Patents

Literature

137results about How to "Solve abnormal noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

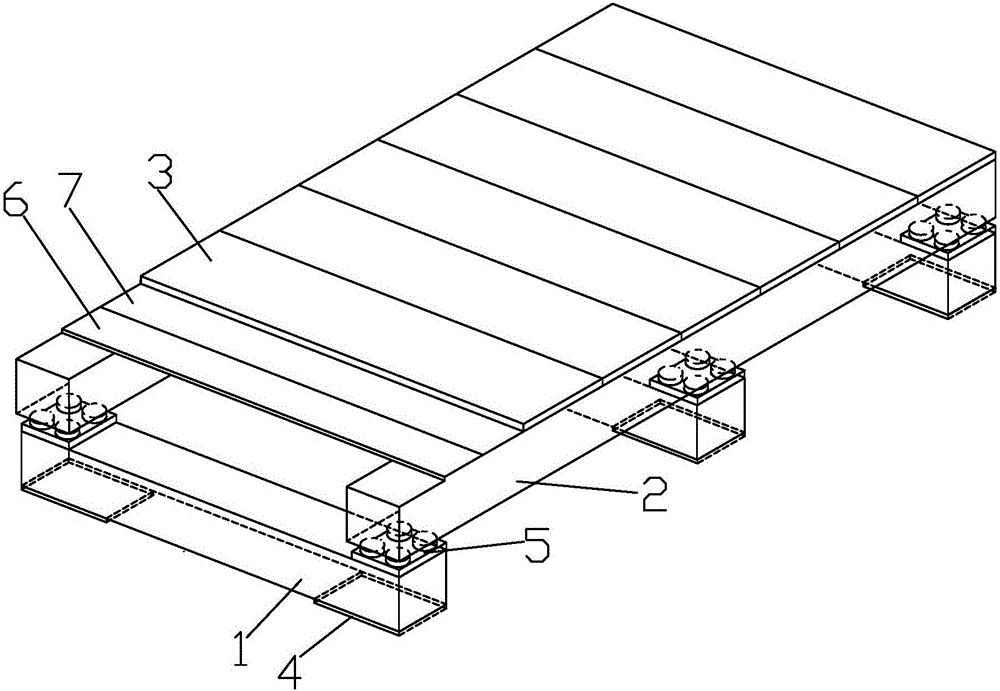

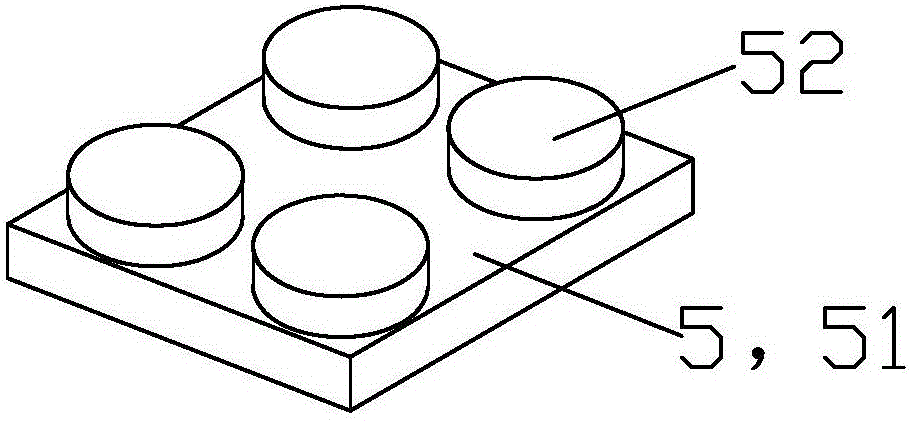

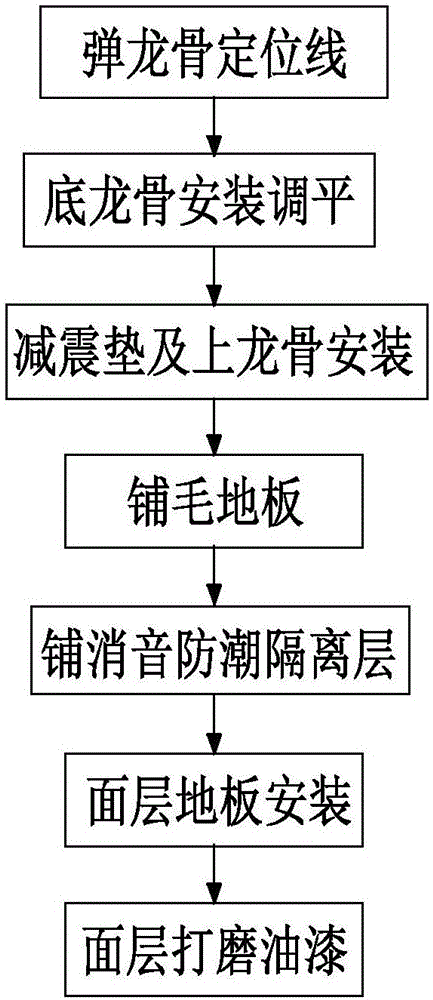

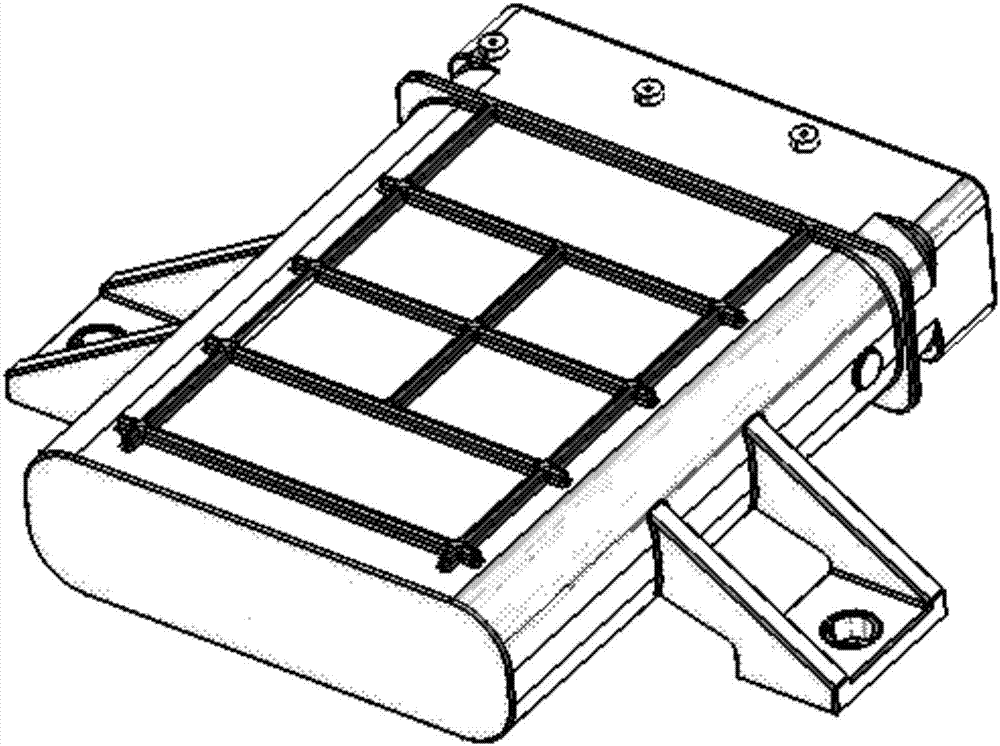

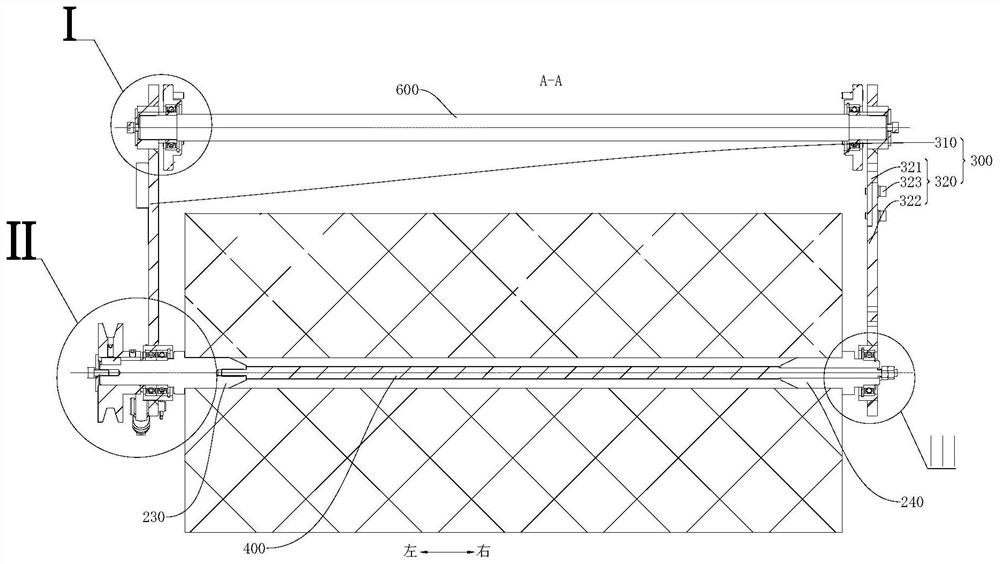

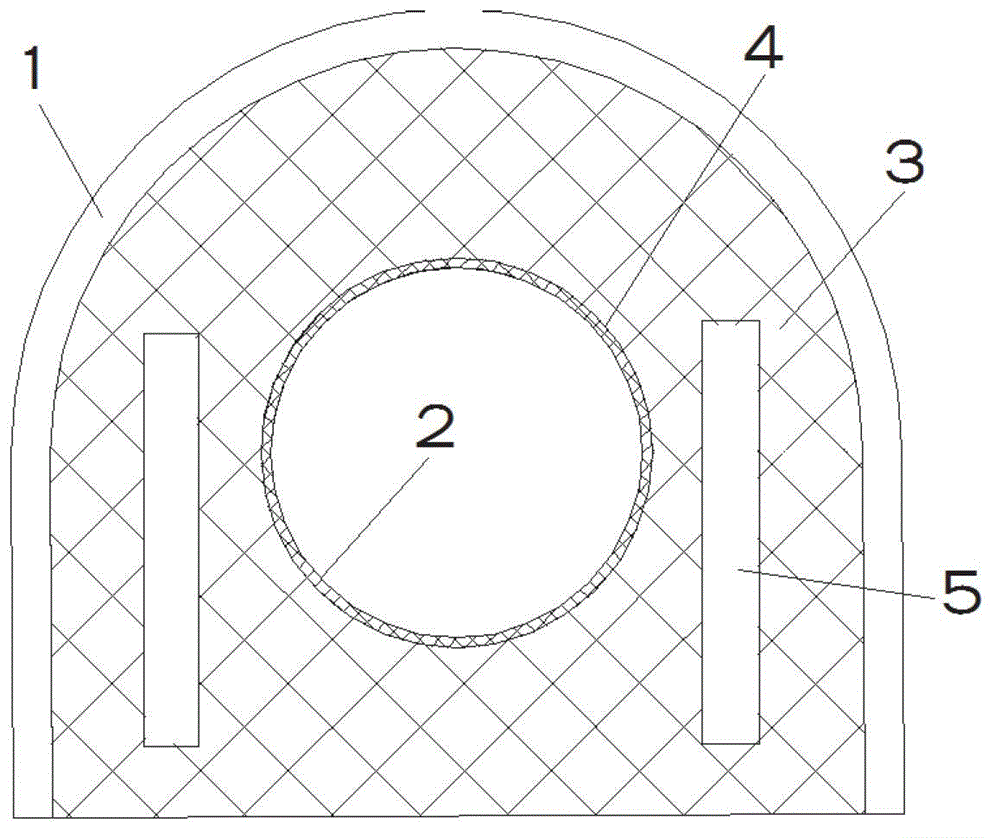

Suspension type sports wood floor system and construction method thereof

InactiveCN106499154AGood shock absorptionGood sports performanceFlooring insulationsResiliently-mounted floorsWork periodEngineering

The invention provides a suspension type sports wood floor system and a construction method thereof. The system comprises a levelling floor mat, a bottom keel, a shock pad, an upper keel, a subfloor, a sound-muffling and moisture-proof isolation layer and a surface floor. The levelling floor mat is arranged under the bottom keel, and is paved on the ground. The upper keel is vertically placed on the upper end of the bottom keel, the shock pad is arranged at the junction portion of the upper keel and the bottom keel and the three parts are fixedly connected, and the subfloor is fixedly arranged on the upper keel. The sound-muffling and moisture-proof isolation layer is paved on the subfloor. The surface floor is positioned on the sound-muffling and moisture-proof isolation layer and fixed on the subfloor. The construction method comprises the steps of paving and levelling the bottom keel, amounting the shock pad, the upper keel, the subfloor, the sound-muffling and moisture-proof isolation layer, the surface floor and the like. According to suspension type sports wood floor system and a construction method thereof, the floor system is good in the performances of sports, stability, moisture-proof and the like, small in deformation, long in service life and free of abnormal sound during use; the construction method is simple, and saves work-period.

Owner:CHANGZHOU NO 1 CONSTR GRP

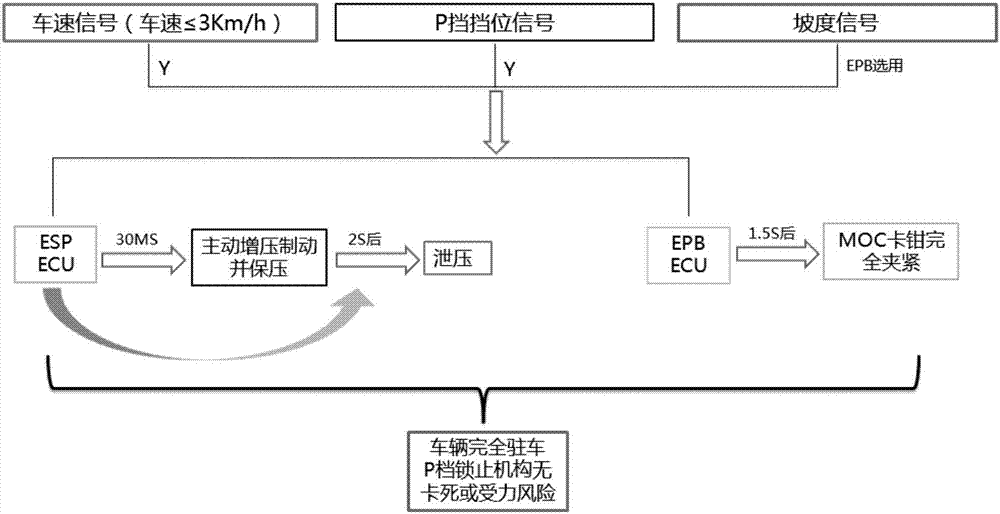

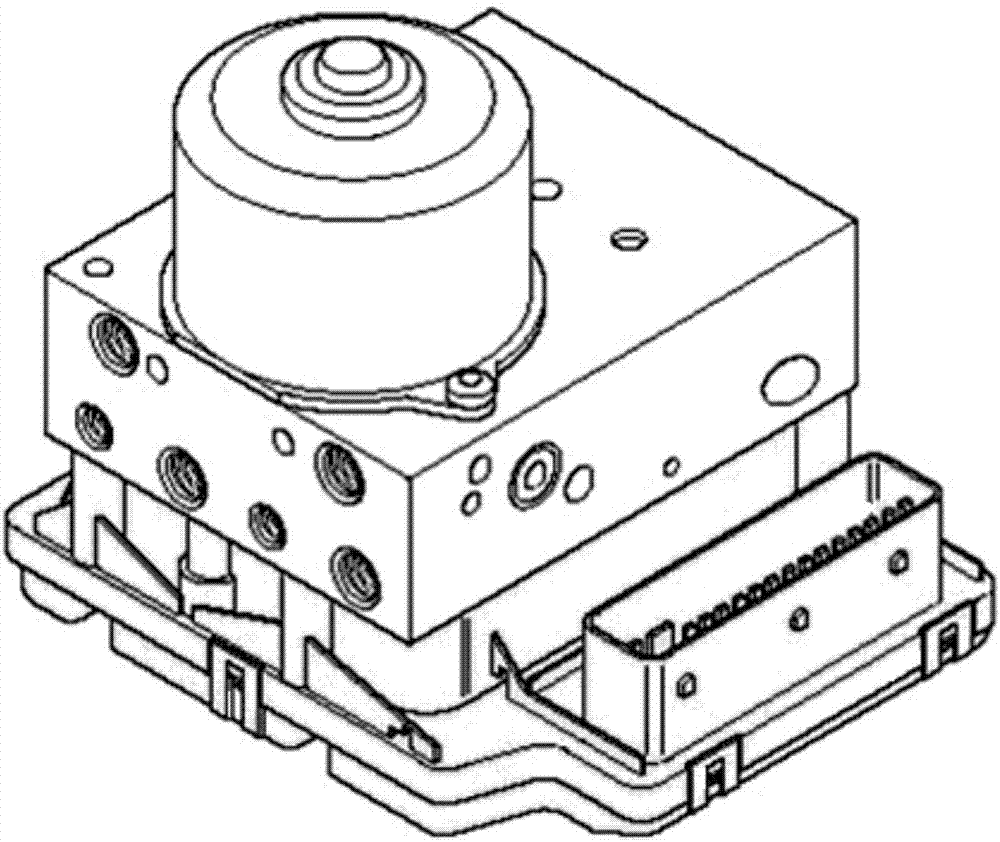

P-gear automatic parking control method based on EPB-ESP (electronic parking brake-electronic stability program) linkage

ActiveCN107985283AAvoid stickingSolve abnormal noiseAutomatic initiationsArea networkStress conditions

The invention discloses a P-gear automatic parking control method based on EPB-ESP (electronic parking brake-electronic stability program) linkage. According to the method, when the speed of a vehicleis lower than or equal to 3Km / h, a gear lever is pushed to a P-gear position, and P-gear signals are transmitted to a CAN (controller area network) by an automatic gearbox. When an electronic stability program detects that vehicle speed and the P-gear signals simultaneously meet conditions, active pressurization is instantly performed, pressure is kept for a certain time, and the vehicle is completely static, so that a P-gear locking mechanism has no rigid impulse. When an electronic parking brake detects that the vehicle speed and the P-gear signals simultaneously meet conditions, clamping is instantly performed, and the vehicle is completely parked within pressure keeping time set by the electronic stability program. The method can avoid the problem of locking of a P-gear lock cylinderand a P-gear lock groove caused by faulty operation of a driver and solves the problem that abnormal sound is generated as P-gear unlocking is performed after the vehicle is parked on ramps in the running process of the vehicle, stress conditions of the locking mechanism are improved, and the service life of the automatic gearbox is prolonged.

