Patents

Literature

39results about How to "Improve overall strength-to-weight ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of organic and inorganic wood composite material

ActiveCN101905471AGood dimensional stabilityImprove anti-corrosion performanceWood impregnation detailsWeather resistanceHardness

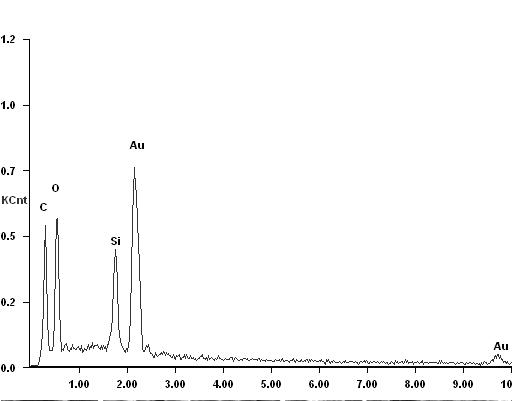

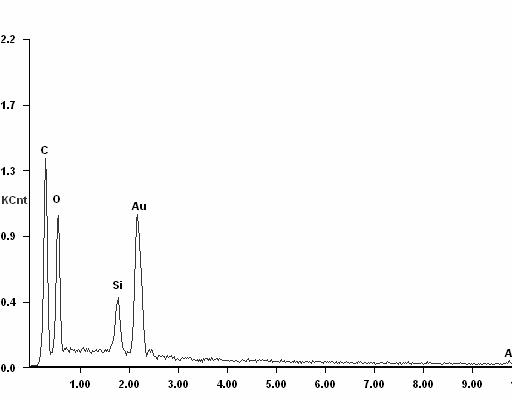

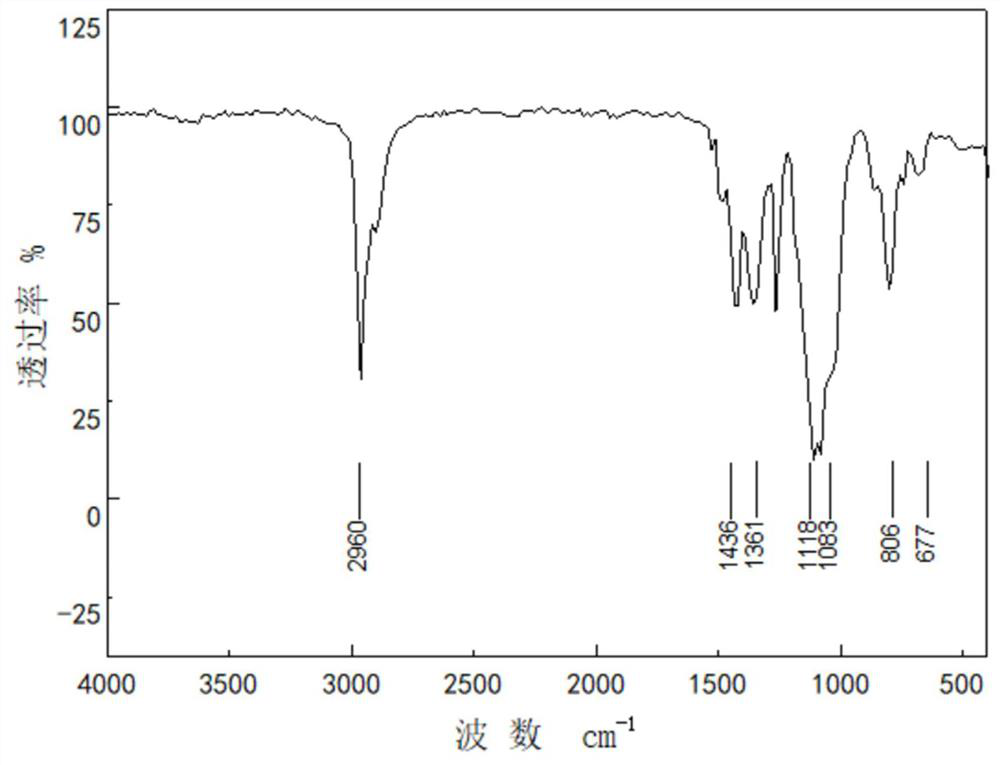

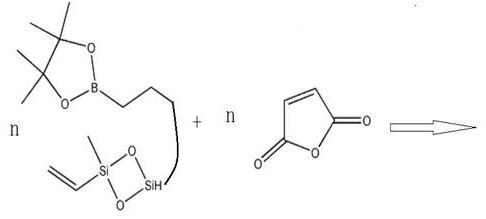

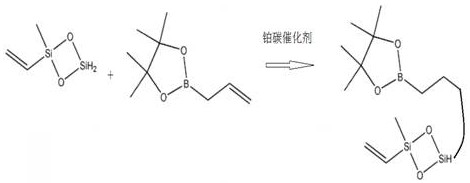

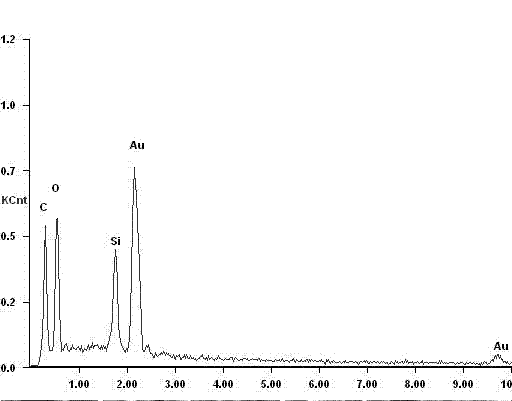

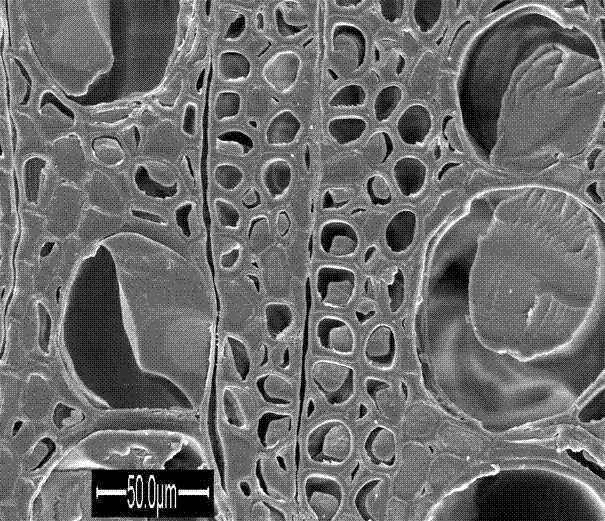

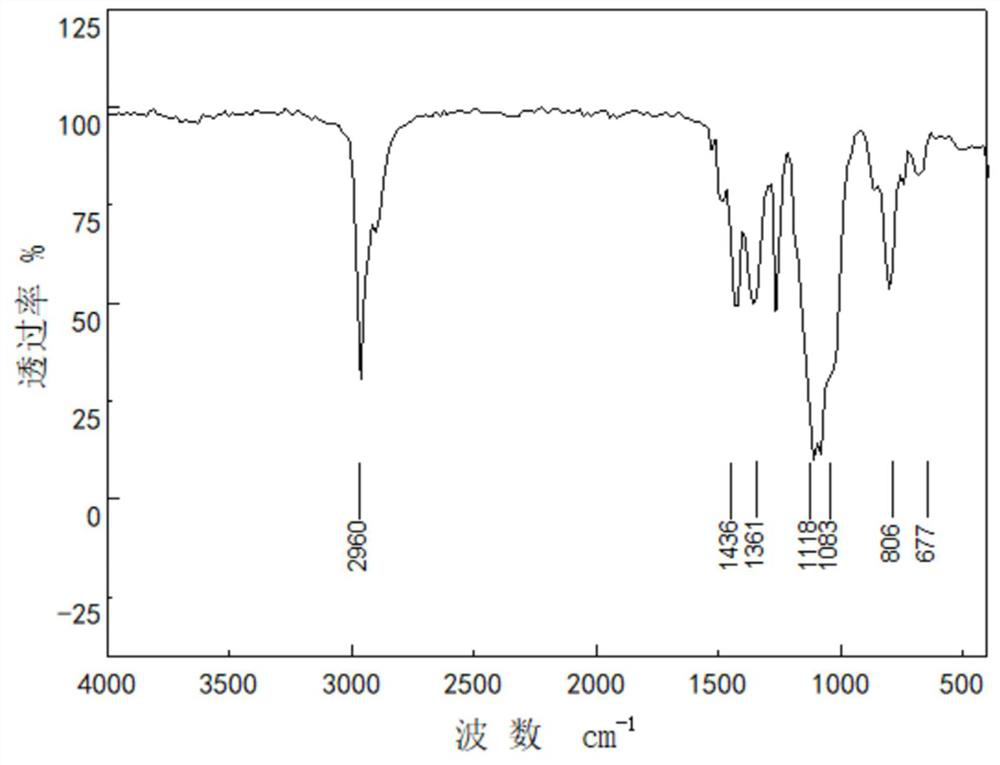

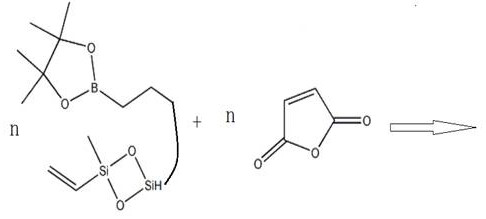

The invention discloses a preparation method of an organic and inorganic wood composite material, relating to the preparation method of a composite material and solving the problems that the wood composite material prepared by the traditional method has poor durability and mechanical property. The method comprises the following steps of: firstly, pre-polymerizing a monomer; secondly, preparing dilute sol; thirdly, impregnating the wood with the dilute sol under the vacuum-pressurizing condition; and fourthly, heating the impregnated wet wood to obtain the organic and inorganic wood composite material. The organic and inorganic wood composite material has higher strength-to-weight ratio; and compared with the wood, the hardness, the wearing resistance, the bending strength, the elastic modulus, the parallel-to-grain compressive strength and other mechanical properties of the organic and inorganic wood composite material are improved by 5 times to maximum extent; and the dimensional stability and the antiseptic property of the organic and inorganic wood composite material are improved by over 50-70 percent. In addition, the duality test shows that the thermal stability and the weather resistance of the organic and inorganic wood composite material are remarkably improved.

