Vacuum type continuous oiling equipment for chain

A vacuum type, chain technology, applied in the direction of coating, surface coating liquid device, etc., can solve the problem of uneven oil attached to the surface of the chain product, uneven oil on the chain, affecting the wear resistance of the product, etc. To achieve the effect of improving life, adjustable vacuum degree and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

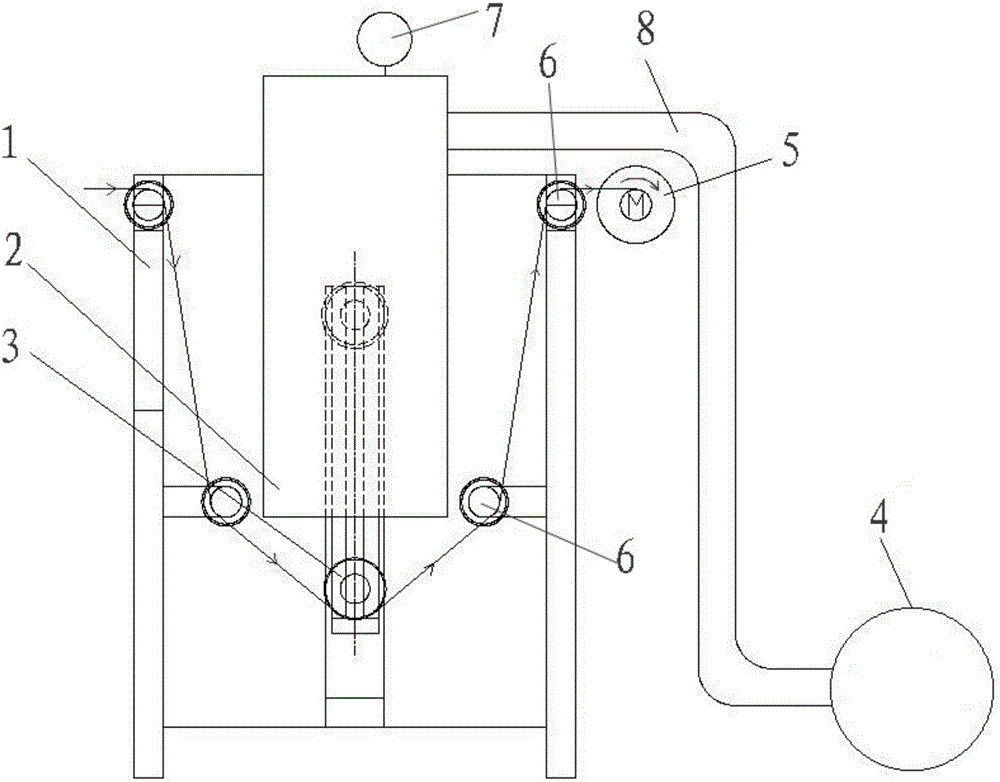

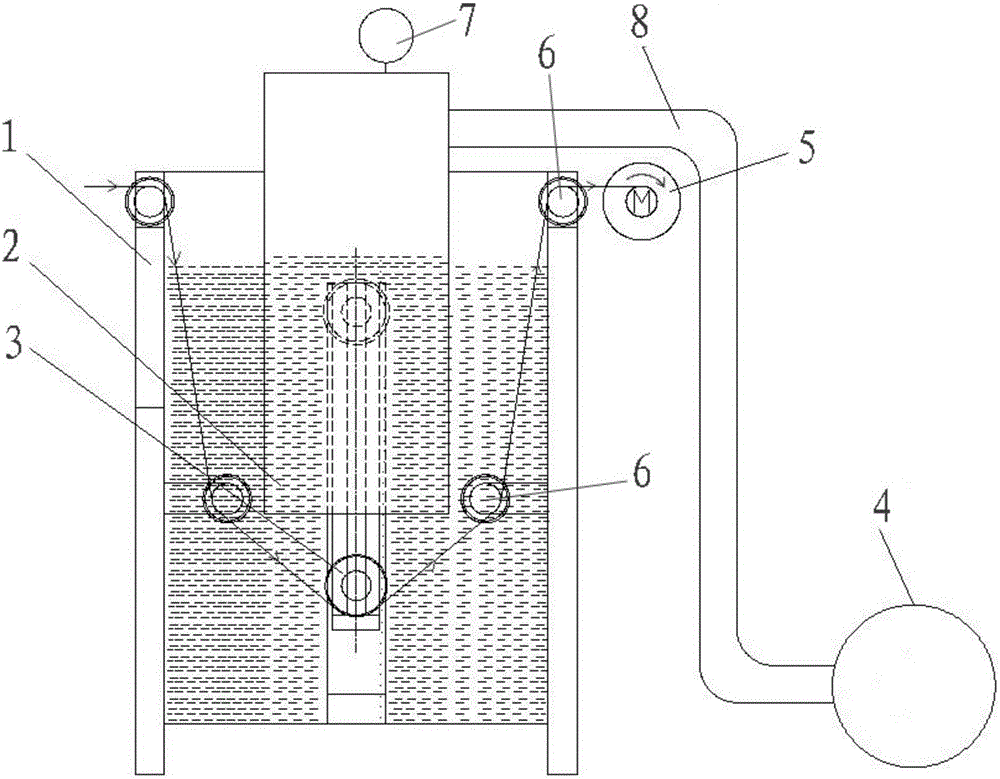

[0015] A chain vacuum type continuous oiling equipment, including a vacuum pump 4, a vacuum cover 2, a drive motor 5, a closed box 1, and a chain reversing system 3 and a chain guide system 6 arranged inside the closed box 1, and the chain bypasses in turn The drive motor 5, the chain guide system 6 and the chain reversing system 3; the closed box body 1 adopts a double-layer structure, and an insulating material is added in the middle of the two-layer structure. The vacuum cover 2 is nested on the upper part of the closed box body 1 , and the vacuum pump 4 is connected to the vacuum cover 2 through a pipeline 8 and communicated with the closed box body 1 . The vacuum cover 2 is made in a grid form. The chain guide system 6 is arranged symmetrically with respect to the chain reversing system 3 , the chain guide system 6 on one side inputs the chain, and the chain guide system 6 on the other side guides the chain into the drive motor 5 .

[0016] The working mode of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com