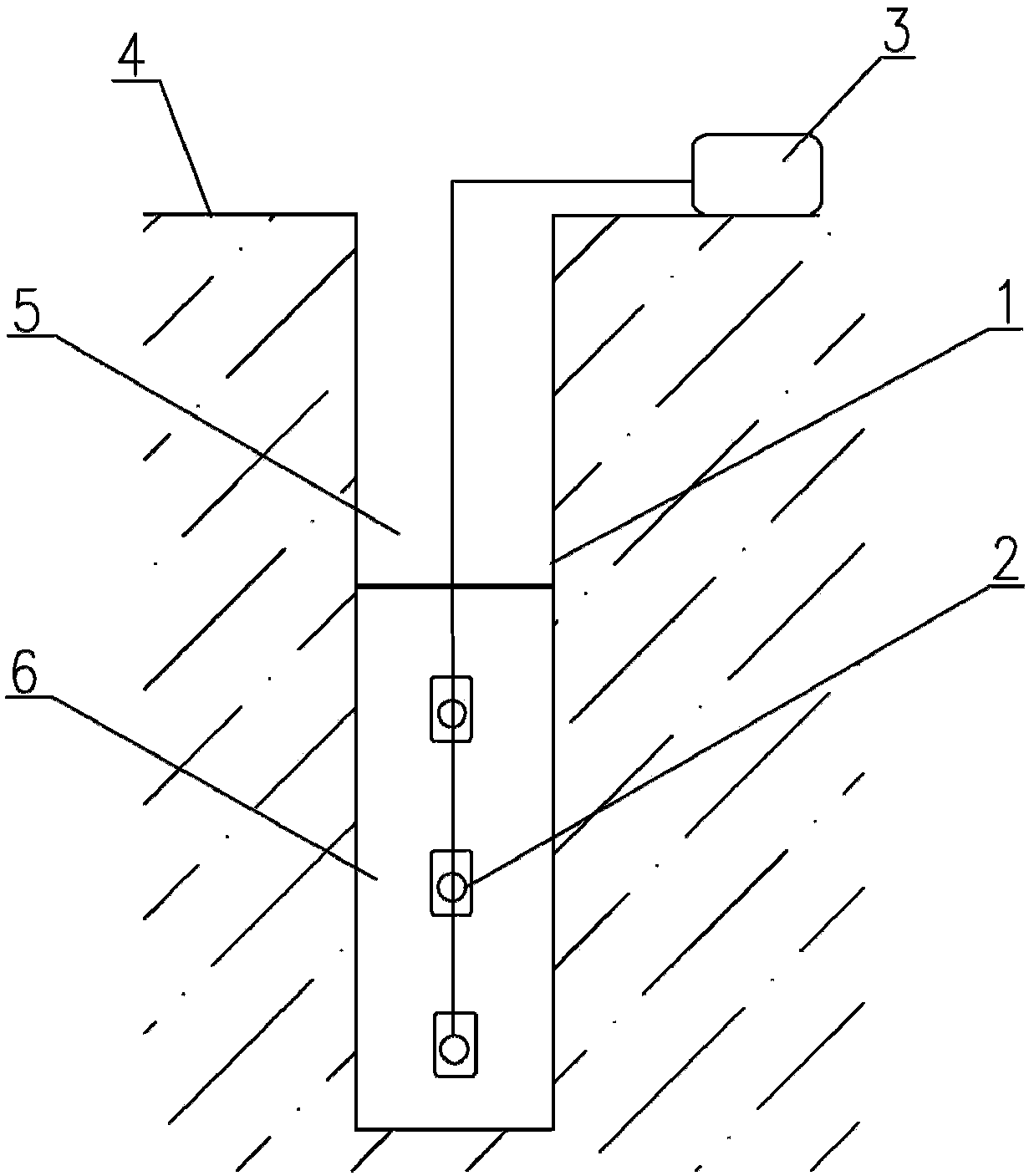

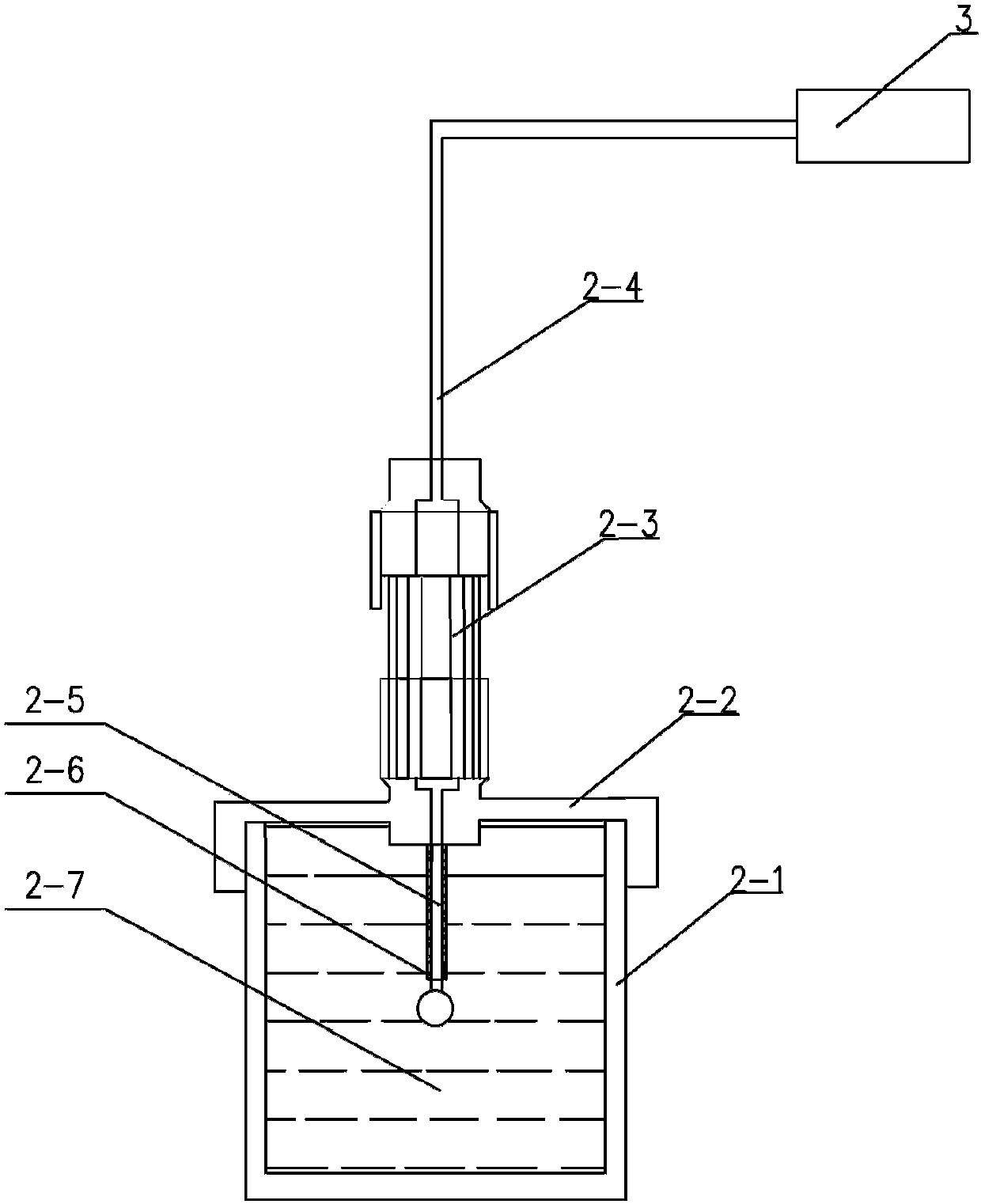

Device and method for on-site testing of explosive detonation velocity and detonation pressure in charge hole

PendingCN107703323ALarge specific heat capacityReduce local high temperatureDevices using electric/magnetic meansMeasurement of explosion forceBurst pressureData collector

The invention relates to the field of mechanics of explosion, in particular to a device and method for on-site testing of the explosive detonation velocity and detonation pressure in a charge hole. The device for the on-site testing of the explosive detonation velocity and detonation pressure in the charge hole includes a water container, a PVDF piezoelectric diaphragm, a connector, a data line, and a data collector. The detonation velocity and detonation pressure method is that a plurality of devices for testing the explosive detonation velocity and detonation pressure are arranged in the charge hole before blasting and are connected with the data collector to form a data acquisition system, a detonation velocity value and a detonation pressure value collected by each device for testing the explosive detonation velocity and detonation pressure are obtained after the blasting, and a detonation velocity average value and a detonation pressure average value of the plurality of devices for testing the explosive detonation velocity and detonation pressure are solved. The device and method in the invention have the advantages of simple structure and convenient use, the system can be used for testing the explosive detonation velocity and detonation pressure, the test is convenient, the precision is high, and the cost is low.

