Operation method of PET wood-plastic composite manufacturing device

A technology for wood-plastic composite materials and manufacturing equipment, which is used in flat products, applications, household appliances, etc., can solve the problems of restricting the production and application of PET wood-plastic composite materials, lack of operation methods, and difficult to process, and achieves durability and comprehensiveness. The effect of improving mechanical properties, improving strength-to-weight ratio and toughness, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

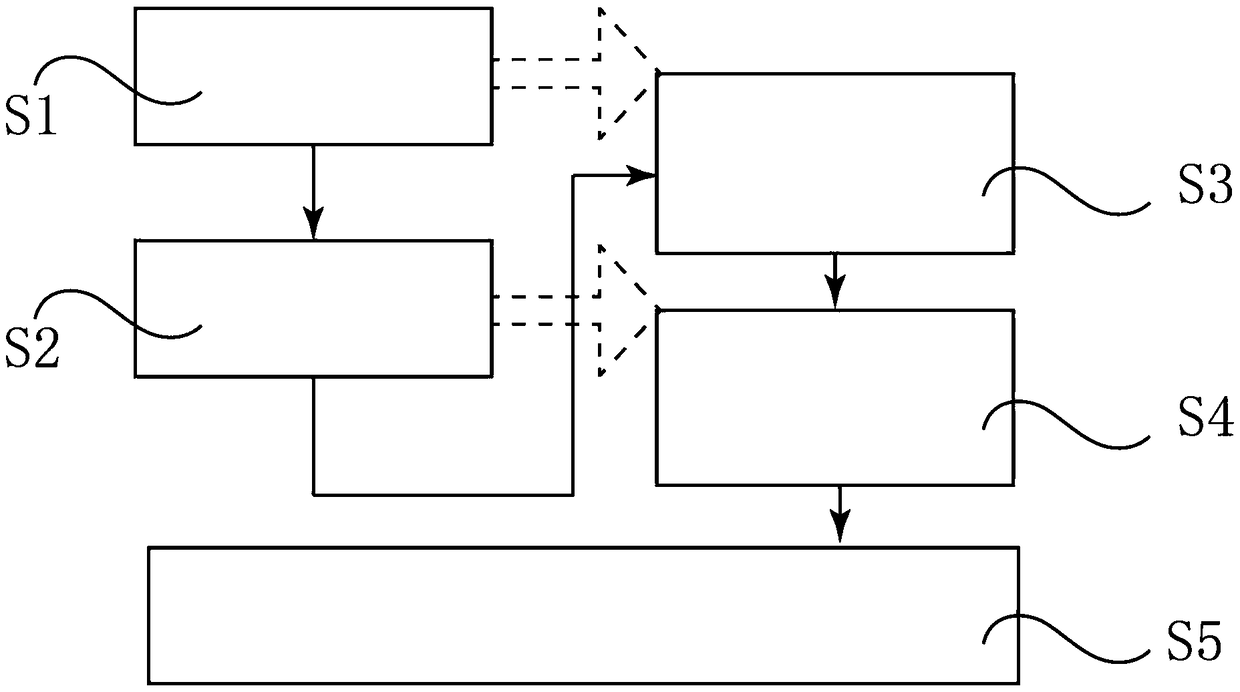

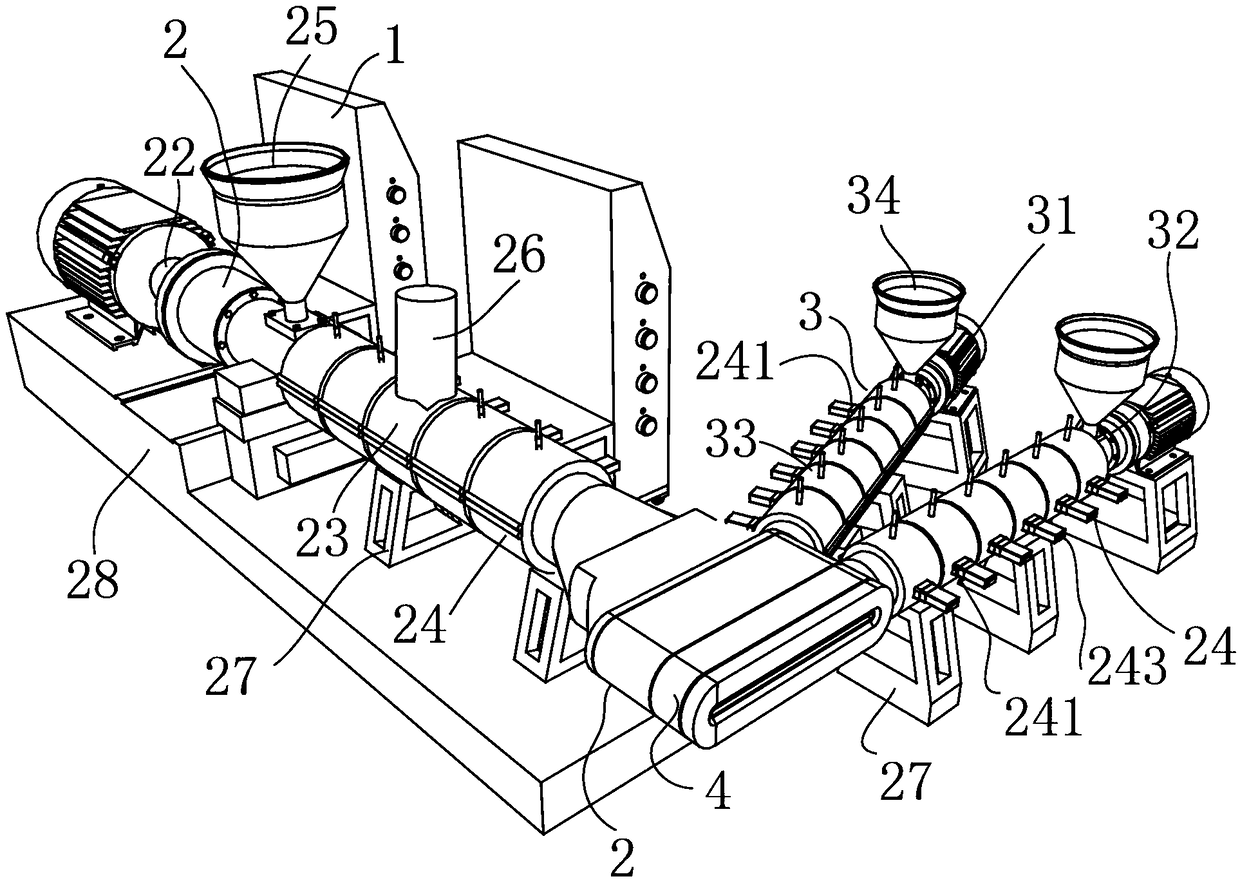

[0041] see figure 1 , figure 2 and image 3 , the embodiment of the present invention provides an operation method of PET wood-plastic composite material manufacturing equipment, the method is used to manufacture PET wood-plastic composite material with a sandwich structure, comprising the following steps: S1, open the main extrusion equipment: open the PET wood-plastic composite material Plastic composite material manufacturing equipment, the PET wood-plastic composite material manufacturing equipment has a control device 1, a main extrusion device 2, an auxiliary extrusion device 3 and a die head connecting the main extrusion device 2 and the auxiliary extrusion device 3 4. Start the control equipment 1 of the PET wood-plastic composite material manufacturing equipment with electricity, the control equipment 1 is electrically connected with the main extrusion equipment 2, after the main extrusion equipment 2 is started, the heating device 24 heats the main extrusion equipm...

no. 2 example

[0045] see figure 1 , figure 2 and image 3 , the operation method of a PET wood-plastic composite material manufacturing equipment provided by the embodiment of the present invention is different from the previous embodiment in that the main extrusion equipment 2 has a power equipment 21, a transmission shaft 22, a barrel 23, a heating device 24. Feeding hopper 25, support 27 and platform base 28; the power equipment 21 is located on the platform base 28, the barrel 23 has a screw, one end of the transmission shaft 22 is connected with the screw and the other end is connected with the power equipment 21 Fixedly connected, the heating device 24 is wrapped around the outer periphery of the barrel 23; the power equipment 21 is located at one end of the main extrusion equipment 2 provided with a drive shaft 22, and the other end of the main extrusion equipment 2 is provided with a mixing section, a melting section, and section, homopolymerization section, foaming agent injecti...

