Porous groove white pad for polishing and grinding and production method

A white pad and hole groove technology, applied in the field of white pad, can solve the problems of reducing the polishing quality, failing to remove debris in time, and affecting the service life of the polishing pad, so as to improve the polishing quality, service life, and chip removal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

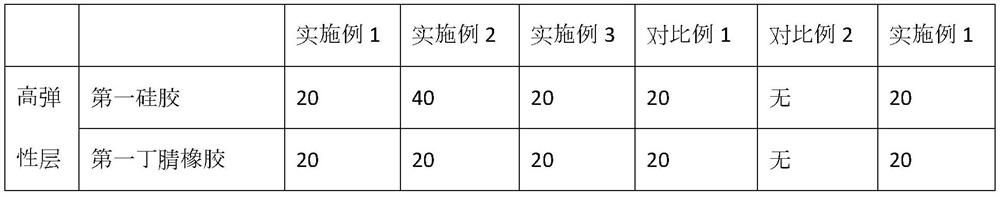

Embodiment 1

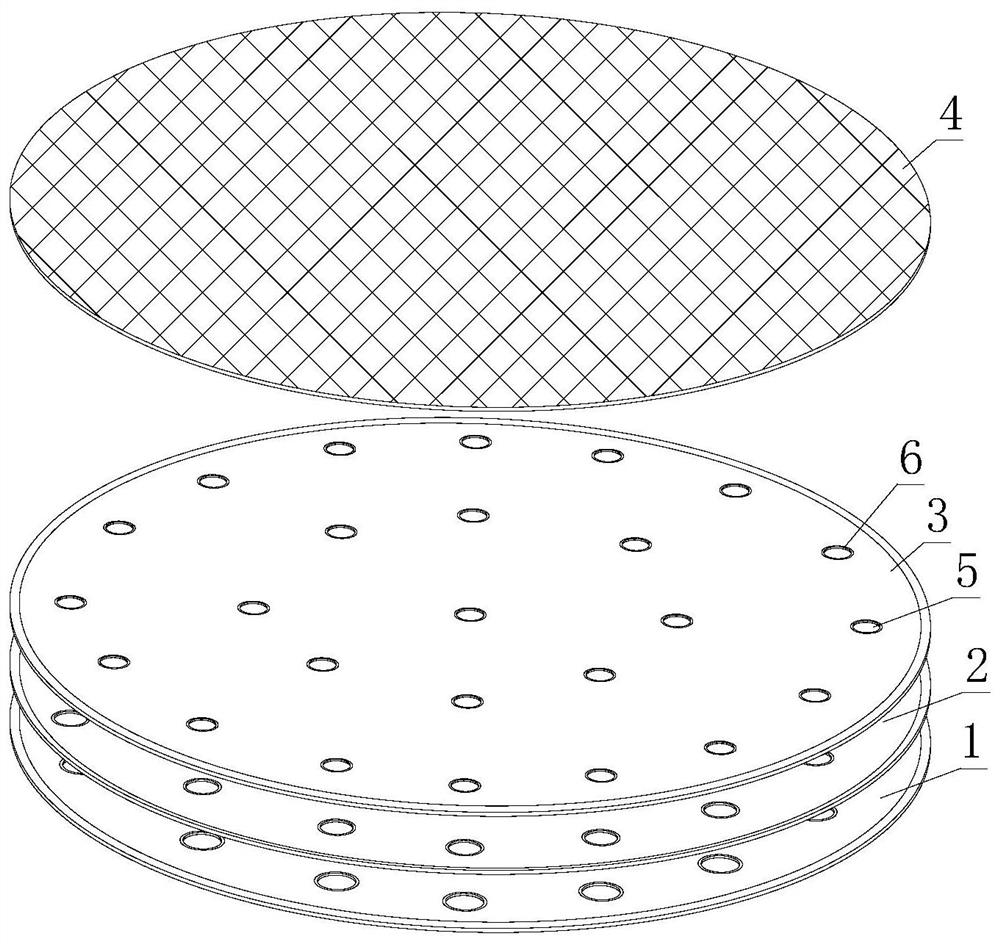

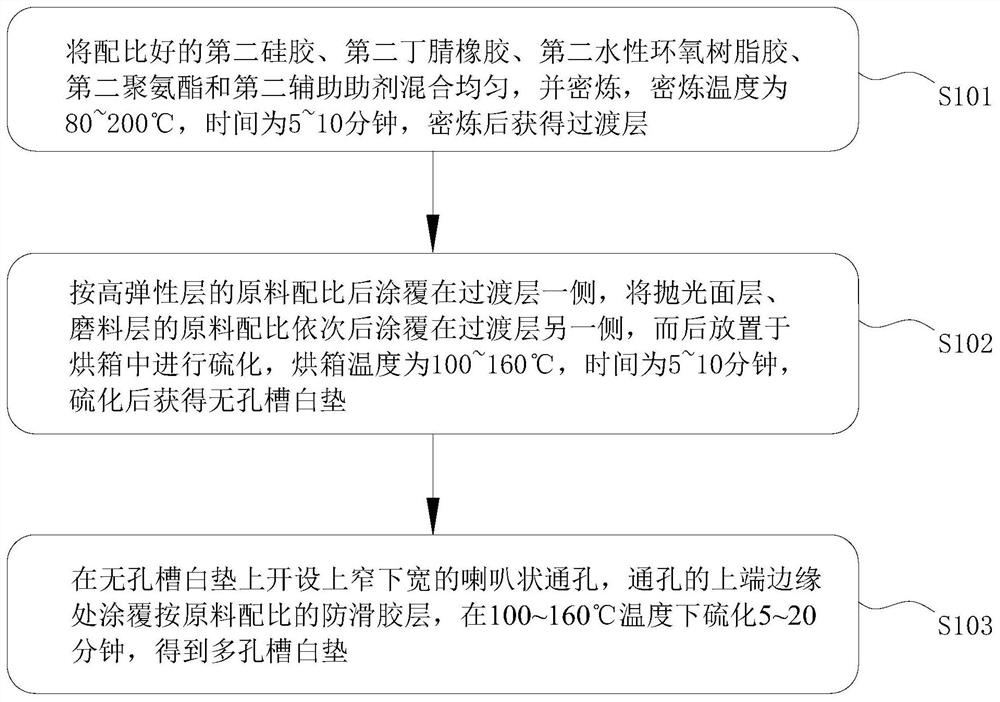

[0045] refer to figure 1 , a porous groove white pad for polishing and grinding, comprising a high elastic layer 1, a transition layer 2, a polishing surface layer 3 and an abrasive layer 4 arranged in sequence from bottom to top, the high elastic layer 1, the transition layer 2, and the polishing surface layer 3 The abrasive material layer 4 is sequentially compounded and connected together, and the high elastic layer 1, the transition layer 2 and the polishing surface layer 3 are overlapped with each other to be provided with a plurality of through holes 5 that are narrow at the top and wide at the bottom. The weight of each component of the raw materials used in the high elastic layer 1 The ratio of servings is as follows:

[0046] 20 parts of the first silica gel;

[0047] 20 parts of the first nitrile rubber;

[0048] 55 parts of the first thermoplastic resin;

[0049] 5 parts of the first auxiliary agent;

[0050] Among them, nitrile rubber is composed of butadiene a...

Embodiment 2