Owner:鞍钢矿业爆破有限公司

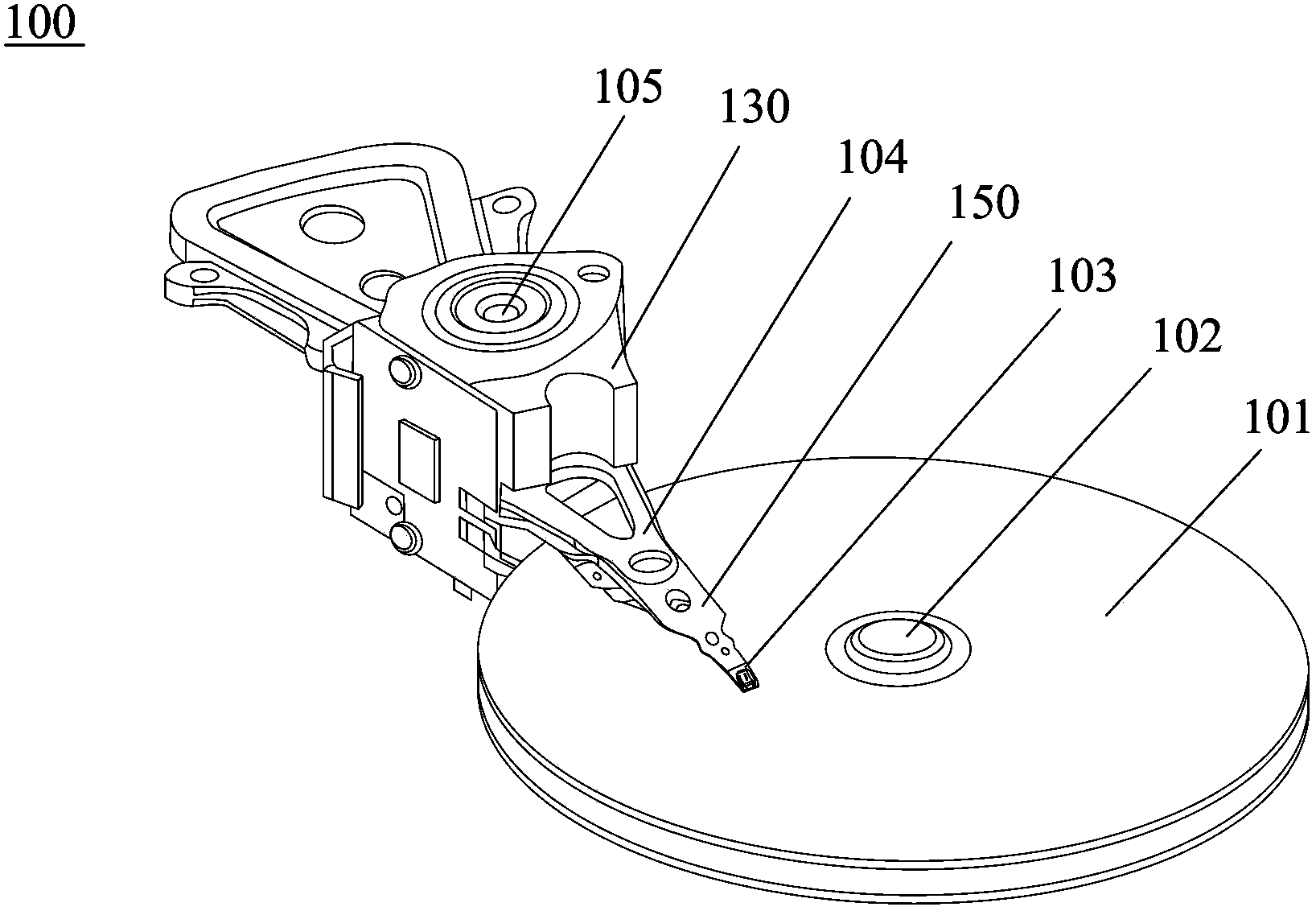

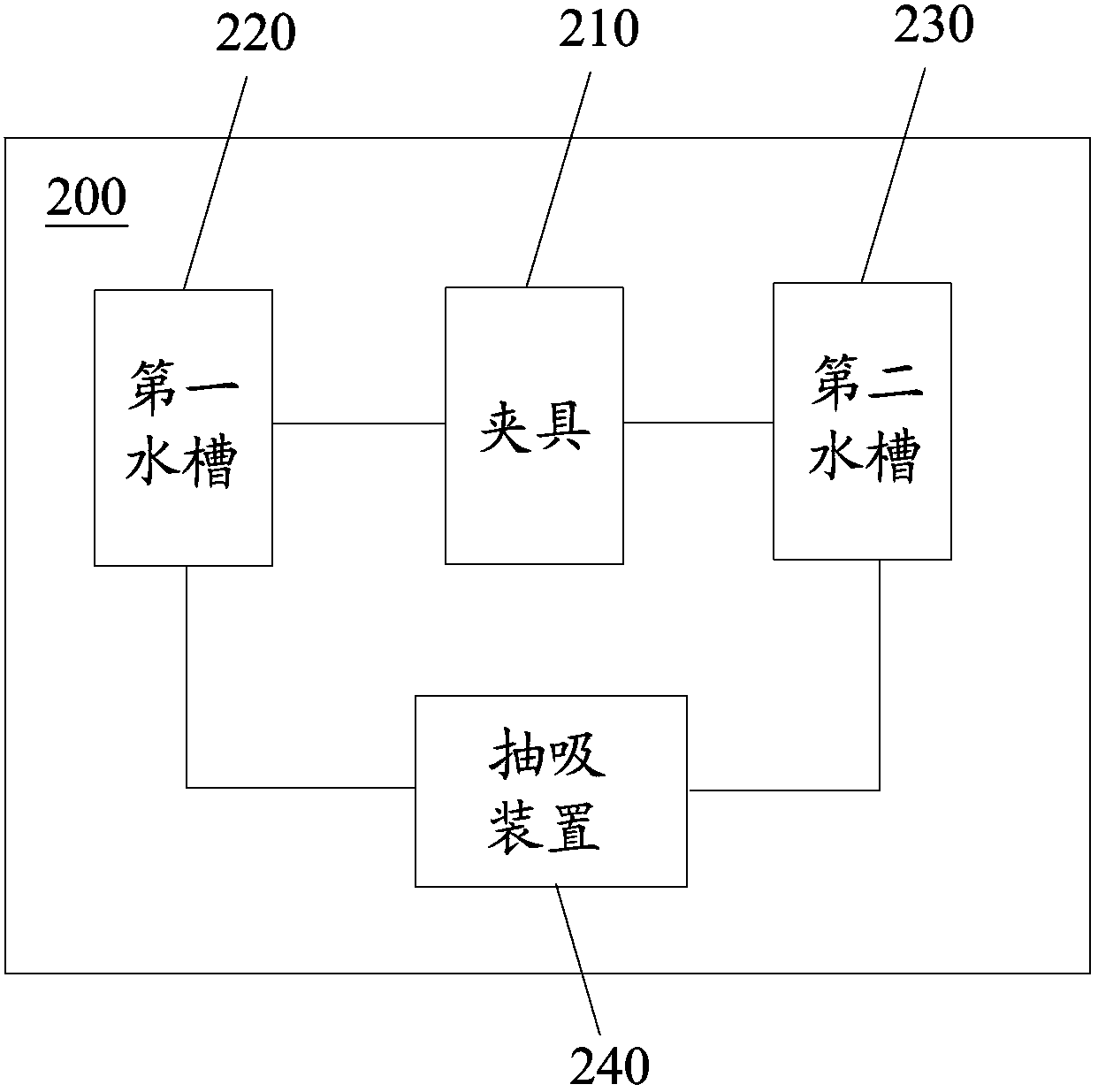

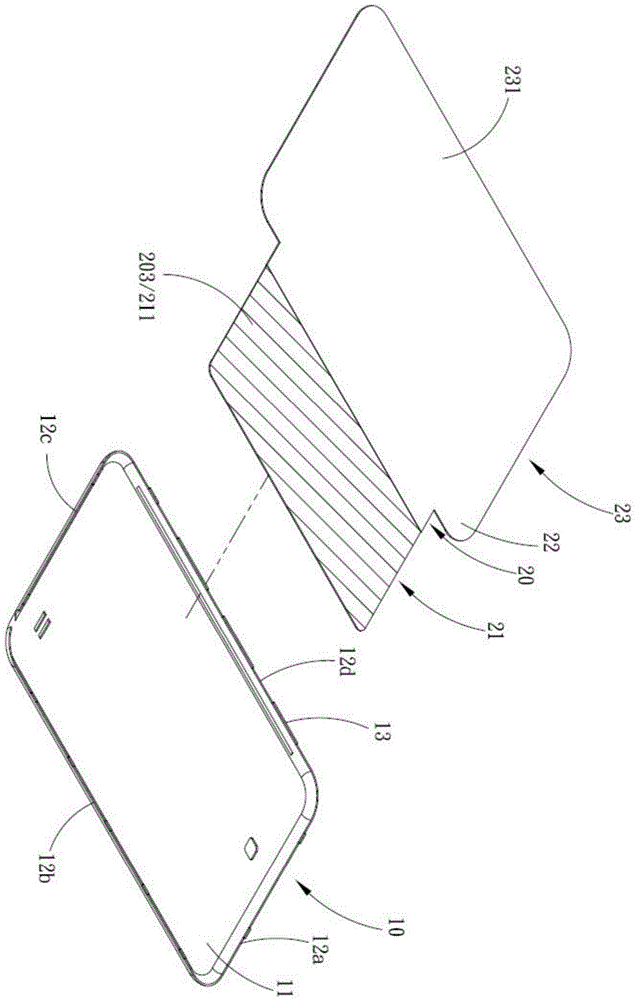

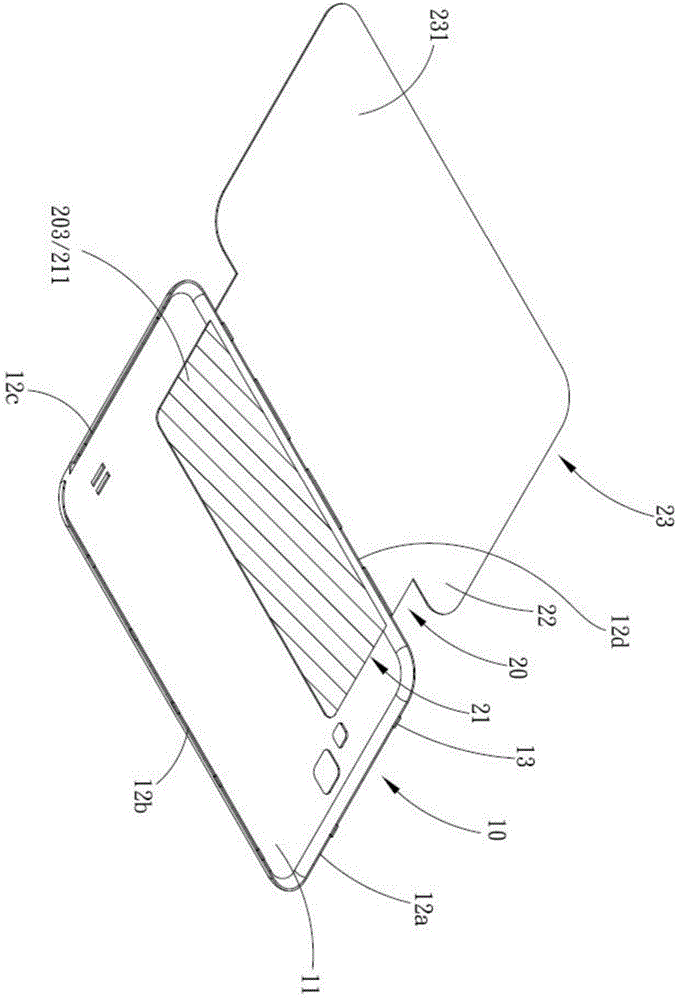

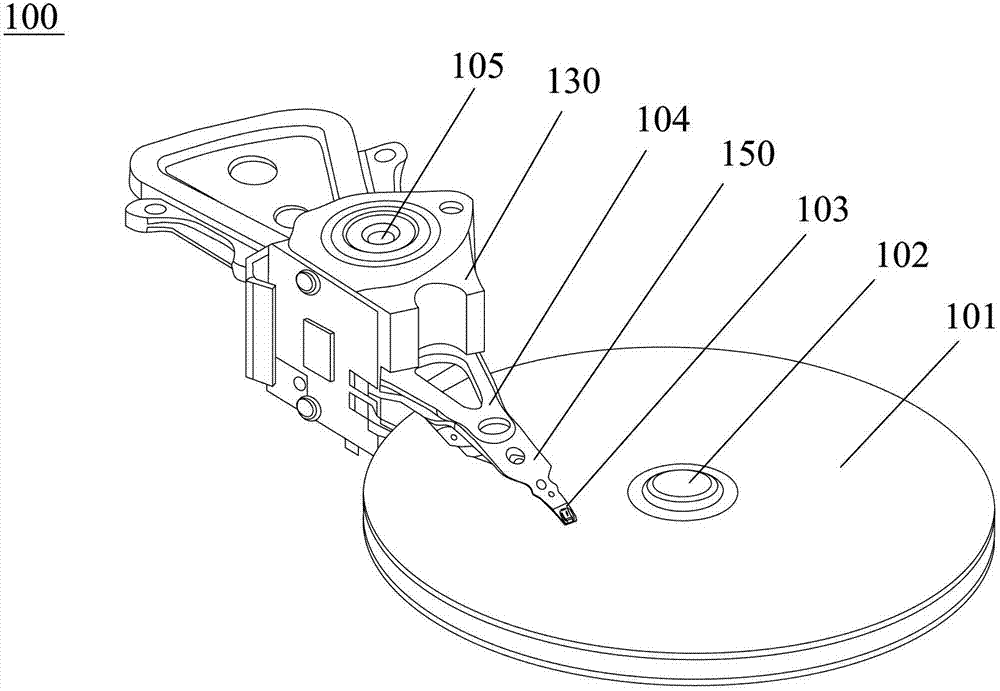

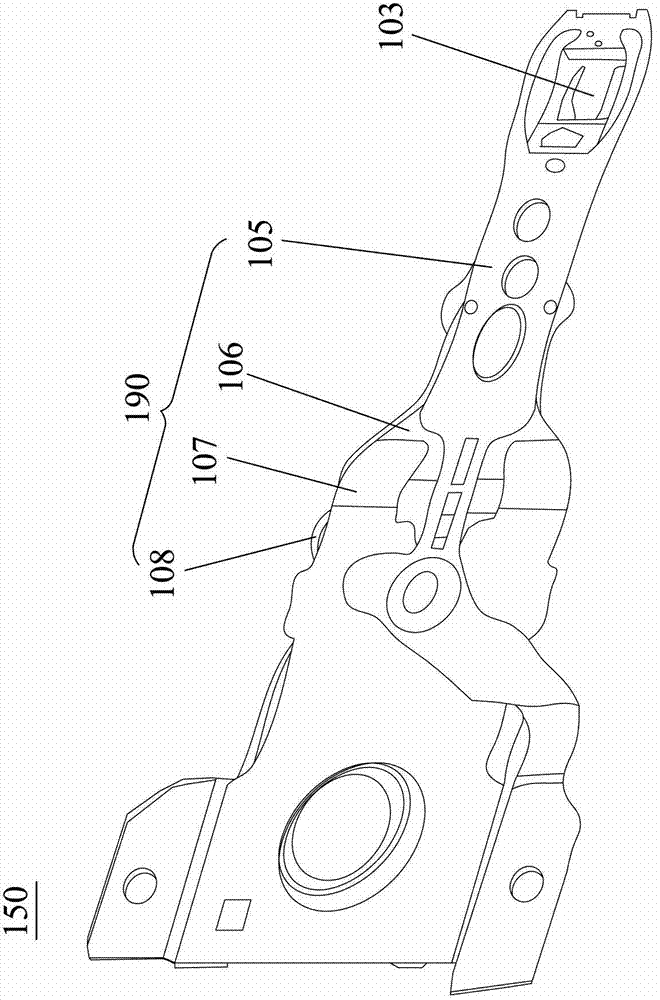

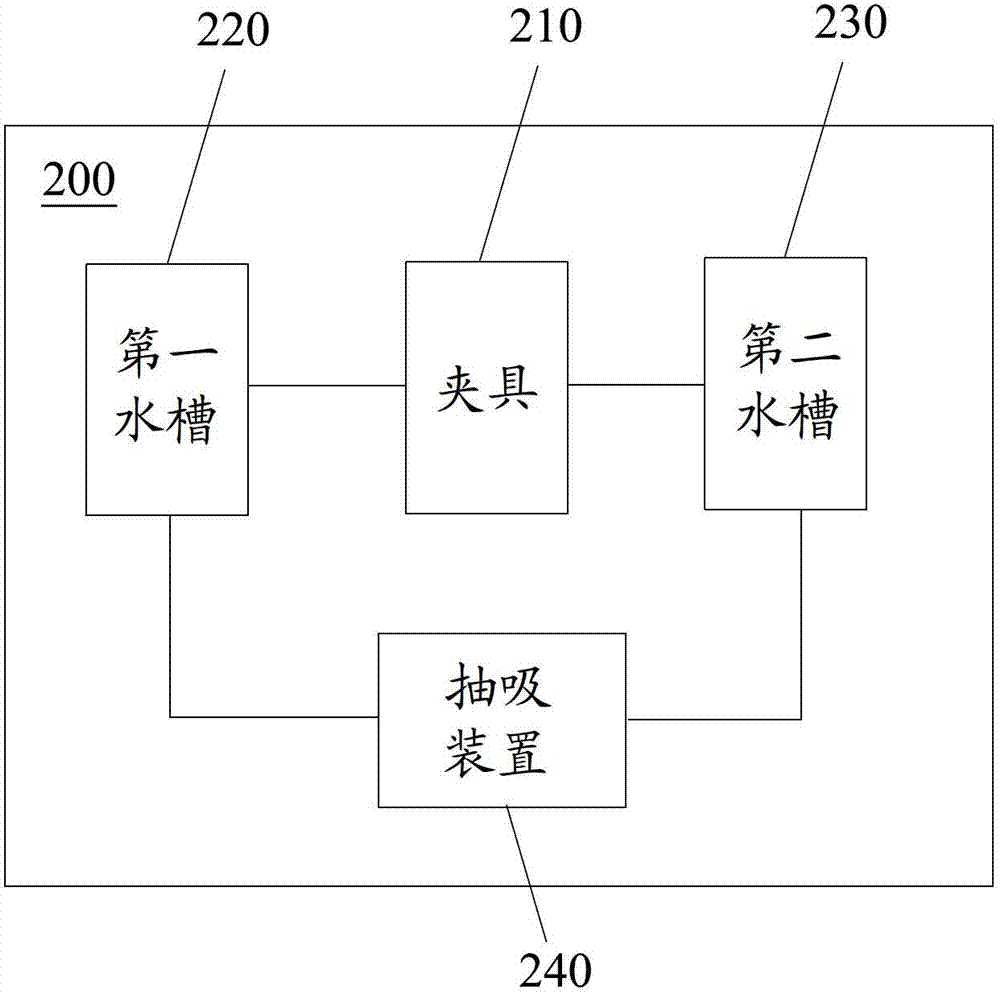

Semiconductor light source bar cooling system and cooling method in aging tests

ActiveCN103514893AQuick retreatImprove thermal stabilityLighting heating/cooling arrangementsFunctional testing of recording headsInlet channelHeat stability

The invention discloses a semiconductor light source bar cooling system in aging tests. The cooling system comprises: a fixture for clamping a semiconductor light source bar, wherein the fixture comprises a housing, and the housing is provided with a water inlet channel and a water outlet channel which are communicated to each other; a first water tank which is connected with the water inlet channel, wherein cooling liquid is contained in the water tank; a second water tank which is connected with the water outlet channel; and a suction device which is connected with the water outlet channel, wherein the suction device is used to suck the cooling liquid in the first water tank to the second water tank at least so as to wash the bottom portion of the semiconductor light source bar to reduce the temperature of the semiconductor light source bar. According to the invention, the heat generated by the semiconductor light source bar in the aging test process can be dissipated, and the advantage of local temperature uniformity can be realized, so the temperature required in the aging tests can be maintained and the heat stability of a HAMR head can be improved. The invention also discloses a corresponding cooling method.

Owner:SAE MAGNETICS (HK) LTD

Protection apparatus with radiating function

InactiveCN105682416AImprove surface heat concentrationReduce local high temperatureCooling/ventilation/heating modificationsHeat conductingEngineering

