Patents

Literature

37results about How to "Prevent moisture deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

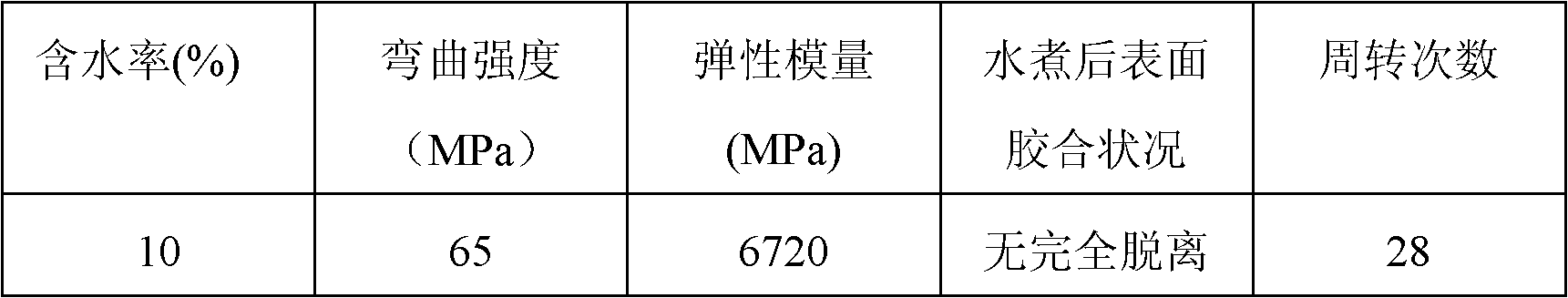

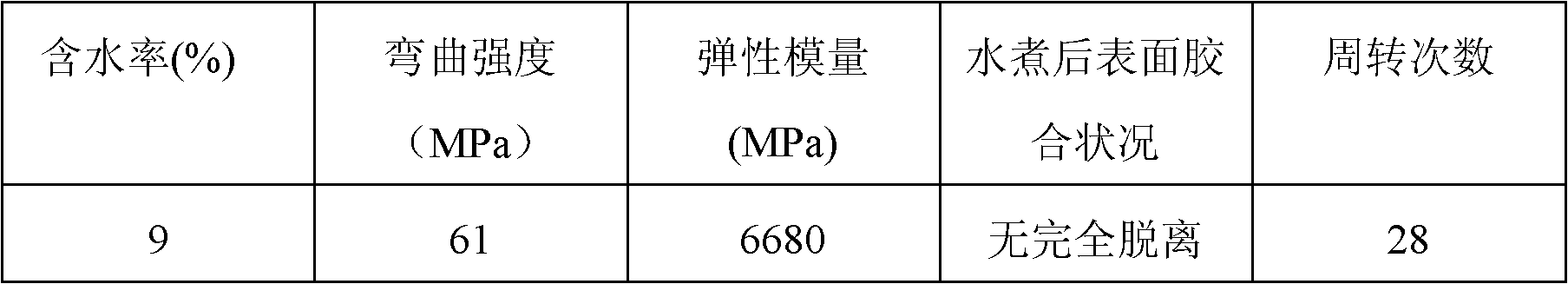

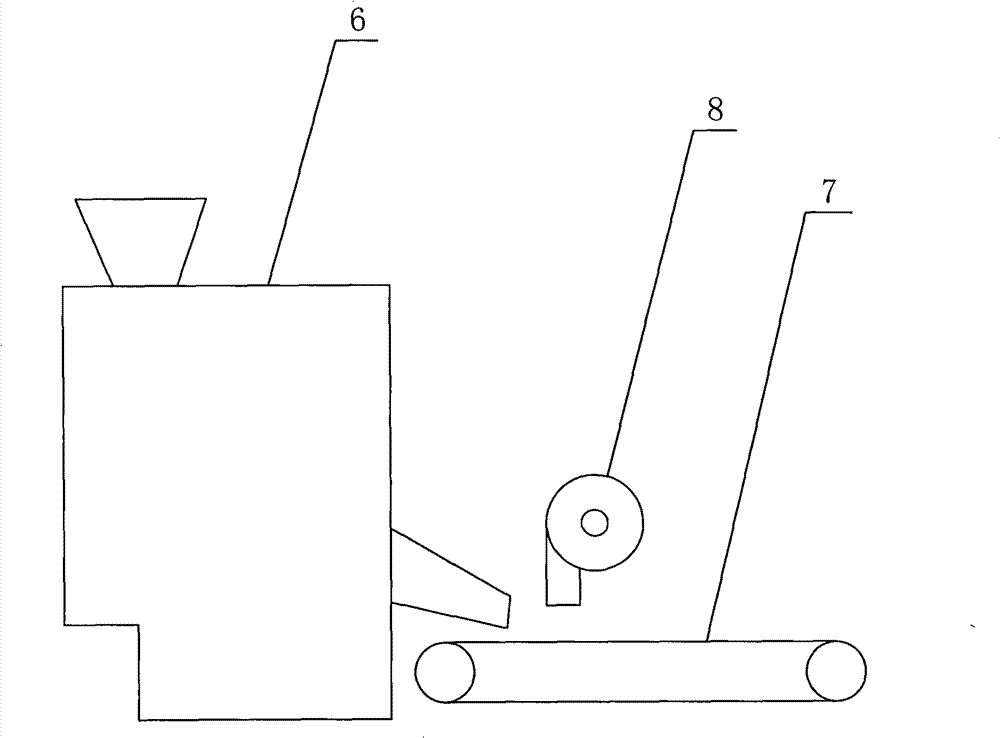

Plastic overlaid plywood building template with large turnover number and preparation method thereof

InactiveCN102425295AEasy to demouldReduce use costLaminationLamination apparatusTurnover timeAdhesive

The invention relates to a plastic overlaid plywood building template with a large turnover number and a preparation method thereof, in particular to a building template and a preparation method thereof. Due to the adoption of the plastic overlaid plywood building template with the large turnover number, the technical problems of the present wooden template or the overlaid plywood building template that a mould is difficult to remove and the turnover number is small during the application process can be solved. The plastic overlaid plywood building template with the large turnover number is characterized in that: a layer of polyolefine laminated surface is adhered on the upper surface and the lower surface of the wooden plywood template. The preparation method comprises the following steps that: after polyolefine material is extruded by a vertical-type three-roller plastic sheet machine set to obtain sheets, a layer of non-woven fabric covers the sheet to be extruded again to obtain the polyolefine laminated surface which is covered by the non-woven fabric; and adhesive is smeared onto the non-woven fabric, then the non-woven fabric which is smeared with the adhesive covers the upper surface and the lower surface of the polished wooden polywood to be pressed so as to obtain the plastic overlaid polywood building template with lage turnover number. The surface of the template is free from being adhered by the cement, the turnover times of the template are 25 to 30 times, and the template can be used for construction engineering.

Owner:卜凡华

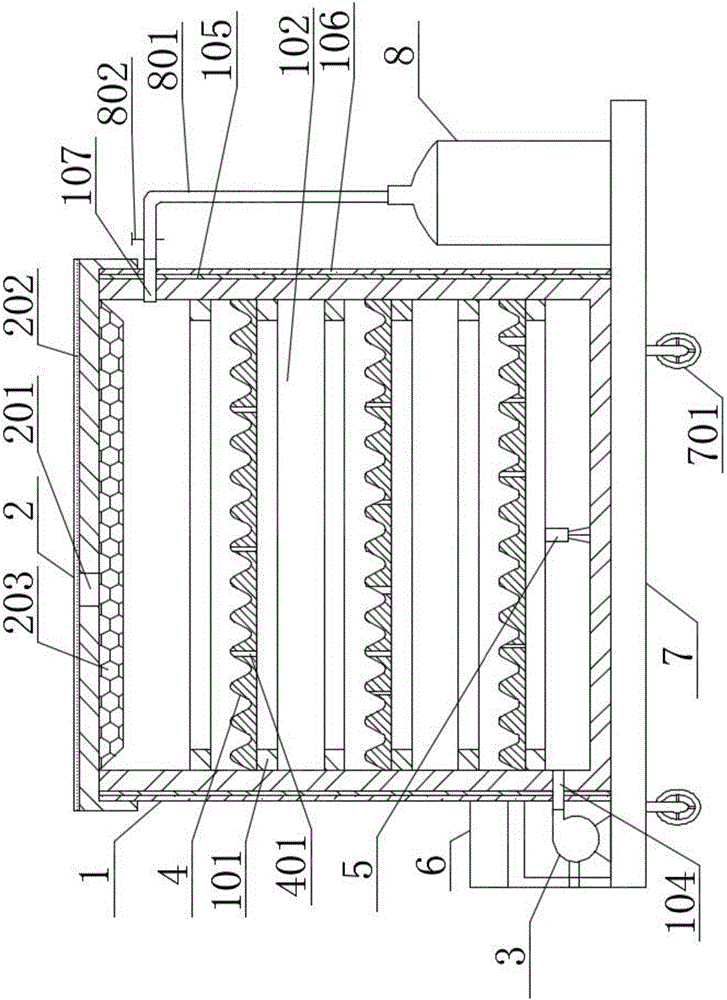

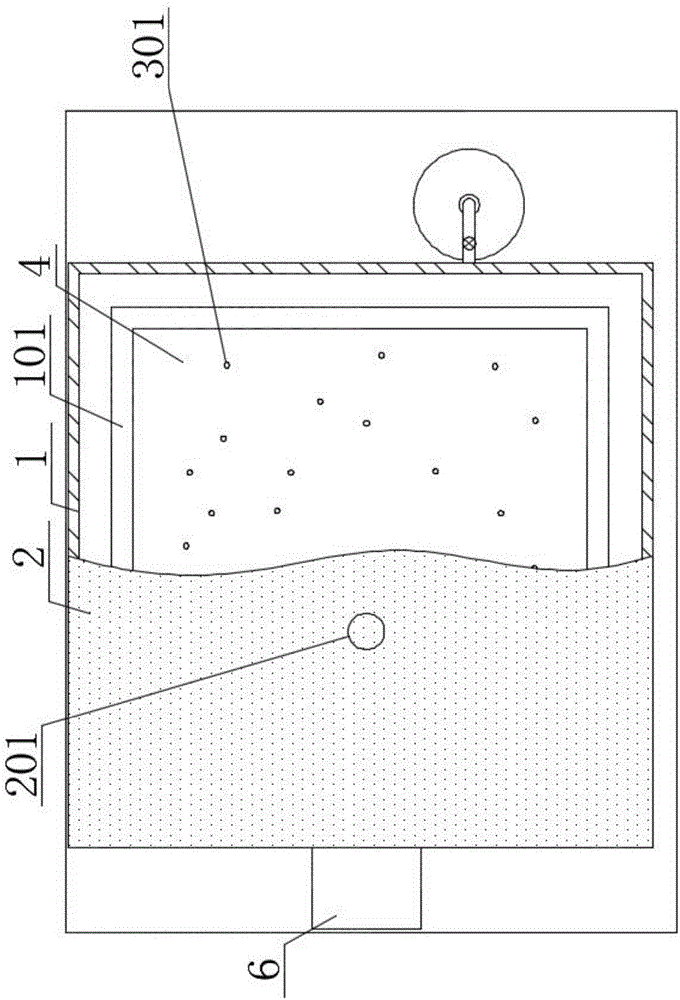

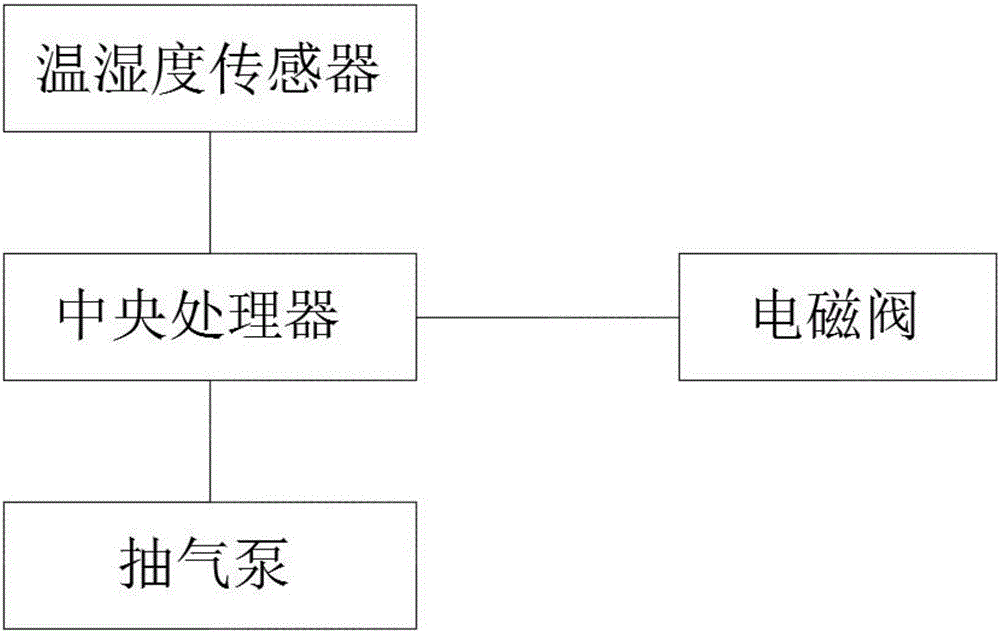

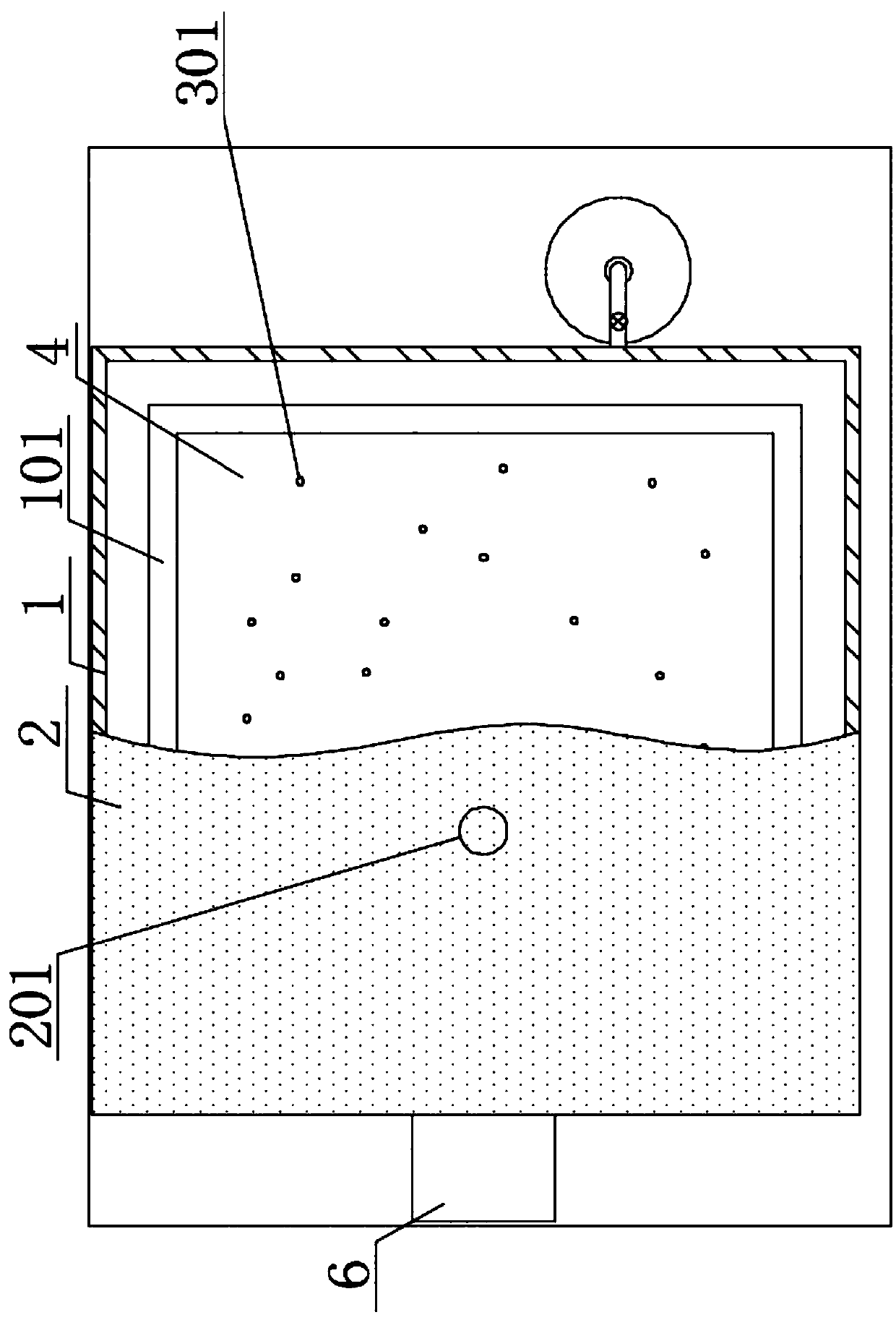

Anti-corrosion conveying box for aromatic fruit

ActiveCN106742567AReduce the temperatureDelayed decayClosuresShock-sensitive articlesInductorSelf feedback

The invention relates to a package box, in particular to an anti-corrosion conveying box for aromatic fruit. The box comprises a box body, a box cover, an air extracting pump and multiple waveform-shaped partition boards. The box cover is buckled with the box body correspondingly. The inner wall of the box body is provided with multiple installing bosses for installing the waveform-shaped partition boards in a surrounding manner. All the installation bosses are arranged at intervals along the height direction of the box body and used for separating the interior of the box body into mutually-parallel accommodating cavities. A first air hole is distributed in the box cover. An air passing film covers the first air hole. Second air holes are arranged in all the waveform-shaped partition boards. An air inlet end of the air extracting pump communicates with the box body through an installing port at the bottom of the box body. A temperature and humidity inductor is arranged in the box body and the temperature and humidity inductor and the air extracting pump are electrically connected with a central processor. The anti-corrosion conveying box for aromatic fruit has following beneficial effects: problems of a conventional storage and transport box such as poor ventilation and easy corrosion of fruits are solved through a self-feedback system.

