Connecting structure for backrest rotating shaft and automobile body of automobile rear-row seat

A rear seat and connection structure technology, which is applied to vehicle seats, back cushions, special positions of vehicles, etc., can solve problems such as backrest bounce, backrest shafts prone to abnormal noise, backrest installation difficulties, etc., to avoid abnormalities No noise problem, excellent quality performance, simple assembly process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with specific embodiments. This invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete and will fully convey the concept of the invention to those skilled in the art, and the present invention will only be defined by the appended claims.

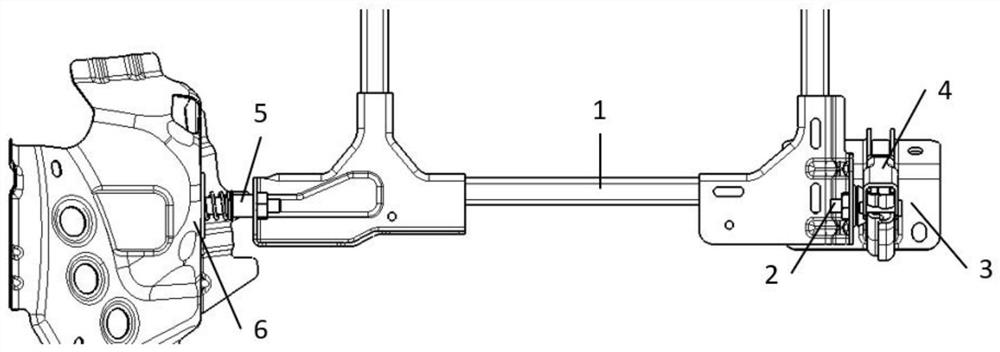

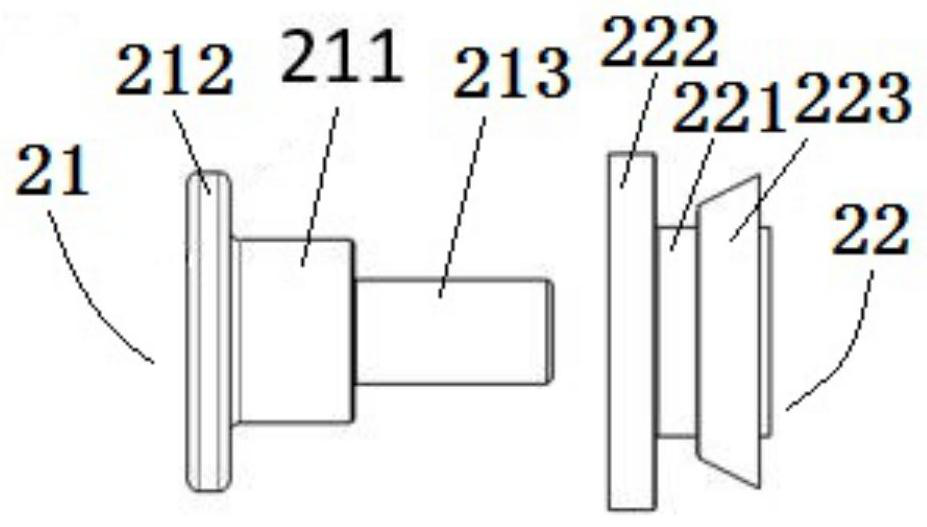

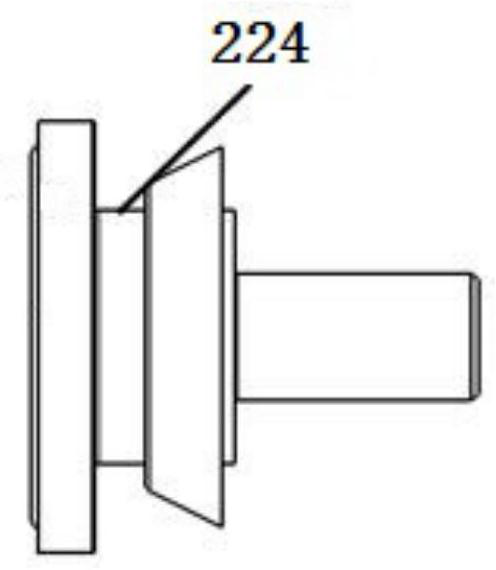

[0036] Such as Figure 1-11 As shown, a connection structure between the rear seat backrest shaft and the vehicle body of an automobile includes a backrest frame 1 and a vehicle body connected to the backrest frame 1 . One side of the back frame 1 is provided with a spring shaft 5, and the vehicle body is provided with a spring shaft installation sheet metal 6 matching with the spring shaft 5 at a posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com