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

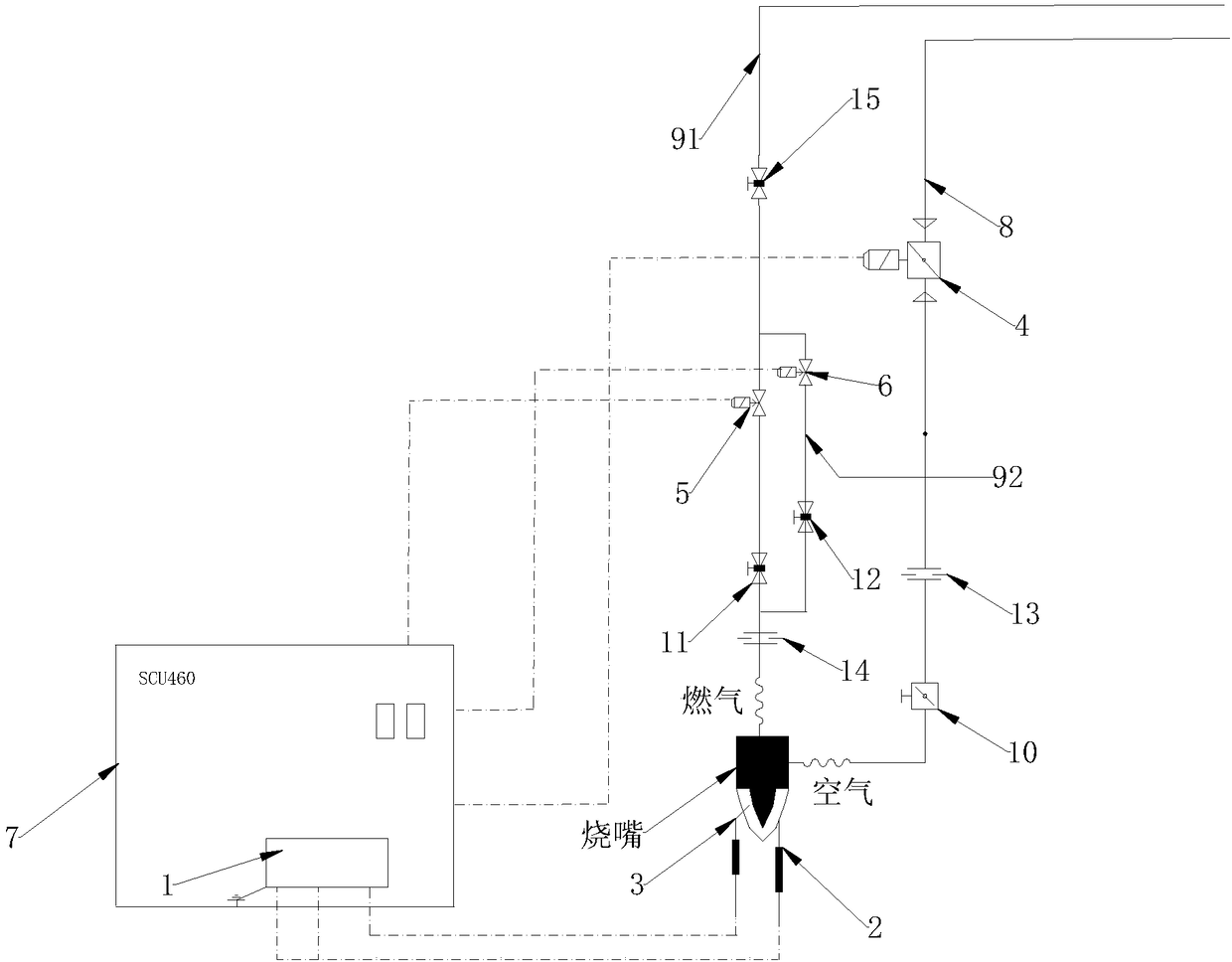

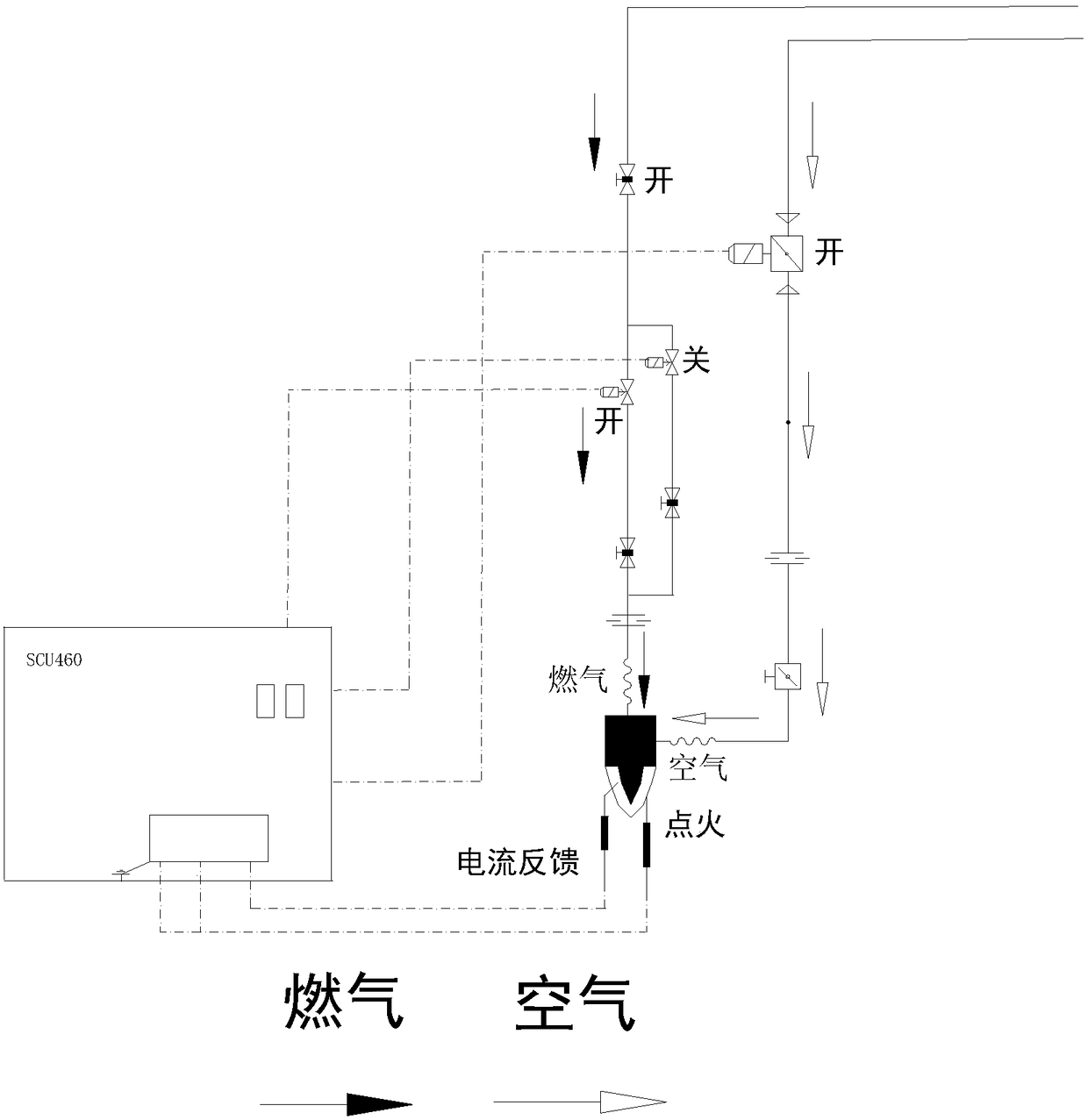

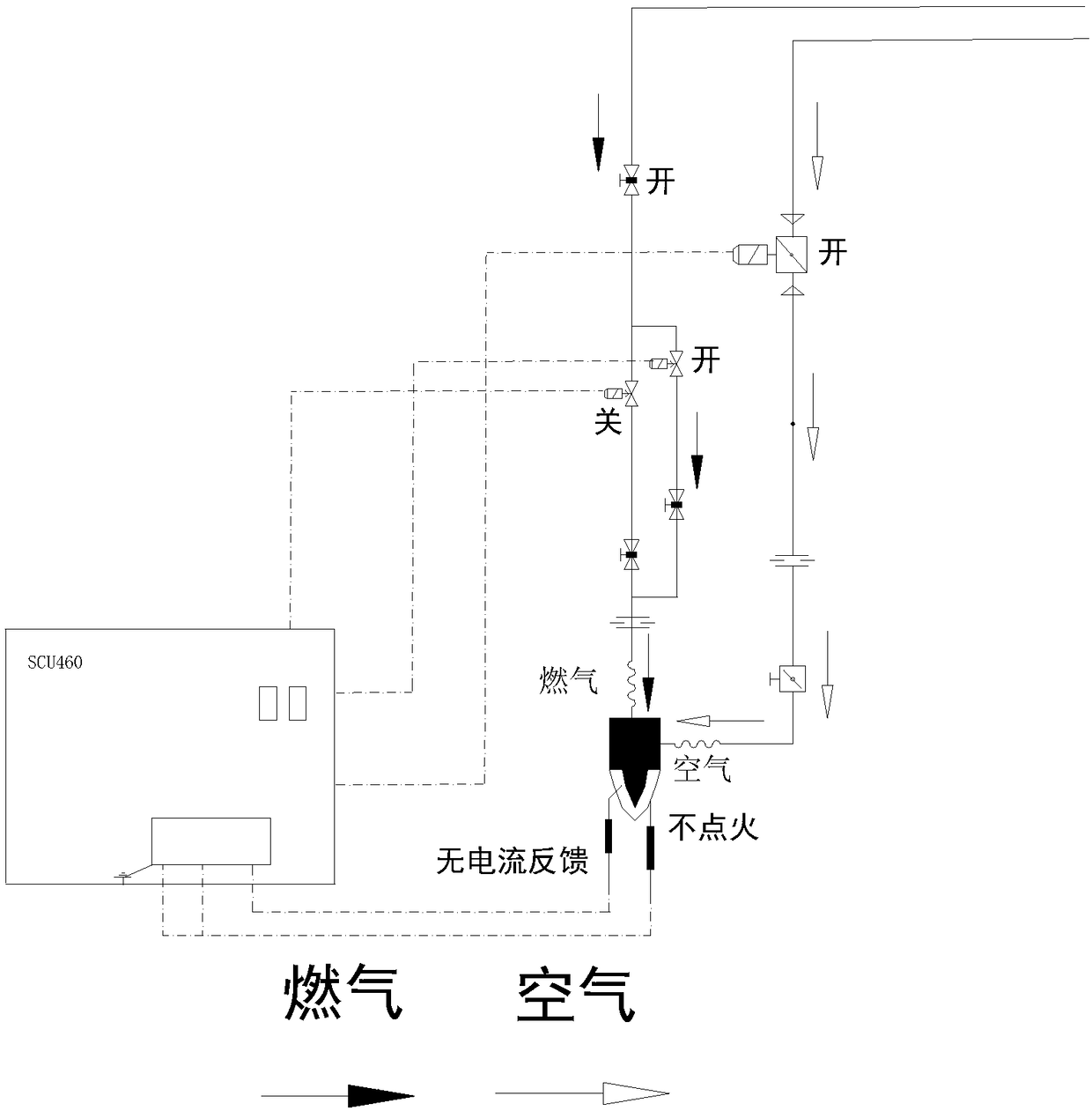

Flameless burner control system, flameless low-NOx burner and control method thereof

PendingCN108386837ARealize automatic switching controlEasy to operateIndirect carbon-dioxide mitigationGaseous fuel burnerFurnace temperatureAutomatic control

The invention discloses a flameless burner control system, a flameless low-NOx burner and a control method thereof. Through application of a control system taking an SCU460 ignition controller as a core, different actions of a plurality of sets of valves can be automatically controlled according to the flameless combustion and flameless combustion temperature conditions; automatic switching control over different working modes of flameless combustion and flame combustion is achieved, and manual switching is not required, so that the control system is easy to operate, and safe and reliable; meanwhile, the flameless combustion and flame combustion of the burner applying the system can be controlled through the SCU460 ignition controller; during flame combustion, when the furnace temperatureis lower than the set temperature, the burner is ignited by an ignition electrode, and the flame can be detected by a detection electrode; the stable and reliable low-temperature combustion process isensured; in the flameless combustion phase, when the furnace temperature is higher than the set temperature, and the ignition electrode is not ignited; gas and air are injected into a furnace for combustion, and surrounding flue gas can be entrained by high-speed airflow injected into the furnace to take part in combustion; and local high temperature of the flame is reduced greatly, and NOx is reduced quickly.