Owner:CHERY COMML VEHICLE ANHUI

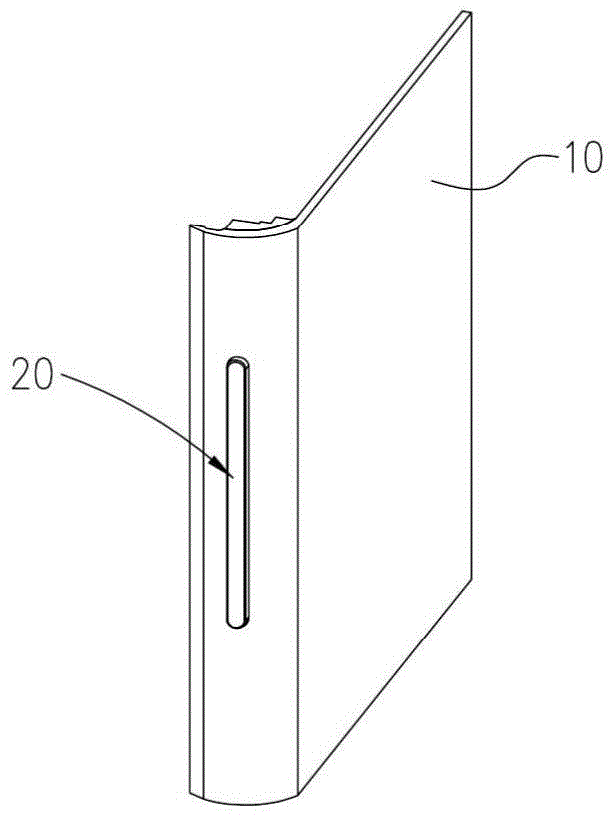

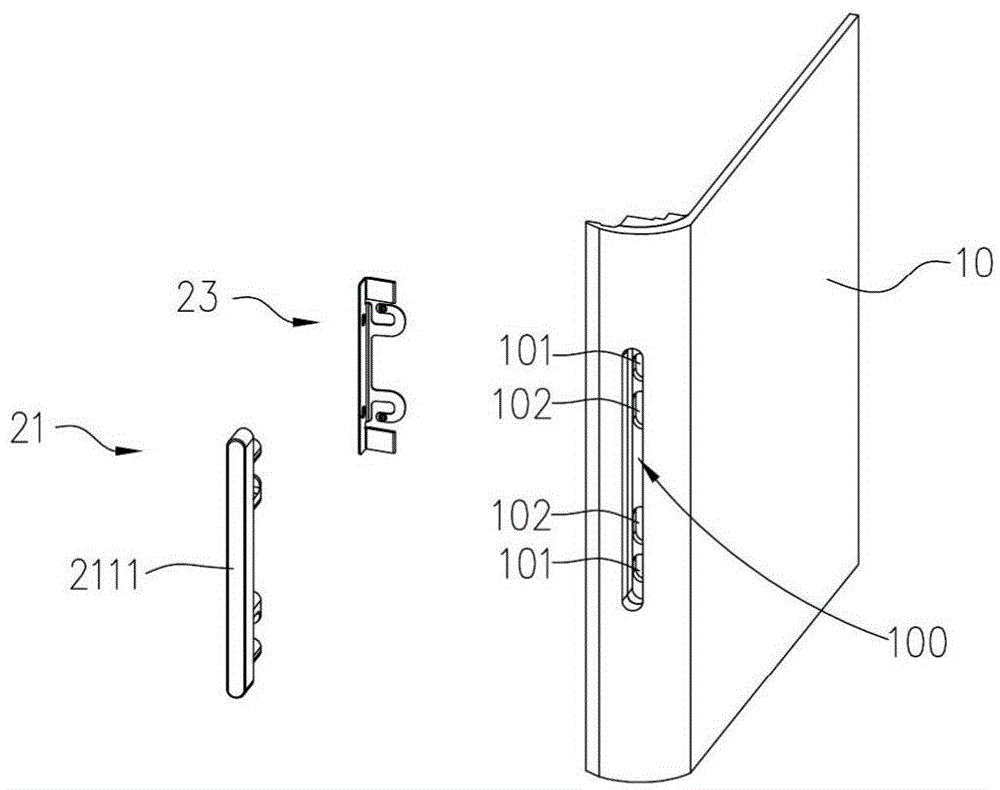

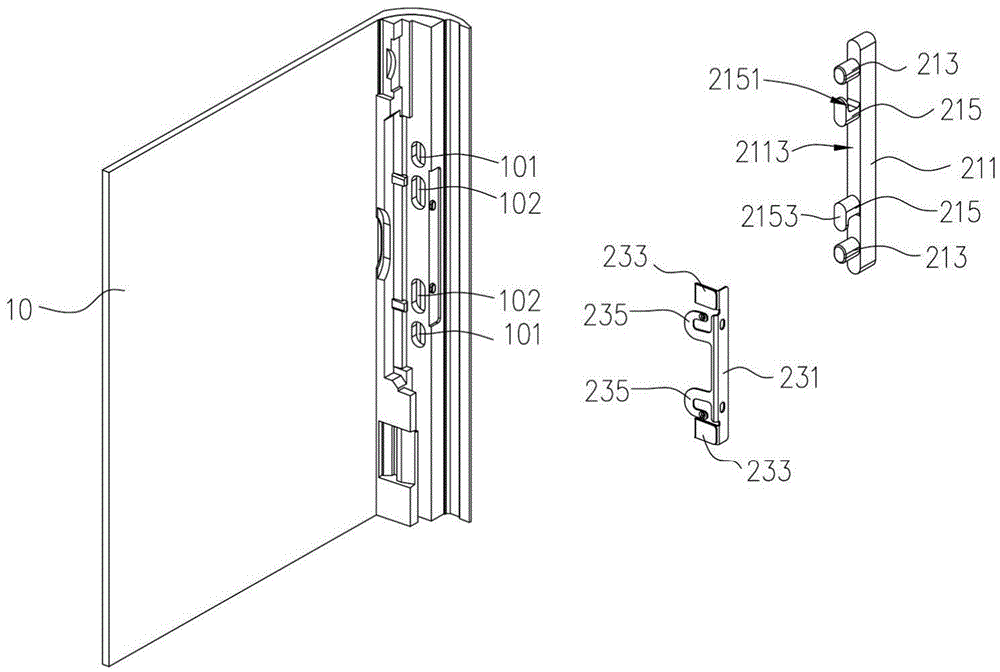

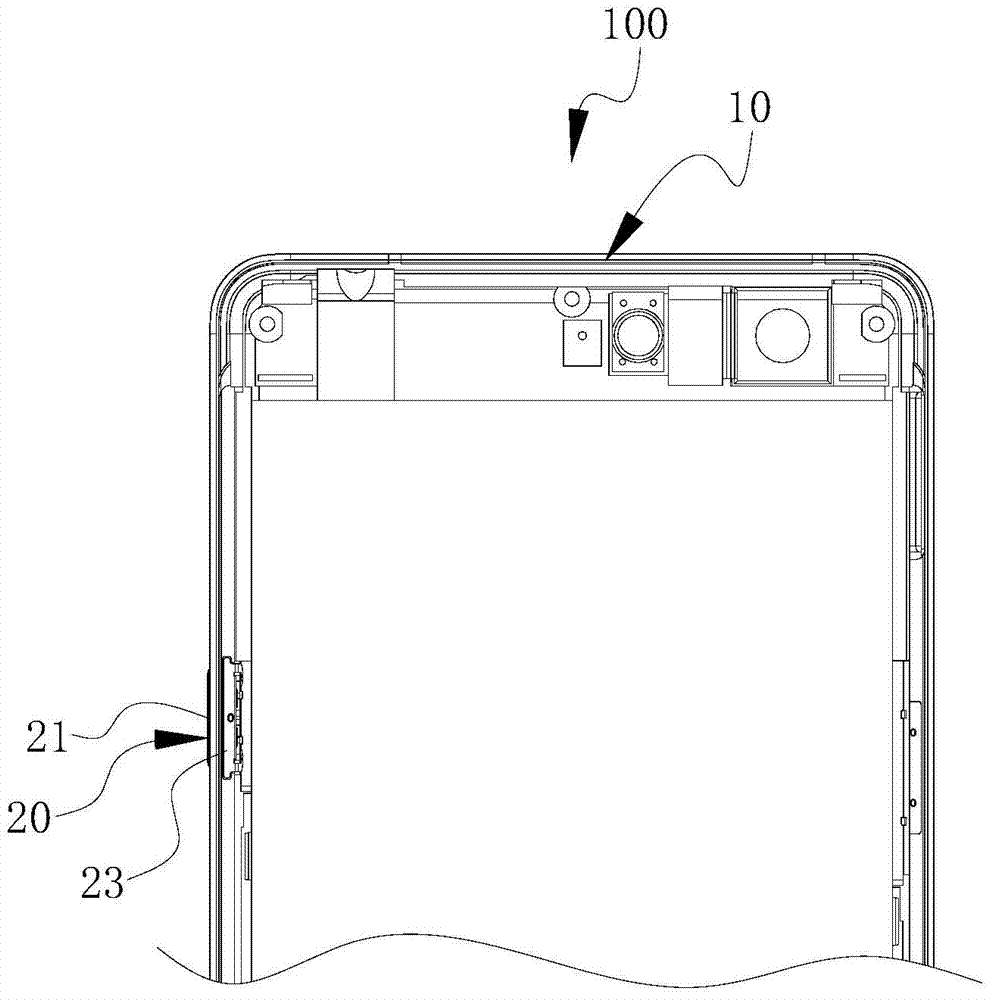

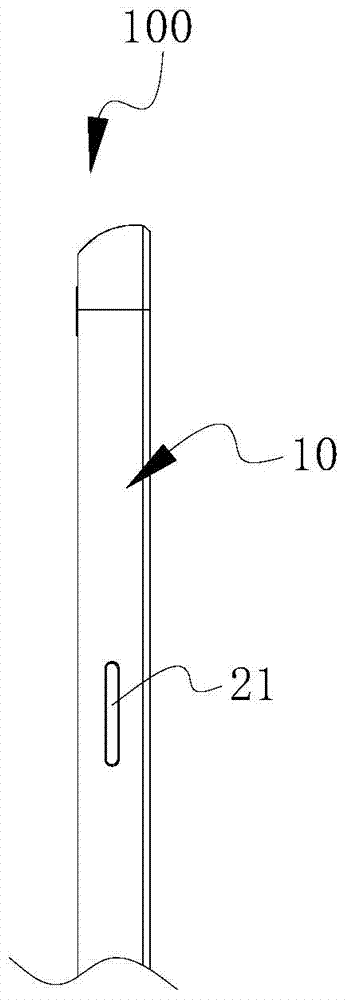

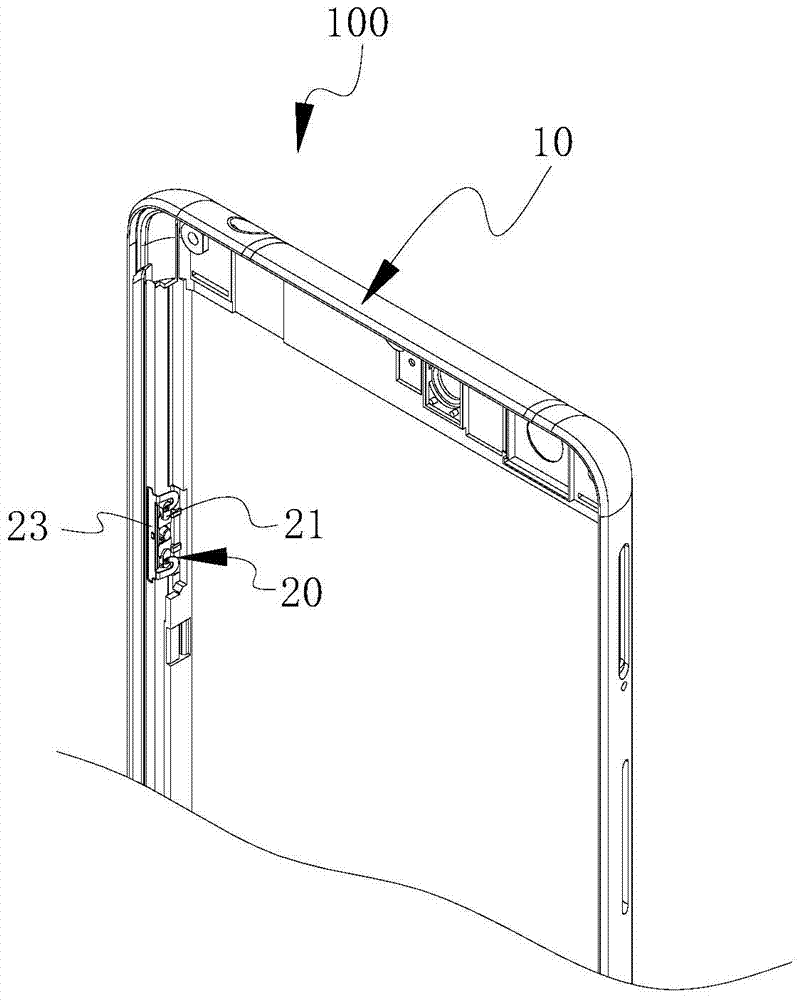

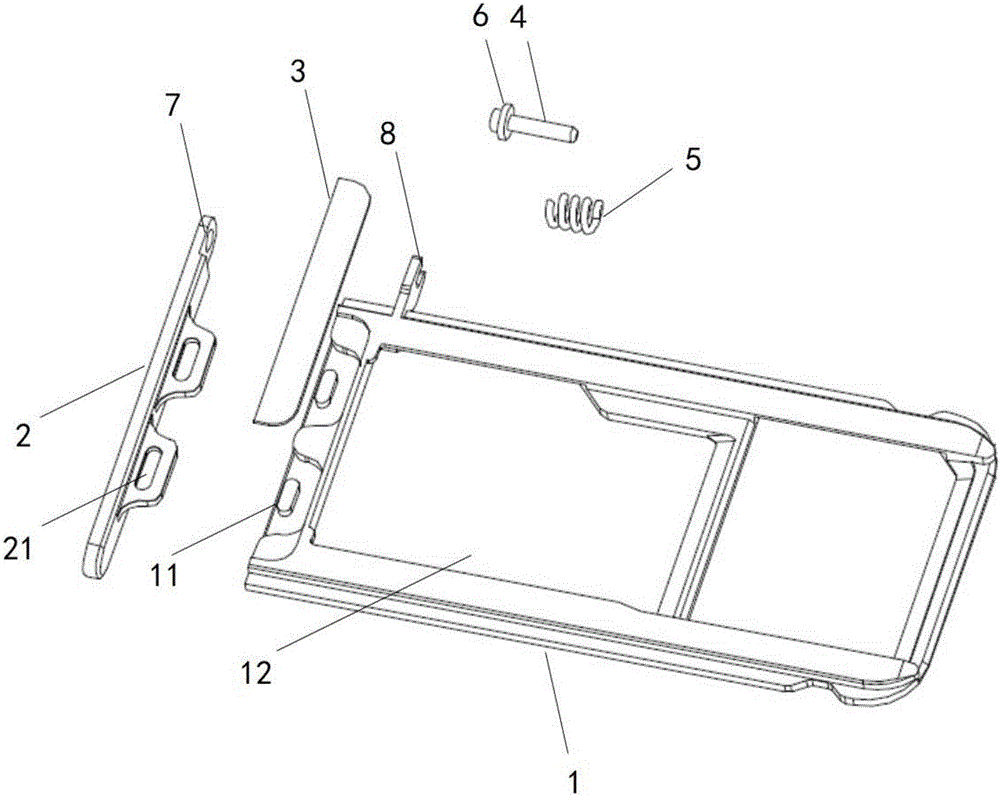

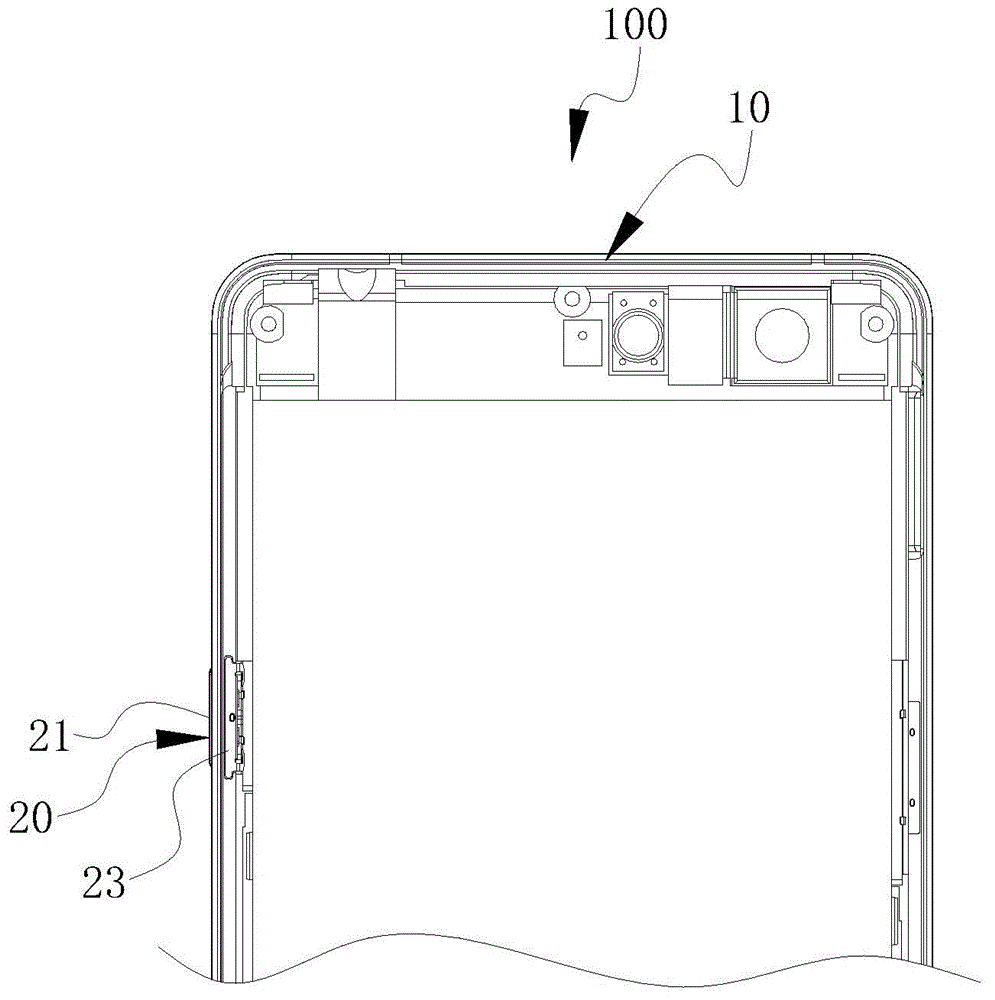

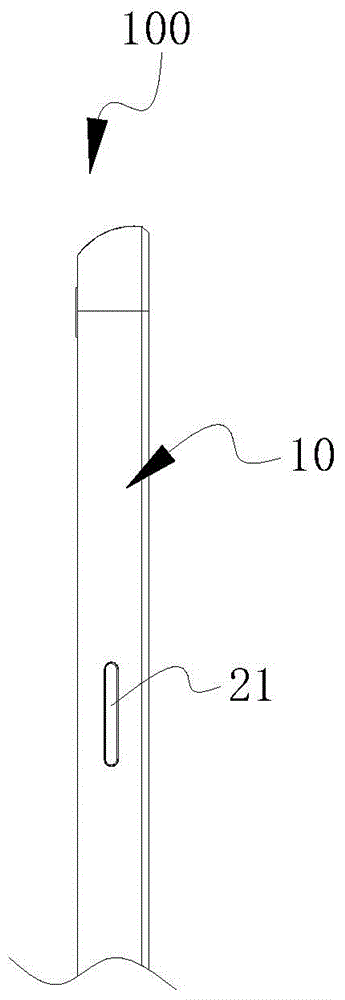

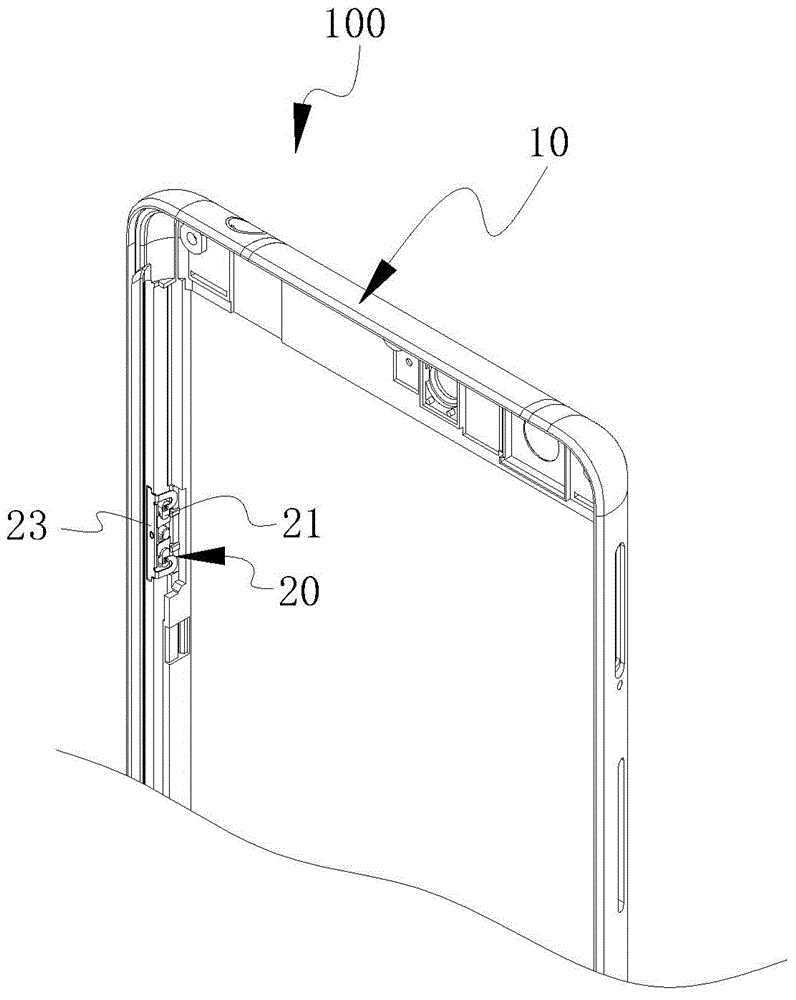

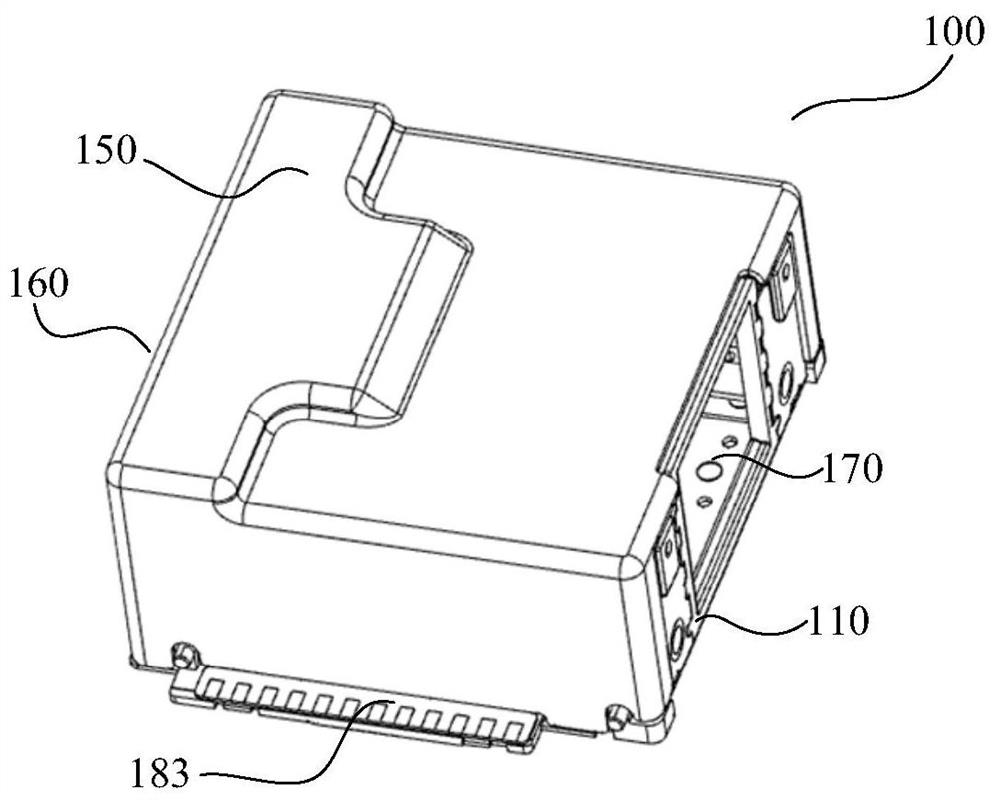

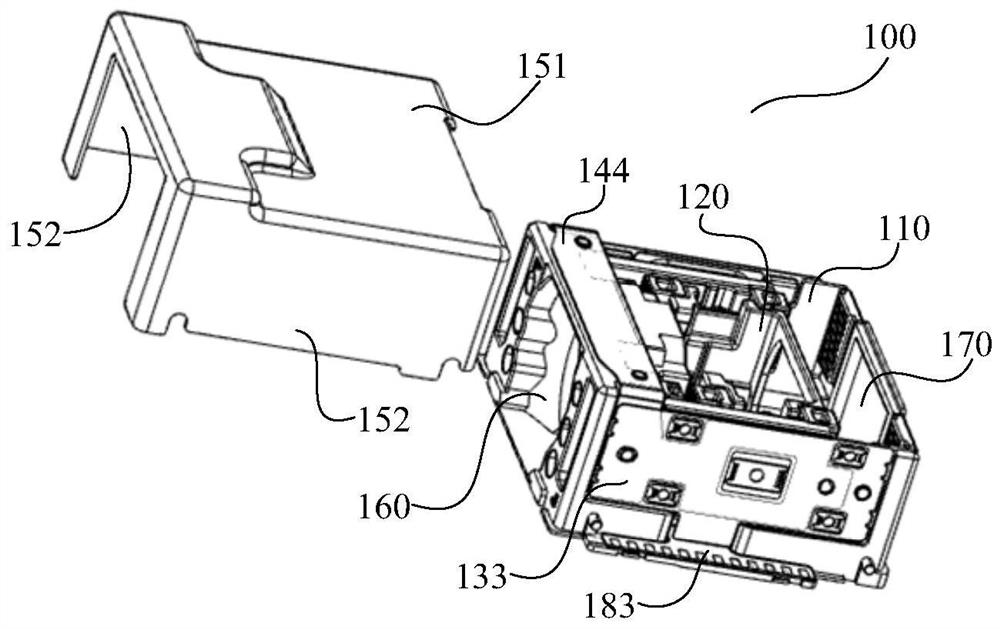

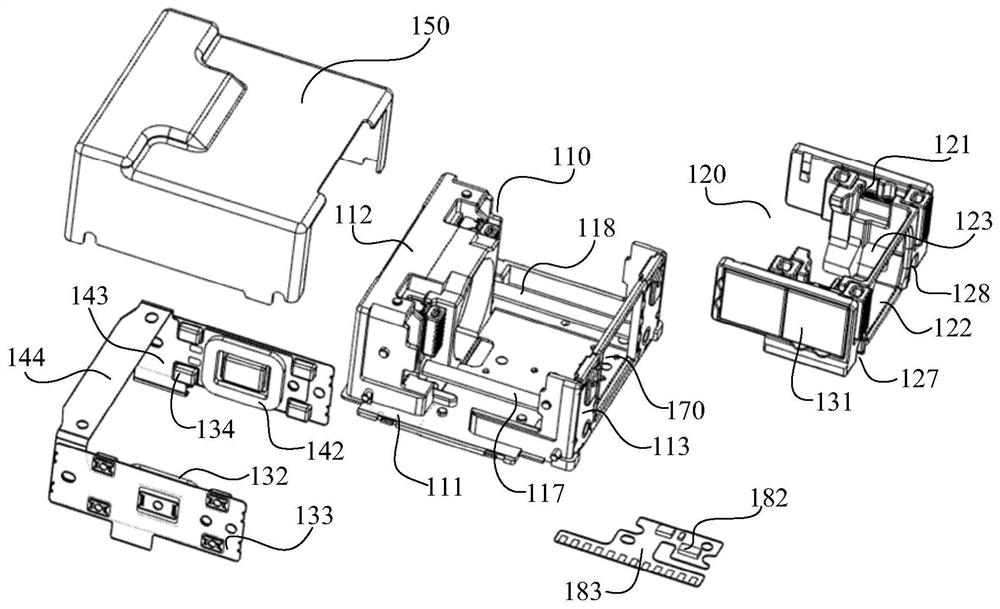

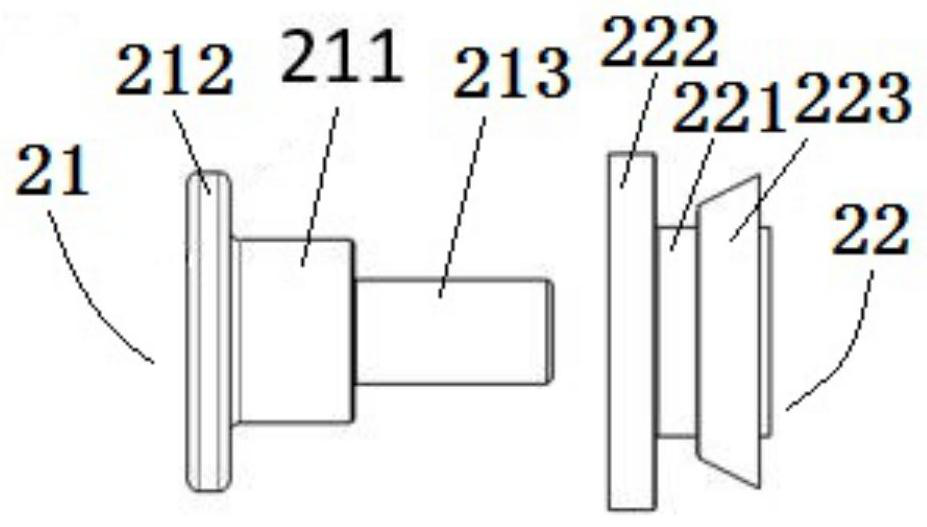

Side key mounting structure and electronic device

ActiveCN104618551AGuaranteed press elasticityNo warping phenomenonTelephone set constructionsKey pressingElectric equipment

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Electronic equipment and side button mounting structure of electronic equipment

InactiveCN104505288ASolve shakingSolve abnormal noiseTelephonic communicationElectric switchesKey pressingElastic compression

The invention provides a side button mounting structure of electronic equipment. The side button mounting structure comprises a side button, a button mounting hole and an elastic compression component, wherein the button mounting hole is formed in the side end of a shell of the electronic equipment; the side button is arranged in the button mounting hole; the elastic compression component is arranged on the side end of the shell, is close to the position of the button mounting hole and comprises a fixing part and a pressing part which is connected with the fixing part; the fixing part is connected and fixed to the side end of the shell; the pressing part is bent to go into the button mounting hole and is connected to the side button. The side button mounting structure provided by the invention is provided with the elastic compression component and is connected and fixed to the side end of the shell through the fixing part of the elastic compression component, and the pressing part of the elastic compression component is bent to go into the button mounting hole and is connected to the side button, so that the button is enabled not to come off outwards, certain pressing elasticity of two ends of the side button is also guaranteed, and the problem that a side button of electronic equipment swings and gives abnormal noise in the prior art is better solved. The invention also provides the electronic equipment.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