Owner:NORTHEAST FORESTRY UNIVERSITY

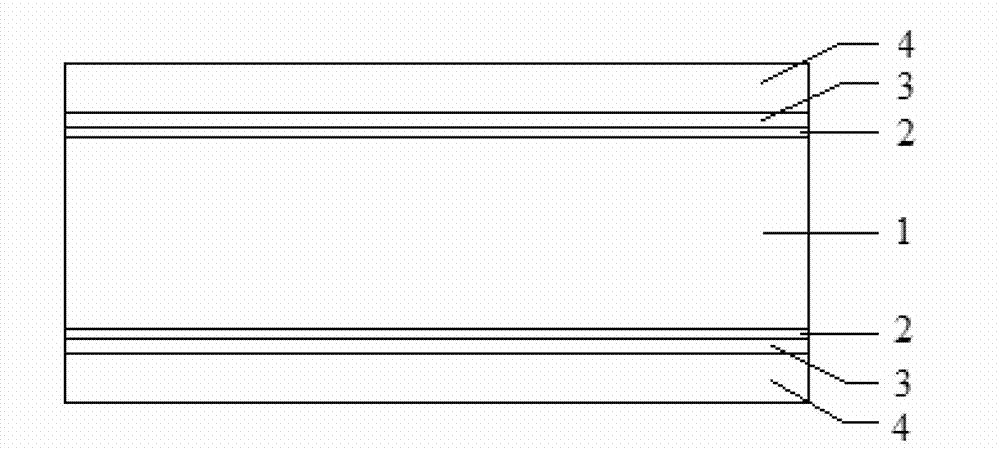

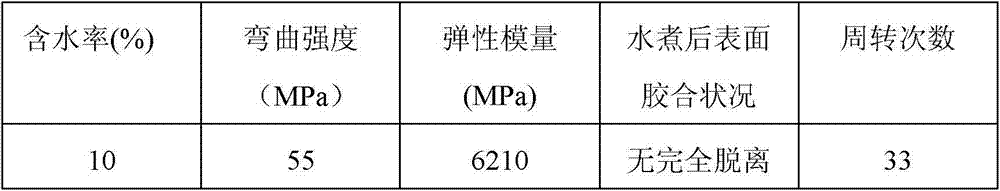

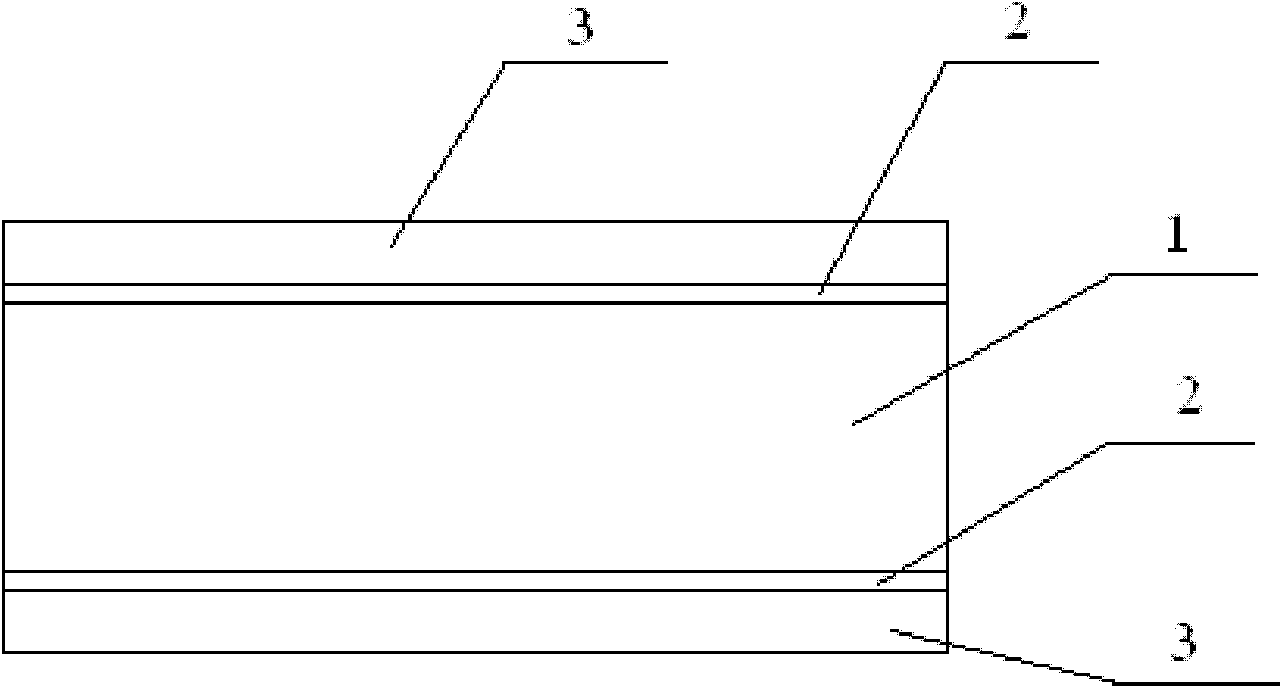

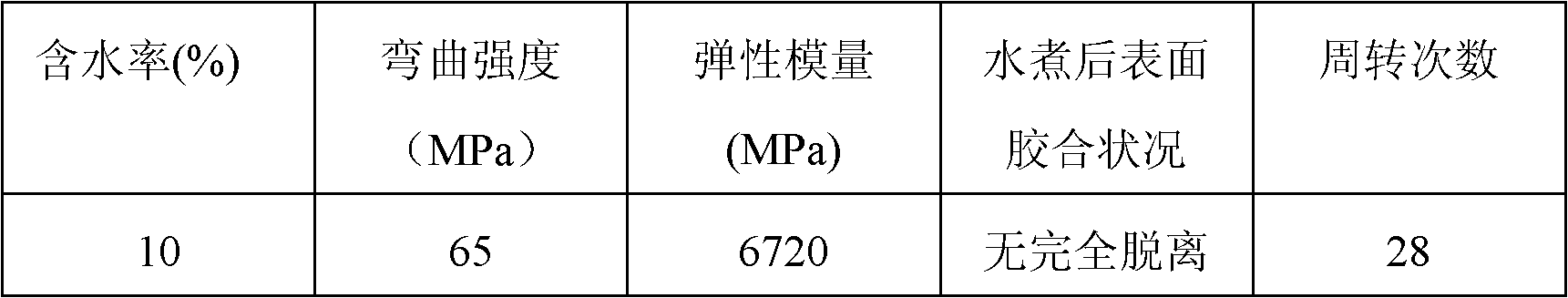

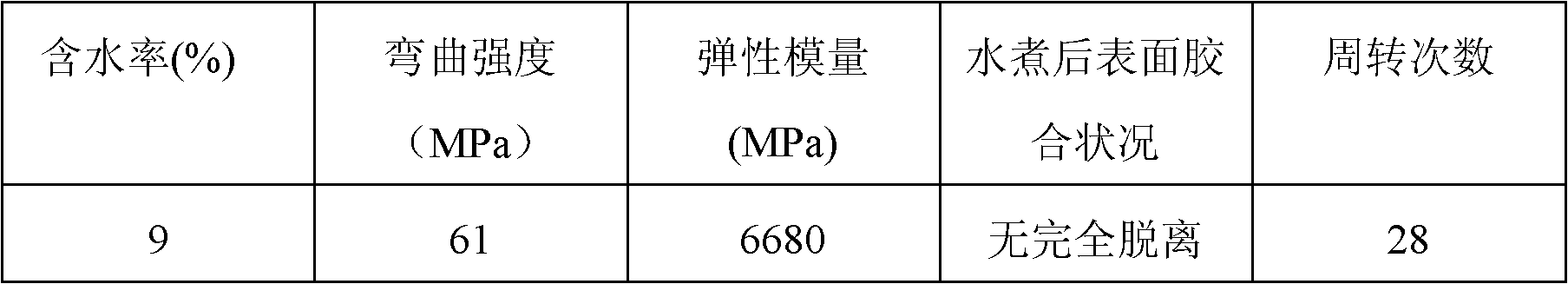

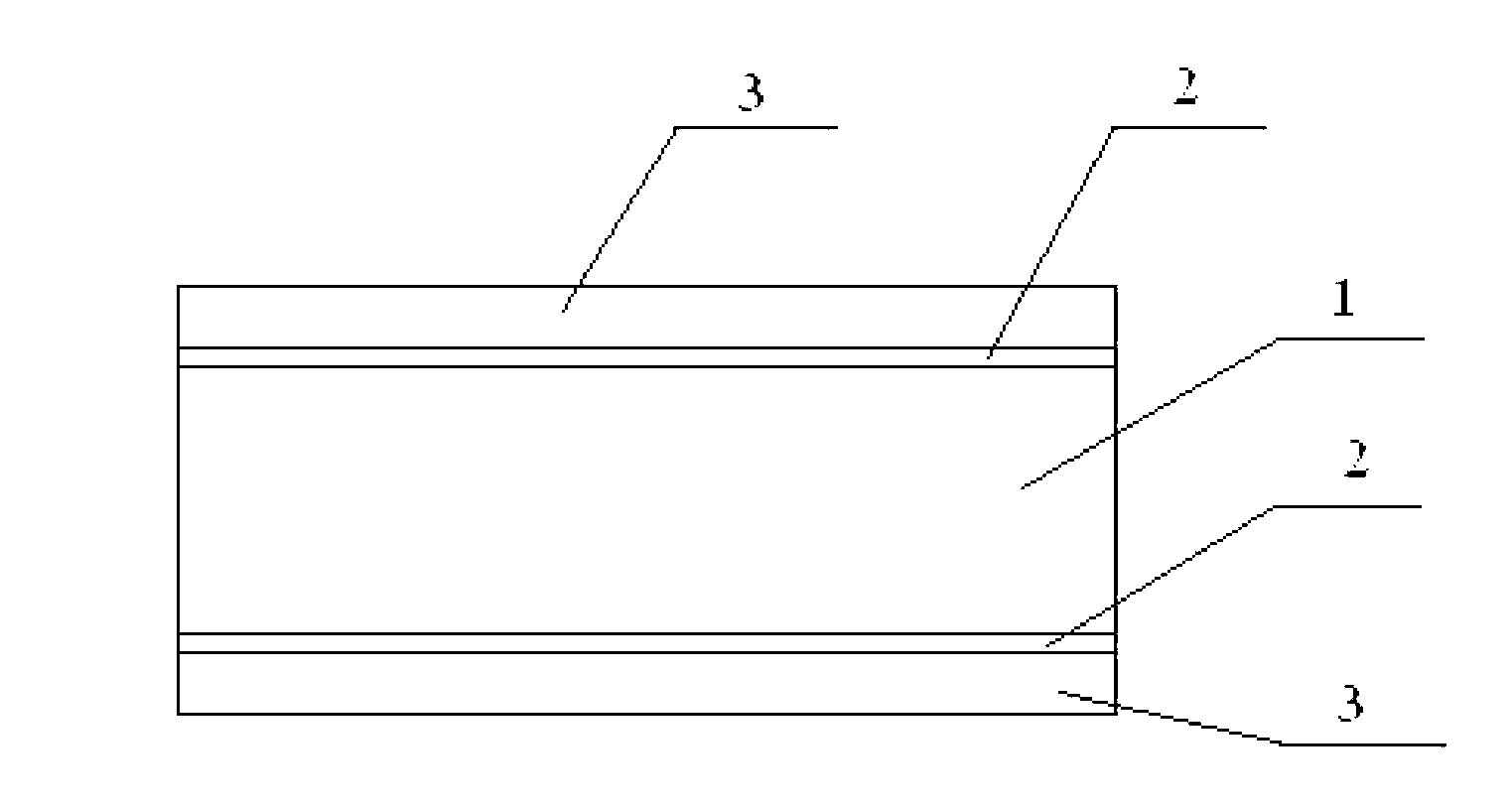

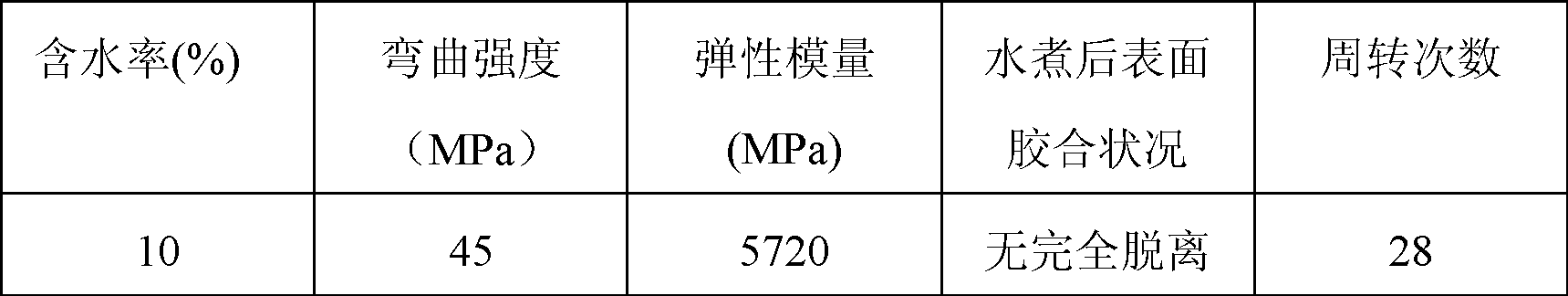

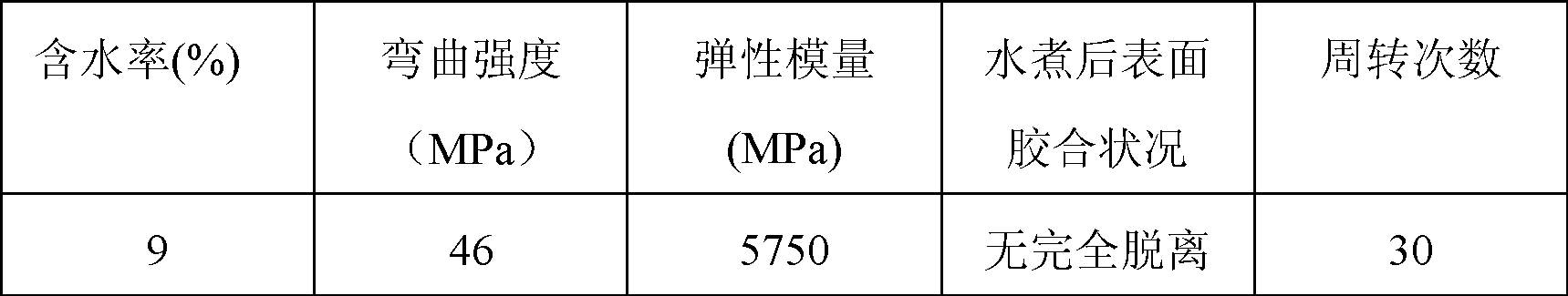

Plastic-coated wooden building template and preparation method thereof

InactiveCN103031948AEasy constructionReduce usageSynthetic resin layered productsWood layered productsPolyolefinFlexural strength

The invention discloses a plastic-coated wooden building template and a preparation method thereof, which relate to a building template and a preparation method thereof and mainly solve the problems that a high-cost performance building template prepared by the current preparation method is low in turnover times and poor in mechanical properties. The preparation method comprises the following steps: firstly, manufacturing a core plate by using a waste template; secondly, manufacturing a polyolefin veneer coated with non-woven fabric; thirdly, gluing double sides of a wood veneer, putting the wood veneer between the polyolefin veneer coated with the non-woven fabric and the core plate, with the same operation for upper and lower surfaces; and finally, pressing. The turnover times of the plastic-coated wooden building template is as high as 30-35 times, which is 10-17% higher than that of the current building template, so that the using cost of the plastic-coated wooden building template is reduced; the plastic-coated wooden building template has the bending strength of 52-55 MPa and an elasticity modulus of 6050-6210 MPa; the plastic-coated wooden building template is high in strength and good in toughness; the preparation method is simple, low in cost and easy to implement, and is applicable to large-scale popularization and application; and the plastic-coated wooden building template has relatively high economic and social benefits and can be applied to the building engineering.

Owner:安徽省崃山建材有限公司

Plastic overlaid plywood building template with large turnover number and preparation method thereof

InactiveCN102425295AEasy to demouldReduce use costLaminationLamination apparatusTurnover timeAdhesive

The invention relates to a plastic overlaid plywood building template with a large turnover number and a preparation method thereof, in particular to a building template and a preparation method thereof. Due to the adoption of the plastic overlaid plywood building template with the large turnover number, the technical problems of the present wooden template or the overlaid plywood building template that a mould is difficult to remove and the turnover number is small during the application process can be solved. The plastic overlaid plywood building template with the large turnover number is characterized in that: a layer of polyolefine laminated surface is adhered on the upper surface and the lower surface of the wooden plywood template. The preparation method comprises the following steps that: after polyolefine material is extruded by a vertical-type three-roller plastic sheet machine set to obtain sheets, a layer of non-woven fabric covers the sheet to be extruded again to obtain the polyolefine laminated surface which is covered by the non-woven fabric; and adhesive is smeared onto the non-woven fabric, then the non-woven fabric which is smeared with the adhesive covers the upper surface and the lower surface of the polished wooden polywood to be pressed so as to obtain the plastic overlaid polywood building template with lage turnover number. The surface of the template is free from being adhered by the cement, the turnover times of the template are 25 to 30 times, and the template can be used for construction engineering.

Owner:卜凡华

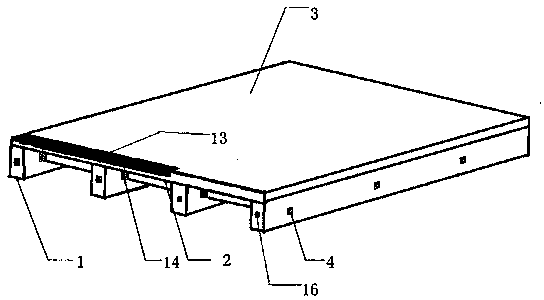

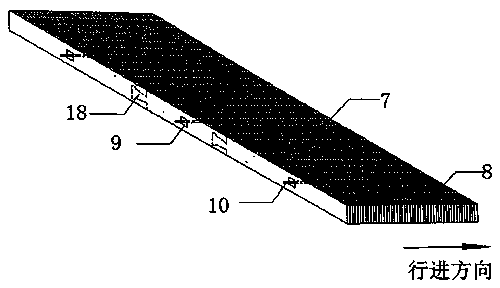

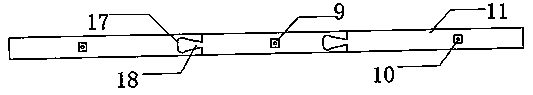

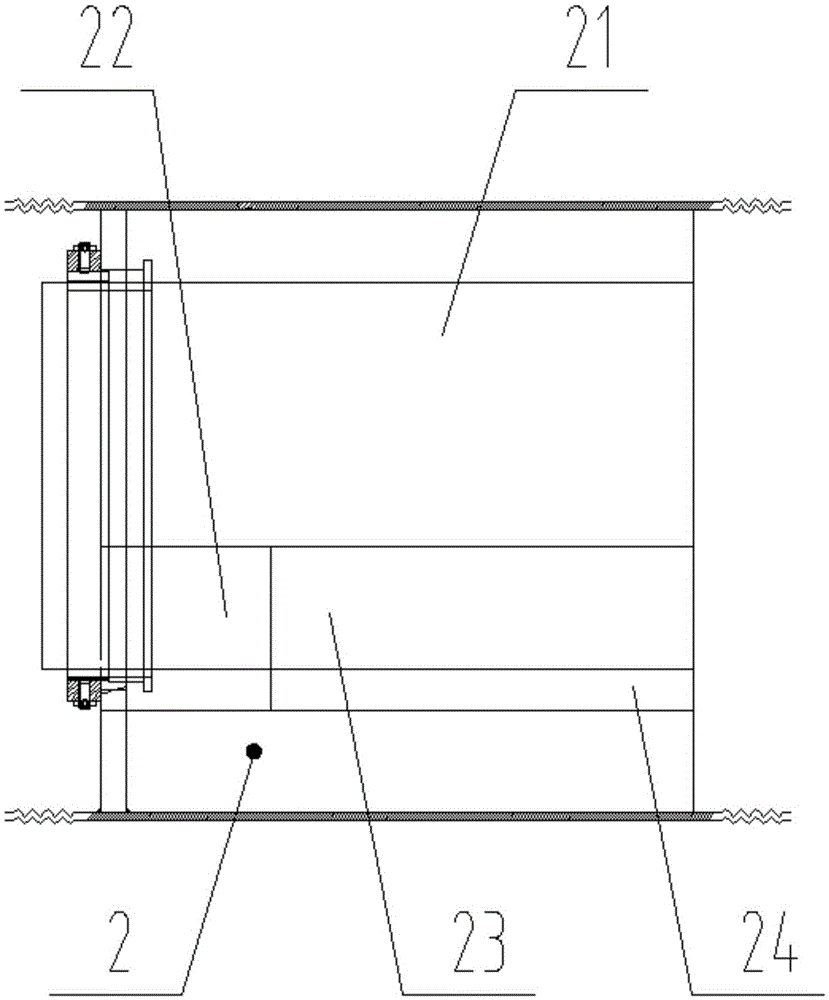

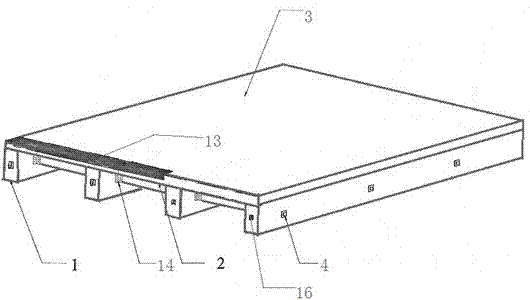

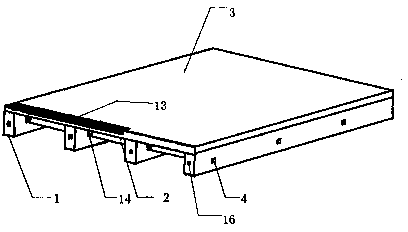

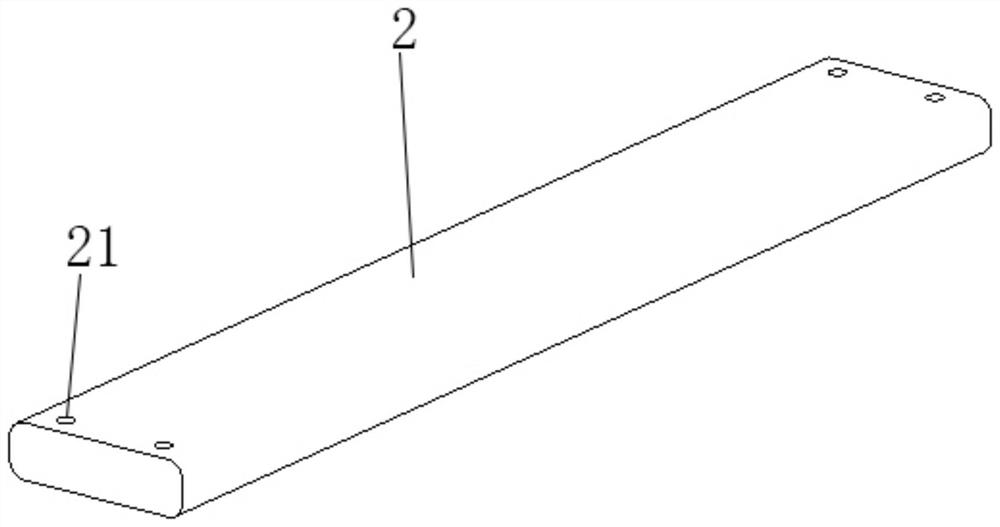

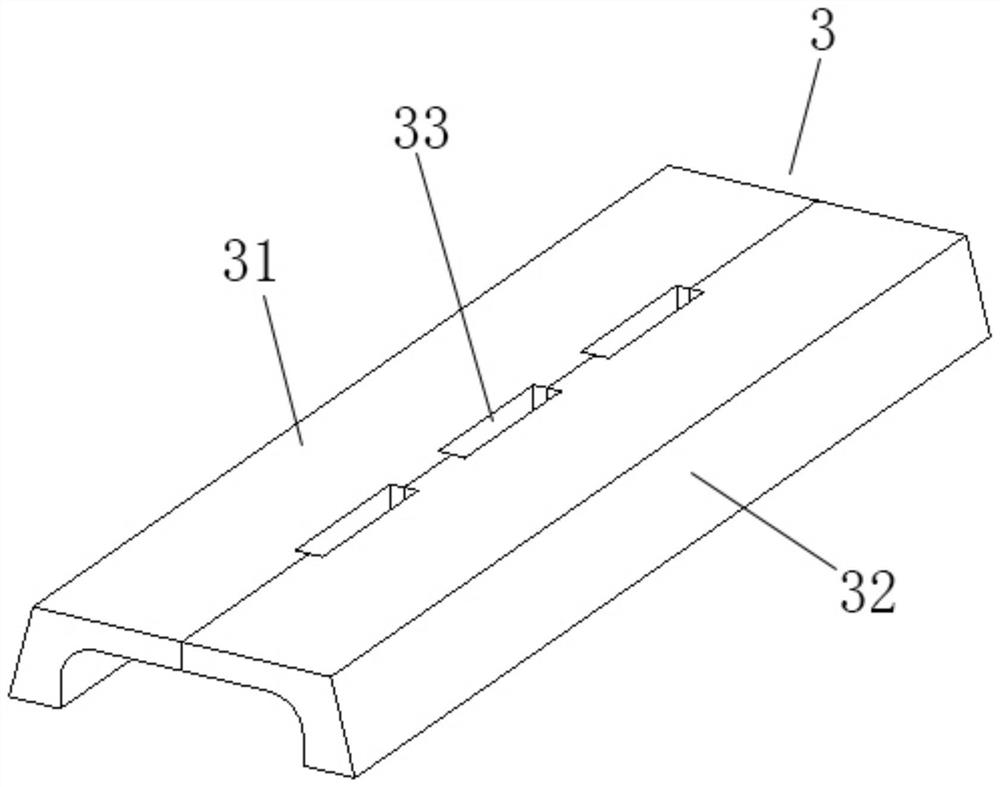

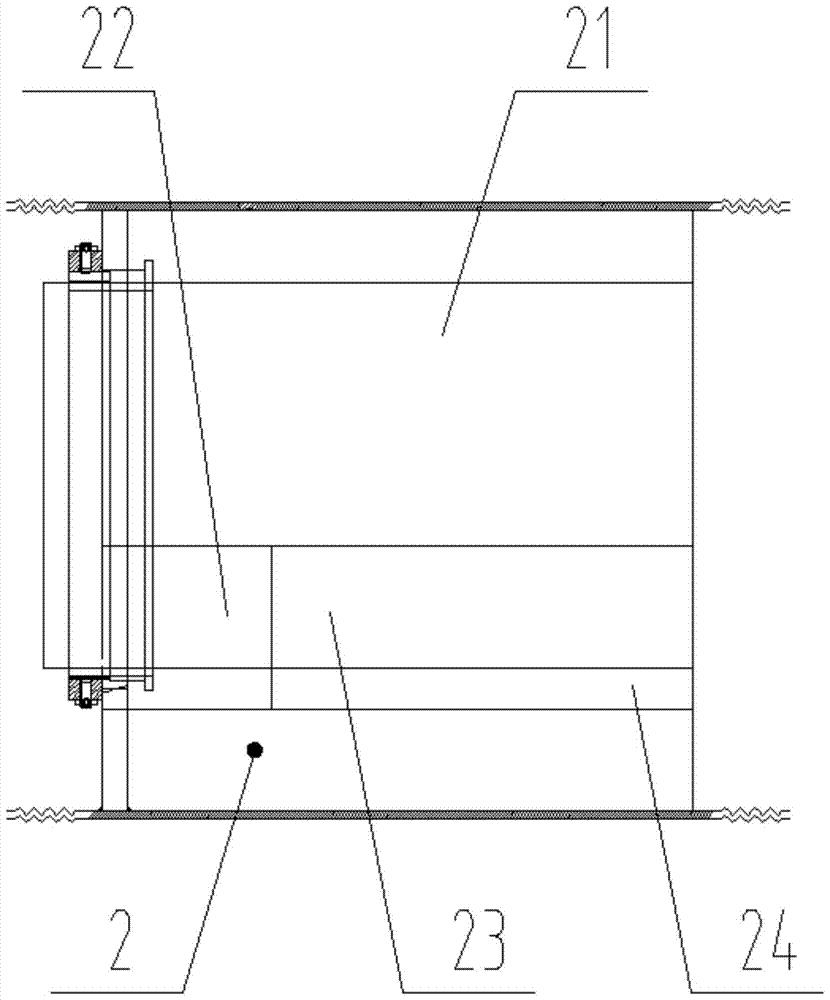

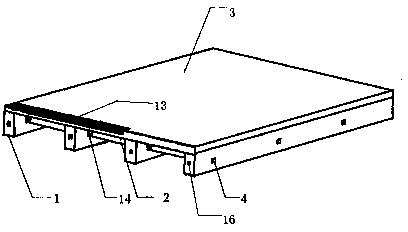

Assembly type bamboo bridge with variable expansion coefficients

ActiveCN103452035AHigh tensile strengthNo possibility of crackingSynthetic resin layered productsBridge structural detailsPolymer sciencePolymer chemistry