Owner:烟台力量知识产权服务有限公司

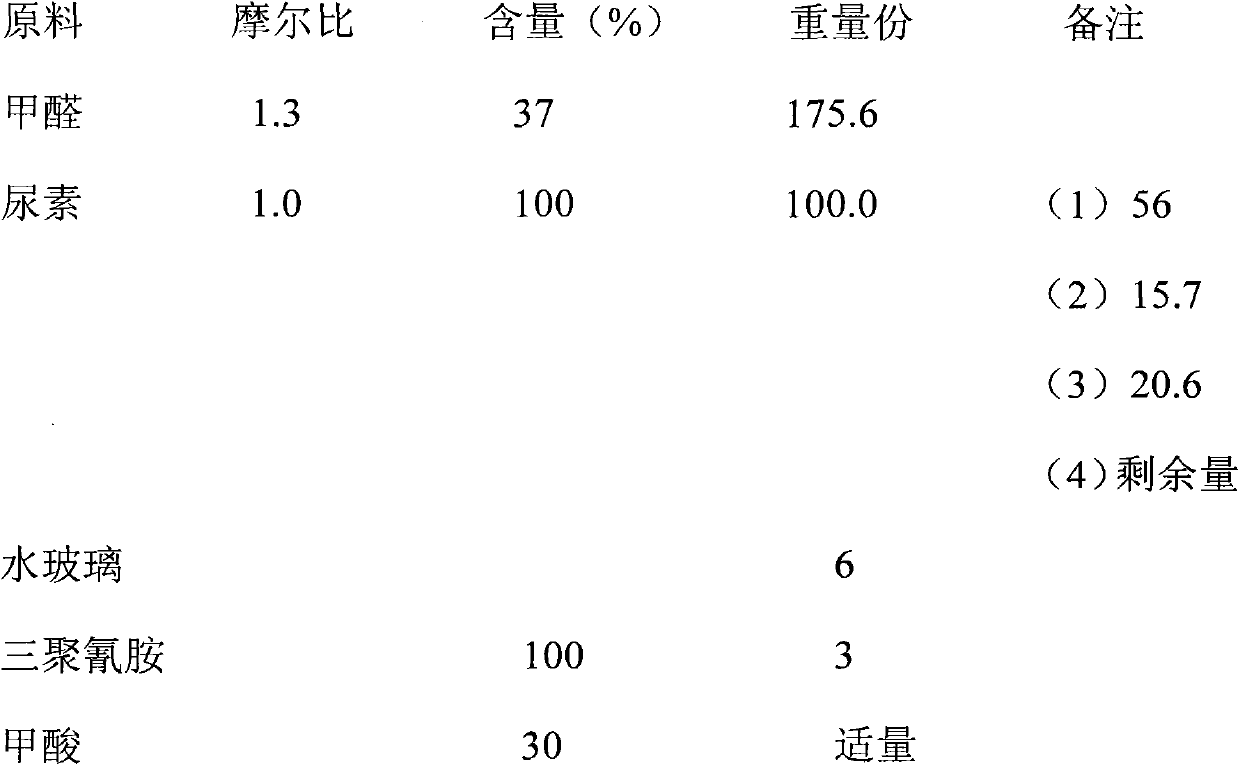

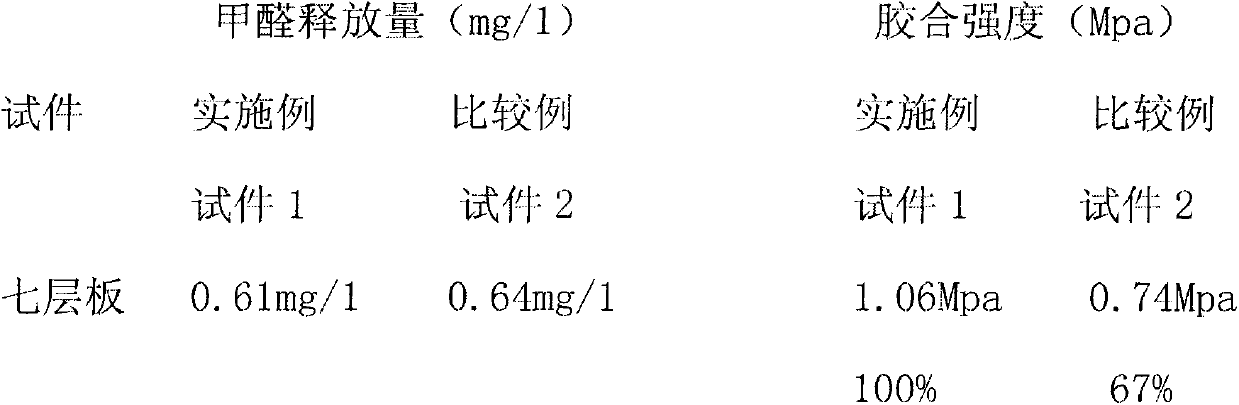

Preparation method for water-glass modified amino resin

InactiveCN103965425ASimple structureHigh bonding strengthAldehyde/ketone condensation polymer adhesivesMedium densitySilicon oxygen

The invention discloses a preparation method for water-glass modified amino resin. According to the preparation method, water glass is employed to replace sodium hydroxide for reacting with urea and formaldehyde and further for forming an inorganically organically combined silicon-oxygen bond. The molar ratio of formaldehyde to urea is 1.1-1.86:1 during reaction, water glass accounting for 1-6% by weight of urea is employed for modification, and urea is added into formaldehyde in 2-4 proportions. The preparation method helps to improve the resin structure and improve the bonding strength, and also helps to reduce the manufacturing cost. The synthesized resin is applicable to produce multi-plywoods, block boards, floor base materials, waterproof templates, particle boards and medium-density fiberboards, and also is applicable to E1-level artificial plates.

Owner:王笑康 +1

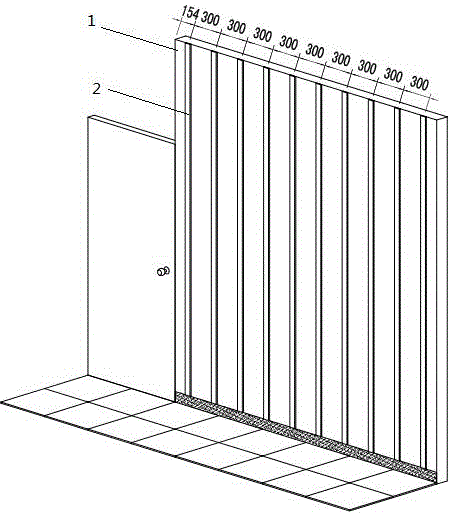

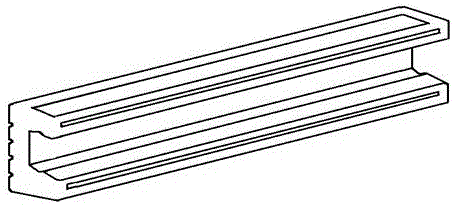

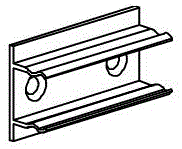

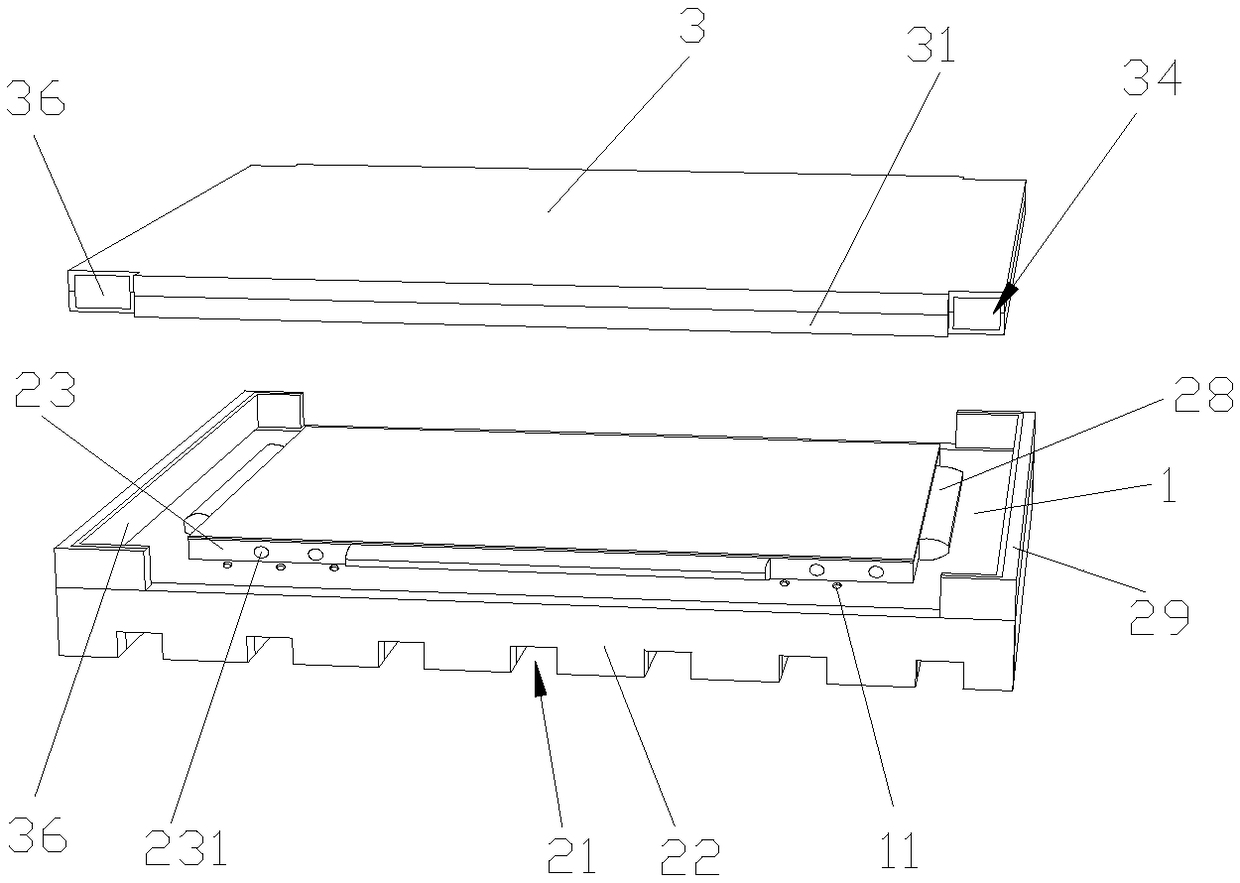

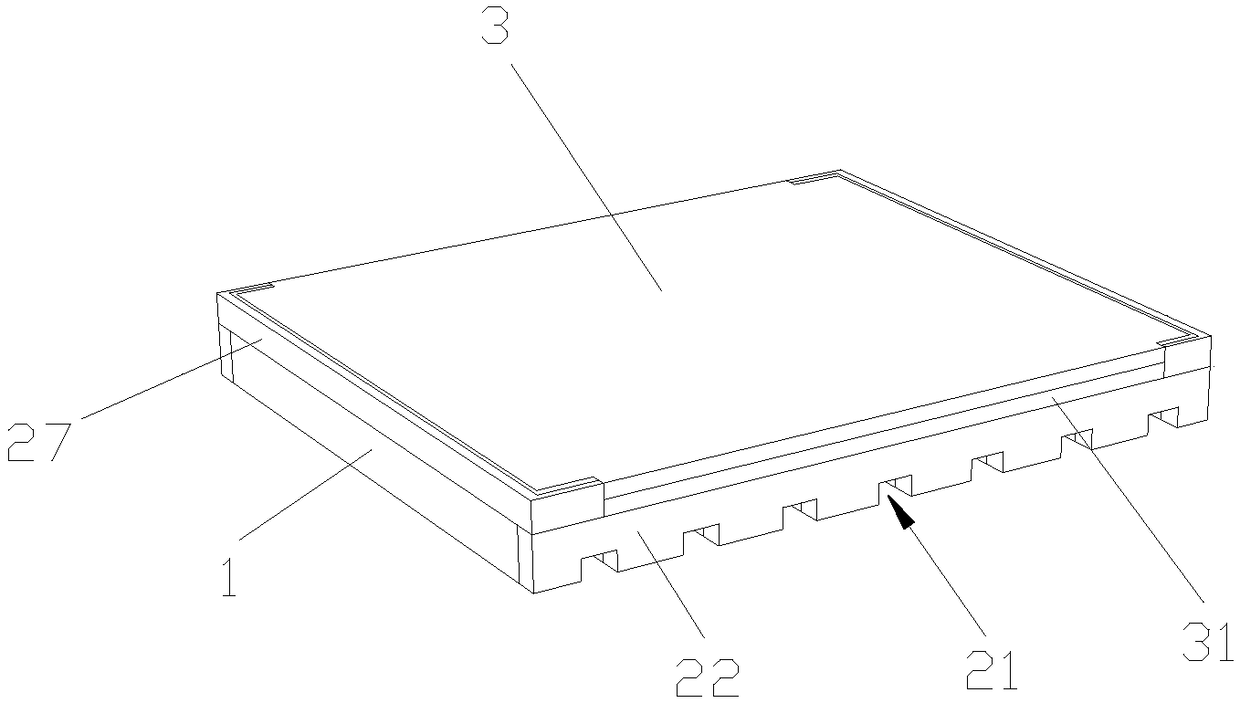

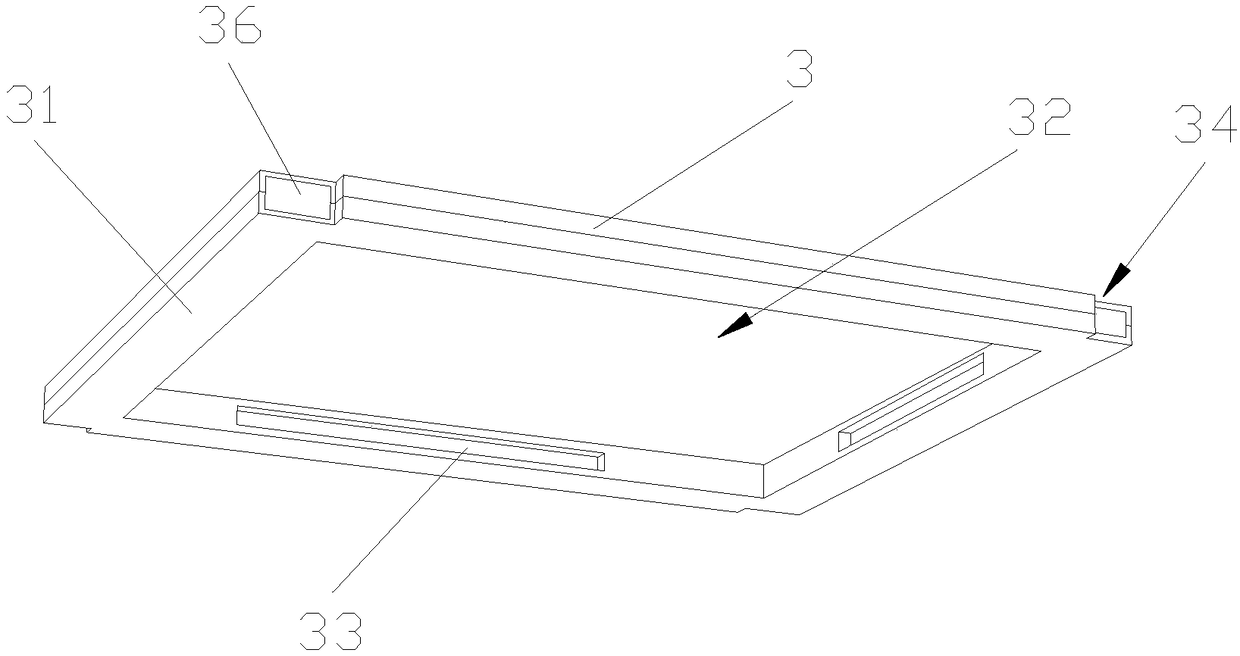

Wall hanging plate installation structure and installation method thereof

InactiveCN105089242AImprove installation efficiencyAvoid injuryCovering/liningsEngineeringWall plate

The invention provides a wall hanging plate installation structure which comprises an installation assembly and a plurality of wall hanging plates. The installation assembly comprises a plurality of clamping plates which are evenly arranged and fixed to a wall in parallel. The wall hanging plate installation structure further comprises a plurality of female aluminum pieces and male aluminum pieces which can be buckled and fixed. The female aluminum pieces are fixed to the clamping plates, the male aluminum pieces are fixed to the back faces of the wall hanging plates, and the wall hanging plates are fixed to the wall through buckling of the female aluminum pieces and the male aluminum pieces. The invention further provides an installation method based on the wall hanging plate installation structure. Compared with the prior art, the wall hanging plate installation structure and the installation method of the wall hanging plate installation structure can lower the installation difficulty, improve the installation efficiency of the wall hanging plates, reduce the cost produced in the process of installing the wall decoration plates and prolong the service life of the wall hanging plates.

Owner:惠州市好的板科技有限公司

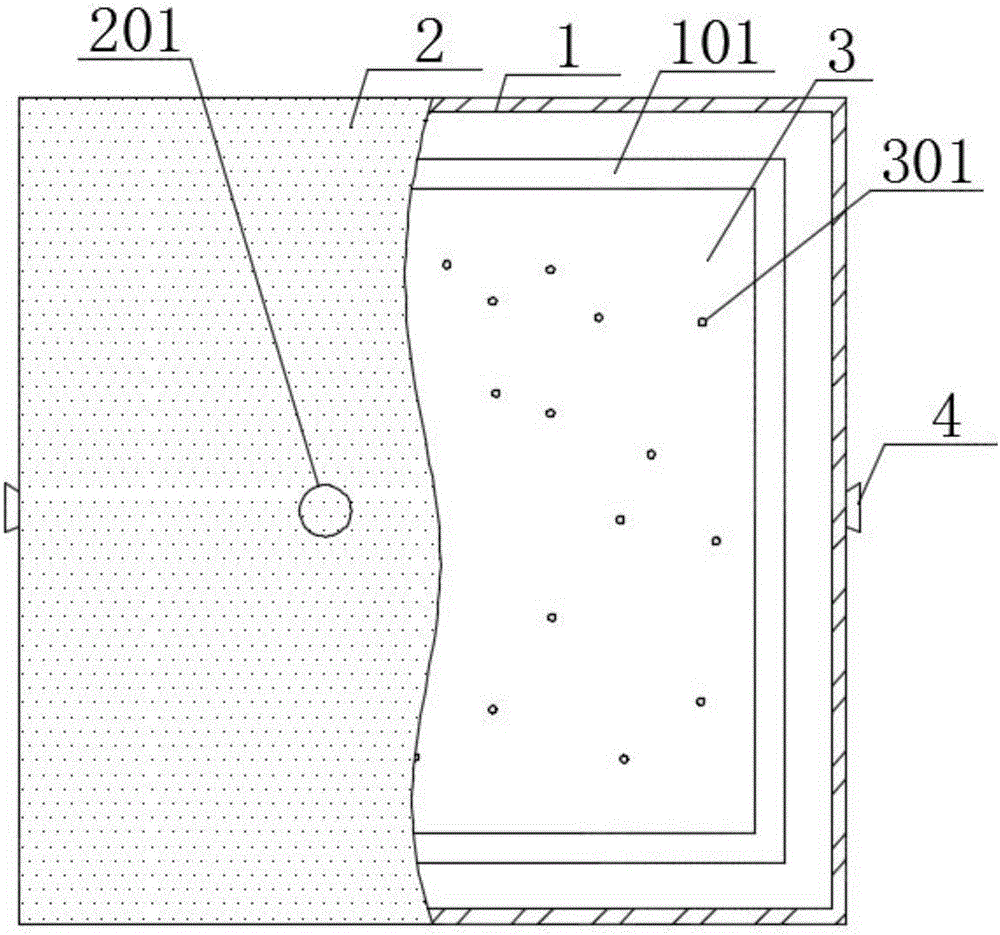

Seepage-preventing wood veneer structure for wall and installing method thereof

The invention discloses a seepage-preventing wood veneer structure for a wall and an installing method thereof. The wood veneer structure comprises a base plate, wherein the bottom surface of the baseplate is provided with a diversion groove, the end faces of the base plate are provided with water absorbing layers, the top face of the base plate is provided with a fixing plate, the end faces of the fixing plate are both provided with sliding grooves, clamping blocks are connected to the sliding grooves through springs, the surface of the fixing plate is provided with an isolating membrane anda sound absorbing layer, and the base plate is connected with a face plate through the fixing plate. The bottom surface of the face plate is provided with a fireproof buffer layer, and the inner sideface of the fireproof buffer layer is provided with a clamping groove. The installing method of the seepage-preventing wood veneer structure comprises the steps that the wall is flatted and dried, akeel support is installed, then the base plate is installed on the keel support, and finally the face plate is installed on the base plate. The seepage-preventing wood veneer structure has the advantages of being higher in installing efficiency, simple to change in a later period, better in dampproof capability and high in firmness.

