Large component assembling and welding deformation auto-real-time monitoring method

A technology for welding deformation and large components, applied in measuring devices, optical devices, instruments, etc., can solve the problems of low degree of automation, manual measurement of deformation, insufficient measuring range, etc., and achieve the effect of improving work efficiency and measuring speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] The pressure vessel of the key equipment of the coal gasification unit of the coal substitution project - the gas return chamber

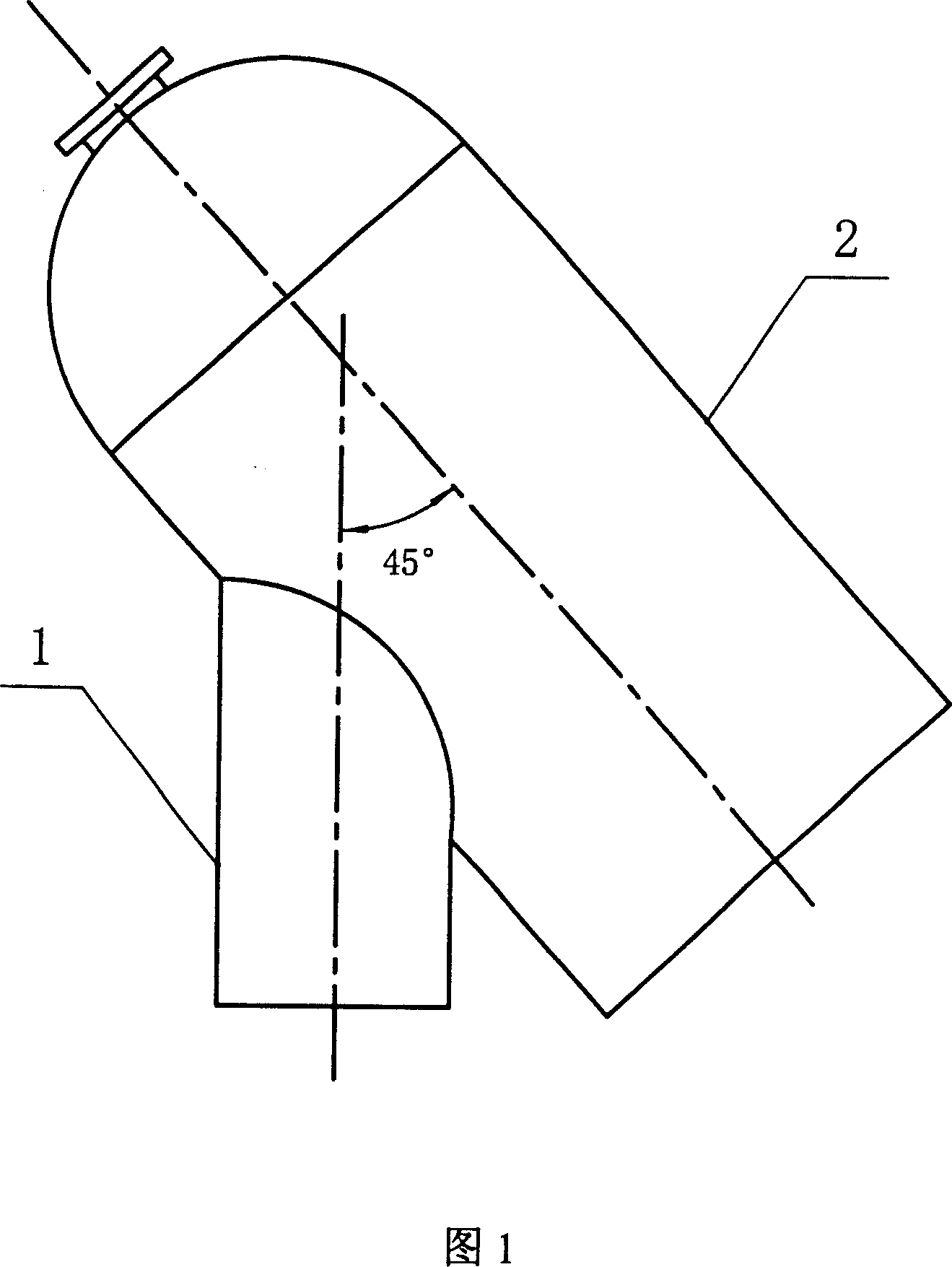

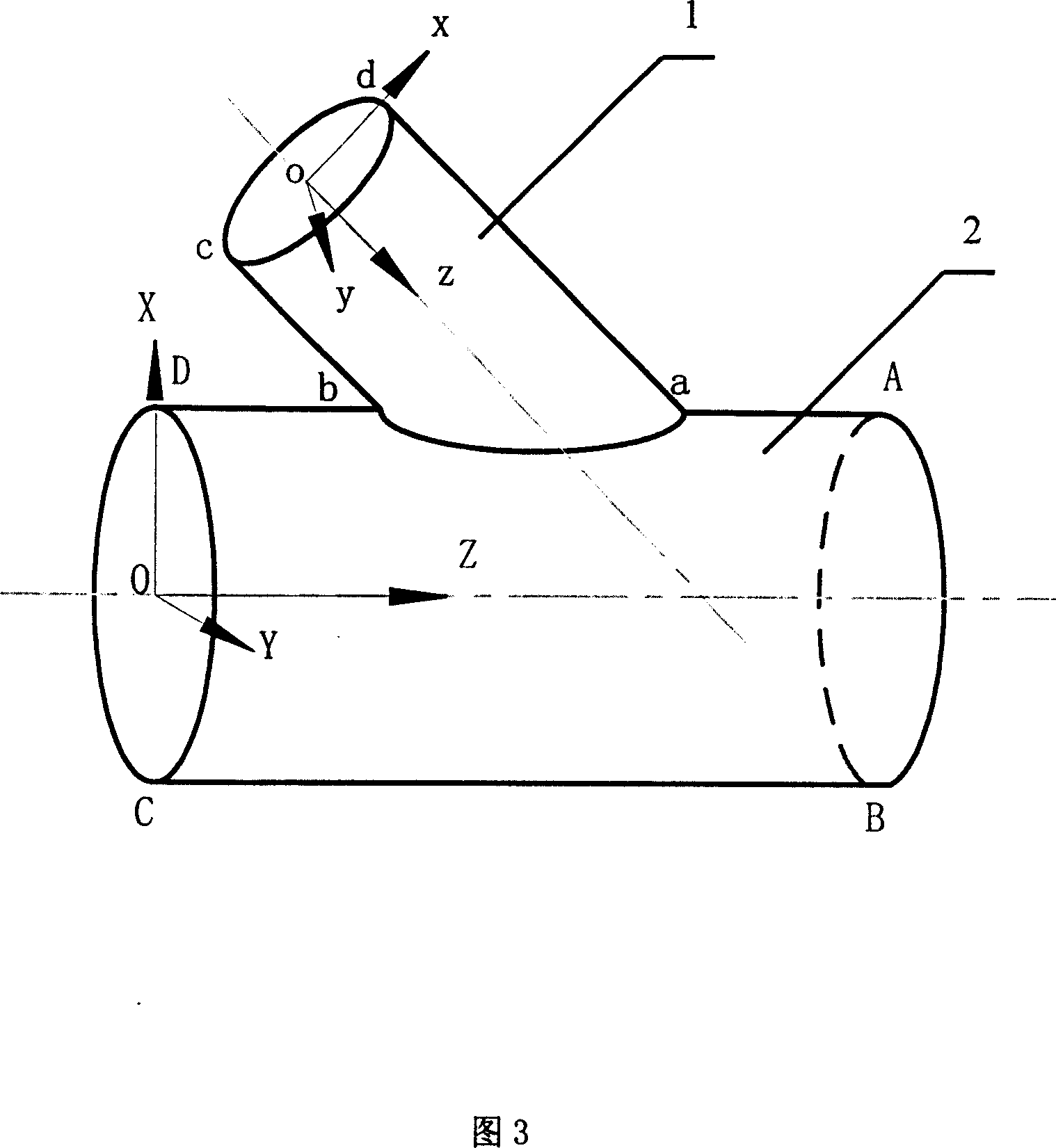

[0061] As shown in Figure 1, it is a schematic diagram of the structure of the gas return chamber. The gas return chamber is composed of an inclined cylinder 1 and a main cylinder 2, with a total weight of about 184 tons. The diameter of the inclined cylinder 1 is φ2440mm, and the height is 3718mm. The main cylinder 2 The diameter is φ3820mm, the height is 9700mm, and the maximum thickness of the cylinder wall is 285mm. It is required that the deviation of the angle between the axis of the main cylinder 2 and the oblique cylinder 1 after welding is ±0.1°, and the two lines must be in the same plane; the focus of the axis is to each end surface The deviation value is ±1mm. It is necessary to ensure that all parameters after installation and welding meet the technical requirements to ensure the smooth progress of the next process.

[0062] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com