Patents

Literature

34results about How to "Sufficient oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

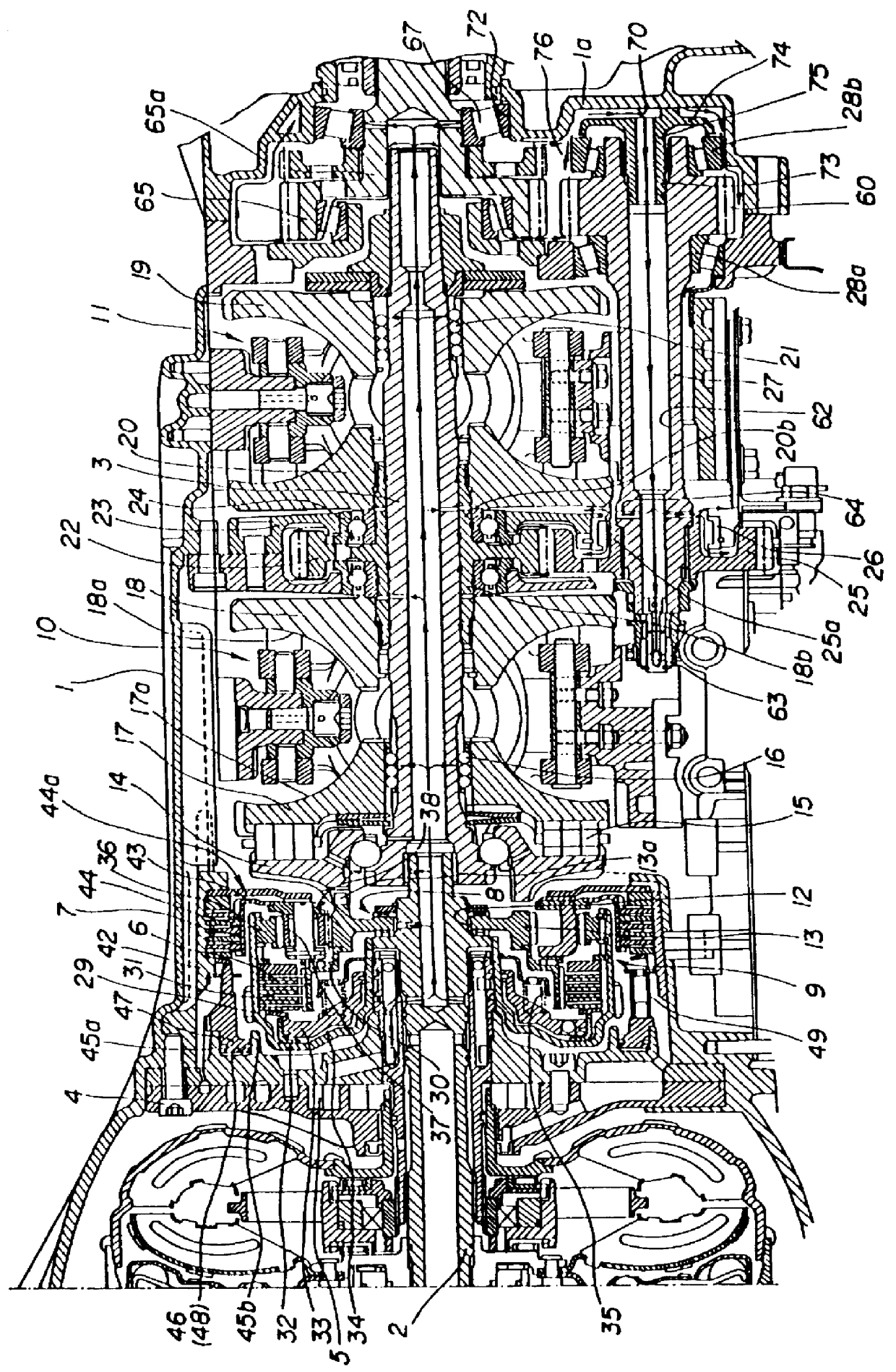

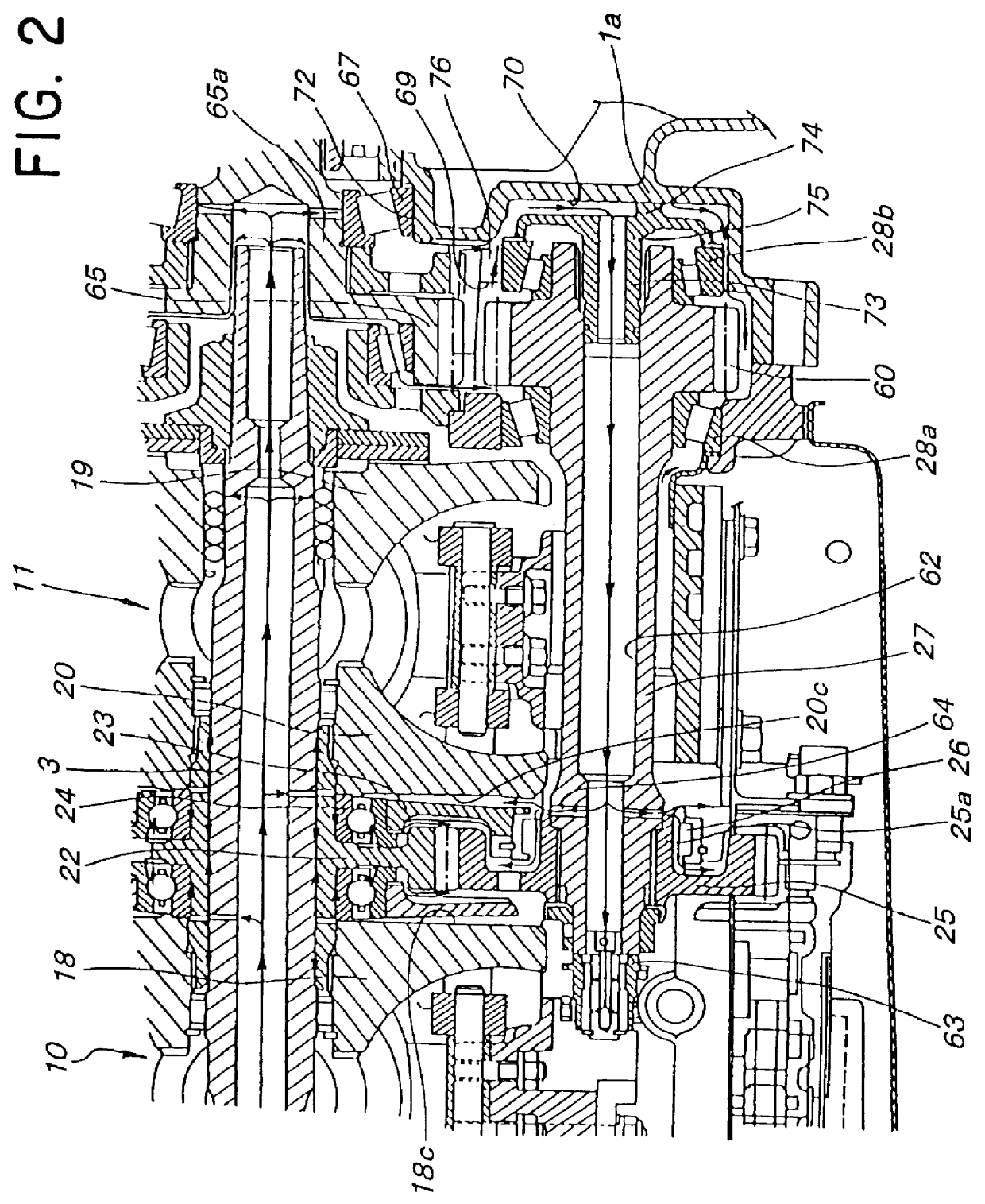

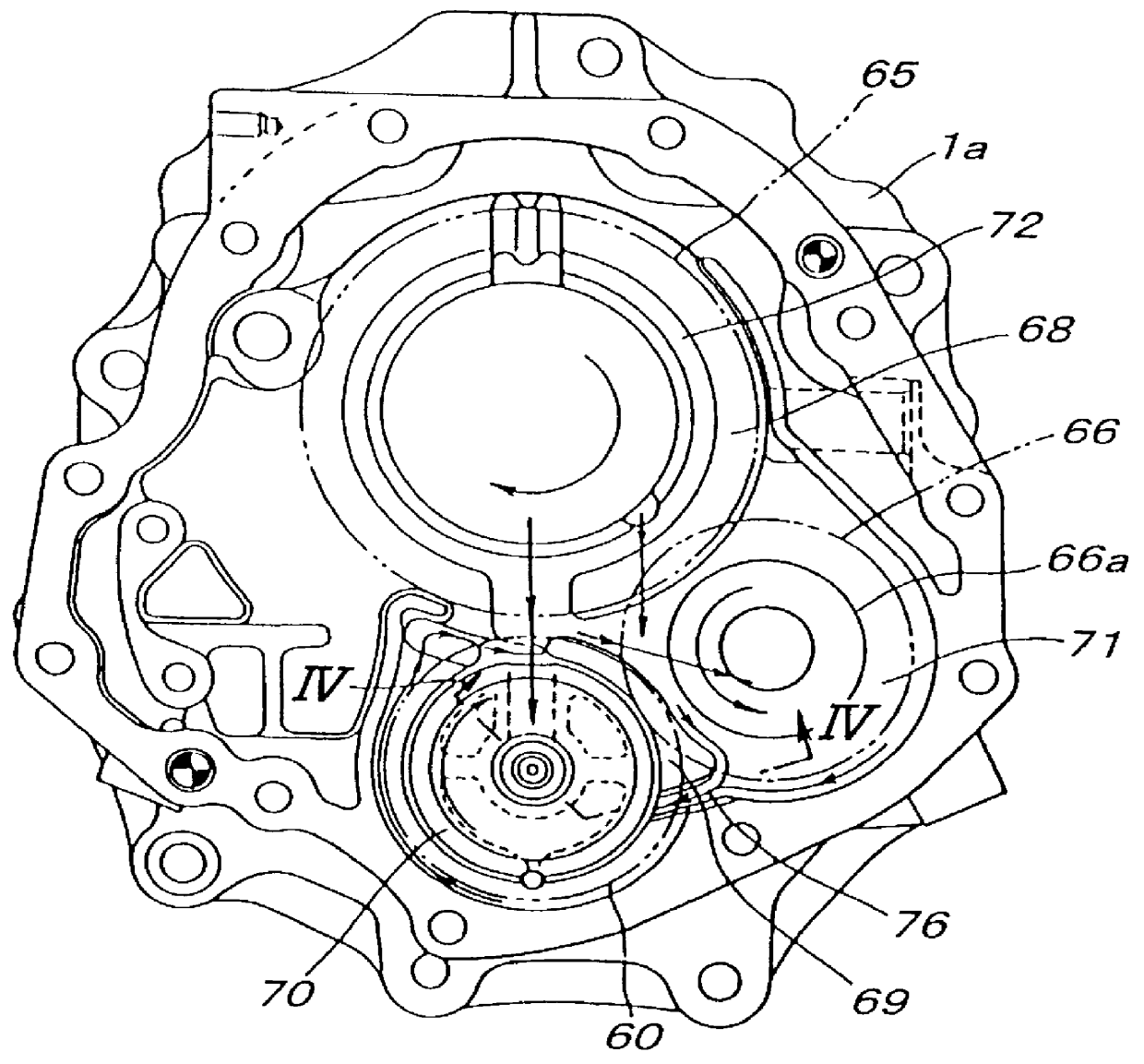

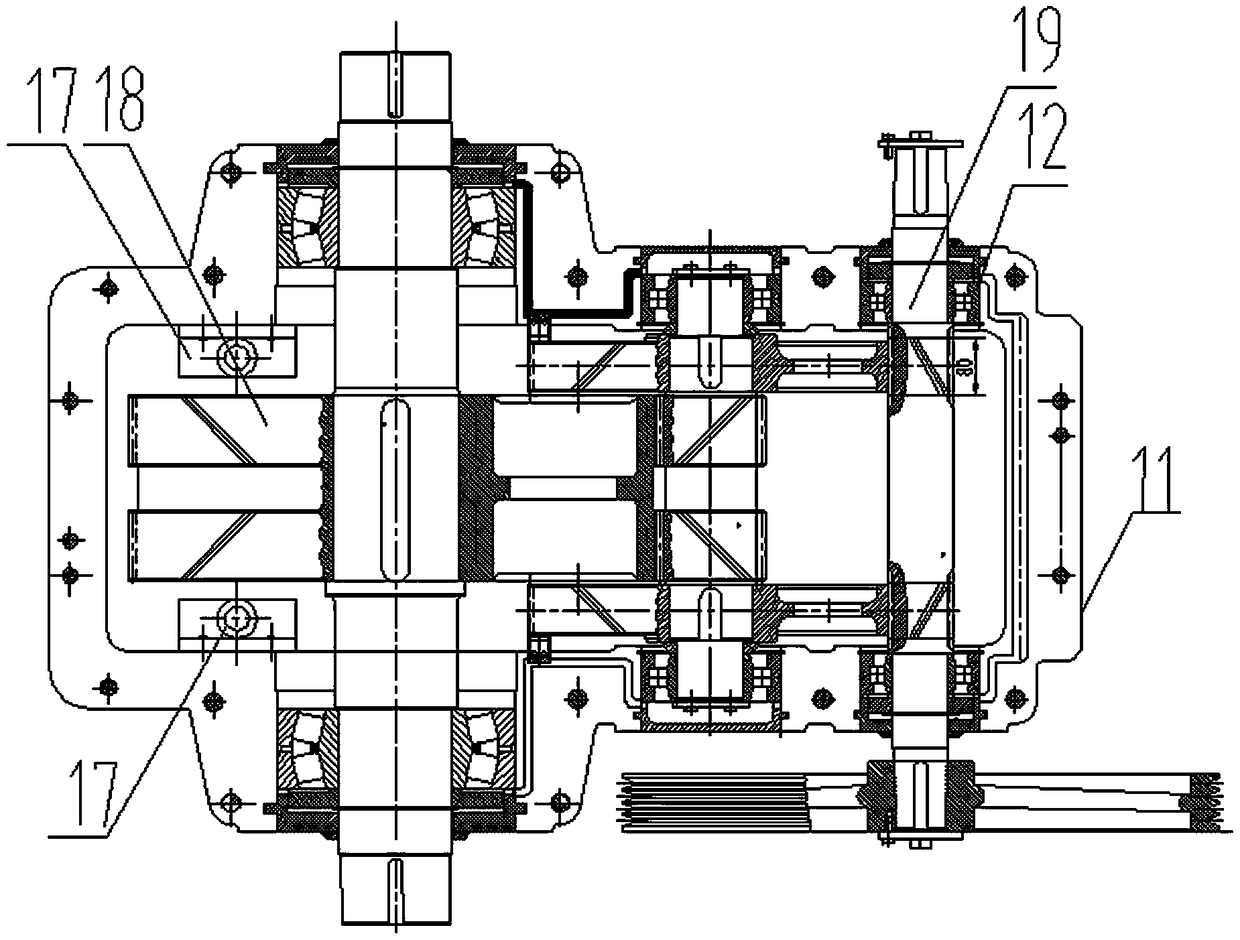

Lubricating structure of transmission

InactiveUS6110070AIncrease volumeSufficient oilGearboxesGear lubrication/coolingEngineeringMechanical engineering

Owner:NISSAN MOTOR CO LTD

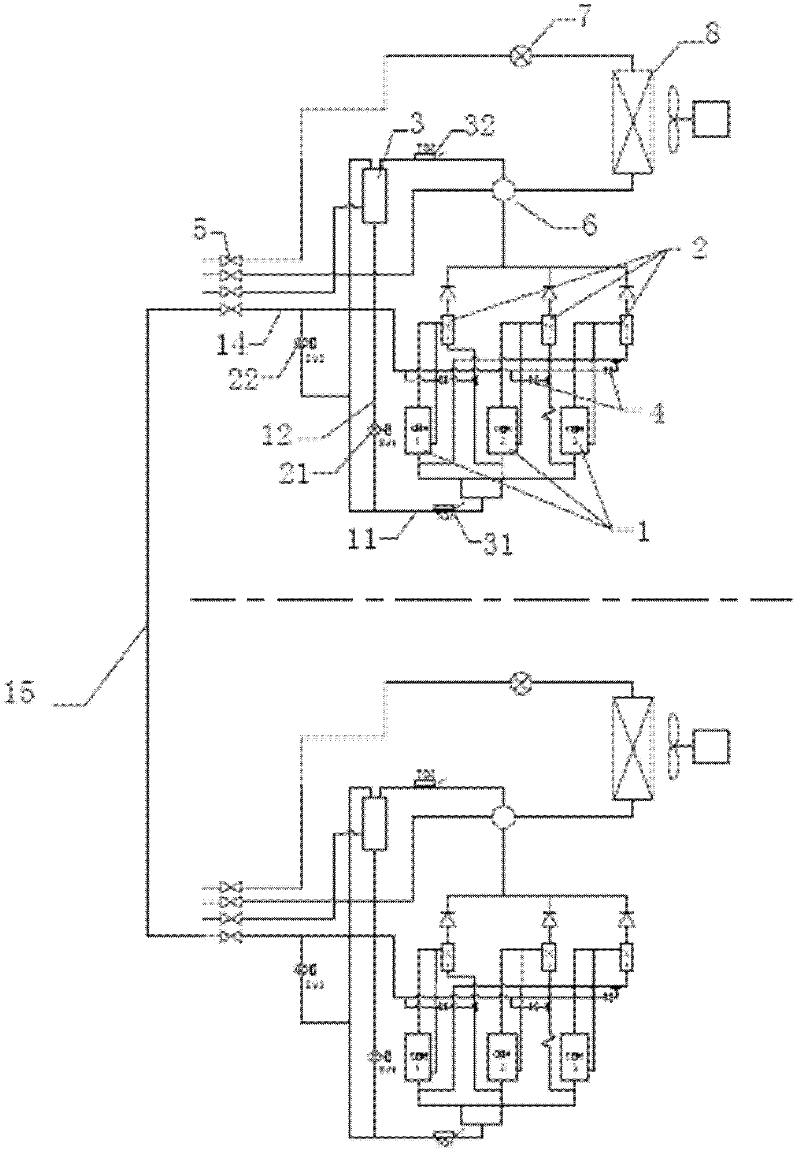

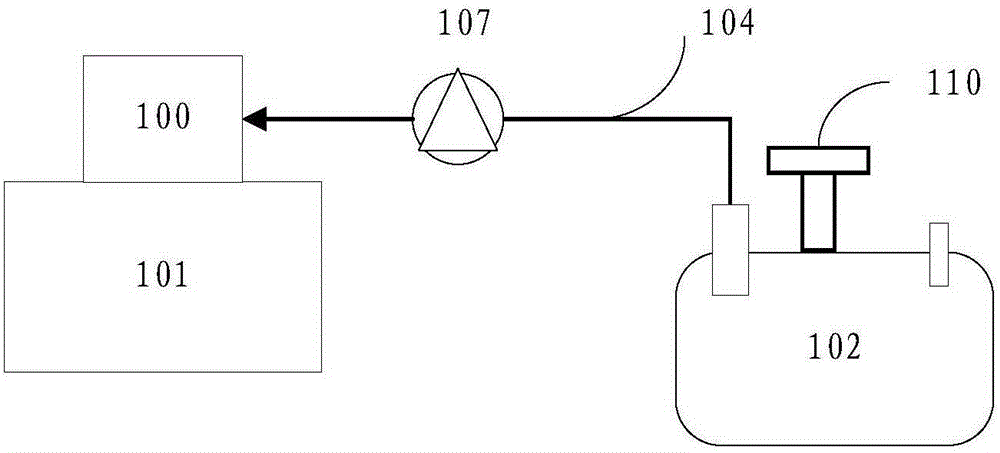

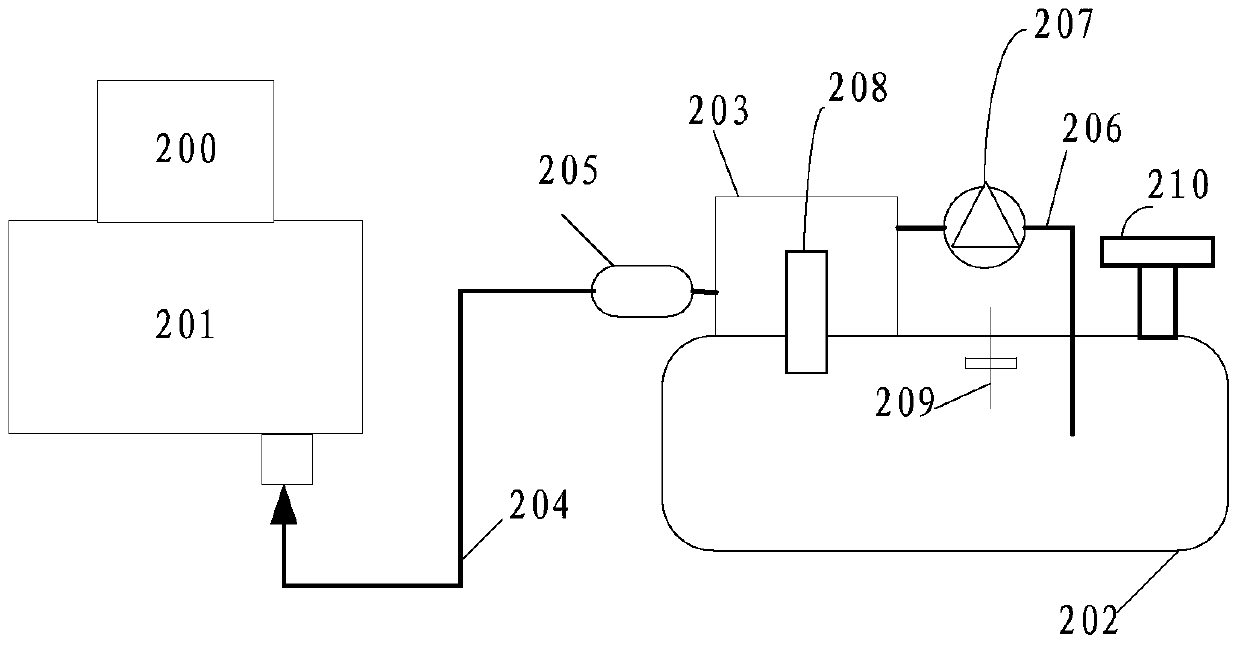

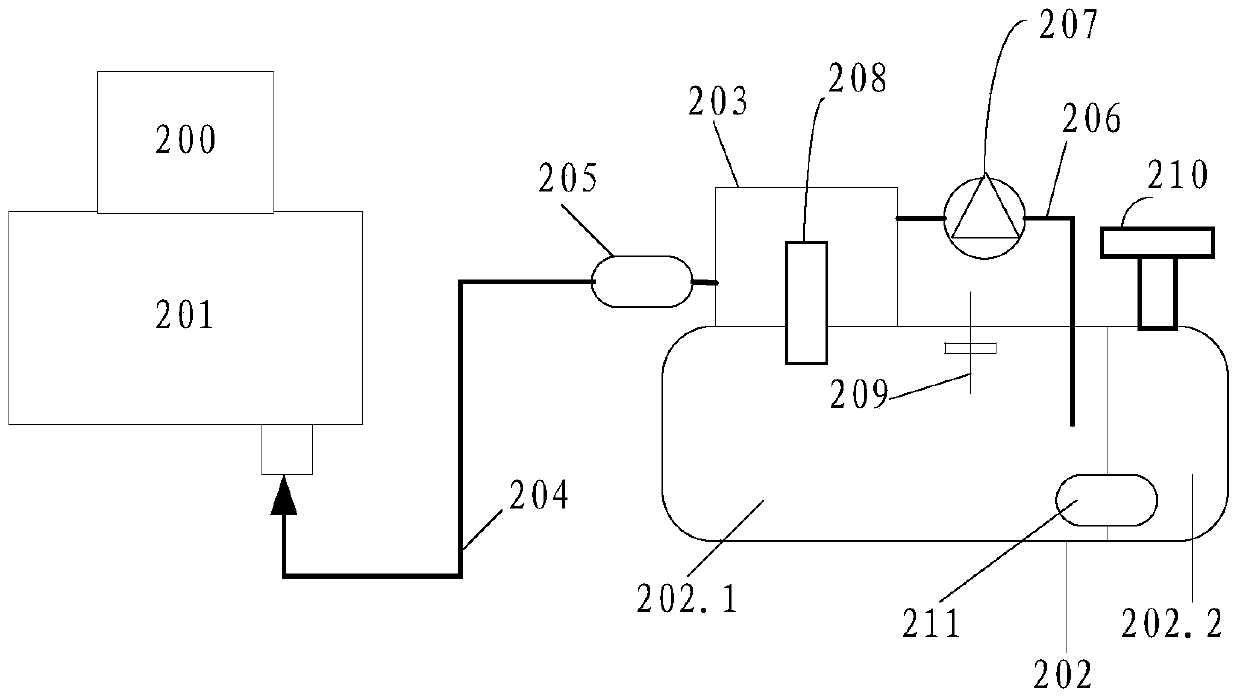

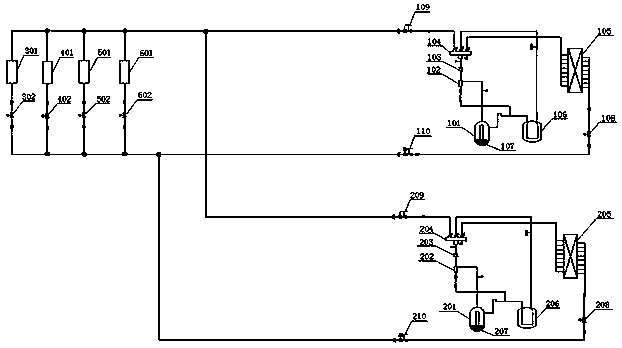

Oil return flow path for multi-connected compressors and control method of oil return flow path

InactiveCN102338505AWork lessSafe and reliable workCompressorFluid circulation arrangementFour-way valveLiquid storage tank

The invention discloses an oil return flow path for multi-connected compressors. A multi-connected outdoor set consists of N outdoor units which are connected in parallel; M compressors which are connected in parallel, a liquid storage tank, a condenser, a fan motor, an electronic expansion valve and a four-way valve are arranged in each outdoor unit; an oil discharge outlet is formed at the bottom of each compressor; an oil discharge pipe is connected between the oil discharge outlet and an air exhaust of each compressor; an oil return pipe is arranged between the bottom of the liquid storage tank of each outdoor unit and main air return pipes of the M compressors in the outdoor unit; an oil separator is connected with the air discharge side of each compressor; the oil separator is provided with a bypass pipe connected to another compressor; the oil separator of each outdoor unit is connected with an oil balance pipe; and the oil balance pipes of the N outdoor units are connected with a main balance pipe. By the oil return flow path, lubricating oil in the multi-connected compressors can be distributed uniformly to ensure that the compressors can run normally and safely.

