Device and method for on-site testing of explosive detonation velocity and detonation pressure in charge hole

A field test and charging hole technology, applied in the field of explosive mechanics, can solve the problems of high cost and unsuitable promotion, and achieve the effects of low cost, convenient testing and good waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

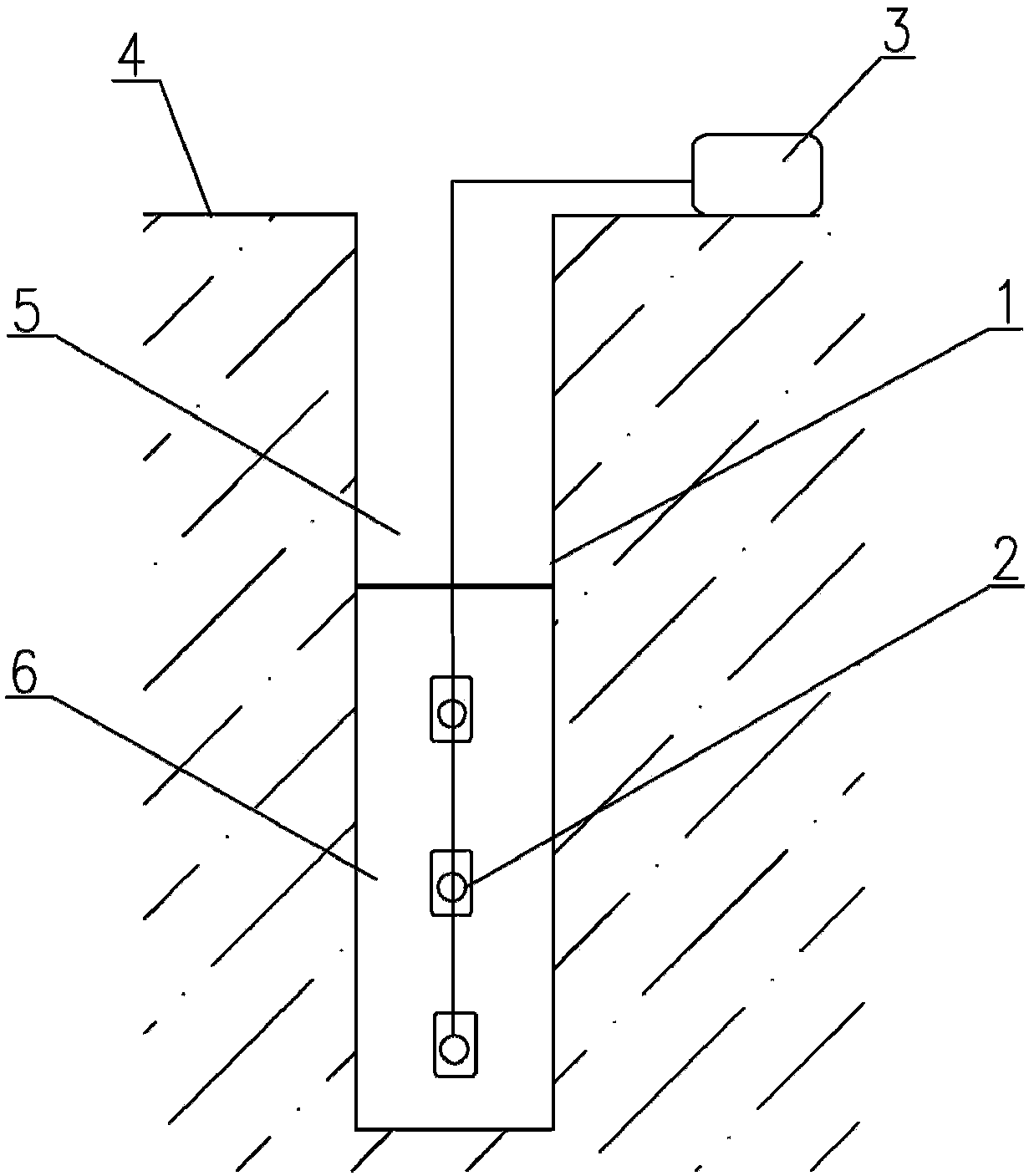

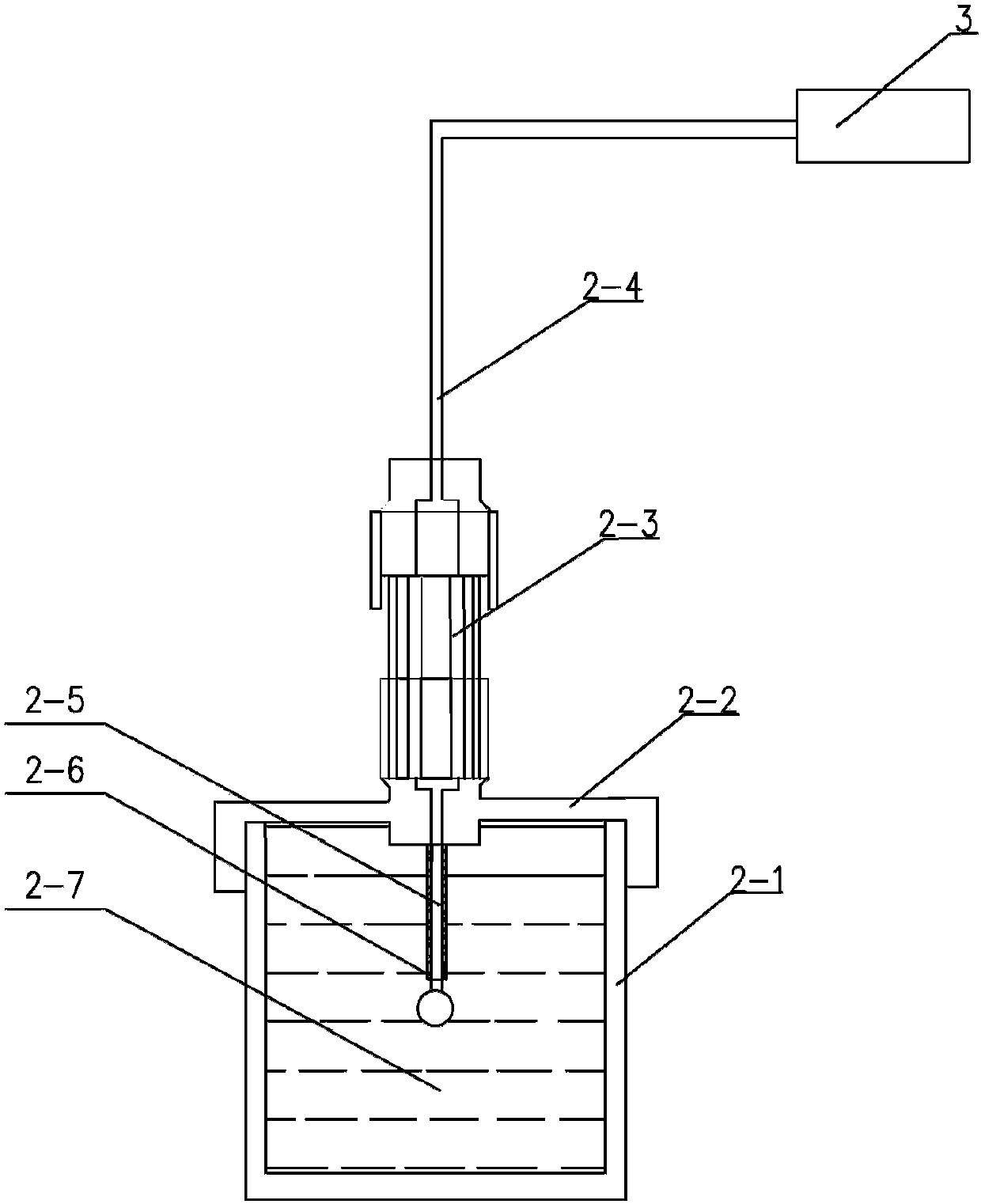

[0035] Tested at a surface mining site. The mine is drilled with a YZ-35 roller cone drilling rig, with a diameter of 250 mm and a depth of 16 meters. It adopts a continuous charge structure. At a distance of 2 meters, 5 meters and 8 meters from the bottom of the borehole, three devices with PVDF piezoelectric diaphragms as pressure sensing elements are arranged to test the detonation velocity and detonation pressure of explosives on-site in the charge hole, marked as measuring points 1. Measuring point 2 and measuring point 3.

[0036]See Table 1 for the burst pressure test values of the three test units and the statistics of the signal arrival time.

[0037] Table 1 Burst pressure test value and signal arrival statistics

[0038]

Measuring point 1

Measuring point 2

Measuring point 3

Explosion pressure (GPa)

9.1

10.2

9.6

Signal arrival time (ms)

25.41

25.94

26.46

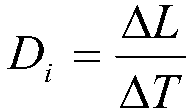

[0039] According to the data listed in the table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com