Owner:湖州韵高木业有限公司

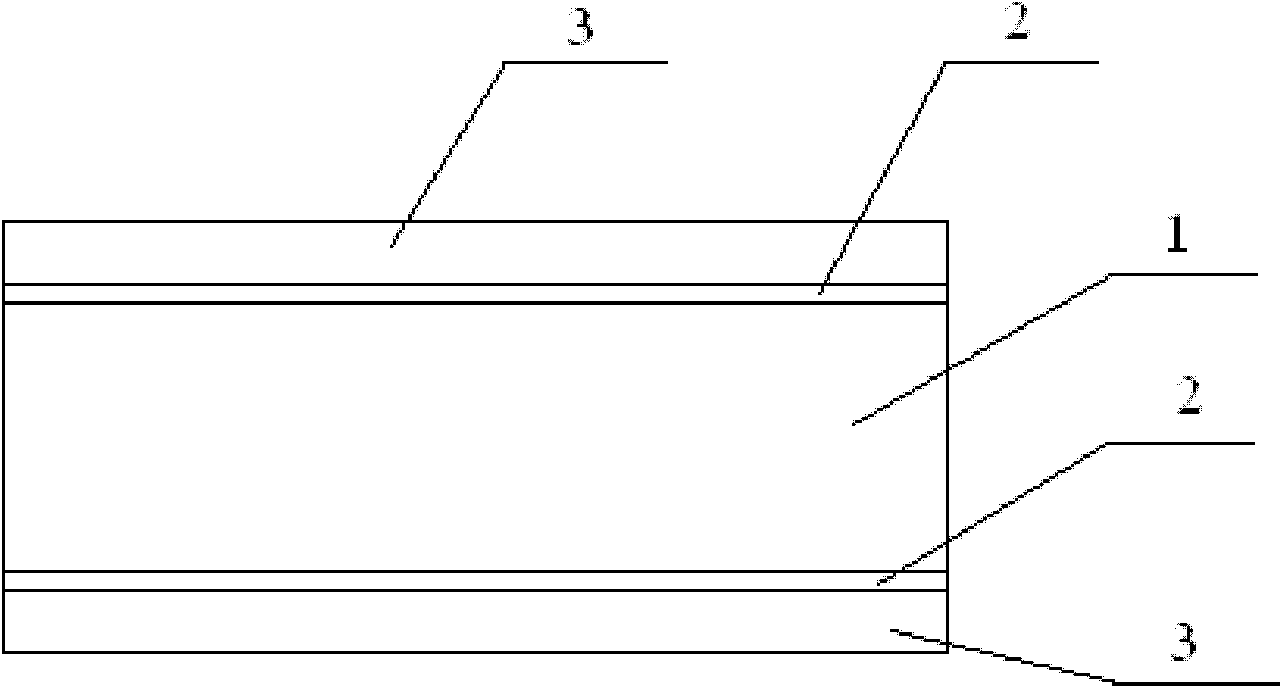

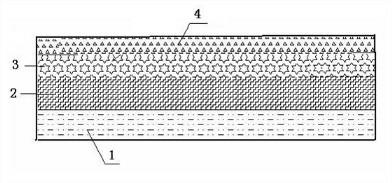

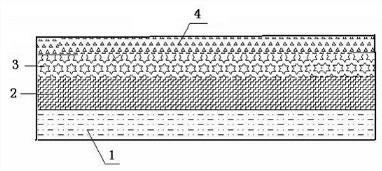

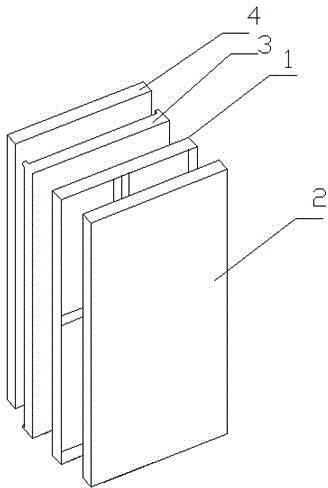

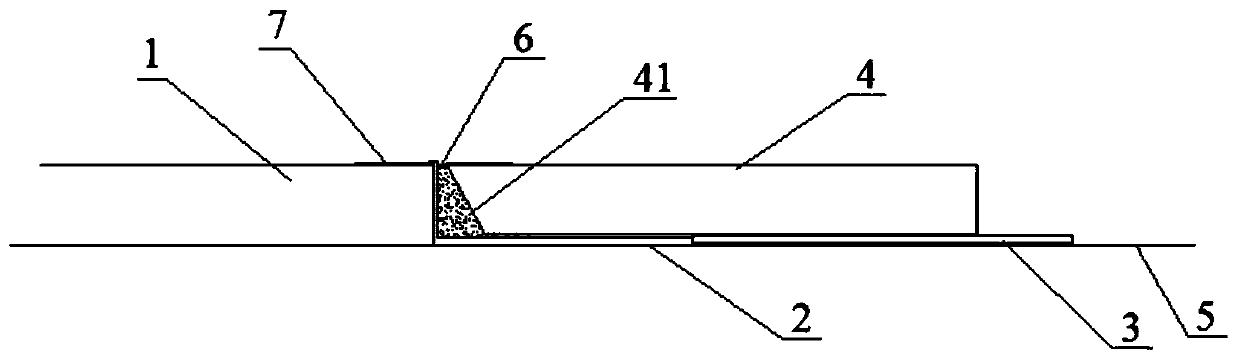

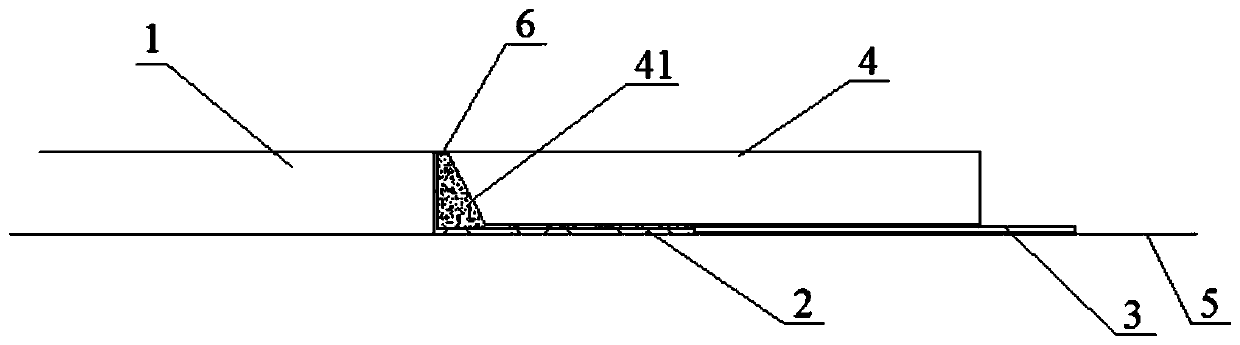

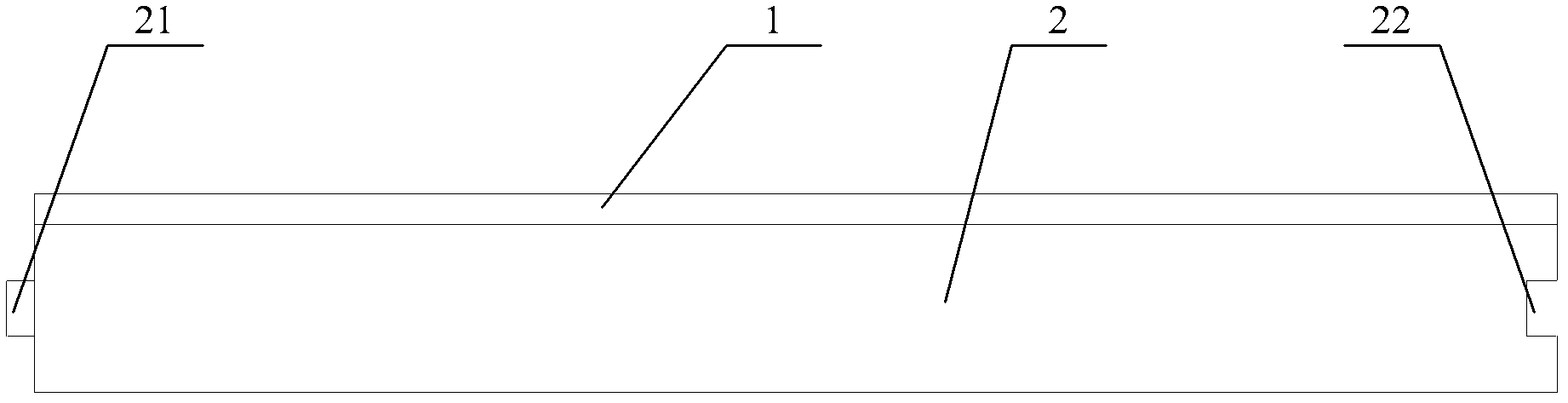

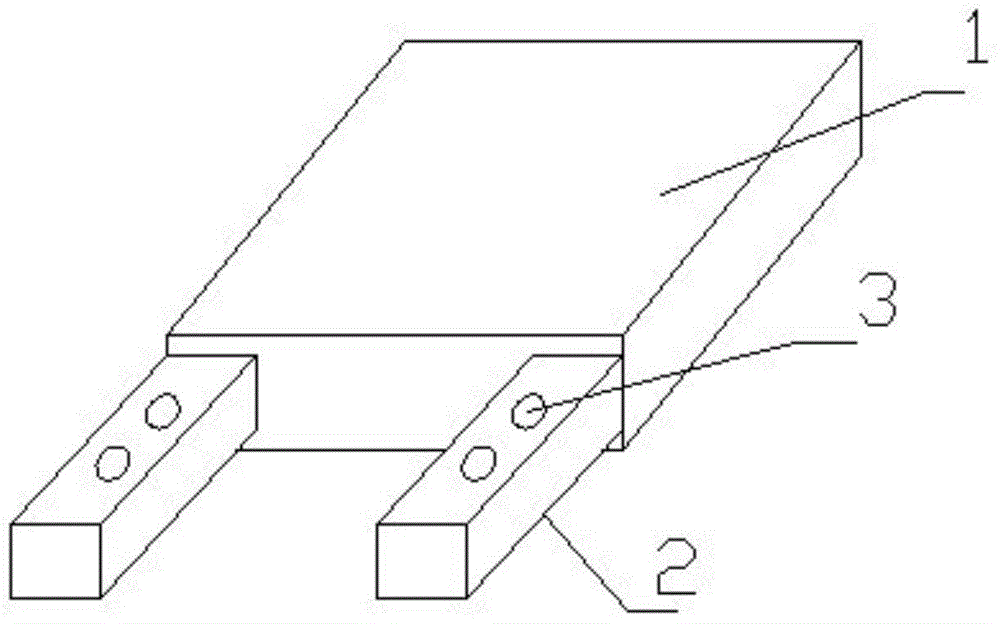

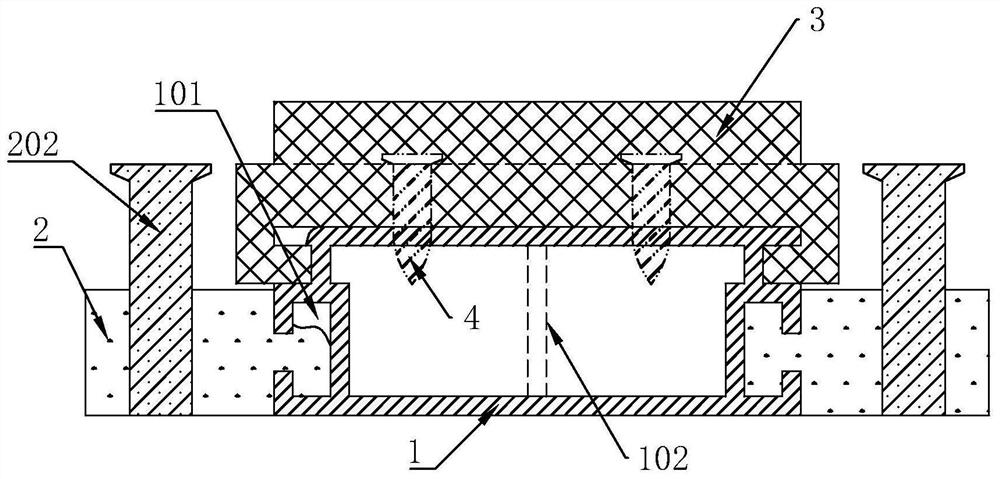

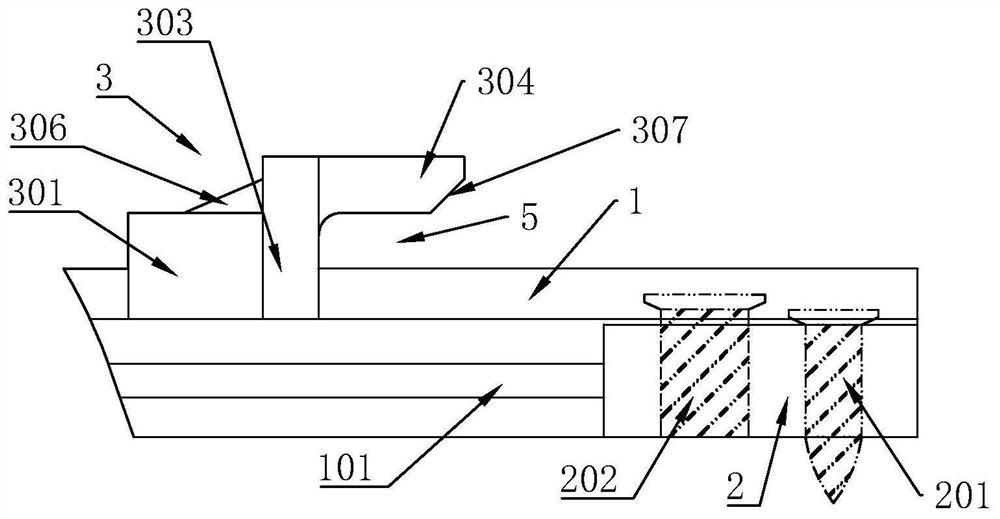

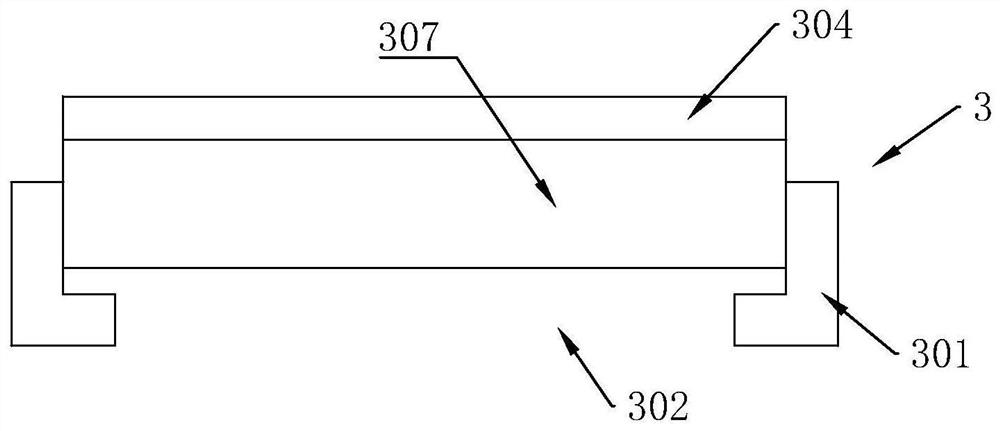

Printed door plate

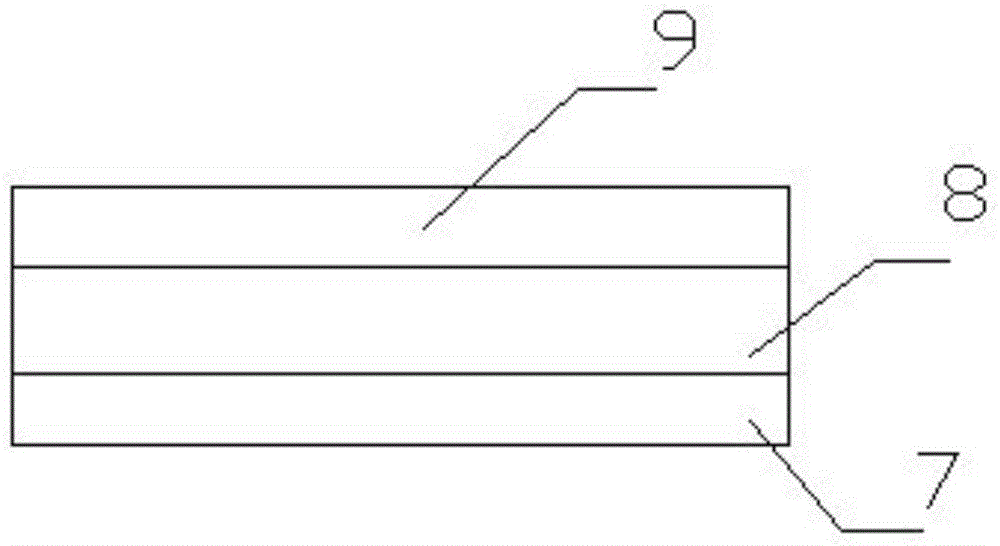

InactiveCN102434069AReasonable structural designPrevent moisture deformationDoor leavesTextile printerThin membrane

The invention discloses a printed door plate. The printed door plate comprises a door plate base material (1), adhesive layers (2), printed films (3) and PP (polypropylene) film layers (4), wherein the adhesive layers (2) are coated on the upper surface and the lower surface of the door plate base material (1); the printed films (3) are bonded on the adhesive layers (2); and the PP film layers (4) are bonded on the printed films (3). The printed door plate disclosed by the invention has the advantages of reasonable structural design, rigidity and durability; particularly, the printing can be planar or three-dimensional printing after the printed films are additionally arranged on the surface of the door plate, has adjustable color which is not easy to fade, and has attractive appearance; moreover, the films can be also used for protecting the door plate and can be used for preventing the door plate from being affected by moisture and deformed due to being exposed in the air for a long time so that the door plate is more sturdy and durable.

Owner:SUZHOU CHAOSHENG PRINTING & PLATEMAKING IND

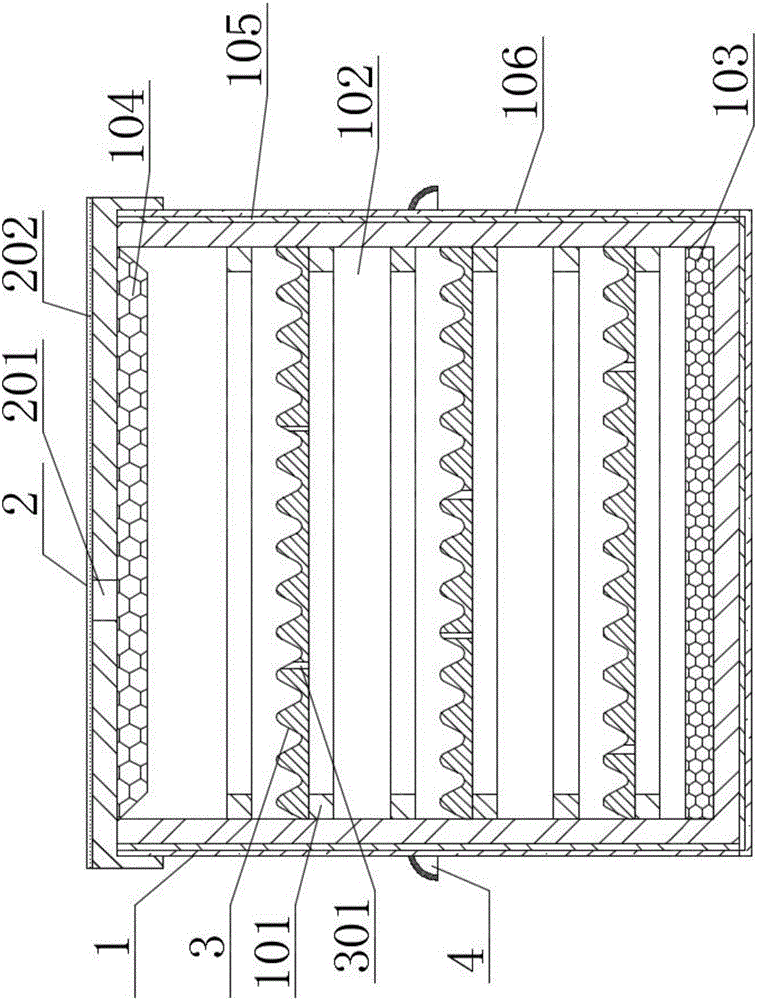

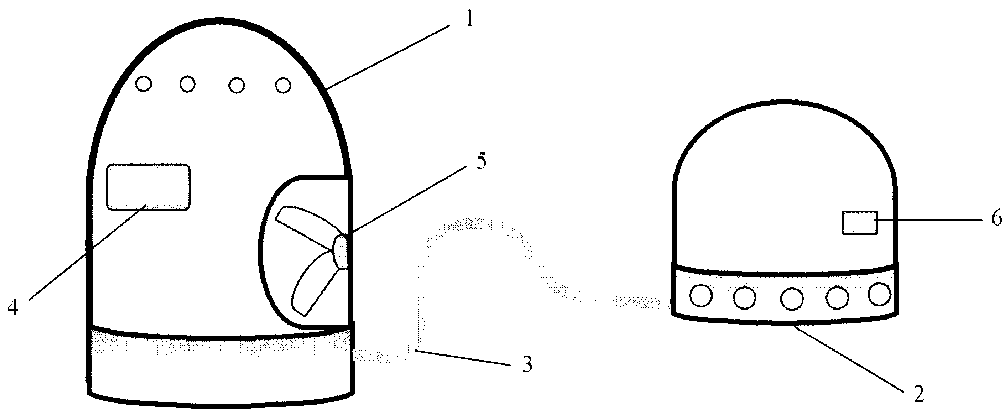

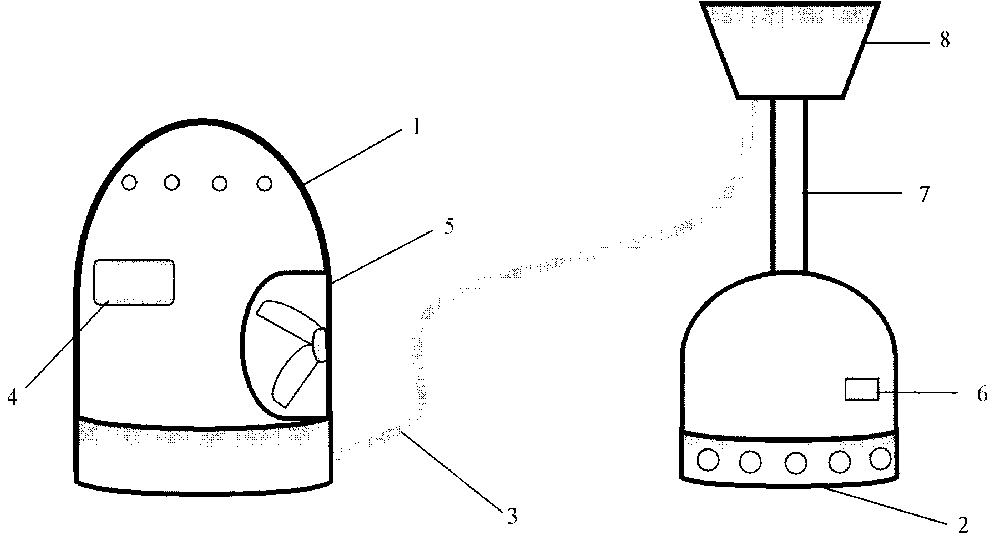

Deformation-preventing and sound-insulating wood door

ActiveCN104818929ASmall water absorptionNot easy to get wet and deformedRadiation protectionFireproof doorsSolid woodPulp and paper industry

The invention discloses a deformation-preventing and sound-insulating wood door. The deformation-preventing and sound-insulating wood door comprises a solid wood frame shaped like a 2x2 grid, an outer plate, a water absorbing laminate and an inner plate, wherein the outer plate and the inner pate are fixed on the solid wood frame through screws; the water absorbing laminate is positioned between the outer plate and the inner plate, and is fixed on the solid wood frame; a gap is formed between the water absorbing laminate and the inner plate; a gap is also formed between the solid wood frame and the outer plate; and the gaps are vacuumized. The deformation-preventing and sound-insulating wood door is low in manufacturing cost, is not liable to deform, and has effects of sound insulation and radiation prevention.