The invention provides an assembly type bamboo bridge. The assembly type bamboo bridge comprises bamboo longitudinal beams (1), bamboo transverse beams (2), bamboo panels (3), transverse pre-stressing tendons (4) and longitudinal pre-stressing tendons (16), the outer surface of a bamboo is sequentially and uniformly coated with a layer of waterborne polyurethane resin, a layer of polyurethane resin, a layer of waterborne polyurethane resin and a layer of resorcinol formaldehyde resin, and the expansion coefficients of the four coating layers are sequentially lessened from the outer surface of the bamboo to outside. The assembly type bamboo bridge provided by the invention has the advantages that the structural strength is large, the ductility is good, a selected material is environment-friendly, standardization degree and assembling degree of structural members are high, the structural integrity is good, the advantages of the material can be fully expressed, and the requirements on normal use and durability of a bridge structure can be met.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

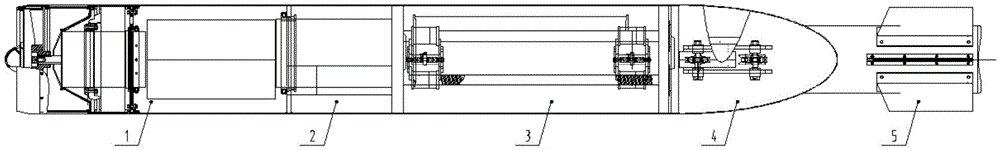

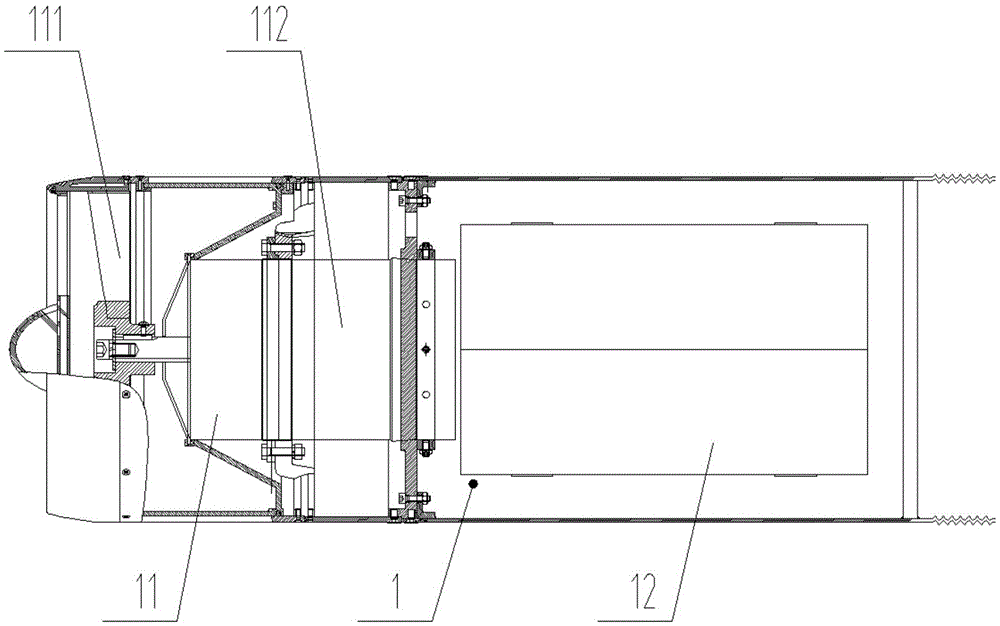

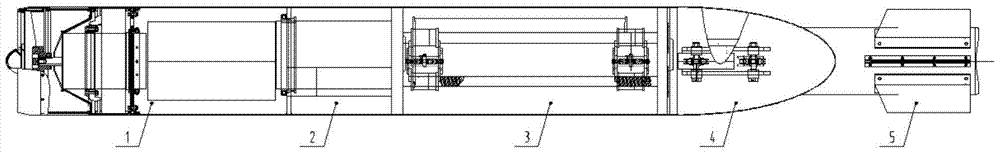

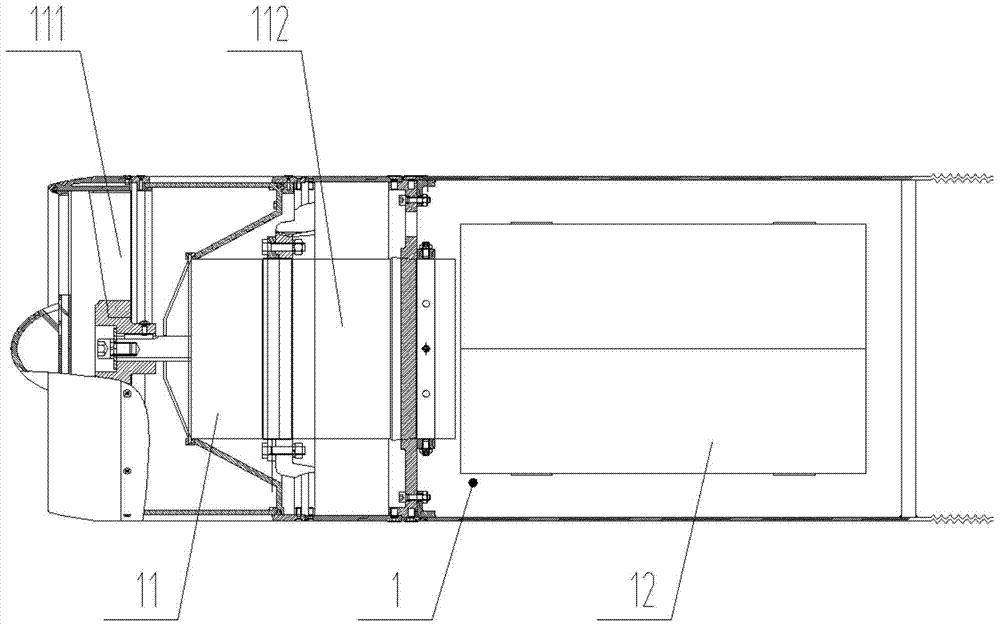

External mounting type aviation electric pod and using method thereof

ActiveCN105539849AHigh degree of automationReduce mechanical wearAircraft componentsLaunching weaponsAir compressionAviation

The invention discloses an external mounting type aviation electric pod. The external mounting type aviation electric pod comprises a pod core and a shell. The pod core is arranged in the shell. High-automation-degree operating design is adopted for the external mounting type aviation electric pod. All operation actions can be completed just through one pilot in a part-time job manner, and therefore the pod can be used for all aircraft with a single seat and multiple seats. Because no hydraulic and air compression systems are arranged, mechanical transmission parts are reduced by 80%, mechanical abrasion is greatly reduced, and the system is single and simplified; rolling of a winch and cable distributing and dragging winding and unwinding speed control precision can be improved, and therefore the fault rate is greatly decreased; and because a cable dragging automatic locking device is arranged, part of cable dragging force is transmitted to a pod body structure, loads on the winch are relieved, and using reliability is greatly improved. A more advanced thin-shell structure is adopted for a pod body, the ratio of strength to weight and the material utilizing rate are greatly increased.