Owner:FOSHAN KEHAO COMBUSTION EQUIP MFG

Microorganism continuous culture device

ActiveCN112226347AUniform heat transferExtended service lifeBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyMicroorganism

The invention belongs to the field of microorganism culture devices, and particularly relates to a microorganism continuous culture device. The device comprises a culture tank and an aeration pipe arranged in the culture tank, and further comprises a heating pipe which surrounds the periphery of the aeration pipe and is used for heating a culture solution in the culture tank. A plurality of baffles distributed in the axial direction of the aeration pipe are further fixed to the aeration pipe, the baffles are annular, the centers of the baffles are sunken downwards, and leaking holes are formedin the positions close to the aeration pipe, of the baffles. The heating pipe spirally surrounds the periphery of the aeration pipe, and the spiral diameter is larger than that of each baffle. The microorganism continuous culture device is simple in structure, convenient to operate and low in manufacturing cost, iron and vanadium attached and deposited on the heating pipe and the culture tank canbe greatly reduced while ore leaching microorganisms are continuously cultured, so that the purpose of continuously obtaining the microorganisms for a long time is achieved, and the service life of the heating device is greatly prolonged.

Owner:CENT SOUTH UNIV

Internal circulating low nitrogen gas burner

ActiveCN112178626AReduce use costSolve the real problemFluegas recirculationGaseous fuel burnerThermodynamicsCombustion chamber

The invention relates to the field of burners and discloses an internal circulating low nitrogen gas burner. A hydrocyclone is sleeved at one end of a first gas pipe, an annular gas head is sleeved onthe outer side of the hydrocyclone and is in clearance fit to the hydrocyclone, a second gas pipe conveys gas to an annular gas head, a dividing pipe sleeves the outer side of the annular gas head, and an isolating part sleeves the outer side of the dividing pipe and form a flue gas channel with the dividing pipe. A plurality of inner ring gas assemblies are located in the flue gas channel and are mounted on the peripheral side of the isolating part. The dividing pipe is used for dividing air to form air for mixing glue gas and air for mixed burning. The air for mixing glue gas generates a negative pressure at a glue gas inlet when flowing through the flue gas channel so as to inhale the flue gas in a burning chamber to take part in burning again. By way of recovering the glue gas directly in vacuum, the flue gas channel is cancelled and the potential safety hazard is eliminated, and the using cost is lowered.

Owner:SHANGHAI NUOTE FEIBO COMBUSTION EQUIP CO LTD

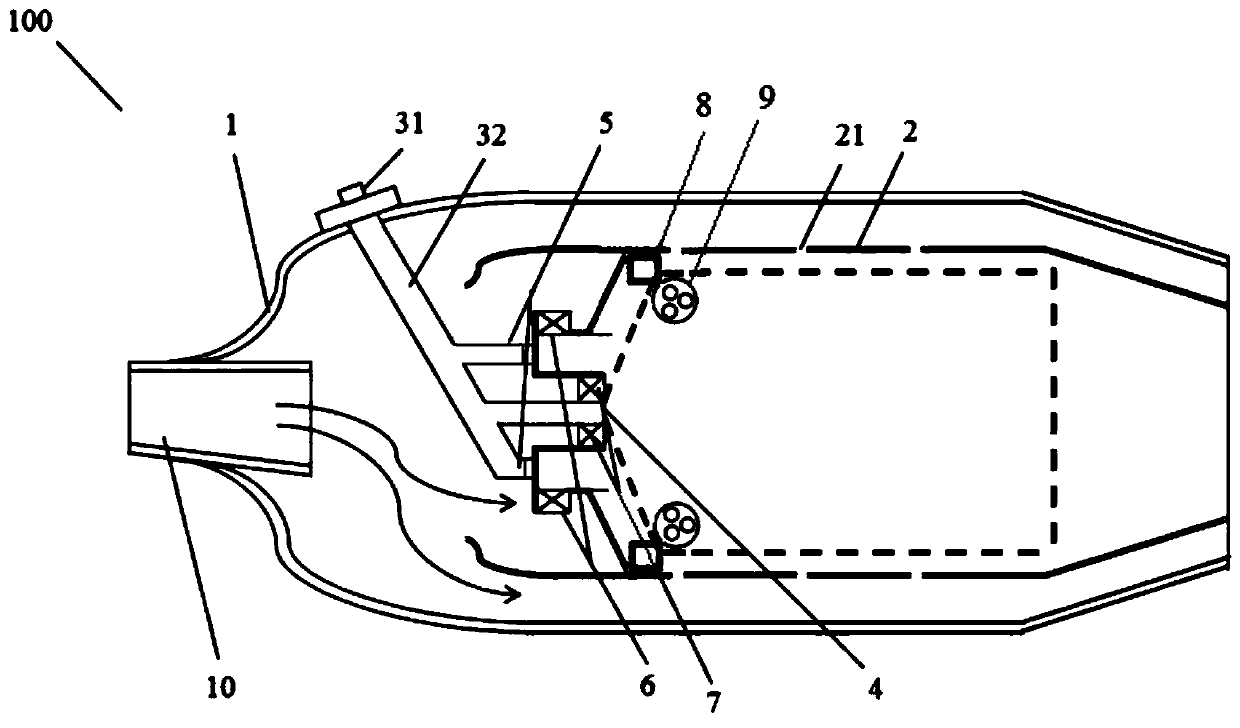

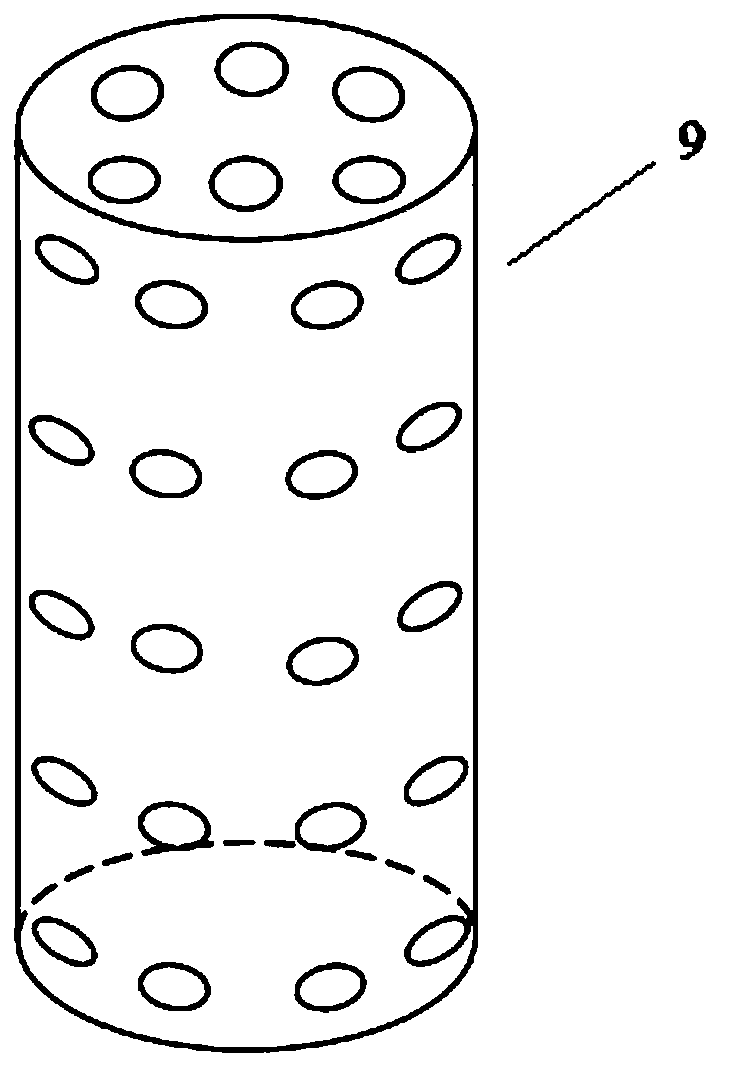

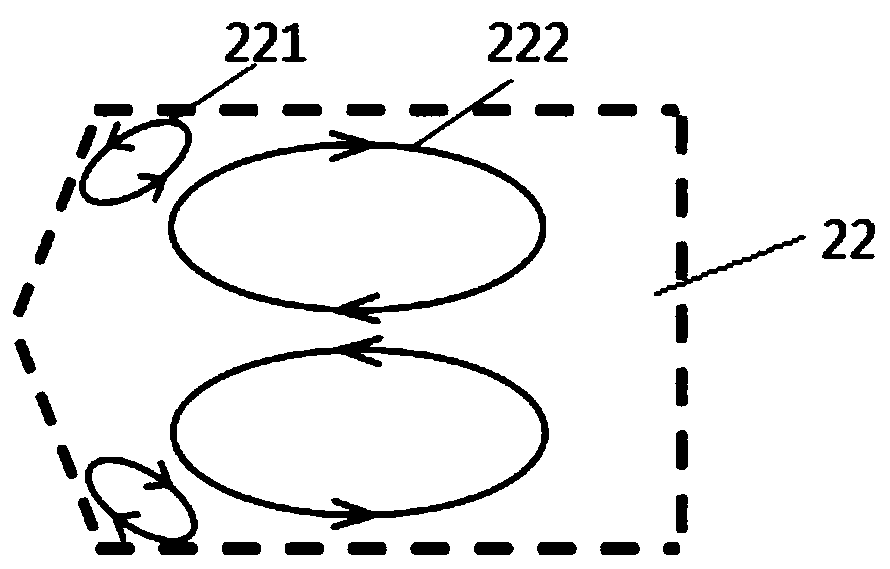

Combustion chamber device for dispersing high-temperature reflux zone at boss

PendingCN111288490AReduce local high temperatureAvoid fire situationsContinuous combustion chamberThermodynamicsSpray nozzle

The invention discloses provides a combustion chamber device for dispersing a high-temperature reflux zone at a boss. The combustion chamber device for dispersing the high-temperature reflux zone at the boss comprises a casing, a flame tube, a fuel channel, an on-duty fuel channel, two fuel inlet channels, radial cyclones, axial cyclones, the boss, porous cylinders and a pressure expanding channel; the flame tube is arranged in the casing and forms an annular cavity with the casing; the fuel channel comprises a fuel spraying nozzle arranged on the casing and an input pipeline connected to thefuel spraying nozzle, and is used for inputting fuel; one end of the on-duty fuel channel is connected with the input pipeline, and the other end of the on-duty fuel channel is positioned at the central position of the head of the flame tube; one end of each fuel input channel is connected with the input pipeline; the other end of each fuel input channel is positioned at the head of the flame tube; the fuel inlet channels are respectively arranged on the two sides of the on-duty fuel channel; the radial cyclones are arranged at outlets of the fuel inlet channels in circumferential directions;the axial cyclones are arranged on the outer side of the on-duty fuel channel in an annular direction; the boss is positioned at the tail end of an inlet sudden enlargement structure of the flame tube; the porous cylinder is longitudinally fixed to the boss; and the pressure expanding channel is formed in the head of the casing and is used for intruding high-speed air flow.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

