Atomizing chamber cooling circulation system and method adopting system to cool atomizing chamber

A circulation system and atomization chamber technology, applied in applications, household appliances, household refrigeration devices, etc., can solve the problems affecting the mechanical properties of ingot forming and the solidification speed of mist-like tiny particles, and achieve the effect of increasing the cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

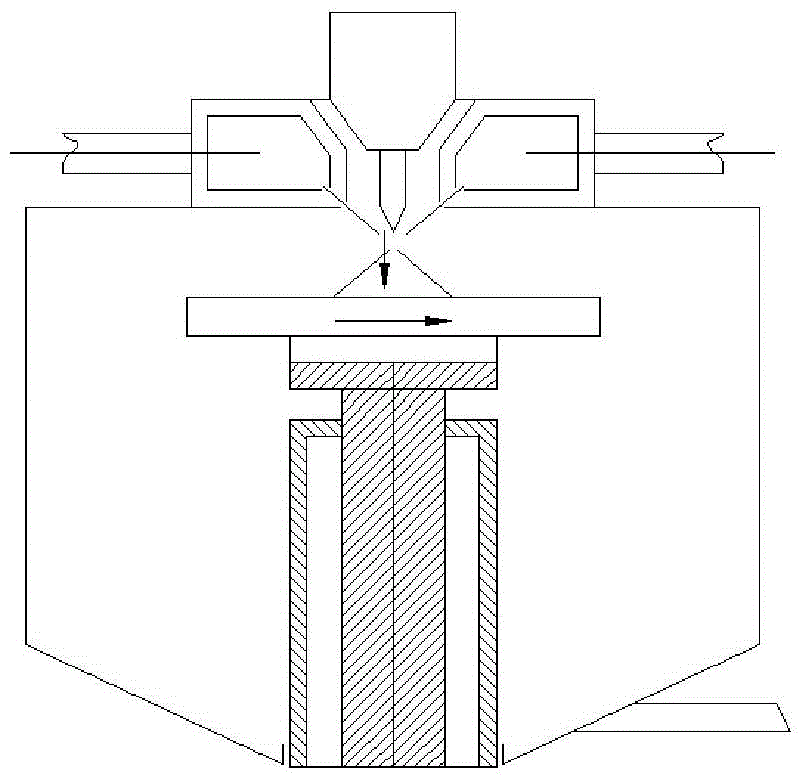

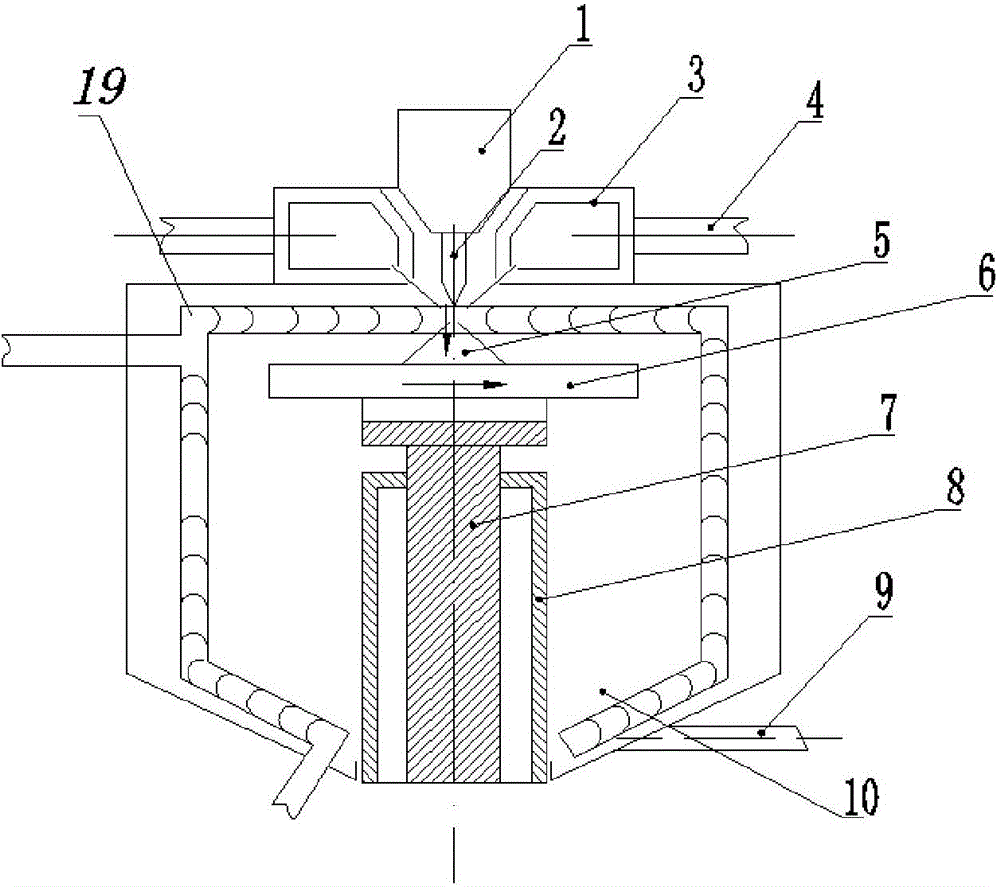

[0037] like Figure 1-4 As shown, an atomization chamber cooling cycle system includes a heat-absorbing structure 19, a cooling device, a circulating power pump, a heat-conducting medium, and a heat-conducting medium delivery pipeline, and the heat-conducting medium delivery pipeline is sequentially connected to the heat-absorbing structure 19, The cooling device and the circulating power pump together form a heat conducting circuit, and the heat conducting medium circulates in the heat conducting circuit under the action of the circulating power pump; the heat absorbing structure 19 is located in the chamber of the atomizing chamber, To absorb the heat in the atomizing chamber, the heat-absorbing structure 19 has a heat-absorbing chamber for the heat-conducting medium to pass through; temperature.