Owner:HUZHOU SHENRUI DOOR IND

Fragrant fruit storage box

InactiveCN106586284AIncrease the areaImprove distributionVenting meansContainers preventing decayActivated carbonWave shape

The invention relates to a packaging box, in particular to a fragrant fruit storage box which comprises a box body, a box lid and a plurality of wave-shaped partition plates. The box lid and the box body are buckled correspondingly. A plurality of installation bosses used for installing the wave-shaped partition plates are arranged on the inner wall of the box body in a surrounding mode. The installation bosses are arranged at intervals in the height direction of the box body. The interior of the box body is divided into a plurality of parallel containing cavities through the wave-shaped partition plates. A first activated carbon adsorption layer is arranged in the containing cavity located on the lowermost layer. A plurality of first venting holes are formed in the box wall of the box lid, and an air-permeable film is laid on the venting holes. The storage box is provided with the wave-shaped partition plates provided with second venting holes, and the box lid is provided with the first venting holes covered with the air-permeable film, so that the problems that an existing storage box is poor in breathability, and fruits are likely to attract flies and insects are solved.

Owner:怀宁佳瑞包装有限公司

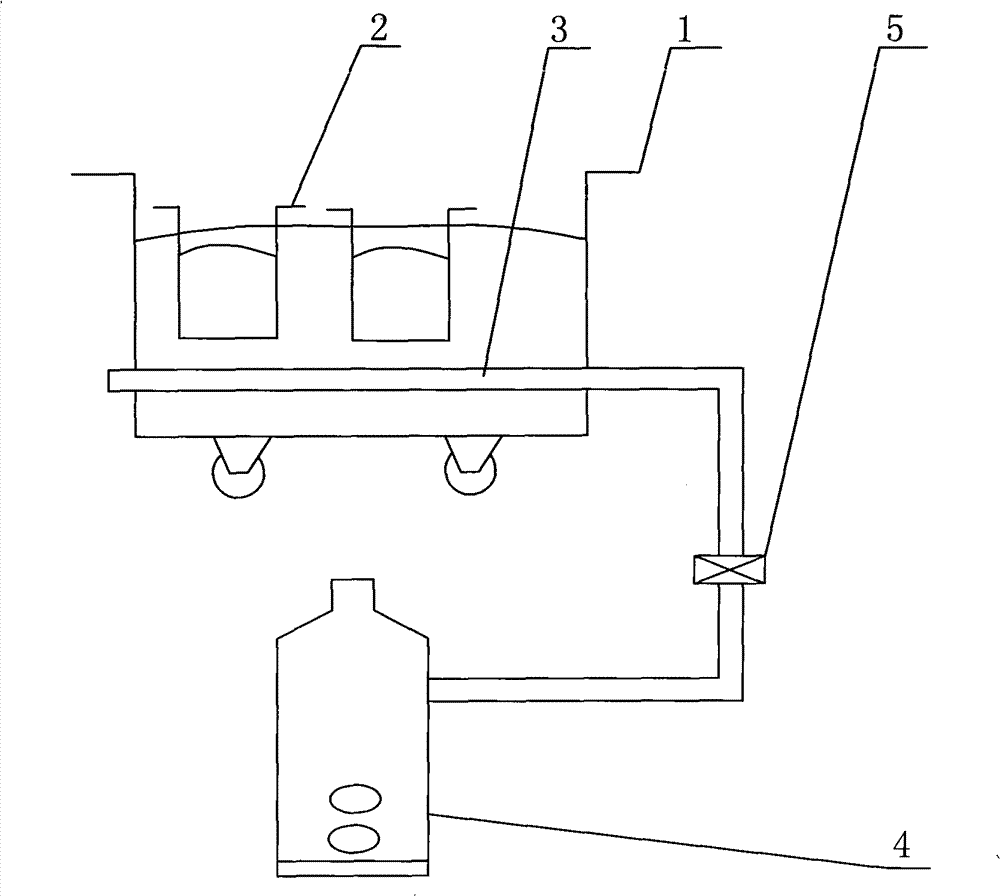

Circulation type indoor spray cooling device

InactiveCN103277851APrevent moisture deformationThe cost increase is not obviousLighting and heating apparatusFree-cooling systemsTemperature controlEngineering

The invention relates to a circulation type indoor spray cooling device. The circulation type indoor spray cooling device comprises a sprayer and a dehumidifier, wherein the sprayer and the dehumidifier are located in separate positions inside a room and are connected through a water guide pipe. The sprayer is provided with a temperature control device. When the temperature of the room is higher than a preset value, the sprayer is automatically started to spray mist, ambient heat is absorbed through atomization to lower the temperature of the ambient air, and the air is circulated through a fan. A humidity inducing switch is arranged inside the dehumidifier. When the humidity of the air inside the room is higher than a preset value, the dehumidifier is automatically started to remove the humidity, the water in the air is separated through dehumidifying to lower the humidity of the ambient air, and the extracted water is conveyed to the sprayer through the water guide pipe for cycle use.

Owner:SHENZHEN CITY FUTIAN DISTRICT SCI & TECH EDUCATION ASSOC FOR JUVENILES

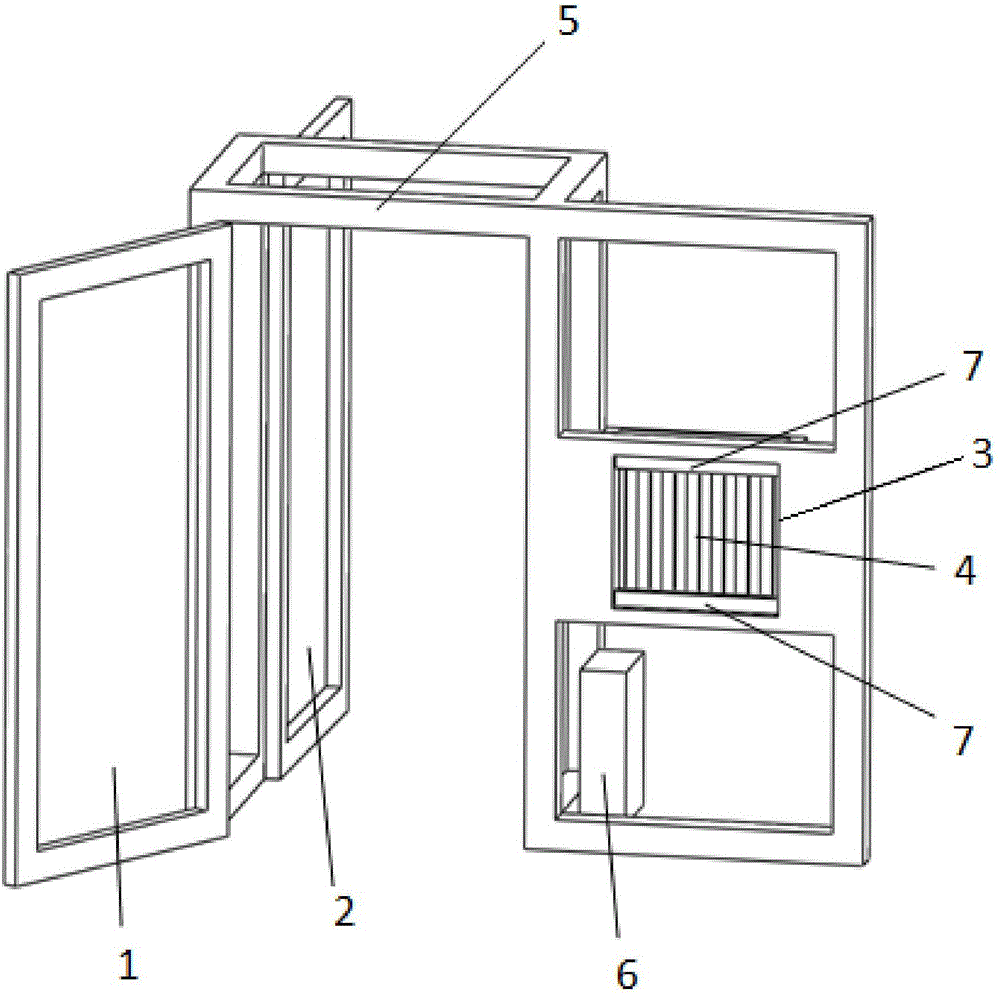

Dampproof door applicable to bamboo warehouse

InactiveCN106401430AKeep straightControl circulationServing doorsWing arrangementsEngineeringClosed space

The invention discloses a dampproof door applicable to a bamboo warehouse. The dampproof door comprises a door frame, a first door body, a second door body, a dehumidifier, a bamboo inlet / outlet, a dampproof curtain and counters. The door frame is divided into two parts, namely the left part and the right part. The first door body and the second door body are arranged at the left side of the door frame, wherein the first door body is arranged in front; the second door body is arranged at the back; and a closed space is formed between the first door body and the second door body. The bamboo inlet / outlet, the dampproof curtain, the counters and the dehumidifier are arranged at the right side of the door frame. According to the dampproof door applicable to the bamboo warehouse, through design of the bamboo inlet / outlet and the two door bodies, air circulation inside and outside the warehouse can be controlled; damp air entering the bamboo warehouse is effectively reduced; the situation that long-strip bamboos are affected with damp and deformed is prevented; and the straight-line shape of each long-strip bamboo is maintained.

Owner:GUANGDONG UNIV OF TECH

Corrugated paperboard and corrugated carton production process

InactiveCN110774716AThe shock absorption performance is fully utilizedReduce usageMechanical working/deformationWrappersPaperboardCarton

The invention provides a corrugated paperboard and a corrugated carton production process. The corrugated paperboard comprises an outer-layer paperboard and an inner-layer paperboard, wherein a firstwaterproof plate layer and a refractory plate layer are sequentially arranged on the upper surface of the outer-layer paperboard from inside to outside, a second waterproof plate layer is arranged onthe lower surface of the inner-layer paperboard, a partition plate is arranged between the outer-layer paperboard and the inner-layer paperboard, a first corrugated paper layer is bonded between the outer-layer paperboard and the partition plate through a flame-retardant glue, wave-shaped corrugated paper, a first hollow corrugated paper core and a second hollow corrugated paper core are symmetrically arranged in the first corrugated paper layer, a second corrugated paper layer is bonded between the inner-layer paperboard and the partition plate through a flame-retardant glue, corrugated paper, a third hollow corrugated paper core and a fourth hollow corrugated paper core are symmetrically arranged in the second corrugated paper layer, each hollow corrugated paper core is filled with EPE pearl wool, and the outer surfaces of each paper core are respectively coated with a smoke eliminating layer. According to the invention, the problems of poor compressive strength, poor damp-proof andwaterproof performance and poor flame-retardant and fireproof performance of the corrugated carton in the background art are solved.

Owner:云南瑞升纸业有限公司

a solid wood door

The invention discloses a solid door. The solid door comprises an upper door, a lower door and a connection bolt. The upper door comprises an upper door body and upper door connection columns. The two upper door connection columns are arranged on the two sides of the end face of the upper door body respectively and provided with bolt through holes. The lower door comprises a lower door body. The lower door body is provided with lower door connection grooves. The depth of the lower door connection grooves is smaller than or equal to half the length of the upper door body. The lower door body is provided with through holes. The through holes are communicated with the lower door connection grooves and perpendicular to the lower door connection grooves. The upper door connection columns penetrate into the lower door connection grooves. Connection bolts penetrate through the through holes and the bolt through holes to connect the upper door body and the lower door body together. The solid door has the advantages of being low in cost, capable of achieving the insect prevention and damp prevention functions, not prone to deformation and easy to carry.