Owner:河北环航科技股份有限公司

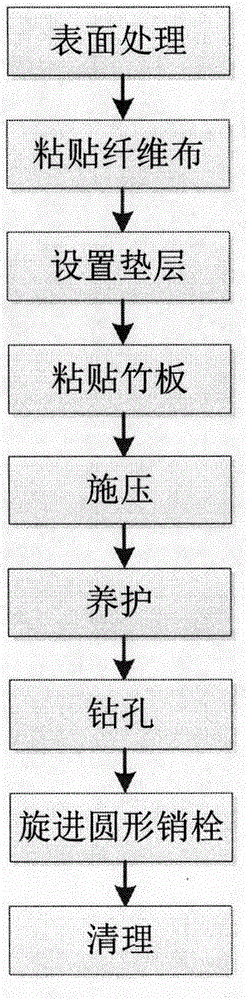

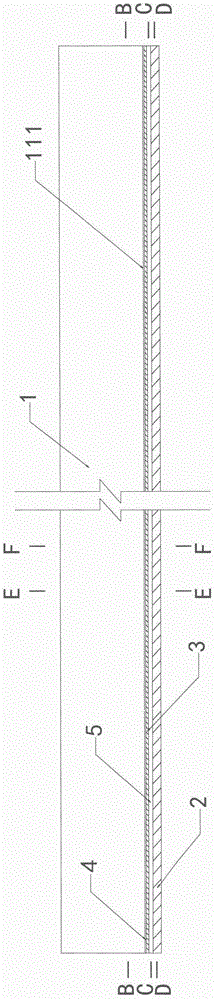

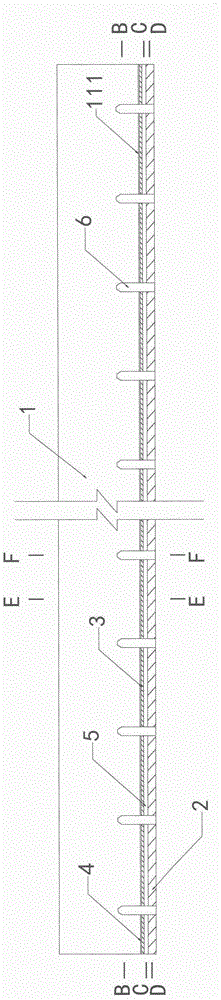

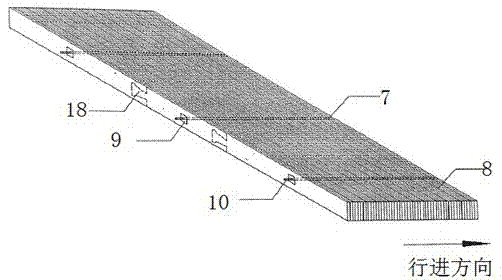

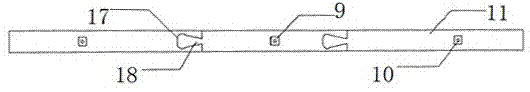

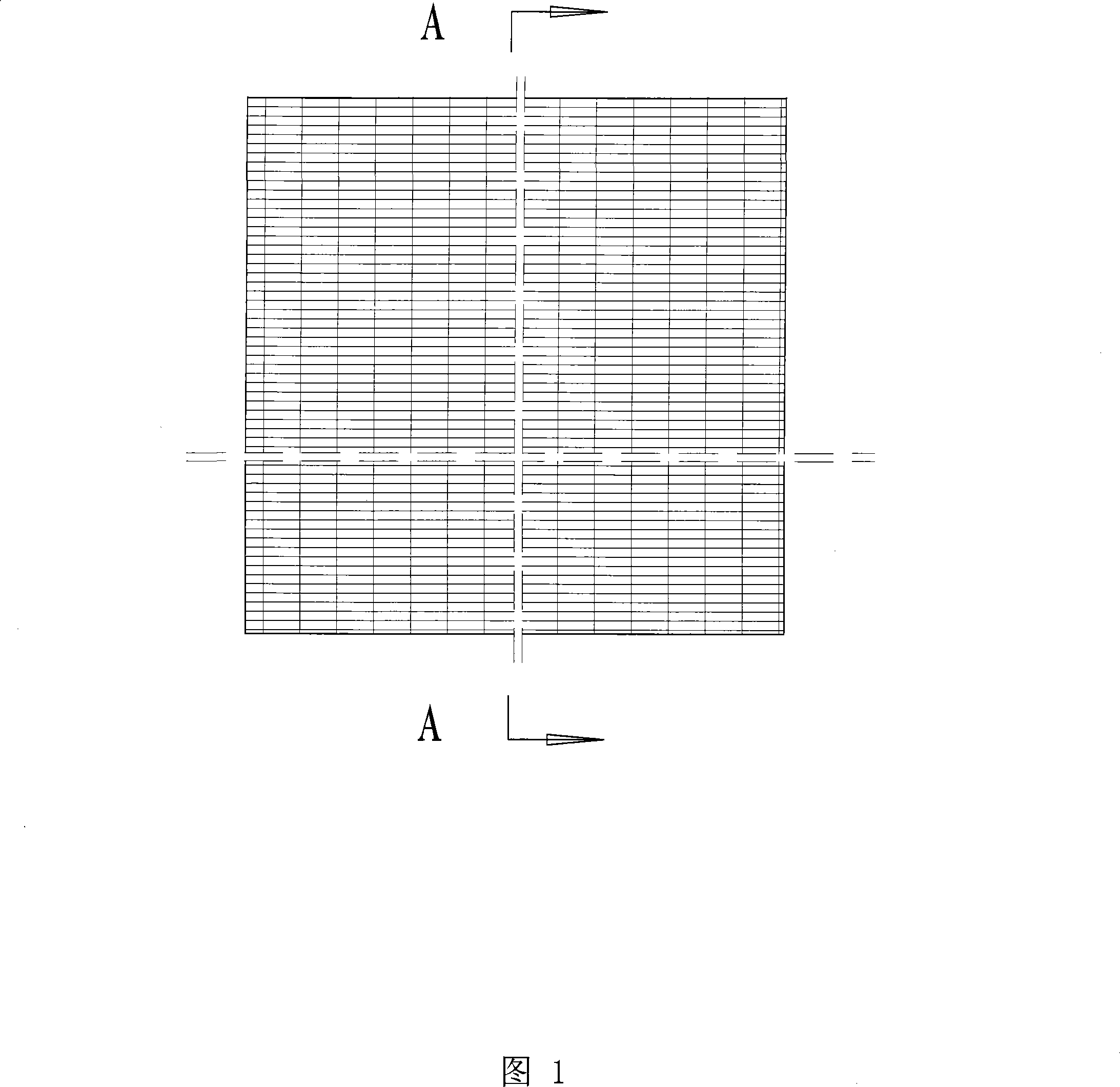

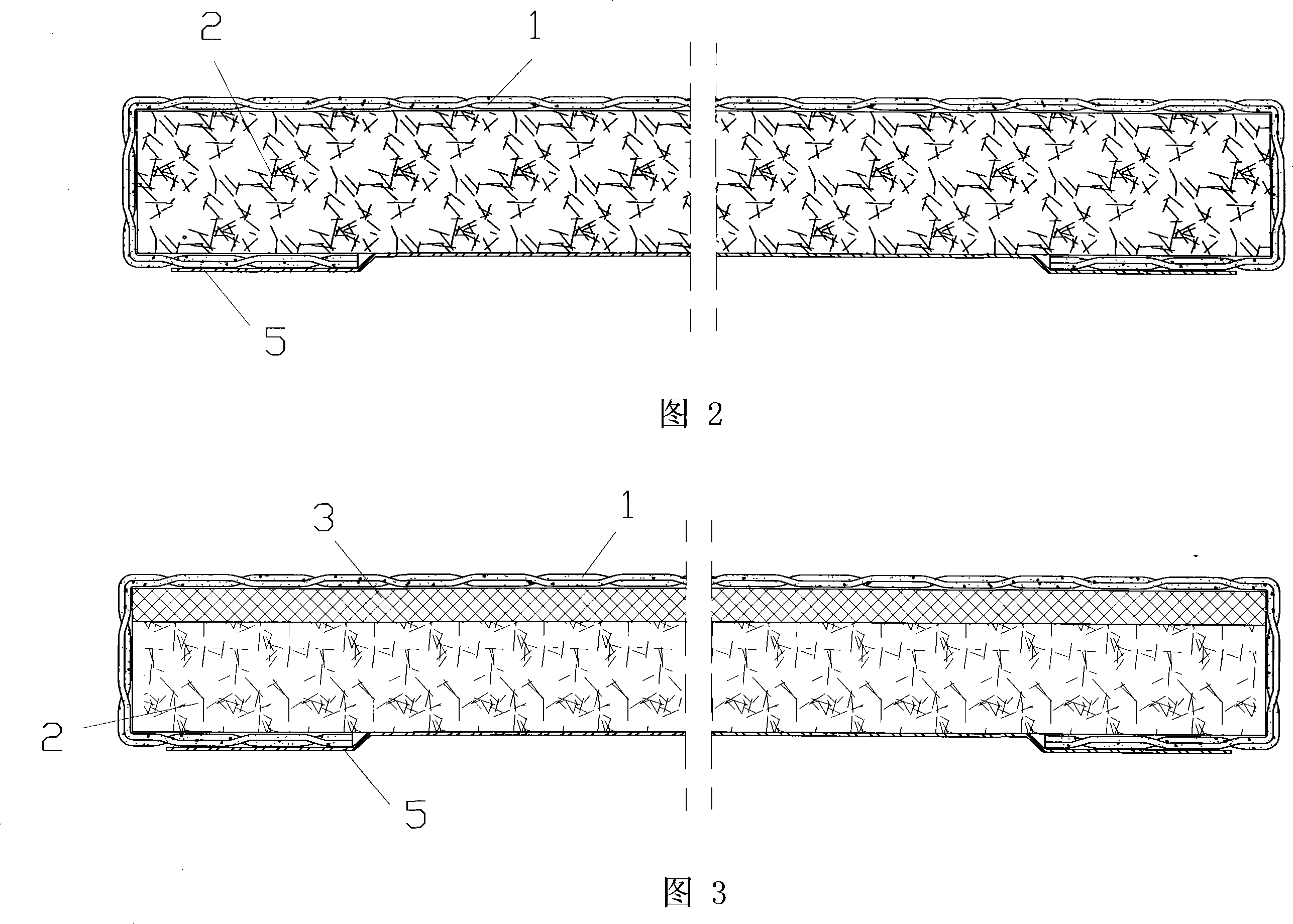

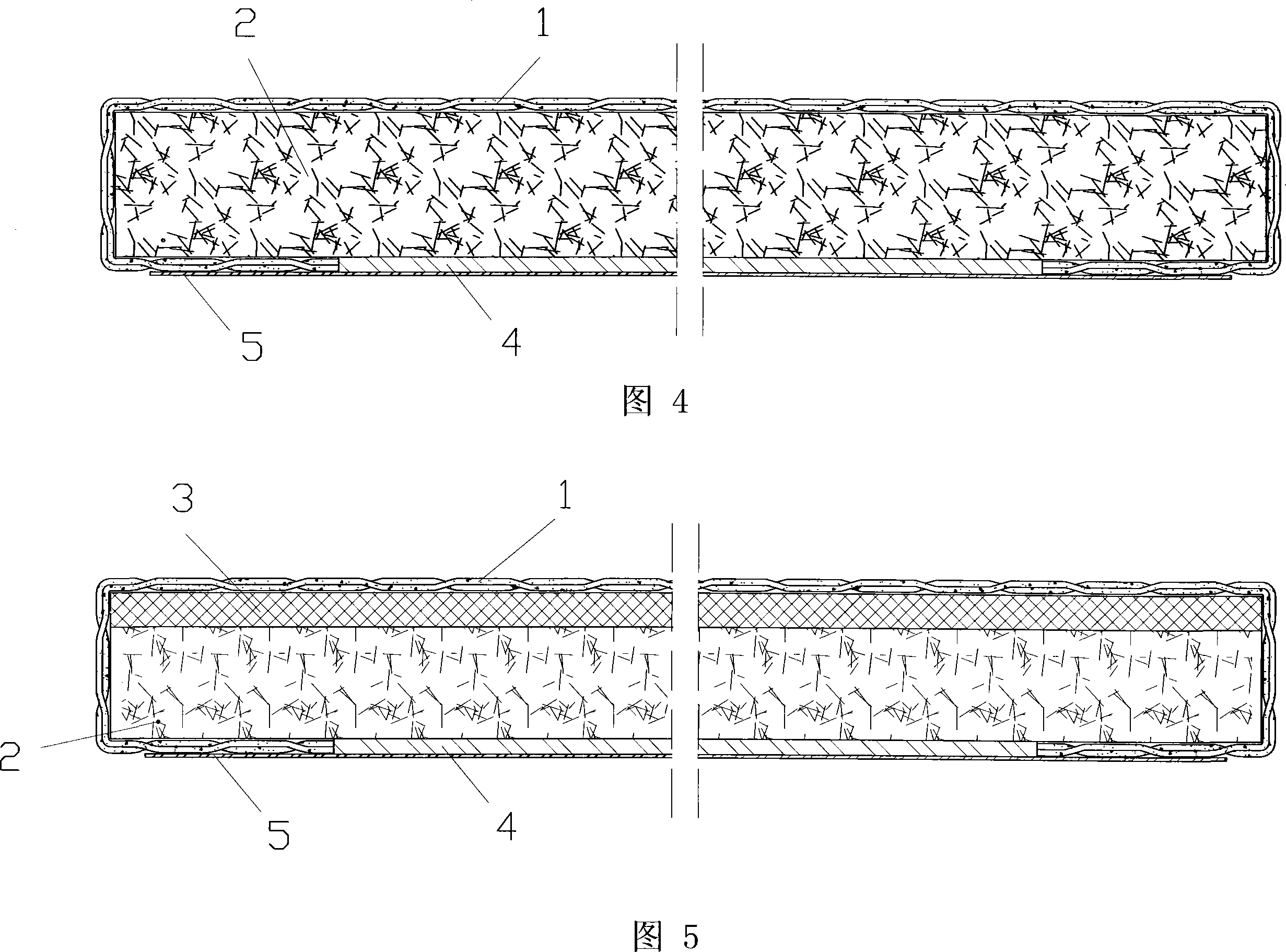

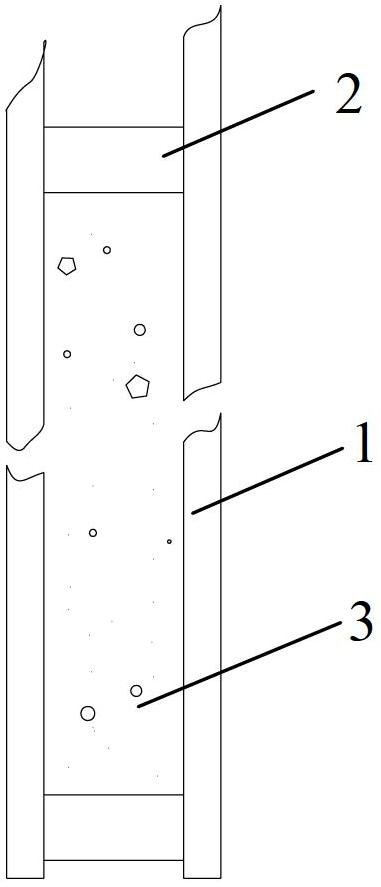

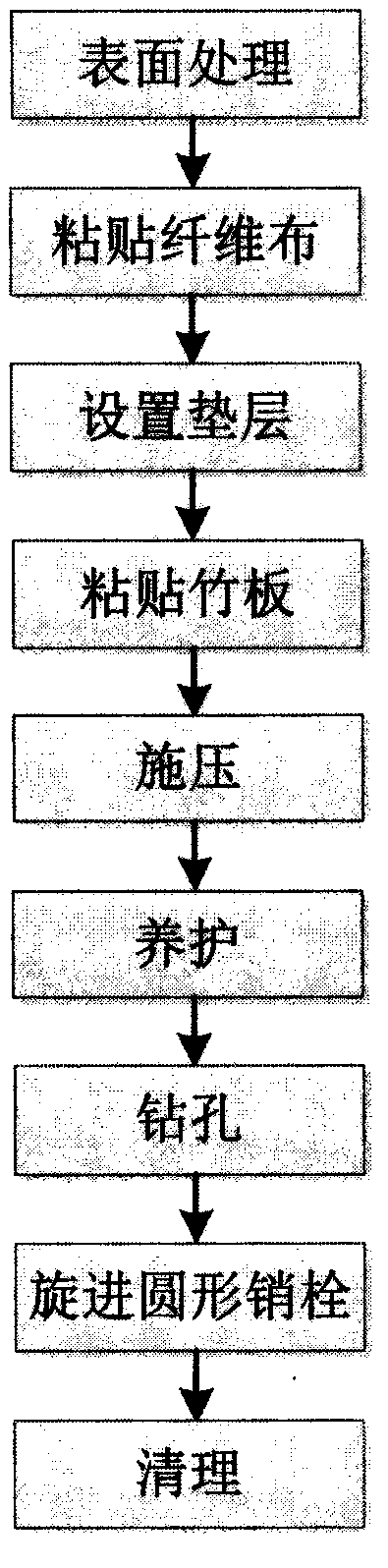

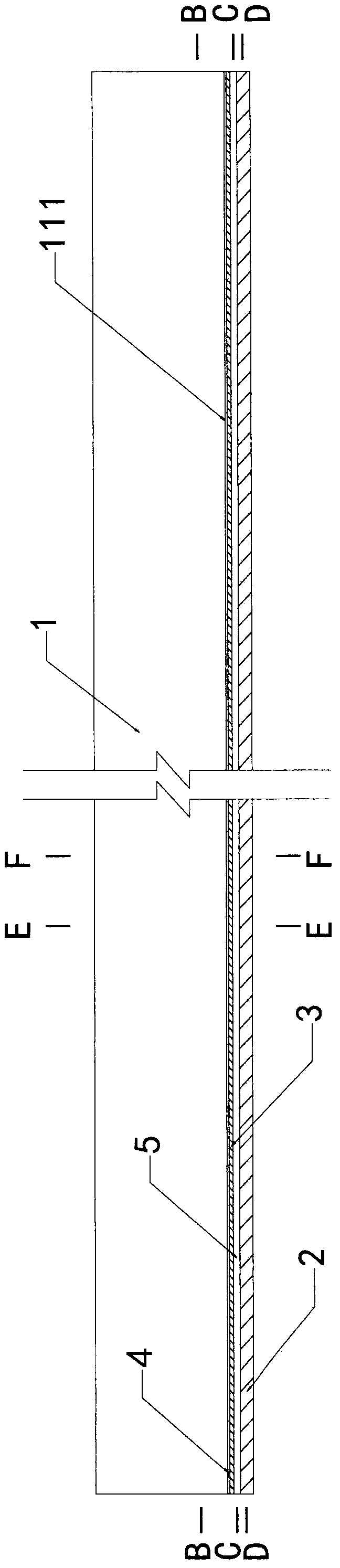

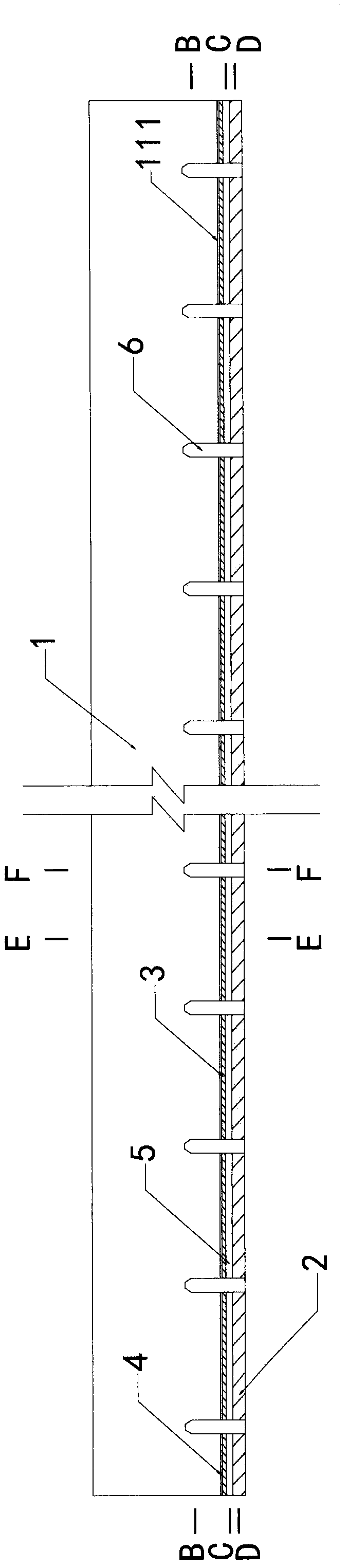

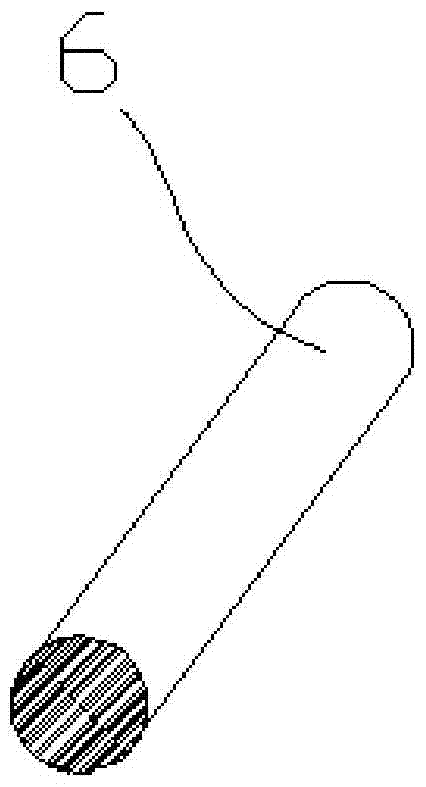

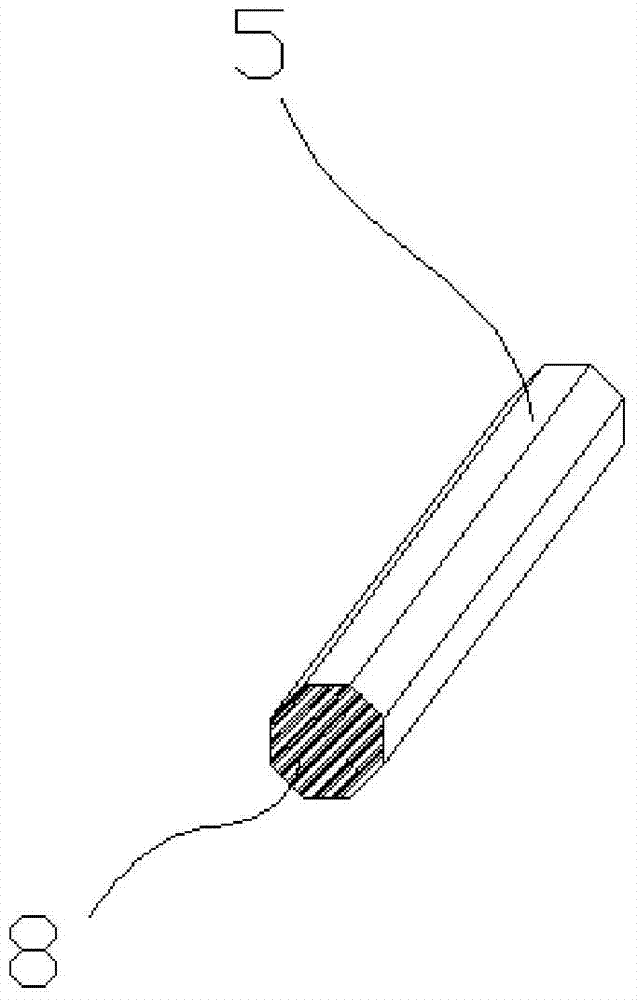

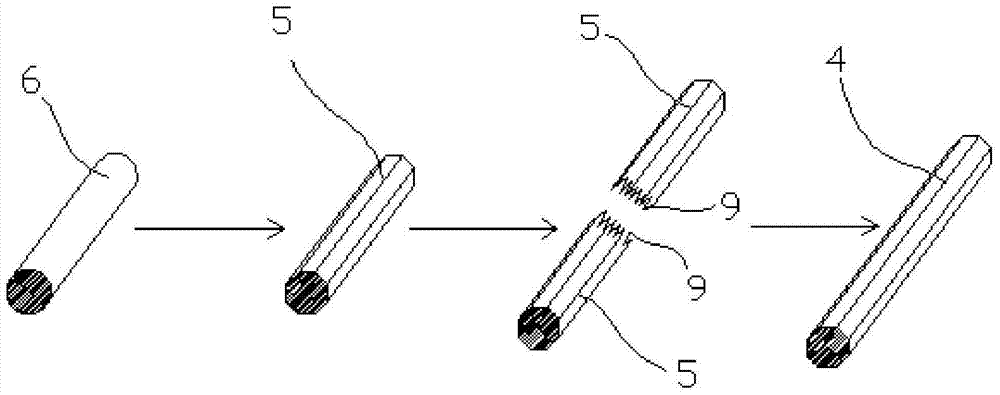

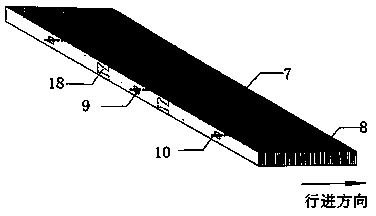

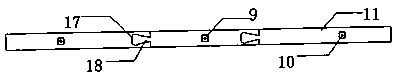

Method for compound reinforcement of wooden beam

The invention belongs to the field of civil engineering and discloses a method for compound reinforcement of a wooden beam. The method is characterized in that at the bottom of the wooden beam (1), fiber cloth (3) is adhered, a base layer (5) is arranged, a bamboo board (2) is adhered and a round bolt (6) is screwed to achieve compound reinforcement of the wooden beam (1). In the method, the bamboo board (2) is used as a reinforcing material, meanwhile the fiber cloth (3) is mechanically anchored, the bonding effect of the bamboo board (2), the fiber cloth (3) and the wooden beam (1) is strengthened through fusion of the round bolt (6) with the bamboo board (2) and the wooden beam (1), and the thickness of epoxy resin glue (4) between the bamboo board (2) and the wooden beam (1) is ensured by arranging the base layer (5) embedded with a solid filling (51). By the adoption of the method, the probability of untimely damage due to bonding layer failure in the wooden beam bending process is reduced, the wooden beam is reinforced by adopting two low-carbon environmentally friendly materials, respective advantages of the two materials are fully played, the bearing capability of the wooden beam is improved, and an original style and features of an old historic building structure restored as the old are achieved.

Owner:NANJING FORESTRY UNIV

Preparation method of wood-like wood-plastic composite sheet material

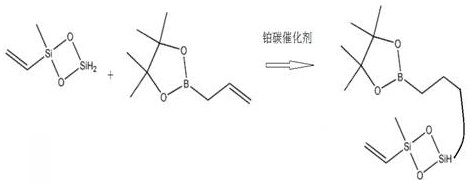

InactiveCN103341938AImprove overall strength-to-weight ratioImprove performancePlastic materialsComposite slab

The invention relates to a preparation method of a wood-like wood-plastic composite sheet material. The preparation method solves the problem that the existing wood-plastic material has a low strength-weight ratio, a high cost and small breadth. The preparation method comprises the following steps of paving bamboo poles and plastic powder in a mold layer upon layer, carrying out hot pressing molding, carrying out cooling, and carrying out demolding. The wood-like wood-plastic composite sheet material is prepared from waste, thin and short bamboo poles and waste and old plastic, has the advantages of simple processes, low cost, large product breadth, low density, high strength, high elastic modulus and creep resistance, and can solve the problem that wood can produce hygroexpansion easily. The preparation method can be used in the fields of house, bridge, vehicle and ship manufacture.

Owner:NORTHEAST FORESTRY UNIVERSITY

Novel energy-saving bamboo bridge

InactiveCN103498412AHigh tensile strengthNo possibility of crackingLighting elementsReed/straw treatmentLight equipmentEngineering

The invention provides a novel energy-saving bamboo bridge. The novel energy-saving bamboo bridge comprises longitudinal bamboo beams (1), transverse bamboo beams (2), bamboo panels (3), transverse pre-stressed trusses (4) and longitudinal pre-stressed trusses (16). A layer of waterborne polyurethane resin, a layer of polyurethane resin, a layer of waterborne polyurethane resin and a layer of resorcinol formaldehyde coat the outer surfaces of all the bamboo materials of the bamboo bridge in sequence. The bamboo bridge further comprises lighting devices and a brightness sensor, and the lighting devices are controlled to be started through the numerical value measured by the brightness sensor. The novel bamboo bridge can start the lighting device according to the brightness and save energy sources.

Owner:ZHONGBEI UNIV

Building template with high cost performance and preparation method thereof

InactiveCN102936952AGood value for moneyCost-effectiveSynthetic resin layered productsLaminationTurnover timePolyolefin

The invention provides a building template with a high cost performance and a preparation method thereof, relates to the building template and the preparation method thereof and mainly solves the problems that the existing waste template cannot be regenerated and reused, a wood template is not easy to de-mould in a use process and the turnover time is low. The product is formed by respectively sticking one layer of a sticking layer on each one of upper and lower surfaces of a core plate. The method comprises the following steps of: taking nails and sorting the waste templates; vertically cutting; leveling; transversely combing, and vertically connecting and combing; transversely splicing; filling holes; drying; sanding double faces with a fixed thickness to prepare the core plate; preparing a non-woven fabric polyolefin sticking face; coating an adhesive on a non-woven fabric of the non-woven fabric polyolefin sticking face; and coating on the upper and lower surfaces of the core plate, and pressing to finish. The building template with the high cost performance disclosed by the invention adopts the core plate made of the waste template, solves the regeneration and reutilization problems of the waste templates, and greatly improves the cost performance of the building template; and the property that the surface activity of the polyolefin sticking face is low is utilized, the template is easy to de-mould, and the turnover time is high.

