Method for prolonging service life of tool and reducing cutting resistance in metal cutting

A metal cutting and cutting resistance technology, which can be used in metal cutting to improve tool life and reduce cutting resistance, and can solve the problems of cutting tools, cutting objects and machine tool contamination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

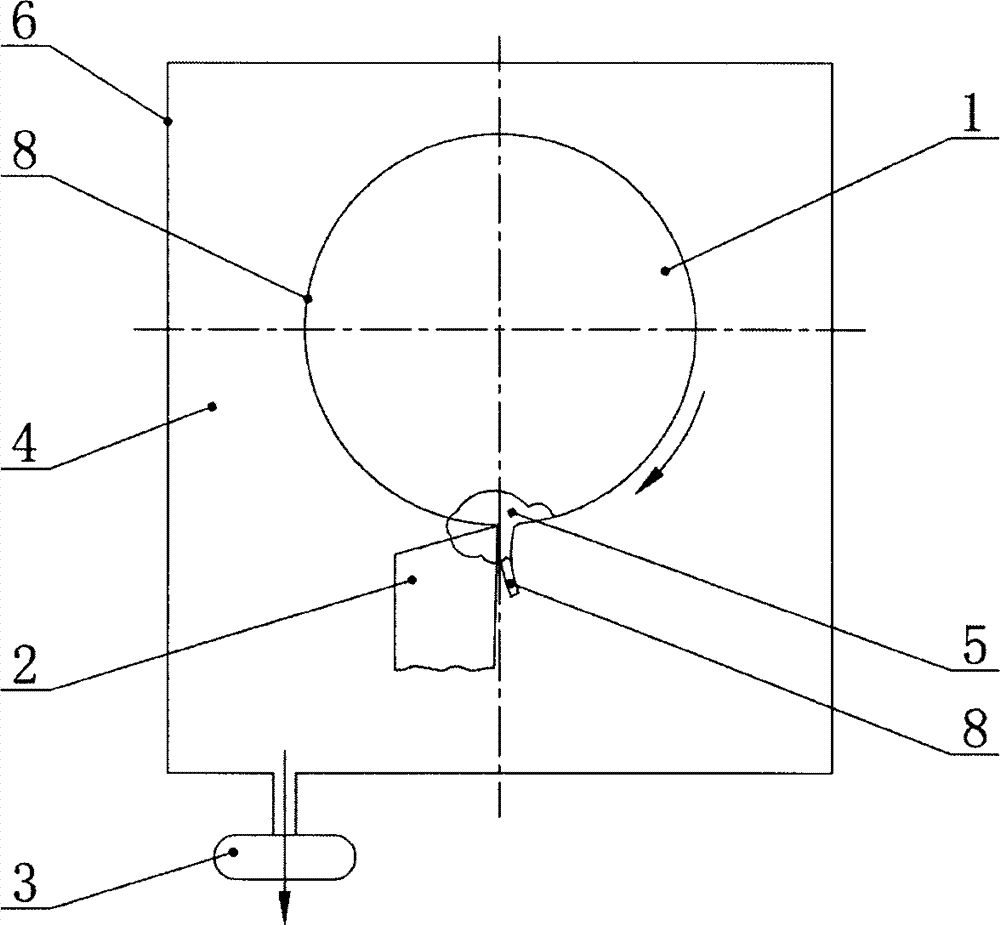

[0009] in figure 1 In the process, the machining part 1 and the machining tool 2 are cut in an environment with low oxygen content created by the vacuum pump 3 and the cutting area 5, and the enclosed space 6 is isolated from the environment 4. The corresponding suction port 7 of the vacuum pump and the machining surface 8 of the corresponding part are continuously evacuated quantitatively to maintain the corresponding vacuum low oxygen state.

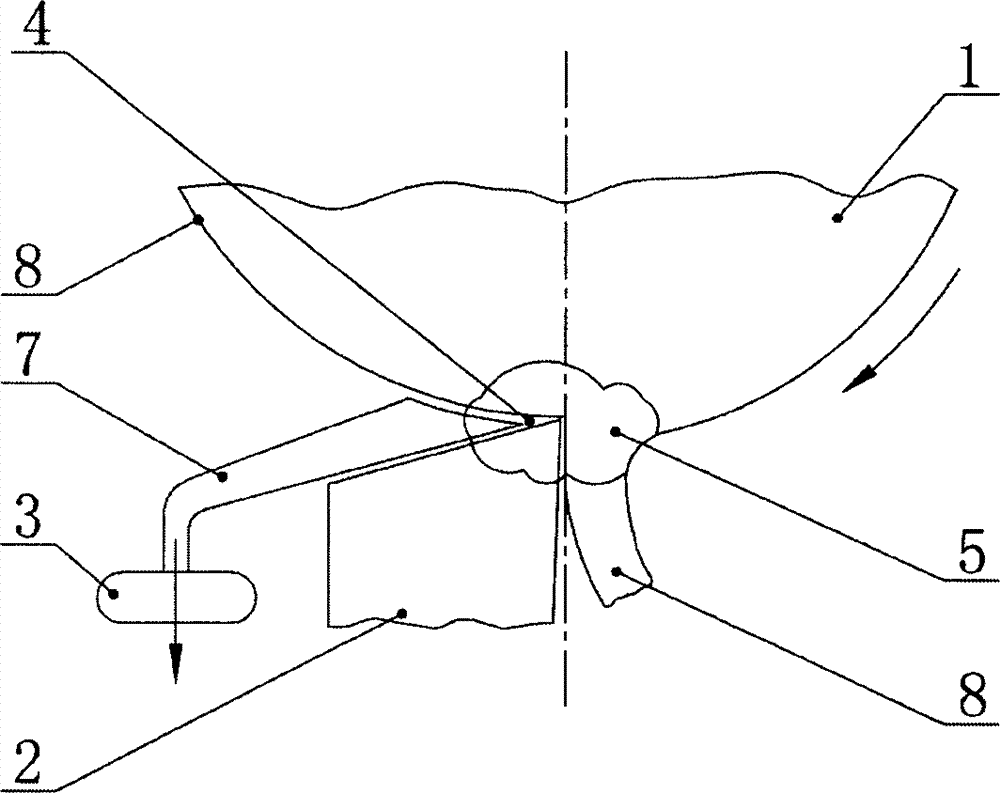

[0010] in figure 2 In the illustrated embodiment, during the cutting process of the machining tool 2 on the machining part 1, the oxygen content index of the cutting area 5 and the enclosed space 6 is high and low, which affects the service life and cutting force of the machining tool 2 and the quality of the machining surface 8 Obviously. The present invention has tested the cutting of steel materials through two implementation methods:

[0011] Use non-alloy steel C45 as the processing material, super alloy P (10…30) as the tool materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com