Owner:HUZHOU SHENRUI DOOR IND

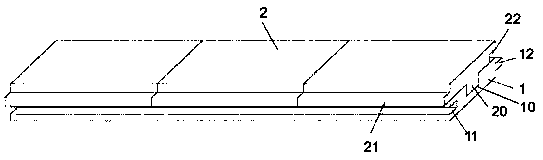

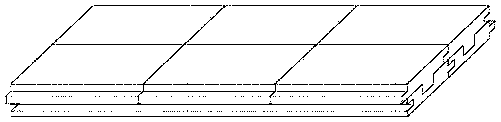

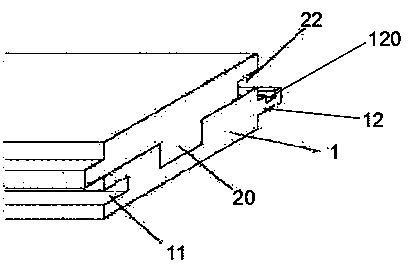

Wood floor

Owner:浙江居美家木业有限公司

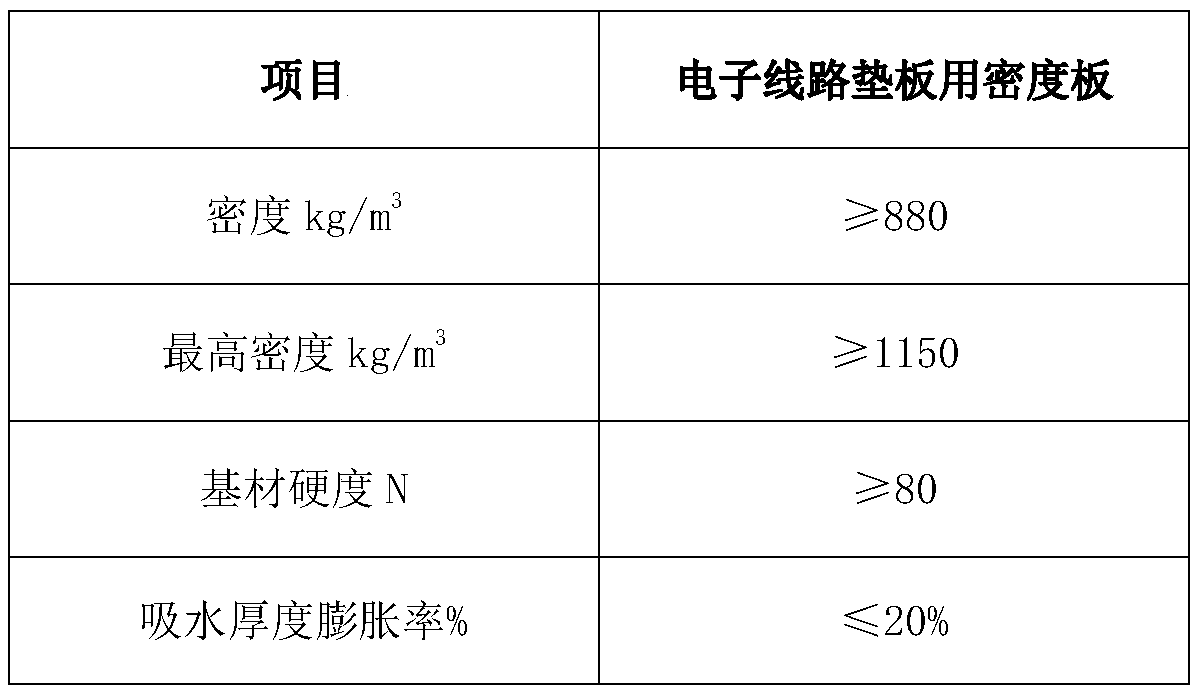

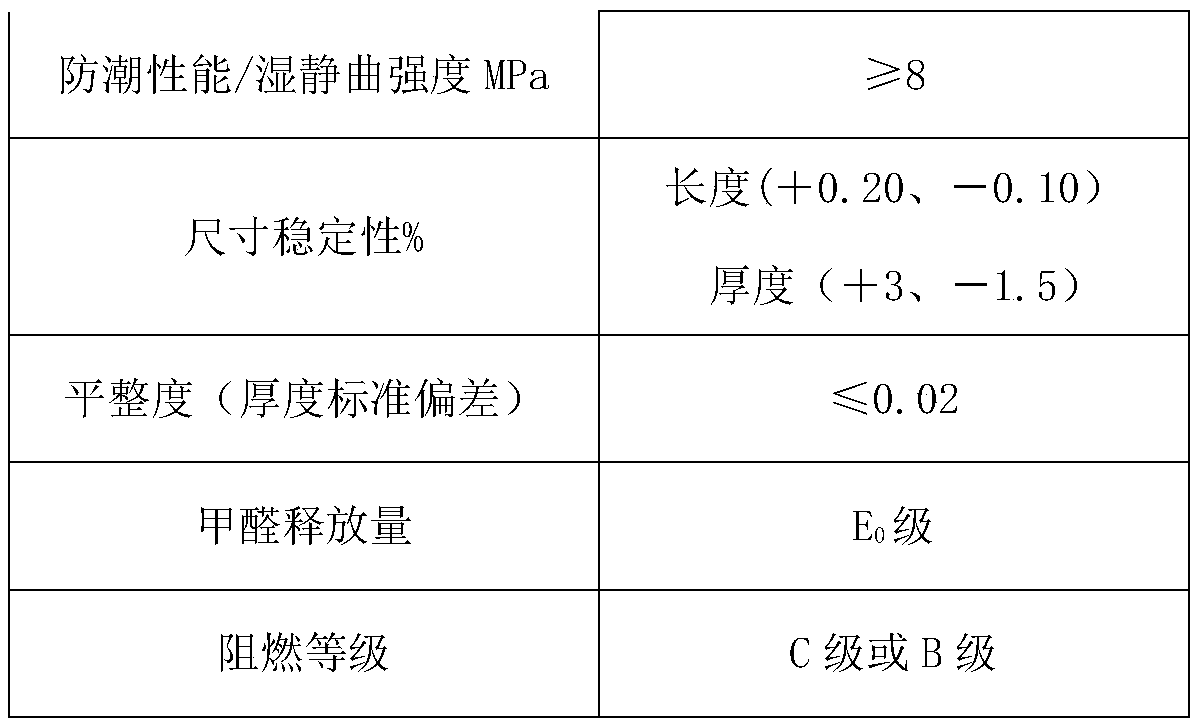

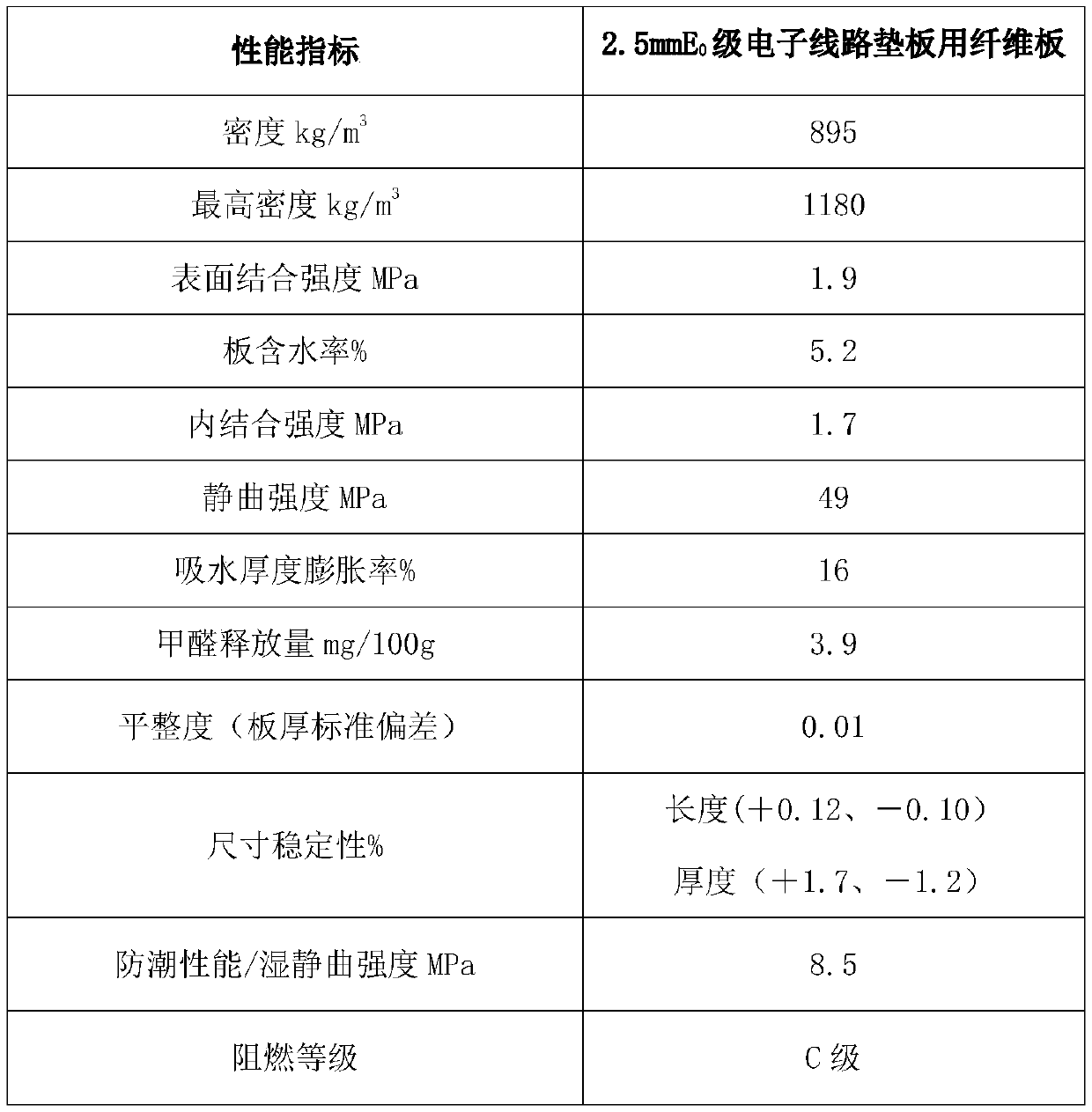

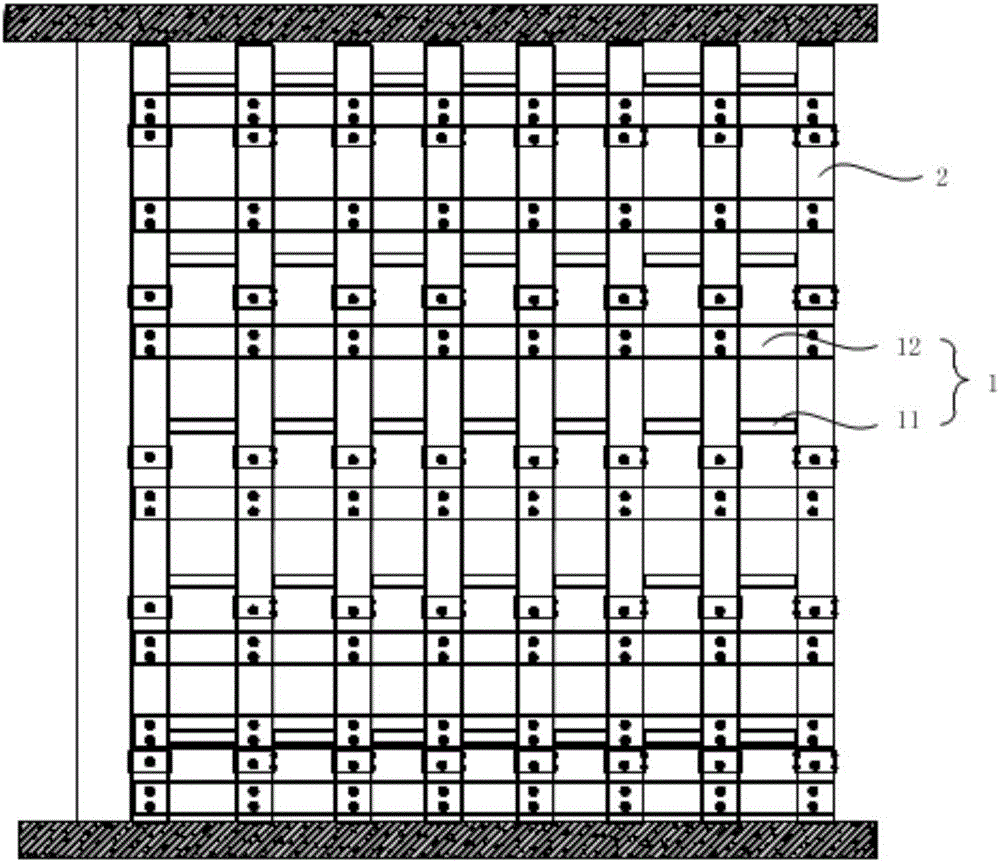

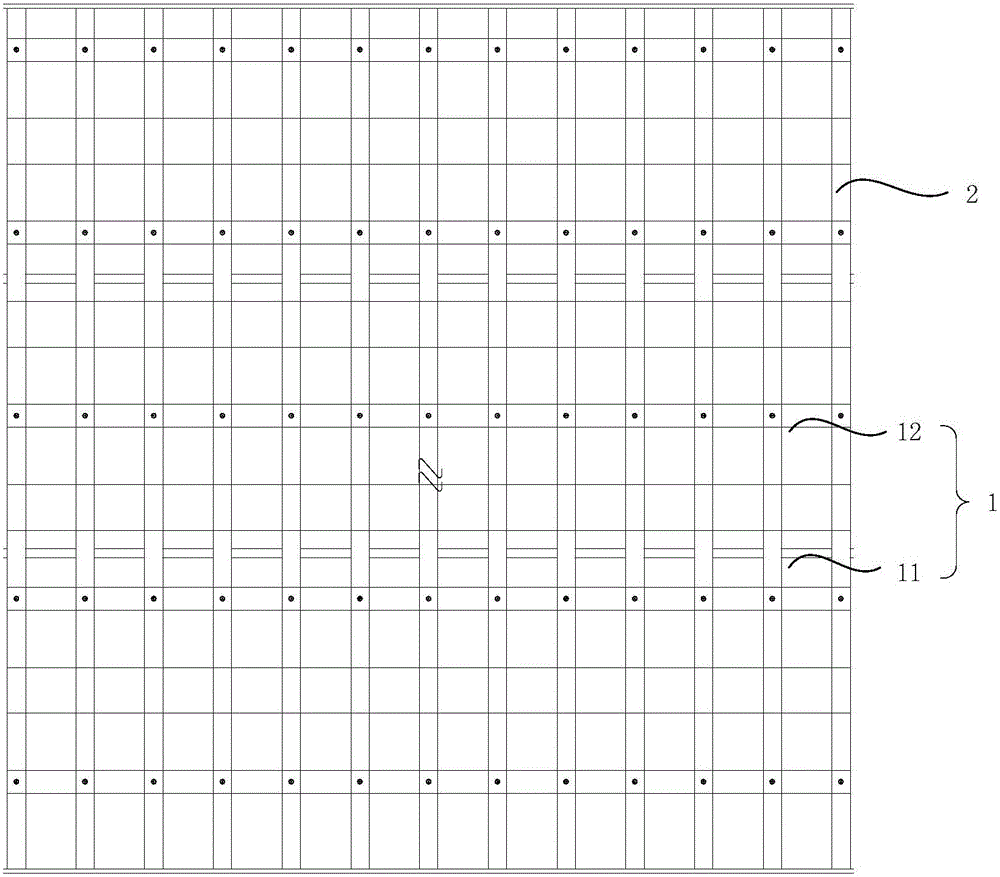

Manufacturing method of density fiberboard for E0-level electronic circuit base plate

ActiveCN110744670AImprove moisture resistanceImprove water resistanceAldehyde/ketone condensation polymer adhesivesFlat articlesProcess engineeringFire retardant

The invention belongs to the technical field of wood processing, and relates to a manufacturing method of a density fiberboard for an E0-level electronic circuit base plate. A secondary gluing technology is adopted, and the manufacturing method comprises the steps that wood peeling, chipping, wood chip screening, washing, pre-cooking, cooking and hot grinding are carried out; adding of waterproofagent and adjusting and applying of an E0-level damp-proof adhesive are carried out; and adding of an auxiliary, drying and sorting, adjusting and applying of an E0-level high-solid-content adhesive,adding of a fire retardant, paving and forming, pre-pressing, hot pressing, turning plate cooling, sanding, inspection and dividing and packaging and warehousing are carried out. The adhesive is addedtwice, so that the pre-curing influence is reduced, the adhesive bonding effect and full wrapping can be brought into full play, and meanwhile energy consumption of a heat energy center is reduced. The produced fiberboard for the E0-level electronic circuit base plate overcomes the defects that the fiberboard is prone to damp deformation and aging, and the hardness is not enough, the service cycle is prolonged, the fire retardant function is added, the combustion risk caused by too high local temperature in the electronic circuit base plate using process is effectively avoided, and the application field of the fiberboard is further expanded.

Owner:DARE WOOD BASED PANEL GRP

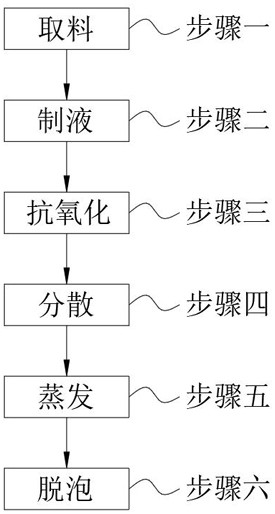

Wood floor clean-care agent

InactiveCN101514272BEasy to useFree from damageNon-ionic surface-active compoundsOrganic non-surface-active detergent compositionsWater basedPolymer

The invention discloses a wood floor clean-care agent which comprises the raw materials with weight percentage: 3-10% of alkyl glycoside, 15-25% of water base acrylic acid copolymer, 5-10% of silicon oil latex, 1-2% of plant essential oil, 3-5% of plant wax emulsion, 1-3% of waterborne polyurethane, 0.1-0.3% of preservative, 0.1-0.3% of chelon, 0.05-0.15% of essence and the rest of de-ionized water. The wood floor clean-care agent has a certain penetrating performance and moisturizing effect when supplementing the wax emulsion and the plant essential oil in the floor and furniture, so as to prevent the floor or the furniture from drying and cracking as well as deforming caused by dry weather, and restore the elasticity of the floor. A protective layer is formed on the surface of the flooror the furniture, so as to play a certain role on covering and mending shadow scratch and prevent the scratch from continuing to become deep and black. Meanwhile, the wood floor clean-care agent has the functions of cleaning, being antistatic and waterproof, sticking no dust, antisepsis, mould prevention, etc.

Owner:武汉斯达日用化工有限公司

Mounting structure of hard package covering skin for wall surface and construction process of mounting structure

The invention relates to a mounting structure of a hard package covering skin for a wall surface and a construction process of the mounting structure. The mounting structure comprises a base layer structure and hard package covering skin plates fixedly connected with the base layer structure, wherein the base layer structure comprises a plurality of transverse frames and a plurality of vertical skeletons intersected with the transverse skeletons; the vertical skeletons are light steel skeletons; the transverse skeletons comprise first skeletons and second skeletons; the first skeletons are fixedly connected with the second skeletons; the second skeletons are a plurality of glass magnesium boards; the hard package covering skin plates comprise glass magnesium boards and covering skins fixedly connected with the glass magnesium boards; the glass magnesium boards are fixedly connected with the second skeletons of the base layer structure. The mounting structure provided by the invention aims to solve the technical problem that the base layer of the conventional hard package covering skin is easy to wet in construction and use processes.

Owner:SHENZHEN ASIANTIME INTIAONAL CONSTR CO LTD

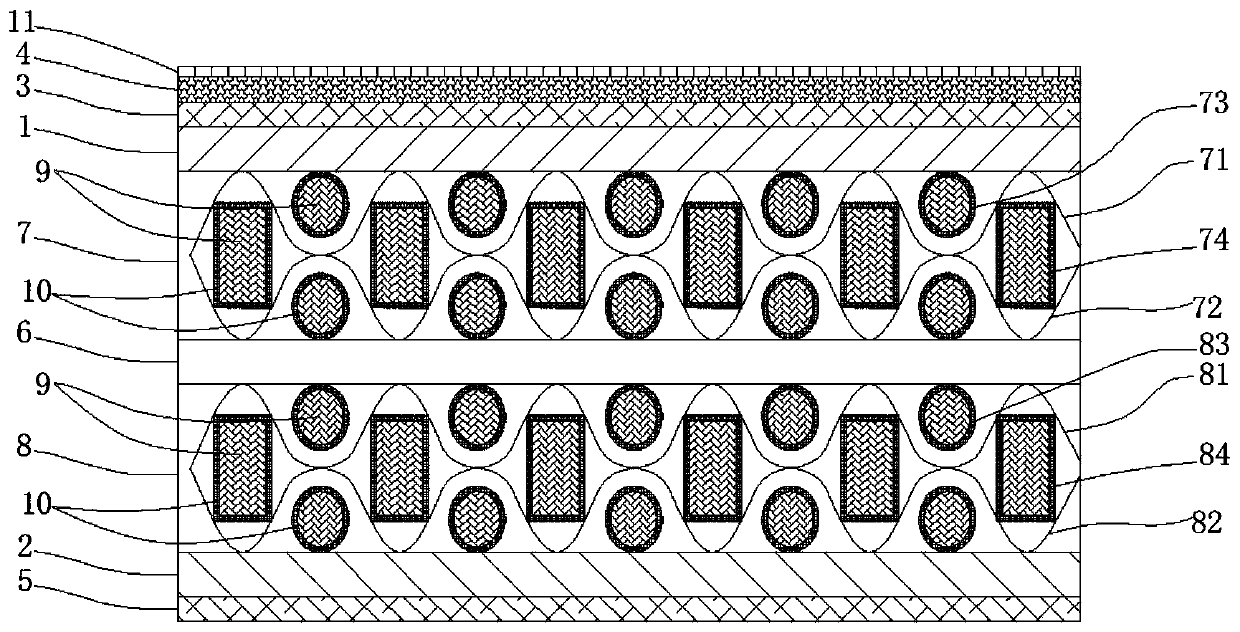

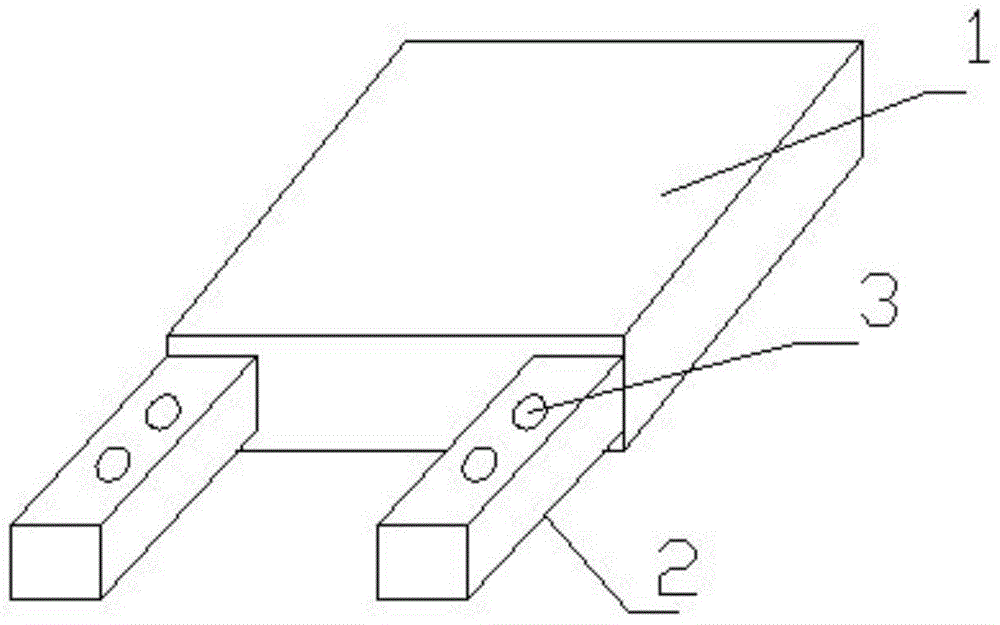

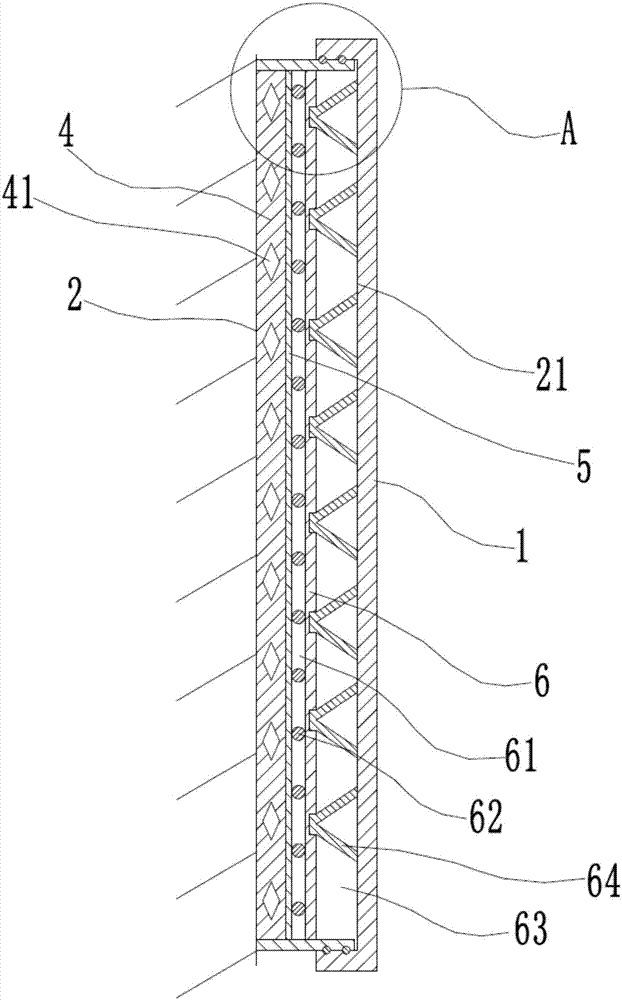

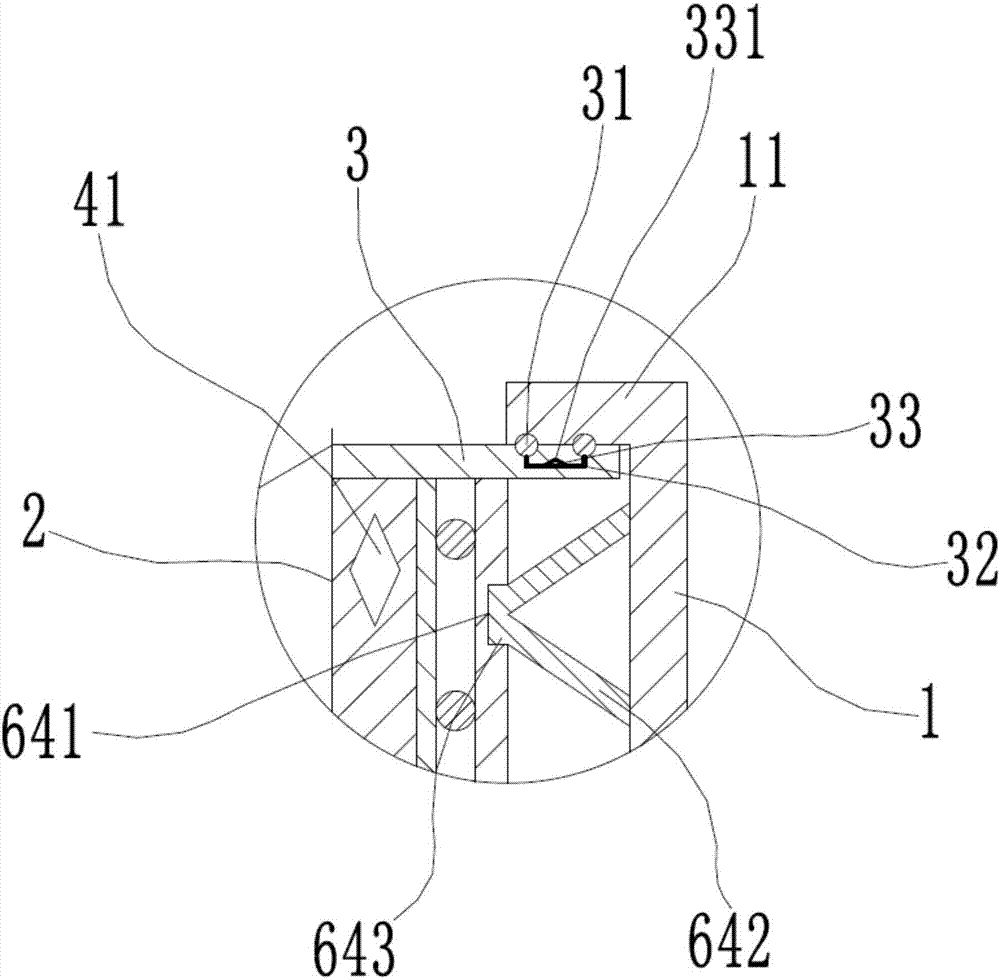

Composite wood-veneer-simulating hanging structure

The invention provides a composite wood-veneer-simulating hanging structure. The two opposite ends of a wood veneer are each connected with a first connector. The first connectors are connected to a wall at the same time. A first cavity is formed between the wood veneer and the wall. A first cushion plate is arranged in the first cavity and laid on the wall. A plurality of second cavities are formed in the first cushion plate. A second cushion plate is laid on the first cushion plate. A third cushion plate is further arranged between the second cushion plate and the wood veneer. A third cavity is formed between the third cushion plate and the second cushion plate, and a plurality of first rolling shafts are arranged in the third cavity. A fourth cavity is formed between the third cushion plate and the wood veneer. A plurality of V-shaped connectors are arranged in the fourth cavity. One ends of the V-shaped connectors are connected with the third cushion plate, and the other opposite ends of the V-shaped connectors are connected with the wood veneer. By means of the composite wood-veneer-simulating mounting structure, the technical problems that a wood veneer is likely to deform due to dampness and also likely to crack, and the upfront pretreatment cost is high in the prior art can be solved.