Owner:安徽省崃山建材有限公司

Waterproofing and air impacting resisting flag fabric and manufacturing method thereof

ActiveCN106884336AImprove dye yieldImprove tear resistanceAntifouling/underwater paintsTransfer printing processNylon 66Solvent

The invention relates to a waterproofing and air impacting resisting flag fabric and a manufacturing method thereof. The waterproofing and air impacting resisting flag fabric is characterized in that high-strength nylon 66 is used as a base material, and a waterproofing coating is arranged on the high-strength nylon 66, wherein a waterproofing paint of the waterproofing coating comprises the following raw materials: 30-35% of solvent type resin silicone oil, 25-30% of methylbenzene, 0.5-1% of a curing agent, 3-5% of a silane coupling agent, 1-3% of a catalyst, and the balance of a thinner; and a pattern is printed on the coated high-strength nylon 66. The fabric is good in waterproofing effect, and high in air impacting resistance; the printing color is uniform; the pattern is clear; the color fastness is high; and the effect of printing one surface to realize a two surface printing effect can be achieved.

Owner:北京邦维高科新材料科技股份有限公司

Assembly type bamboo bridge

ActiveCN103437271AHigh tensile strengthNo possibility of crackingSynthetic resin layered productsBridge structural detailsPolymer sciencePolymer chemistry

The invention provides an assembly type bamboo bridge. The assembly type bamboo bridge consists of bamboo longitudinal beams (1), bamboo transverse beams (2), bamboo panels (3), a transverse pre-stressing tendon (4) and a longitudinal pre-stressing tendon (16). All bamboos used by the assembly type bamboo bridge are soaked in a gum dipping tank which contains polyurethane resin and phenolic resin before being assembled, and boiled for 10-15 minutes at 100 DEG C-110 DEG C, wherein the volume ratio of the polyurethane resin to the phenolic resin is (2-2.5):1; and then, the bamboos are got out and dried, and a layer of waterborne polyurethane resin, a layer of polyurethane resin, a layer of waterborne polyurethane resin and a layer of resurcinolformaldehyde resin are uniformly coated on the outer surfaces of all bamboos in sequence. The assembly type bamboo bridge is large in structural strength, good in drawability, green and environment-friendly in used materials, standard in structural components, high in assembly degree, good in structural integrity, and capable of sufficiently bringing the advantages of the materials into play, and satisfying the normal use and durability needs of the bridge beam structure.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

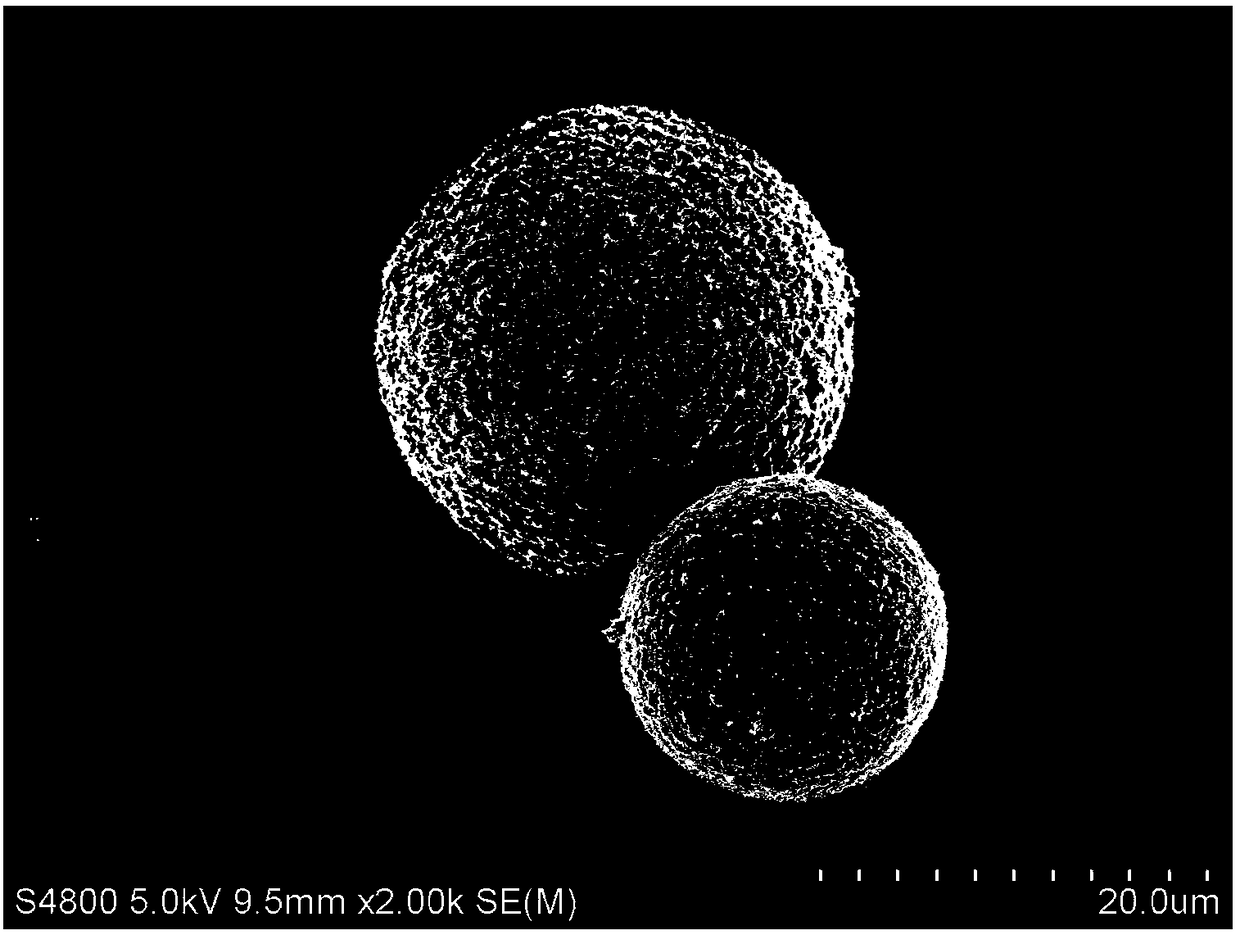

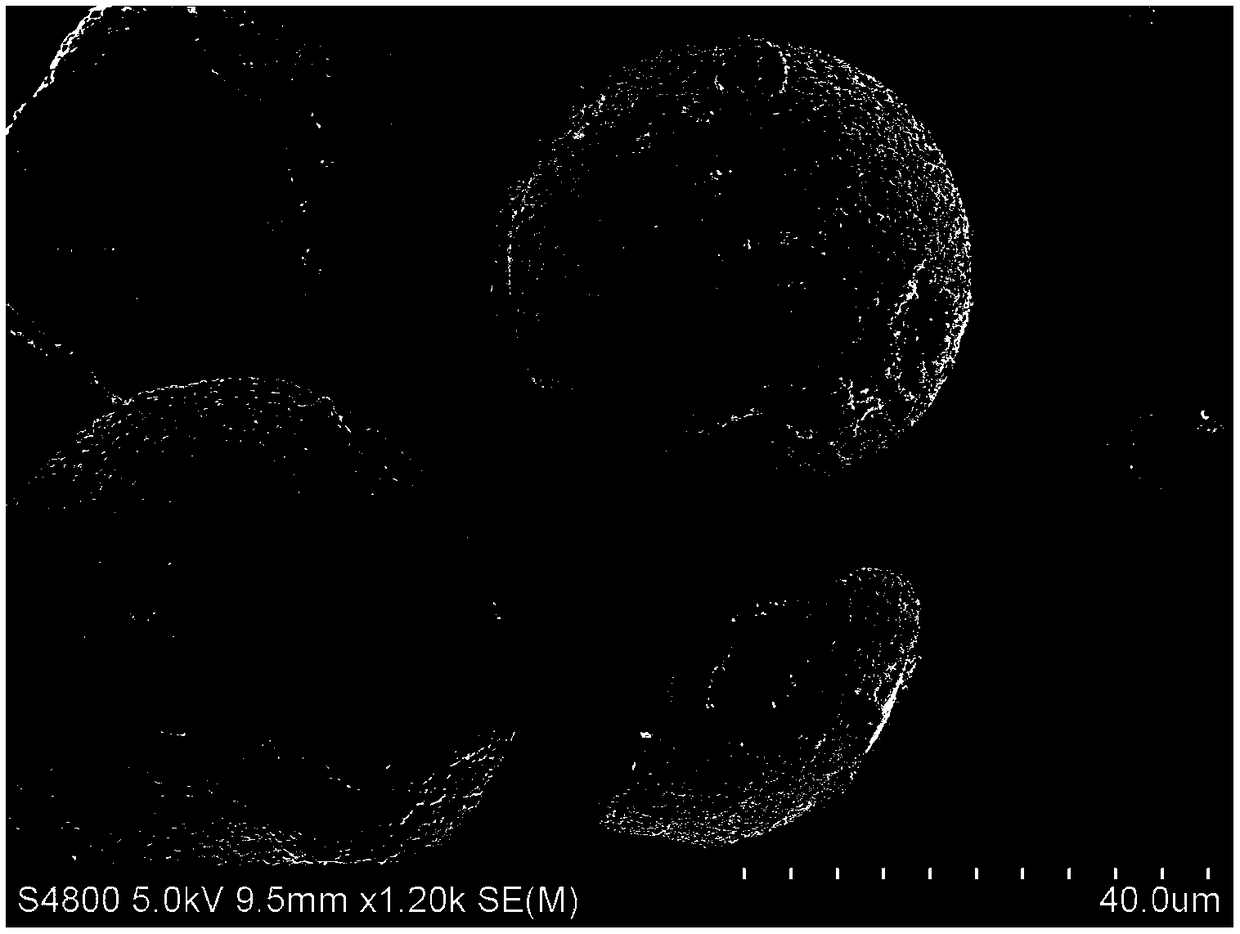

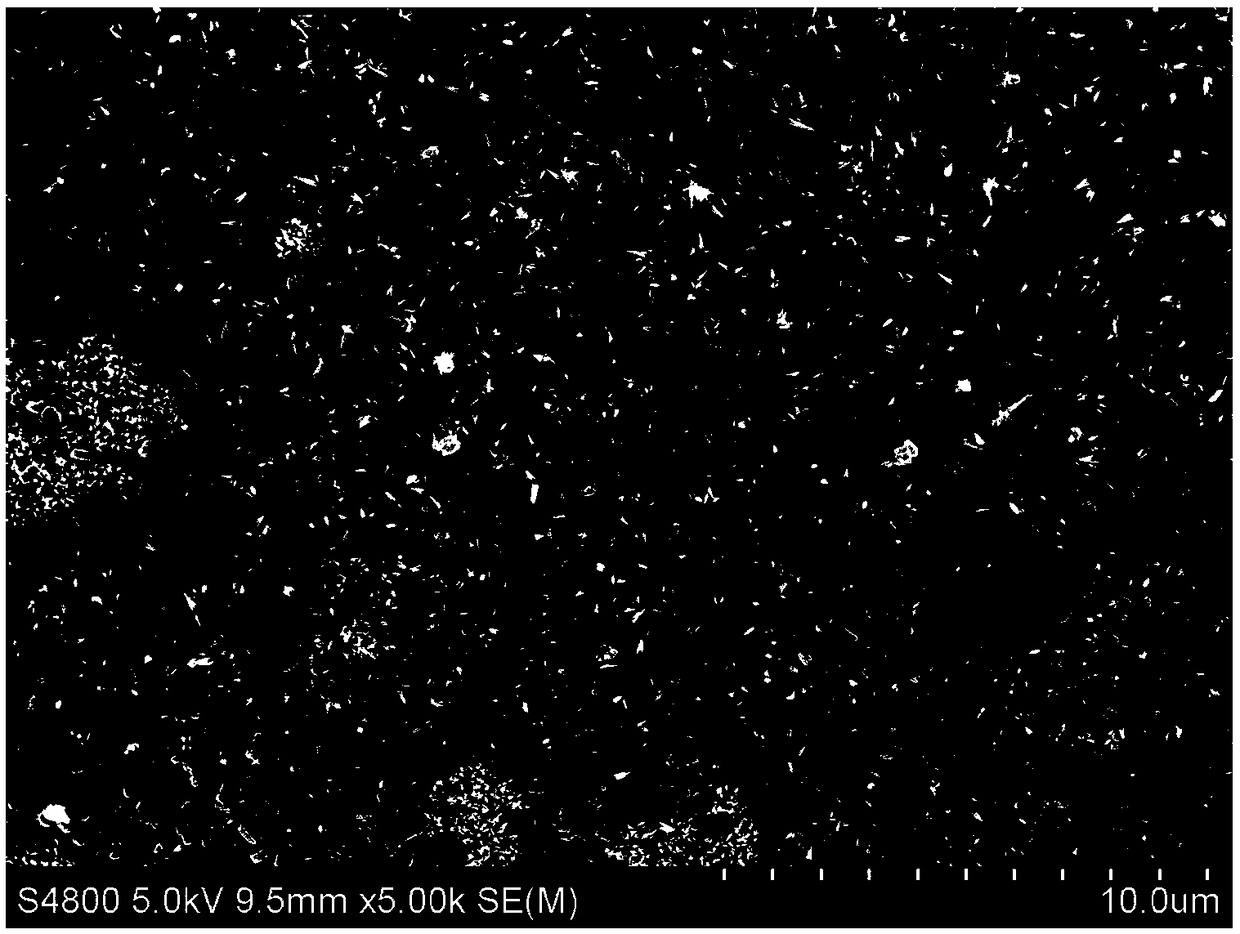

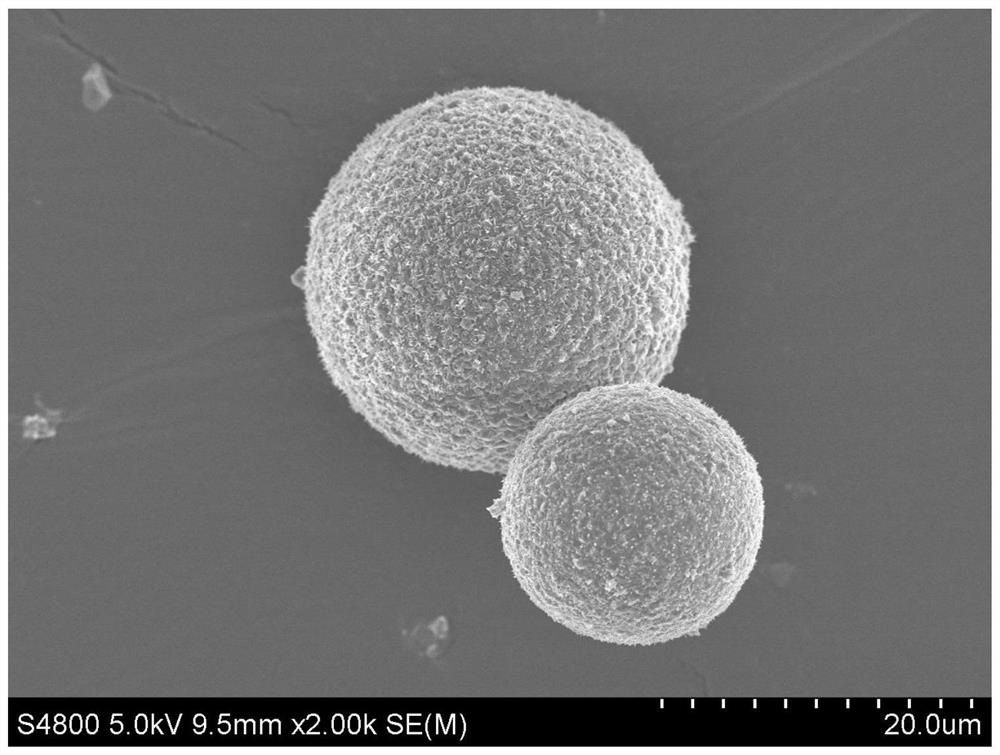

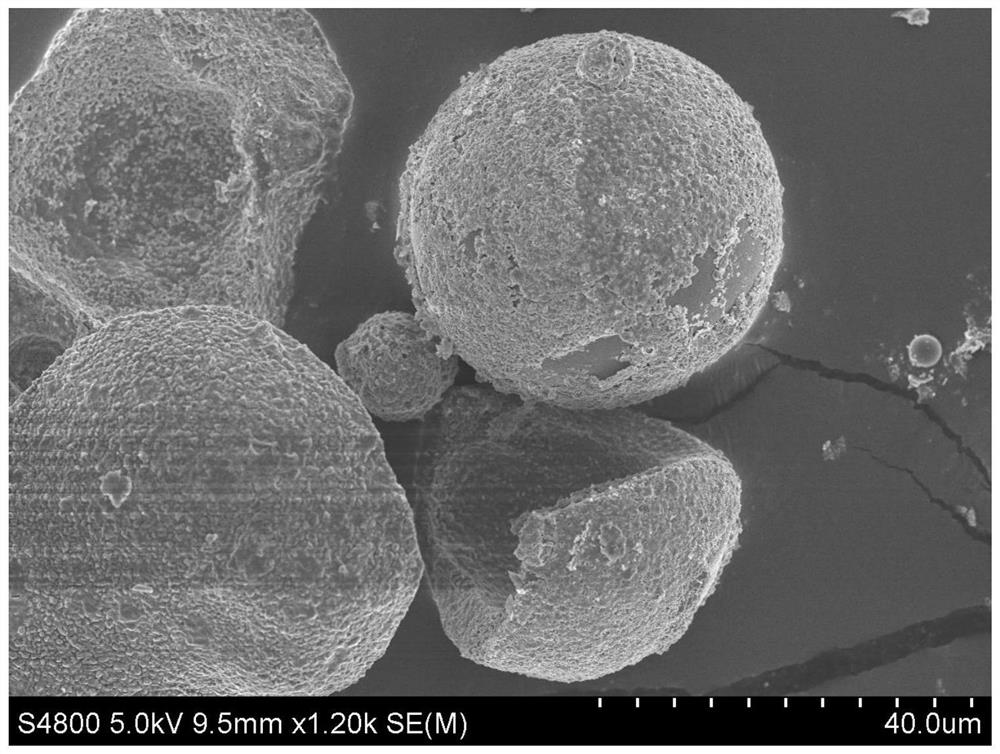

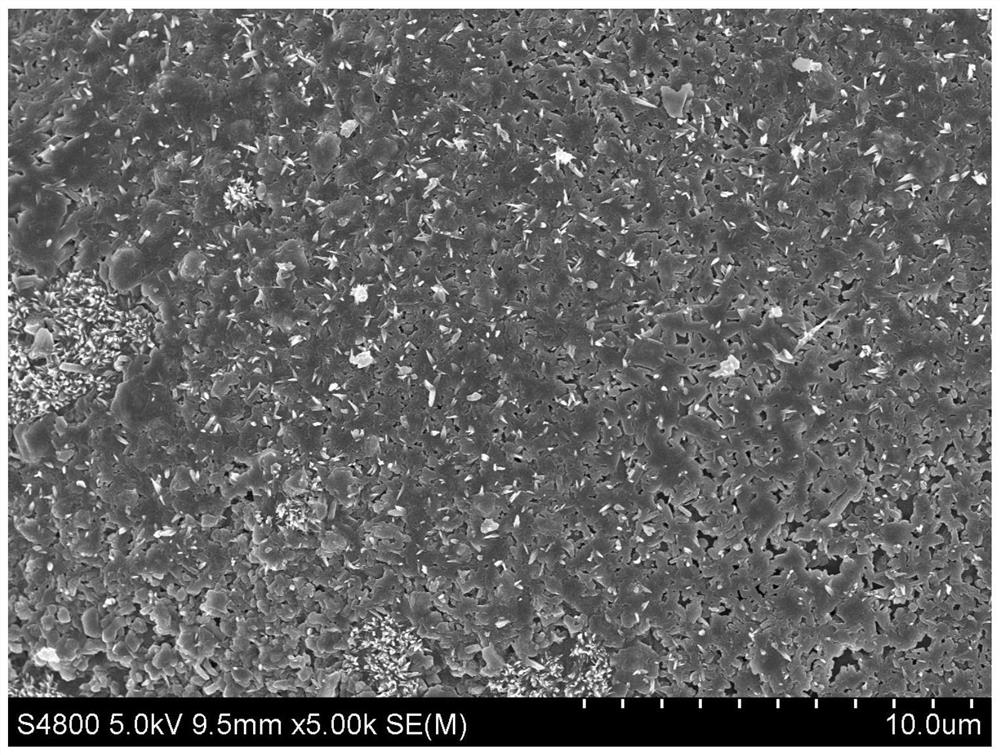

Method for preparing hollow micro-nano carbon spheres from lignin by means of microwave-assisted heating

ActiveCN108584913AEvenly heatedImprove overall strength-to-weight ratioCarbon preparation/purificationMicro nanoMicrowave power

The invention discloses a method for preparing hollow micro-nano carbon spheres from lignin by means of microwave-assisted heating. The method includes placing the lignin in a microwave reactor, and filling the microwave reactor with carrier gas to eliminate air in the microwave reactor; switching on the microwave reactor, keeping the flow of the carrier gas unchanged, and heating the microwave reactor at the heating rate of 50-150 DEG C / min until the temperature of the microwave reactor with the microwave power of 800-2000 W reaches 350-550 DEG C; adjusting the microwave power of the microwave reactor until the microwave power reaches 300-800 W, heating the microwave reactor until the temperature of the microwave reactor reaches 600-800 DEG C, and preserving heat for 10-60 minutes; turning off the microwave reactor, keeping the flow of the carrier gas unchanged, cooling the microwave reactor until the temperature of the microwave reactor is lower than 150 DEG C and then turning off the carrier gas to obtain solid products which are the hollow micro-nano carbon spheres. The method has the advantages that a novel way can be provided to utilizing the lignin, which is a waste resource, in a high-value manner, and novel basic materials can be hopefully provided to the field of carbon materials.