[0076] The difference between the present embodiment and the first embodiment is only that the proportion of the raw materials in the high elastic layer 1 is different. In the present embodiment, the ratio of the parts by weight of the raw materials used in the high elastic layer 1 is as follows:

[0077] 40 parts of the first silica gel;

[0078] 20 parts of the first nitrile rubber;

[0079] 35 parts of the first thermoplastic resin;

[0080] 5 parts of the first auxiliary agent;

[0081] Wherein, the component weight of the first silica gel is increased to 40 parts, and the weight part of the first thermoplastic resin is correspondingly reduced to 35 parts, and the elasticity index of the high elastic layer 1 is adjusted by changing the component weight parts to adapt to white The height of the pad is deformed.

Embodiment 3

[0083] The difference between the present embodiment and the first embodiment is only that the raw material composition ratio of the transition layer 2 is different. In the present embodiment, the ratio of the parts by weight of the raw materials used in the transition layer 2 is as follows:

[0084] 15 parts of the second silica gel;

[0085] 5 parts of the second nitrile rubber

[0086] 30 parts of the second water-based epoxy resin glue;

[0087] 48 parts of the second polyurethane;

[0088] 2 parts of the second auxiliary agent;

[0089] Wherein, the hardness and elasticity of the transition layer 2 are between the highly elastic layer 1 and the polishing surface layer 3, and when the white pad is bent and deformed toward the polishing surface layer 3, the polishing surface layer 3 with low deformation and the high elasticity layer with high deformation are linked together. Layer 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com