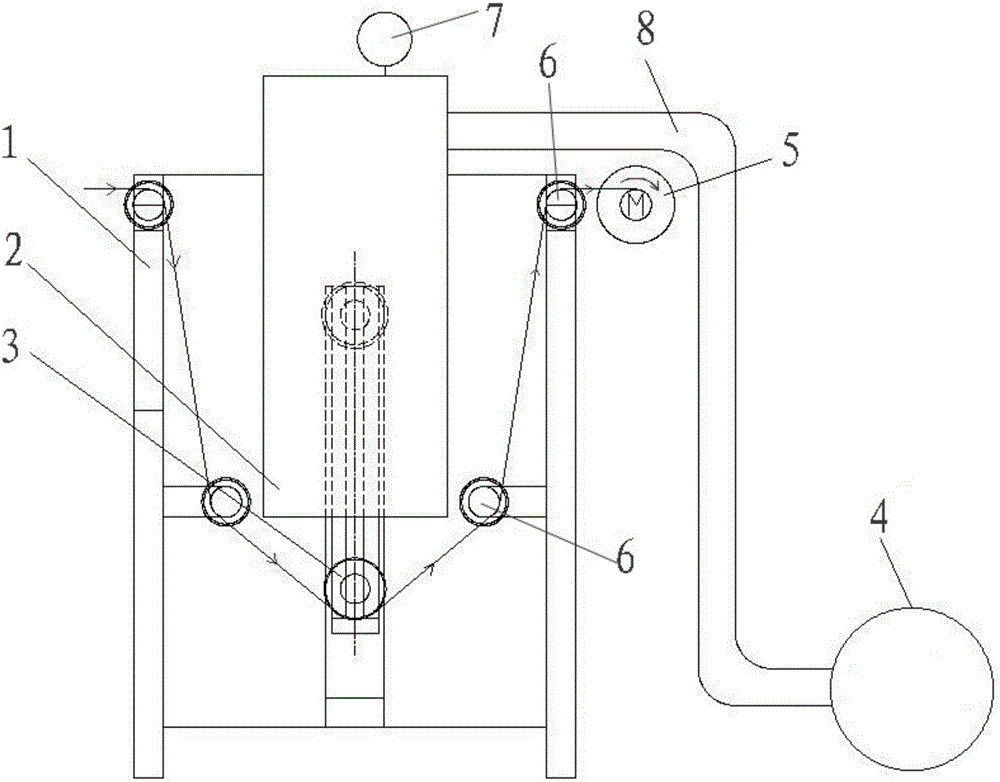

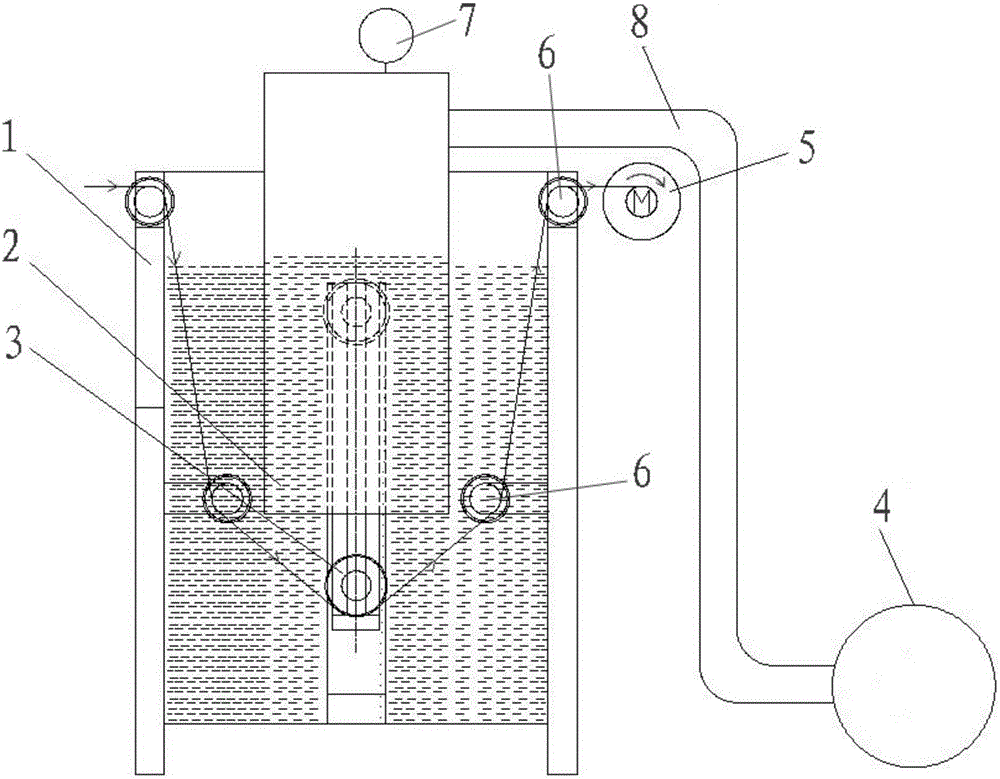

Vacuum type continuous oiling equipment for chain

InactiveCN105797915AReduce frictionReduce local high temperatureLiquid surface applicatorsCoatingsDrive motorVacuum pump

The invention relates to vacuum type continuous oiling equipment for a chain. The vacuum type continuous oiling equipment comprises a vacuum pump, a driving motor, a sealed box body, a chain reversing system and a chain guiding system, wherein the chain reversing system and the chain guiding system are arranged in the sealed box body. The chain is sequentially wound round the driving motor, the chain guiding system and the chain reversing system. The vacuum pump is connected into the sealed box body through a pipeline. According to the vacuum type continuous oiling equipment for the chain, the effect that the vacuum degree is adjustable can be achieved; bubbles can be generated in the process that air is pumped out, can be burst when colliding chain parts and has a cleaning effect on the chain; and the abrasion resistance of the chain is improved by 15%, and oil fume can be exhausted in a concentrated mode.

Owner:青岛征和链传动有限公司

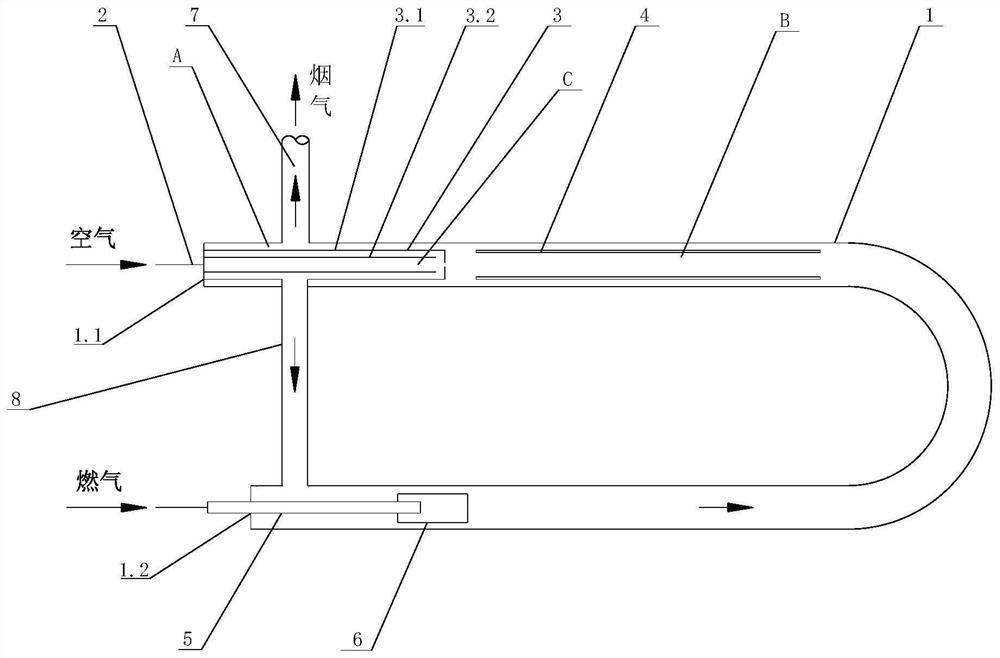

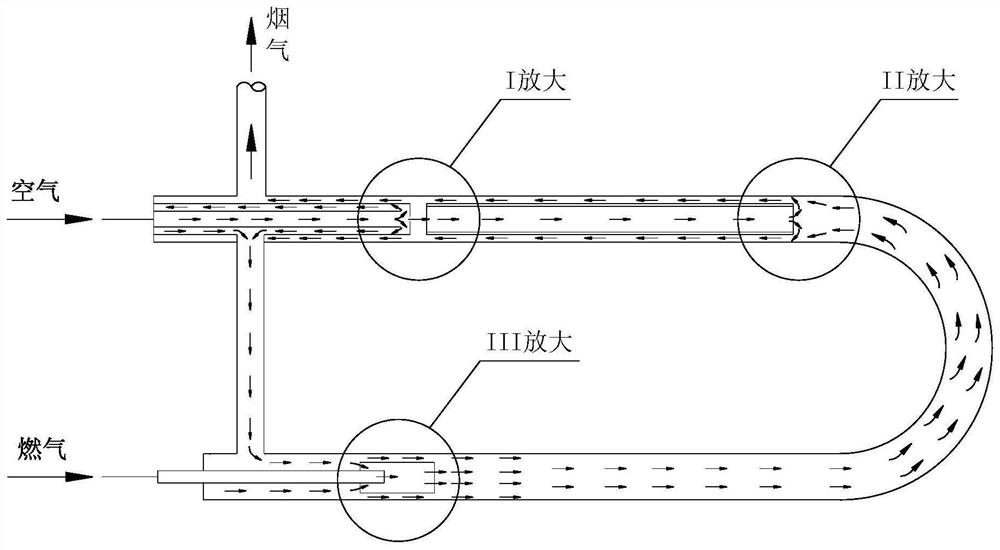

Two-end type radiant tube staged combustion device and using method

ActiveCN113864781AReduce local high temperatureReduce generationIndirect carbon-dioxide mitigationGaseous fuel burnerEngineeringReaction zone

The invention discloses a two-end type radiant tube staged combustion device and a using method. The two-end type radiant tube staged combustion device comprises a U-shaped radiant tube, an air inlet hole is formed in the air end of the radiant tube, an air supply pipe is arranged outside the air inlet hole, and a gas pipe hole is formed in the gas end of the radiant tube; a heat exchanger and a fluid director are arranged in the air end of the radiant tube in a separated mode, the heat exchanger is communicated with the air inlet hole, a gas supply pipe is installed on the gas pipe hole, part of the end of the gas supply pipe extends into the radiant tube, and an outlet of the gas supply pipe is sleeved with an air distributor; a smoke exhaust pipe is installed on the outer wall of the air end of the radiant tube, and an air connecting pipe is arranged between the air end and the gas end of the radiant tube; and the air connecting pipe extends into the air end of the radiant tube and is connected with the heat exchanger. According to the device, all reaction areas are adjusted to be in fuel-rich combustion so that the local high temperature of a flame area can be reduced, and meanwhile, a large amount of CO is generated to reduce NOx, so that the generation amount of NOx is greatly reduced.