Owner:TCL AIR CONDITIONER WUHAN

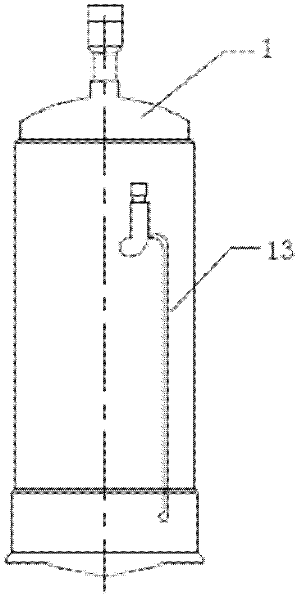

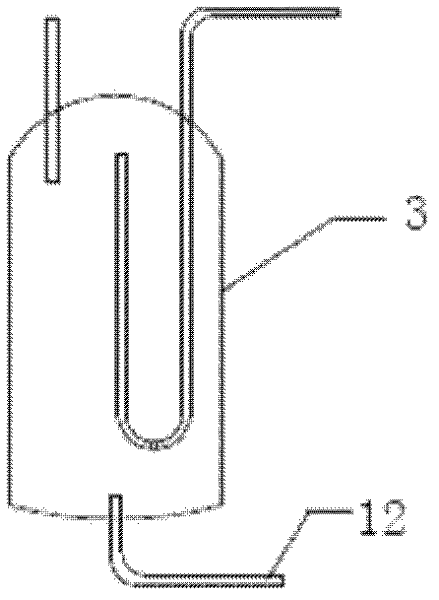

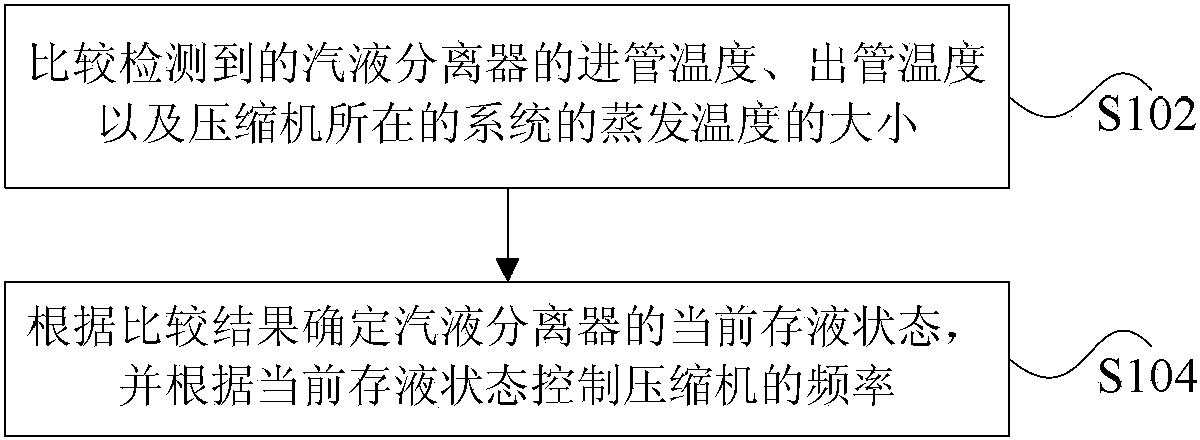

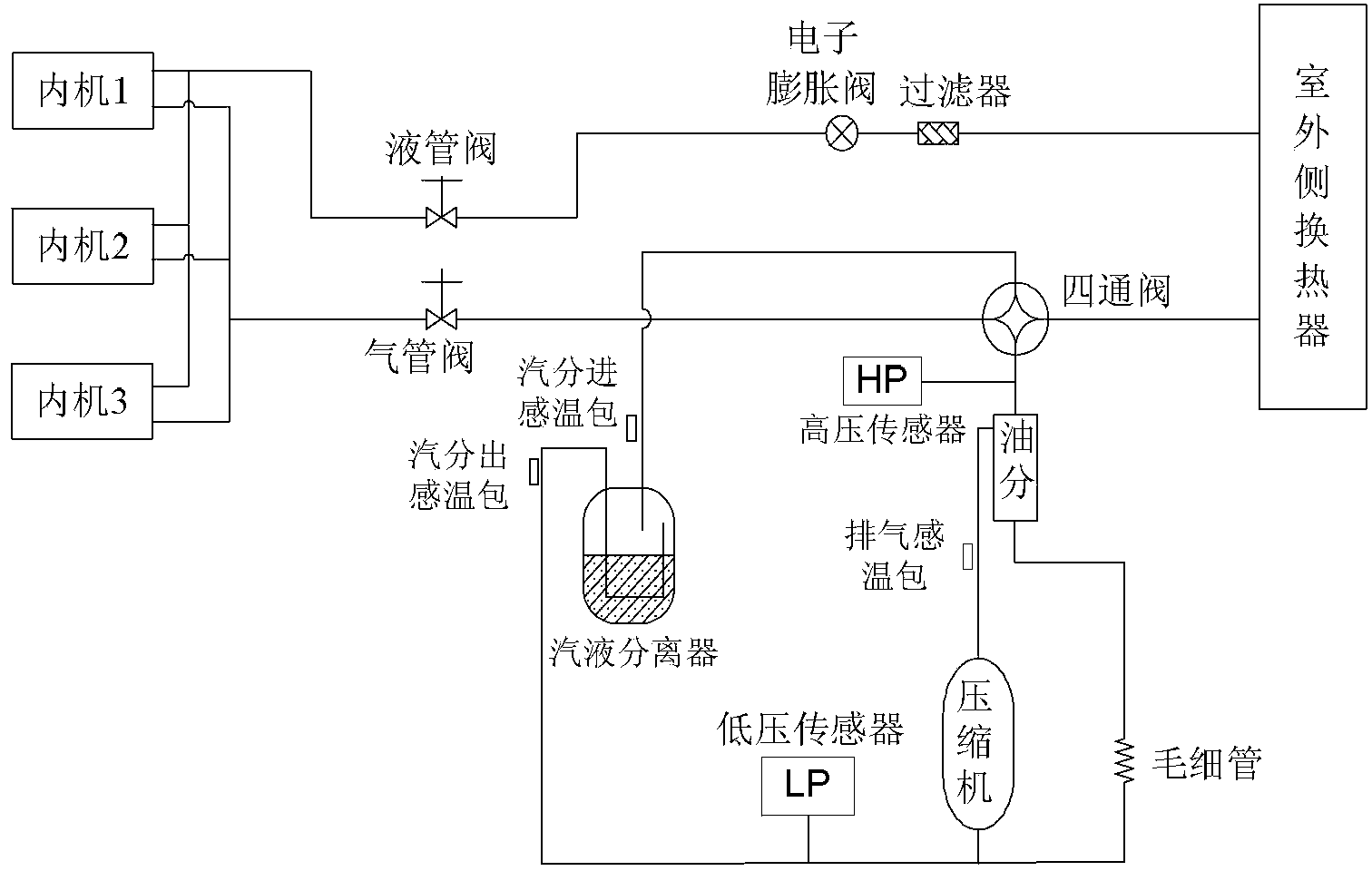

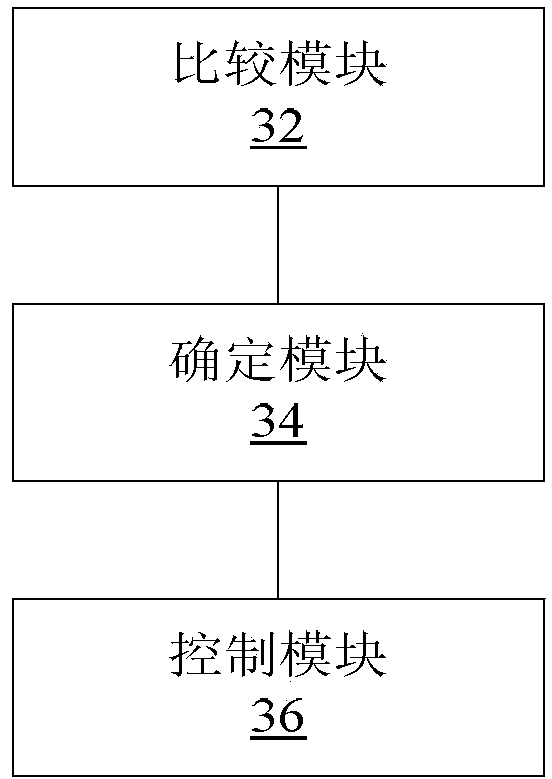

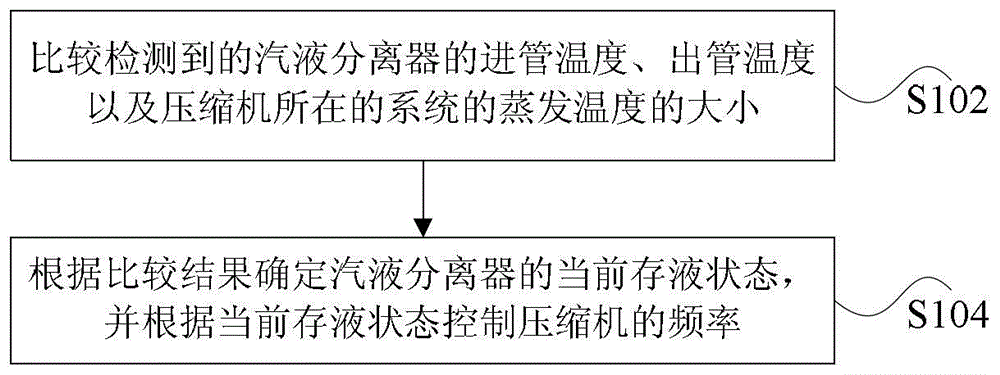

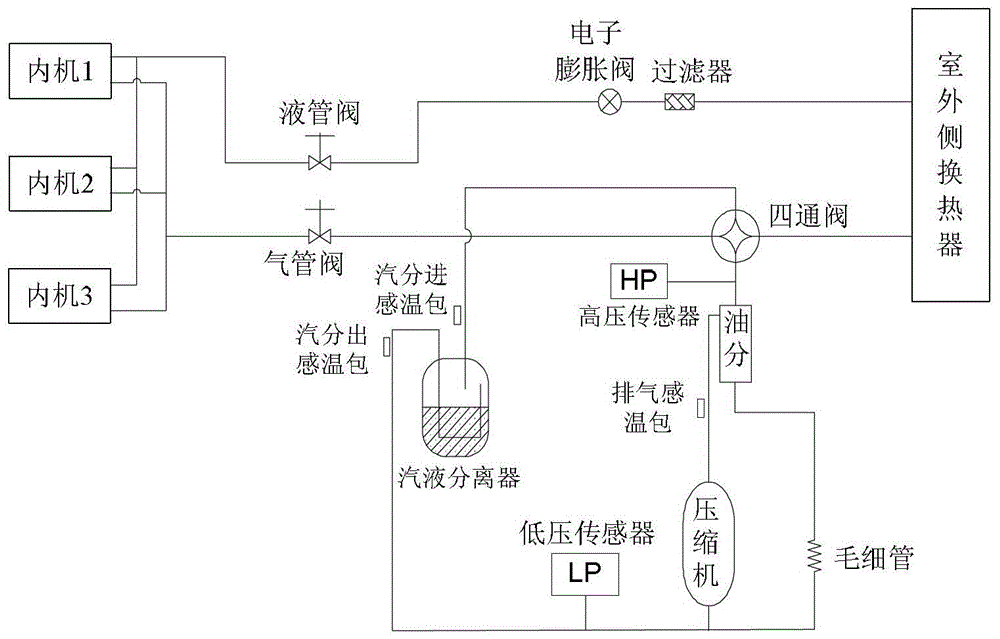

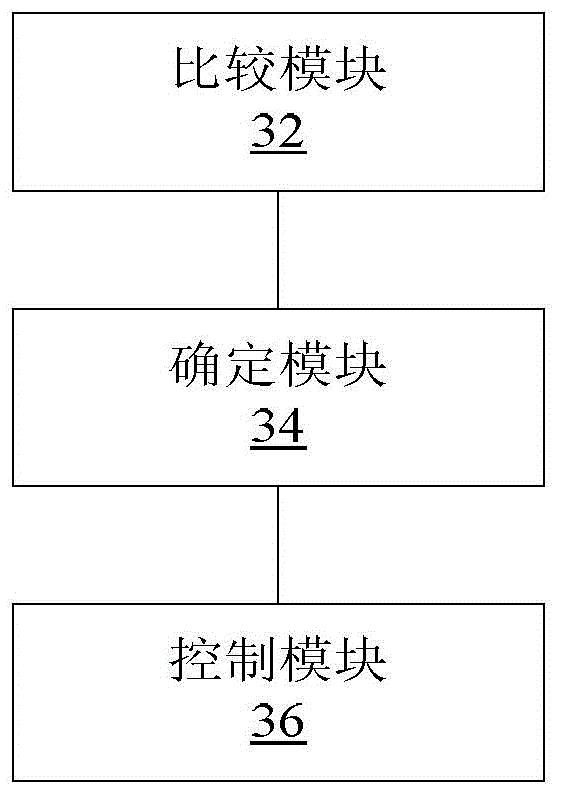

Method and device for controlling frequency of compressor

ActiveCN103671044ASufficient oilGuaranteed heating effectPump controlPositive-displacement liquid enginesEngineeringHigh pressure

The invention discloses a method and device for controlling the frequency of a compressor. The method includes the steps that the detected pipe inflow temperature and the detected pipe outflow temperature of a vapor-liquid separator are compared with the evaporation temperature of a system where the compressor is located; the current liquid accumulation state of the vapor-liquid separator is determined according to the comparison result, and the frequency of the compressor is controlled according to the current liquid accumulation state. According to the method, the current liquid accumulation state of the vapor-liquid separator is determined through the pipe inflow temperature and the pipe outflow temperature of the vapor-liquid separator and the evaporation temperature of the system and then the frequency of an electronic expansion valve and the frequency of the compressor are controlled according to the current liquid accumulation state so that a mixture of oil and liquid in the vapor-liquid separator can be timely transferred. Thus, the problem that when liquid in the vapor-liquid separator is too much, oil cannot return timely is solved, sufficient oil amount of the compressor is guaranteed, refrigerants return to the high pressure side timely, and heating effect is guaranteed.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

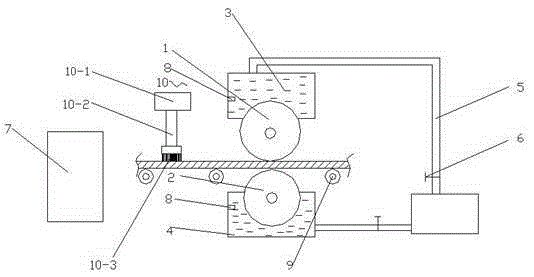

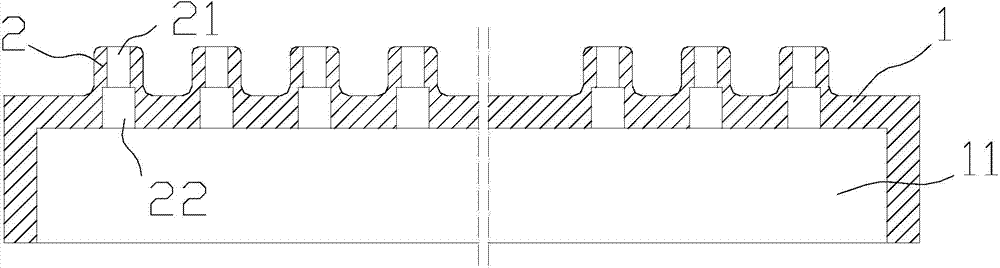

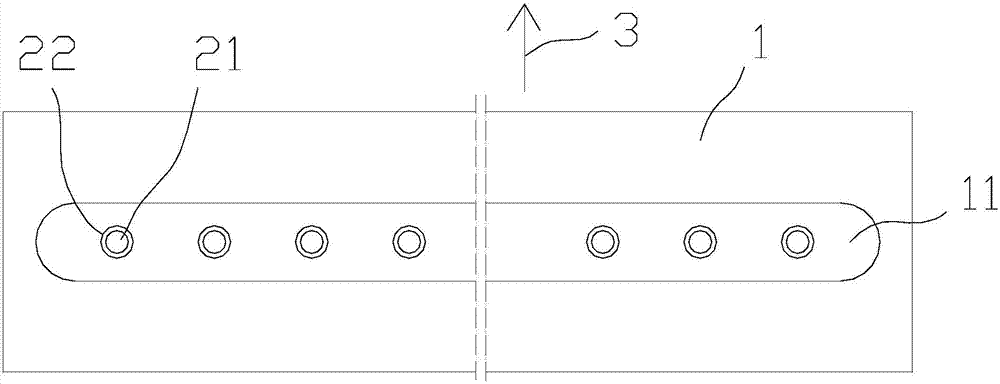

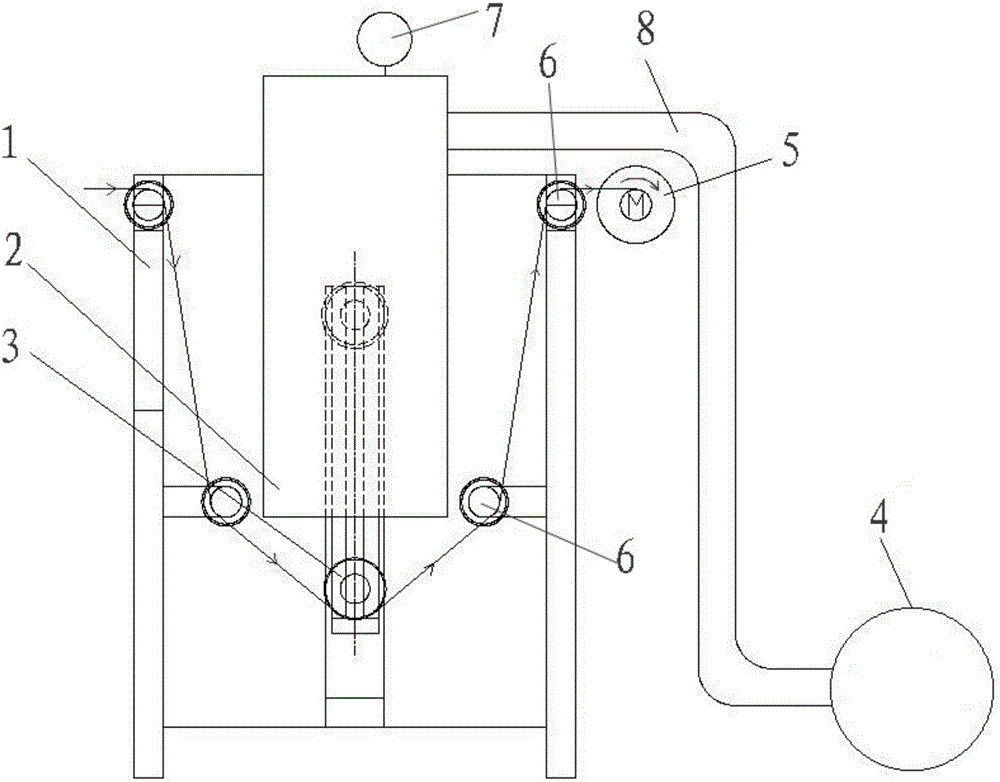

Plate oiling device

InactiveCN106694303AReasonable structureSufficient oilLiquid surface applicatorsCoatingsLiquid level sensorOil storage

The invention relates to an oiling device, and especially a plate oiling device. The plate oiling device comprises a plate, an upper oiling roller and a lower oiling roller, an upper oil storage tank is arranged at the upper side of the upper oiling roller, a part of the upper oiling roller stretches into the upper oil storage tank, a lower oil storage tank is arranged at one side of the lower oiling roller, a part of the lower oiling roller deeps into the lower oil storage tank, the upper oil storage tank and the lower oil storage tank are respectively provided with oil inlet tubes connected with an oil barrel, every oil inlet tube is provided with a solenoid valve, every solenoid valve is connected with a controller, the upper oil storage tank and the lower oil storage tank are respectively provided with liquid level sensors, and the liquid level sensors are connected with the controller. The plate oiling device has the advantages of reasonable structure, good functionality, high automation degree, facilitation of the working intensity of workers, and improvement of the product quality.