no. 3 example

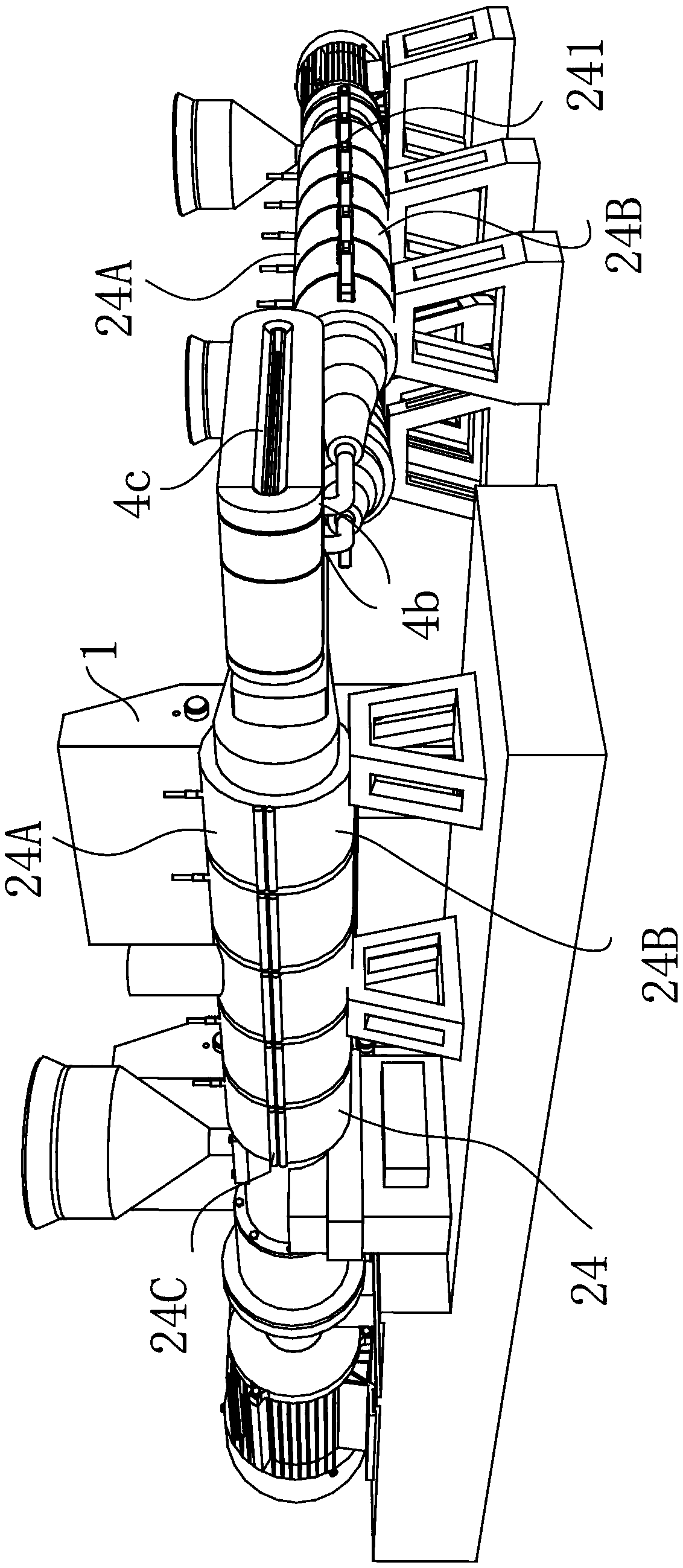

[0048] see Figure 4 , Figure 6 and Figure 7 , an operation method of PET wood-plastic composite material manufacturing equipment provided by an embodiment of the present invention. Such as Figure 4 , Figure 6 and Figure 7 As shown, the die head 4 in step S1 has a main input port 4a, an auxiliary input port 4b and an output port 4c, and the main input port 4a is connected to the mixing cooling section of the main extrusion device 2; the die head 4 The main input end 4a of the main input end 4a has an interface boss 41, and the interface boss 41 includes an annular base 411 and an annular convex portion 412, and the annular base 411 is integrally connected with the annular convex portion 412, and the annular base 411 is connected to the barrel 23, The annular convex portion 412 is connected to the conical structure 42, the conical structure 42 is provided with a PET channel 421 which is hollow inside and the outside is provided with a flow groove 422 and a shrinking s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com