Cut gas flow-guide device capable of being bidirectionally embedded into internal combustion engine

A technology of a flow guiding device and an internal combustion engine, which is applied in the directions of combustion air/combustion-air treatment, charging system, mechanical equipment, etc., can solve the problems of increased manufacturing cost, difficult assembly, and decline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

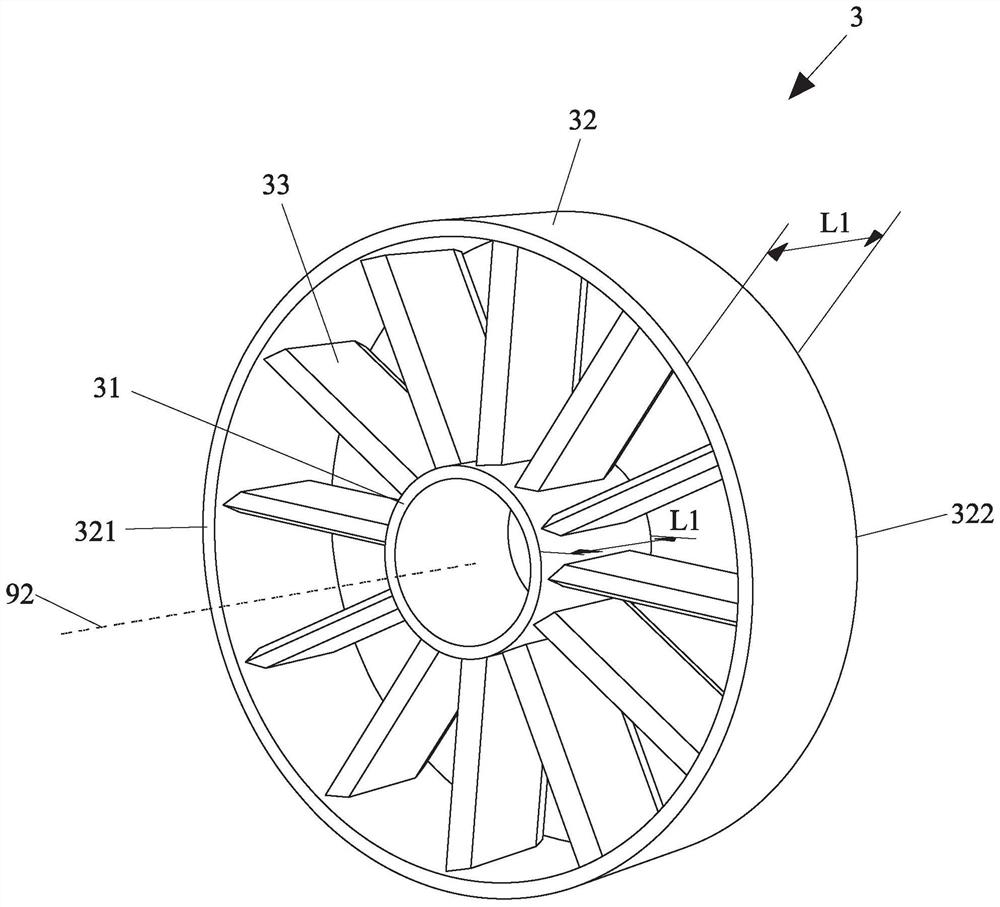

[0026] See Figure 3 to Figure 6 As shown, it is a schematic diagram of the three-dimensional structure, the three-dimensional structure from another perspective, the front view and the rear view of the preferred embodiment of the cutting gas guiding device that can be inserted into the internal combustion engine in two directions according to the present invention. The cutting gas guide device 3 capable of being inserted into the internal combustion engine in two directions according to the present invention includes a core ring structure 31, an outer ring structure 32 and a plurality of guide parts 33. The core ring structure 31 is a hollow cylinder. The outer ring structure 32 and the core ring structure 31 are a hollow cylinder with the same axis 92, and the outer ring structure 32 accommodates the core ring structure 31. The outer ring structure 32 has a first end surface 321 and a first end surface 321. Two end surfaces 322, the first end surface 321 and the second end s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com