Owner:李磊

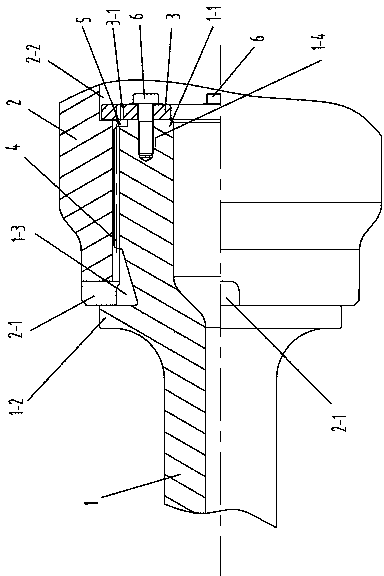

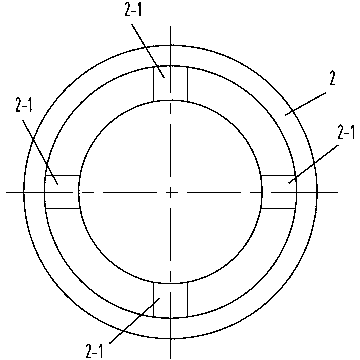

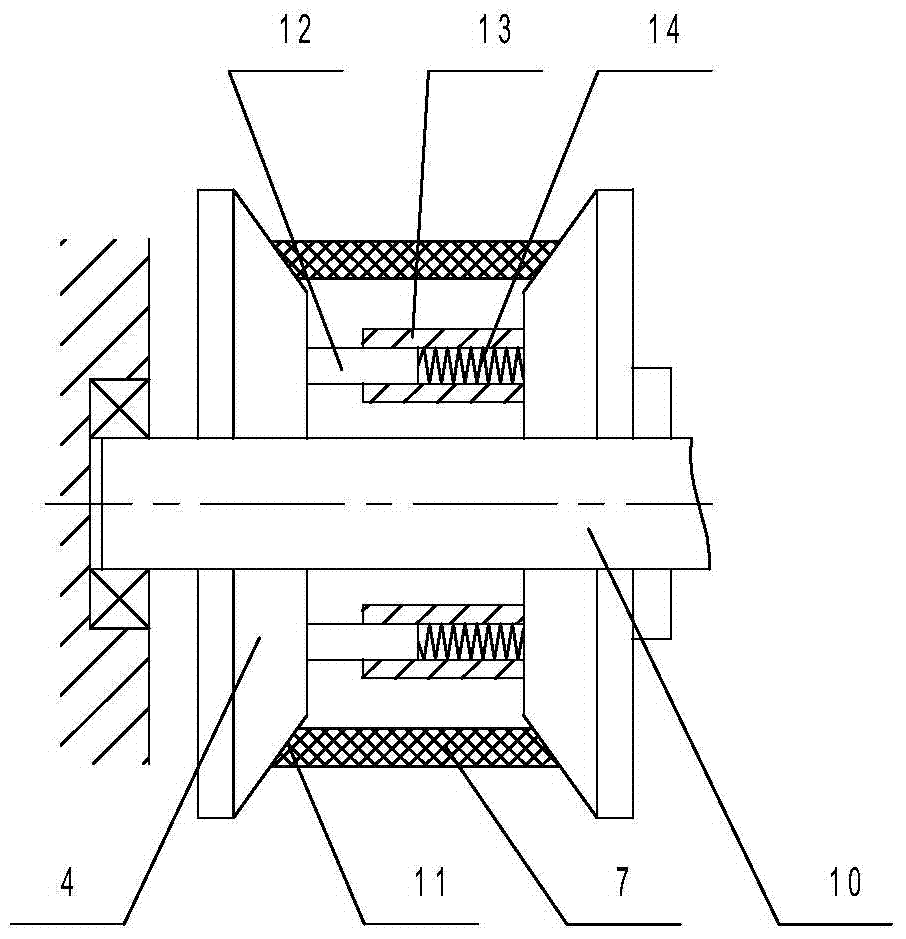

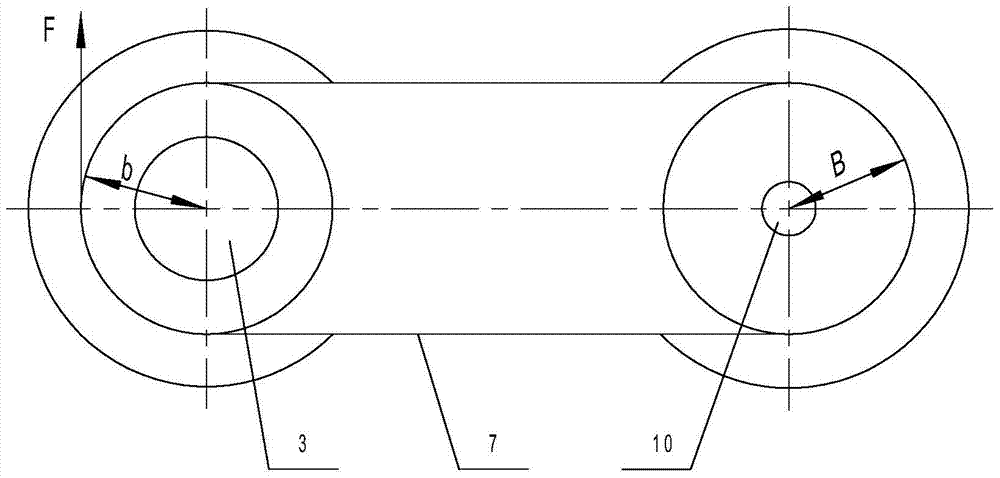

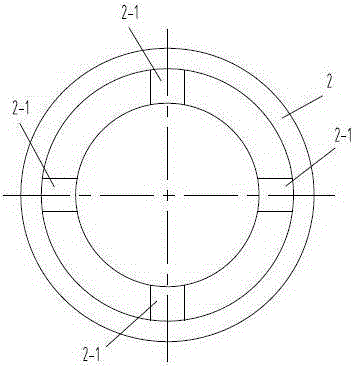

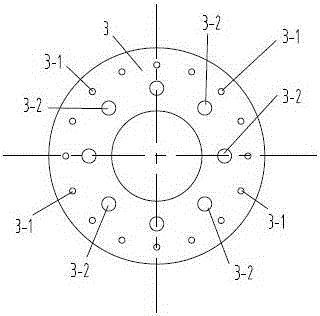

Lubricating structure of rotating spline

Owner:CRRC QISHUYAN INSTITUTE CO LTD

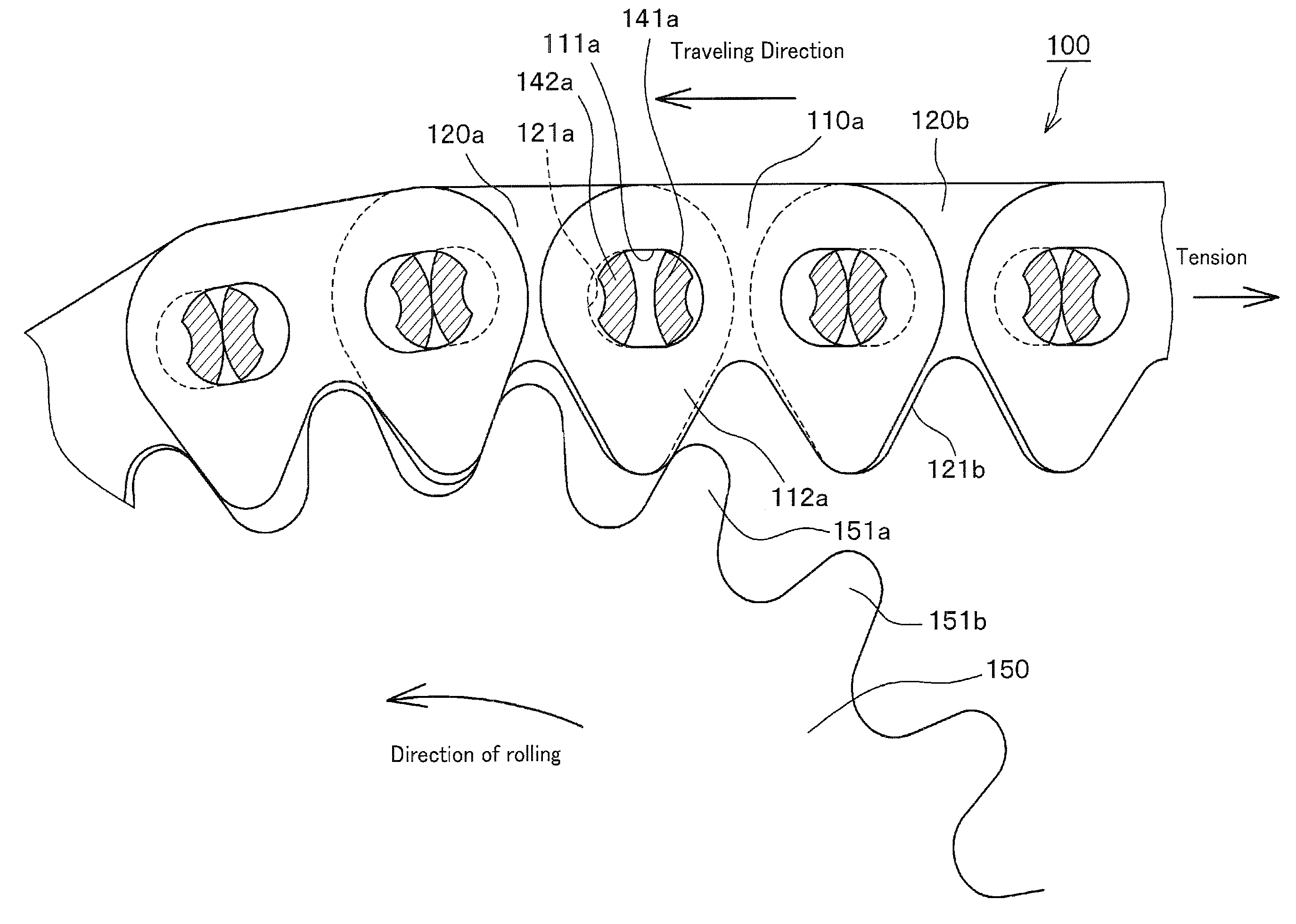

Silent chain

In a chain transmission incorporating a silent chain engaged with a sprocket, the plates of the chain are connected by sets of rocker pins extending through pin holes in the plates. The pin holes are elongated toward the center of each plate, and the elongation of each pin hole is greater than the maximum amount by which the distance between points on the respective rocker pins of each set increases when said chain is inflected to the maximum extent permitted by the sprocket in a portion of the chain in seating engagement with said sprocket.

Owner:TSUBAKIMOTO CHAIN CO

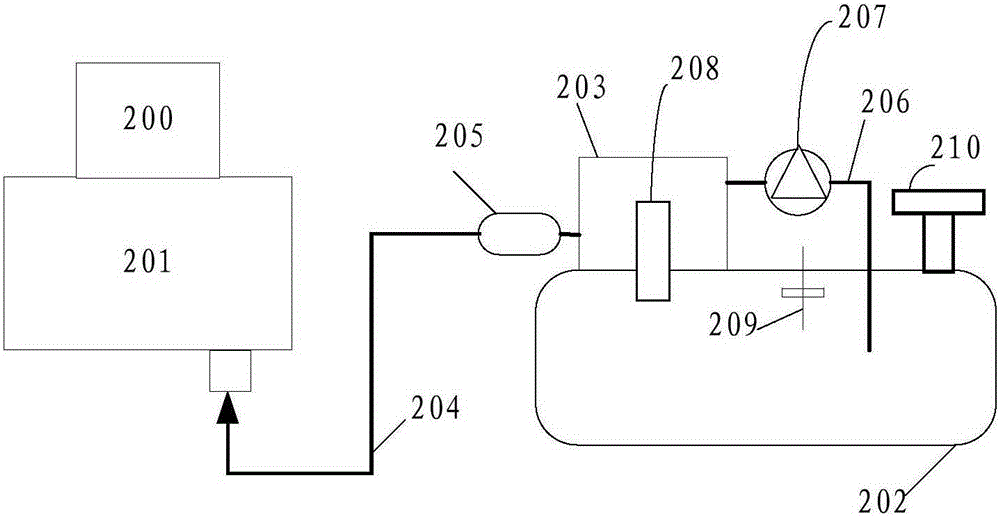

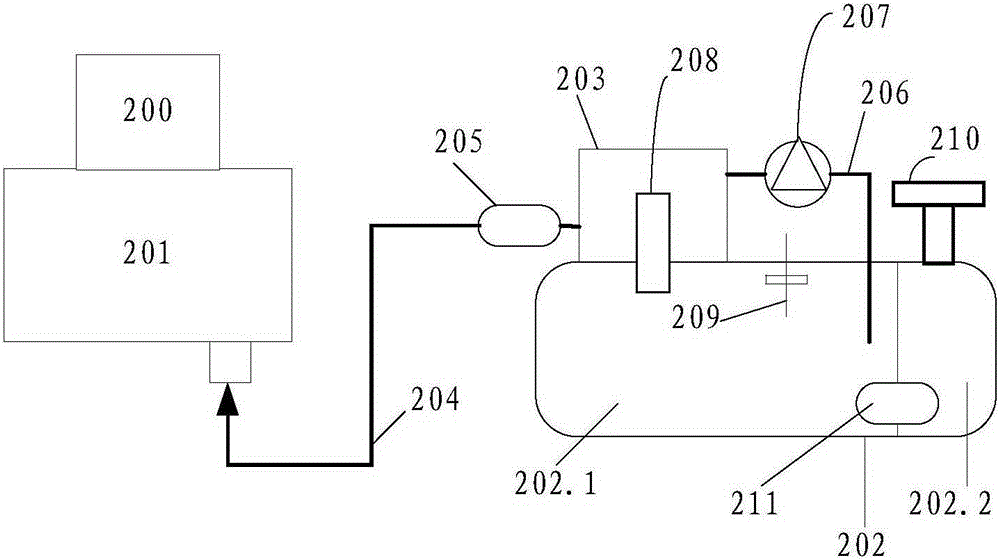

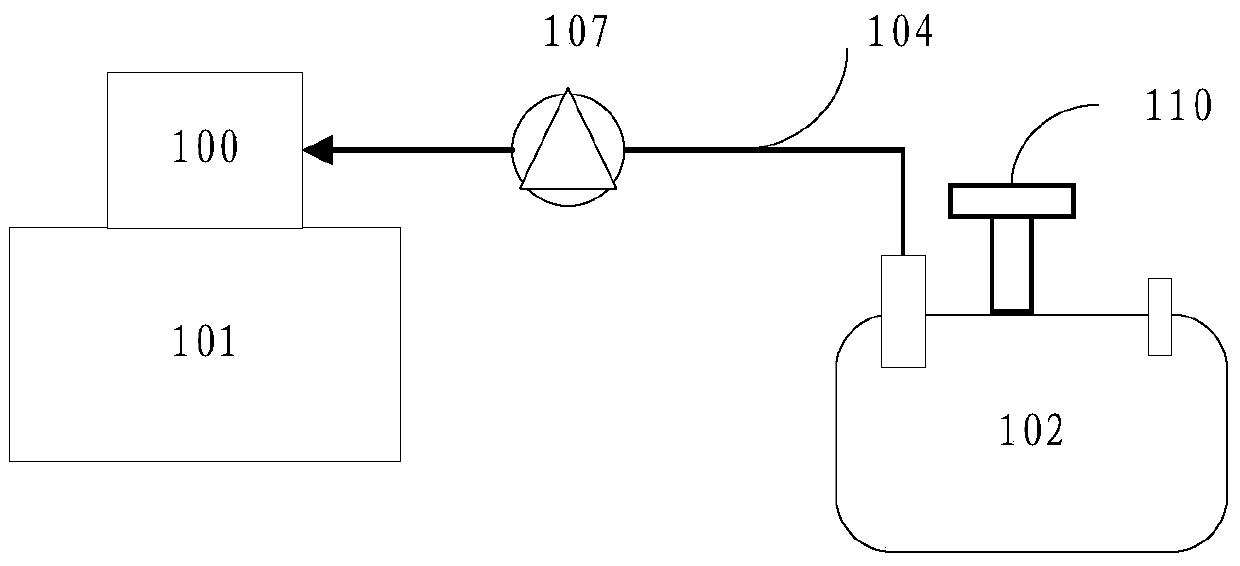

Engine oil supplementation system and oil supplementation method thereof

ActiveCN105221212AOil levelSufficient oilEngine levelsLubricant conduit arrangementsWhite gasHigh pressure

The invention discloses an engine oil supplementation system and an oil supplementation method thereof, and belongs to the technical field of engines. The system comprises an oil pan, an auxiliary engine oil tank and an oil supplementation cavity formed in the upper portion of the auxiliary engine oil tank. The oil pan is connected with the oil supplementation cavity through an oil supplementation pipe. A first one-way valve is arranged on the oil supplementation pipe. The oil supplementation cavity is connected with the auxiliary engine oil tank through an oil inlet pipe provided with an oil pump. The oil pump pumps oil to the oil supplementation cavity from the auxiliary engine oil tank according to a preset running mode. When the oil level of the oil supplementation cavity is higher than the oil level of the oil pan, the first one-way valve is opened, the oil supplementation cavity supplements oil to the oil pan. The first one-way valve is arranged on the oil supplementation pipe, and therefore it can be ensured that when an engine oil transportation unit is arranged in the oil pan in advance, lubricating oil in the oil pan can not flow into the oil supplementation cavity or the auxiliary engine oil tank. High-pressure gas generated in the engine running process can not arrive at the auxiliary engine oil tank through the oil supplementation pipe and can not flow out of the oil inlet of the auxiliary engine oil tank, and the white gas discharge phenomenon can not happen to the oil inlet.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