Owner:SUZHOU MEIRUIDE BUILDING DECORATION CO LTD

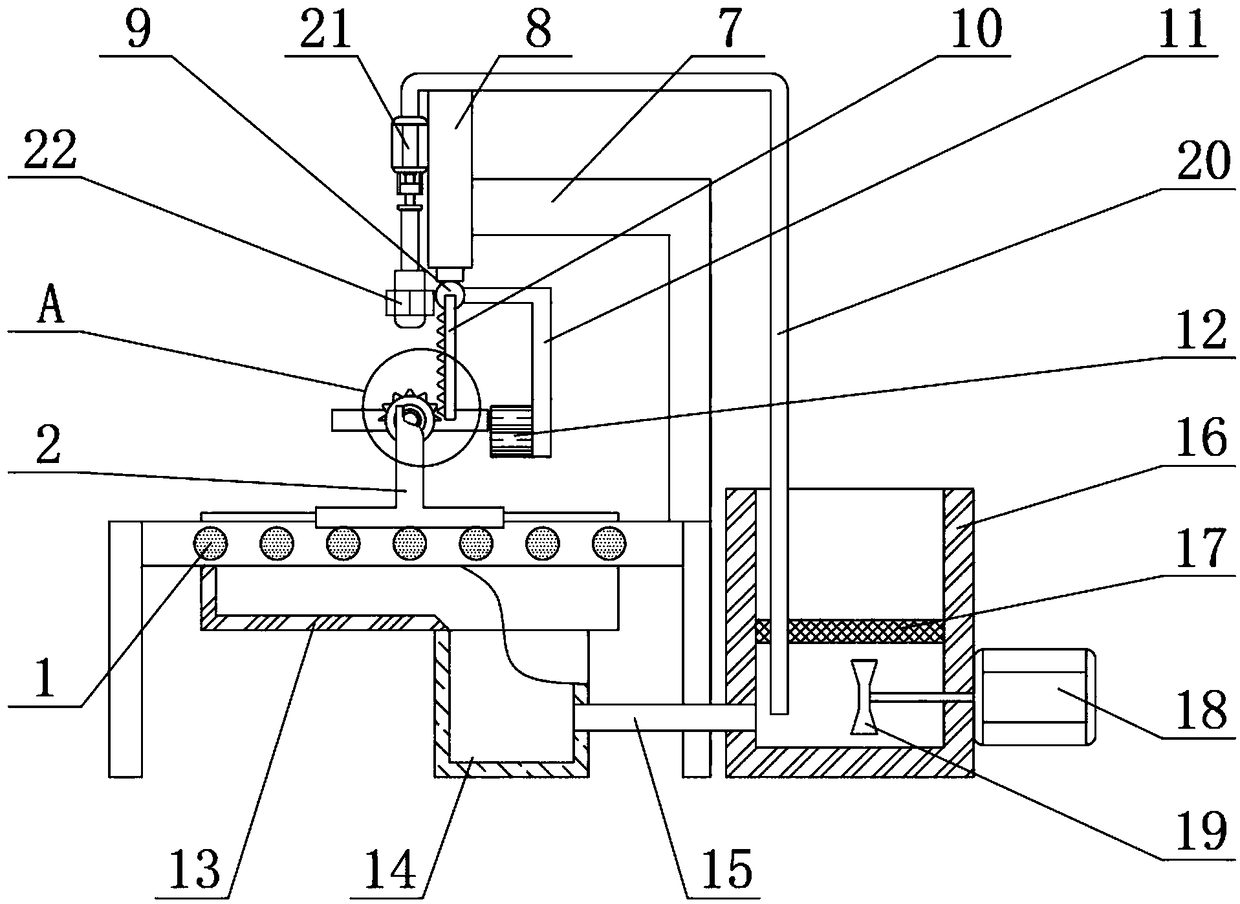

Plate paint spraying device for electric fire box production

The invention relates to the technical field of plate paint spraying, in particular to a plate paint spraying device for electric fire box production. The device comprises a rolling barrel conveyor and a support; the top ends of the rolling barrel conveyor on the front side and the rear side are rotationally connected with the bottom end of the support, a spring is fixedly connected to the rear end of the support at the front side, and a rubber disc is rotationally connected to the rear end of the spring at the front side; a horizontally arranged plate is arranged at the rear end of the rubberdisc at the front side, and a gear is fixedly connected to the outer side of the rubber disc, the reverse rotation of the plate is realized through the rubber disc. According to the device, the rubber disc, the gear and a rack are arranged, the reverse rotation of the plate is realized, painting of the back face and the side face of the plate are facilitated, the side face of the plate is prevented from being affected with damp deformation, the electric fire box can be conveniently and stably spliced, manual painting is not needed, time and labor are saved, leakage coating is prevented, and quality of a finished product paint plate is guaranteed; and the design concept is ingenious, the design is reasonable, huge safety benefits and wide application prospects are achieved, and the deviceis worthy of popularization and use.