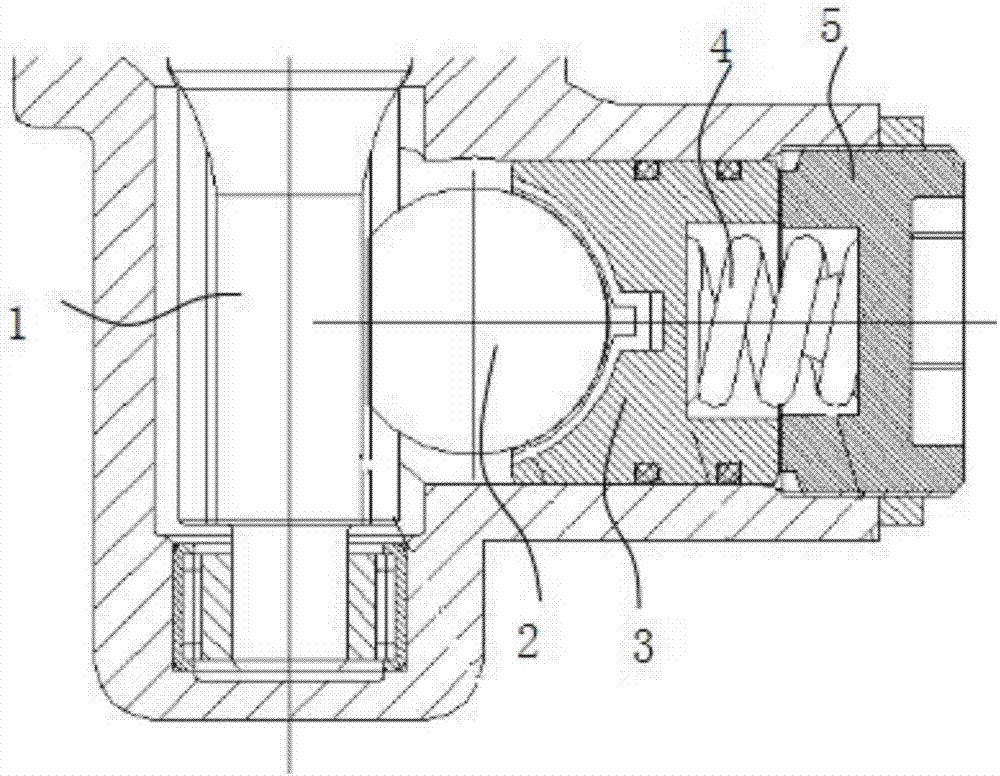

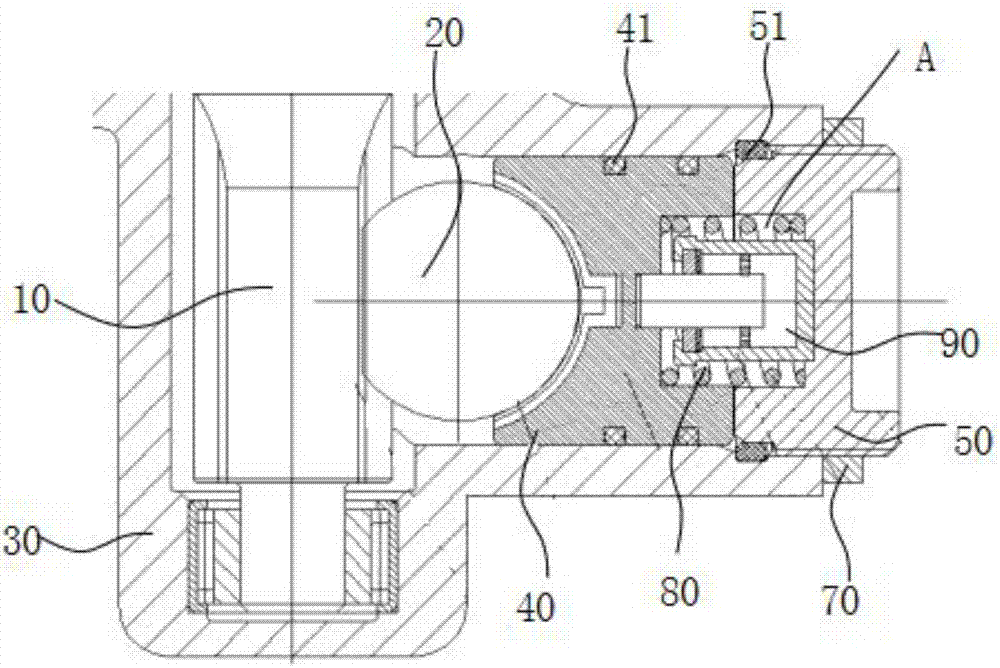

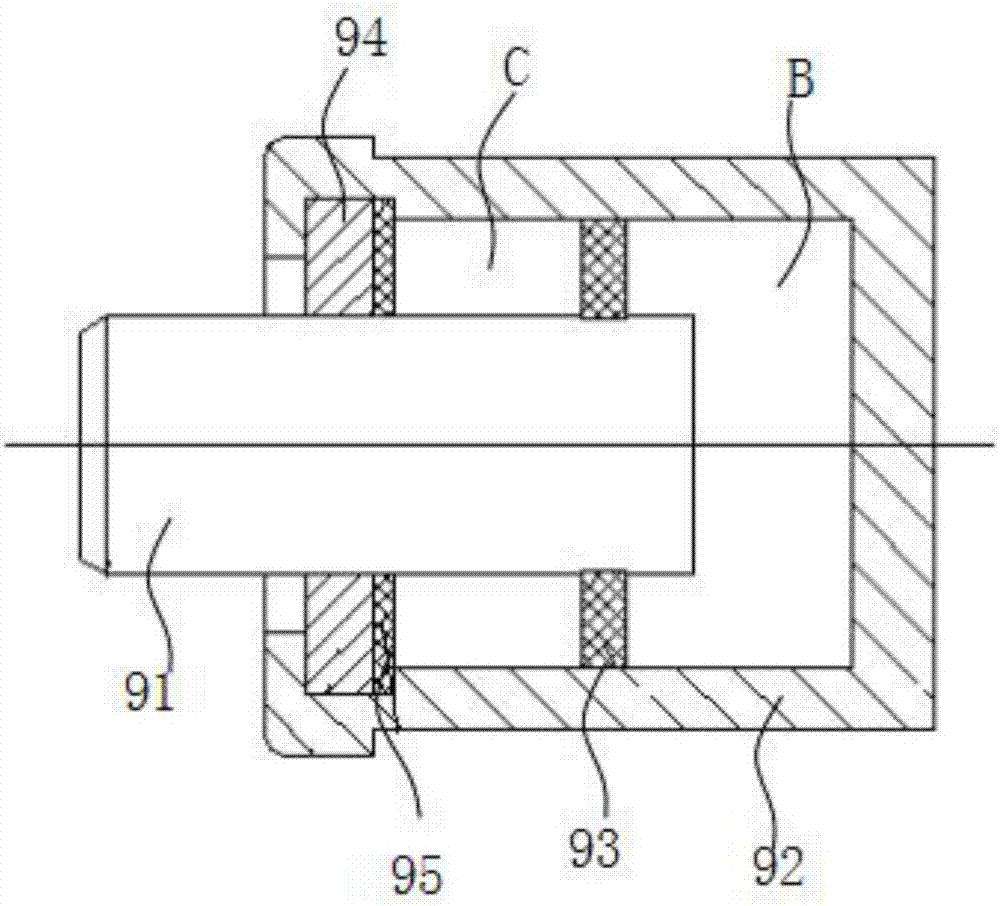

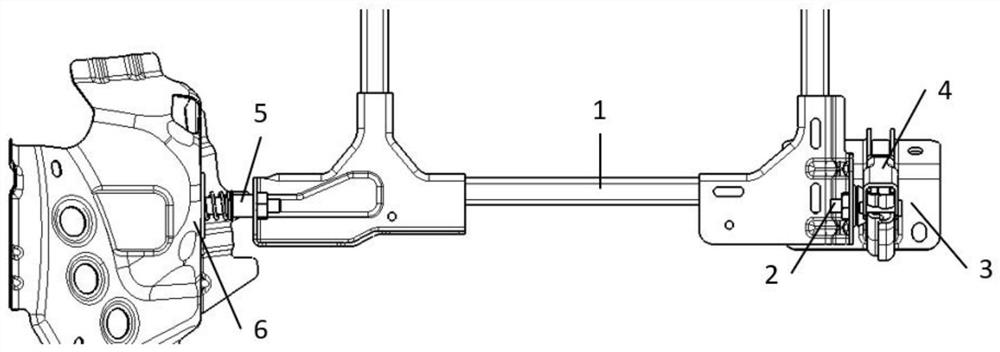

Steering gear gap adjustment mechanism

InactiveCN107226127AAvoid collisionSolve abnormal noisePortable liftingMechanical steering gearsButt jointCoil spring

The invention aims to provide a steering gear gap adjustment mechanism which can effectively reduce abrasion among parts and is small in occupied space. The steering gear gap adjustment mechanism comprises a steering input gear shaft and a rack which are mutually engaged; a pressing block and an adjustment screw plug are provided with concave parts with openings being opposite; the two concave parts are in butt joint to constitute a chamber; the chamber is internally provided with a spiral spring; one end of the spiral spring abuts against the pressing block, and the other end of the spiral spring abuts against the adjustment screw plug; the chamber is further internally provided with a damping unit; the end of a piston rod of the damping unit abuts against the pressing block; and the pressure in a valve cavity of the damping unit drives the piston rod to move towards the pressing block. When the rack overcomes resistance of the spiral spring and the pressing block and continues to move towards the adjustment screw plug, resistance generated by a mixture in the first valve cavity prevents the rack from continuing to move, thus the pressing block and the adjustment screw plug are made to make slow contact with each other through reaction force generated by compression of the spiral spring and compression of the damping unit to avoid impact of the pressing block and the adjustment screw plug with great energy, and therefore, the abnormal sound problem can be effectively solved.

Owner:CHERY AUTOMOBILE CO LTD

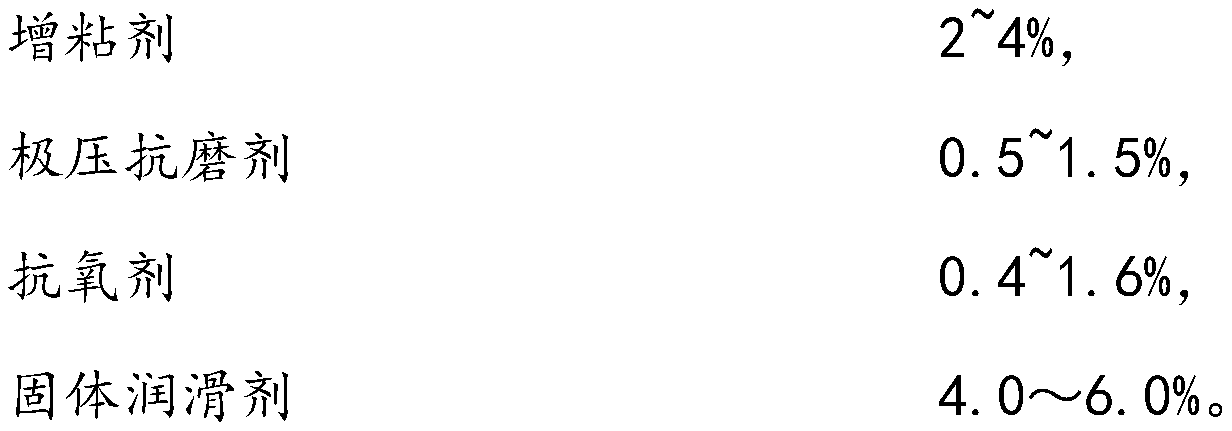

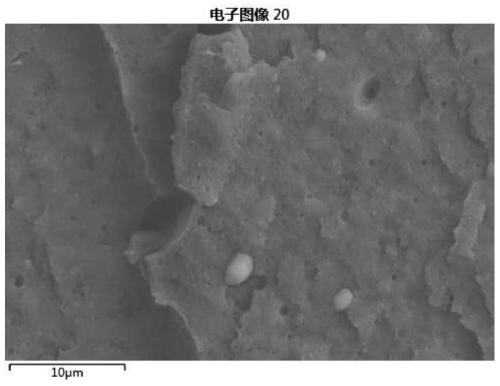

Lubricating grease composition of automobile steering combination switch and preparation method

InactiveCN110157525AImprove adhesionImprove wear reduction performanceLubricant compositionAntioxidantEngineering

The invention relates to the technical field of lubricating greases, and discloses a lubricating grease composition of an automobile steering combination switch. The lubricating grease composition comprises the following components in percent by mass: 85-90% of a base oil and 10-15% of a thickener, and comprises in percent by the total mass of the above two components: 2-4% of a tackifier, 0.5-1.5% of an extreme pressure anti-wear agent, 0.4-1.6% of an antioxidant, and 4.0-6.0% of a solid lubricant. According to the lubricating grease composition of the automobile steering combination switch and a preparation method, the overall formula is simple, the lubricating grease for the automobile steering combination switch has the characteristics of excellent adhesion, plastic compatibility, shear resistance, wear reduction, noise reduction, electrical conductivity and long life, the practical performance of the lubricating grease is improved, the lubricating grease is suitable for using in the contact friction between a metal and a plastic, a plastic and a plastic in the temperature range of 40 DEG C-130 DEG C, the service life of a combination switch for automobiles can be effectively improved, problems of abnormal noise, short circuit, jam and the like of the combination switch for automobiles can be effectively avoided, and the use is convenient.

Owner:安徽和欣润滑科技有限公司

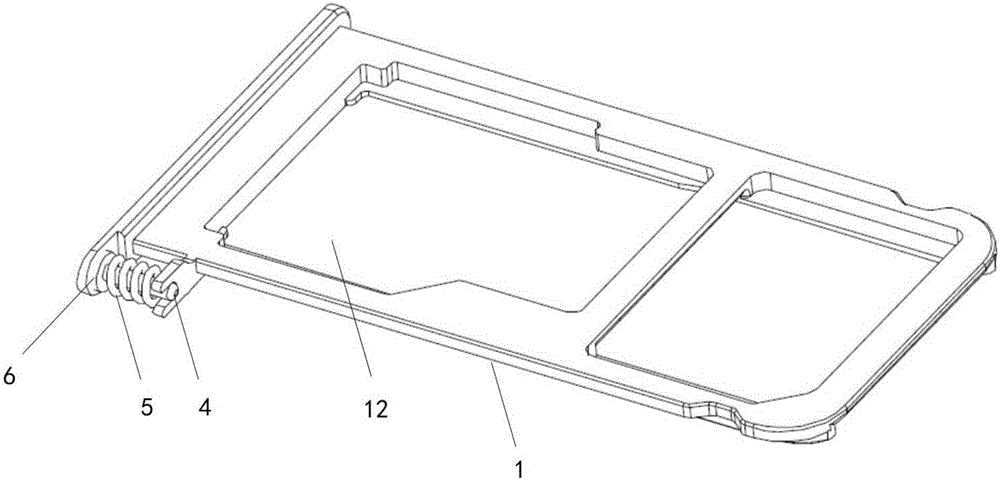

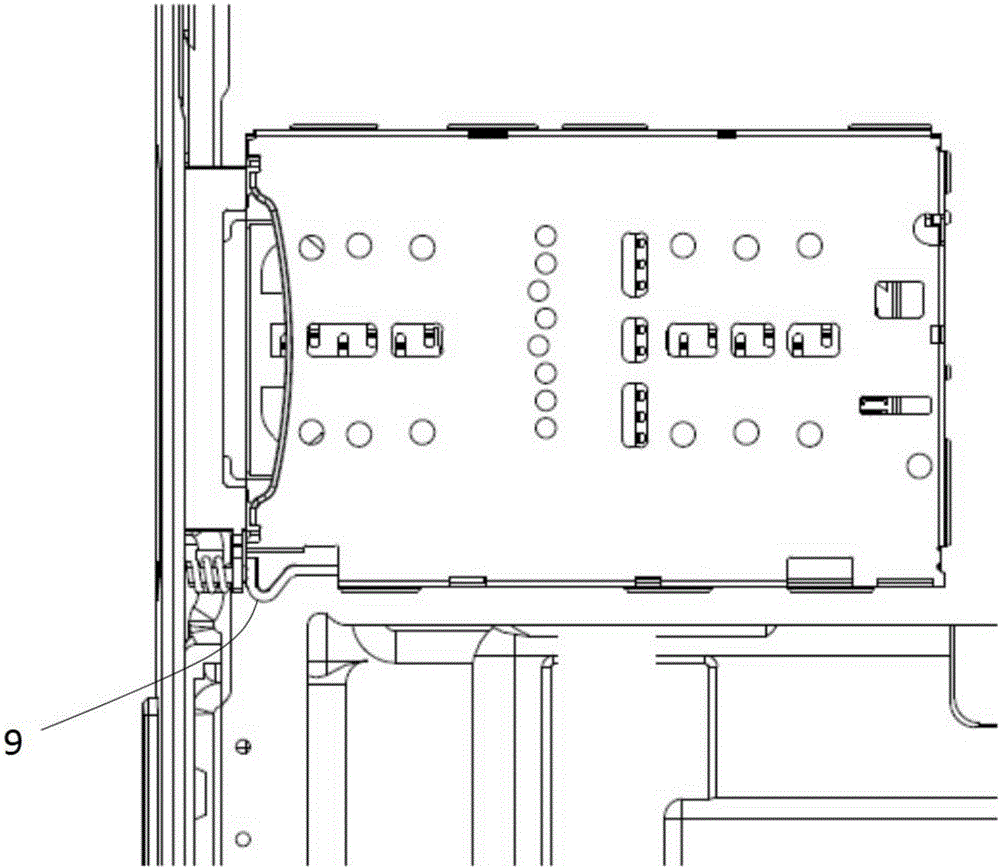

Card holder and mobile phone

InactiveCN106412163AEasy to take outEasy to operateTelephone set constructionsEngineeringCard holder

The invention discloses a card holder and a mobile phone. A technical problem that a card holder can not be taken out until a special card needle is used in the prior art can be solved. The card holder comprises a card holder support, a door plate, a baffle, and a center. A lip side is arranged approaching one end of the center, wherein the diameter of the cross section of the lip side is larger than that of the cross section of the center. A first through hole and a second through hole that cooperate with the center are formed in the door plate and the card holder support. The center passes through the first through hole and the second through hole and then is abutted against and contact with a clamp seat push rod after passing through the second through hole. According to the invention, the card holder can be processed conveniently and assembled simply; and dustproof and waterproof effects are realized.

Owner:QIKU INTERNET TECH SHENZHEN CO LTD

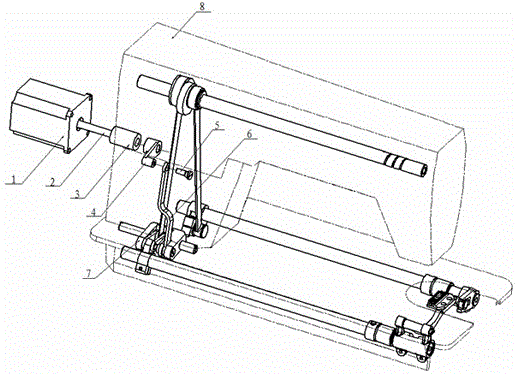

Industrial sewing machine with electronic stitch length adjusting mechanism

InactiveCN105040297AEasy to controlChange directionSewing-machine control devicesEngineeringControl theory

The invention relates to the field of sewing equipment, in particular to an industrial sewing machine with an electronic stitch length adjusting mechanism. The industrial sewing machine is controlled through a stepping motor, the functions of electronic stitch length adjusting, electronic backward stitching and electronic dense sewing are achieved, when the stitch length is adjusted, sewing for the stitch length with several millimeters can be achieved as long as digits are input on an operation panel, the coincidence of forward stitching and backward stitching can be adjusted through the operation panel, fast switching of backward stitching and dense stitching can be achieved, the structure is more simple, and operation is more convenient. The industrial sewing machine with the electronic stitch length adjusting mechanism comprises a machine head and further comprises a stepping motor, a stitch length adjusting crankshaft and a stitch length adjusting connecting rod. The stepping motor is arranged on the right end face of the machine head, the motor shaft of the stepping motor is arranged on a shaft sleeve on the machine head, a crankshaft is fixed to the front end of the motor shaft, the crankshaft and one end of the stitch length adjusting connecting rod are connected through a screw, and the other end of the stitch length adjusting connecting rod is connected with the stitch length adjusting crankshaft.

Owner:XIAN TYPICAL IND

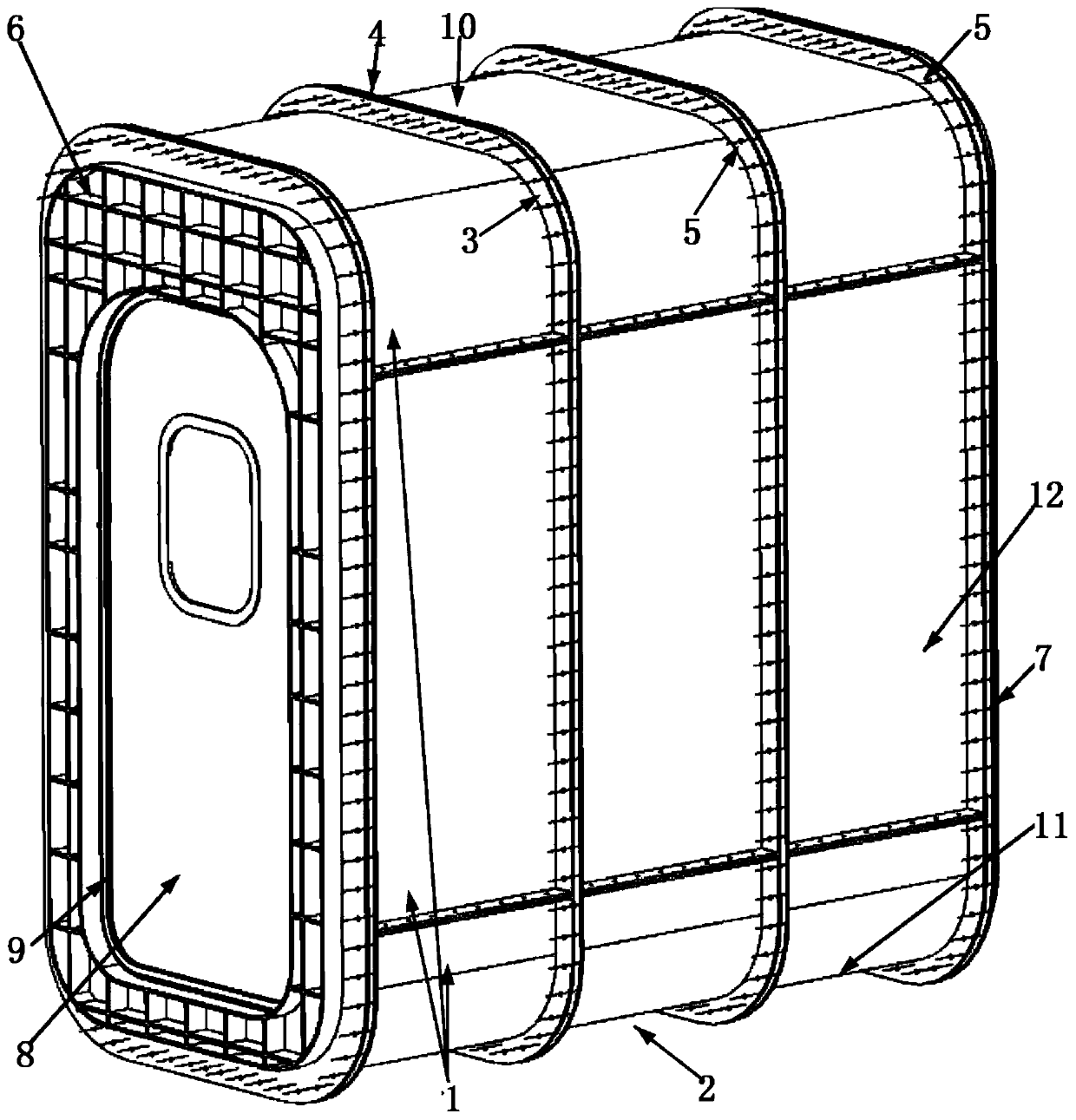

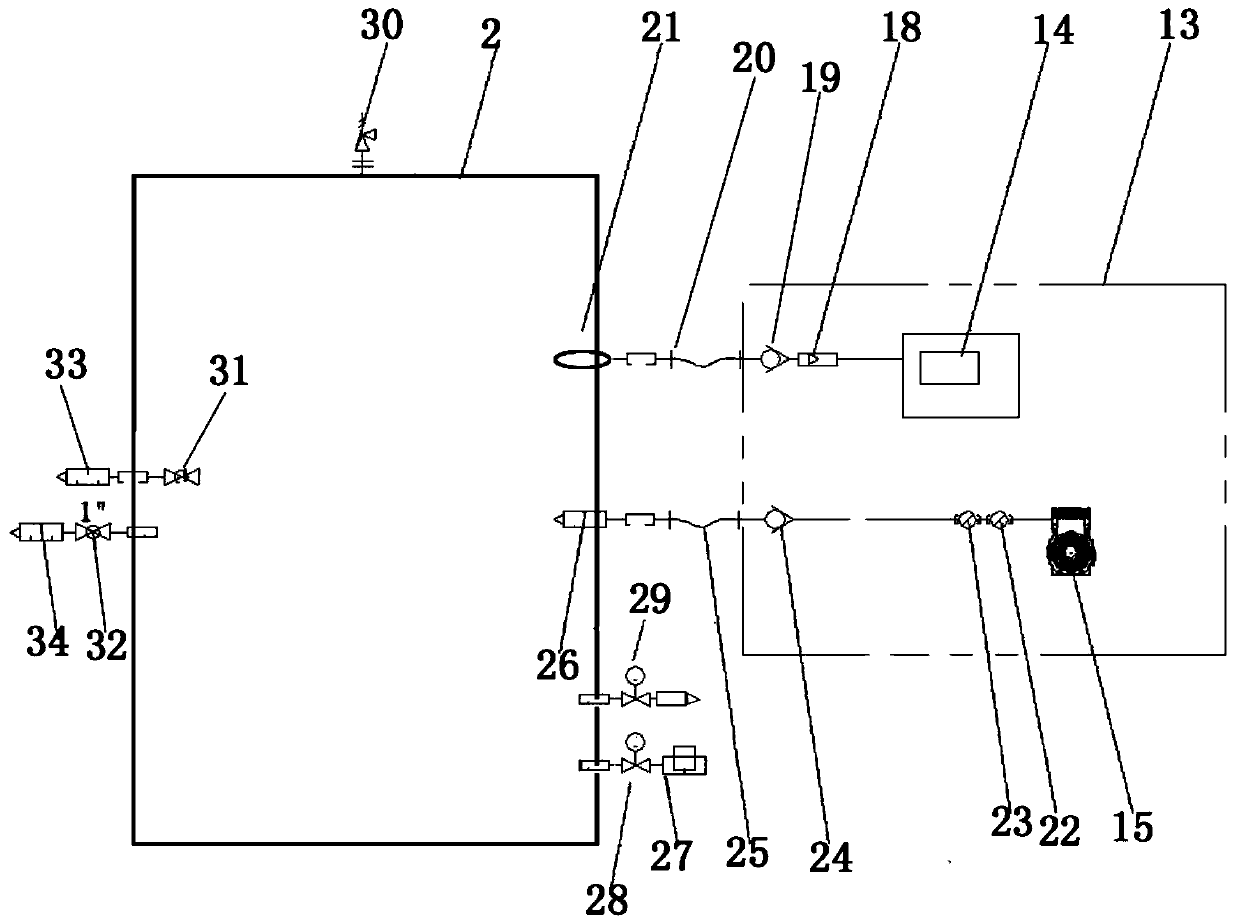

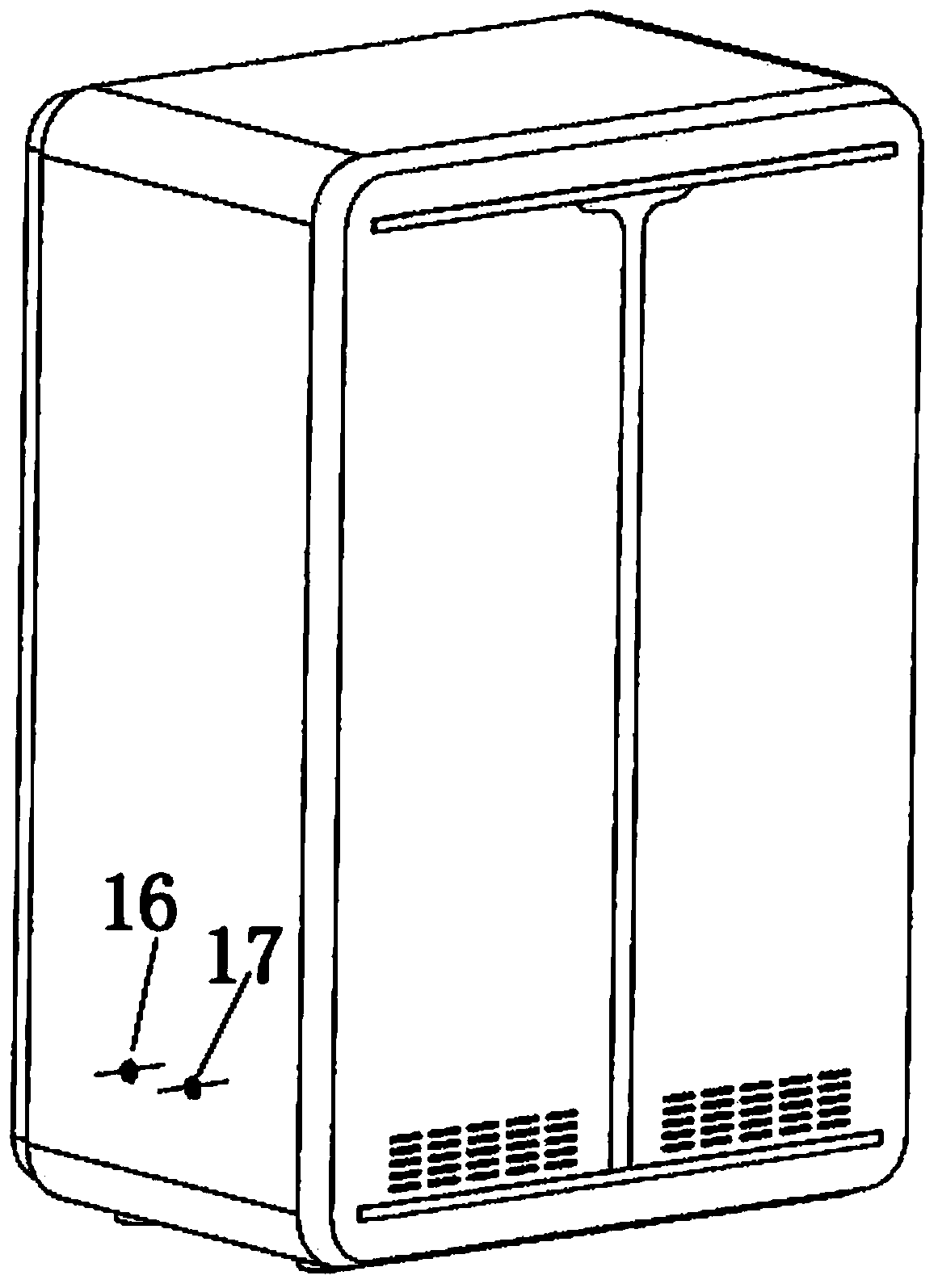

Module-type assembled air boost device and system

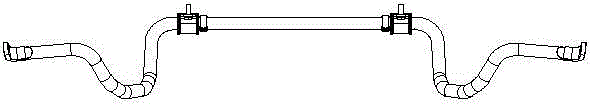

PendingCN110638596AMeet pressure requirementsSolve abnormal noiseBreathing protectionTreatment roomsAir filtrationAir compressor