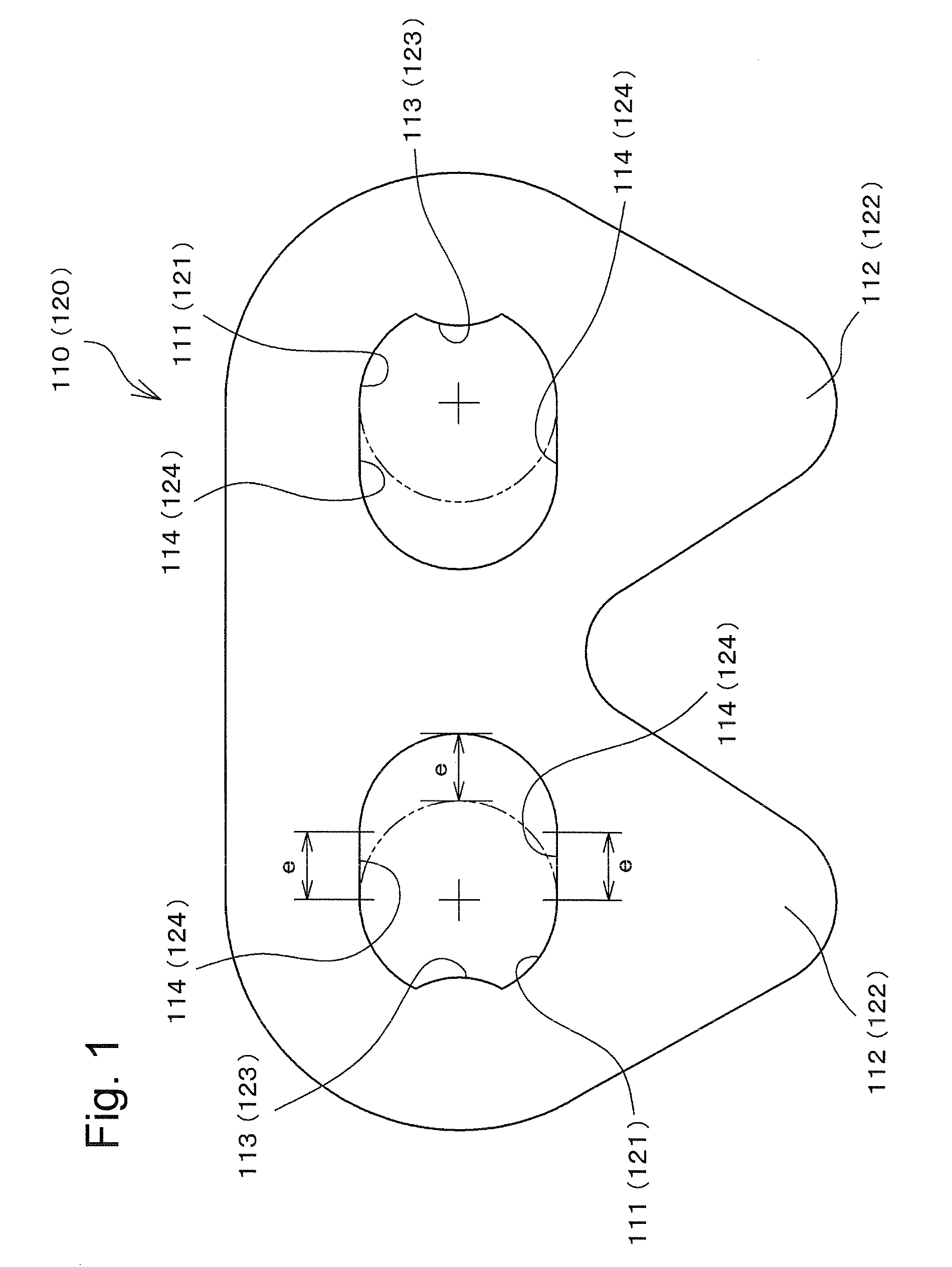

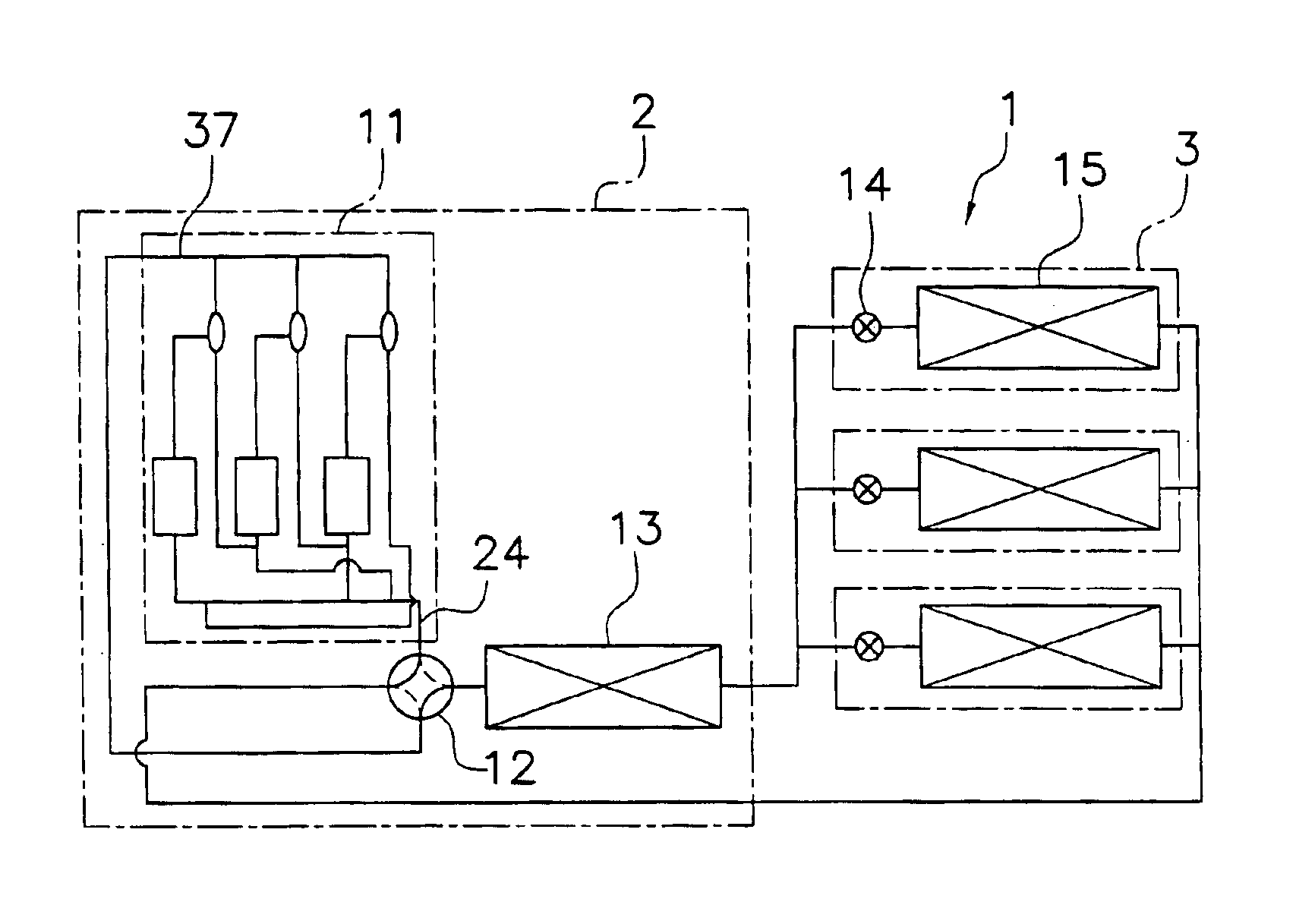

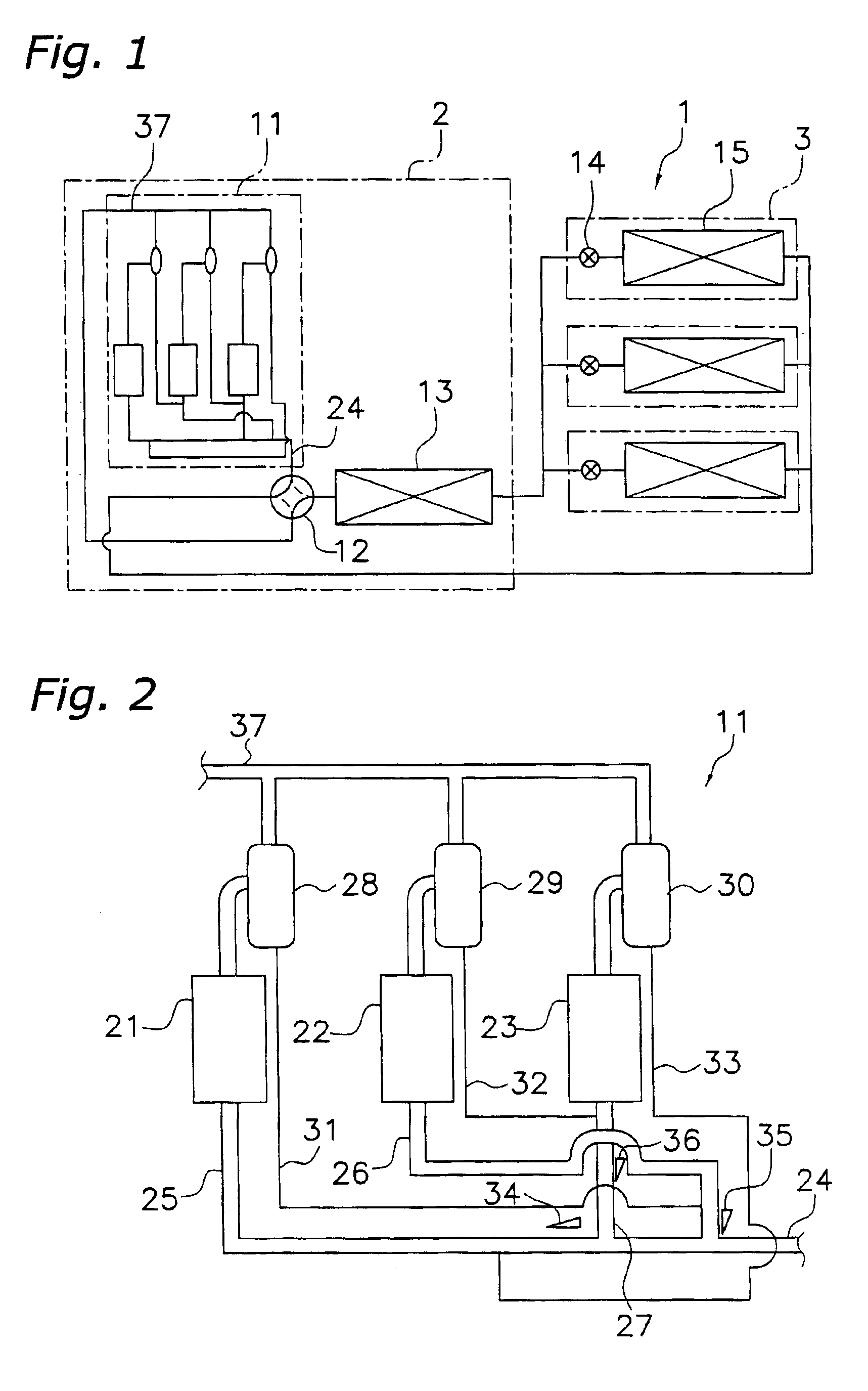

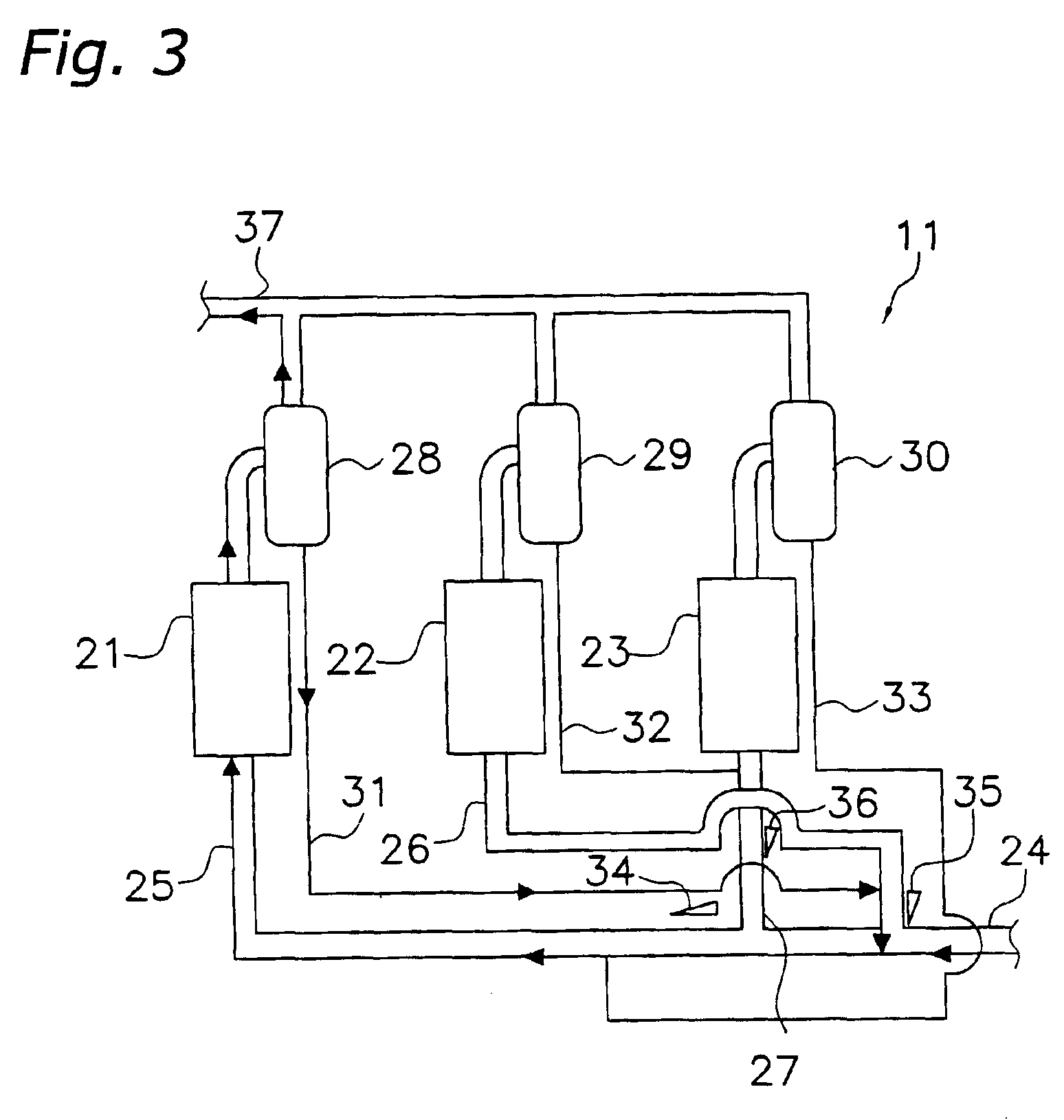

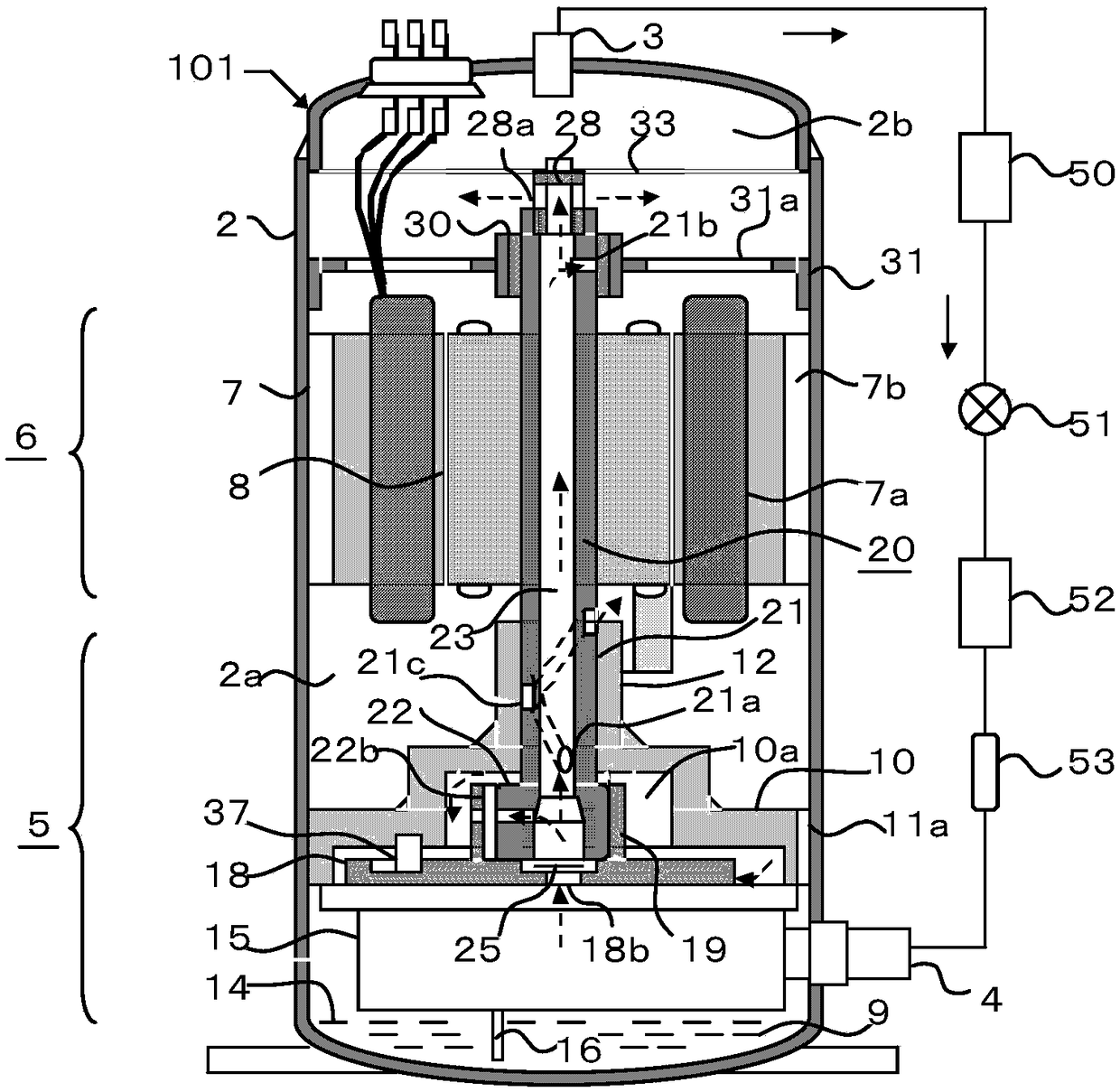

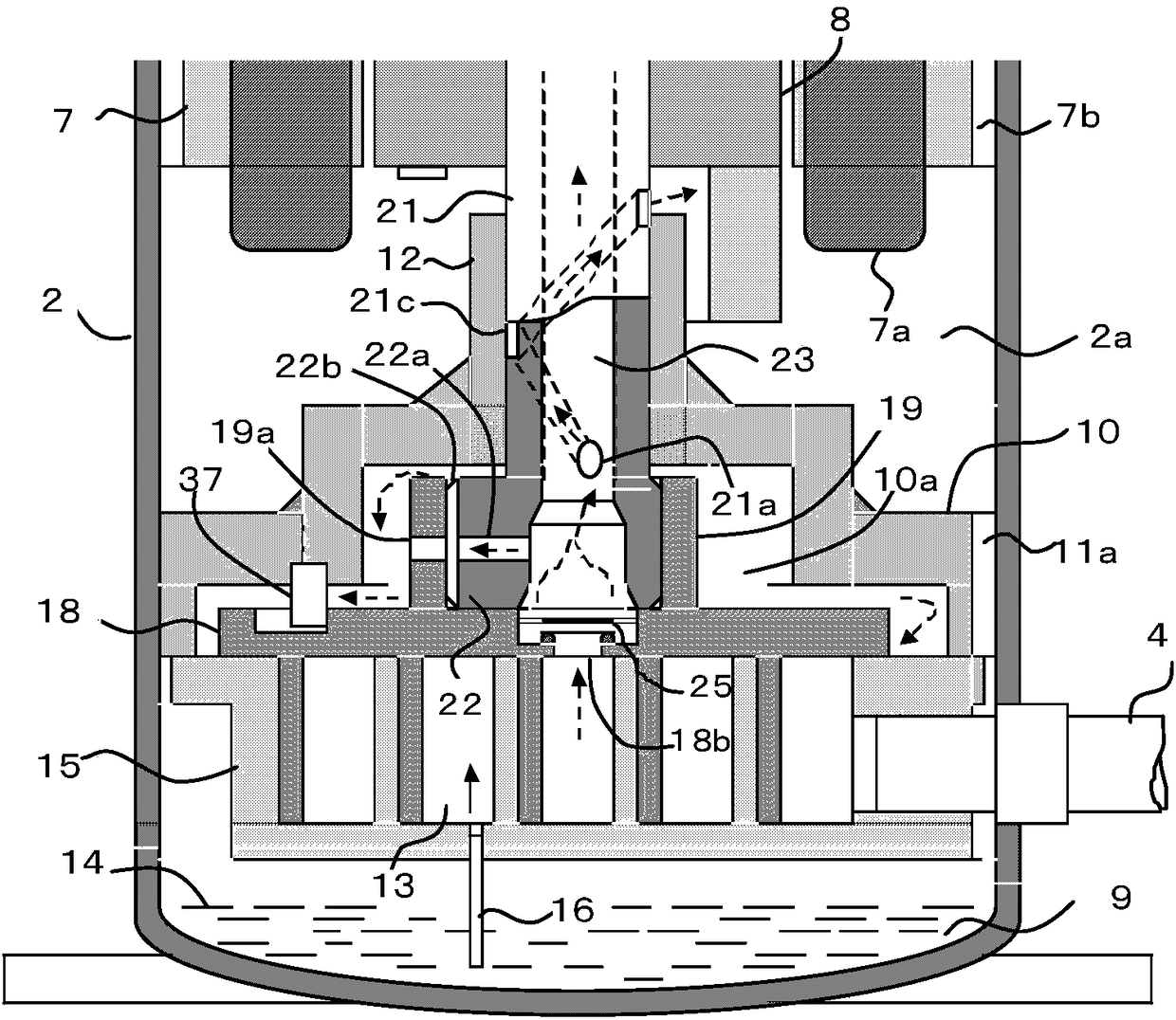

Compression mechanism for refrigeration system

InactiveUS6948335B2Sufficient oilReliable deliveryCompressorPositive displacement pump componentsRefrigerationRefrigerant

The present invention provides an oil equalizing circuit for a refrigeration system provided with a plurality of compression mechanisms, the oil equalizing circuit being capable of supplying sufficient oil to the compressors that are running during partial load operation. The refrigeration system compression mechanism is provided with the following: first, second, and third compressors; a refrigerant intake main pipe; first, second, and third intake branch pipes connected to the intake sides of the compressors; first, second, and third oil separators connected to the discharge sides of the compressors; and first, second, and third oil return pipes provided on the oil separators. The first oil return pipe is configured such that oil is delivered to the refrigerant intake main pipe due to gravity when only the first compressor is running. The second oil return pipe is configured such that oil is delivered to the refrigerant intake main pipe due to gravity when only the first and second compressors are running.

Owner:DAIKIN IND LTD

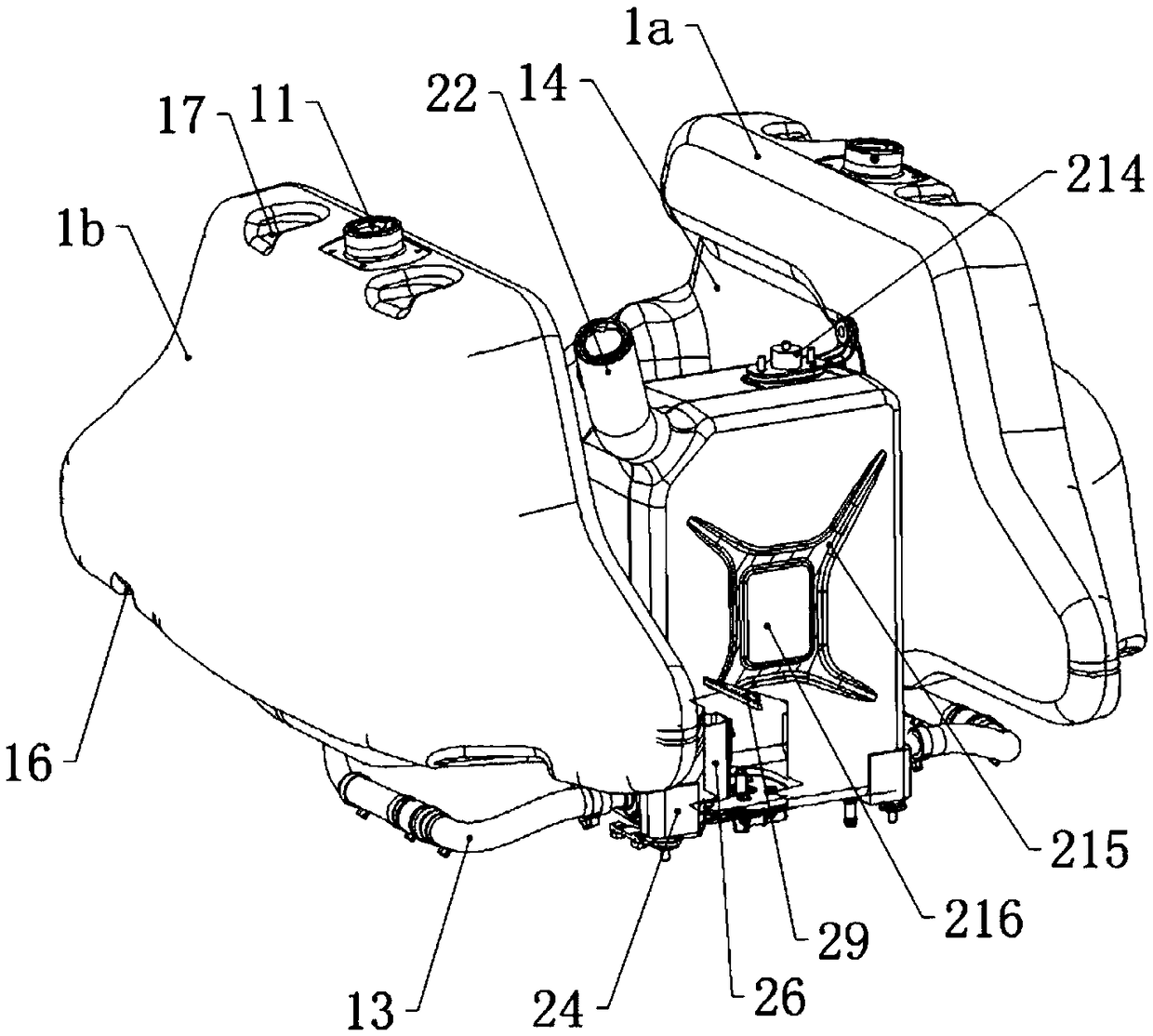

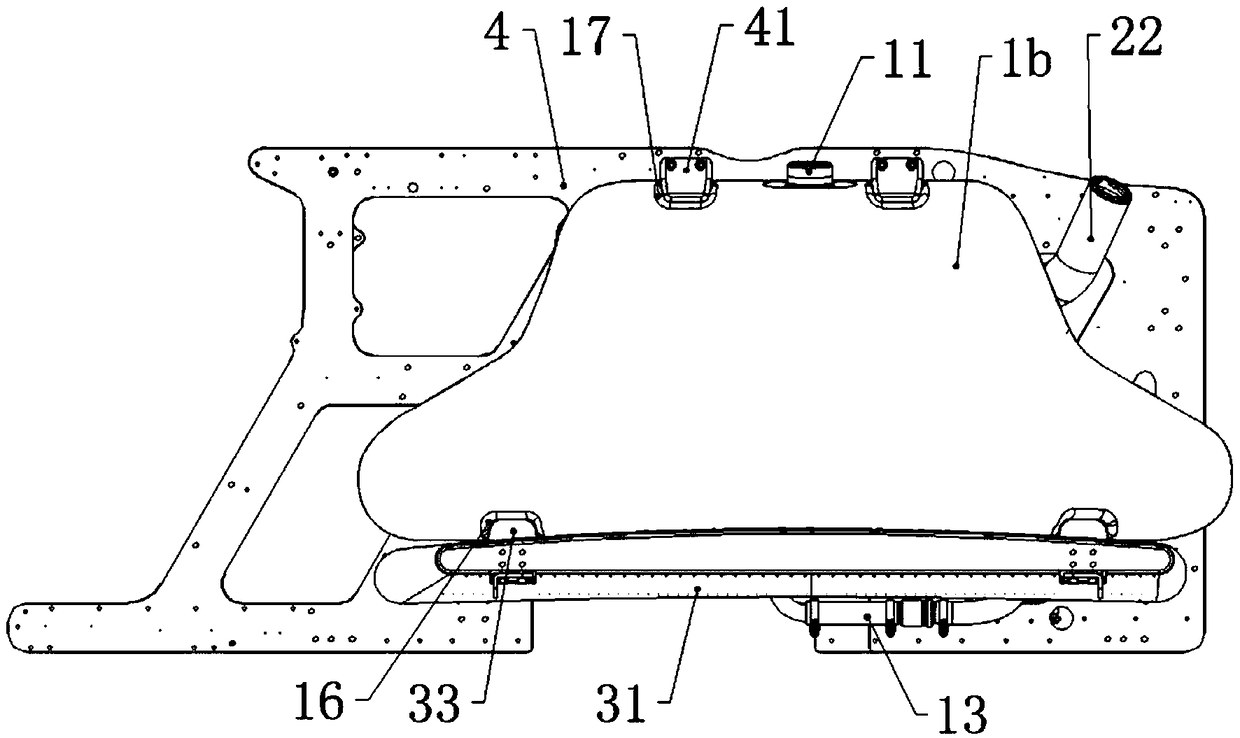

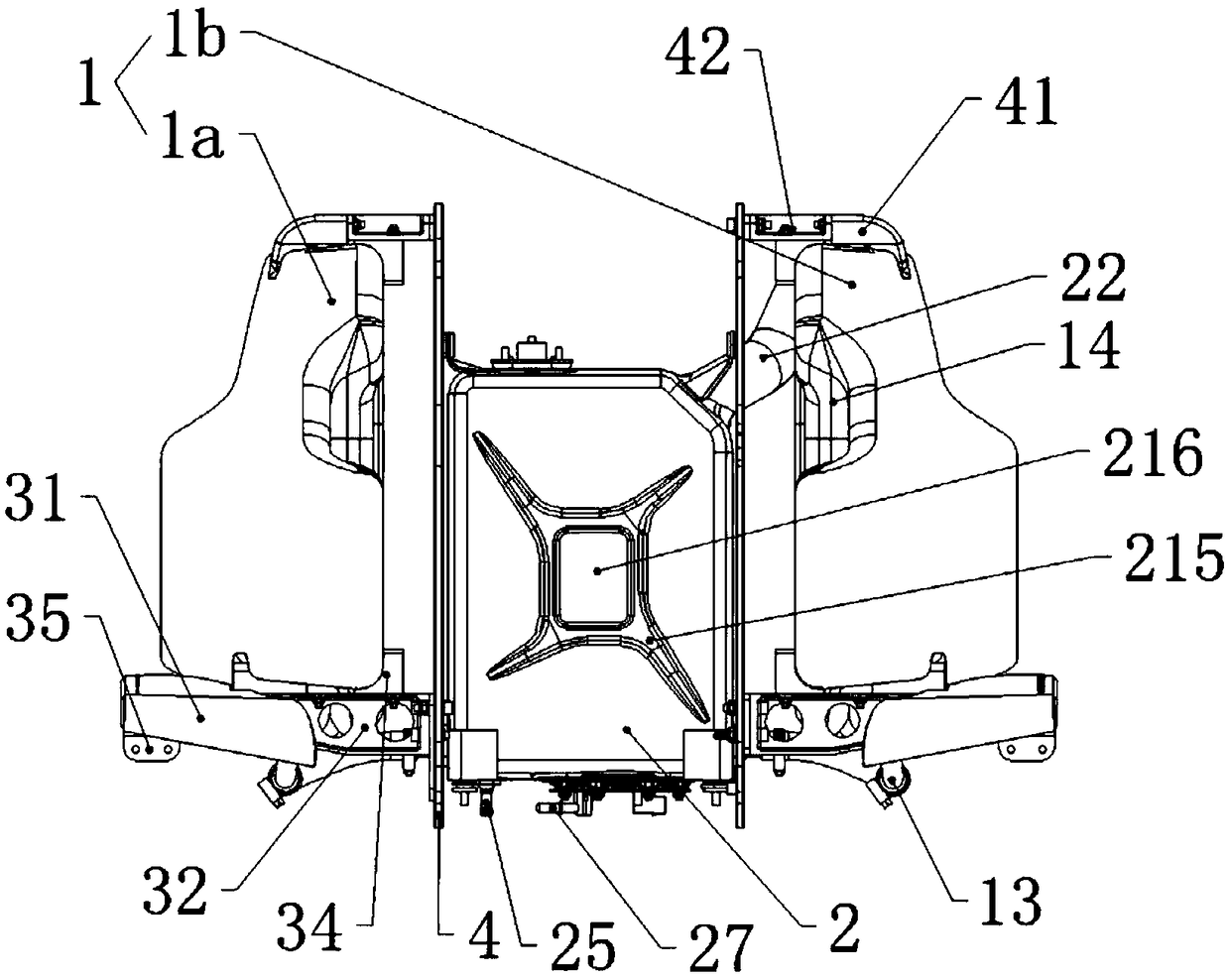

Helicopter fuel tank assembly and helicopter

The invention discloses a helicopter fuel tank assembly and a helicopter. The helicopter fuel tank assembly comprises an external fuel tank and an internal fuel tank, and an inner cavity of the external fuel tank is communicated with an inner cavity of the internal fuel tank; the external fuel tank comprises a left fuel tank body and a right fuel tank body; the internal fuel tank is located between the left fuel tank body and the right fuel tank body. The helicopter fuel tank assembly can cooperate with the integrated arrangement of a helicopter body, the space of the helicopter body is fullyutilized, the external fuel tank is added, the fuel load of an fuel tank system is increased, and the time of endurance is prolonged.

