a solid wood door

A technology of solid wood door and solid wood layer, applied in the direction of door leaf, etc., can solve problems such as affecting physical health, difficulty in opening, affecting aesthetic opening and closing, etc., and achieves the effect of simple and easy assembly method, convenient and simple handling, and simple and convenient assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

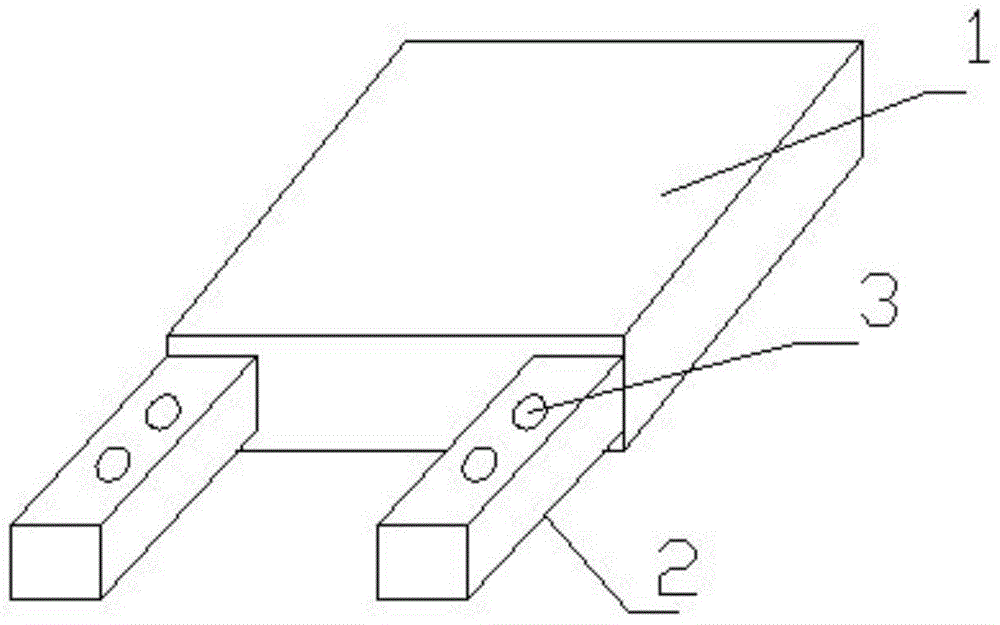

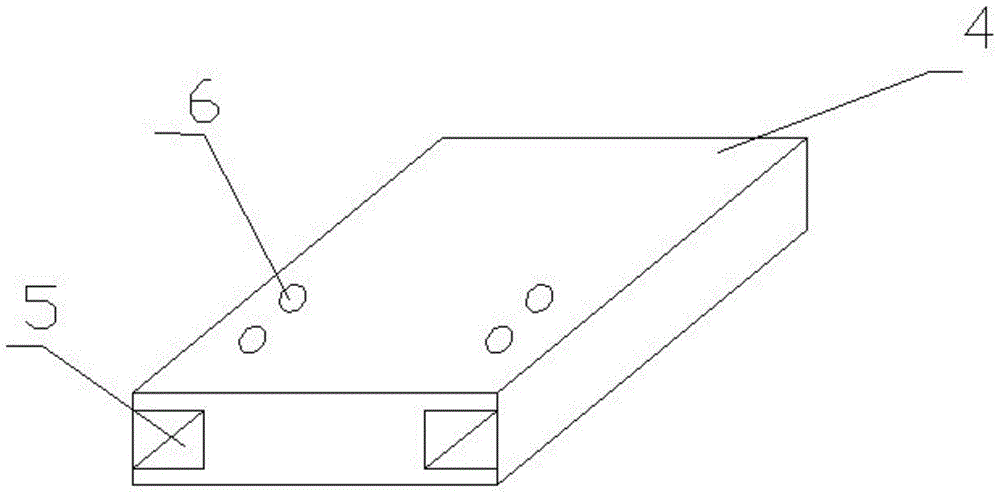

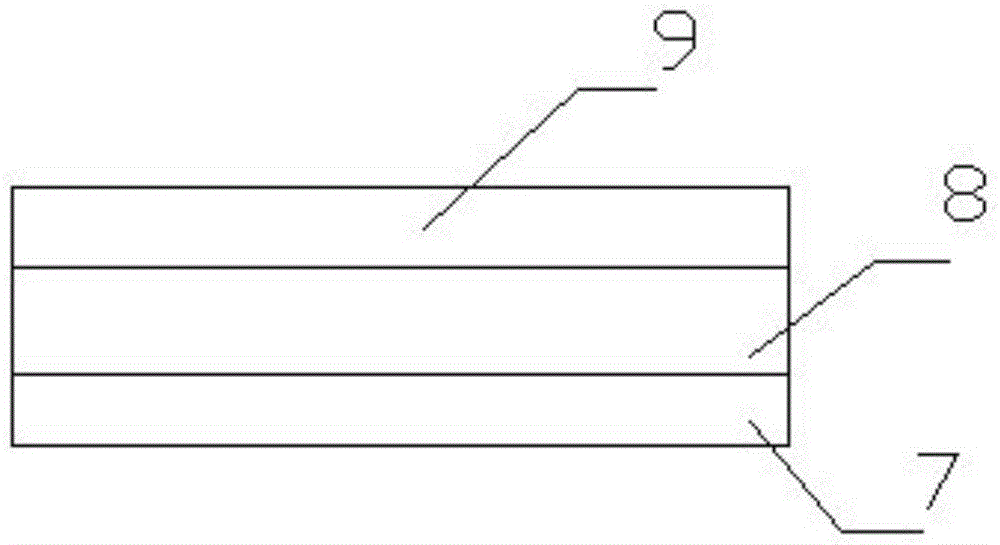

[0031] This embodiment includes an upper door, a lower door and connecting bolts. The upper door includes an upper door body 1 and an upper door connecting column 2. There are two upper door connecting columns 2, which are respectively installed on both sides of the end face of the upper door body 1. The upper door connecting column 2 Bolt through holes 3 are arranged on the top, and the lower door includes a lower door body 4. A lower door connecting groove 5 is arranged on the lower door body 4. The depth of the lower door connecting groove 5 does not exceed half of the length of the lower door body 4. The lower door The body 4 is provided with a through hole 6, the through hole 6 is connected with the lower door connecting groove 5, and the through hole 6 is perpendicular to the lower door connecting groove 5; the upper door connecting column 2 penetrates the lower door connecting groove 5, and the connecting bolt The upper door body 1 and the lower door body 4 are connected...

Embodiment 2