Owner:苏州家望宝科技有限公司

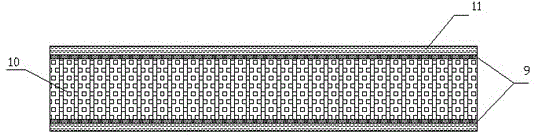

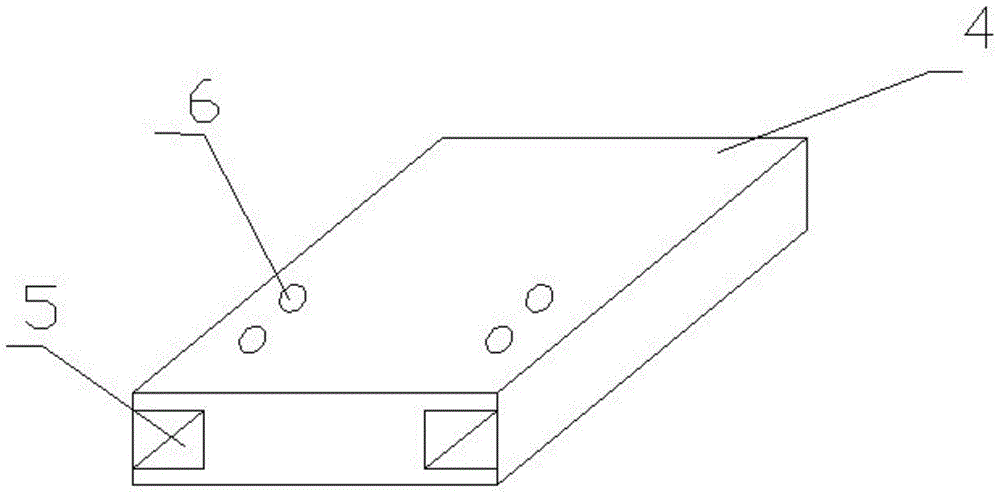

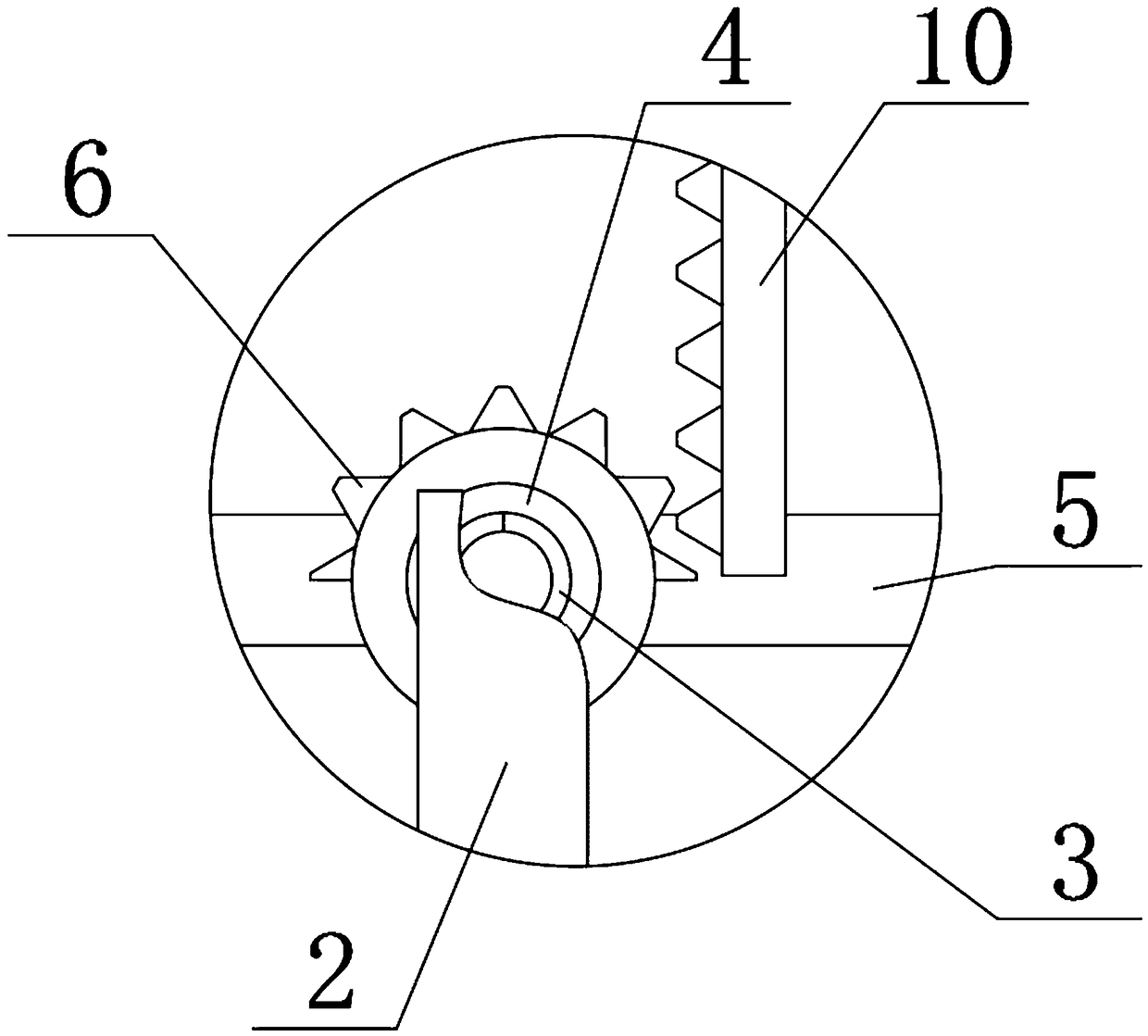

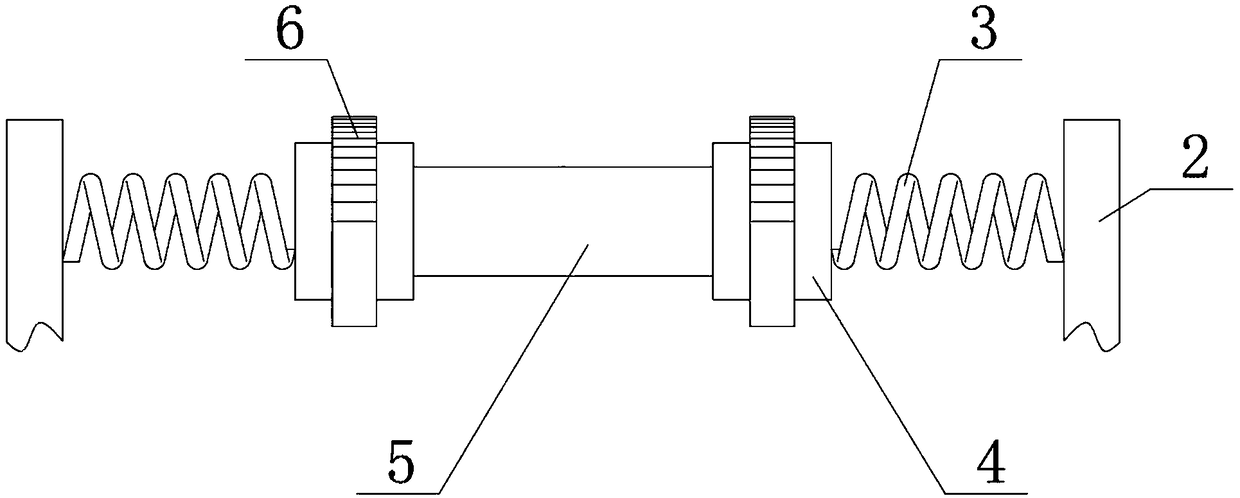

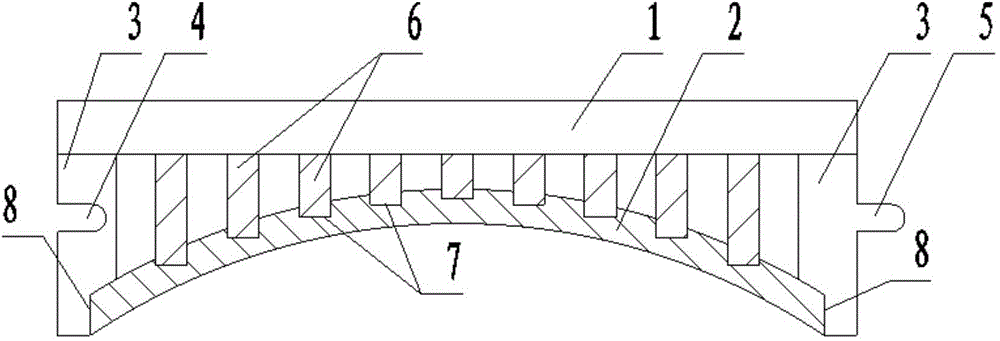

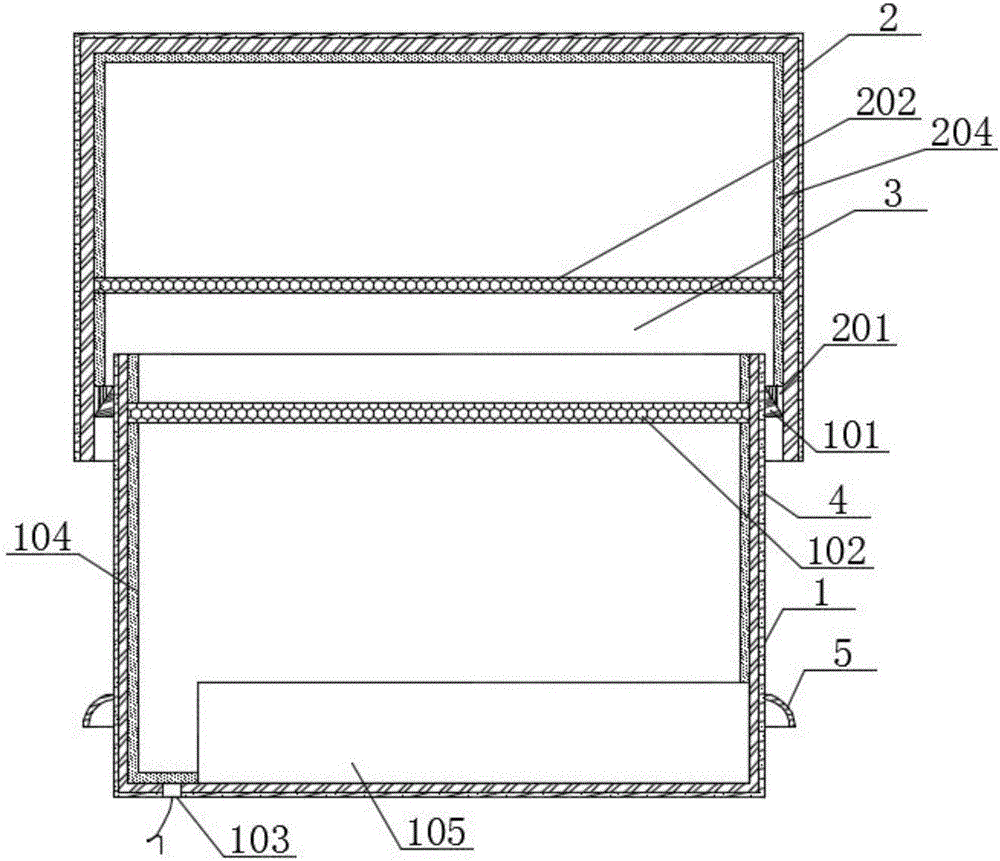

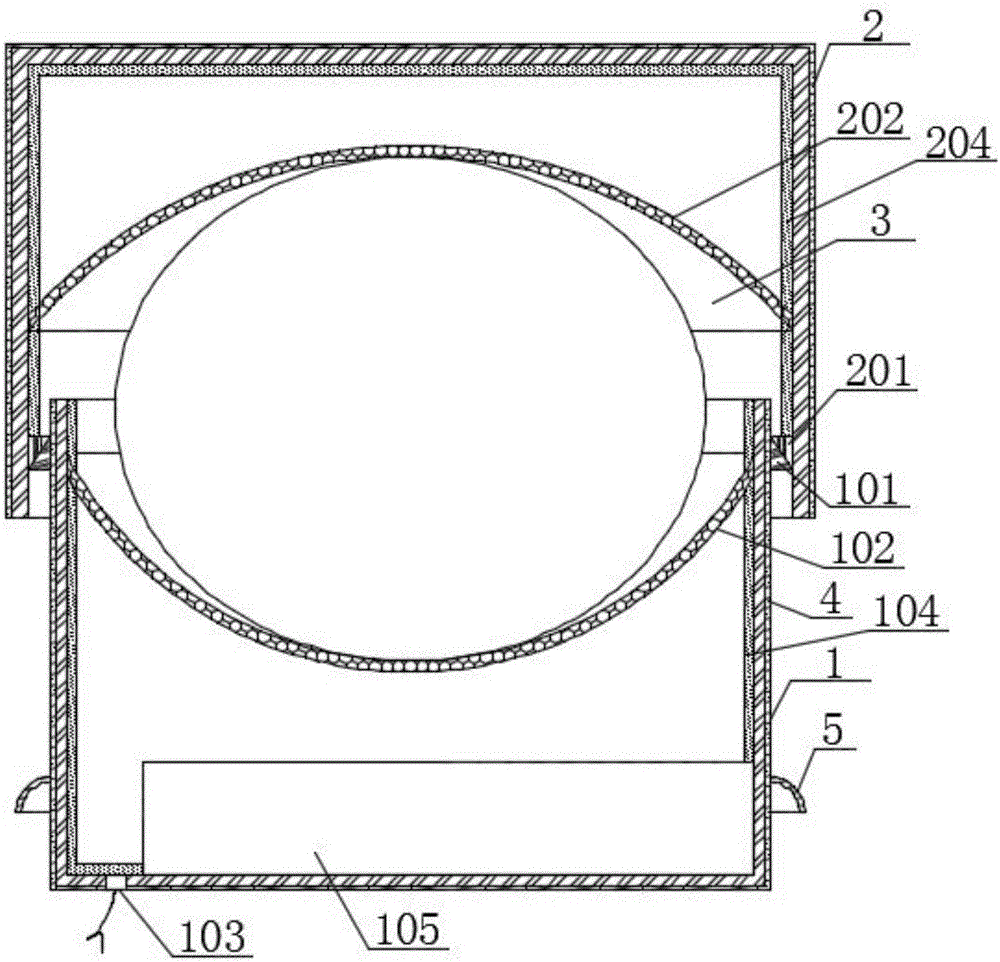

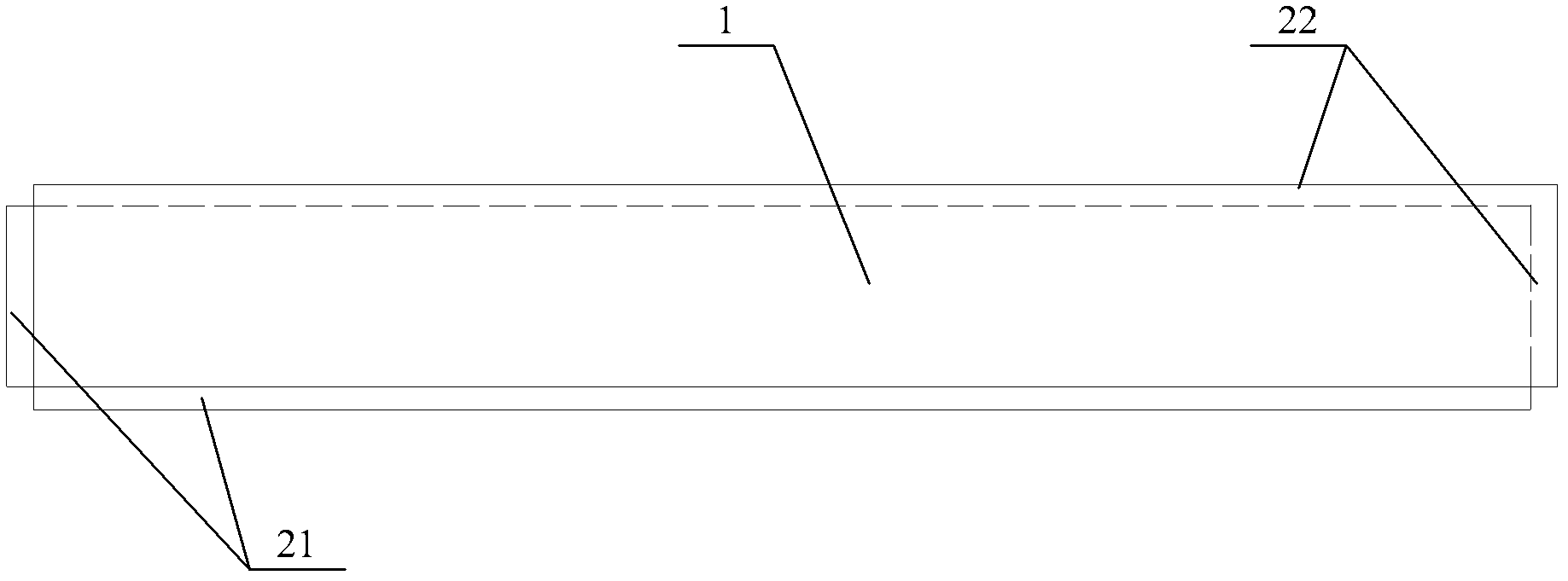

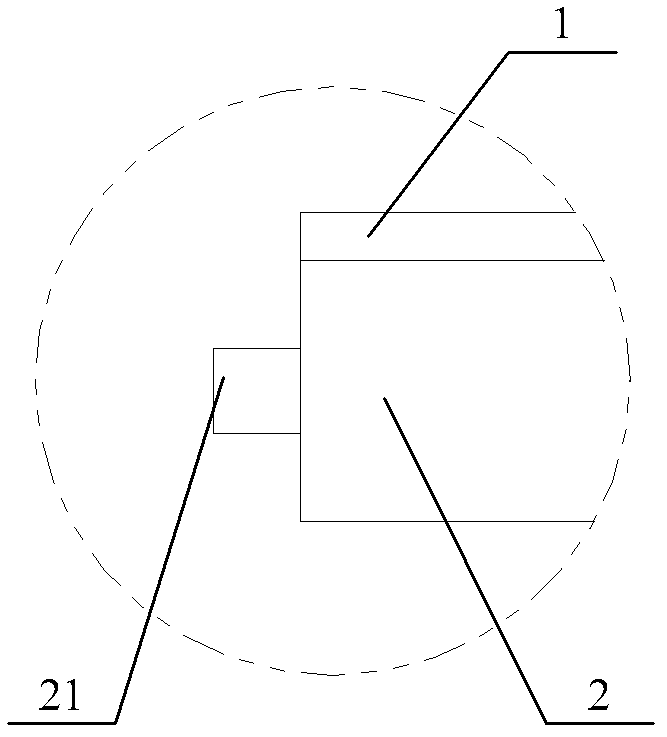

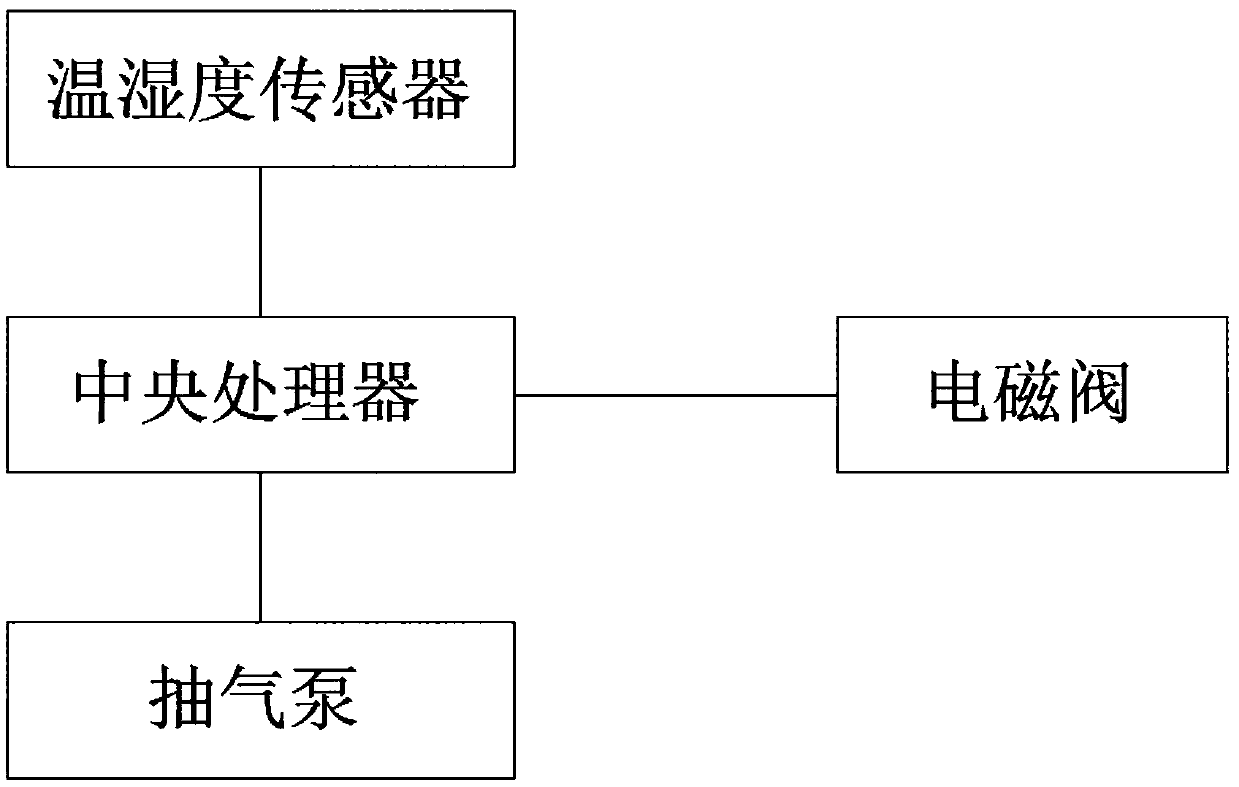

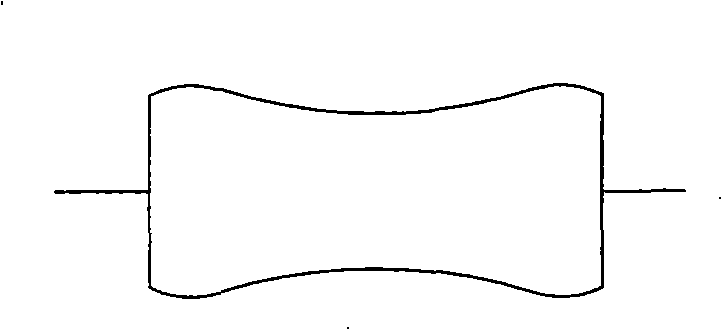

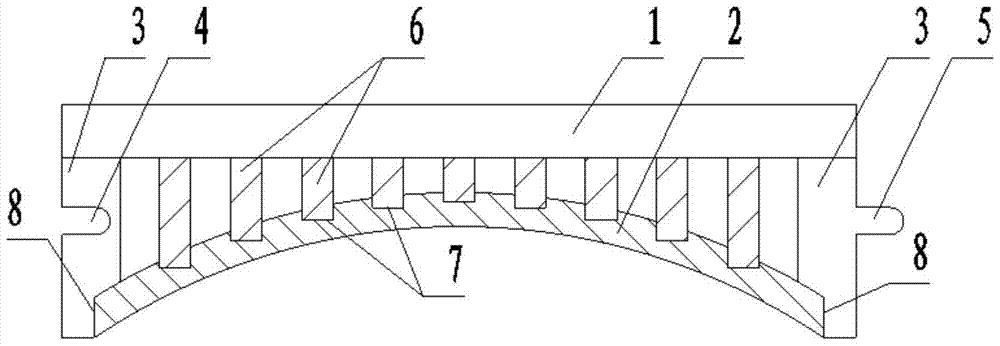

Compression-resistant anti-deformation high-strength solid wood floor

The invention discloses a compression-resistant anti-deformation high-strength solid wood floor. The compression-resistant anti-deformation high-strength solid wood floor comprises a solid wood floor body (1), and an arch-shaped supporting plate (2) is arranged below the solid wood floor body (1). The two sides of the arch-shaped supporting plate (2) are connected with side plates (3). The side plate (3) located on one side of the arch-shaped supporting plate (2) is provided with a tenon (4), and the side plate (3) located on the other side of the arch-shaped supporting plate (2) is provided with a rabbet (5). A plurality of reinforcing plates (6) are arranged between the arch-shaped supporting plate (2) and the solid wood floor body (1). The arch-shaped supporting plate is arranged for scattering pressure and improving the overall compression-resistant capability and anti-deformation capability. Due to the fact that the reinforcing plates are arranged for connecting the arch-shaped supporting plate and the solid wood floor body, the compression resistance and the anti-deformation performance of the whole solid wood floor are further improved. Moreover, the arch-shaped supporting plate can prevent the bottom of the solid wood floor from being affected with damp and deforming, and the dampproof performance is improved. The solid wood floor not only can improve the strength but also has the advantages of being resistant to compression and capable of preventing deformation and damp.

Owner:ZHEJIANG RAYCHER WOOD IND

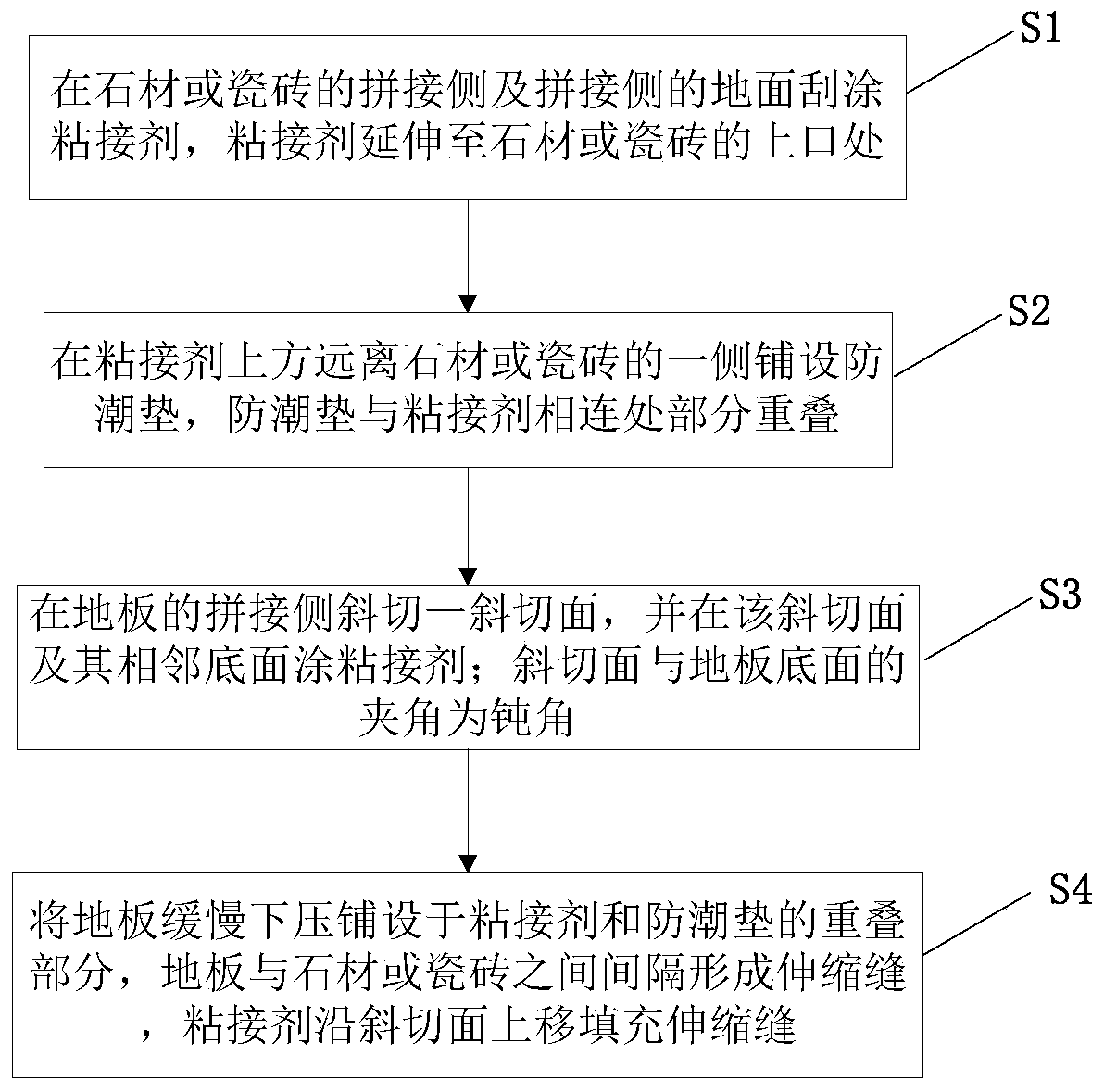

Splicing method and structure of floor and stone or tile

PendingCN109881864APrevent moisture deformationRealize seamless splicingFlooring insulationsAdhesiveEngineering

The invention discloses a splicing method and structure of a floor and stone or tile, and relates to the field of floor installation. The splicing method includes the steps that an adhesive is scrapedand applied on the adjacent ground on the stone or tile splicing side, one side of the adhesive is scraped and applied to an upper opening of the stone or the tile in an extending mode, and the otherside of the adhesive is scraped and applied at a distance; a moisture-proof pad is laid on the other side of the adhesive, the moisture-proof pad partially overlaps with the adhesive on the connecting position, a diagonal plane is obliquely cut on the splicing side of the floor, and the adhesive is applied on the diagonal plane and the adjacent bottom surface of the diagonal plane; and the included angle between the diagonal plane and the floor bottom surface is the obtuse angle, the floor is laid on the adhesive and the moisture-proof pad on the ground, an expansion joint is left between thefloor and the stone or the tile, and the floor is slowly pressed, so that the adhesive is moved up along the diagonal plane to fill the expansion joint. The splicing method can realize seamless splicing of the floor and the stone or the tile, the elegant appearance and attractiveness are achieved, the dirt and dust are not prone to being hidden, the ground is flat and easy to clear, and the flooron the splicing position with the stone or the tile can be further prevented from being deformed by being affected with damp.

Owner:舍奢(武汉)家居有限公司

Storage and transport box for fragile fruit

InactiveCN106742804ALimit range of movementReduce respirationPackaging under vacuum/special atmosphereSealingEngineeringVacuum tube

The invention relates to a package box, in particular to a storage and transport box for fragile fruit. The box comprises a box body and a box cover. The box cover wraps and is buckled at the upper end of the box body. The outside of the box body is provided with a first sealing ring. The inside of the box cover is provided with a second sealing ring. The first sealing ring corresponds to the second sealing ring. The interior of the box body is provided with a first elastic storage net. The edge of the first elastic storage net is arranged on the inner wall of the box body in an enclosing manner. The interior of the box cover is provided with a second elastic storage net. The edge of the second elastic storage net is arranged on the inner wall of the box cover in an enclosing manner. The first elastic storage net and the second elastic storage net are buckled correspondingly to form a storage bin. The bottom of the box body is provided with a flexible vacuumized pipe joint. The flexible vacuumized pipe joint communicates with an external vacuumized device. Through the vacuumized storage bin, conventional problems arising from the need of cushioning foam for packages during fruit transport such as resources waste and environmental pollution are solved.

Owner:怀宁佳瑞包装有限公司

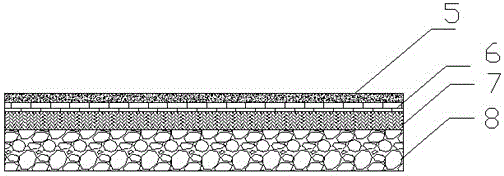

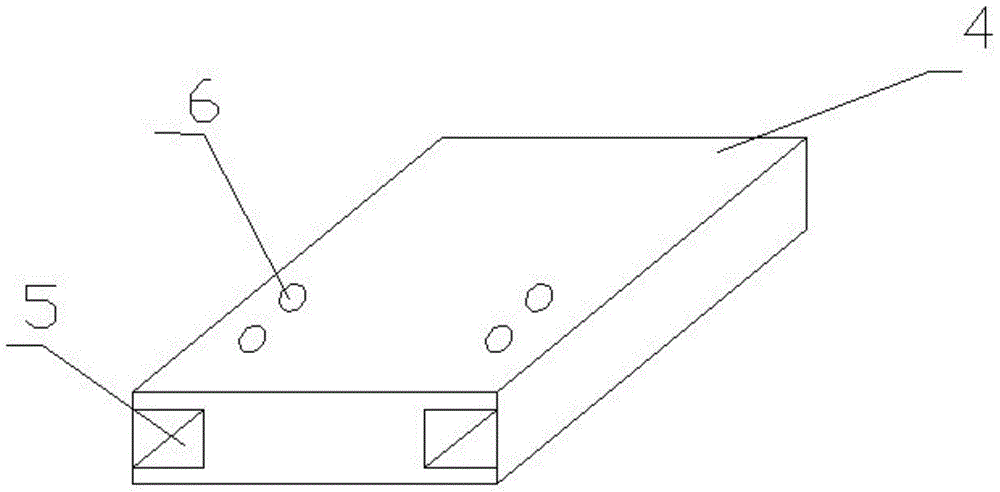

Composite floor

InactiveCN102628315AReduce deformation ratePrevent moisture deformationFlooringSurface layerThermal expansion

The invention provides a composite floor, which comprises a surface layer plate and a base layer plate with a low coefficient of heat expansion, wherein the surface layer plate is attached to the base layer plate; and a bulge and a groove, which correspond to each other, are formed on the side surface of the base layer plate, and can be buckled with a groove and a bulge formed on another composite floor. According to the composite floor provided by the invention, the coefficient of heat expansion of the base layer plate is low, so that the deformation rate of the composite plate under different circumstances can be reduced, and the composite floor can be prevented from being moistened and deformed; and the bulge and the groove are formed on the side surface of the base layer plate, the spliced laying of the composite floor can be achieved through the matching between the bulge and the groove, so that the composite floor is assembled and disassembled conveniently.