Owner:珠海隆华直升机科技有限公司

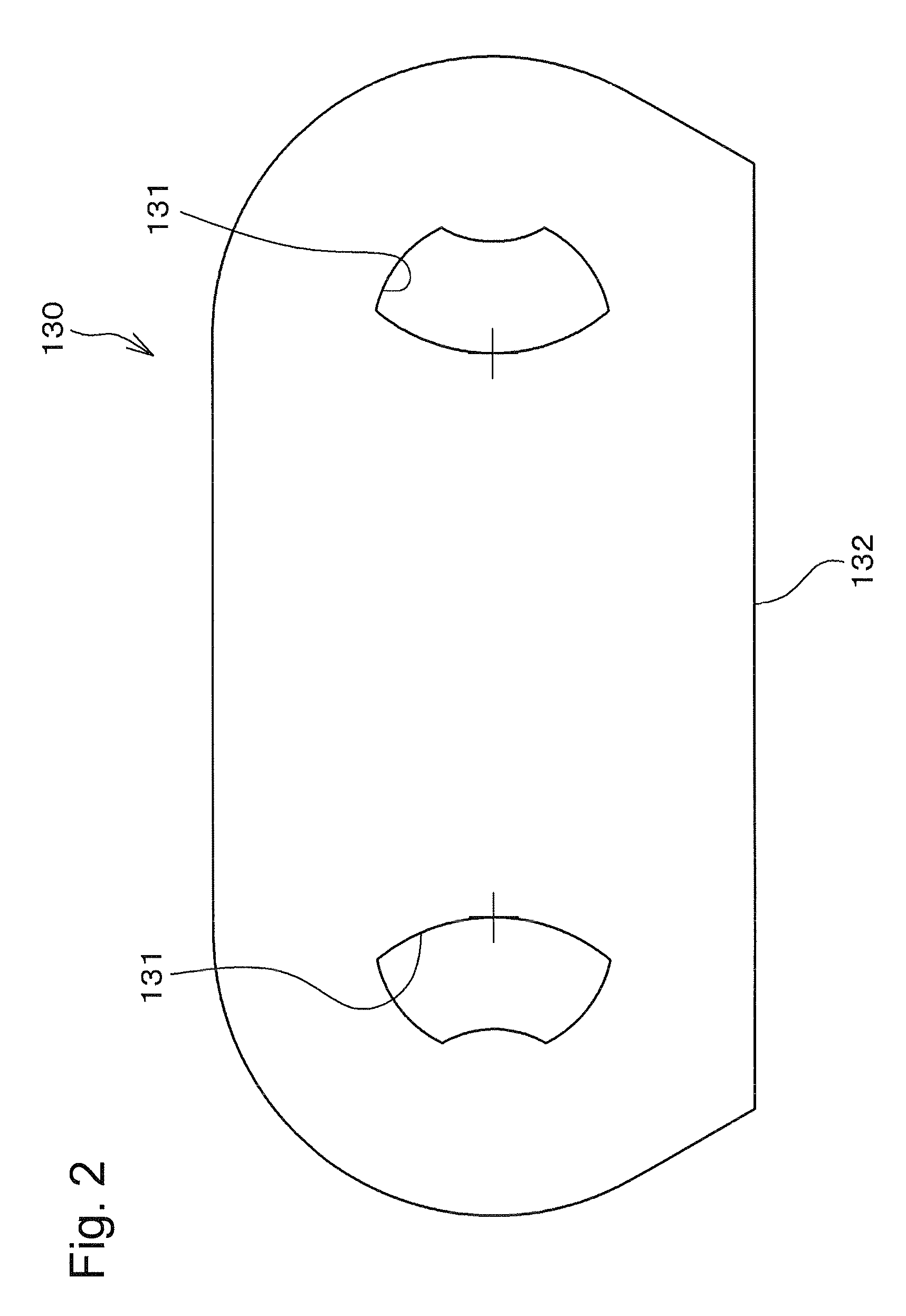

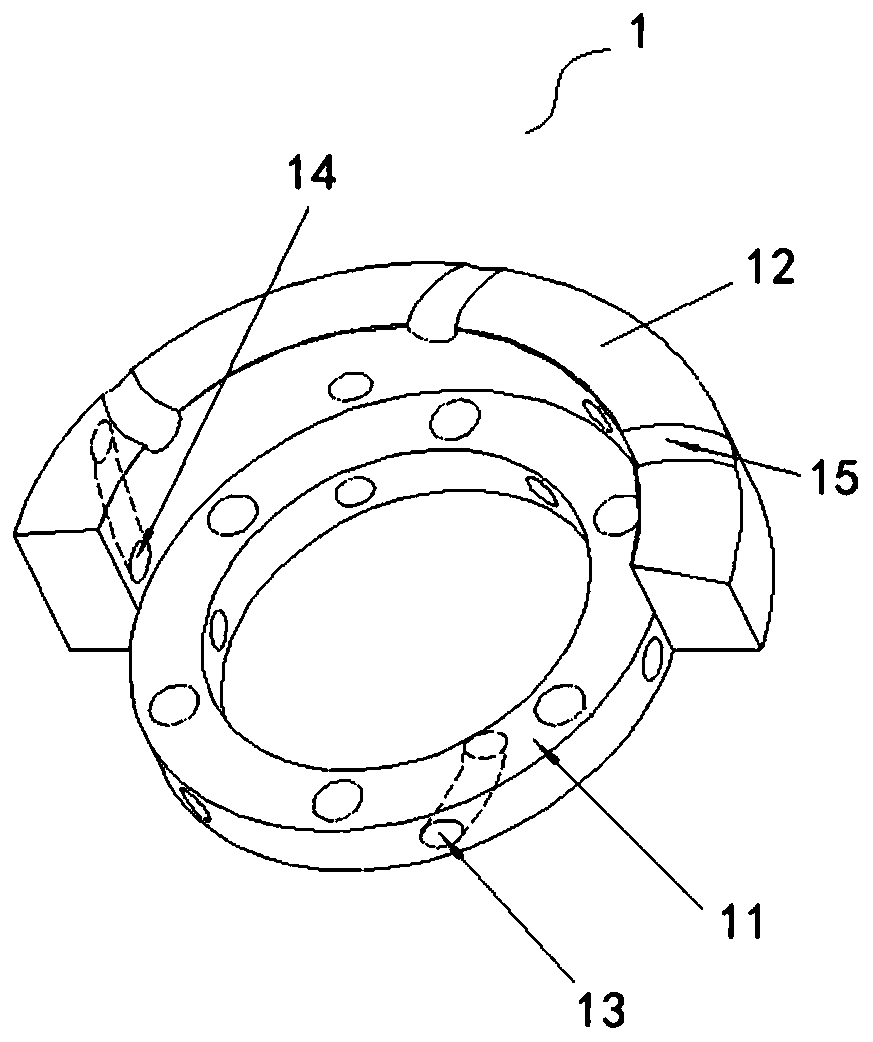

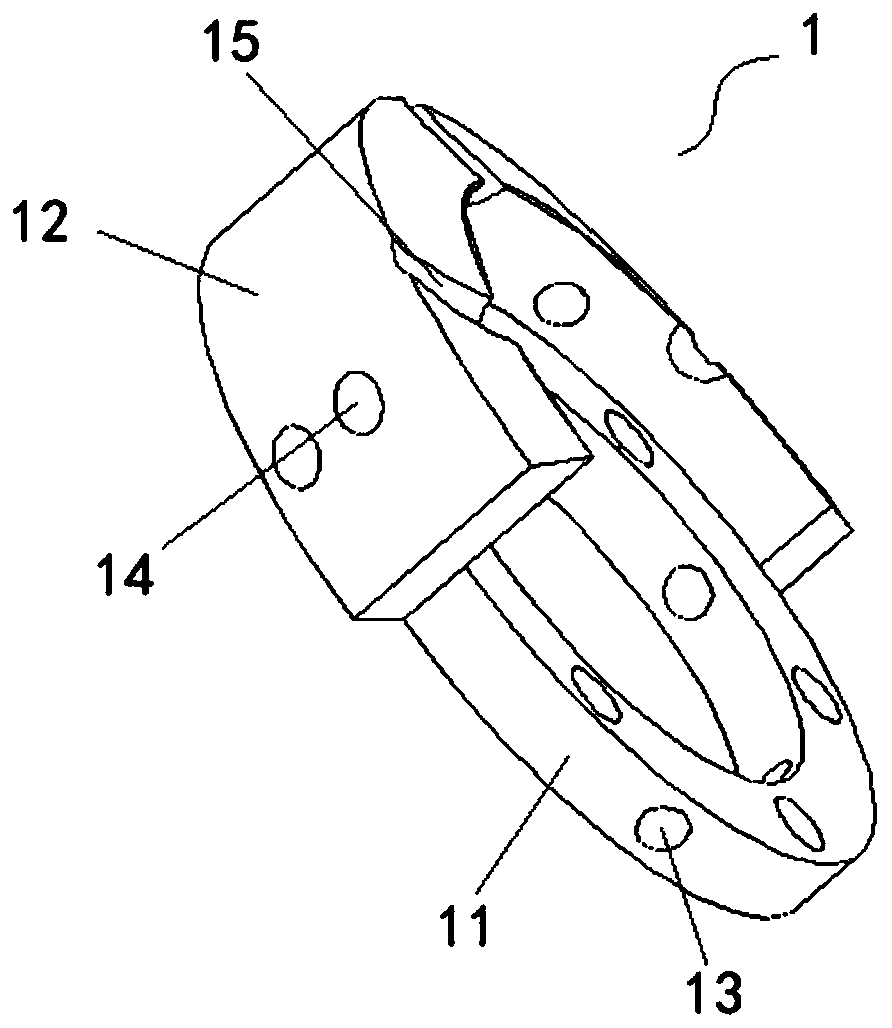

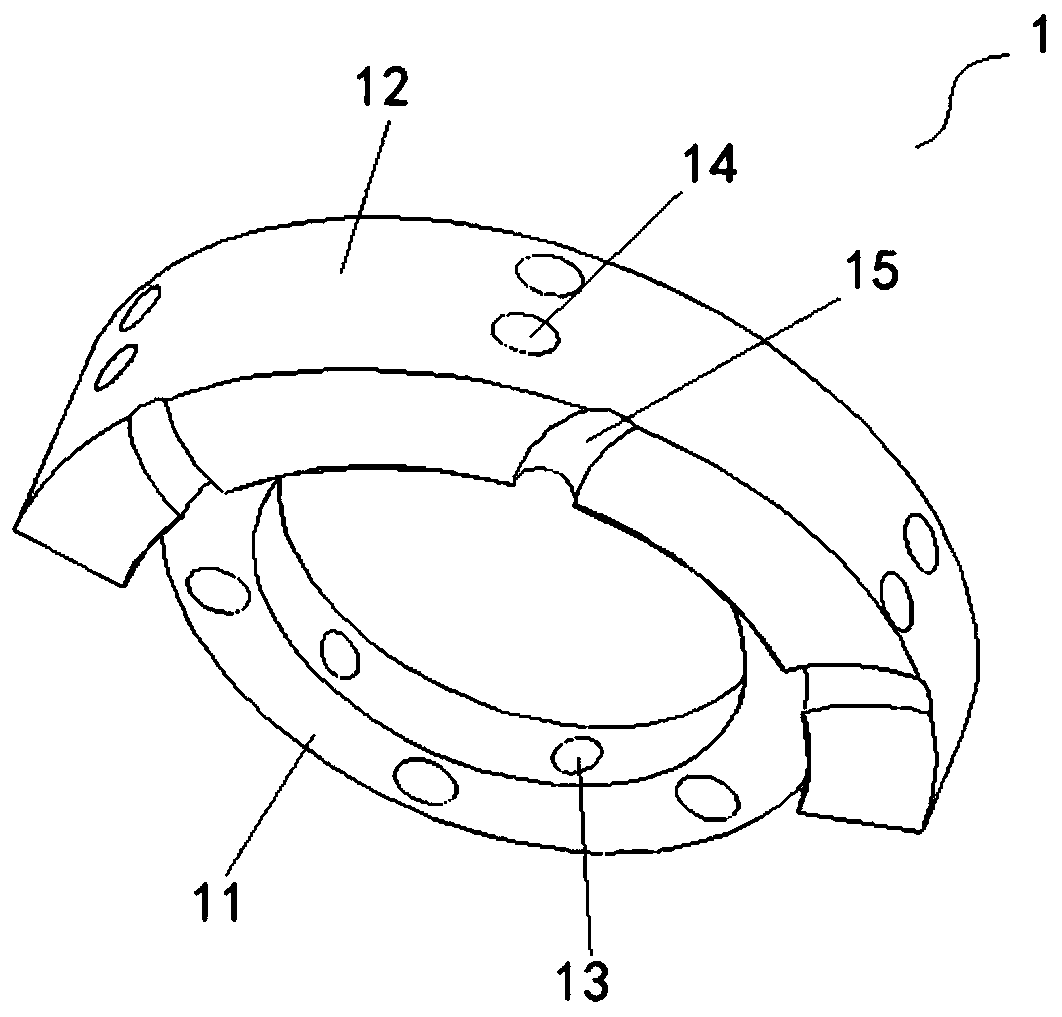

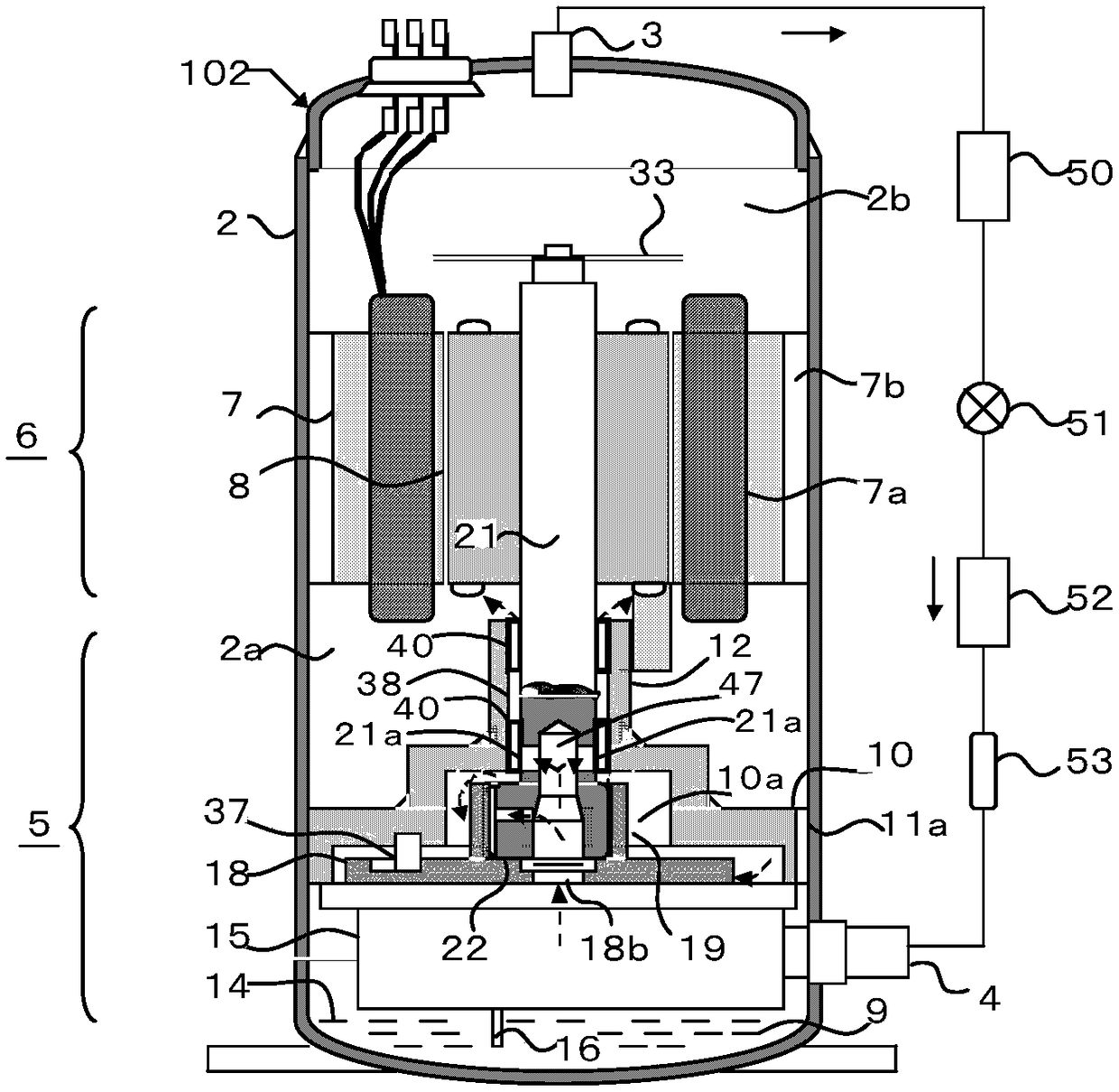

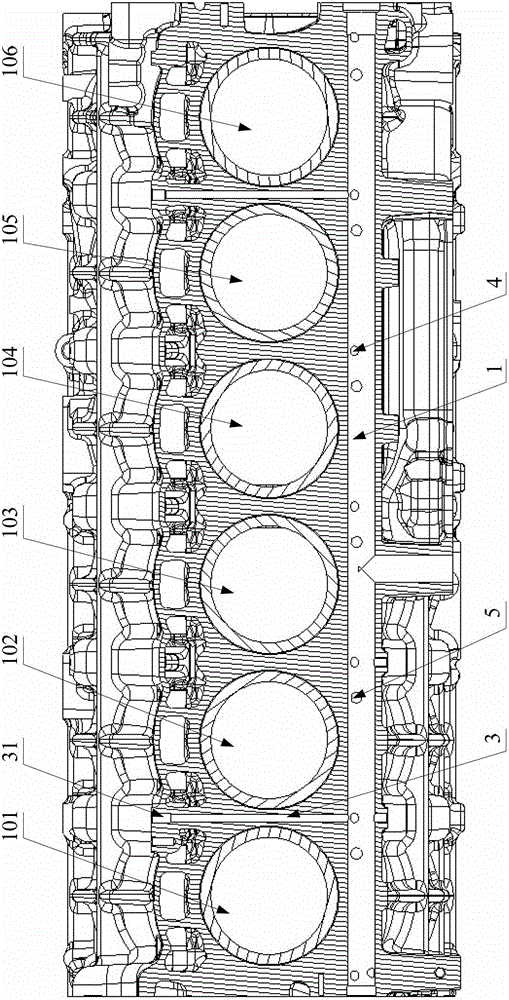

Compressor, motor thereof, and rotor balance blocks thereof

PendingCN110011472ASpeed up flowSpeed up the flow rateRotary/oscillating piston combinations for elastic fluidsMagnetic circuit rotating partsLubricationEngineering

The invention discloses a compressor, a motor thereof, and rotor balance blocks thereof. The rotor balance blocks comprise bottom plates which are annular structures, bosses which are installed on theouter ring surfaces of the annular structures, fluid passages which pass through annular walls set on the annular structures, and / or the fluid passages pass through the bosses, and the extension direction of the fluid passages and the rotor rotation direction of the motor are the same time. According to the rotor balance blocks provided by the invention, the fluid passages are set on the bottom plates and / or steps, the extension direction of the fluid passages and the rotor rotation direction of the motor are the same time, which means that the paths of the fluid passages are similar to centrifugal lines, when cooling oil flows in the motor, the flow rate of the cooling oil can be significantly accelerated through the design of the fluid passages, therefore, the return speed of the cooling oil can be greatly improved, the sufficient amount of oil in an oil pool is maintained, and the lubrication effect and operational reliability of the compressor are ensured.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Spraying device baffle plate for forming metalized film screen zone

InactiveCN104775091ASufficient oilScreen with clearVacuum evaporation coatingSputtering coatingSpray nozzleOil pressure

The invention belongs to the technical field of metalized film processing and discloses a spraying device baffle plate for forming a metalized film screen zone. A gas storage chamber for storing screening oil vapor is arranged inside the baffle plate which is provided with nozzles which are distributed along the length direction and used for spraying the screening oil to the surface of the film, oil spray holes communicated with the gas storage chamber are formed in the middle of the nozzles, and a branch gas storage chamber with an enlarged section for buffering the pressure is formed at the inlet end of the oil spray hole of each nozzle on the top of the gas storage chamber, wherein the depth of the branch gas storage chamber is 0.1-0.15cm. By forming the branch gas storage chambers, pressure buffering regions are arranged between the inner cavity of the spray device and the nozzles, so that the oil pressures of the nozzles are tend to be consistent, and therefore, the problem that the edge of the metalized film screen zone is blurry and black is eliminated and the electric performance of the metalized film is improved.