Owner:SHAANXI UNIV OF SCI & TECH

Basalt type continuous fiber coiled and reinforced bamboo-wood combined pipe

InactiveCN104806871ALow densityLow costElongated constructional elementsSynthetic resin layered productsGlass fiberVolumetric Mass Density

The invention discloses a basalt type continuous fiber coiled and reinforced bamboo-wood combined pipe. The pipe comprises inner fiber reinforced resin, single-board laminated timber and / or bamboo, medium fiber reinforced resin, another single-board laminated timber and / or bamboo, and a surface fiber reinforced resin which are sequentially coiled from inside to outside; the fiber reinforced resin is resin soaked basalt fiber, glass fiber, aramid fiber and carbon fiber; the bamboo is one or a plurality of bamboo strips, bamboo plates, spliced plates, bamboo splits and expanded bamboo; the single-board laminated timber is one or a plurality of poplar, eucalyptus, birch, cedarwood, masson pine and pinus sylvestris. With the adoption of the pipe, the cost is greatly reduced, the density is reduced, and the ratio of strength to weight is obviously increased.

Owner:BEIJING FORESTRY UNIVERSITY

Tatami

InactiveCN101172007AExtensive sources of raw materialsLow costStuffed mattressesSpring mattressesDistortionEngineering

The invention relates to a tatami, which comprises a core layer arranged at the middle part, a folding surface arranged on the upper surface, a piece of anti-skid cloth arranged on the lower surface, a bottom liner arranged between the core layer and the anti-skid cloth, and an elastic layer arranged between the core layer and the folding surface. The core layer is of a wheat straw plate. The wheat straw plate comprises pulverized paddy straw and wheat straw adhered by isocyanate pitch adhesive and then molded. The tatami performed according to the invention has the advantages of low production cost, environmental protection, and no harm to the human body. The straw plate is uneasy to be wetted, therefore, the distortion is unable to produce, and the straw plate is mildew proof and vermin proof. The straw plate has higher strength and weight ratio, thereby the tatami performed according to the invention has light weight, high strength, and no extra reinforced layer is needed.

Owner:苏州新轻铁建材有限公司

Microcrystalline foamed wall block prepared by using polishing powder and preparation method thereof

InactiveCN110565869ALow thermal conductivityImprove insulation effectConstruction materialSurface layering apparatusFire protectionAdditive ingredient

The invention discloses a microcrystalline foamed wall block prepared by using polishing powder. The wall block is prepared from the following raw materials in parts by weight: 70-90 parts of microcrystalline frit, 12-25 parts of mineral raw materials and 2.5-10 parts of chemical raw materials; the microcrystalline frit is prepared from the following raw materials in percentage by mass: 60-80% ofpolishing powder, 15-25% of ore powder and 5-17% of ingredient powder. By adjusting the formula and improving the preparation process, the microcrystalline foamed wall block with significantly improved compressive strength, good thermal insulation performance and high fire resistance is prepared, and the requirements of building materials for energy saving, environmental protection, high strengthand fire protection can be better met.

Owner:洛阳北玻轻晶石技术有限公司

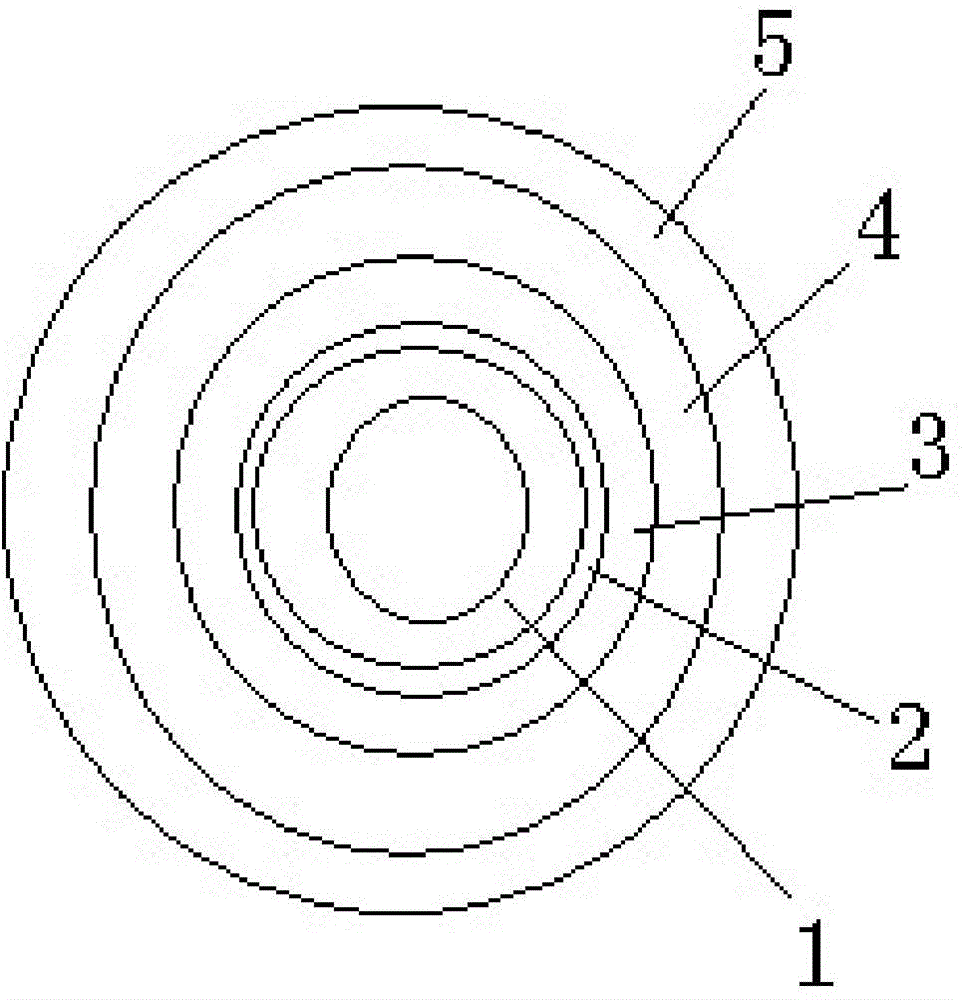

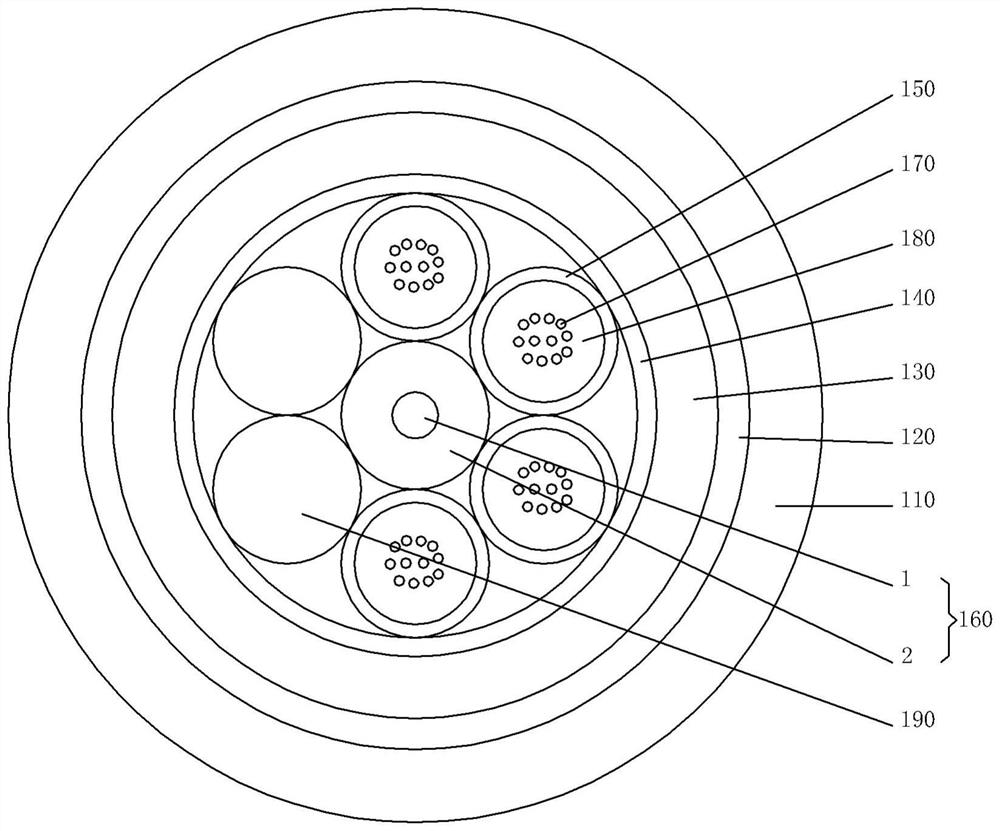

Novel optical cable for communication between underwater equipment and equipment in cabin body

PendingCN111856673AImprove flexibilityReduce weightFibre mechanical structuresEngineeringMechanical engineering

The invention provides a novel optical cable for communication between underwater equipment and equipment in a cabin body, which is light in weight, easy to bend, good in water resistance, wear resistance, oil resistance, low-temperature flexibility and flame retardance, and capable of realizing rapid wiring and repeated folding and unfolding use. A central reinforcing member, a loose tube, a wrapping tape, an inner sheath, an aramid fiber braid layer and an outer sheath are sequentially arranged at the radial center of the cable from inside to outside. The central reinforcing member is an aramid fiber extrusion molding flame-retardant sheath. Optical fibers are distributed in an inner cavity of the loose tube. Internal spaces of the optical fiber and the loose tube are filled with fiber paste. The loose tube is twisted around the central reinforcing member to form an equivalent circular cable core, the wrapping tape wraps an equivalent outer ring of the cable core, the inner sheath wraps an outer ring of the wrapping tape, the aramid fiber braid layer is annularly distributed on the outer ring of the inner sheath, and the outer sheath wraps the outer ring of the aramid fiber braidlayer.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