Owner:武汉钢铁有限公司

Low NOx heat storage flat flame burner and combustion control method

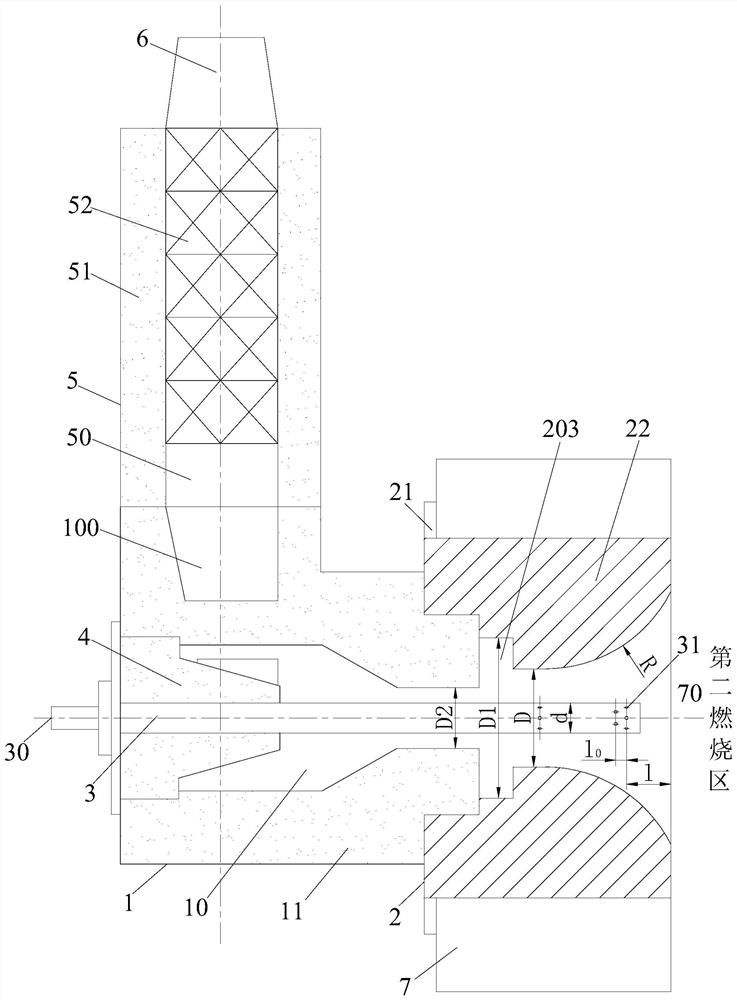

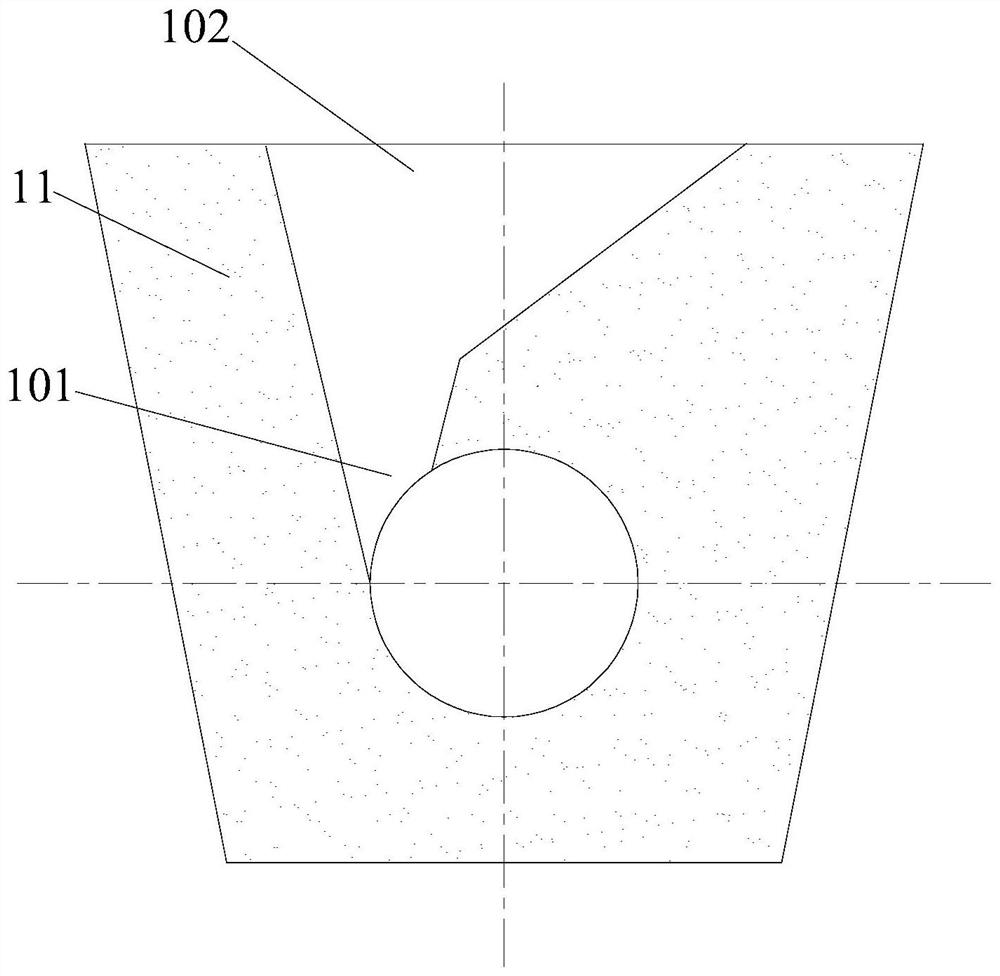

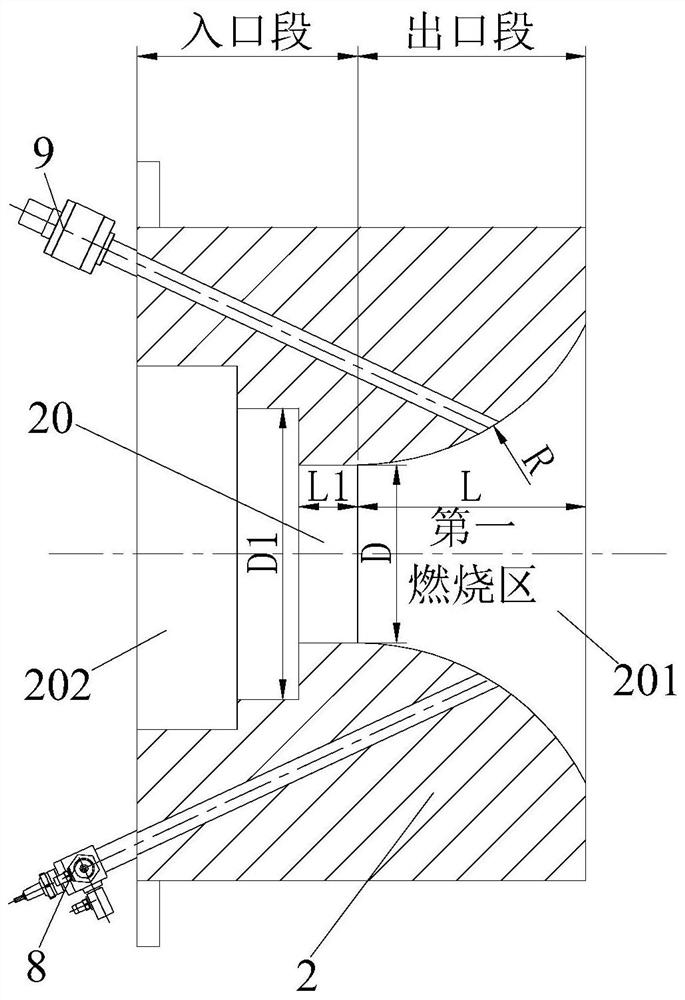

PendingCN111928240AEmission reductionSimple structureIndirect carbon-dioxide mitigationGaseous fuel burnerThermodynamicsCombustor

The invention belongs to the technical field of industrial burners, and particularly relates to a low NOx heat storage flat flame burner and a combustion control method, which are applied to industrial furnaces in iron and steel, non-ferrous metal, machines, ceramics and other industries. The low NOx heat storage flat flame burner comprises a burner head, a burner block and a gas pipe, the burnerhead is installed on the burner block, and the gas pipe is installed on the burner head and matched with the burner block. The low NOx heat storage flat flame burner is structurally characterized in that the burner block includes a burner block cavity and a burner block shell, the burner block cavity is arranged in the burner block shell and comprises an outlet section and an inlet section, the inlet section communicates with the outlet section, the burner head is installed on the inlet section, a reflowing cavity is formed between the burner head and the inlet section, the burner block is provided with reflowing holes, and the reflowing holes communicate with the reflowing cavity. Internal reflowing of the burner is carried out by means of the characteristics of the burner, the local hightemperature can be effectively reduced, the flame temperature is reduced, and NOx emissions are remarkably reduced.