Owner:ANHUI TONGFENG ELECTRONICS

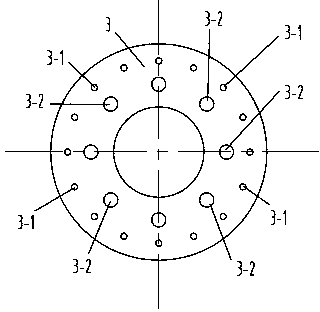

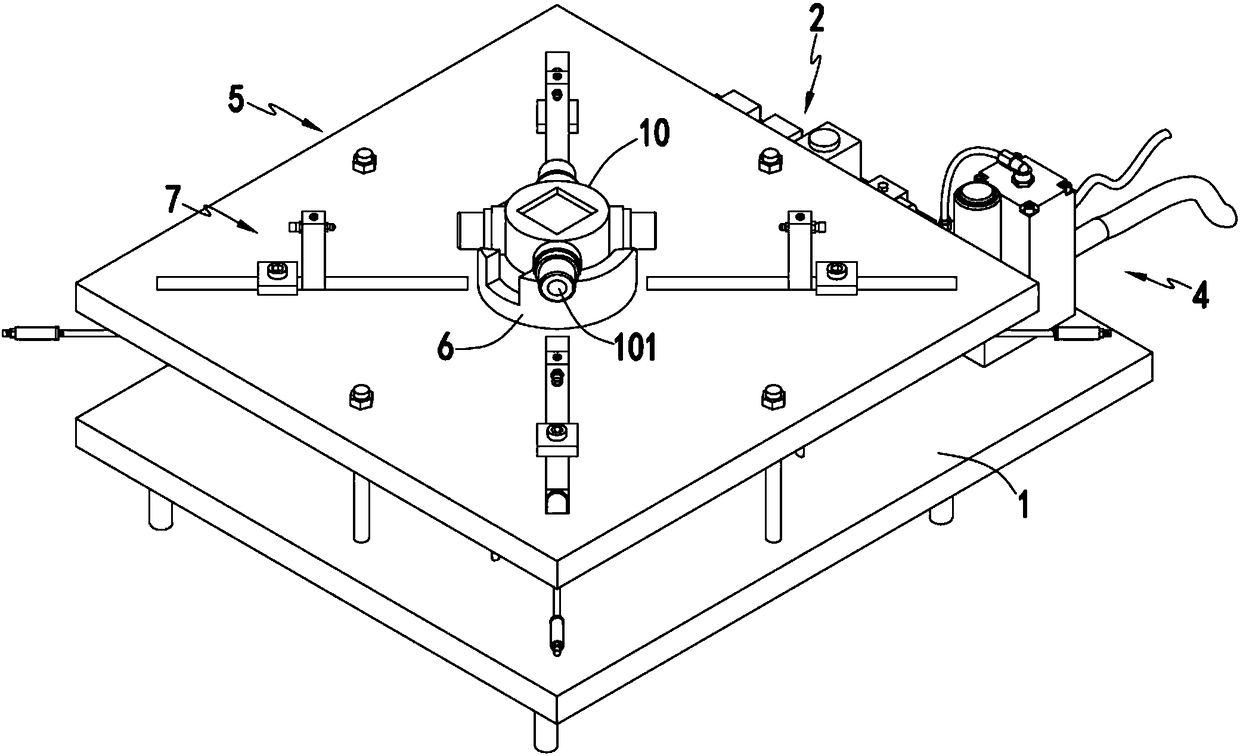

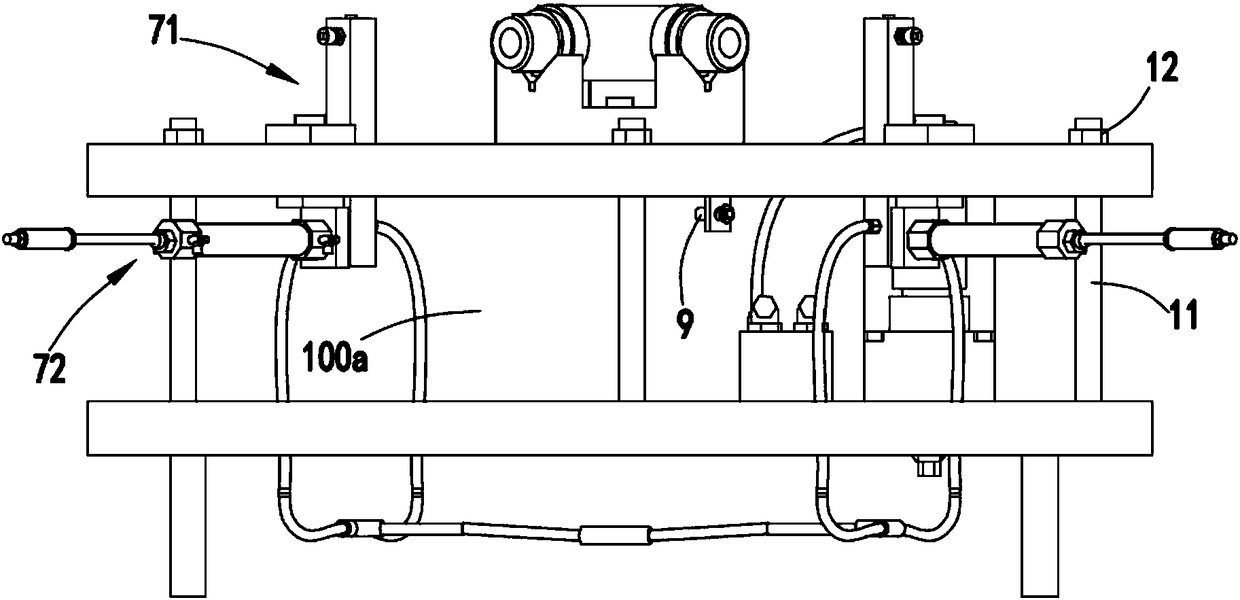

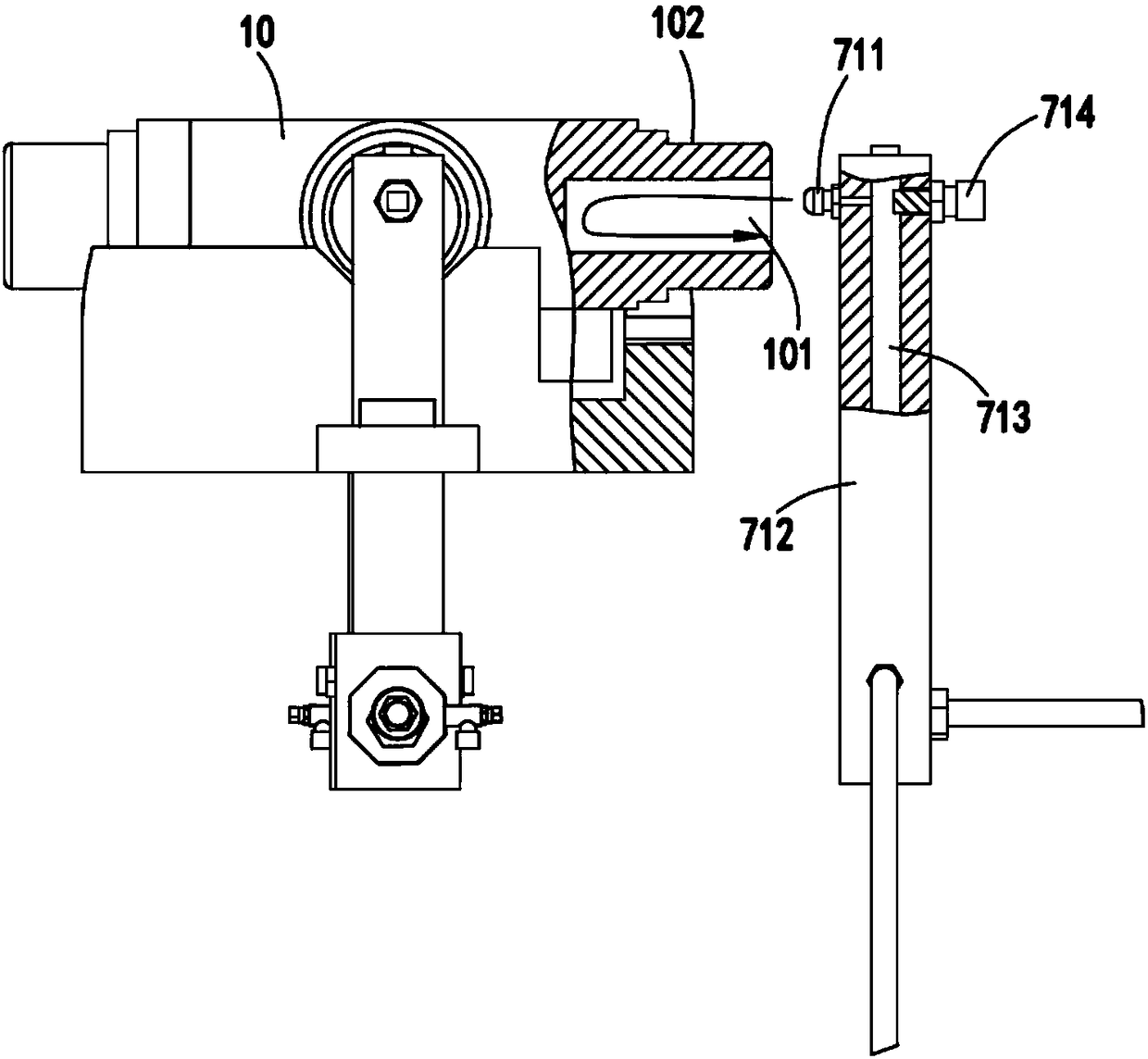

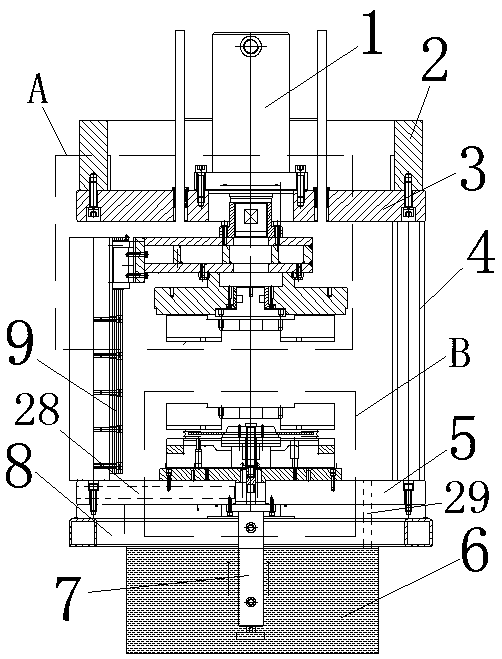

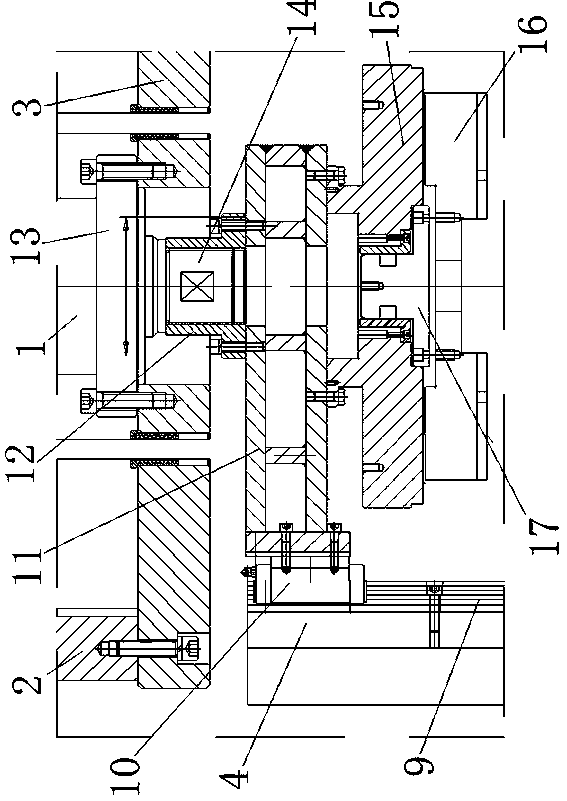

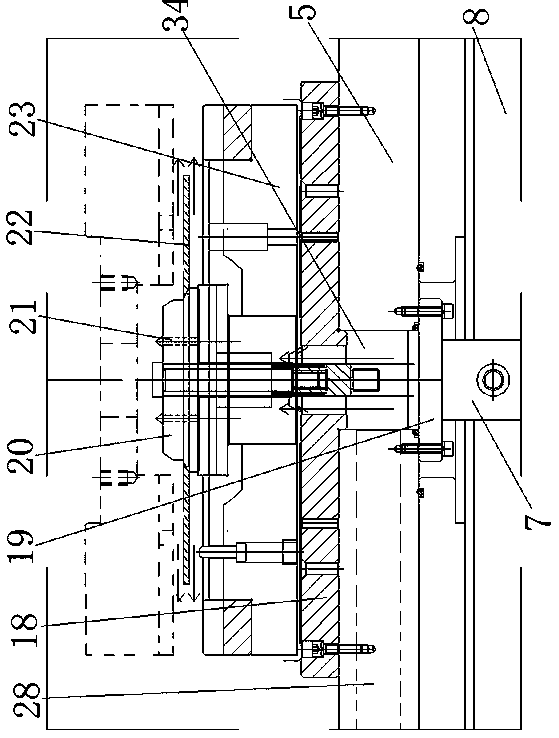

Candan universal joint synchronization oil injection equipment and method thereof

PendingCN108302314AQuick oil injectionSame lengthYielding couplingConduits/junctionsInjection equipmentUniversal joint

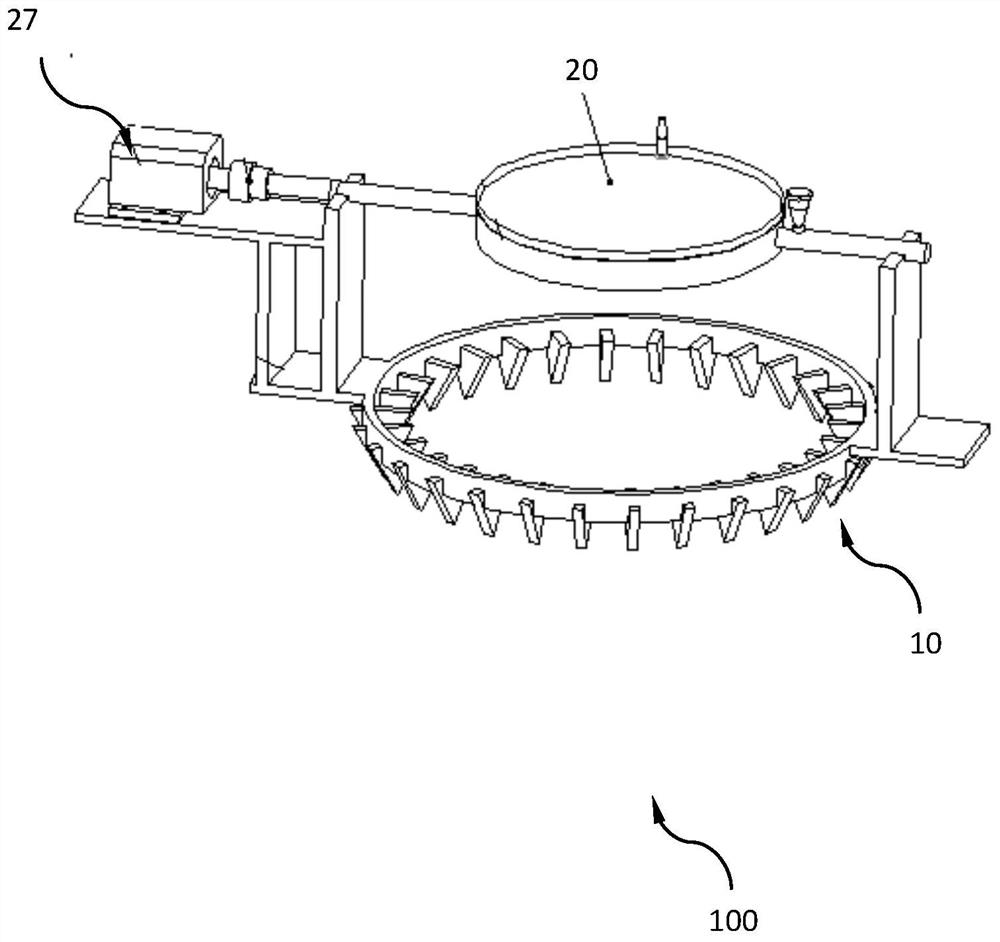

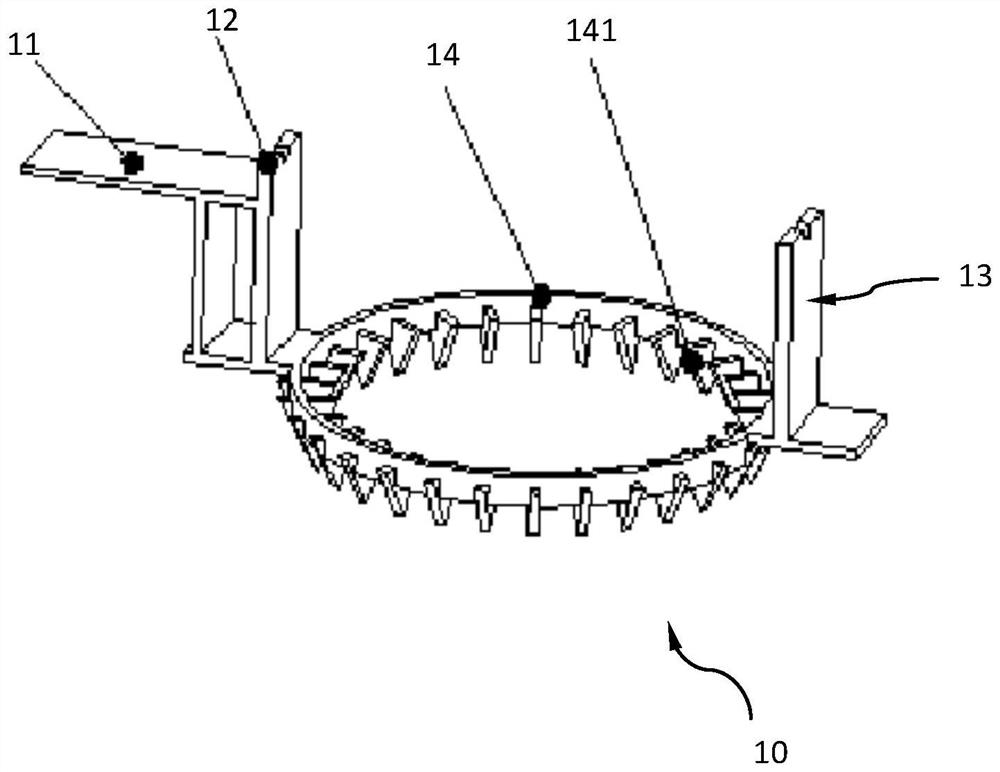

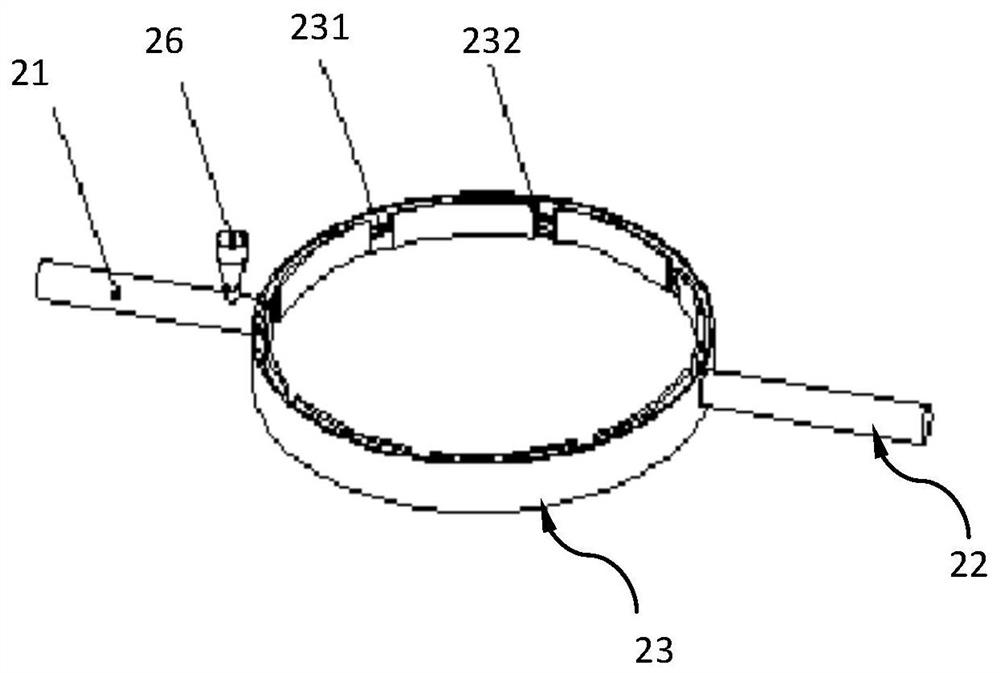

The invention relates to candan universal joint synchronization oil injection equipment and a method thereof. The candan universal joint synchronization oil injection equipment comprises a base, an electric control device installed on the base, an air inlet control device and an oil feeding device, a guide supporting unit is arranged above the base and is provided with a positioning clamp for positioning a candan universal joint, and oil injection devices corresponding to the oil injection hole in a one-to-one manner are arranged on the periphery of the positioning clamp along the circumferential route; the multiple oil injection devices are controlled by the air inlet control device to synchronously move towards the center position of the candan universal joint in the radial directions ofthe oil injection holes corresponding to the oil injection devices in position, oil is injected from the oil injection devices to the oil injection holes through control of an oil supply device afterthe oil injection devices are moved to the specific positions, and the oil inlet control device controls the oil injection devices to reset after oil injection is finished. The candan universal jointsynchronization oil injection equipment and the method solve the problems that multiple holes need to be subject to oil injection one by one in the candan universal joint oil injection process, the oil injection efficiency is low, oil amount in all holes is difficult to balance, oil injection into blind holes are prone to being brought out after oil injection resetting is carried out, the oil amount in the blind hole is insufficient, and consequently the product using effect is influenced.