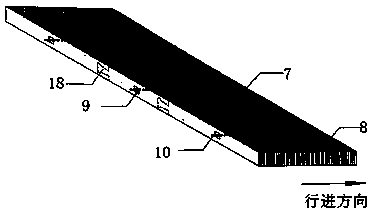

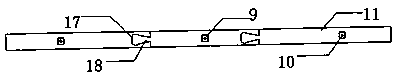

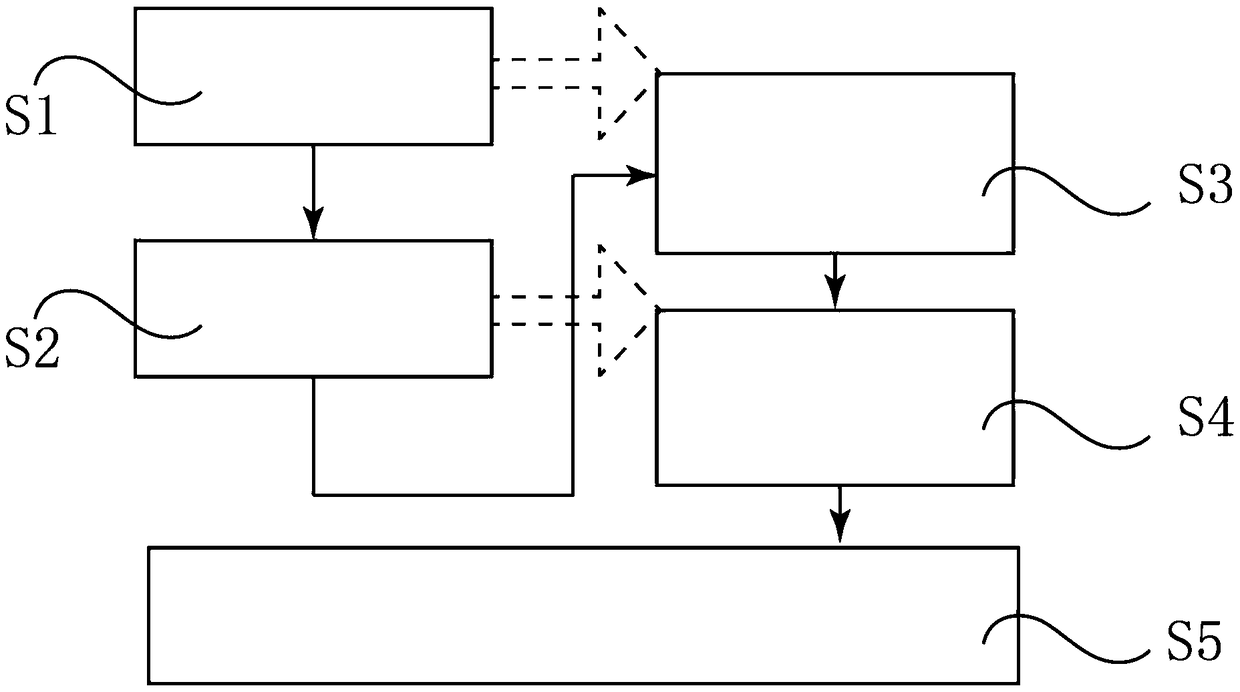

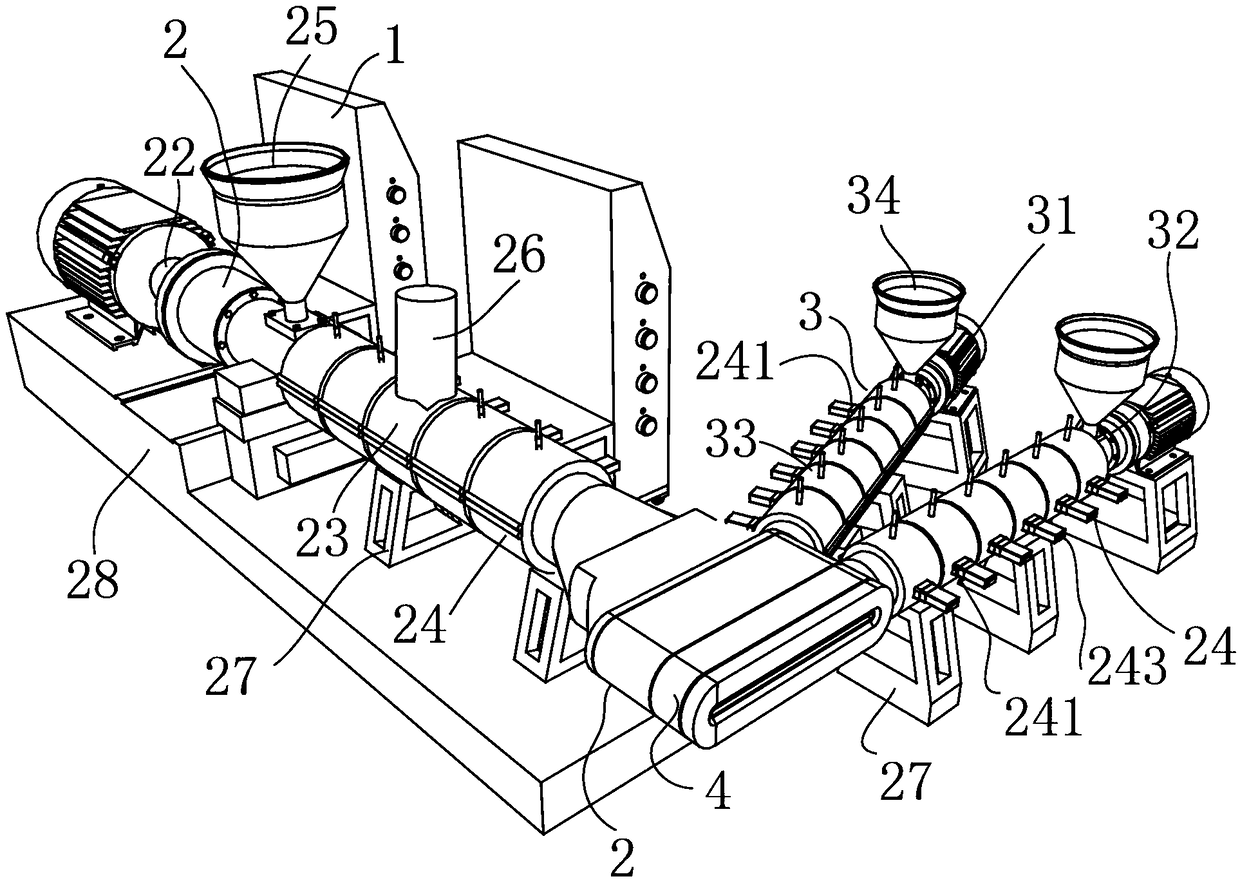

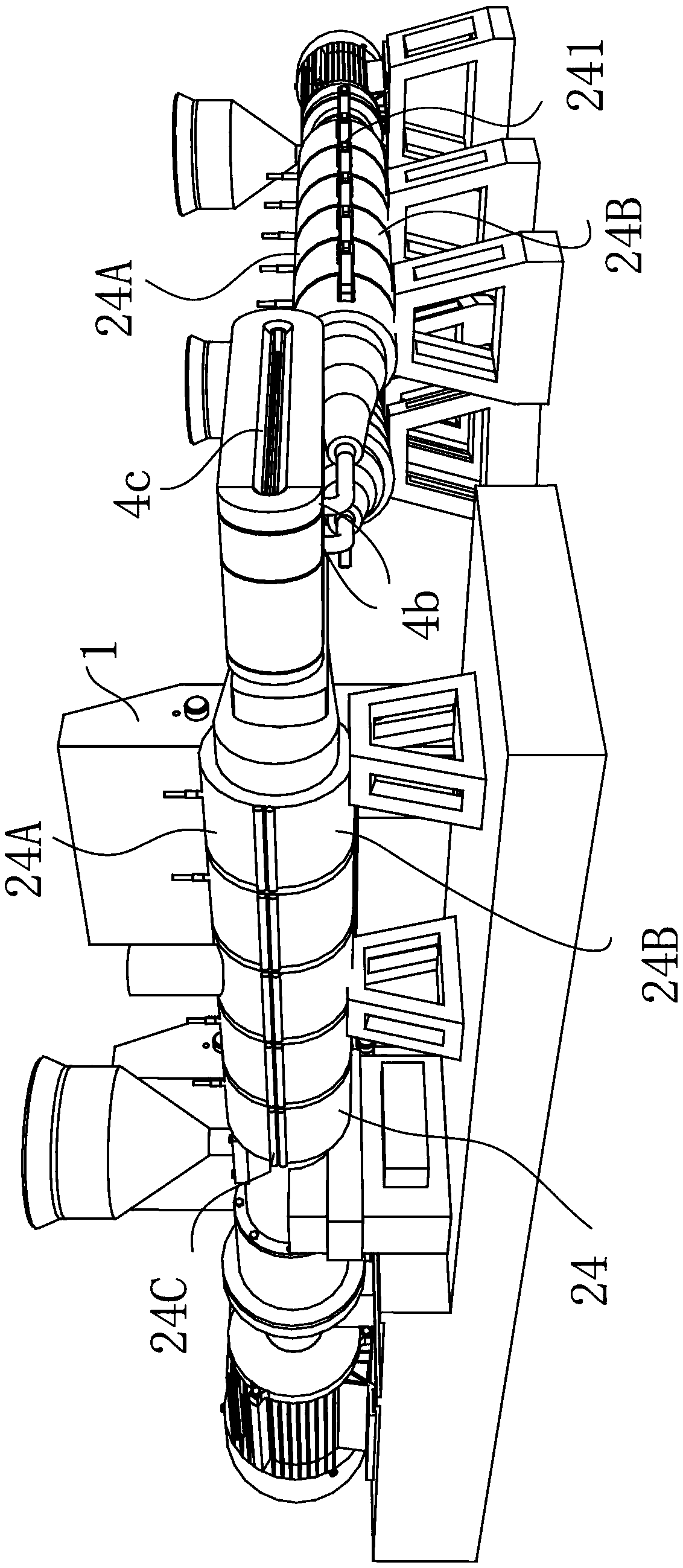

Operation method of PET wood-plastic composite manufacturing device

ActiveCN108608633ARealize multi-layer co-extrusionImprove overall strength-to-weight ratioFlat articlesControl equipmentMachining

The invention provides an operation method of a PET wood-plastic composite manufacturing device, belongs to the technical field of composite preparation methods, and particularly relates to an operation method of a PET wood-plastic composite manufacturing device. The method is used for manufacturing PET wood-plastic composites with interlayer structures and comprises the steps that S1, a control device is powered on to be started, and a main extrusion device is started; S2, an auxiliary extrusion device is started; S3, prepared main materials are added into a feed hopper; S4, prepared auxiliary materials are added into an auxiliary feed hopper; and S5, operation for extrusion machining and post-machining is carried out. The device is provided with the control device, the main extrusion device, the auxiliary extrusion device and a mold head, wherein the main extrusion device and the auxiliary extrusion device are connected through the mold head. By adoption of the operation method of the PET wood-plastic composite manufacturing device, wood-plastic composites and products can be manufactured conveniently and efficiently.

Owner:SOUTH CHINA AGRI UNIV

Non-load partition wall board for inner wall

InactiveCN102691377AReduce weightImprove overall strength-to-weight ratioHeat proofingSound proofingKeelUltimate tensile strength

The invention relates to a building material and an artificial board and discloses a non-load partition wall board for an inner wall. The board comprises two layers of stack-up wood-wool structural slabs and a keel arranged between the two layers of wood-wool structural slabs and used for supporting the wood-wool structural slabs, multiple hollow cavities are formed between the wood-wool structural slabs and the keel; and the wood-wool structural slabs are made of wood wool or straw wires. The board provided by the invention has the advantages that the weight is light; the density is less than one quarter of that of gypsum or a gypsum strand board and a cemented strand board and less than half of that of a large oriented strand board; the board is fireproof, flame-resisting, waterproof, high in strength-weight ratio, quake-proof, soundproof and noise-eliminating; after being subjected to fireproof and waterproof treatment and other treatments, the wood-wool structural slabs achieve the fireproof performance above the B1 level and the waterproof performance meeting the national construction wall material requirements; the construction weight of an inner wall is greatly reduced; the quake-proof performance, fire-proof performance, water resistance, soundproof performance, noise-eliminating performance and other performances of the construction are enhanced; and the construction intensity and the material damage in use are reduced.

Owner:QINHUANGDAO YUYUAN WOOD

High-strength environment-friendly plywood and manufacturing method thereof

InactiveCN111906862AHigh strengthImprove physical strengthFibre treatmentHeating/cooling textile fabricsFiberAdhesive

The invention relates to the field of plywood preparation, in particular to high-strength environment-friendly plywood and a manufacturing method thereof. The method comprises the steps of veneer surface pretreatment, fiber cloth gluing, plywood preparation and the like. A layer of fiber cloth is added in the middle of a composite board, the modified fiber cloth has the excellent characteristics of high strength-weight ratio, high temperature resistance, corrosion resistance, aging resistance, fatigue resistance and the like, the physical strength of the plywood can be effectively improved, the excellent characteristics of original materials can be kept, advantage complementation can be achieved, advantages of the fiber cloth and a wood material are comprehensively exerted, the strength ofthe plywood is improved, and a novel high-strength plywood material which is small in variability, high in strength-weight ratio and resistant to aging is formed. An adhesive adopted by the inventionis an environment-friendly adhesive, does not contain free formaldehyde, does not have the problem of formaldehyde release, is safe and environment-friendly plywood, and can be safely applied to thefields of home decoration, furniture manufacturing, bearing materials and the like.

Owner:广西经纬木业有限公司

Preparation method of organic and inorganic wood composite material

ActiveCN101905471BGood dimensional stabilityImprove anti-corrosion performanceWood impregnation detailsWeather resistanceHardness

Owner:NORTHEAST FORESTRY UNIVERSITY

A kind of high-strength environment-friendly plywood and its manufacturing method

InactiveCN111906862BHigh strengthImprove physical strengthFibre treatmentLiquid/gas/vapor removalFiberAdhesive

The invention relates to the field of plywood preparation, in particular to a high-strength environment-friendly plywood and a manufacturing method thereof; including: veneer surface pretreatment, fiber cloth gluing and plywood preparation steps; the invention adds a layer of fiber in the middle of the composite board After modification, this kind of fiber cloth has excellent characteristics such as high strength-to-weight ratio, high temperature resistance, corrosion resistance, aging resistance, and fatigue resistance. It can effectively improve the physical strength of plywood, and not only maintain the excellent characteristics of the original materials, Complementary advantages can also be achieved, and the advantages of fiber cloth and wood materials can be fully utilized to improve the strength of plywood, forming a new type of high-strength plywood material with small variability, high strength-to-weight ratio, and aging resistance; the adhesive used in the present invention is The environmentally friendly adhesive does not contain free formaldehyde and has no formaldehyde release problem. It is a kind of plywood that can be safe and environmentally friendly. It can be safely used in home decoration, furniture manufacturing, load-bearing materials and other fields.

Owner:广西经纬木业有限公司

Composite rib reinforced ECC-composite square steel tube hollow column

PendingCN113323150AStrong buckling abilityImprove buckling resistanceClimate change adaptationHeat proofingSteel tubeLap joint

The invention discloses a composite rib reinforced ECC-composite square steel tube hollow column. The composite rib reinforced ECC-composite square steel tube hollow column comprises a composite square steel tube assembly, an external ECC and a composite rib cage, wherein the composite square steel tube assembly comprises four square steel tubes arranged in a shape like a Chinese character 'Tian', the external ECC is wrapped with the composite square steel tube assembly, the composite rib cage is arranged in the external ECC, the composite rib cage is formed by connecting longitudinal ribs and FRP stirrups, the longitudinal ribs are in lap joint with the inner sides of the FRP stirrups, the longitudinal ribs are perpendicular to the plane where the FRP stirrups are located, the composite rib cage and the external ECC form an outer protective layer, the ratio of the thickness of the external ECC to the length of the outer side of the composite square steel tube assembly is 0.5, and the distance between the surface of the external ECC and the axes of the longitudinal ribs is not smaller than 35mm. The hollow column is high in strength-to-weight ratio, and the square steel tubes are hollow, so that the structure meets the strength requirement with a small section; and the composite square steel tube assembly formed by combining the four square steel tubes is improved in bearing capacity and rigidity compared with a single square steel tube. In addition, the composite rib reinforced ECC-composite square steel tube hollow column has the advantages of being excellent in anti-seismic property, high in durability, good in fire resistance and the like.

Owner:SICHUAN UNIV

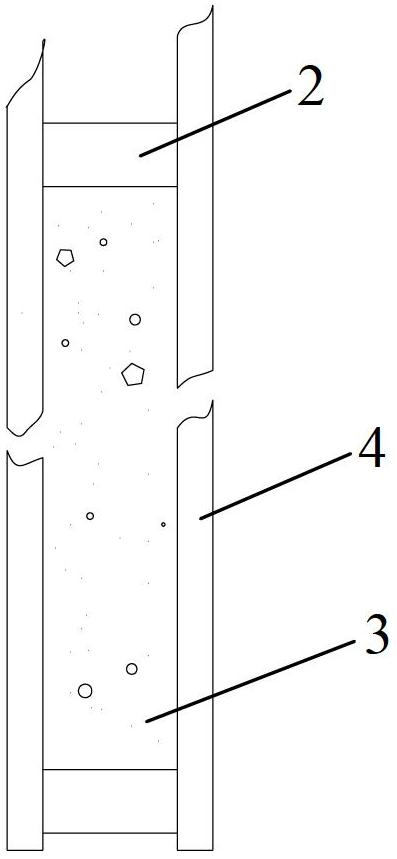

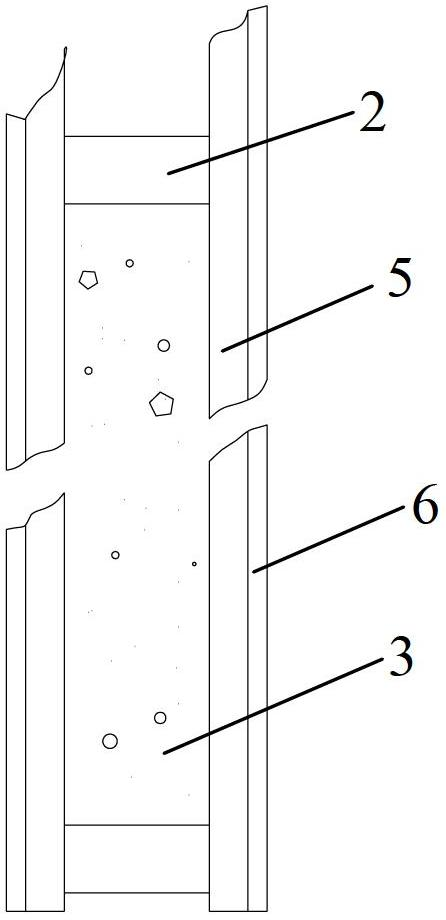

A method for compositely strengthening wooden beams

ActiveCN105952182BHigh tensile strengthImprove overall strength-to-weight ratioBuilding repairsFiberEpoxy

The invention belongs to the field of civil engineering and discloses a method for compound reinforcement of a wooden beam. The method is characterized in that at the bottom of the wooden beam (1), fiber cloth (3) is adhered, a base layer (5) is arranged, a bamboo board (2) is adhered and a round bolt (6) is screwed to achieve compound reinforcement of the wooden beam (1). In the method, the bamboo board (2) is used as a reinforcing material, meanwhile the fiber cloth (3) is mechanically anchored, the bonding effect of the bamboo board (2), the fiber cloth (3) and the wooden beam (1) is strengthened through fusion of the round bolt (6) with the bamboo board (2) and the wooden beam (1), and the thickness of epoxy resin glue (4) between the bamboo board (2) and the wooden beam (1) is ensured by arranging the base layer (5) embedded with a solid filling (51). By the adoption of the method, the probability of untimely damage due to bonding layer failure in the wooden beam bending process is reduced, the wooden beam is reinforced by adopting two low-carbon environmentally friendly materials, respective advantages of the two materials are fully played, the bearing capability of the wooden beam is improved, and an original style and features of an old historic building structure restored as the old are achieved.

Owner:NANJING FORESTRY UNIV

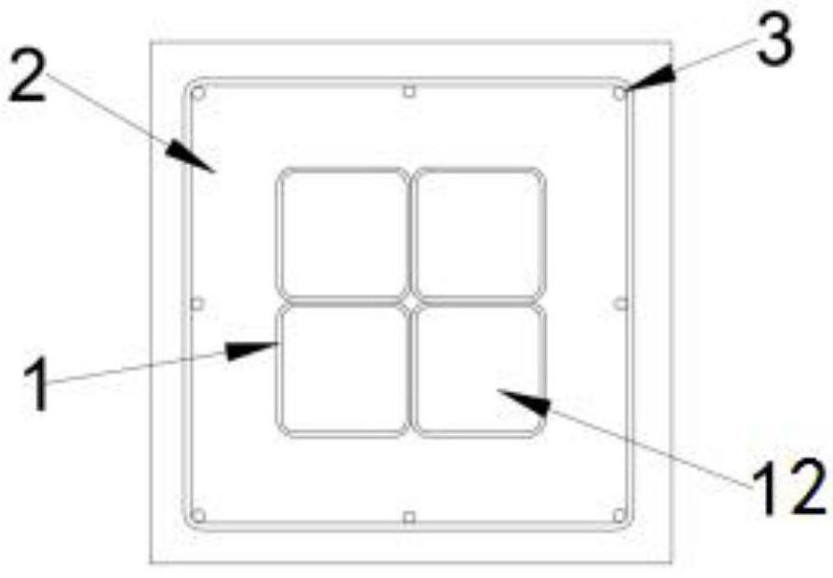

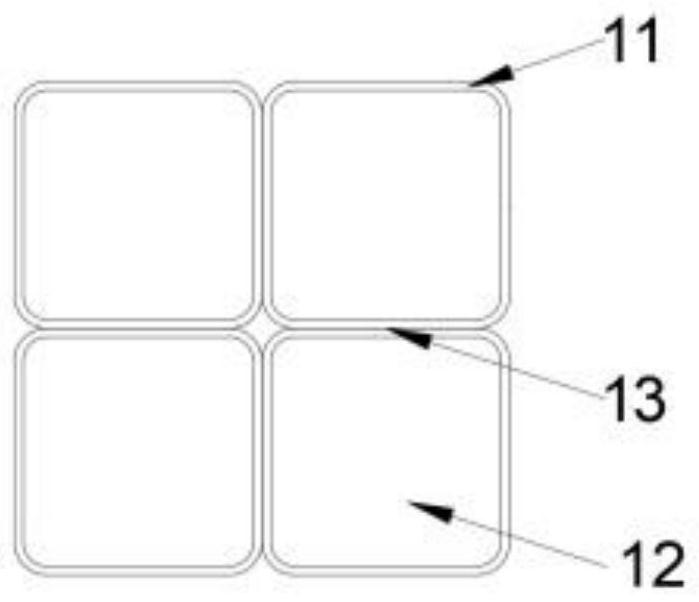

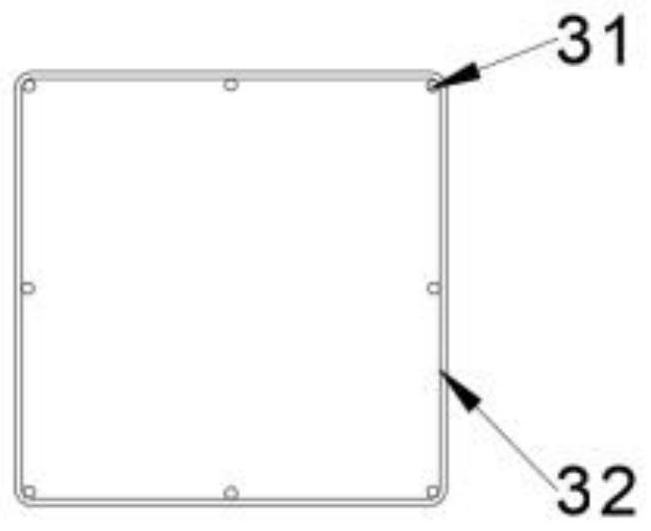

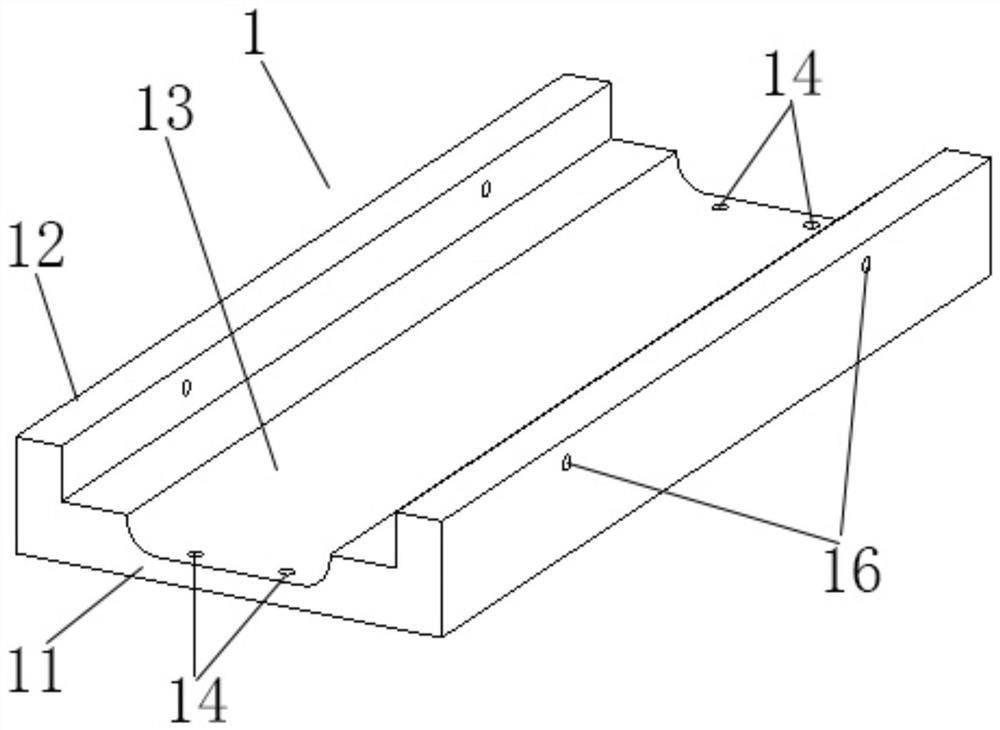

A kind of high strength-to-weight ratio C-shaped wooden structural material pressing mold and method

InactiveCN110434971BImprove overall strength-to-weight ratioFast preparationWood working apparatusEngineeringMechanical engineering

The invention discloses a pressing die and a method of a C-shaped wooden structural material with the high strength-weight ratio. The pressing die comprises a base, a core rod, clamps, pressurizing blocks, wedge blocks and pressure releasing blocks, wherein the base is of a groove-shaped structure with a U-shaped section, the base is composed of a bottom plate and side walls located on the two sides of the bottom plate, a groove is formed in the bottom plate, the groove is used for placing the core rod and the C-shaped wooden structural material, the core rod is used for wrapping the C-shapedwooden structural material around the outer wall of the core rod, the clamps are used for pressing C-shaped material flanges and curled edges of the C-shaped wooden structural material, a plurality ofpressurizing holes are formed in the joint between the left clamp and the right clamp, the pressurizing blocks are block bodies which are matched with the pressurizing holes and are detachably placedin the pressurizing holes, the two wedge blocks are arranged between the side wall of one of the two sides of the base and the left clamp and the side wall of the other one of the two sides of the base and the right clamp correspondingly, and the plurality of pressure releasing blocks are used for pressurized unloading of the wedge blocks and detaching the die. According to the pressing die and the method, the C-shaped wooden structural material with low cost can be quickly manufactured.