Owner:王春安 +3

An aromatic fruit antiseptic transport box

ActiveCN106742567BReduce rotImprove distributionClosuresShock-sensitive articlesElectricityWaveform shaping

The invention relates to a package box, in particular to an anti-corrosion conveying box for aromatic fruit. The box comprises a box body, a box cover, an air extracting pump and multiple waveform-shaped partition boards. The box cover is buckled with the box body correspondingly. The inner wall of the box body is provided with multiple installing bosses for installing the waveform-shaped partition boards in a surrounding manner. All the installation bosses are arranged at intervals along the height direction of the box body and used for separating the interior of the box body into mutually-parallel accommodating cavities. A first air hole is distributed in the box cover. An air passing film covers the first air hole. Second air holes are arranged in all the waveform-shaped partition boards. An air inlet end of the air extracting pump communicates with the box body through an installing port at the bottom of the box body. A temperature and humidity inductor is arranged in the box body and the temperature and humidity inductor and the air extracting pump are electrically connected with a central processor. The anti-corrosion conveying box for aromatic fruit has following beneficial effects: problems of a conventional storage and transport box such as poor ventilation and easy corrosion of fruits are solved through a self-feedback system.

Owner:烟台力量知识产权服务有限公司

Solid door

ActiveCN104612556AEasy to assemble by yourselfEasy assemblyDoor leavesElectrical and Electronics engineering

The invention discloses a solid door. The solid door comprises an upper door, a lower door and a connection bolt. The upper door comprises an upper door body and upper door connection columns. The two upper door connection columns are arranged on the two sides of the end face of the upper door body respectively and provided with bolt through holes. The lower door comprises a lower door body. The lower door body is provided with lower door connection grooves. The depth of the lower door connection grooves is smaller than or equal to half the length of the upper door body. The lower door body is provided with through holes. The through holes are communicated with the lower door connection grooves and perpendicular to the lower door connection grooves. The upper door connection columns penetrate into the lower door connection grooves. Connection bolts penetrate through the through holes and the bolt through holes to connect the upper door body and the lower door body together. The solid door has the advantages of being low in cost, capable of achieving the insect prevention and damp prevention functions, not prone to deformation and easy to carry.

Owner:HUZHOU SHENRUI DOOR IND

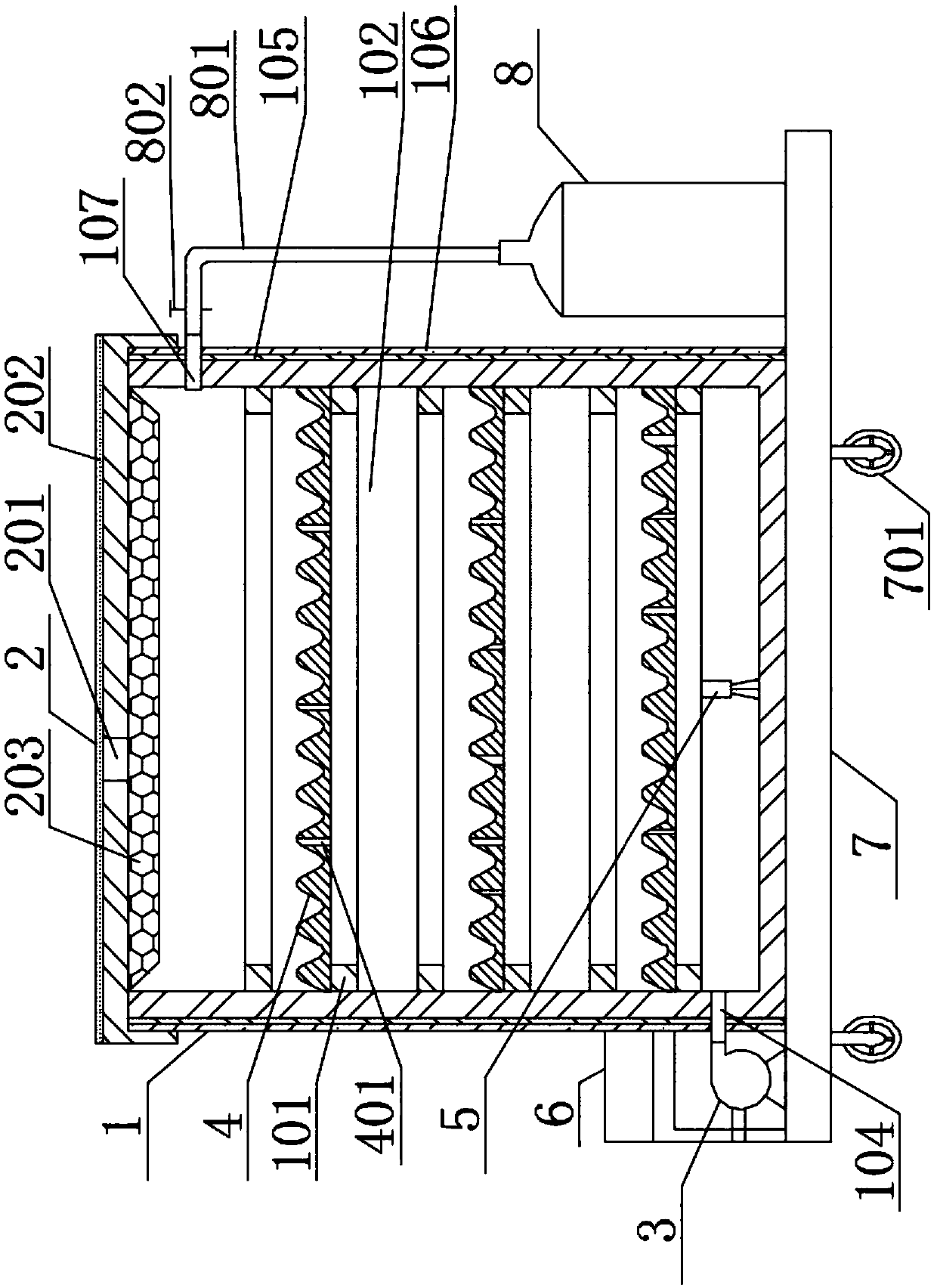

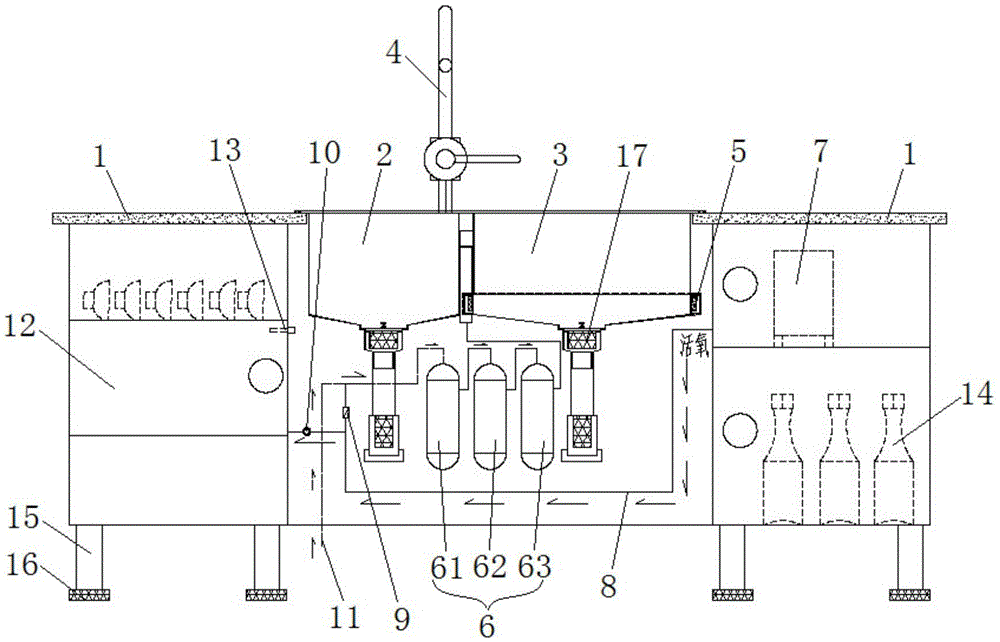

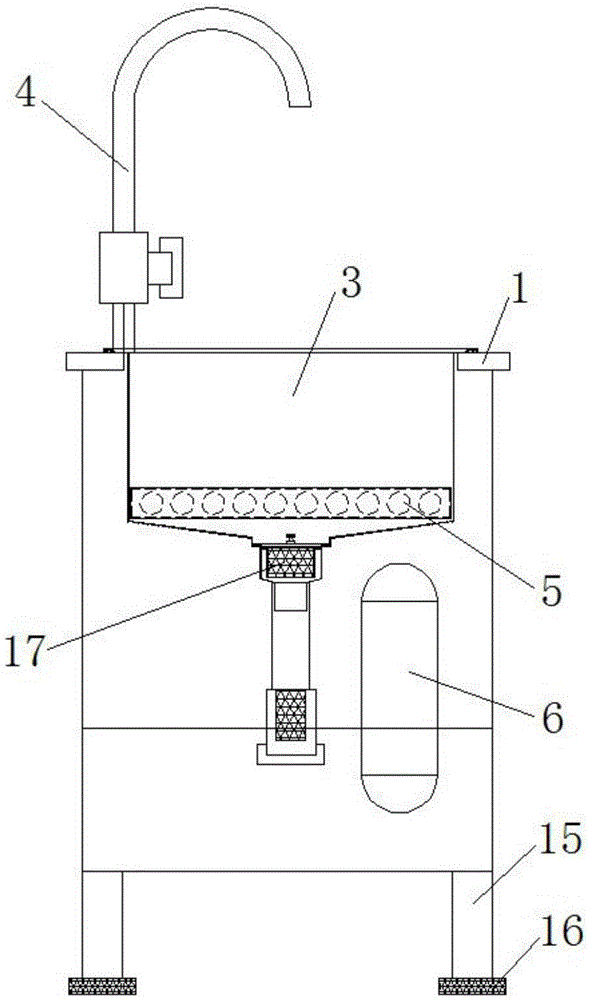

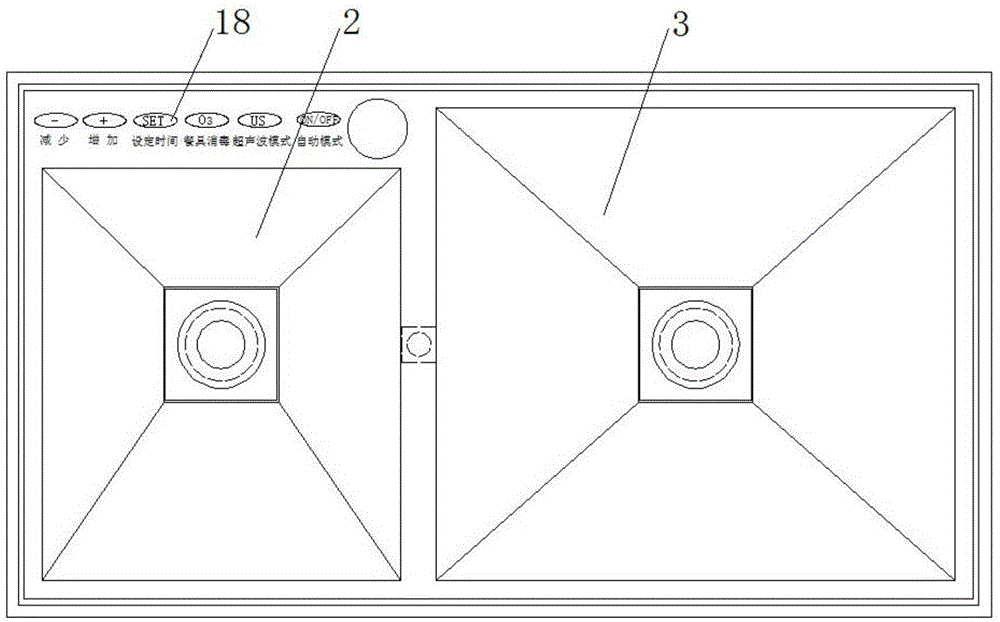

An integrated purification device with frequency conversion piezoelectric ultrasonic and ozone action

InactiveCN103919512BEfficient degradationEasy to cleanMultistage water/sewage treatmentTableware washing/rinsing machinesElectric controlElectromagnetic valve

Owner:江苏一比百节能环保科技有限公司

Manufacture process for peeling broad beans

InactiveCN101828591BReduce labor intensityShort soaking timeEggs preservationVegetable peelingCold airWarm water

The invention discloses a manufacture process for peeling broad beans. The process comprises the following steps of: raw material soaking: soaking broad beans in warm water and stirring; peeling and dewatering the soaked broad beans, wherein the soaked broad beans are firstly peeled in a sheller and then blown and dewatered by using a dewatering blower; carrying out alternate air drying of hot air and cold air on the dewatered broad beans in drying equipment; and cooling and packaging the broad beans dried by air. The invention shortens the drying time, dried bean kernels have no deformation,and the effects of drying, air drying and cooling are good.

Owner:周富禄

A hanging structure and a hanging system using the hanging structure

The invention discloses a hanging-mounting structure and a hanging-mounting system applying the same. The hanging-mounting structure comprises a supporting sliding rail, sliding blocks are mounted atthe two ends of the supporting sliding rail in an inserted mode correspondingly and extend to the exterior of the supporting sliding rail, and fastening elements and leveling elements are mounted on the positions, located outside the supporting sliding rail, of the sliding blocks in a threaded mode. A hanging-mounting part is mounted on one side of the supporting sliding rail in an inserted mode,and connecting elements are arranged between the hanging-mounting part and the supporting sliding rail. A hanging-mounting gap is formed between the hanging-mounting part and the other side of the supporting sliding rail. Quick mounting, hanging-mounting and leveling are achieved, the structure is simple, the hanging-mounting and supporting effects on the hanging-mounting part is good, the construction procedure is simple, the construction period is short, the work efficiency is high, and the construction cost and the labor cost are low; meanwhile, the hanging-mounting structure and the hanging-mounting part are good in cooperation and easy to replace, after cooperation, tensile force exists between the hanging-mounting structure and the hanging-mounting part, thus the problem that the hanging-mounting part is damped and thus deforms is avoided, and the reusability is effectively guaranteed; and in addition, according to the hanging-mounting structure, the attractiveness of the hanging-mounting part after hanging-mounting is advantageously improved, the performance cost ratio is high, environmental protection is achieved, and pollution is avoided.

Owner:潍坊优丽雅装饰软包制品有限公司

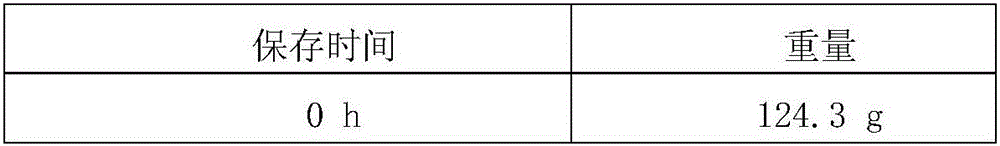

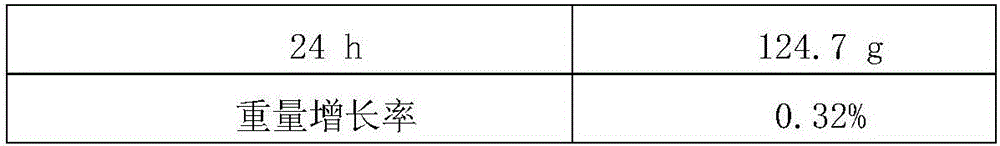

Damp-proof burning incense and preparation method thereof

InactiveCN106614560AImprove moisture resistanceLow weight gainBiocidePest repellentsAdhesiveParaffin oils

The invention discloses damp-proof burning incense and a preparation method thereof. The damp-proof burning incense is prepared from plant raw materials, paraffin, an adhesive and water. The dissolved paraffin is sprayed into a closed container filled with the plant raw materials through a charging opening by an air compressor, the nozzle air flow rate is controlled to be 30-90 m / s, the temperature of compressed air is controlled to be 10-25 DEG C higher than the melting point of the paraffin, the adhesive and the water are added into the closed container after stirring is carried out for a certain time, the water content of the mixture in the closed container is 40-60%, stirring continues to be carried out, finally, the mixture in the closed container is transferred into an extruder hopper, die extrusion molding is carried out, the product is dried till the water content is smaller than or equal to 10%, and the damp-proof burning incense is obtained. Surface hydrophilicity loci of the plant raw materials are closed through the paraffin, the damp-proof burning incense is prepared in combination with the adhesive, and the situation that burning incense is affected with damp to deform or peel off in the plum rain season of spring in the south can be effectively avoided.

Owner:FUJIAN AGRI & FORESTRY UNIV

A high-strength solid wood floor that resists compression and deformation

The invention discloses a compression-resistant anti-deformation high-strength solid wood floor. The compression-resistant anti-deformation high-strength solid wood floor comprises a solid wood floor body (1), and an arch-shaped supporting plate (2) is arranged below the solid wood floor body (1). The two sides of the arch-shaped supporting plate (2) are connected with side plates (3). The side plate (3) located on one side of the arch-shaped supporting plate (2) is provided with a tenon (4), and the side plate (3) located on the other side of the arch-shaped supporting plate (2) is provided with a rabbet (5). A plurality of reinforcing plates (6) are arranged between the arch-shaped supporting plate (2) and the solid wood floor body (1). The arch-shaped supporting plate is arranged for scattering pressure and improving the overall compression-resistant capability and anti-deformation capability. Due to the fact that the reinforcing plates are arranged for connecting the arch-shaped supporting plate and the solid wood floor body, the compression resistance and the anti-deformation performance of the whole solid wood floor are further improved. Moreover, the arch-shaped supporting plate can prevent the bottom of the solid wood floor from being affected with damp and deforming, and the dampproof performance is improved. The solid wood floor not only can improve the strength but also has the advantages of being resistant to compression and capable of preventing deformation and damp.

Owner:ZHEJIANG RAYCHER WOOD IND

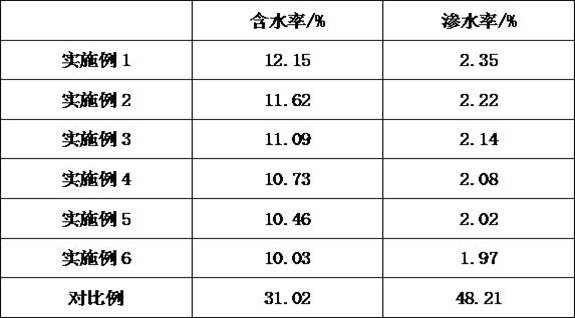

Waterproof protective material for deep well and preparation method of waterproof protective material

The invention discloses a waterproof protective material for a deep well and a preparation method of the waterproof protective material. The waterproof protective material is prepared from water-based polymethyl silicone resin, deionized water, butyl stearate, an antioxidant, a water repellent agent, carboxymethylcellulose, polyacrylamide, fatty glyceride and a coloring agent. The water-based coating comprises the following components in parts by weight: 78-84 parts of water-based polymethyl silicone resin, 15-19 parts of deionized water, 3-5 parts of butyl stearate, 2-4 parts of an antioxidant, 2-4 parts of a water repellent agent, 1-3 parts of carboxymethylcellulose, 2-4 parts of polyacrylamide, 1-3 parts of fatty glyceride and 1-3 parts of a coloring agent. The hydrophobic agent formed by mixing the dimethyl silicone oil, the calcium palmitate and the microcrystalline wax is added, so that the waterproof performance of the material is greatly improved, the problem of underground water leakage is not easy to occur after long-term use, a protective layer is maintained, the problems of damp deformation, cracking and collapse of a deep well are avoided, and the use is safer.

Owner:河南蓝翎环科防水材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com