Owner:ZHEJIANG QIDIE AUTOMOBILE PARTS CO LTD

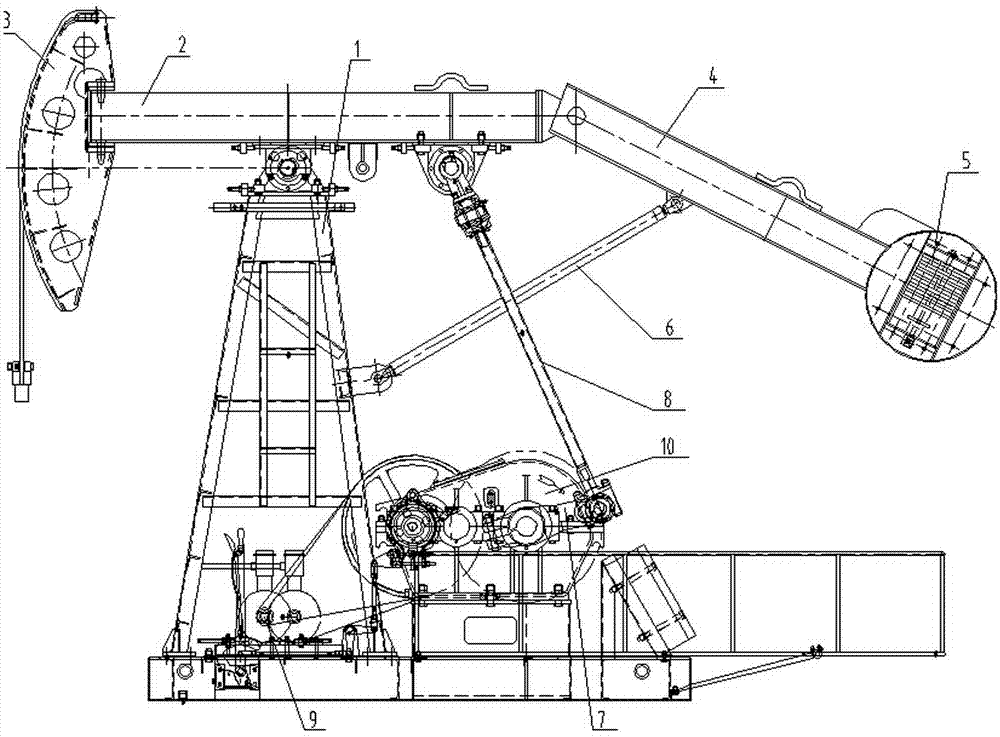

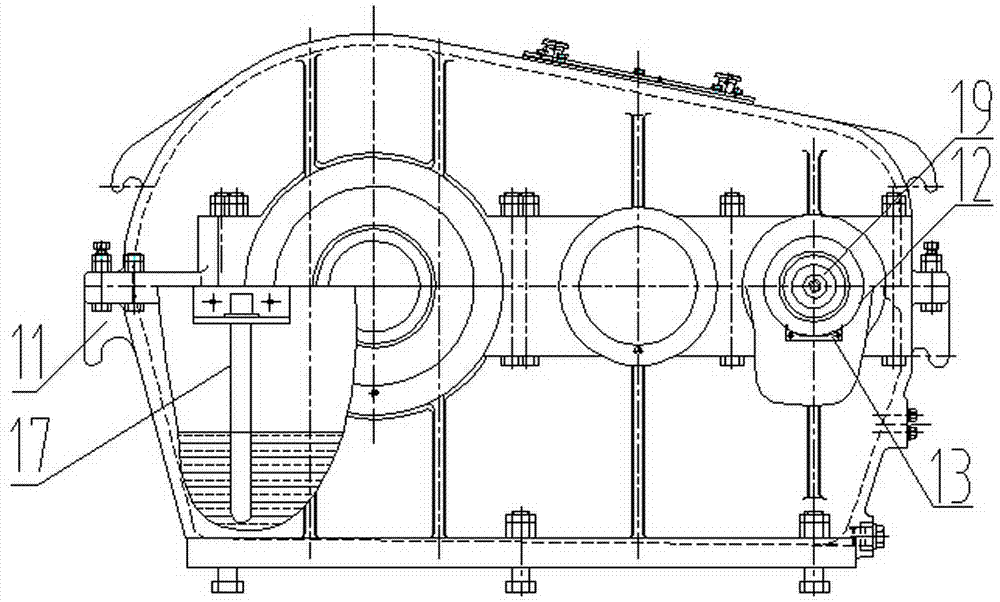

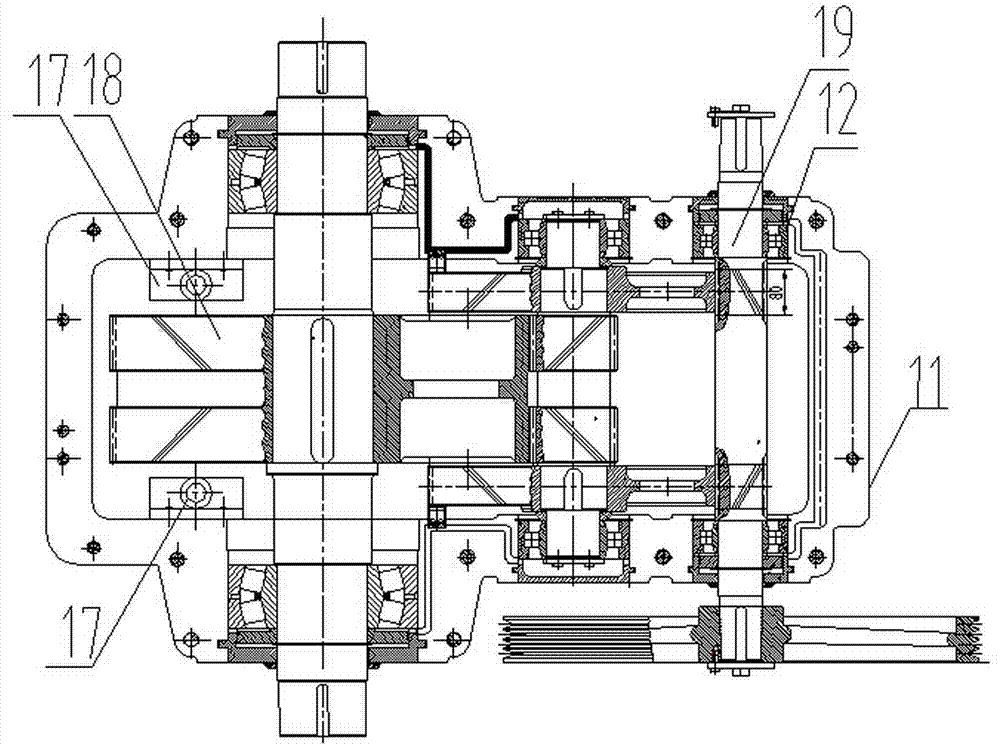

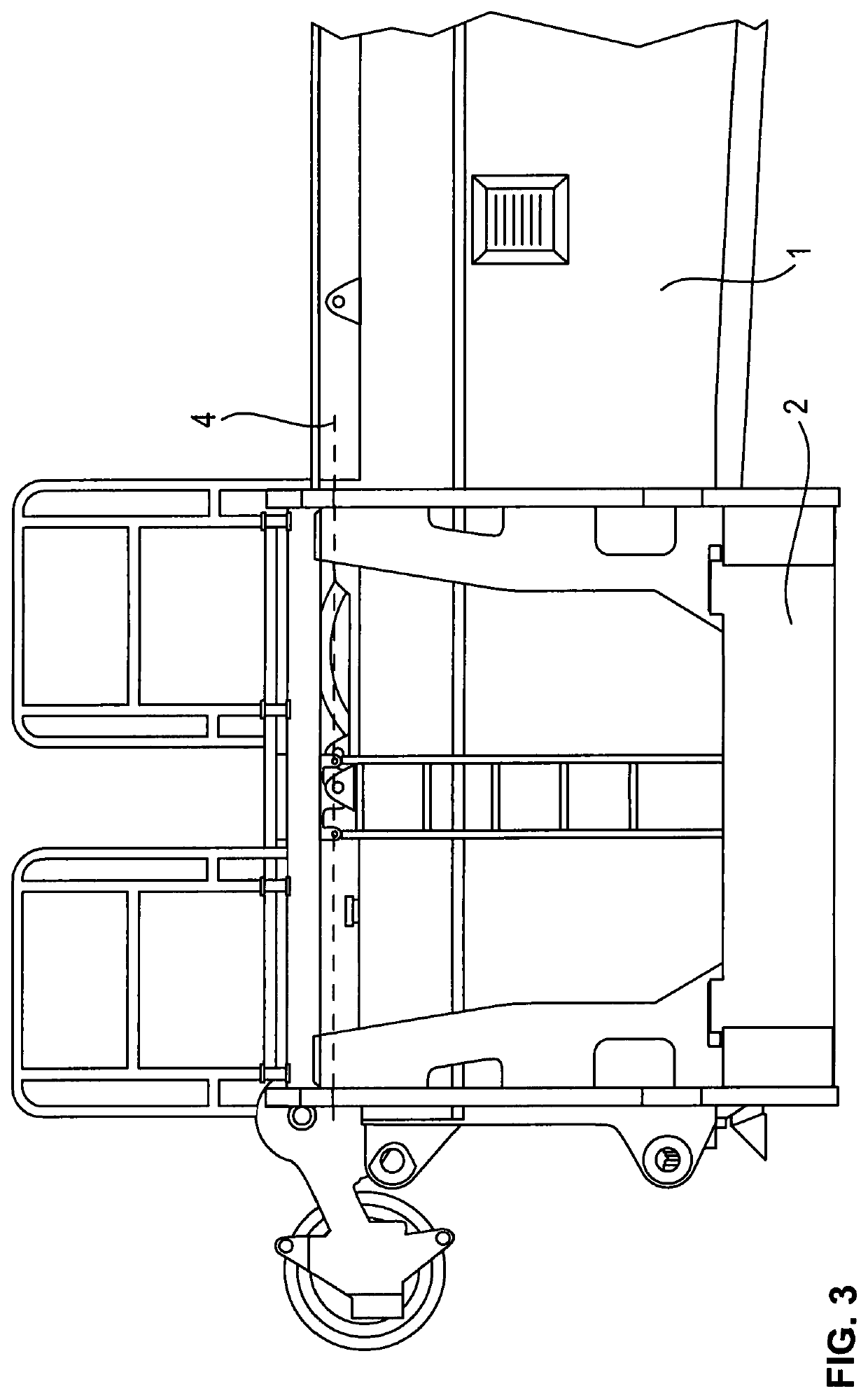

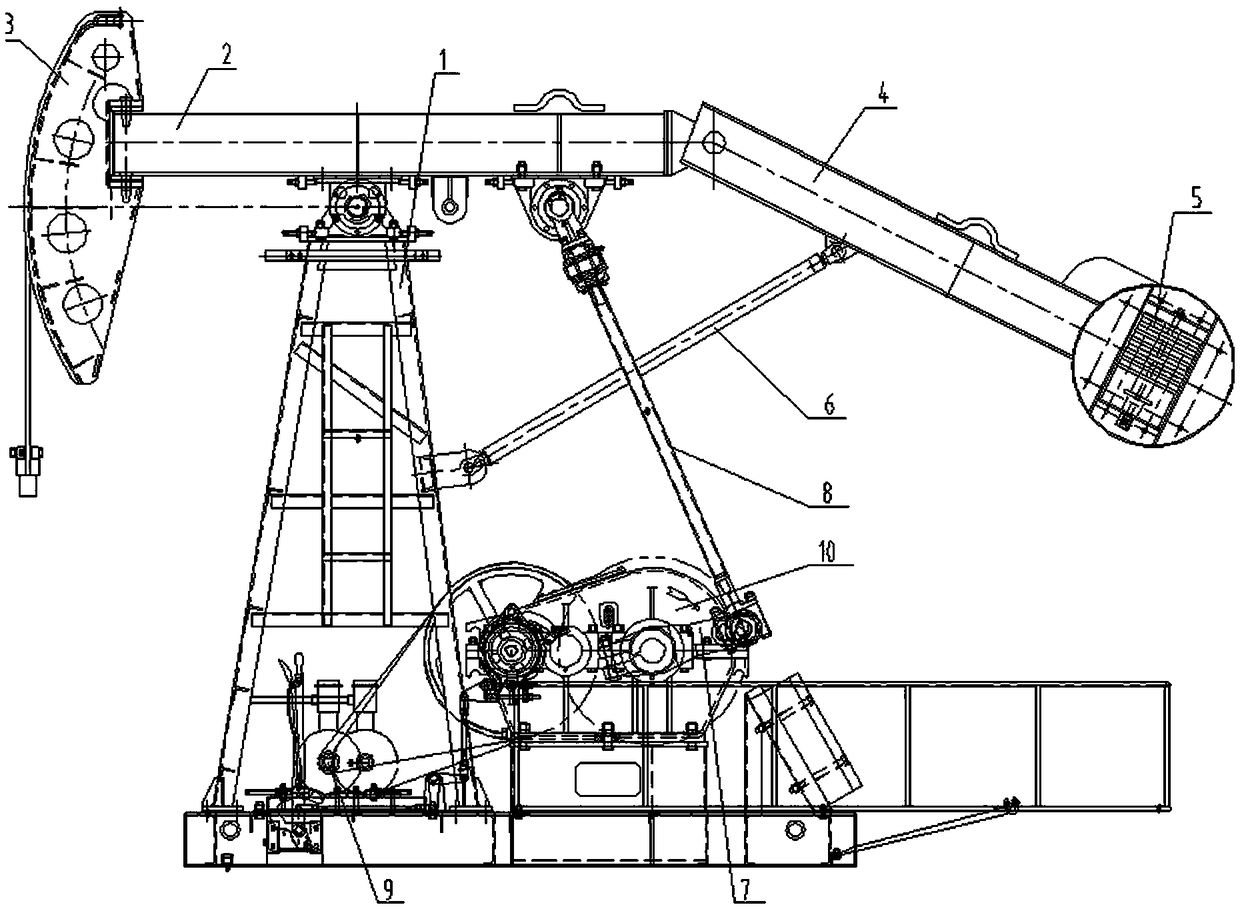

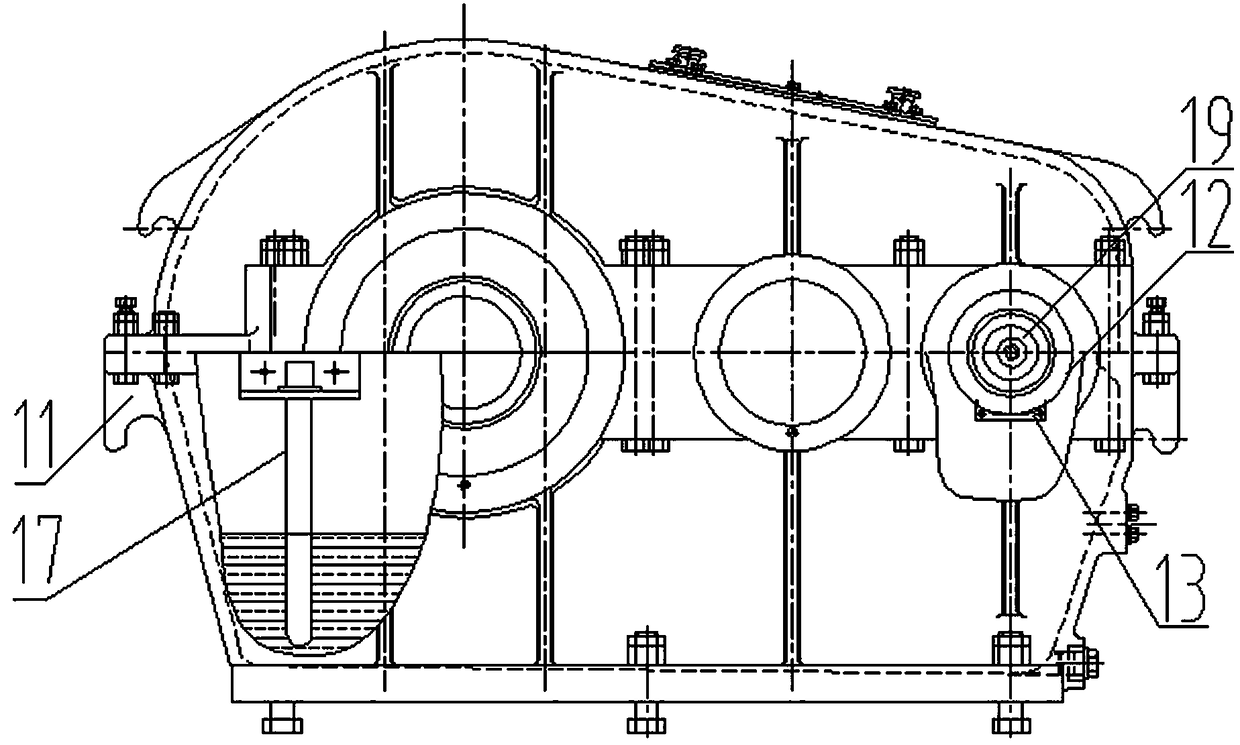

Beam-pumping unit

The invention discloses a beam-pumping unit, which comprises a bracket, a reducer, a crank, a connecting rod, a beam, a horse head, constant-temperature heaters, a balance arm, a balance block and a supporting rod, wherein the beam is movably connected to the bracket; the horse head is fixedly arranged on one end of the beam; the balance arm is movably connected to the other end of the beam; the balance block is fixedly arranged on the balance arm; one end of the support rod is movably connected to the bracket; the other end of the supporting rod is movably connected to the balance arm; the reducer is connected with the crank; the connecting rod is movably connected between the crank and the beam; the constant-temperature heaters are fixedly arranged in the tank body of the reducer for heating lubricating oil. The beam-pumping unit has the two technical advantages that the peak value current of a motor can be reduced when the horse head moves to an upper stop, the peak value current of a motor and the valve current torque of the reducer are reduced when the horse head moves to a lower stop, and the lubricating oil in the reducer can be prevented from icing or becoming a thick state under a low-temperature state.

Owner:SICHUAN JINXIN CO LTD

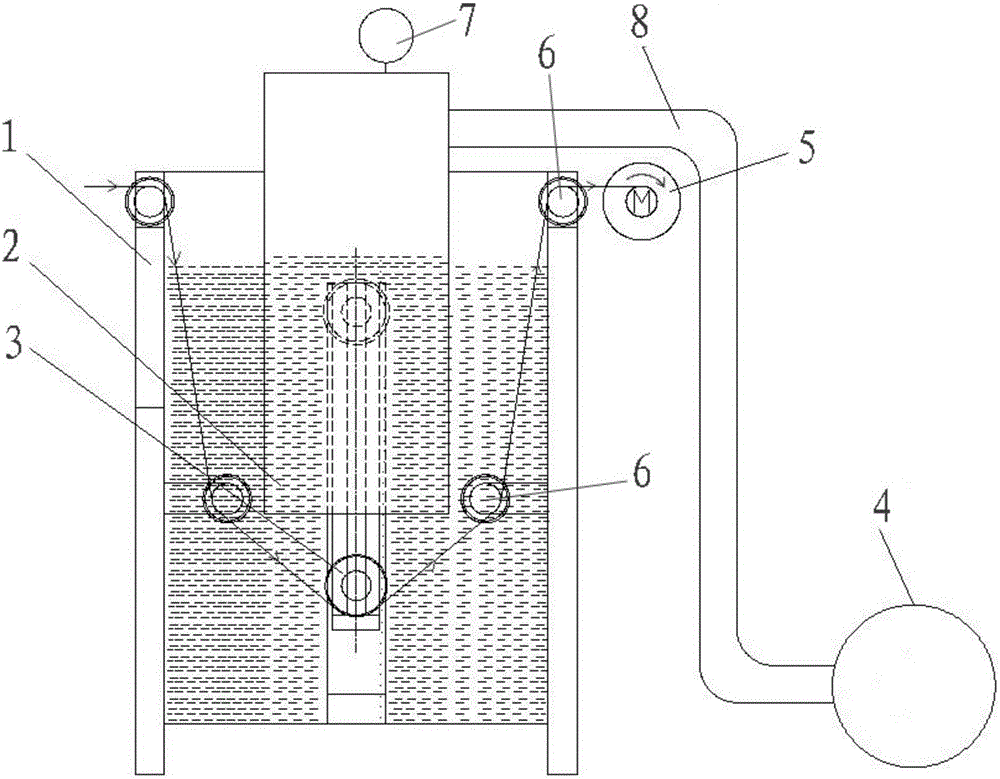

Vacuum type continuous oiling equipment for chain

InactiveCN105797915AReduce frictionReduce local high temperatureLiquid surface applicatorsCoatingsDrive motorVacuum pump

The invention relates to vacuum type continuous oiling equipment for a chain. The vacuum type continuous oiling equipment comprises a vacuum pump, a driving motor, a sealed box body, a chain reversing system and a chain guiding system, wherein the chain reversing system and the chain guiding system are arranged in the sealed box body. The chain is sequentially wound round the driving motor, the chain guiding system and the chain reversing system. The vacuum pump is connected into the sealed box body through a pipeline. According to the vacuum type continuous oiling equipment for the chain, the effect that the vacuum degree is adjustable can be achieved; bubbles can be generated in the process that air is pumped out, can be burst when colliding chain parts and has a cleaning effect on the chain; and the abrasion resistance of the chain is improved by 15%, and oil fume can be exhausted in a concentrated mode.

Owner:青岛征和链传动有限公司

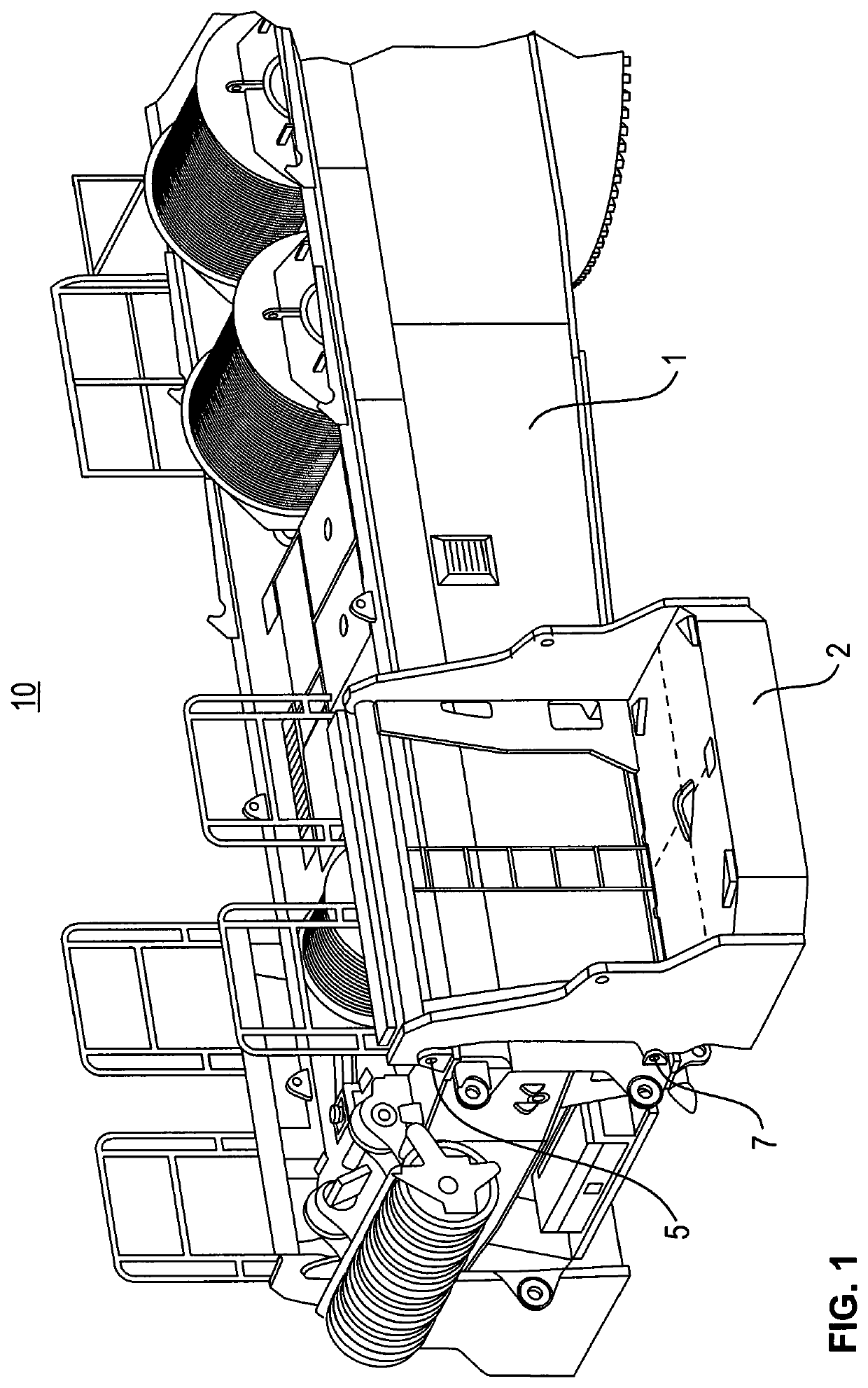

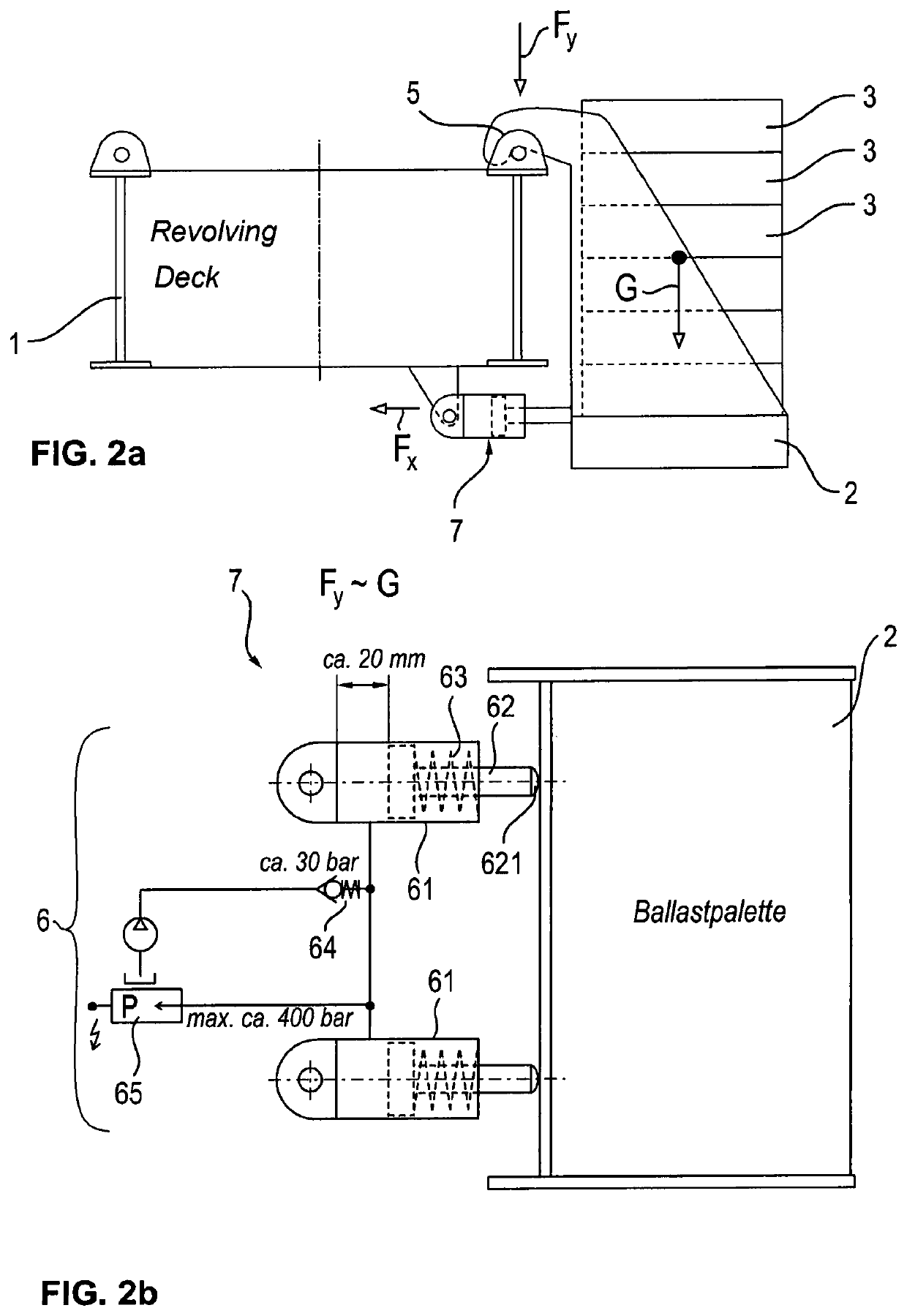

Crane having an apparatus for determining the effective counterweight of said crane

ActiveUS10486945B2Control loadImprove reliabilityFluid pressure measurement using pistonsApparatus for force/torque/work measurementCouplingAbutment

The invention relates to a crane having at least one apparatus for determining the effective counterweight of said crane comprising at least one receiver for receiving at least one counterweight body; at least one coupling that is configured to pivotably couple the receiver with the further structure of the crane; and at least one abutment that is configured to limit the pivot range of the receiver.

Owner:LIEBHERR WERK EHINGEN

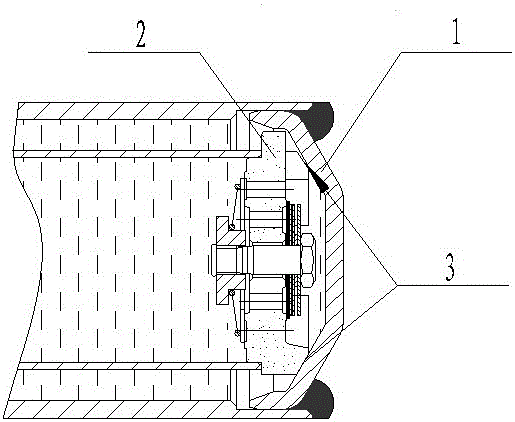

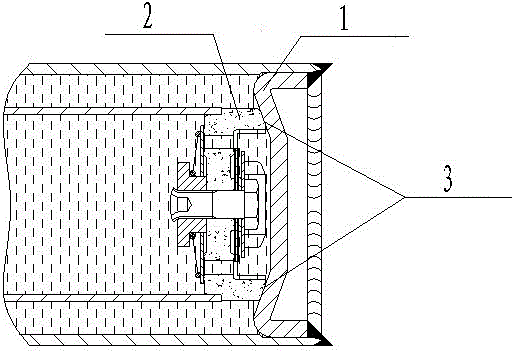

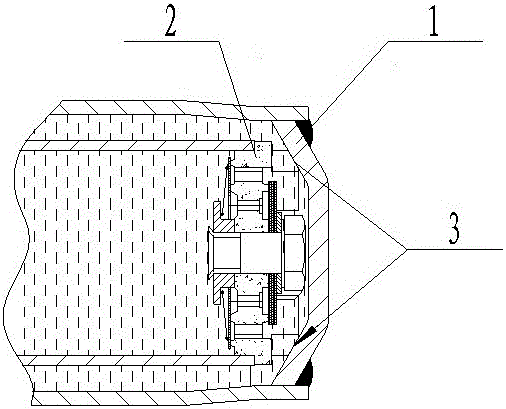

Bottom valve seat and shock absorber capable of automatically positioning the bottom valve body of the shock absorber in the bottom valve seat

ActiveCN103791020BResolve frictionRealize automatic positioningSpringsShock absorbersShock absorberValve seat

The invention discloses a bottom valve base allowing automatic positioning of a shock absorber bottom valve body inside the bottom valve base and relates to an automotive shock absorber part. The bottom valve base allowing automatic positioning of the shock absorber bottom valve body inside the bottom valve comprises a first conical surface, a second conical surface and double layer steps, wherein the double layer steps are arranged on the first conical surface and the second conical surface. Compared with the prior art, the bottom valve base allowing automatic positioning of the shock absorber bottom valve body inside the bottom valve base has the advantages of solving the problem that positioning of the shock absorber bottom valve body on the bottom valve base is not stable for a long time, enabling shock absorber production to be stable and good in uniformity and meanwhile solving the potential failure mode that the shock absorber has abnormal sound and is large in frictional force and serious in lateral side abrasion.