[0038] It should be noted that the heat transfer medium is water, and the cooling device is a cooling tower 15 .

[0039] This embodiment also includes a heat transfer medium st...

Embodiment 2

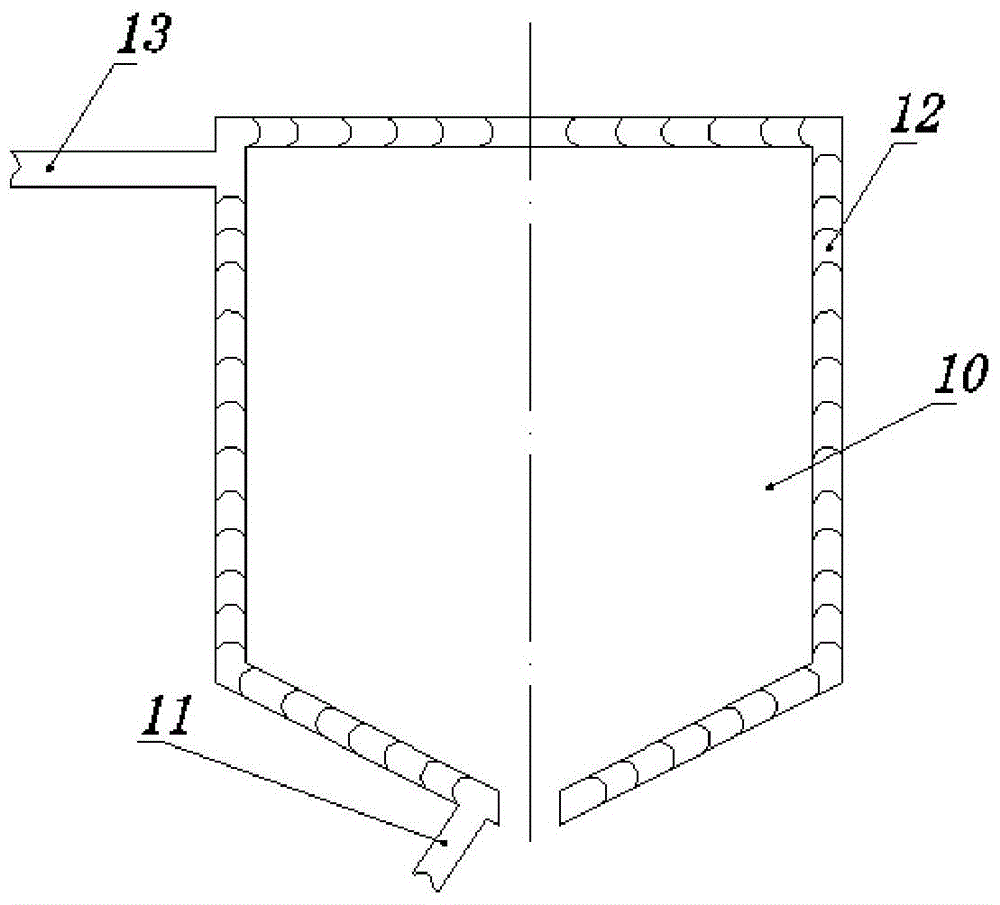

[0049] The heat-absorbing structure 19 in this embodiment is different from the heat-absorbing structure 19 in Embodiment 1. The heat-absorbing structure 19 in this embodiment includes an inner cylinder and an outer cylinder, and the outer cylinder is formed by setting the inner cylinder cover inside. The heat-absorbing chamber, the shape of the inner cylinder and the shape of the outer cylinder are all symmetrical about the axis of the vertical direction, and the central axis of symmetry of the inner cylinder coincides with the central axis of symmetry of the outer cylinder . The side wall forming the inner cylinder has a corrugated structure directed towards the central axis of symmetry of the inner cylinder.

Embodiment 3

[0051] In this embodiment, compared with the first embodiment, the atomization chamber cooling cycle system further includes an automatic control device, and the automatic control device includes: a temperature sensor, a water level sensor, a flow regulating valve and a control unit. The temperature sensor includes a first temperature sensor, a second temperature sensor, a third temperature sensor and a fourth temperature sensor, and the first temperature sensor is installed at the heat transfer medium inlet to detect the temperature of the heat transfer medium entering the heat absorption chamber , the second temperature sensor is installed at the outlet of the heat-conducting medium to detect the temperature of the heat-conducting medium flowing out of the heat-absorbing chamber, and the third temperature sensor is installed in the chamber of the atomizing chamber to detect the temperature of the heat-conducting medium flowing out of the heat-absorbing chamber Temperature, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com