The invention relates to a module-type assembled air boost device and system. The device comprises a cabin body formed by a plurality of assembled monomers connected in sequence, a cabin sealing member and a fixing member are arranged between two adjacent monomer reinforcing rings, the cabin sealing member is embedded in the gap between the monomer reinforcing rings, a cabin door is formed in themiddle of a front sealing head, and the contact edge of the cabin door and and the front sealing head is provided with a door sealing member. In the module-type assembled air boost system, an oxygen generator is connected to a glass rotor flowmeter, the glass rotor flowmeter is connected to a first check valve, the first check valve is connected to a first quick-plug hose, and the first quick-plughose is connected to a diffuse oxygen-supply port located inside the cabin; and an air compressor is connected to a water separation-air filtration device, the water separation-air filtration deviceis connected to a precision filter, the precision filter is connected to a second check valve, the second check valve is connected to a second quick-plug hose, and the second quick-plug hose is connected to a first muffler located inside the cabin. According to the present invention, module-type assembly and a split design of cabin body are adopted, which meets the pressure bearing conditions of the cabin body after assembly, and is convenient for transportation and installation.

Owner:烟台宏远氧业股份有限公司

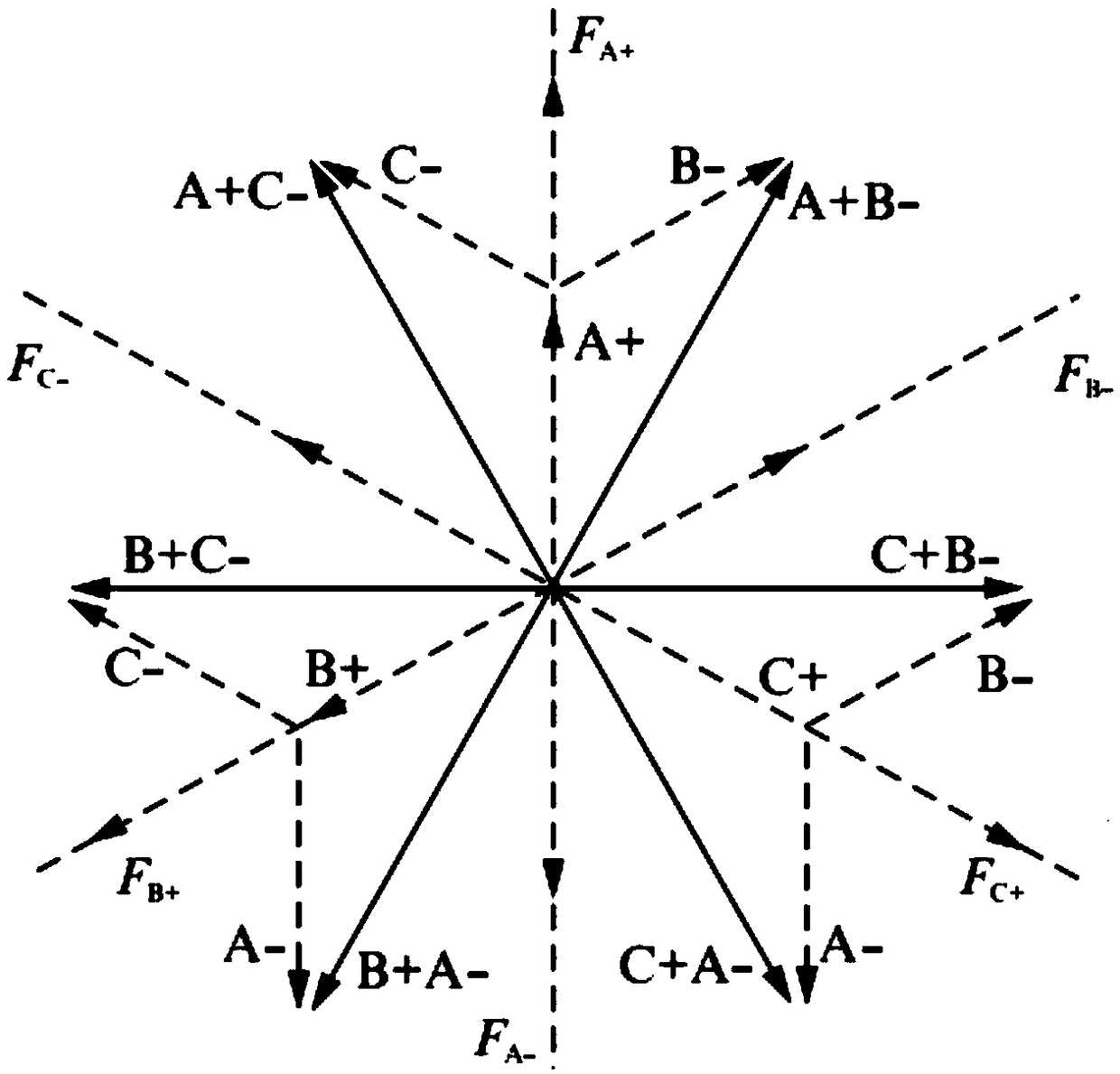

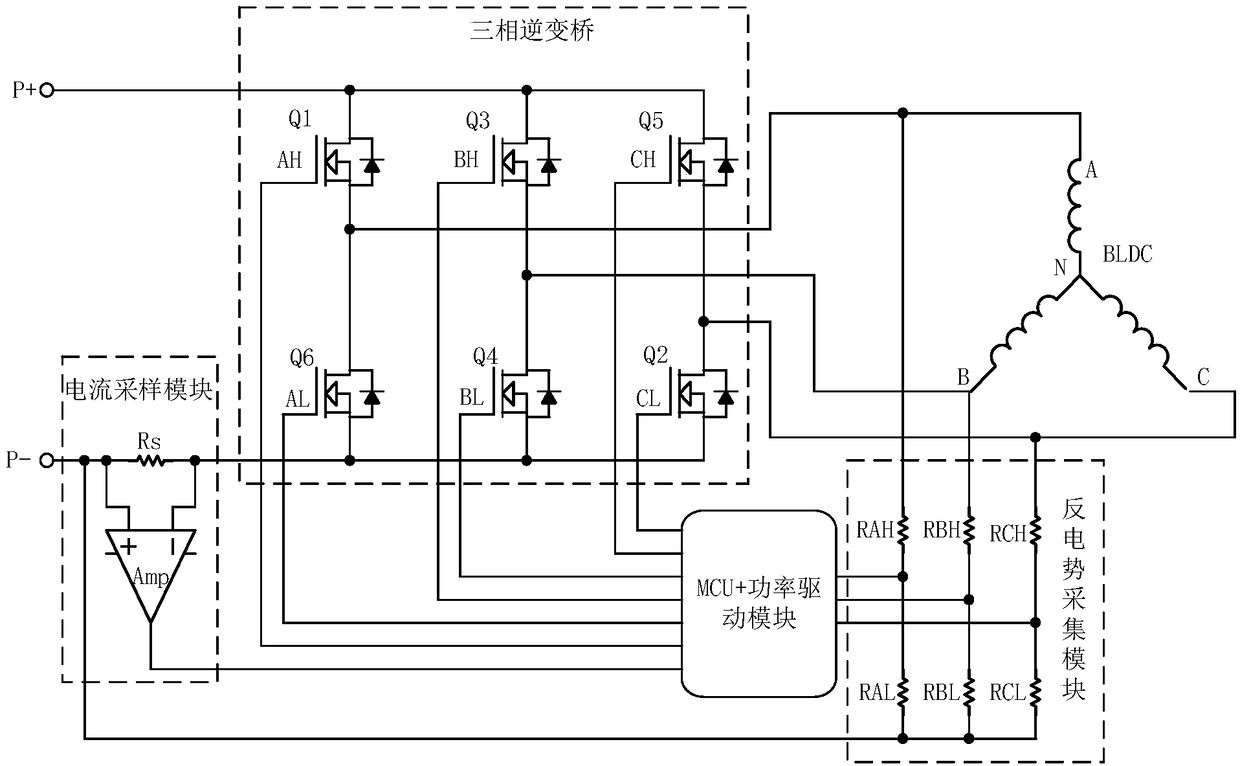

Rotor positioning method, positioning device and control system for brushless direct current motor

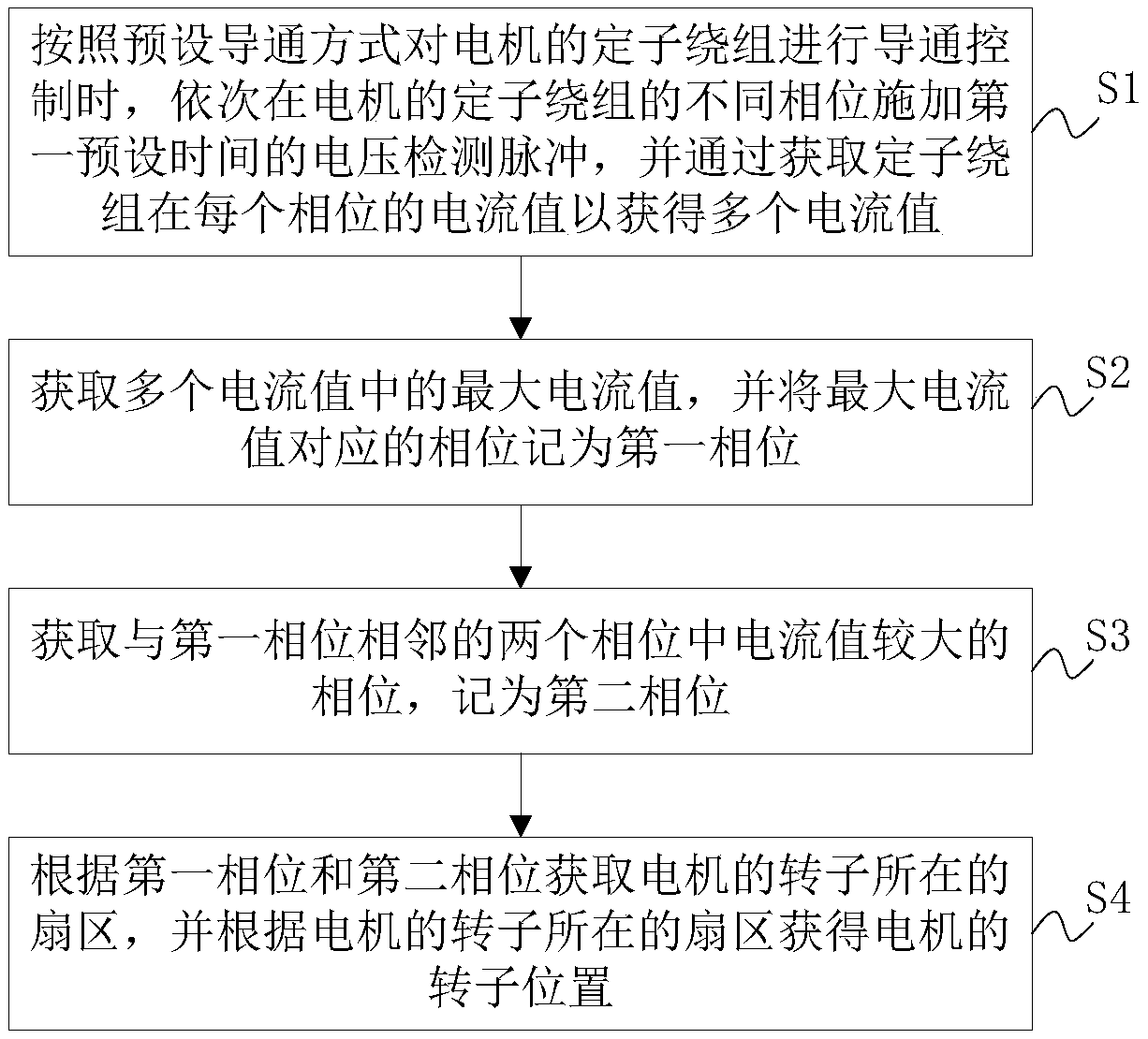

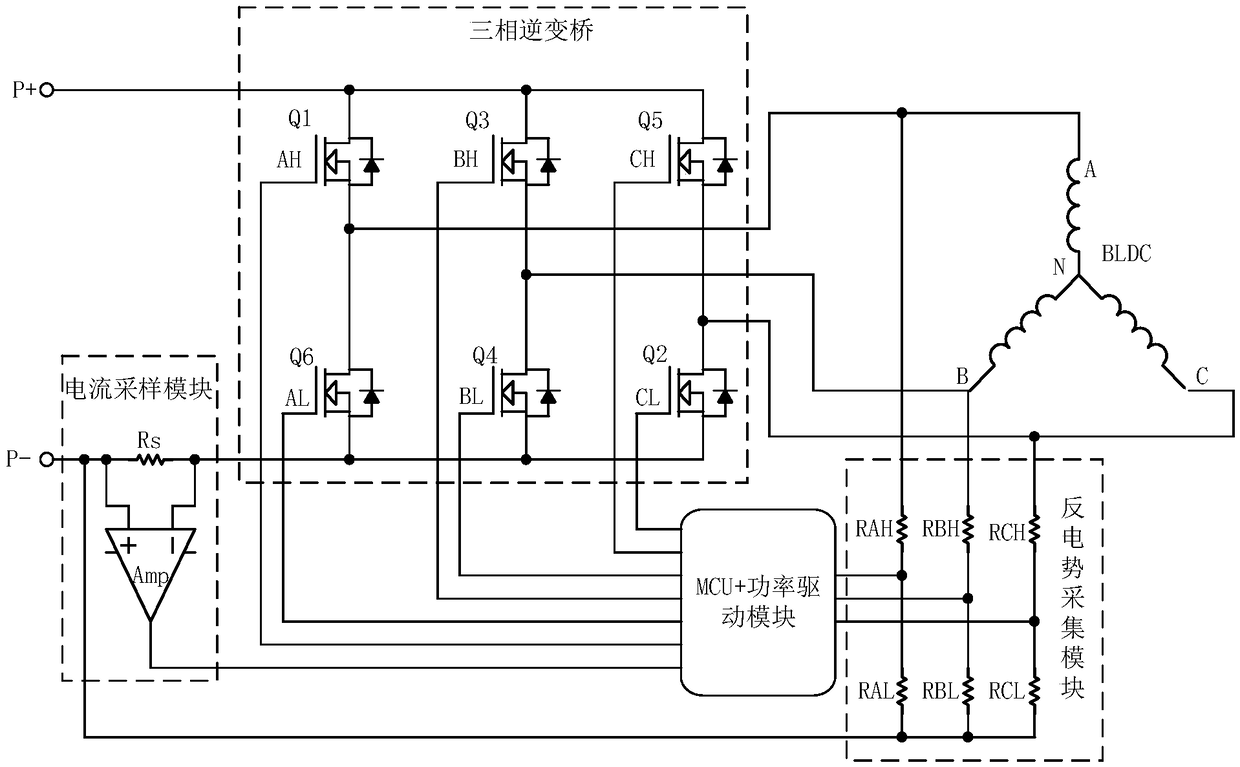

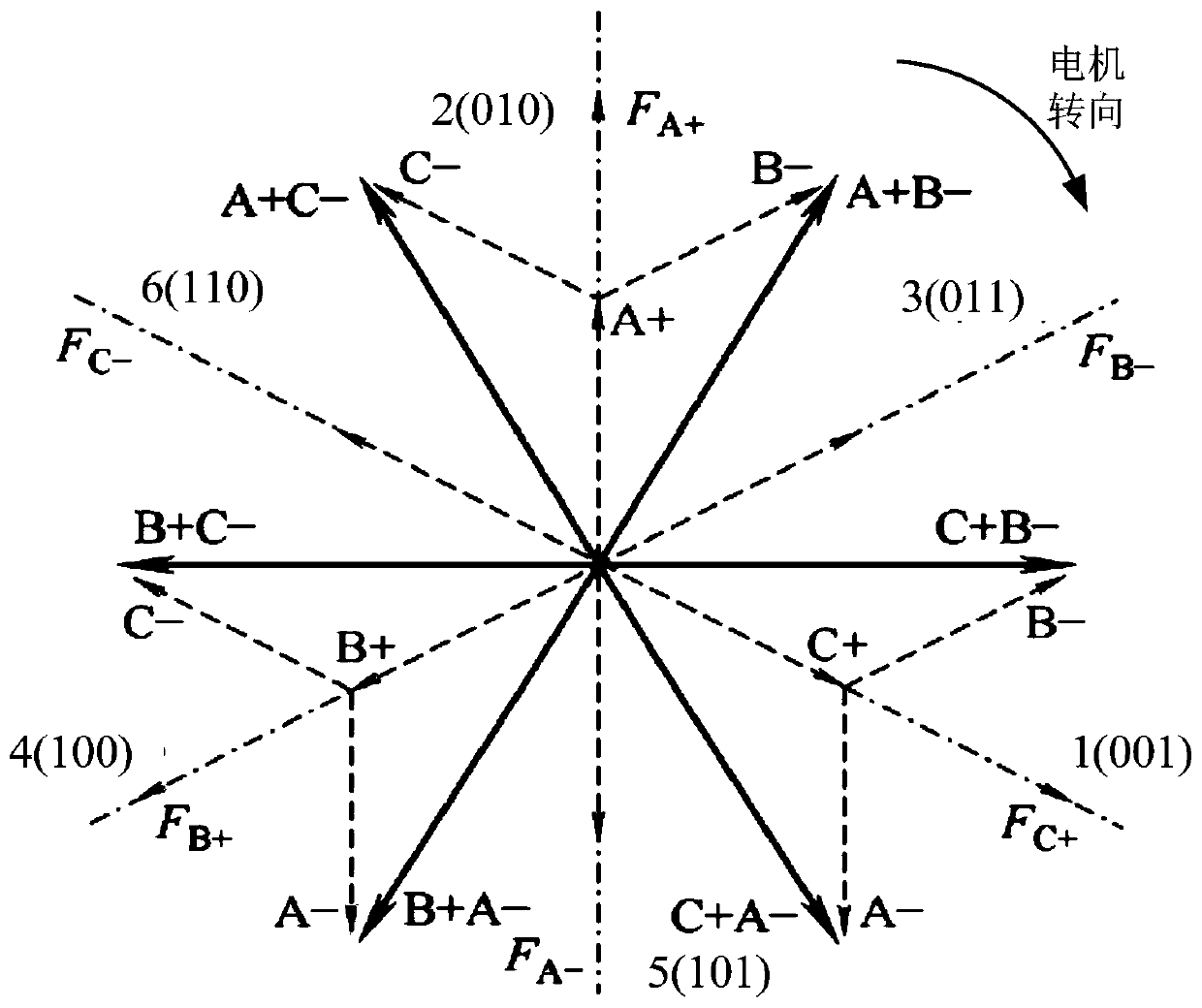

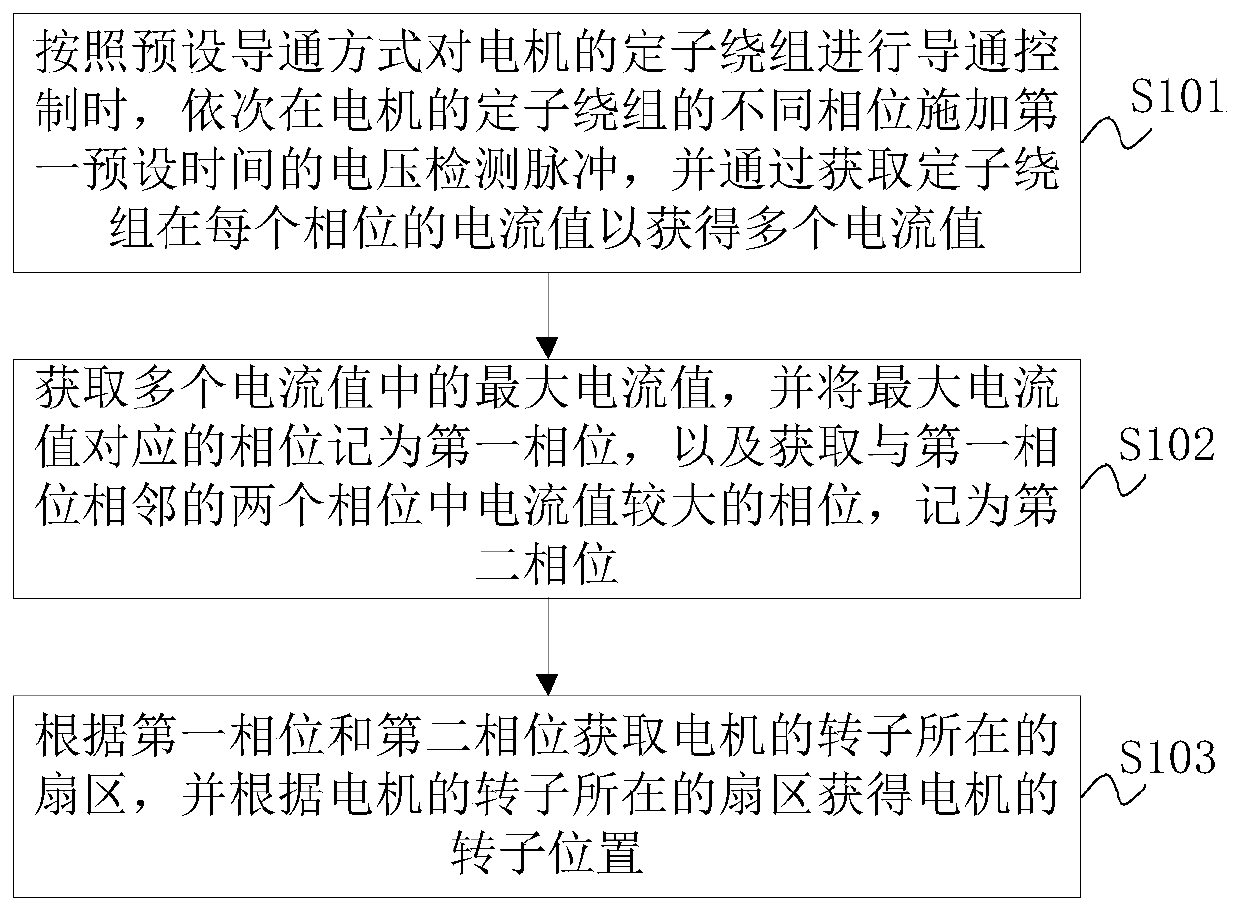

ActiveCN108631661AReduce the time to start positioningSimplified rotor position identification methodStarter arrangementsControl systemElectric machine

The invention discloses a rotor positioning method, a rotor positioning device and a control system for a brushless direct current motor, wherein the positioning method comprises the following steps:when performing conduction control on the stator windings of the motor according to a preset conduction mode, applying a voltage detecting pulse of a first preset time to different phases of the stator windings of the motor in turn, and obtaining a plurality of current values by acquiring current values of the stator windings at each phase; acquiring a maximum current value among the plurality ofcurrent values, and marking the phase corresponding to the maximum current value as the first phase; acquiring the phase in which the current value is larger in the two phases adjacent to the first phase, and marking the same as the second phase; obtaining a sector in which the rotor of the motor is located according to according to the first phase and the second phase, and obtaining the positionof the rotor of the motor according to the sector in which the rotor is located. Therefore, the position of the rotor of the motor may be quickly and accurately obtained without the appearance of theproblem of abnormal noise as well as jitter and positioning errors. In addition, the method is simple, and the blind spotless positioning may be realized.