Owner:SICHUAN NINGJIANG SHANCHUAN MACHINERY

An automatic pancake machine

The automatic pancake machine includes: a bracket; a pancake maker with an outer casing, a pie plate assembly and a drive group arranged in the outer casing; the outer casing has a chassis and an upper cover matching the chassis, the chassis and the upper cover form a concave cavity, and the chassis includes a bottom plate And the side wall extending upwards on the edge of the bottom plate, the inside of the side wall has a chassis oil passage, the inner surface of the side wall has a plurality of chassis oil outlets, and the chassis oil outlets are used to communicate with the chassis oil passage and the concave cavity, and the cake pan assembly has mutual Two symmetrical cake trays, the cake tray has multiple pie tray oil inlets matching the chassis oil outlet, multiple cake tray oil passages and multiple through holes through the pie tray, the pie tray passes through the pie tray oil inlet Fastened and fixed on the chassis, the pie plate oil channel communicates with the chassis oil channel through the cake plate oil inlet, and the multiple pie plate oil channels include multiple annular oil channels and at least one straight oil channel that communicates with all the annular oil channels. The straight oil passage and at least one annular oil passage communicate with the oil inlet of the pie plate, and a plurality of through holes are arranged in a ring.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

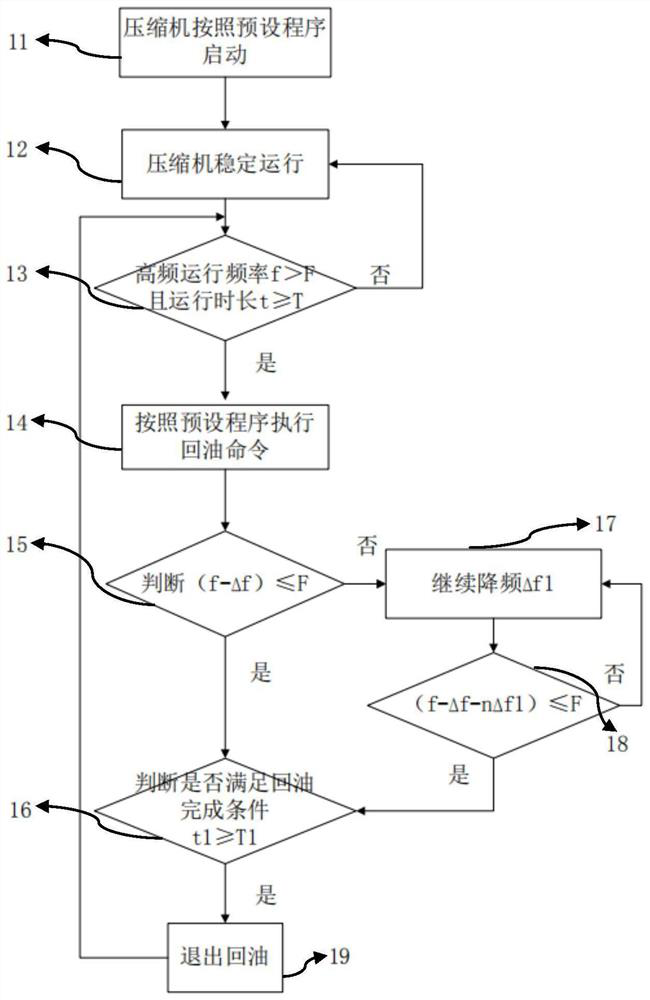

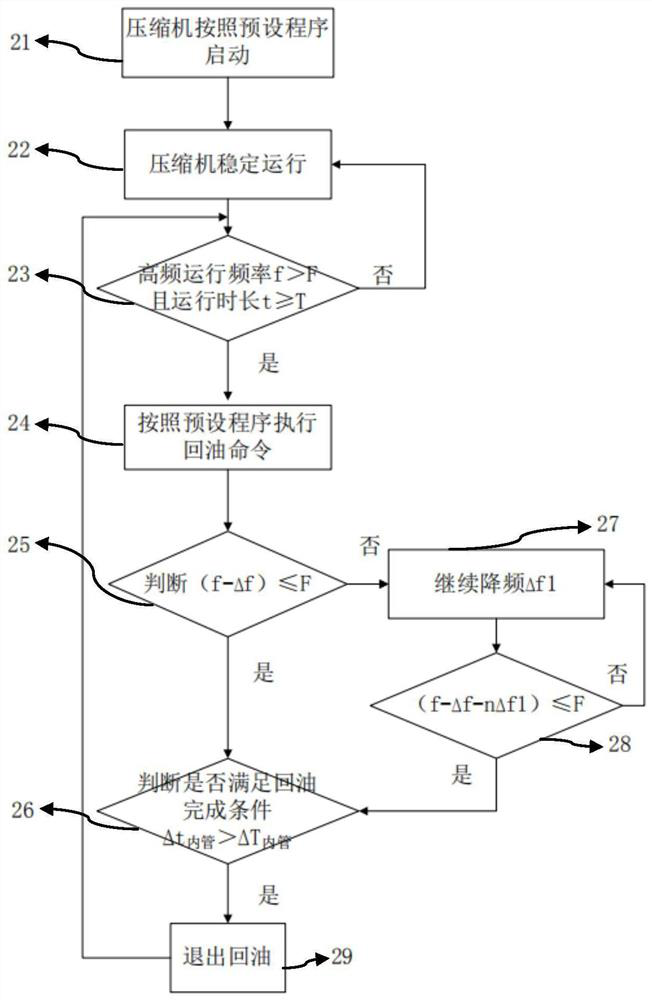

Oil return control method of inverter compressor and air conditioner

PendingCN113959048ASolve the problem of oil shortageSufficient oilMechanical apparatusLighting and heating apparatusControl theoryInverter compressor

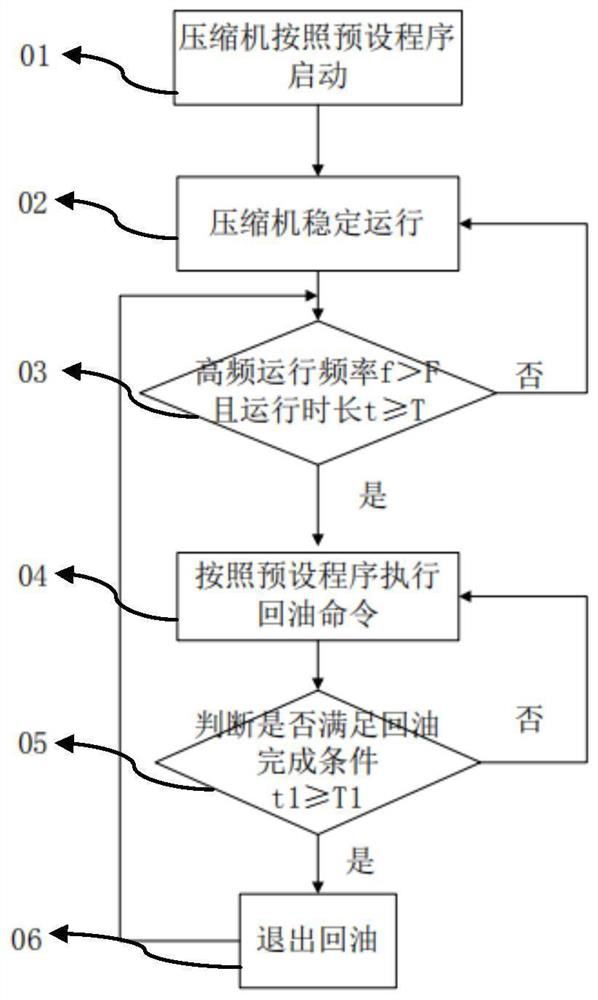

The invention discloses an oil return control method of an inverter compressor and an air conditioner. The oil return control method of the inverter compressor comprises the following steps that the compressor is started to operate; the high-frequency operation duration t of the compressor is obtained, and when the high-frequency operation duration t meets the condition that t is greater than or equal to T, and T is the preset duration representing oil shortage in the compressor, an oil return program for reducing the operation frequency of the compressor is executed; and whether an oil return completion condition is met in the execution process of the oil return program, if so, the oil return program is quitted, and if not, the oil return program is continuously executed. According to the oil return control method of the inverter compressor and the air conditioner, the problem of oil shortage in the compressor caused by high oil output rate of the compressor under the condition of high-frequency operation is mainly solved, the compressor executes a frequency reduction oil return program after high-frequency stable operation exceeds the set time T, so that more sufficient oil in the compressor is maintained, and abrasion caused by long-time oil shortage is avoided.

Owner:GREE ELECTRIC APPLIANCES INC

Beam pumping unit

The invention discloses a beam-pumping unit, which comprises a bracket, a reducer, a crank, a connecting rod, a beam, a horse head, constant-temperature heaters, a balance arm, a balance block and a supporting rod, wherein the beam is movably connected to the bracket; the horse head is fixedly arranged on one end of the beam; the balance arm is movably connected to the other end of the beam; the balance block is fixedly arranged on the balance arm; one end of the support rod is movably connected to the bracket; the other end of the supporting rod is movably connected to the balance arm; the reducer is connected with the crank; the connecting rod is movably connected between the crank and the beam; the constant-temperature heaters are fixedly arranged in the tank body of the reducer for heating lubricating oil. The beam-pumping unit has the two technical advantages that the peak value current of a motor can be reduced when the horse head moves to an upper stop, the peak value current of a motor and the valve current torque of the reducer are reduced when the horse head moves to a lower stop, and the lubricating oil in the reducer can be prevented from icing or becoming a thick state under a low-temperature state.

Owner:SICHUAN JINXIN CO LTD

Method for producing maduro wrapper by high temperature and high humidity fermentation and maduro wrapper made thereof

The invention relates to a method for producing Maduro wrappers by high-temperature and high-humidity fermentation and the Maduro wrappers made thereof. The above-mentioned production method comprises: loosening selected tobacco leaves, and then immersing the petioles of the loosened tobacco leaves in warm water The handle is taken out, and the tobacco leaves after soaking the handle are moistened to increase the moisture content of the tobacco leaves to 20-30%, then the tobacco leaves are sealed in a self-sealing bag, equilibrated for a period of time, taken out, and then the tobacco leaves are fully loosened and then soaked in warm water to remove The surface of the tobacco leaves is exposed to water, then the tobacco leaves are equilibrated for a period of time, the tobacco leaves are flattened one by one, and then the flattened tobacco leaves are fermented. The wrapper produced by the invention is dark brown, has uniform color, sufficient oil content and luster, and meets the demands of different products and markets for the Maduro wrapper.

Owner:HUBEI CHINA TOBACCO IND

Compressor frequency control method and device

ActiveCN103671044BSufficient oilGuaranteed heating effectPump controlPositive-displacement liquid enginesVapor liquidVapor–liquid separator

The invention discloses a method and device for controlling the frequency of a compressor. The method includes: comparing the detected inlet pipe temperature and outlet pipe temperature of the gas-liquid separator and the evaporation temperature of the system where the compressor is located; Determine the current liquid storage state of the gas-liquid separator, and control the frequency of the compressor according to the current liquid storage state. Through the present invention, the temperature of the inlet and outlet pipes of the gas-liquid separator and the evaporation temperature of the system are used to determine the current liquid storage state of the gas-liquid separator, and then control the frequency of the electronic expansion valve and compressor according to the current liquid storage state, so that the gas-liquid The oil-liquid mixture in the separator is transferred to solve the problem that the gas-liquid separator cannot return oil in time when there is a lot of liquid, so as to ensure that the compressor oil is sufficient, and the refrigerant returns to the high-pressure side in time to ensure the heating effect.

Owner:GREE ELECTRIC APPLIANCES INC

Tobacco yellowing synergism compound mixture and use method thereof

PendingCN107141075AInhibit or reduce absorptionSolve the problem of nutrient deficiency in the later stage of growthBiocidePlant growth regulatorsDiseaseAdditive ingredient

The invention discloses a tobacco yellowing synergism compound mixture and a use method thereof. The mixture comprises a compound A and a compound B, wherein the compound A is an onion and garlic liquid mixture which is used in the maturation stage of tobacco and can inhibit or reduce nitrogen absorption of plants, and the compound B is P2O5 or K2O or ZnSO4 or MnSO4 or other mineral elements and can solve the problem of nutrient deficiency in the later growth stage of crops and promote tobacco yellowing synergism in cooperation with the onion and garlic liquid mixture. The compound mixture can improve the nutritional resistance of plants, enhance the disease resistance, relieve leaf diseases, reduce the color difference between leaves at the same portions of tobacco plants and ensure the uniformity of tobacco maturing and yellowing; cured tobacco has high elasticity and toughness, orange tobacco is obtained, the color and luster are improved, and the oil content is high; the proportion of green tobacco is substantially reduced, the quality and yield of tobacco are improved, and the economic benefit is significant. The effective ingredients of the compound mixture are plant tissue extracts and are free of environmental pollution, safe and environmentally friendly.

Owner:郑州惠农有害生物防治有限公司

Automatic adjustable variable speed oil pump

ActiveCN105065893BReduce power consumptionImprove work efficiencyLubricating pumpsEngineeringSingle cone

The invention discloses an automatically adjustable variable speed oil pump, which comprises a rotating shaft (10) of an oil pump main body (1) and a power output shaft (3) of an engine connected through a transmission mechanism; the transmission mechanism includes four single-cone rollers (4 ) and belt (7), four single-cone rollers (4) are two pairs, and the conical surfaces of every pair of two single-cone rollers (4) are opposite and coaxial; wherein a pair of single-cone rollers ( 4) It is limited and slidingly matched with the rotating shaft (10) in the circumferential direction, and the distance between the two single-tapered rollers (4) is adjustable; the other pair of single-tapered rollers (4) and the power output shaft (3) are circumferentially Limiting and sliding fit, the distance between the two single-cone rollers (4) is adjustable; the belt (7) is wrapped around the two pairs of single-cone rollers (4). After adopting the above structure, unnecessary energy loss can be reduced, hydraulic power and mechanical power can be reduced, thereby improving the working efficiency of the engine.

Owner:NINGBO SHENGLONG AUTOMOTIVE POWERTRAIN SYSTEM CO LTD

Engine oil replenishment system and oil replenishment method thereof

ActiveCN105221212BSufficient oilThere will be no white gas phenomenonEngine levelsLubricant conduit arrangementsFirst FillFuel tank

The invention discloses an engine oil replenishment system and an oil replenishment method thereof, belonging to the technical field of engines. The system includes an oil pan, an auxiliary engine oil tank, and an oil supply chamber set on the upper part of the auxiliary engine oil tank; the oil pan and the oil supply chamber are connected through an oil supply pipe, and a first check valve is arranged on the oil supply pipe; the oil supply chamber and the auxiliary machine The oil tank is connected through an oil inlet pipe provided with an oil pump; wherein, the oil pump pumps oil from the auxiliary oil tank to the oil charge chamber according to the preset operation mode; when the oil level in the oil charge chamber is higher than the oil level in the oil pan, the first check valve When it is opened, the oil supply chamber supplies oil to the oil pan. By arranging the first one-way valve on the oil supply pipe, it can not only ensure that when the oil transport unit is pre-installed in the oil pan, the lubricating oil in the oil pan will not flow into the oil supply chamber or the auxiliary oil tank. Moreover, the high-pressure gas generated during the operation of the engine will not reach the auxiliary oil tank through the oil supply pipe, and will emerge from the oil inlet of the auxiliary oil tank, and white gas will not appear in the oil inlet.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

Clutch driven disc heat treatment machining tool

PendingCN110918745AGuaranteed leveling accuracyGuaranteed deformationShaping toolsFurnace typesEngineeringHeat balance

The invention discloses a clutch driven disc heat treatment machining tool, belongs to the technical field of clutch machining and aims to directly carry out quenching and leveling of a driven disc atthe same time. The tool comprises an upper hydraulic mechanism and a lower hydraulic mechanism. The tool is advantaged in that profiling and quenching are carried out at the same time, flattening precision of a workpiece is guaranteed, deformation of parts under the conditions of high temperature and high pressure can be prevented while the flatness requirement is met, flatness of the driven discis ensured by ensuring the deformation of the part, so the high-temperature leveling procedure is reduced, in the quenching and cooling process of the part, the heat balance flow of the quenching oilquantity can be adjusted, that the oil quantity is sufficient during quenching is guaranteed, and the part can obtain the good quenching effect.

Owner:CHANGCHUN YIDONG CLUTCH

Scroll compressor and refrigeration cycle device with scroll compressor

PendingCN108457857ASufficient to maintain concentrationAchieve lubricationRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringRefrigeration

The invention discloses a scroll compressor and a refrigeration cycle device with the scroll compressor. An electric motor, a compression mechanism part and lubricating oil are contained in a sealingshell of the scroll compressor, wherein the electric motor consists of a stator, a rotor and the like; the compression mechanism part is driven by the electric motor; the lubricating oil is used for lubricating the compression mechanism part; the compression mechanism part comprises a stationary disc, a movable disc, a crankshaft, a first bearing, oil-containing gases and a sliding surface; the crankshaft is fixed with the rotor; the first bearing is positioned between the movable disc and the rotor and is connected with the crankshaft in a sliding manner; the oil-containing gases are discharged from a compression chamber consisting of the stationary disc and the movable disc; the sliding surface is used for at least lubricating the crankshaft and the first bearing. According to the scrollcompressor disclosed by the invention, the lubricating oil can uniformly and rapidly lubricate sliding parts.

Owner:GUANGDONG MEIZHI COMPRESSOR

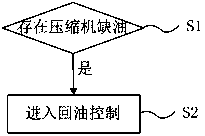

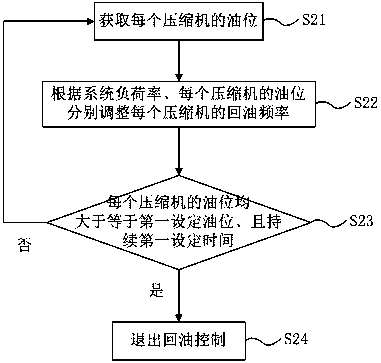

A method for controlling oil return in a multi-line system

ActiveCN107218741BSufficient oilImprove oil return reliabilityCompressorMechanical apparatusProcess engineeringControl theory

The invention discloses a method for controlling oil return of a multi-connection system. The multi-connection system includes an indoor unit and a plurality of outdoor units, and the plurality of outdoor units are respectively connected to the indoor unit; the method includes: judging the multi-connection Whether there is compressor oil shortage in the system; if so, enter the oil return control: obtain the oil level of each compressor; adjust the oil return frequency of each compressor according to the system load rate and the oil level of each compressor; It affects the normal operation of the system, and realizes directional and precise oil return to ensure sufficient oil in each compressor, improves the reliability of oil return, and improves the reliability of system operation.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +1

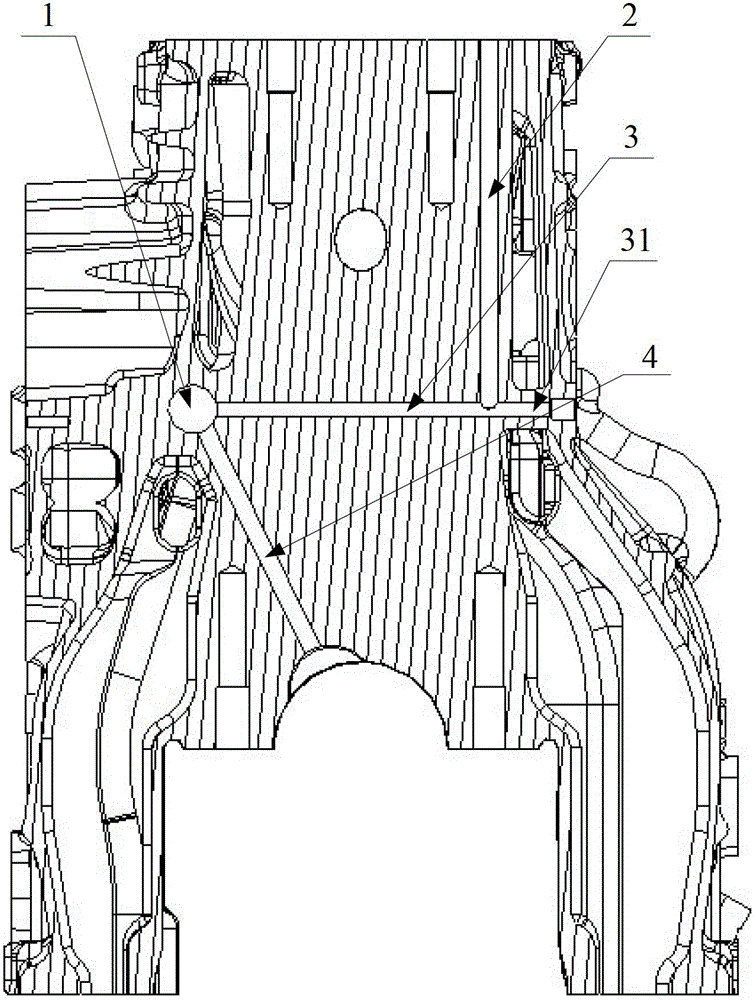

Engine and lubricating system thereof

ActiveCN103423012BShorten the delivery routeShort response timeCylinder headsCylindersCylinder blockOverhead camshaft

The invention provides a lubricating system of an engine. The lubricating system of the engine comprises a main oil way arranged on an engine cylinder body and an auxiliary oil way communicated with the main oil way. The auxiliary oil way comprises a cylinder cover with an opening facing the engine, a vertical oil way used for lubricating the cylinder cover and a transverse oil way communicated between the main oil way and the vertical oil way, and the transverse oil way is arranged between two adjacent cylinders of the engine. According to the lubricating system of the engine, the vertical oil way and the transverse oil way are arranged in the middle of the engine, a conveying line of lubricating oil is shortened, pressure loss in the conveying process of the lubricating oil is reduced, and therefore the conveying efficiency of the lubricating oil is improved. Meanwhile, the requirements for the lubricating oil of an overhead camshaft of the engine are met. In addition, the requirement for lubricating of a crank shaft, a connection rod and an auxiliary part on the lateral face of the cylinder body is simultaneously met, the design requirements for other auxiliary oil ways are reduced, the conveying line of the lubricating oil is simplified, the manufacturing process is relatively simple, and the machining cost is reduced. The invention further provides the engine.

Owner:安徽汉马发动机有限公司

Bottom valve base allowing automatic positioning of shock absorber bottom valve body inside bottom valve base and shock absorber

ActiveCN103791020ASolve positioningSolve abnormal noiseSpringsShock absorbersEngineeringShock absorber

The invention discloses a bottom valve base allowing automatic positioning of a shock absorber bottom valve body inside the bottom valve base and relates to an automotive shock absorber part. The bottom valve base allowing automatic positioning of the shock absorber bottom valve body inside the bottom valve comprises a first conical surface, a second conical surface and double layer steps, wherein the double layer steps are arranged on the first conical surface and the second conical surface. Compared with the prior art, the bottom valve base allowing automatic positioning of the shock absorber bottom valve body inside the bottom valve base has the advantages of solving the problem that positioning of the shock absorber bottom valve body on the bottom valve base is not stable for a long time, enabling shock absorber production to be stable and good in uniformity and meanwhile solving the potential failure mode that the shock absorber has abnormal sound and is large in frictional force and serious in lateral side abrasion.

Owner:SICHUAN NINGJIANG SHANCHUAN MACHINERY

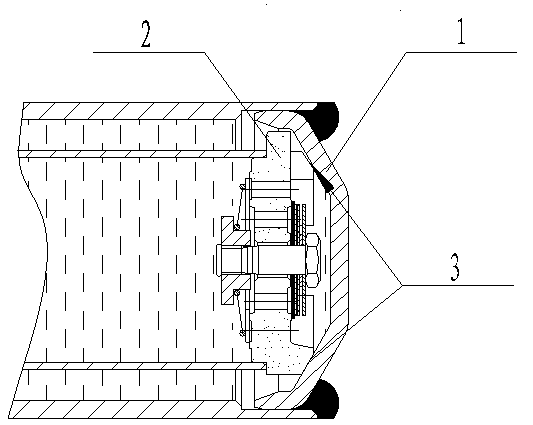

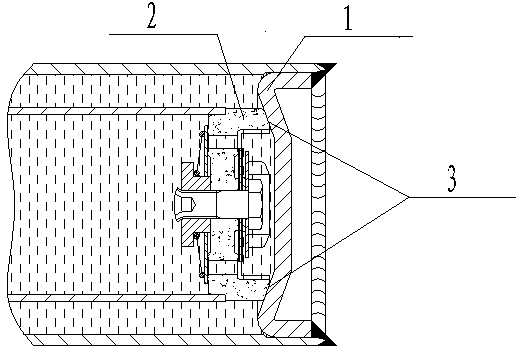

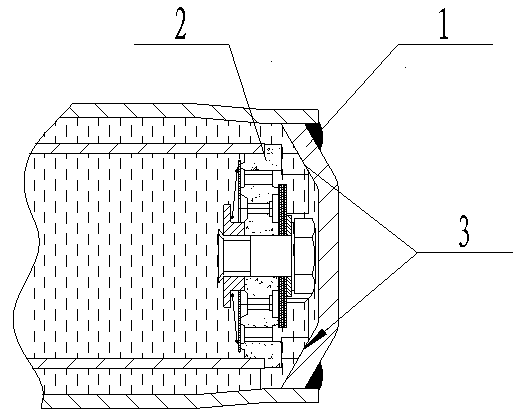

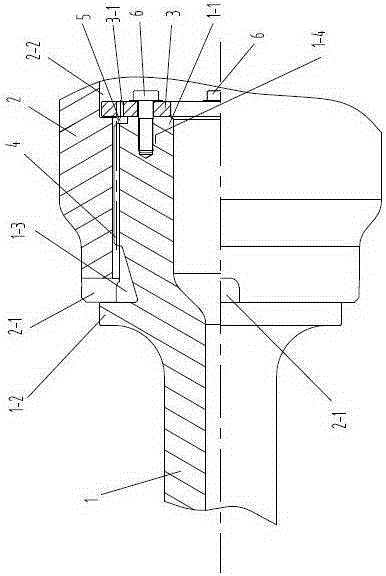

Lubrication structure of rotary spline

ActiveCN103671853BGuaranteed lubrication effectSufficient oilGear lubrication/coolingMechanical engineeringLubrication

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com