Bottom valve base allowing automatic positioning of shock absorber bottom valve body inside bottom valve base and shock absorber

An automatic positioning and shock absorber technology, which is applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve problems such as abnormal sound of shock absorbers, side wear, unstable positioning, etc., and achieve the purpose of solving abnormal noise , accurate positioning, guaranteed damping force and normal use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

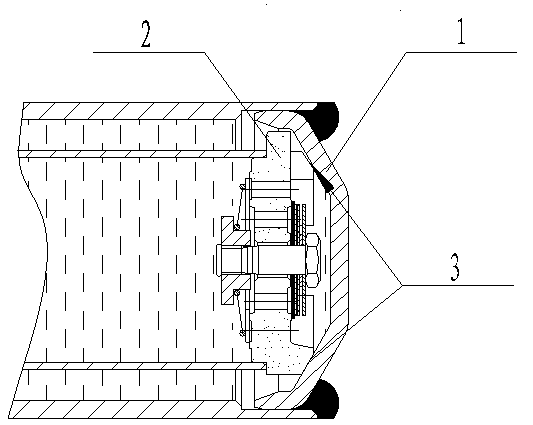

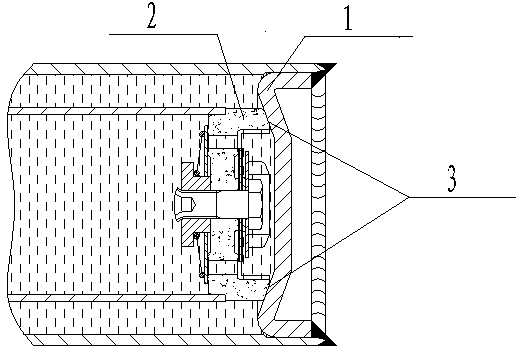

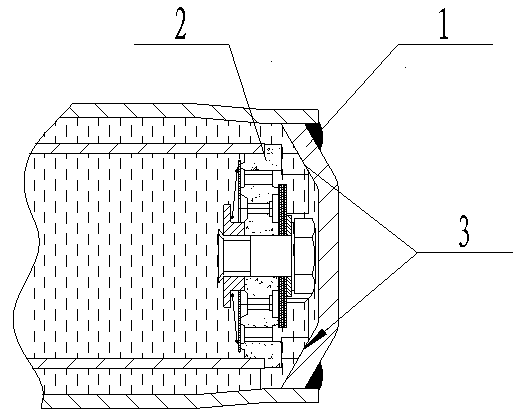

[0023] Such as Figure 5 As shown, the shock absorber includes a bottom valve seat 1 , a bottom valve body 2 and an oil storage cylinder 5 .

[0024] Such as Figure 4 As shown, the bottom valve seat 1 includes a first conical surface 31, a second conical surface 32, a first step 41 and a second step 42, and the first step 41 and the second step 42 are respectively arranged on the first conical surface. 31 and 32 on the second conical surface.

[0025] The bottom valve seat 1 is a sheet metal part, and the first tapered surface 31, the second tapered surface 32, the first layer of steps 41 and the second layer of steps 42 are on the same axis.

[0026] In order to ensure the coaxiality of the first conical surface 31, the second conical surface 32, the first step 41 and the second step 42, when the bottom valve seat 1 is manufactured, it is necessary to draw out the exce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com