Cleaning device

A technology for cleaning equipment and driving shafts, which is applied in the field of cleaning and can solve the problems of increased clearance between the roller brush and the shaft shoulders at both ends, axial movement of the roller brush, and time-consuming replacement of the roller brush.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

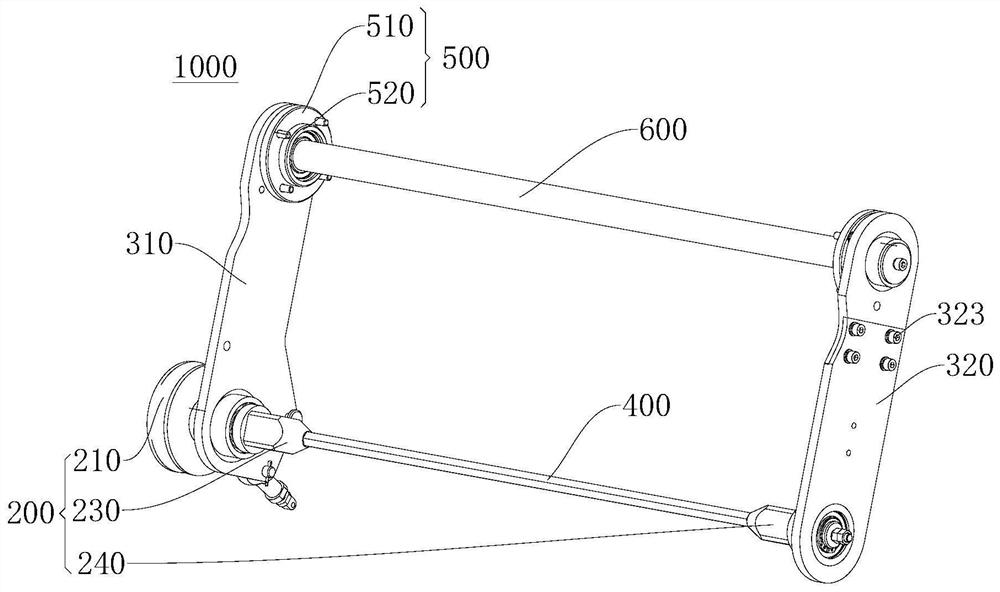

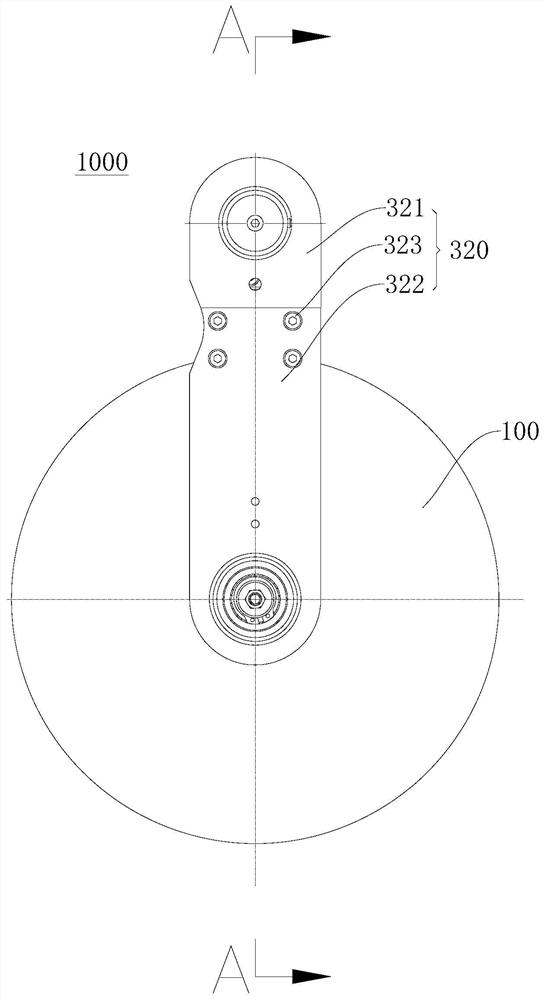

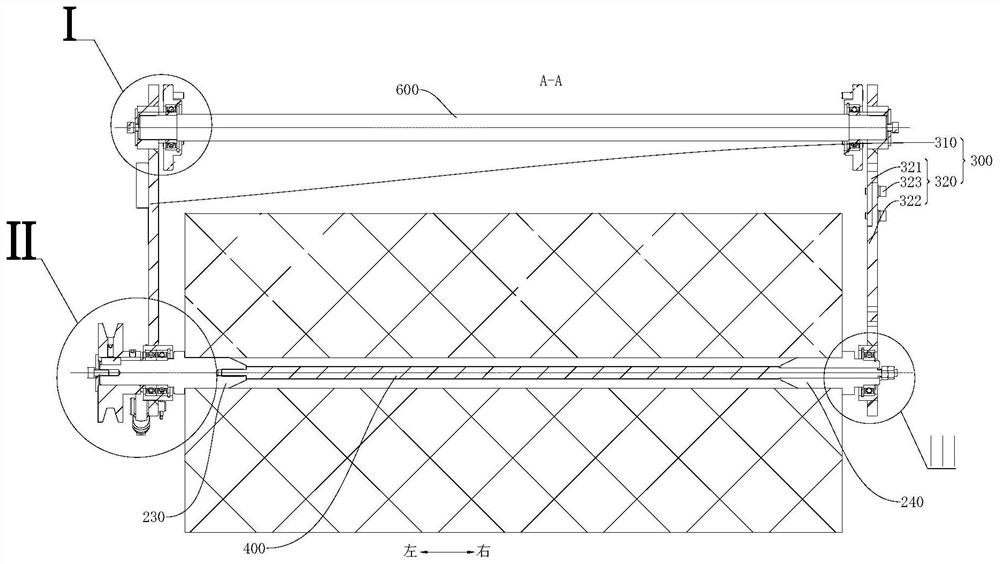

[0041] Refer below Figure 1-Figure 12 A cleaning device 1000 according to an embodiment of the present invention is described. The cleaning equipment 1000 aims to solve the time-consuming and laborious replacement and disassembly of the roller brush 100 during use, and the axial movement of the roller brush 100 caused by the side-mounted bending moment of the transmission belt during the rotation of the roller brush 100, which causes large abnormal noise and wear. exacerbated problem.

[0042] The cleaning device 1000 according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com