Owner:JIANGSU MIDEA CLEANING APPLIANCES +1

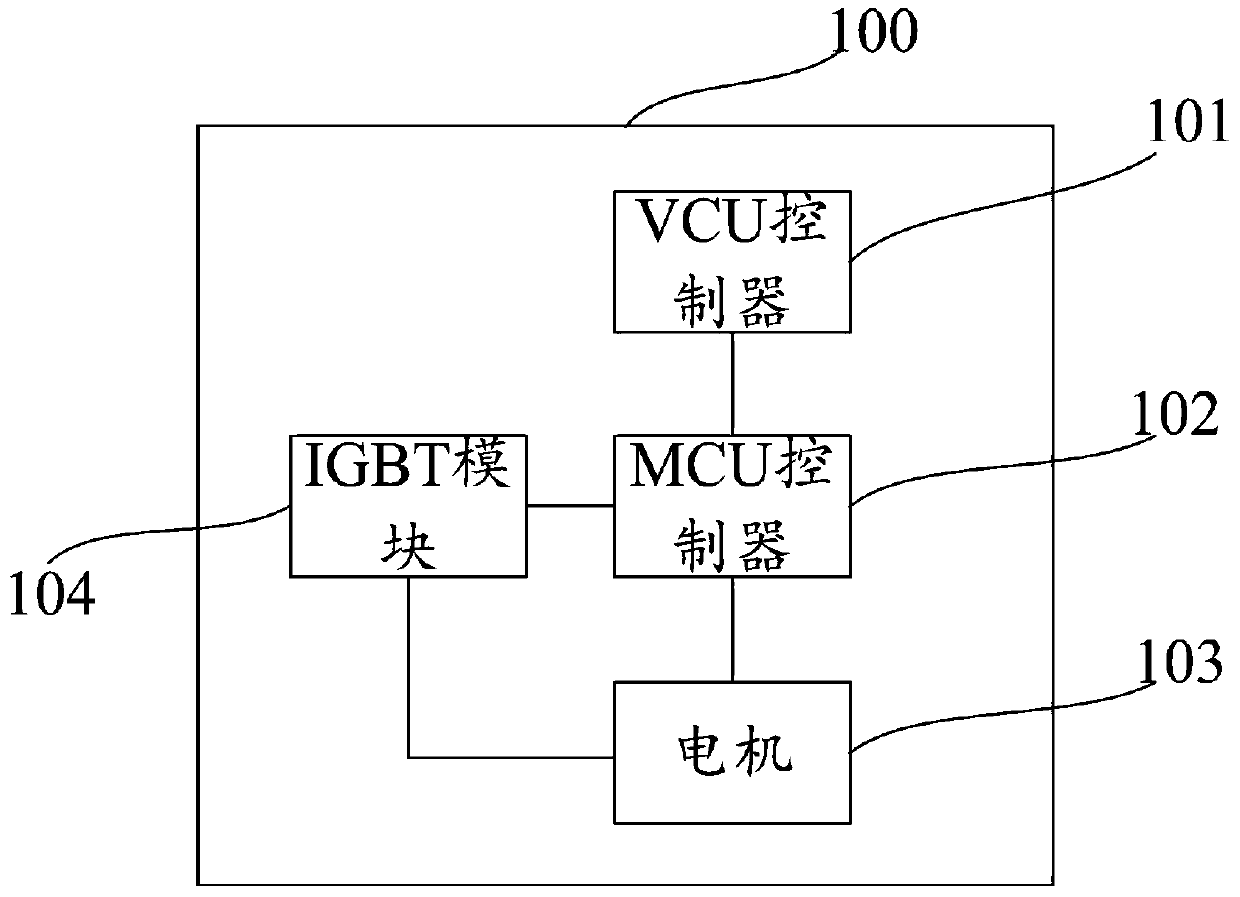

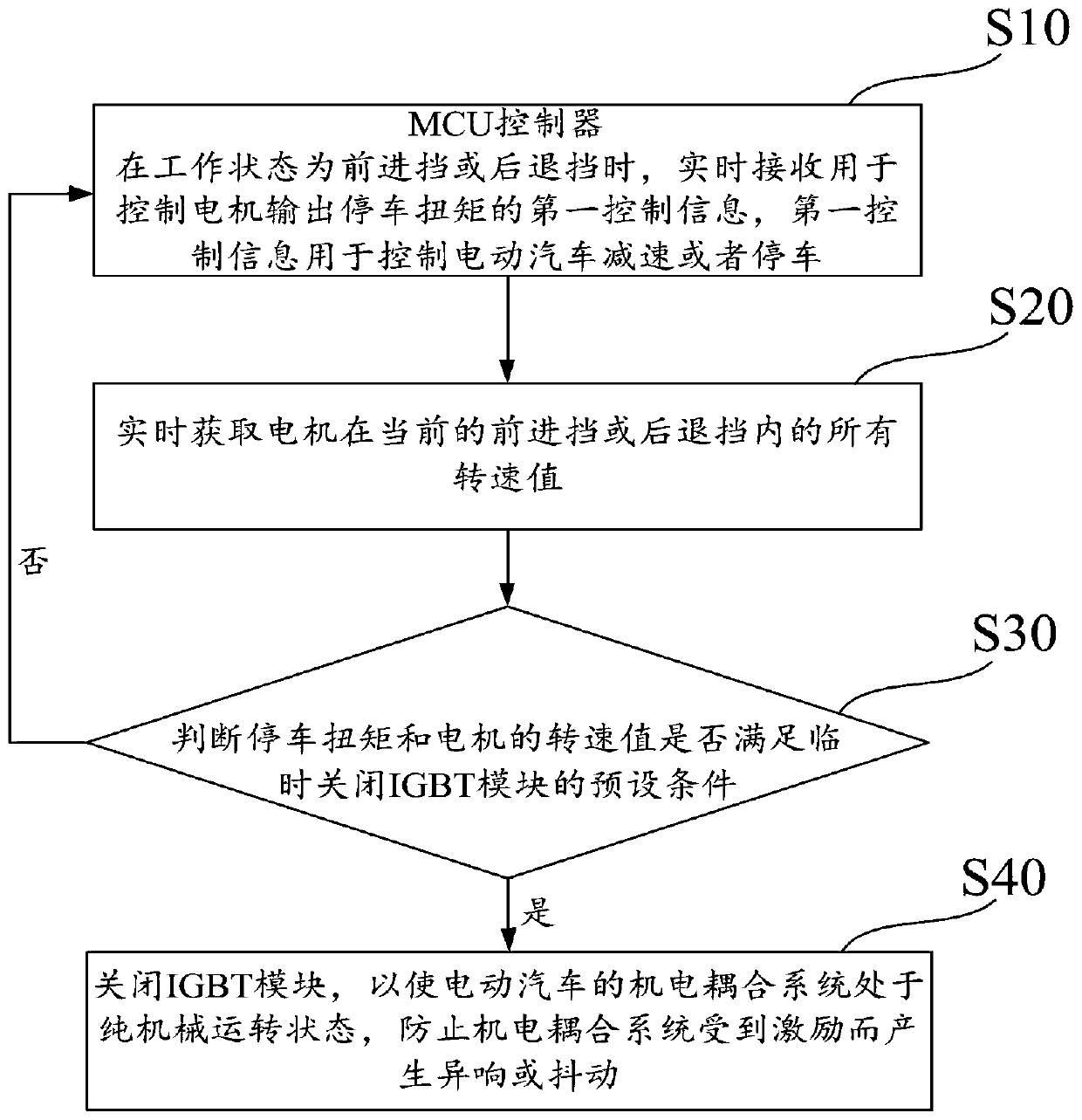

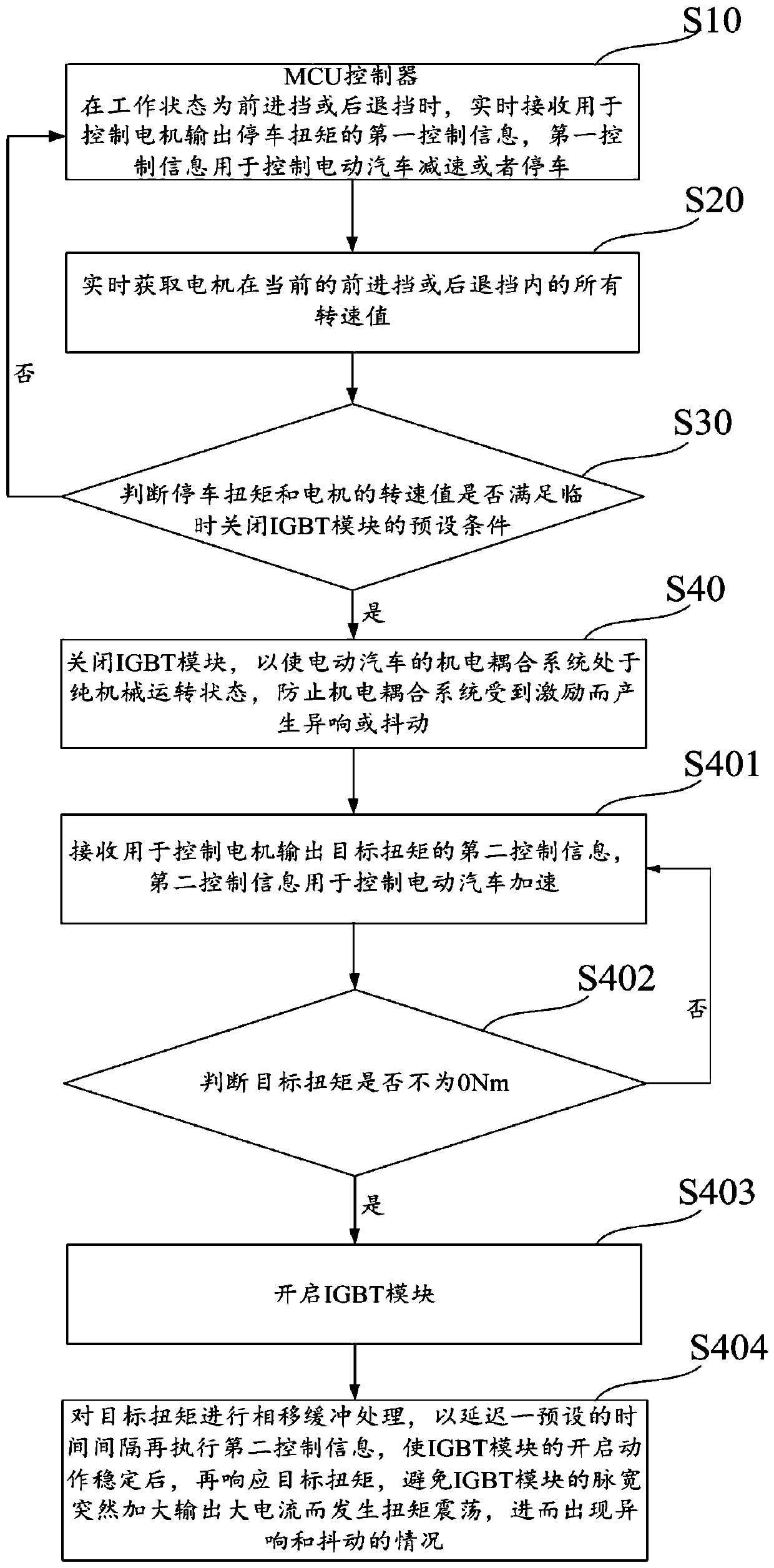

Electric automobile, control method and control device of electric automobile and controller

ActiveCN110303902ASolve abnormal noiseFix jitterSpeed controllerElectric energy managementElectric machineryEngineering

The invention provides an electric automobile, a control method and a control device of the electric automobile and a controller. The control method comprises the following steps that when the work state is the advancing gear or the retreating gear, first control information for controlling a motor to output the parking torque is received in real time, and the first control information is used forcontrolling electric automobile deceleration or parking; all rotation speed values of the motor at the current advancing gear or retreating gear are obtained in real time; whether the parking torqueand the rotation speed value of the motor meet the temporary IGBT module stopping preset conditions or not is judged; and if the parking torque and the rotation speed value of the motor meet the temporary IGBT module stopping preset conditions, an IGBT module is stopped, accordingly, an electromechanical coupling system of the electric automobile is in a pure machine running state, and electromechanical coupling system abnormal sounds or shaking caused by motivation is prevented.

Owner:INVT ELECTRIC VEHICLE DRIVE TECH SHENZHEN CO LTD

Electronic device and key mounting structure

InactiveCN105072220ANo warping phenomenonImprove experience comfortElectric switchesTelephone set constructionsKey pressingElastic compression

The invention provides a side button mounting structure of electronic equipment. The side button mounting structure comprises a side button, a button mounting hole and an elastic compression component, wherein the button mounting hole is formed in the side end of a shell of the electronic equipment; the side button is arranged in the button mounting hole; the elastic compression component is arranged on the side end of the shell, is close to the position of the button mounting hole and comprises a fixing part and a pressing part which is connected with the fixing part; the fixing part is connected and fixed to the side end of the shell; the pressing part is bent to go into the button mounting hole and is connected to the side button. The side button mounting structure provided by the invention is provided with the elastic compression component and is connected and fixed to the side end of the shell through the fixing part of the elastic compression component, and the pressing part of the elastic compression component is bent to go into the button mounting hole and is connected to the side button, so that the button is enabled not to come off outwards, certain pressing elasticity of two ends of the side button is also guaranteed, and the problem that a side button of electronic equipment swings and gives abnormal noise in the prior art is better solved. The invention also provides the electronic equipment.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Heat exchange device and air-conditioning equipment

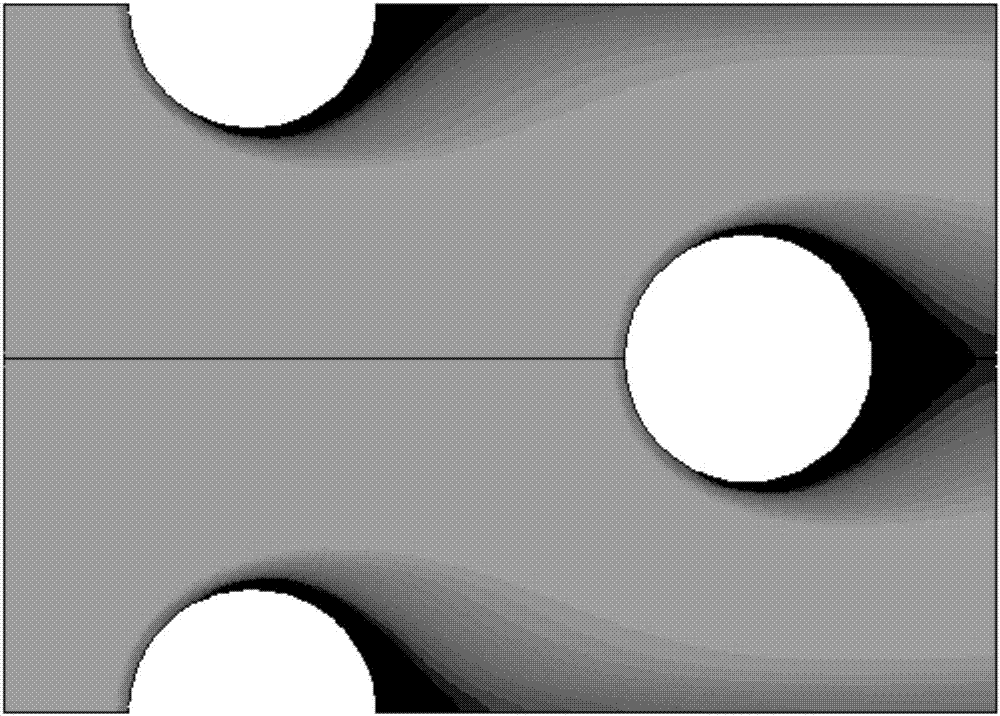

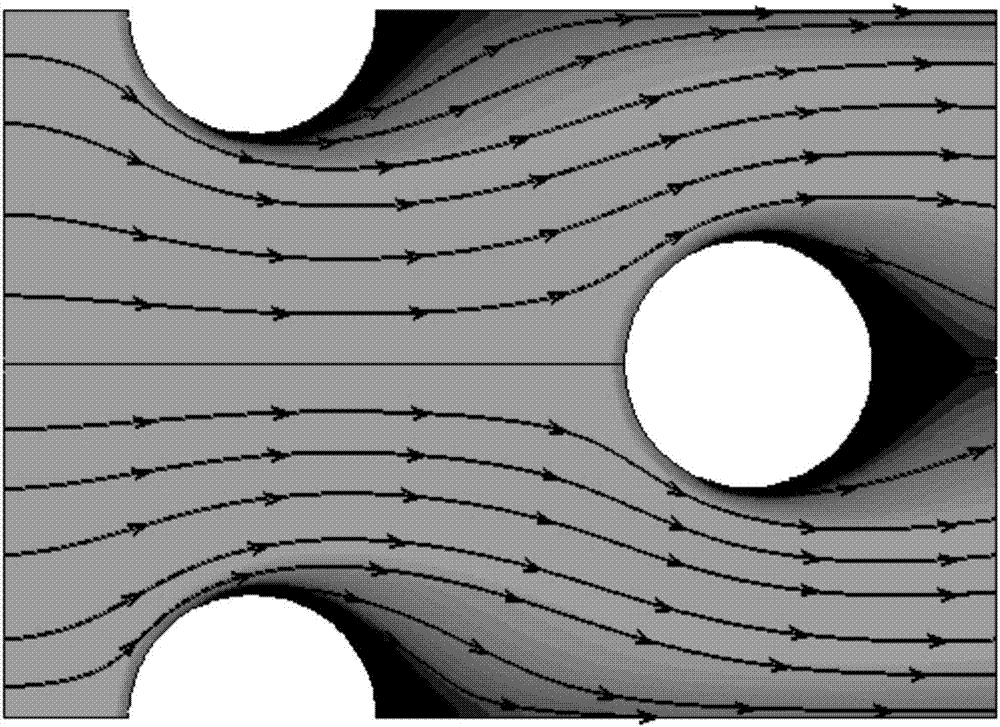

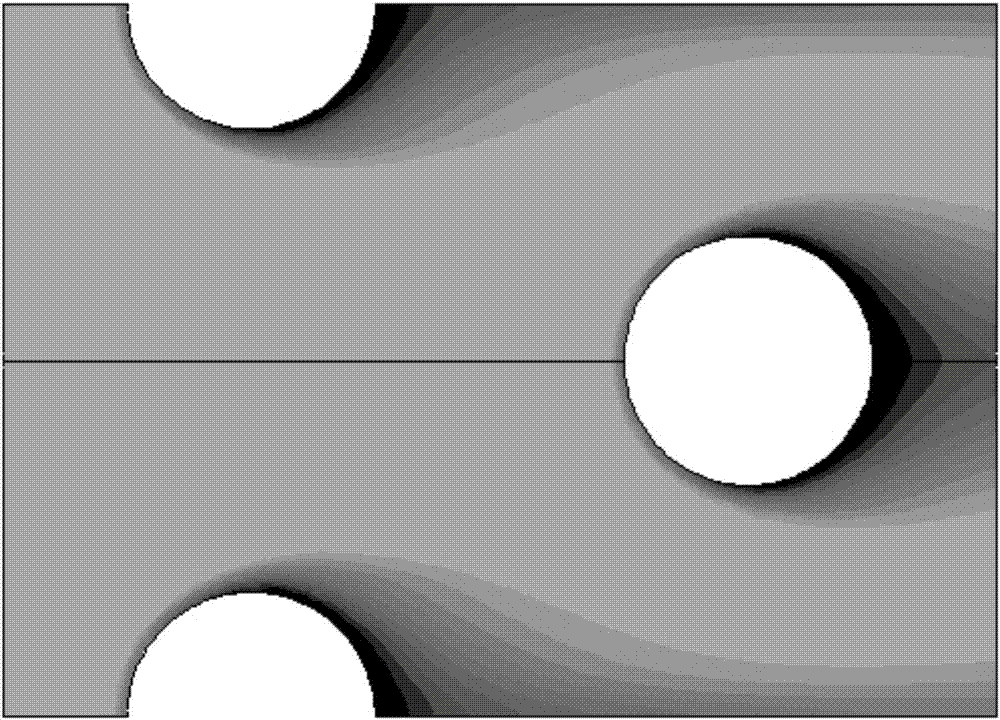

InactiveCN108006941AGuaranteed heat transfer efficiencyFull play of heat exchange effectLighting and heating apparatusSpace heating and ventilation detailsBusiness efficiencyBlind zone

The invention provides a heat exchange device and air-conditioning equipment. The heat exchange device comprises at least two subsidiary heat exchangers arranged in the wind direction; each subsidiaryheat exchanger comprises at least one row of refrigerant pipes and fins mounted on the refrigerant pipes in a sleeving manner; and the transverse pipe center distance of the refrigerant pipes betweenany two adjacent subsidiary heat exchangers ranges from 8 mm to 35 mm. According to the heat exchange device provided in the scheme, an air flow can extend fully and smoothly when flowing among the refrigerant pipes of the adjacent subsidiary heat exchangers, air flow blind zones and weak wind zones on the leeward sides of the refrigerant pipes can be reduced, all the refrigerant pipes in the subsidiary heat exchangers in the upstream and downstream positions of the wind direction can make full contact with the air flow, the problem that the refrigerant pipes in the subsidiary heat exchangersin the downstream position of the wind direction cannot exchange heat effectively due to the fact that the refrigerant pipes are located in the air flow blind zones or the weak wind zones is avoided,the problem that the wind force on the subsidiary heat exchangers in the downstream position of the wind direction is greatly reduced due to the excessively large transverse pipe center distances ofthe refrigerant pipes between among any subsidiary heat exchangers can also be avoided with the design, and the overall energy efficiency ratio of the air-conditioning equipment is increased.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Dust collector and control method, device and system of brushless direct current motor

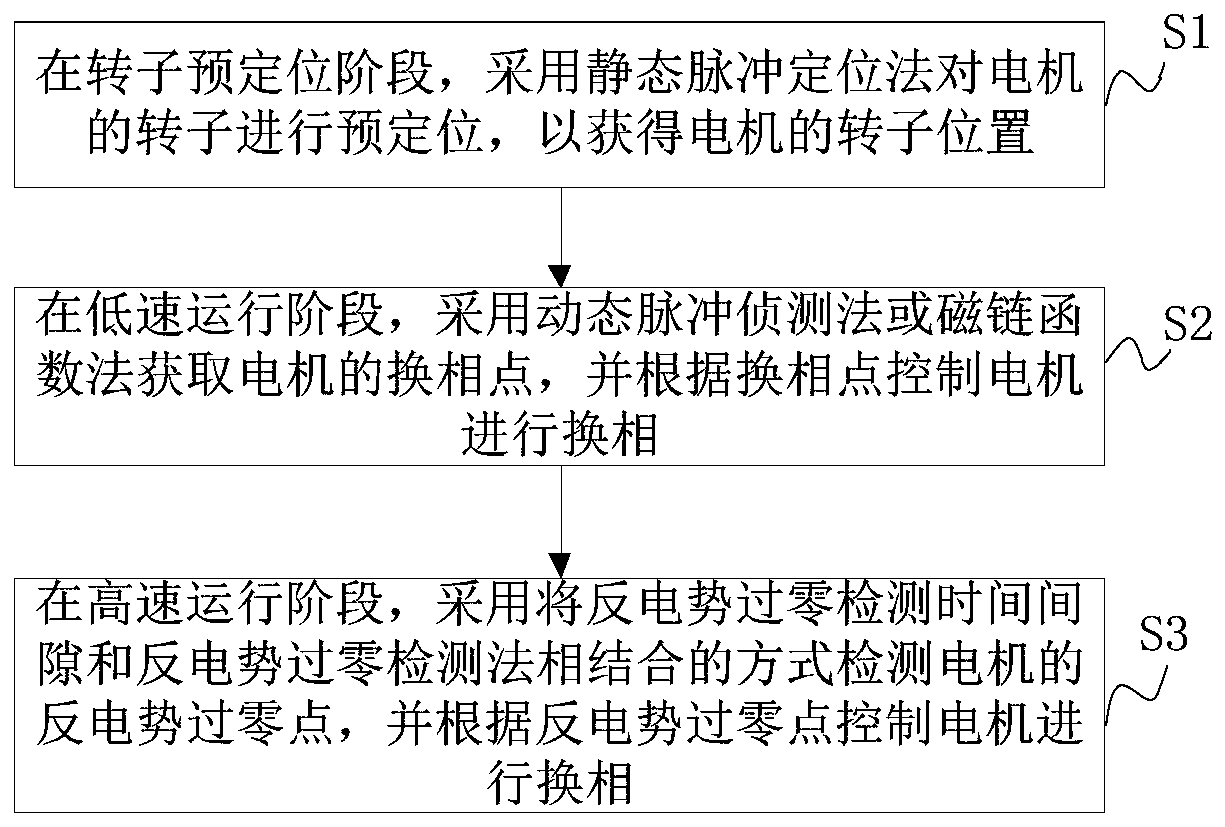

InactiveCN111384880ARun accuratelyGuaranteed uptimeElectronic commutation motor controlElectric motor controlDC - Direct currentElectric machine

The invention discloses a control method, device and system for a dust collector and a brushless direct current motor, and the method comprises that: in a rotor pre-positioning stage, the pre-positioning of a rotor of the motor is performed through employing a static pulse positioning method so as to obtain the position of the rotor of the motor; in a low-speed operation stage, a dynamic pulse detection method or a flux linkage function method is adopted to obtain a commutation point of the motor, and the motor is controlled to perform commutation according to the commutation point; and in themedium-high speed operation stage, the counter potential zero-crossing point of the motor is detected in a mode of combining the counter potential zero-crossing detection time interval and the counter potential zero-crossing detection method, and the motor is controlled to perform phase commutation according to the counter potential zero-crossing point. Therefore, the starting and positioning time of the motor can be greatly reduced, the motor is ensured not to rotate reversely during starting, abnormal sound and jitter during positioning are solved, accurate commutation of the motor in a low-speed operation stage can be realized, the reliability is high, a counter electromotive force zero-crossing point can be timely and accurately detected, and the motor is ensured to stably operate atan extremely high rotating speed.

Owner:JIANGSU MIDEA CLEANING APPLIANCES +1

Dry-type transformer low-voltage coil winding die

PendingCN111192759AAvoid quality problems of abnormal noiseIncrease production costInductances/transformers/magnets manufactureTransformerClassical mechanics

The invention discloses a dry-type transformer low-voltage coil winding die which comprises a connecting plate, an upper inner die, a lower inner die and bolts, an upper die steel plate is bent into 3-10 continuous arc surfaces, and the adjacent arc surfaces are tangent; the arc surfaces on the two sides of the lower inner die are composed of 2-5 sections of arc surfaces, and the adjacent arc surfaces are tangent; and the upper inner die and the lower inner die are connected into a columnar whole by bolts through the connecting plate. The problems that according to a traditional long circulardry-type transformer foil type low-voltage coil winding mold, a coil cannot be wound tightly, abnormal sounds of coil loads are prone to being caused, mold deformation is prone to being caused by long-term shaping of the mold, the thickness of coil foil is limited, large-capacity products are not facilitated, and the cost is reduced are solved.