[0033] This embodiment includes an upper door, a lower door and connecting bolts. The upper door includes an upper door body 1 and an upper door connecting column 2. There are two upper door connecting columns 2, which are respectively installed on both sides of the end face of the upper door body 1. The upper door connecting column 2 Bolt through holes 3 are arranged on the top, and the lower door includes a lower door body 4. A lower door connecting groove 5 is arranged on the lower door body 4. The depth of the lower door connecting groove 5 is not more than half of the length of the lower door body 4. The lower door The body 4 is provided with a through hole 6, the through hole 6 is connected with the lower door connecting groove 5, and the through hole 6 is perpendicular to the lower door connecting groove 5; the upper door connecting column 2 penetrates the lower door connecting groove 5, and the connecting bolt The upper door body 1 and the lower door body 4 are connecte...

Embodiment 3

[0040]This embodiment includes an upper door, a lower door and connecting bolts. The upper door includes an upper door body 1 and an upper door connecting column 2. There are two upper door connecting columns 2, which are respectively installed on both sides of the end face of the upper door body 1. The upper door connecting column 2 Bolt through holes 3 are arranged on the top, and the lower door includes a lower door body 4. A lower door connecting groove 5 is arranged on the lower door body 4. The depth of the lower door connecting groove 5 does not exceed half of the length of the lower door body 4. The lower door The body 4 is provided with a through hole 6, the through hole 6 is connected with the lower door connecting groove 5, and the through hole 6 is perpendicular to the lower door connecting groove 5; the upper door connecting column 2 penetrates the lower door connecting groove 5, and the connecting bolt The upper door body 1 and the lower door body 4 are connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com