Online monitoring device and monitoring method for punching machine

A monitoring device and stamping machine technology, applied in the field of stamping machine processing, can solve the problems of increased production costs, high missed detection rate, and large waste, and achieve the effects of avoiding waste, low missed detection rate, and reducing measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

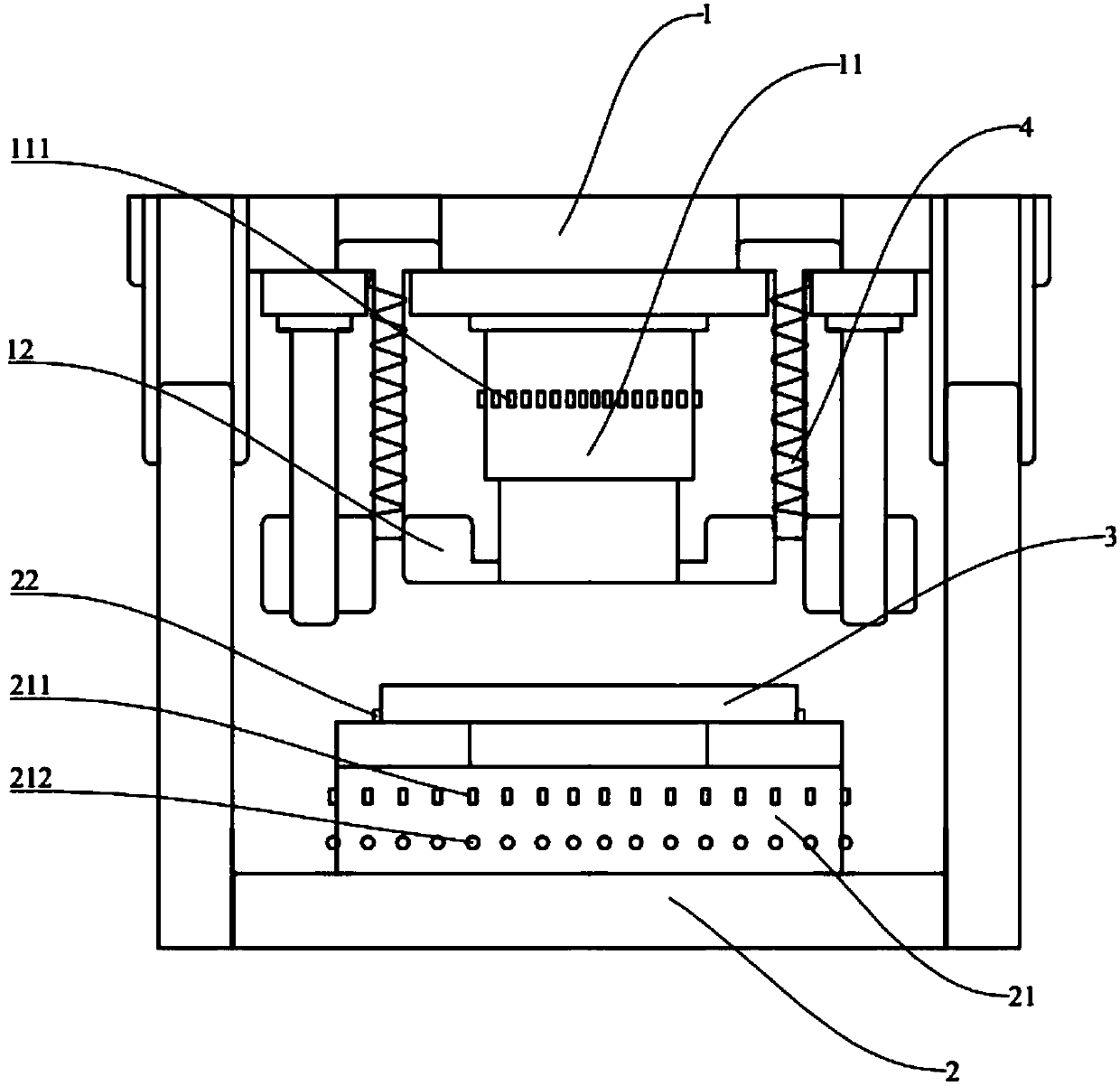

[0034] Such as figure 1 As shown, an online monitoring device for a punching machine includes a connected punching machine and a computer. The punching machine includes an upper die base 1 and a lower die base 2. The middle part of the upper die base 1 is provided with a connected motor and a cylindrical embossing embossment. Die 11, preferably, the embossing punch 11 is a stepped shaft, the end of the embossing punch protrudes from one side of the lower mold base, and the motor drives the embossing punch to reciprocate up and down in the vertical direction; An embossing platform 21 is provided on the top, and the upper end surface of the embossing platform 21 is used to place the tablet 3, and at least two positioning columns 22 are also arranged on the upper end surface of the embossing platform, and the material sheet 3 is placed between the positioning columns 22 , it is preferable to set the positioning columns as 4 respectively limited at the four corners of the tablet; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com