Owner:HANGZHOU ZHONGJING TECH CO LTD

Cooling system and cooling method of semiconductor light source bar in aging test

ActiveCN103514893BQuick retreatImprove thermal stabilityLighting heating/cooling arrangementsFunctional testing of recording headsInlet channelEngineering

Owner:SAE MAGNETICS (HK) LTD

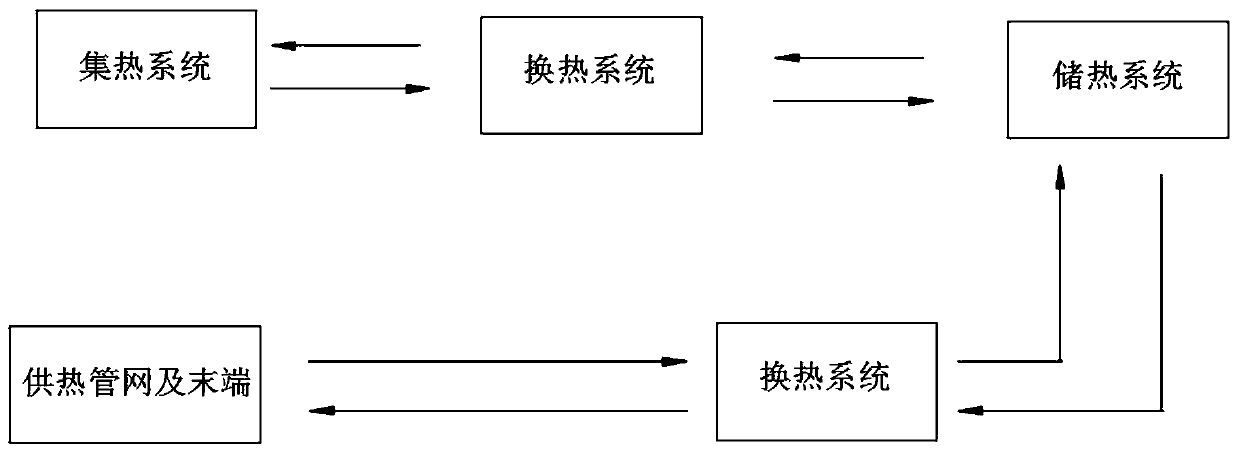

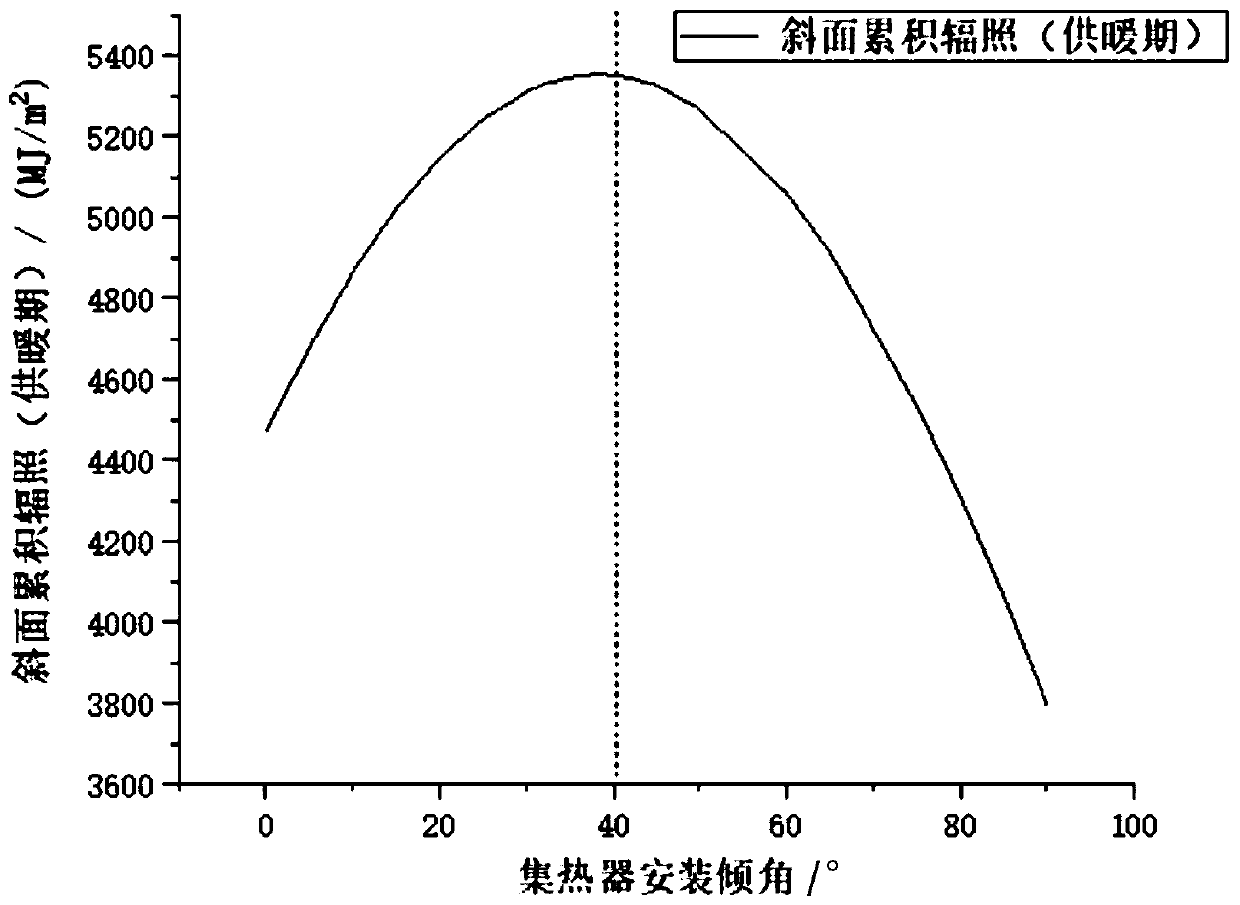

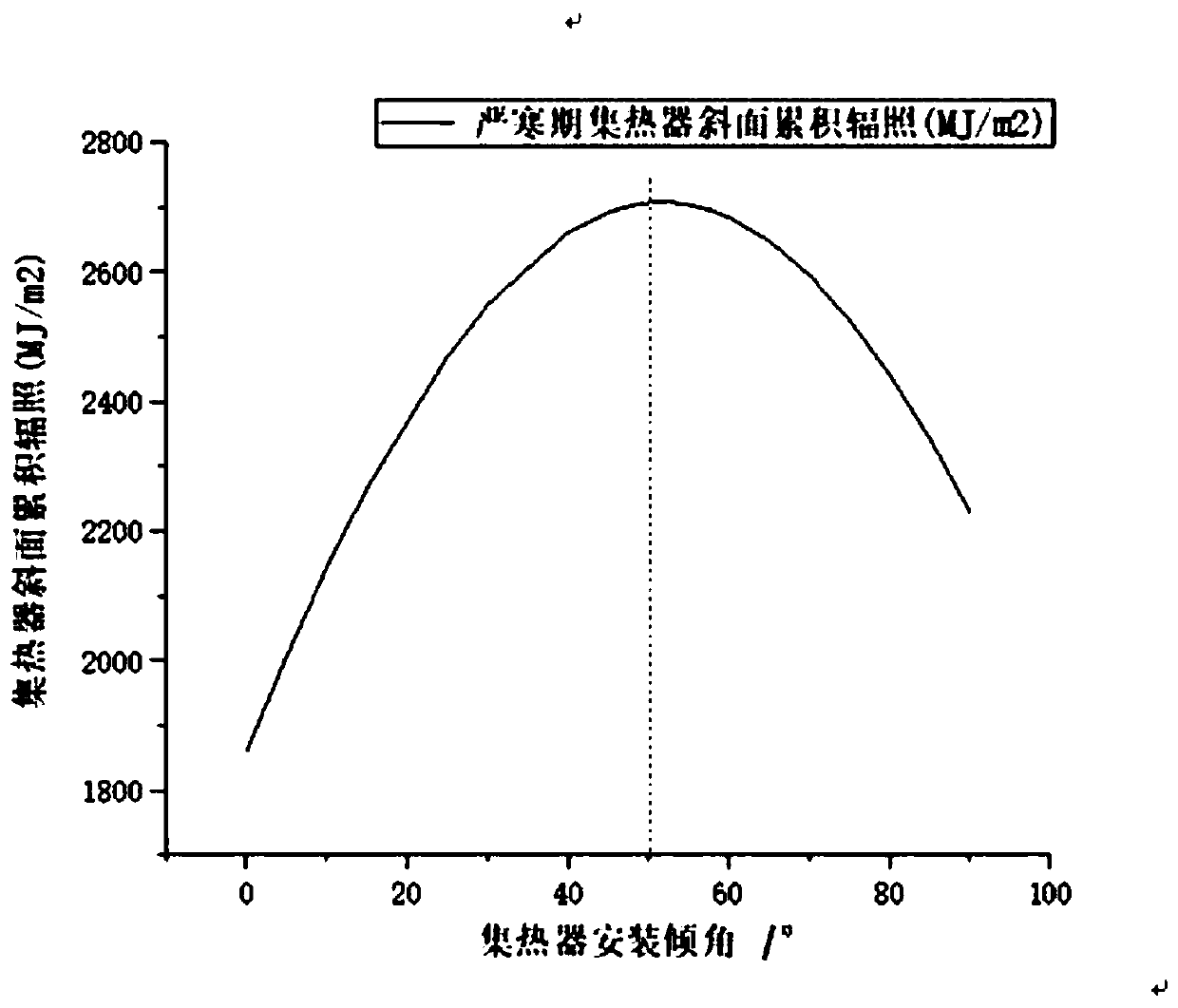

Solar centralized heating system for high-cold high-altitude area

PendingCN110454853AImprove solar utilizationImprove reliabilitySolar heating energyCentral heating with accumulated heatSuper coolingAnti freezing

The invention discloses a solar centralized heating system for a high-cold high-altitude area. The solar centralized heating system comprises a heat collecting system, a heat storage system and a heating pipe network as well as a terminal, wherein a heat exchange system is arranged between the heat collecting system and the heat storage system, a heat exchange system is arranged among the heat storage system, the heating pipe network and the terminal; the heat collecting system consists of a plurality of flat plate type solar heat collectors with a high solar utilization rate; and an anti-freezing device and an overheat-preventing system are further arranged on the heating system. The solar centralized heating system solves the problems that the heating system cannot operate under a super-cooling condition and the heating system cannot guarantee safety operation under an overheating condition, so that system operation stability is effectively improved, and therefore, economical efficiency and safety of the solar centralized heating system are generally guaranteed, and implementation and popularization, in the high-cold high-altitude area, of the solar centralized heating system arefacilitated.

Owner:北京中环合创环保能源科技有限公司

Method for prolonging service life of tool and reducing cutting resistance in metal cutting

InactiveCN104275623AReduce local high temperatureExtended service lifeMaintainance and safety accessoriesEngineeringOxygen content

Traditional metal cutting is carried out in air, the local oxygen-content index of a cutting area has greater influences on the service life and the cutting force of a machining tool, and oxygen is the main factor of tool and part oxidative wear, so that the oxygen is quantitatively controlled in the local cutting area. The invention provides a method for prolonging the service life of the tool and reducing the cutting resistance in metal cutting. A cutting environment with the low oxygen content is manufactured in the cutting area through a vacuum pump, a low-oxygen environment for metal cutting is manufactured by reducing the oxygen in the state of local high temperature generated in cutting, the life cycle of a cutting tool is prolonged by more than ten times in the low-oxygen environment (the oxygen content is 10 percent of the usual oxygen content of the air) through a closed space or a semi-closed space, the machining precision is improved, and the negative influence on the surface of a cutting workpiece is reduced.

Owner:张然 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com