Owner:BEIHAI YINHE TECH TRANSFORMER

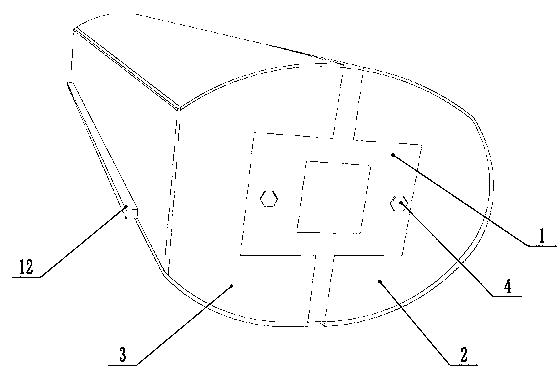

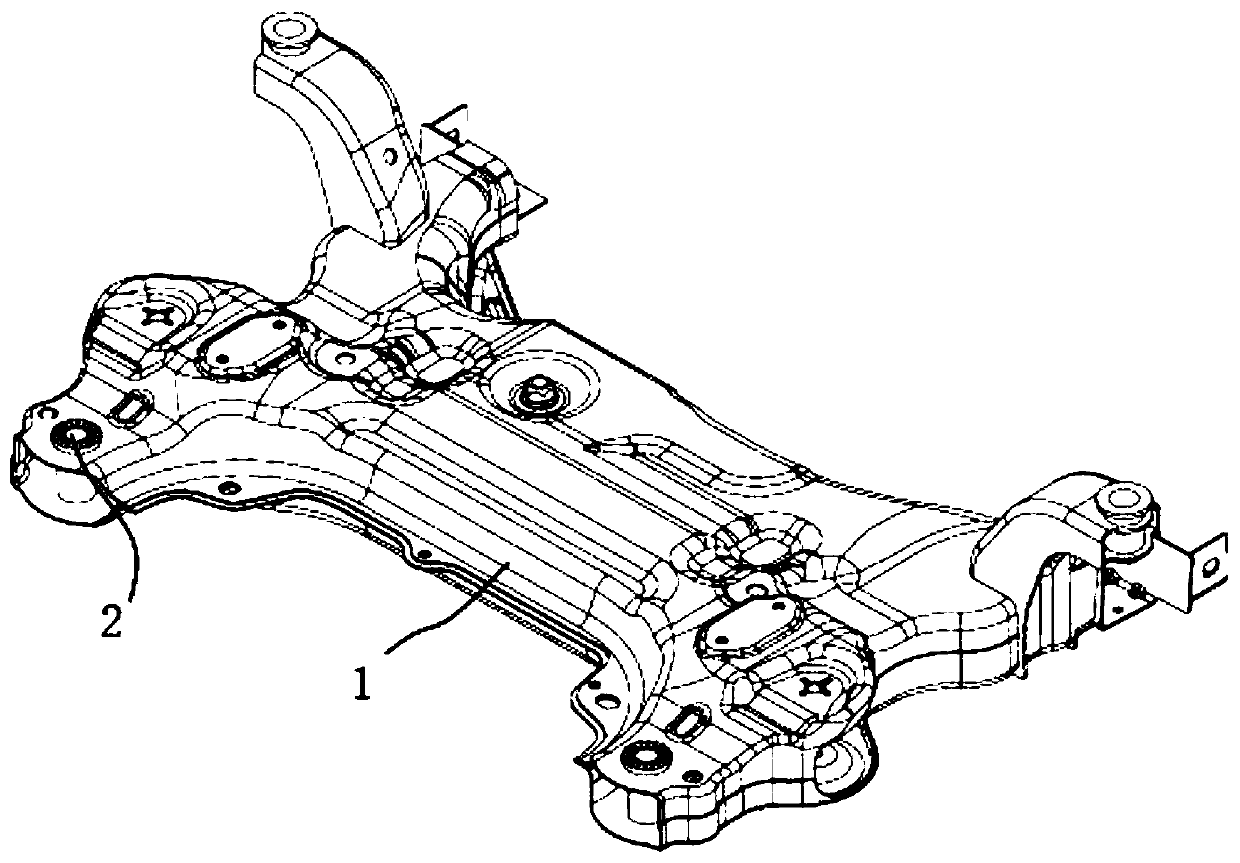

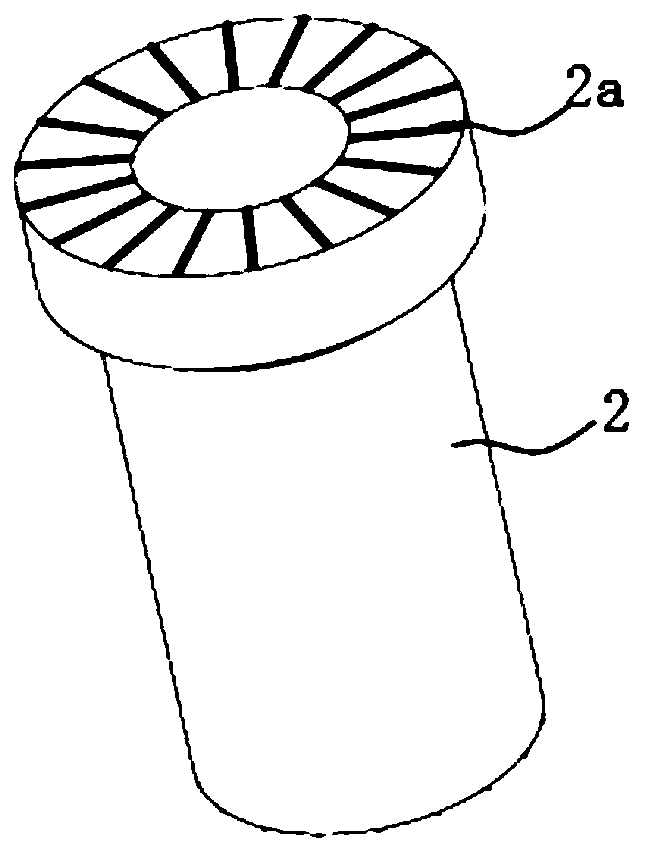

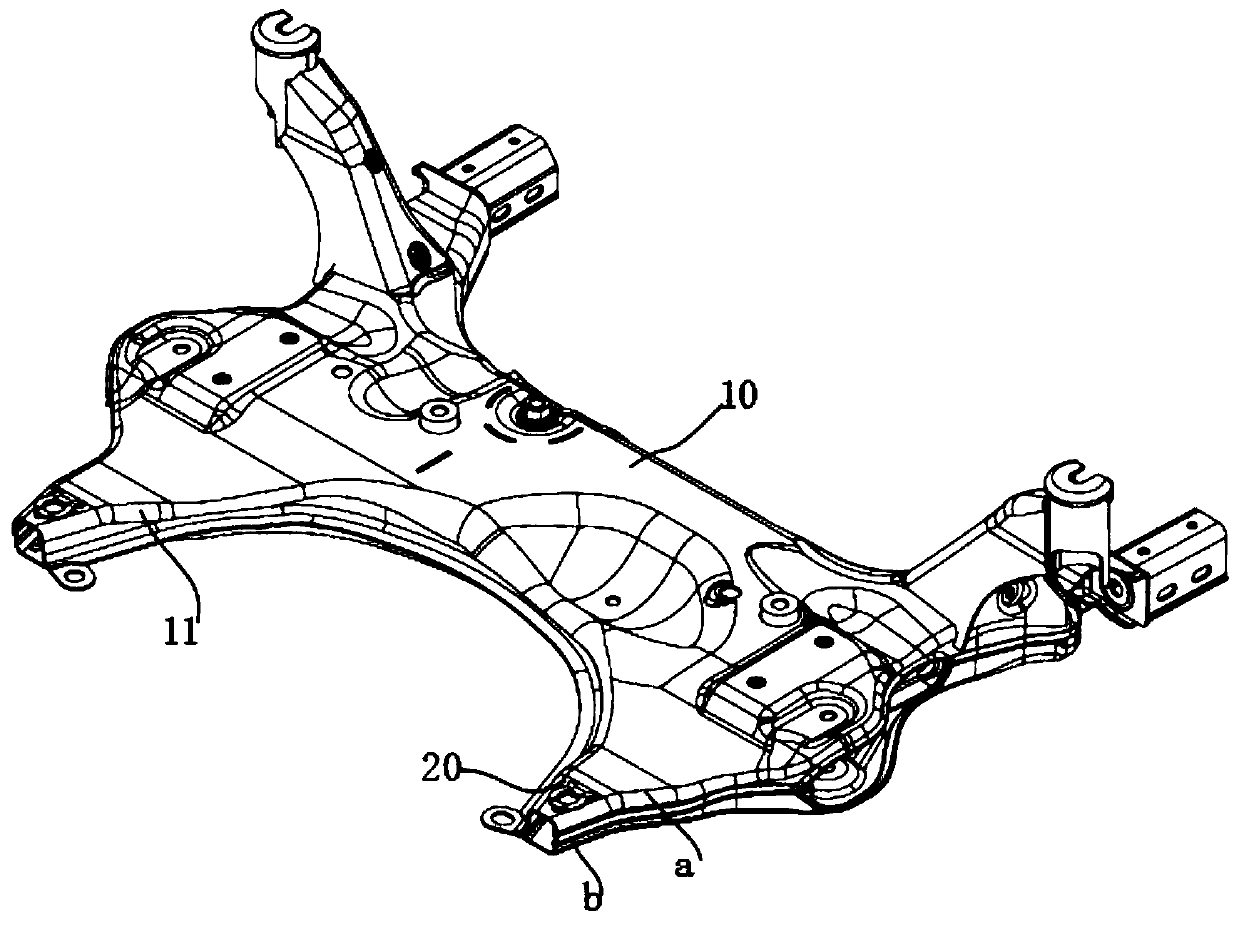

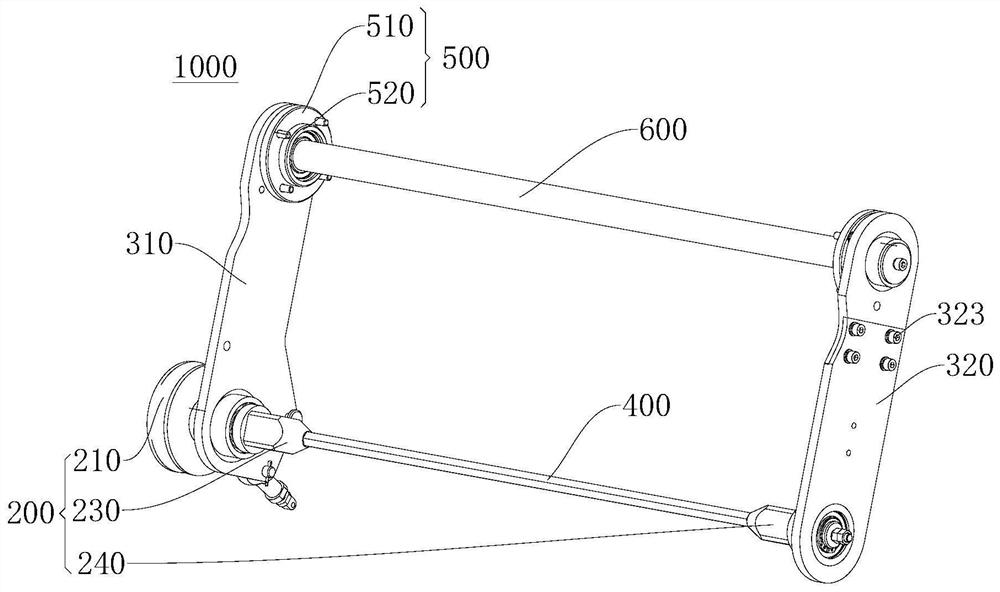

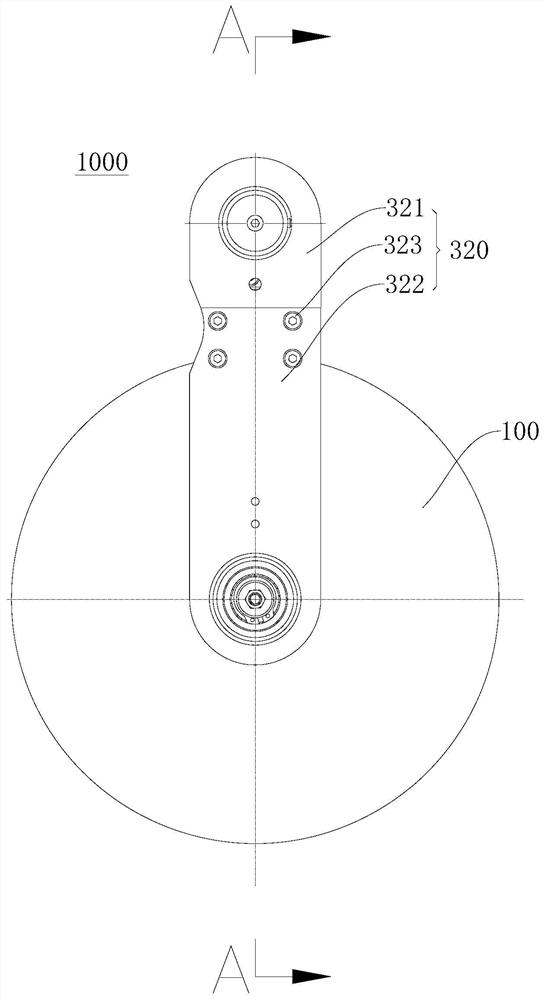

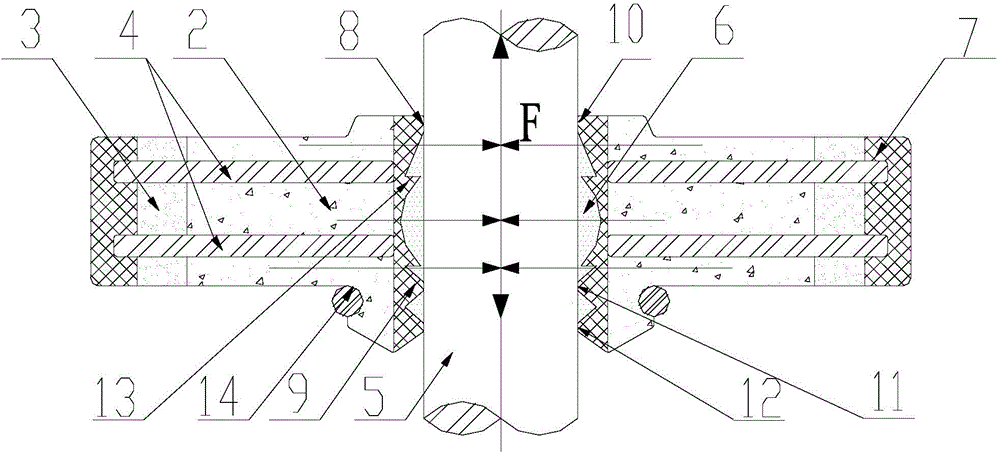

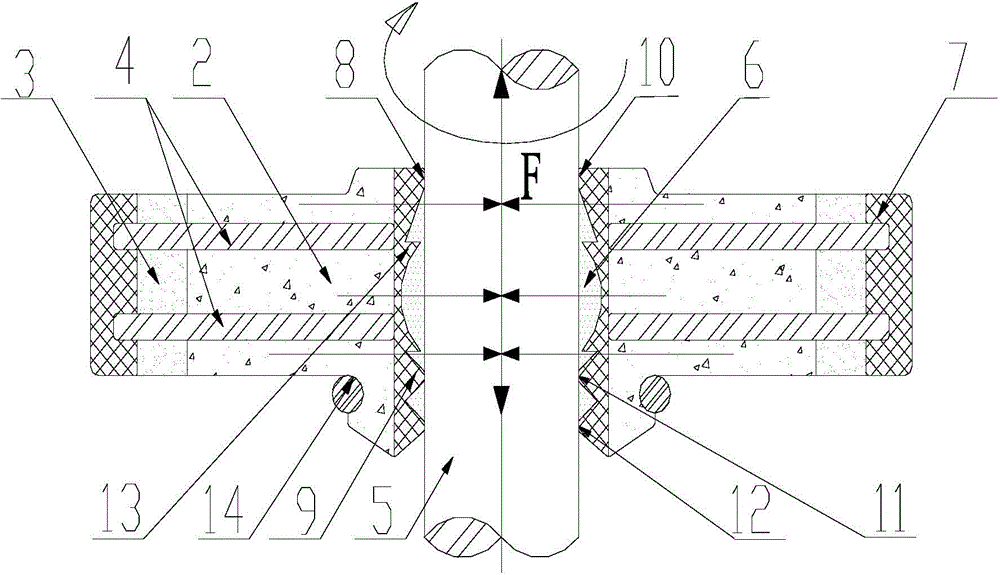

Auxiliary frame structure

The invention aims to provide an auxiliary frame structure capable of solving bolt slippage and abnormal sound and simple in structure. The auxiliary frame structure comprises an auxiliary frame body,wherein supporting arms are symmetrically arranged on the left side and the right side of the auxiliary frame body, ball gaskets are arranged on the supporting arms, the ball gaskets comprises gasketbodies fixedly connected with the supporting arms, steel balls are pressed and riveted on the gasket bodies, and the steel balls protrude out of the upper surfaces of the gasket bodies. In the scheme, after the gasket bodies are arranged on the supporting arms, the gasket bodies are tightly snapped with a vehicle body in a matched mode, and the steel balls, a vehicle body plate and an auxiliary frame upper plate are snapped together at higher pressure, so that the auxiliary frame does not generate slippage and abnormal sound under a large impact load relative to the vehicle body.

Owner:CHERY AUTOMOBILE CO LTD

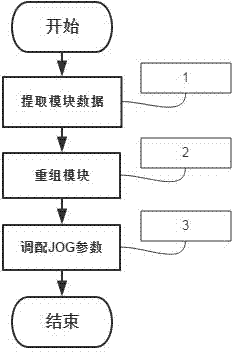

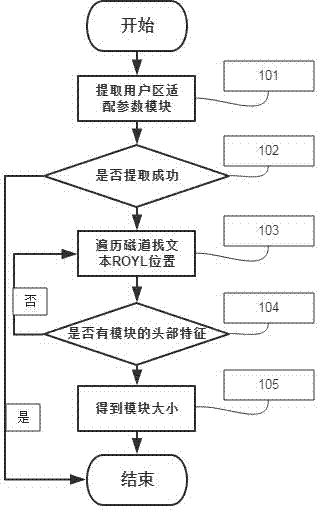

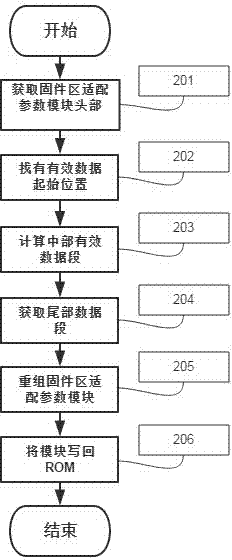

Method for repairing firmware region adaption parameter module of Western Digital hard disk

ActiveCN104731532AFix seek errorSolve knockingInput/output to record carriersComputer moduleData needs

The invention discloses a method for repairing a firmware region adaption parameter module of a Western Digital hard disk. The method comprises the steps that 1 data of a user region adaption parameter module of a breakdown hard disk are extracted; 2 the firmware region adaption parameter module is reassembled according to the data of the user region adaption parameter module; 3 a JOG adaption parameter is deployed. According to the method, data needed by the firmware region adaption parameter module can be found accurately, and the firmware region adaption parameter module is reassembled; a parameter of the firmware region adaption parameter module is adjusted, so that the aim of repairing the hard disk is achieved; the problems that the hard disk track seeking is wrong, the disk is knocked, the abnormal noise is occurred and a data region cannot be read and written are solved, and the problem that the adaption cannot be completely fit after repairing is not occurred.

Owner:XLY SALVATIONDATA TECHNOLOGY INC

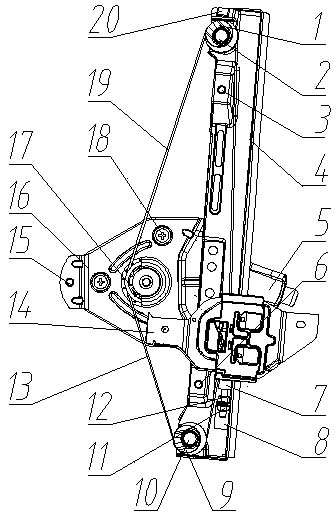

Window regulator with adjustable buffering block

The invention discloses a window regulator with an adjustable buffering block. A motor support of a motor is connected with an installing plate, a reel is installed on one side of the installing platethrough a reel rotating shaft, a guide rail support is arranged on one side of the motor support, a regulator upper fixing screw is arranged on the upper portion of the guide rail support, a regulator lower fixing screw is arranged on the lower portion of the guide rail support, a guide rail is arranged on the guide rail support, an upper guiding wheel is installed on one side of the upper end ofthe guide rail support, a lower guiding wheel is installed on one side of the lower end of the guide rail support, a sliding block is arranged on the guide rail on the guide rail support, a bottom dead center fixing support is arranged on one side of the lower guiding wheel, the bottom end of the adjustable buffering block is inserted into a fixing rack of the bottom dead center fixing support and fixed through a locking nut and an adjusting nut, the sliding block moves to the lower portion and then presses the adjustable buffering block, and an upper steel wire rope and a lower steel wire rope are wound around the reel separately and penetrate through the upper guiding wheel and the lower guiding wheel respectively to be connected with the sliding block. The problem is solved that a buffering block is easily abraded; the adjustable buffering block can effectively compensate for the abrasion of the buffering block.