Owner:NANJING FORESTRY UNIV

A kind of plug-in aviation electric pod and using method

ActiveCN105539849BHigh degree of automationReduce mechanical wearAircraft componentsLaunching weaponsAviationAir compression

The invention discloses an external mounting type aviation electric pod. The external mounting type aviation electric pod comprises a pod core and a shell. The pod core is arranged in the shell. High-automation-degree operating design is adopted for the external mounting type aviation electric pod. All operation actions can be completed just through one pilot in a part-time job manner, and therefore the pod can be used for all aircraft with a single seat and multiple seats. Because no hydraulic and air compression systems are arranged, mechanical transmission parts are reduced by 80%, mechanical abrasion is greatly reduced, and the system is single and simplified; rolling of a winch and cable distributing and dragging winding and unwinding speed control precision can be improved, and therefore the fault rate is greatly decreased; and because a cable dragging automatic locking device is arranged, part of cable dragging force is transmitted to a pod body structure, loads on the winch are relieved, and using reliability is greatly improved. A more advanced thin-shell structure is adopted for a pod body, the ratio of strength to weight and the material utilizing rate are greatly increased.

Owner:河北环航科技股份有限公司

A new type of solid wood board and its processing method

InactiveCN105171855BImprove stabilityImprove overall strength-to-weight ratioWood veneer joiningWood layered productsSolid woodPrism

Owner:广西贺州市灵峰木业科技有限公司

Assembly type bamboo bridge

ActiveCN103437271BHigh tensile strengthNo possibility of crackingSynthetic resin layered productsBridge structural detailsPre stressPre stressing

The invention provides an assembly type bamboo bridge. The assembly type bamboo bridge consists of bamboo longitudinal beams (1), bamboo transverse beams (2), bamboo panels (3), a transverse pre-stressing tendon (4) and a longitudinal pre-stressing tendon (16). All bamboos used by the assembly type bamboo bridge are soaked in a gum dipping tank which contains polyurethane resin and phenolic resin before being assembled, and boiled for 10-15 minutes at 100 DEG C-110 DEG C, wherein the volume ratio of the polyurethane resin to the phenolic resin is (2-2.5):1; and then, the bamboos are got out and dried, and a layer of waterborne polyurethane resin, a layer of polyurethane resin, a layer of waterborne polyurethane resin and a layer of resurcinolformaldehyde resin are uniformly coated on the outer surfaces of all bamboos in sequence. The assembly type bamboo bridge is large in structural strength, good in drawability, green and environment-friendly in used materials, standard in structural components, high in assembly degree, good in structural integrity, and capable of sufficiently bringing the advantages of the materials into play, and satisfying the normal use and durability needs of the bridge beam structure.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

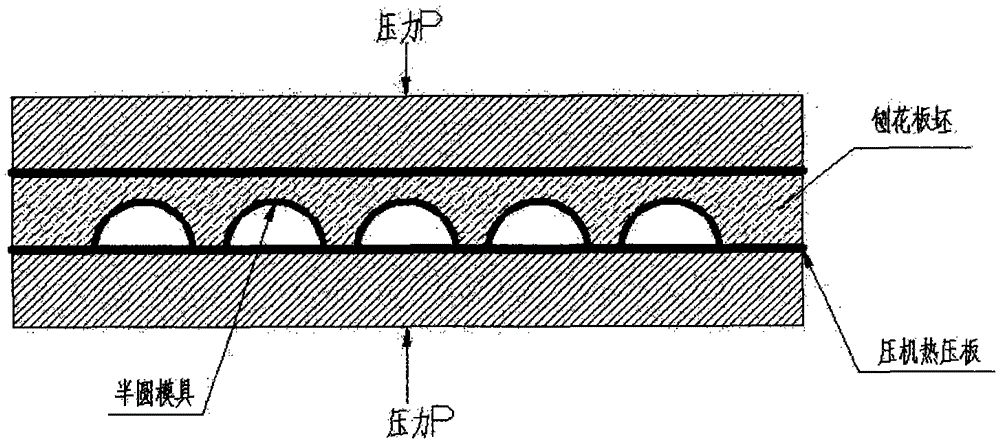

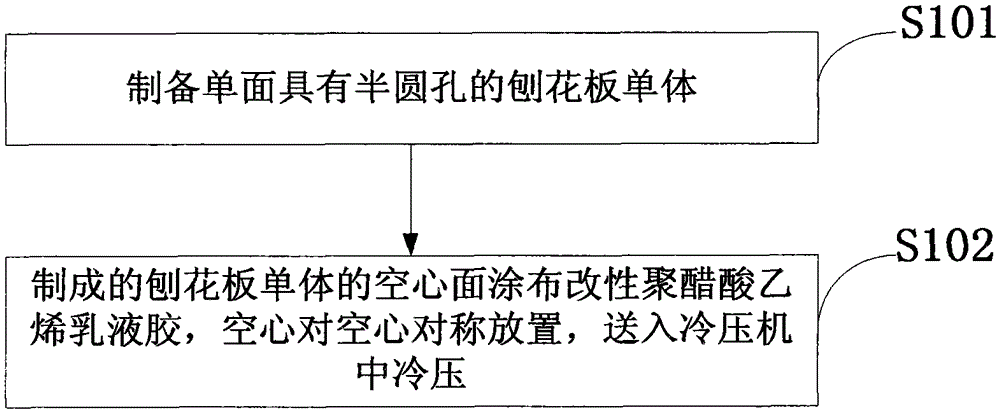

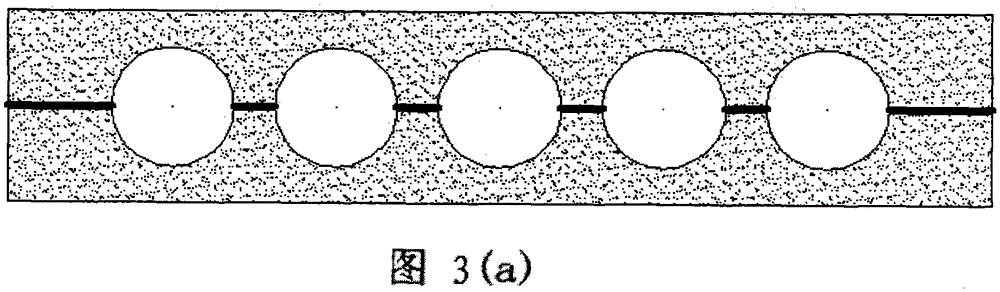

A method for producing hollow particleboard by two-step flat pressing method

InactiveCN103264429BImprove mechanical propertiesReduce formaldehyde emissionWood working apparatusDomestic articlesPolyvinyl acetateEmulsion

The invention discloses a method utilizing a two-step flat pressing process to produce hollow-core particleboards and composite boards. The method includes: producing single particleboards, and allowing each single particleboard to have a semicircular hole in a single face; coating modified polyvinyl acetate emulsion on a hollow-core face of each of two single particleboards, allowing the hollow-cores of the two single particleboards to be symmetrical, and then feeding the two signal particleboards into a cold pressing machine for cold pressing. By the method, the defects of direct flat pressing and extrusion methods are overcome, and the produced particleboards and composite boards are excellent in dynamic performance, low in formaldehyde emission, high in ratio of strength to weight and the like, can be used directly without applying veneers on surfaces, and is widely applicable to building and furniture industries. In addition, single-layer or multi-layer pressing machines are utilized, equipment cost is saved due to the fact that no new equipment needs to be purchased, and specific significance is provided for small and medium-sized artificial board enterprises.

Owner:NANJING FORESTRY UNIV

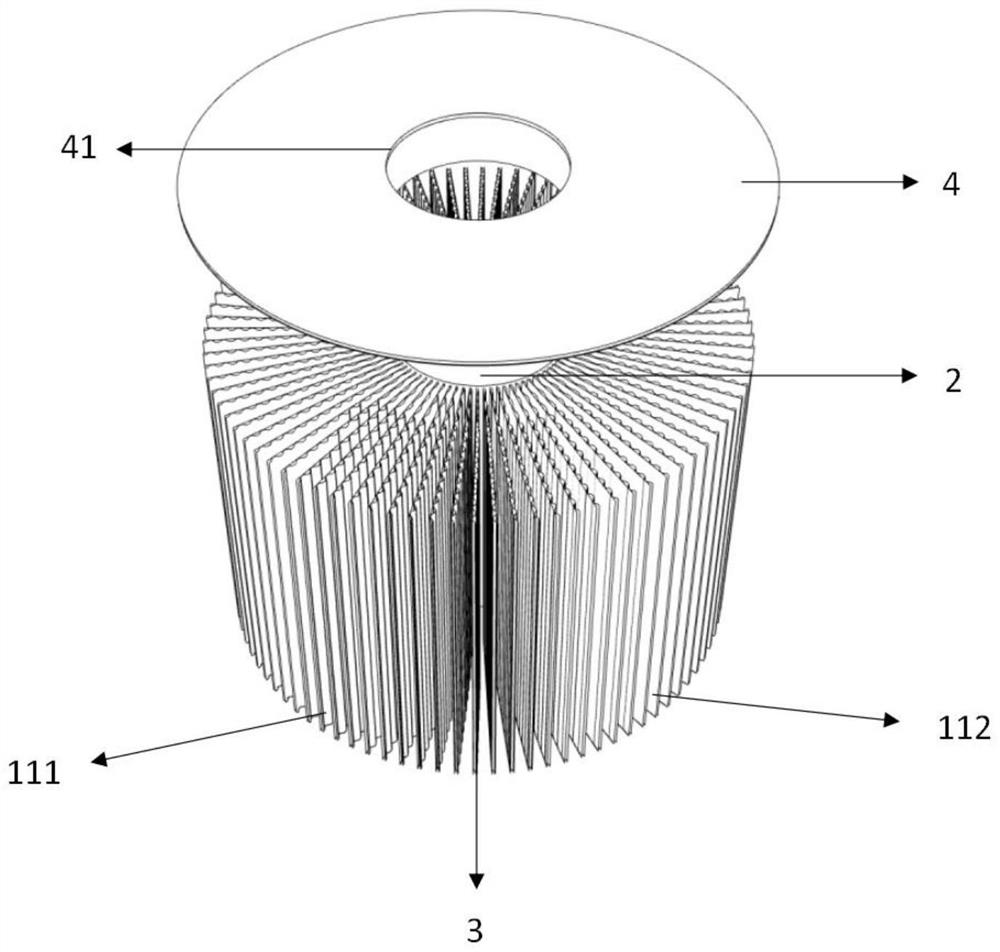

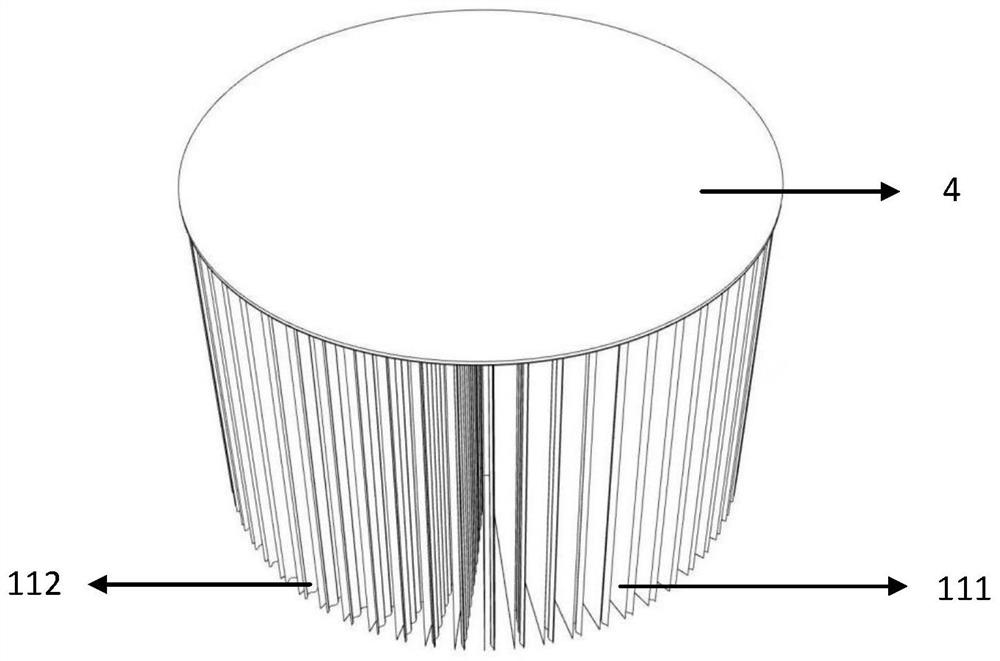

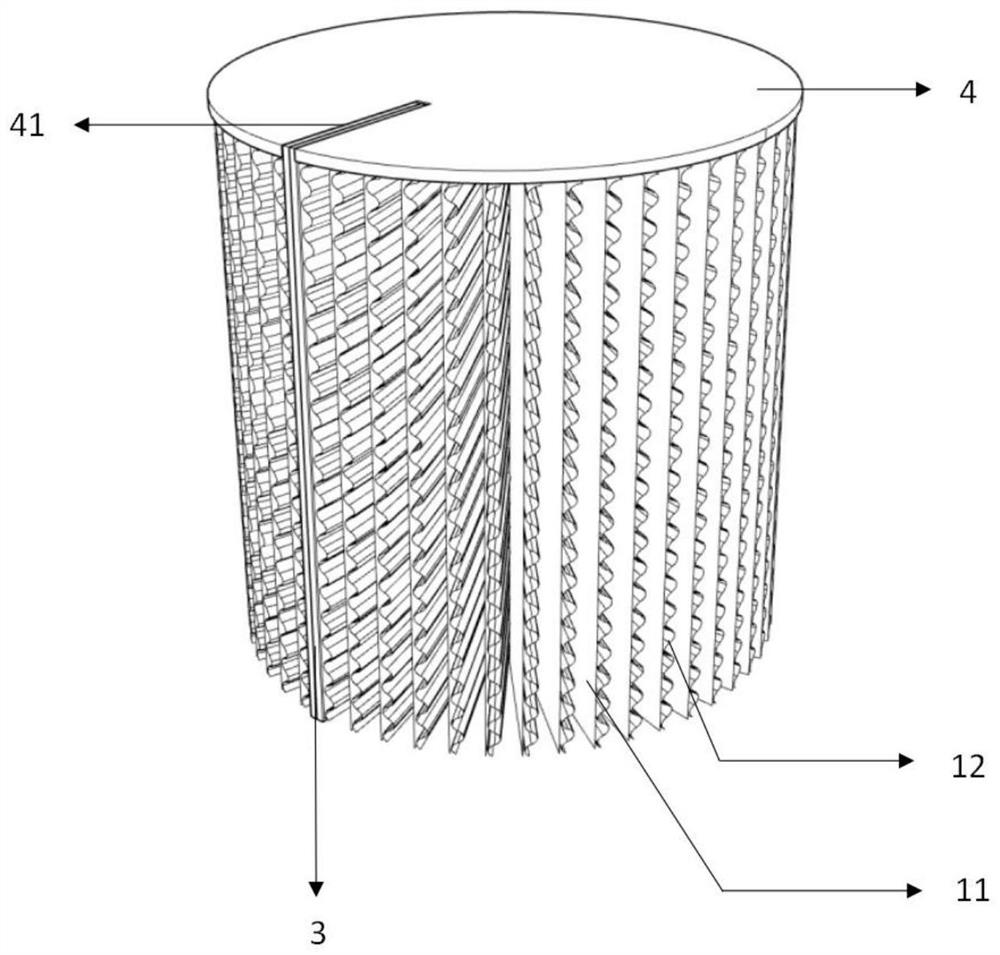

Stacked corrugated annular stretching furniture structure and process thereof

PendingCN114680492AGood load-bearing strengthSimple processMechanical working/deformationFurniture partsComposite materialHollow cylinder

The invention discloses a stacked corrugated annular stretching structure and a process thereof. The stacked corrugated annular stretching structure is formed by annularly unfolding n corrugated units along a covering film, covering a panel and fixing. The hollow corrugated unit is formed by stacking n + 1 plane base bands and n corrugated base bands, an auxiliary plate is glued and pressed on the plane base band on the outermost side of the stacked corrugations, and a covering film is pasted on the surface of only one side. When in use, the auxiliary plate is annularly stretched and unfolded along the covering film and is combined and fixed. The stacked corrugated annular stretching structure is characterized in that the n corrugated units are in a radial shape and are perpendicular to the ground to support the panel, and the middle of each corrugated unit is a hollow cylinder. The forming method comprises the following steps that S1, the stacked corrugations are prepared; s2, glue pressing, drying and shaping; and S3, pasting a side film. The unfolding method comprises the following steps that S1, the auxiliary plate is annularly unfolded, combined and then fixed; s2, fixing the seat surface;

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

A method for preparing hollow micro-nano carbon spheres by microwave-assisted heating of lignin

ActiveCN108584913BEvenly heatedImprove overall strength-to-weight ratioCarbon preparation/purificationMicro nanoPhysical chemistry

The invention discloses a method for preparing hollow micro-nano carbon spheres by microwave assisted heating of lignin. Firstly, the lignin is placed in a microwave reactor, and then a carrier gas is passed through to remove the air therein; then the microwave reactor is turned on and kept loaded. The air flow rate is constant, and the temperature is raised to 350-550°C at a heating rate of 50-150°C / min, wherein the microwave power is 800-2000W; then the microwave power is adjusted to 300-800W, and the heating rate is 10-50°C / min. To 600-800°C, keep warm for 10-60 minutes; finally close the microwave reactor, keep the flow rate of the carrier gas constant, after cooling down to below 150°C, turn off the carrier gas, and the obtained solid product is hollow micro-nano carbon spheres. The invention will provide a new approach for high-value utilization of waste resource lignin, and is also expected to provide a new type of basic material for the field of carbon materials.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com