Owner:周启城

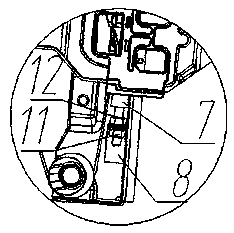

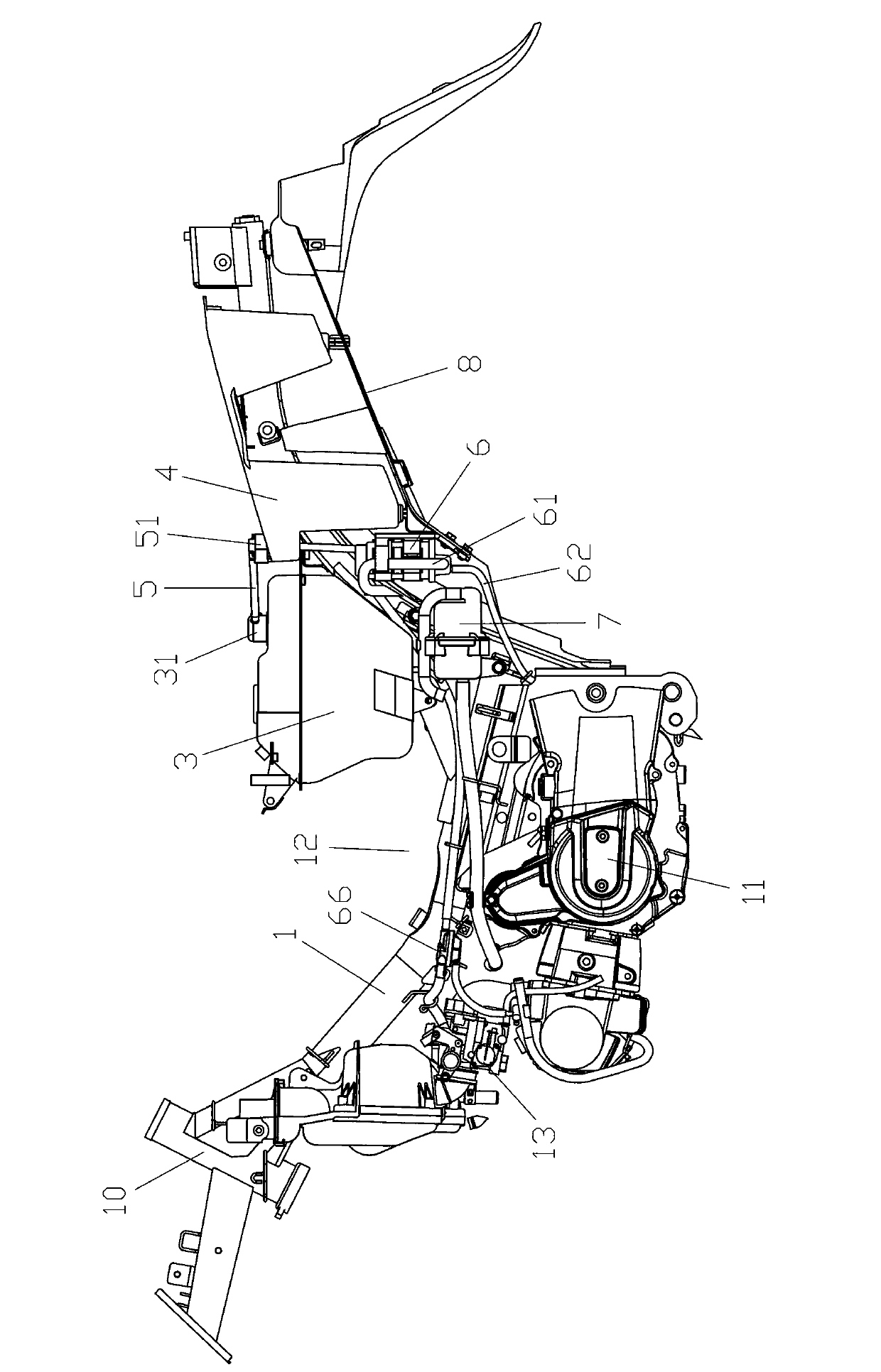

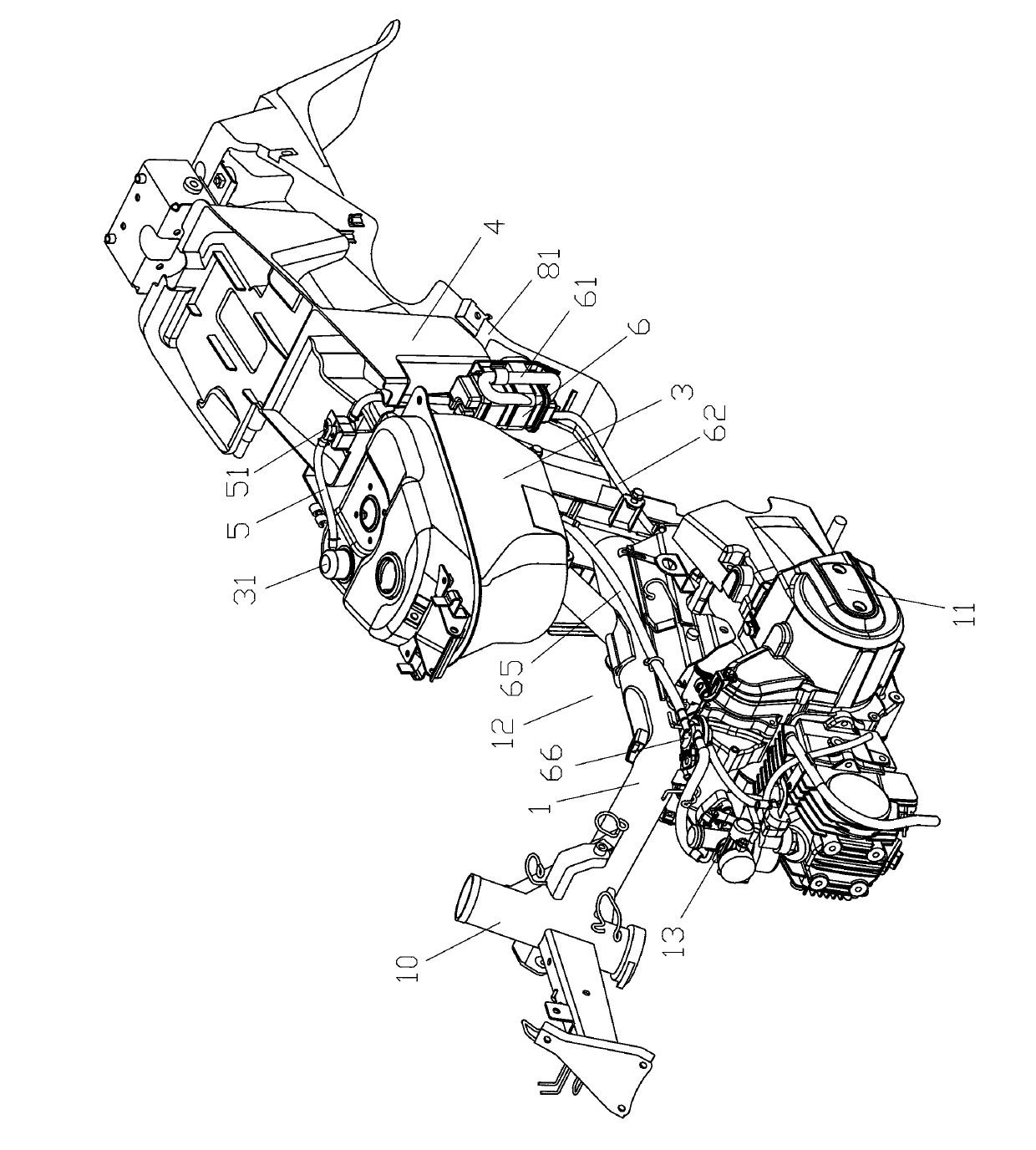

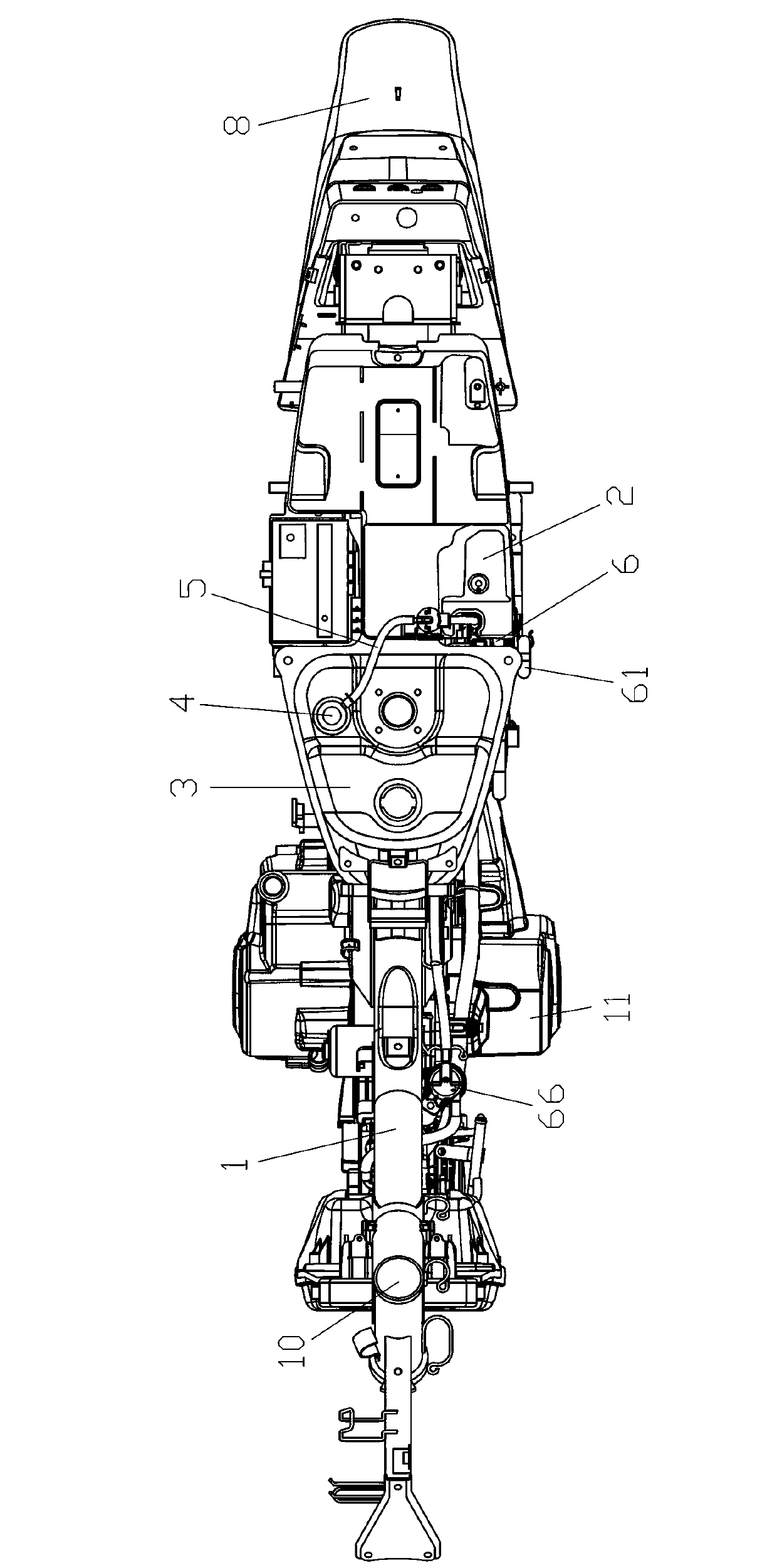

Fuel evaporation configuration structure of straddle type motorized cart

ActiveCN103121483AAvoid interferenceEasy to installFuel tanksCycle containersVehicle frameEvaporation

The invention discloses a fuel evaporation configuration structure of a straddle type motorized cart. The fuel evaporation configuration structure of the straddle type motorized cart comprises a head tube, a main cart frame, and a back cart frame, a concave-shaped straddle part which facilitates riders to stride a cart body in one foot is formed between the main cart frame and the back cart frame, a fuel tank which is at least partly overlapped with the concave-shaped straddle part and a tool box on the back position of the fuel box are arranged on the back cart frame, the fuel tank and the tool box are arranged below a cart seat, an oil-gas separator on the fuel tank is connected with a carbon tank through an absorption tube, the back cart frame is a single beam which an independent cart frame stretches to a back top position, the carbon tank is arranged inside space between the fuel tank and the tool box of the cart body, the carbon tank is vertically arranged, and at least partial carbon tank is overlapped with the fuel tank when the cart is overlooked. The fuel evaporation configuration structure of the straddle type motorized cart ensures capacity of the fuel tank and the tool box and compact cart body. Additional protective components are unnecessary due to the fact that the carbon tank is protected by the fuel tank, the tool box, and a cart body cover.

Owner:JIANGMEN DACHANGJIANG GROUP CO LTD

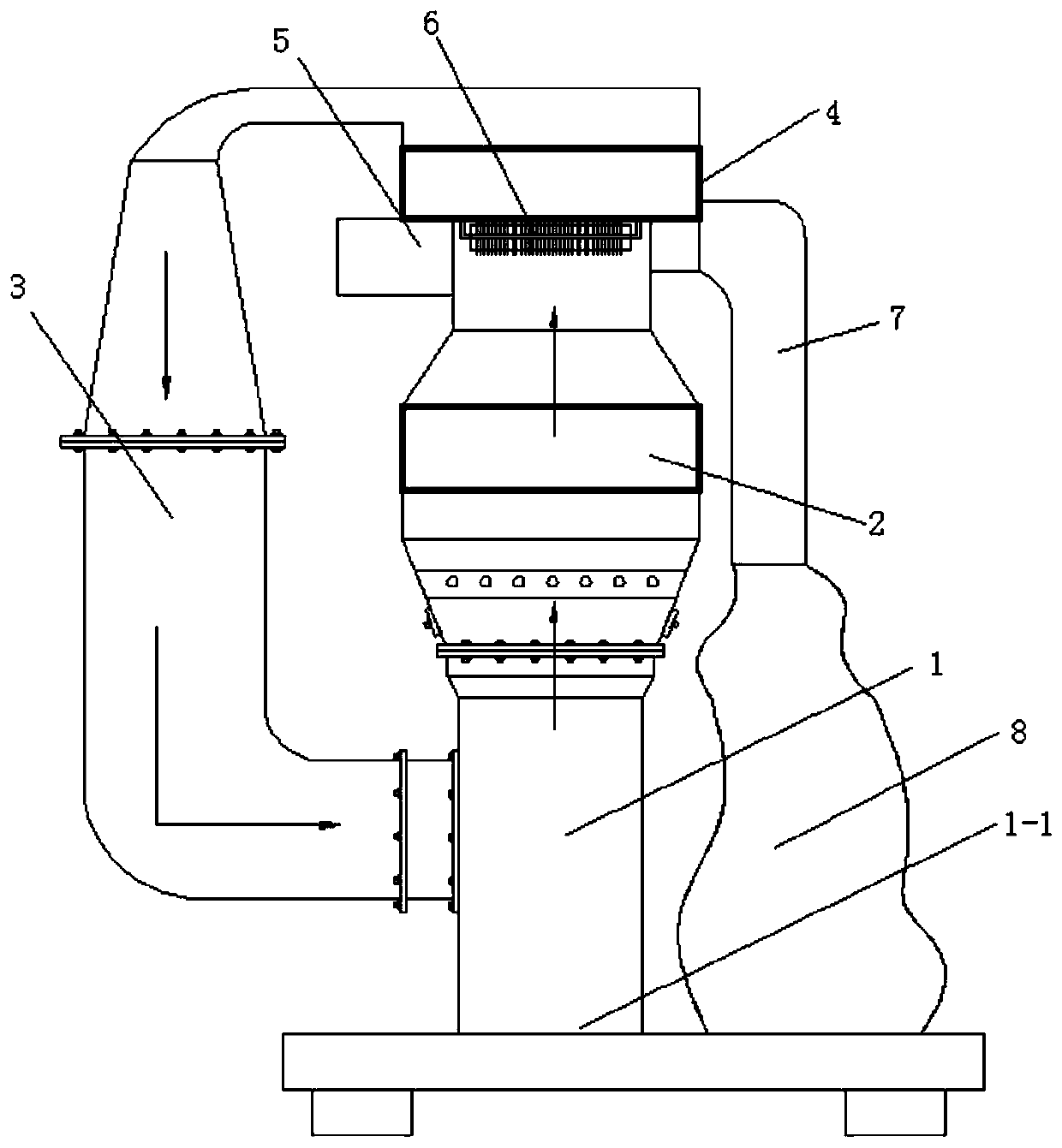

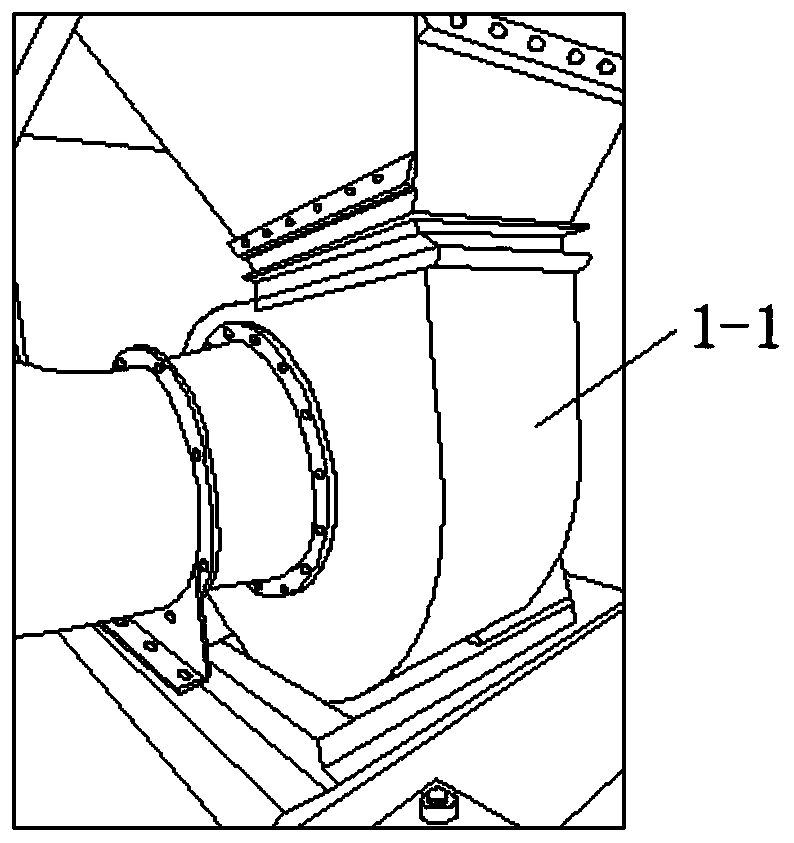

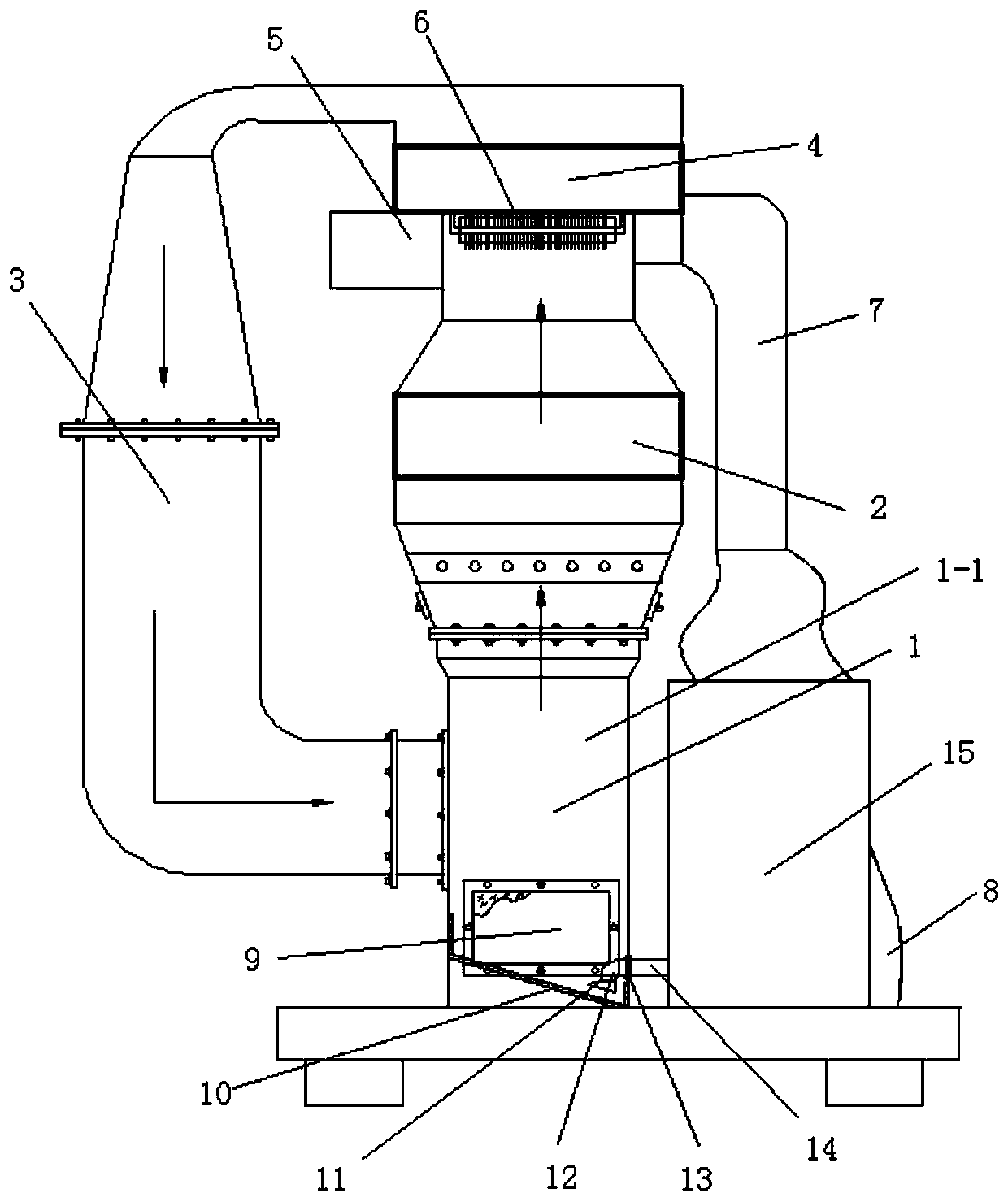

Anti-blocking suction device of winnowing and impurity removal equipment of stem screening line

PendingCN111359885ASolve the blockageSolve abnormal noiseTobacco preparationGas current separationProcess engineeringNylon mesh

The invention provides an anti-blocking suction device of winnowing and impurity removing equipment of a stem screening line. The anti-blocking suction device comprises an impurity removal fan, a nylon-net cut-stem conveying line, a wind power circulation loop, a nylon-net impurity conveying belt, a blowing fan, a roller brush, an impurity discharging channel and an impurity collecting cloth bag;an observation window is formed in the lower part of a fan box body of the impurity removal fan; a material guide plate for obliquely collecting materials is mounted at the bottom in the fan box body;a cut stem suction cover is arranged above the lowest part of the material guide plate; the cut stem suction cover communicates with the tail end of a pipe opening of a dust suction pipe, extending into the fan box body, of a dust collector through a 90-degree elbow; and the dust collector is arranged on the outer side of the fan box body and is connected with a platform frame body of the fan boxbody into a whole. According to the device, the problems of cut stem accumulation blockage and suction discharging in the fan box body are effectively solved; the device is simple in structure, easyto implement, reliable in sealing and convenient to disassemble; cut stems accumulated in the box body can be subjected to suction discharging in a centralized and timely manner; and the device is economical, practical, labor-saving, efficient and reliable.

Owner:CHINA TOBACCO SHAANXI IND

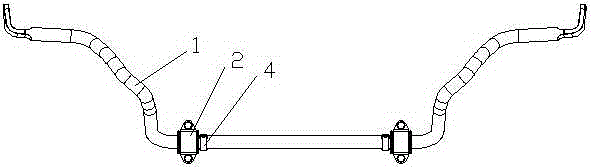

Transverse stabilization bar mounting structure used for vehicle

The invention discloses a transverse stabilization bar mounting structure used for a vehicle. A transverse stylization bar is fixedly installed on an auxiliary frame assembly through two pressing plates which are spaced for a certain distance, and a rubber bushing is arranged between each pressing plate and the transverse stylization bar. Two limiting clamping hoops are fixedly arranged on the transverse stylization bar. A politef fiber cloth layer is arranged on the inner wall of each rubber bushing. An opening communicating the outer wall with the inner wall is formed in the axial direction of each rubber bushing. According to the transverse stabilization bar mounting structure, politef fiber cloth is added to the inner walls of the rubber bushings, friction force between the stylization bar and the rubber bushings is lowered, the problem that in the running process of the vehicle, rubber bushings of a stabilization bar have abnormal sound and are excessively large in retarding force due to twist motion of the stabilization bar is well solved, the problem of wearing and failure of the rubber bushings is improved, and the reliability and durability of the rubber bushings are enhanced.

Owner:力帆科技(集团)股份有限公司

Cleaning device

The invention discloses cleaning equipment. The cleaning equipment comprises a rolling brush, and a shaft hole penetrating through the rolling brush in the axial direction is formed in the middle of the rolling brush; the cleaning equipment further comprises a driving assembly which comprises a driving part, a flexible belt, a driving shaft and a driven shaft, the driving shaft and the driven shaft are inserted into the two ends of the shaft hole of the rolling brush respectively, shaft shoulders are arranged on the driving shaft and the driven shaft, and the driving part and the driving shaft are in transmission connection through the flexible belt; the cleaning equipment further comprises a rack which comprises a shell, a first swing arm and a second swing arm, the rolling brush is located in the shell, the first swing arm and the second swing arm are located at the two axial ends of the rolling brush, one end of the first swing arm and one end of the second swing arm are rotationally connected with the shell, and the driving shaft and the driven shaft are rotationally connected with the other end of the first swing arm and the other end of the second swing arm respectively; the cleaning equipment further comprises a tensioning piece which is located in the shaft hole, and the two ends of the tensioning piece are connected with the driving shaft and the driven shaft correspondingly, so that shaft shoulders of the driving shaft and the driven shaft abut against the two axial end faces of the rolling brush correspondingly. According to the cleaning equipment, the driving shaft and the driven shaft can be tensioned through the tensioning piece.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Voice coil motor, camera module and electronic equipment

PendingCN114488459AEasy to useSolve abnormal noiseMountingsPropulsion systemsCamera moduleMechanical engineering

The invention provides a voice coil motor, a camera module and an electronic device. The voice coil motor comprises a base (110); the sliding rail assembly is arranged in the front-back direction; the movable seat (120) is used for bearing a first lens and is arranged on the base (110) in a sliding manner through the sliding rail assembly; the first electromagnetic driving assembly (130) and the second electromagnetic driving assembly (140) are used for providing driving force for the movable seat (120) so as to drive the movable seat (120) to slide in the front-back direction relative to the base (110); the first electromagnetic driving assembly (130) and the second electromagnetic driving assembly (140) are arranged on the two sides of the sliding rail assembly respectively. According to the voice coil motor, the structure of the voice coil motor is improved, so that the voice coil motor has a large stroke, and the use requirements of long-focus shooting and macro shooting can be met at the same time.

Owner:HUAWEI TECH CO LTD

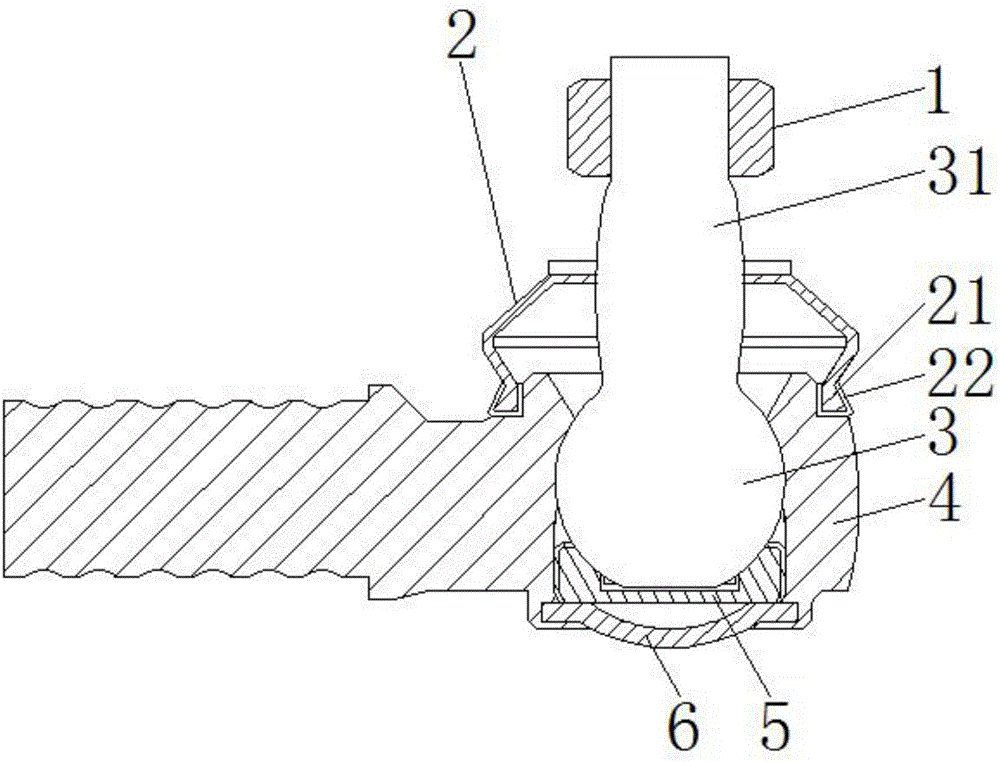

Novel automobile steering pull rod assembly

The invention discloses a novel automobile steering pull rod assembly. The novel automobile steering pull rod assembly comprises a nut, a dustproof cover, a riveting head, a mounting groove, a ball stud, a connecting part, a connector shell, a ball seat and a rear cover, wherein a thread is arranged at the top of the connecting part; the nut is connected with the connecting part; the bottom of the connecting part is connected with the ball stud; the connector shell is internally provided with a containing cavity; the ball stud is arranged in the containing cavity; the bottom of the ball stud is connected with the ball seat; the rear cover is arranged at the bottom of the ball seat; the mounting groove is formed in the top of the connector shell; the riveting head is arranged in the mounting groove. The novel automobile steering pull rod assembly disclosed by the invention is mainly composed of the connector shell, the ball stud, the ball seat, the rear dover, the dustproof cover, the nut and the like, and upper and lower steel ball bowls and a spring in a traditional automobile steering pull rod assembly are cancelled, so that the size is reduced, and friction of a ball head and the steel ball bowls in the previous time is eliminated; axial deformation of the ball stud is reduced after the spring is compressed in the previous time; the problems of loosening and abnormal sounds are solved and the service life is prolonged.

Owner:HUBEI WANLIANDA AUTO PARTS

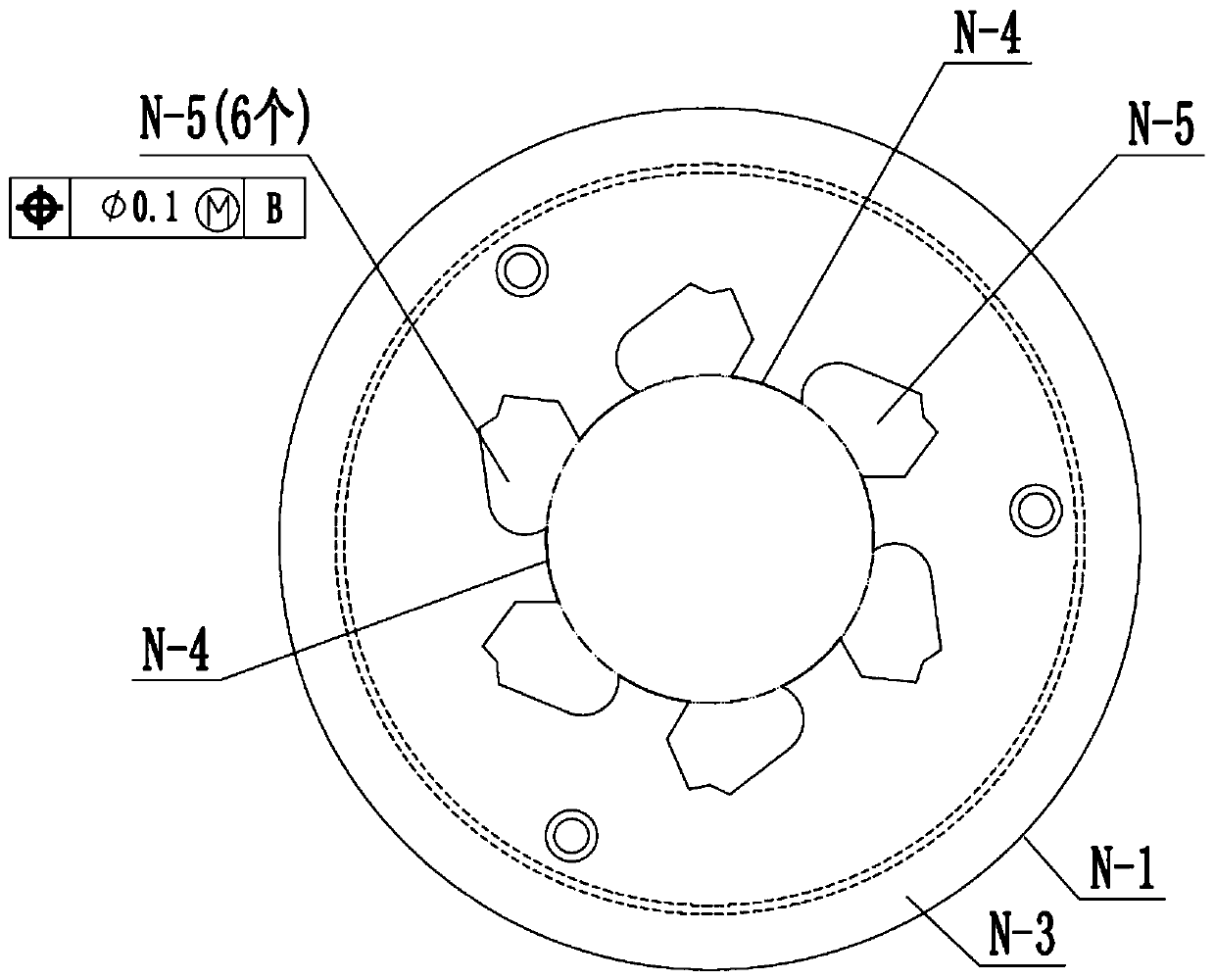

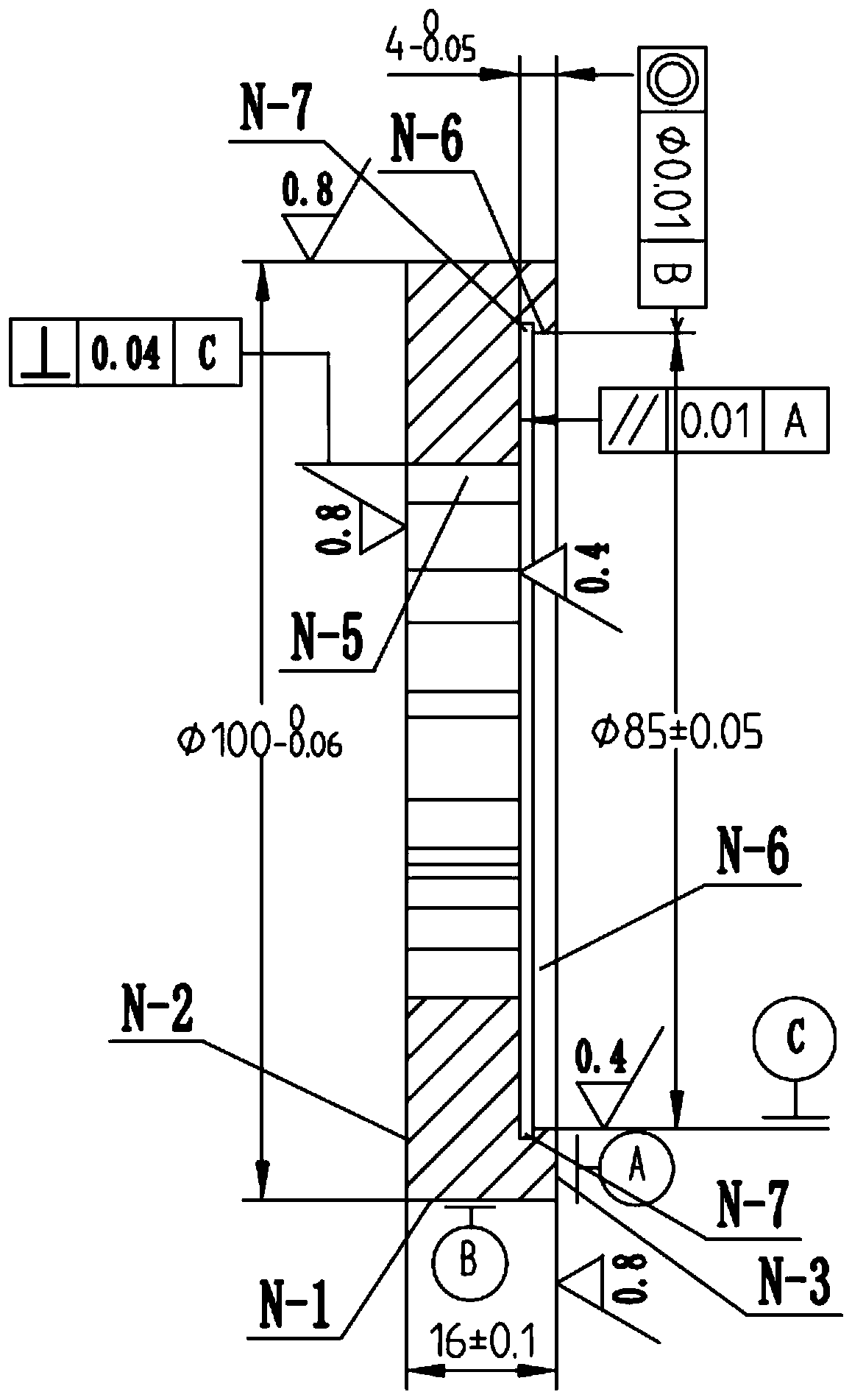

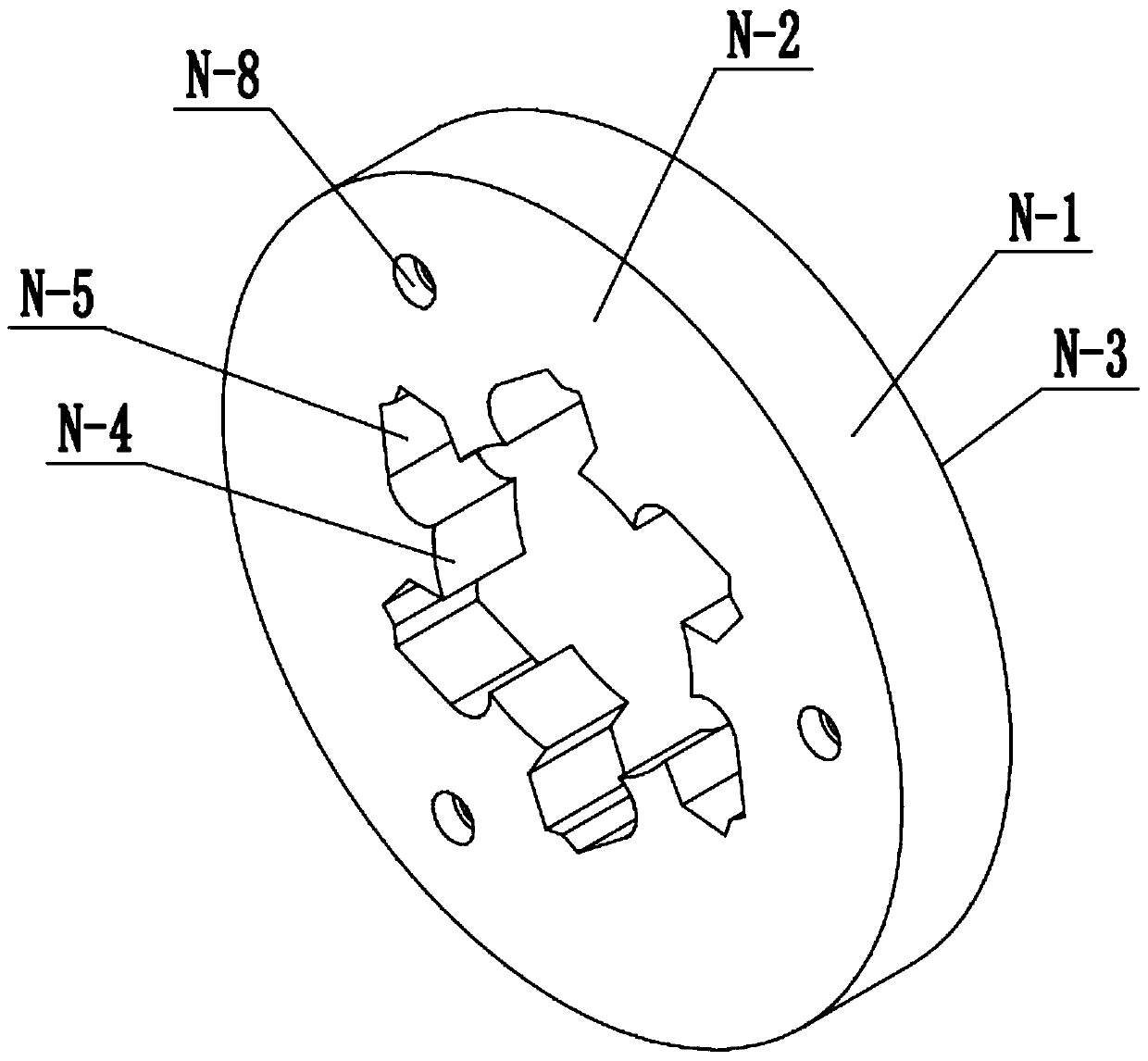

Processing process method for outer ring

The invention discloses a processing process method for an outer ring which adopts a 20Cr material. The processing process method is characterized by comprising the following steps: S10, forging to obtain blank; S2, roughly turning an outer circle, a first end surface, a second end surface and an inner hole in sequence; S30, broaching grooves; S40, extruding the grooves; S50, cleaning cuttings andgreasy dirt on the surface of a part; S60, finely turning the inner hole, the first end surface, the outer circle, a settling table, a tool withdrawal groove and a second end surface in sequence, wherein machining allowance is required to leave for the diameter and the depth of the settling table; S70, inspecting a dimension; S80, filing and extruding mouth edges of the grooves to remove burrs; S90, drilling; S100, performing thermal treatment; S110, performing thermal treatment inspection; S120, performing shot blasting; S130, finely turning the settling table; S140, cleaning and preventingrust; and S150, inspecting and warehousing. The processing process method can be used for outer ring manufacturing and processing, and can be used for solving the technical problem that a short service life and abnormal sound are easily caused by insufficient roughness and precision of grooves of the outer ring.

Owner:重庆申耀机械工业有限责任公司

Connecting structure for backrest rotating shaft and automobile body of automobile rear-row seat

PendingCN112721760ASimplify the assembly processEasy to assembleBack restsDismountable/non-dismountable seatsControl theoryMechanical engineering

The invention discloses a connecting structure for a backrest rotating shaft and an automobile body of an automobile rear-row seat. The connecting structure comprises a backrest framework and the automobile body connected with the backrest framework. A spring rotating shaft is arranged on one side of the backrest framework, and a spring rotating shaft mounting metal plate matched with the spring rotating shaft is arranged at the position, corresponding to the spring rotating shaft, of the automobile body; a step rotating shaft is arranged on the other side of the backrest framework, and a step rotating shaft installation support assembly matched with the step rotating shaft is arranged at the position, corresponding to the step rotating shaft, of the vehicle body. The seat backrests are installed independently and do not influence each other, the whole assembly process is simple and convenient, the manufacturing tolerance of the seat and a vehicle body is absorbed through the spring rotating shafts, meanwhile, force is applied to the seat backrests for restraining, the abnormal sound problem of the seat backrest rotating shafts due to up-down jumping and left-right shaking of the seat can be effectively avoided, and the service life of the seat is prolonged. And the seat has excellent quality performance.

Owner:东风延锋汽车座椅有限公司

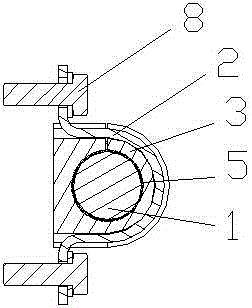

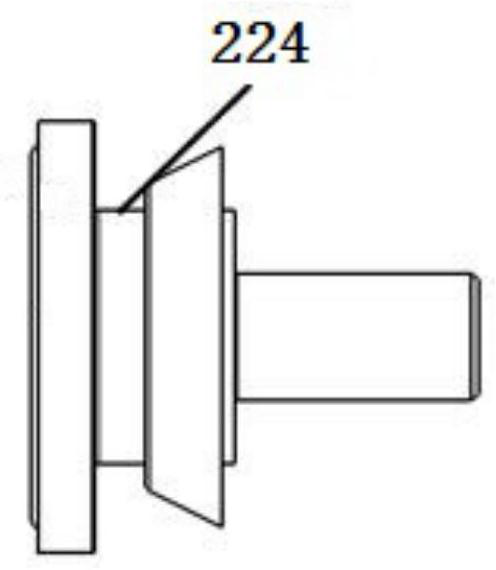

Stabilizer bar bushing structure of motor vehicle

InactiveCN102941790AExtended service lifeSolve abnormal noiseInterconnection systemsFrictional coefficientEngineering

The invention provides a stabilizer bar bushing structure of a motor vehicle, which is applied in the technical field of stabilizer bars of motor vehicles. The stabilizer bar bushing structure of the motor vehicle comprises a bushing structure body (1) and an internal bushing (2), wherein the bushing structure body (1) and the internal bushing (2) are connected through a rubber layer (3); and the internal bushing (2) is fixedly connected with the rubber layer (3). In the stabilizer bar bushing structure of the motor vehicle, the internal bushing is mounted on a perforation of the rubber layer and the rubber layer is mounted on the stabilizer bar bushing structure body, so that in the driving process of the motor vehicle, the stabilizer bar twists in the bushing structure continuously; in the twisting process of the stabilizer bar, the stabilizer rod is contacted with the internal Teflon bushing; and the internal bushing is made of the Teflon bushing material which has high rub resistance and low friction coefficient, so that the problem of abnormal sound caused by friction of the stabilizer bar and the rubber layer of the conventional bushing structure is effectively solved and the service life of the stabilizer bar bushing is prolonged.

Owner:ANHUI YUFENG AUTOMOTIVE TECH

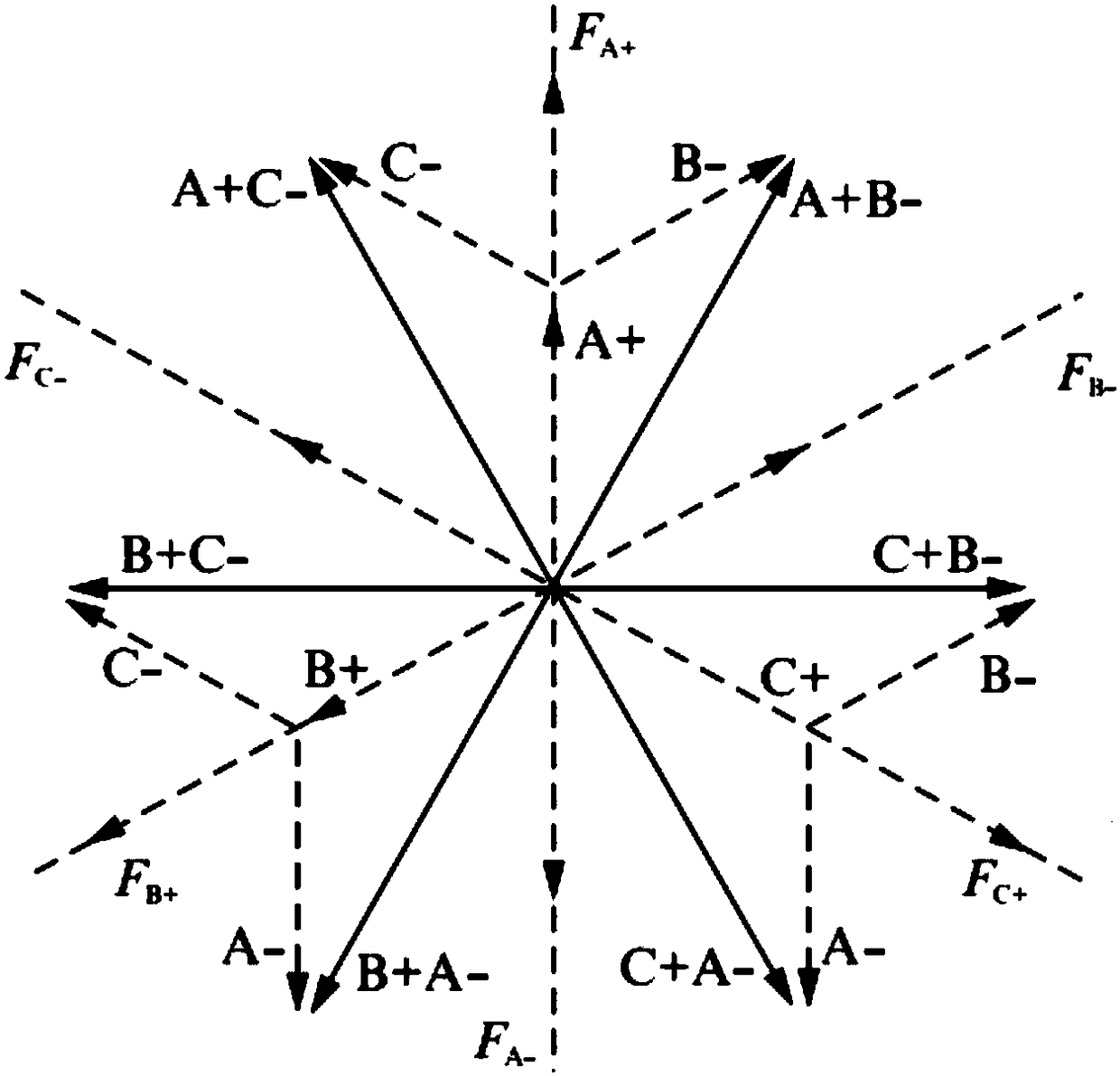

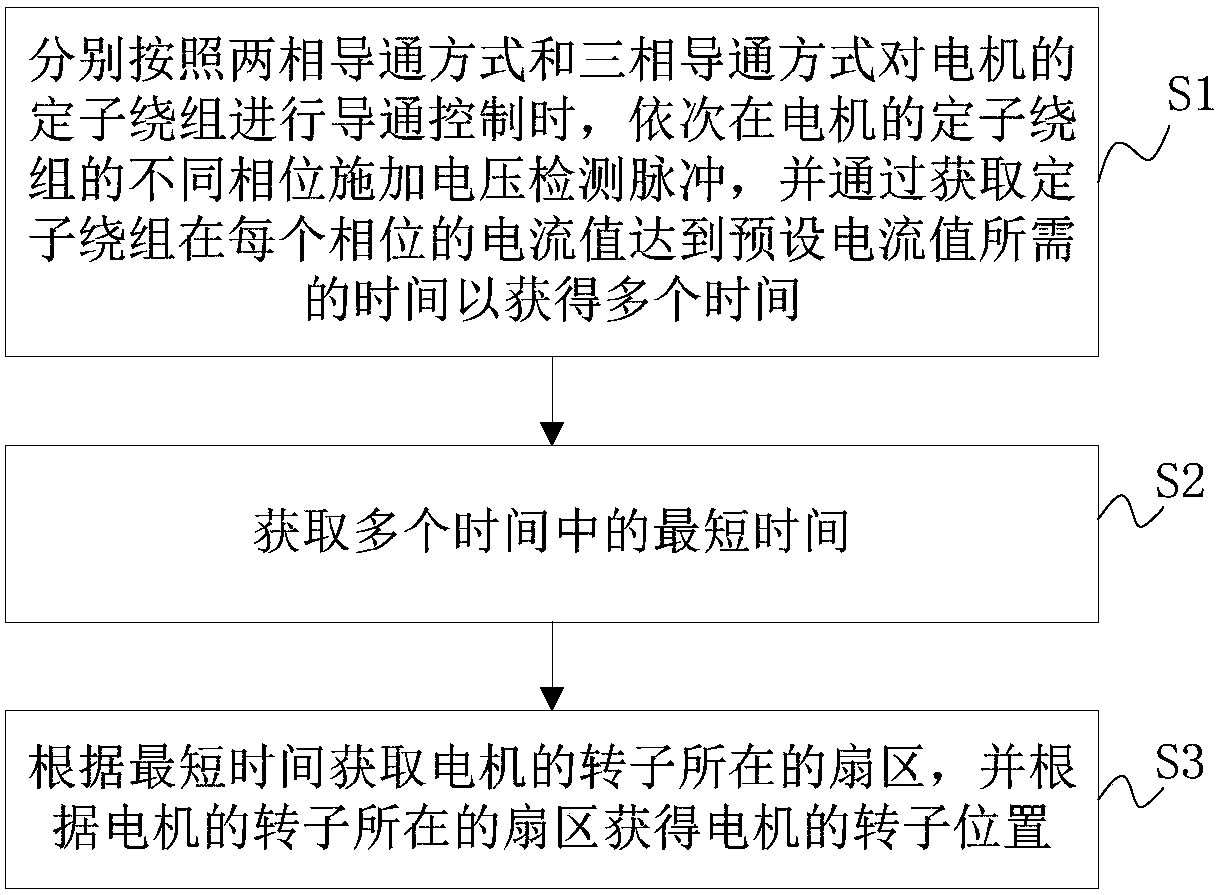

Rotor positioning method, rotor positioning device and control system of brushless direct current motor

ActiveCN108448951AShorten the timeWill not reverseElectronic commutatorsStarter arrangementsControl systemThree-phase

The invention discloses a rotor positioning method, a rotor positioning device and a control system of a brushless direct current motor. The positioning method comprises the following steps: when conduction control is carried out on a stator winding of the motor according to a two-phase conduction mode and a three-phase conduction mode respectively, applying voltage detection pulses at different phase positions of the stator winding of the motor in sequence, and reaching the time required for a preset current value to obtain multiple time by obtaining the current value of the stator winding ateach phase position; obtaining the shortest time in the multiple time; obtaining the section of the rotor of the motor according to the shortest time, and obtaining the rotor position of the motor according to the section of the rotor of the motor. Therefore, the rotor position of the motor can be obtained quickly and accurately, the problems of abnormal sound, shaking and positioning mistakes cannot appear, and the method is simple and can realize non-blind area positioning.

Owner:JIANGSU MIDEA CLEANING APPLIANCES +1

Low-shrinkage HIPS composite material for solving abnormal sound, and preparation method thereof

The invention discloses a low-shrinkage HIPS composite material for solving abnormal sound, and a preparation method thereof. The material comprises, by weight, 60-80 parts of HIPS resin, 3-10 parts of a rubber composite material, 8-20 parts of a reinforcing agent, 3-10 parts of a blocking agent, 0.3-1.5 parts of a weather-proof agent, 0.1-0.6 part of an antioxidant and 0.1-0.6 part of a lubricant. The material not only has excellent strength, toughness and dimensional stability, but also can play a role in vibration and noise reduction, can solve the common abnormal sound problem of current household appliances and improve the living environment of people, and is low in comprehensive cost and wide in application range.

Owner:合肥圆融新材料有限公司

Self-healing sealing device based on mangneto deformation rubber

InactiveCN104482218ACompensation for Elastic Deterioration FailureAchieving Elastic Deterioration FailureEngine sealsSelf-healingEngineering

The invention discloses a self-healing sealing device based on mangneto deformation rubber. The self-healing sealing device at least comprises inner layer traditional rubber, first outer layer mangneto deformation rubber, second outer layer mangneto deformation rubber and an annular framework, wherein a radial magnetic field is added to the first outer layer mangneto deformation rubber, an axial magnetic field is added to the second outer layer mangneto deformation rubber, the annular framework is embedded inside the two pieces of mangneto deformation rubber and is used for maintaining the integral shape of the sealing device, the inner layer traditional rubber, the first outer layer mangneto deformation rubber and the second outer layer mangneto deformation rubber are respectively in an annular shape and are in coaxial radially attached arrangement, and a sealing cavity formed between the inner layer traditional rubber and a magnetic conduction body moving shaft is filled with lubricating grease. The self-healing sealing device can be used for similar reciprocating mechanisms such as high-speed-moving greater-pressure-difference high-speed rail trains or hanging shock absorbers of heavy locomotives, and similar rotating mechanisms such as helicopter rotors, rotating machinery and wind power generation equipment, the long-period dynamic sealing or static sealing can be realized, good self-healing functions are realized, and in addition, the relatively simple structure is adopted, so that the stability and the durability of the sealing device are improved.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com