A method for producing hollow particleboard by two-step flat pressing method

A chipboard and hollow technology, which is applied in the field of hollow particleboard production by two-step flat pressing method, can solve the problems of difficult production of thin boards, difficulty in demoulding, high water absorption thickness expansion rate, etc., and achieve equipment cost saving, excellent mechanical properties, and low formaldehyde The effect of release volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

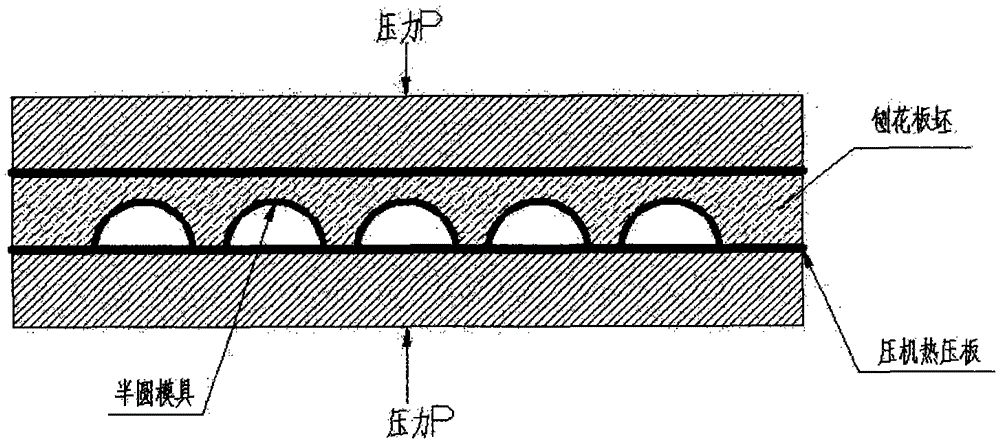

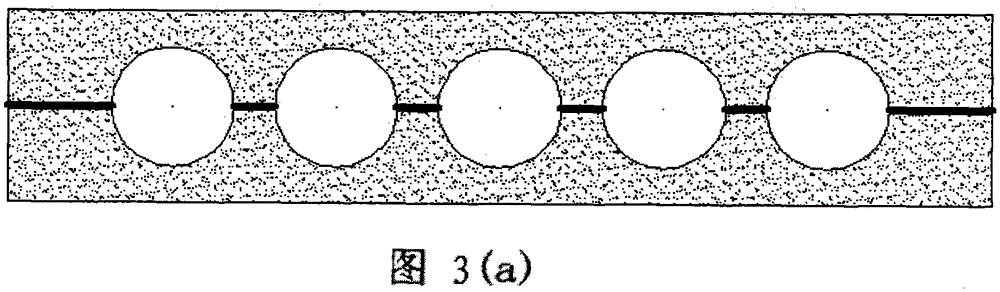

[0060] Dimensional Design of Hollow Particleboard Particleboard:

[0061] Dimensions: 400×400××40mm; Hollow radius: 15mm; A1: 10mm; A2: 5mm; A3: 5mm; Hollow rate K: 64.8%,

[0062] Process parameters:

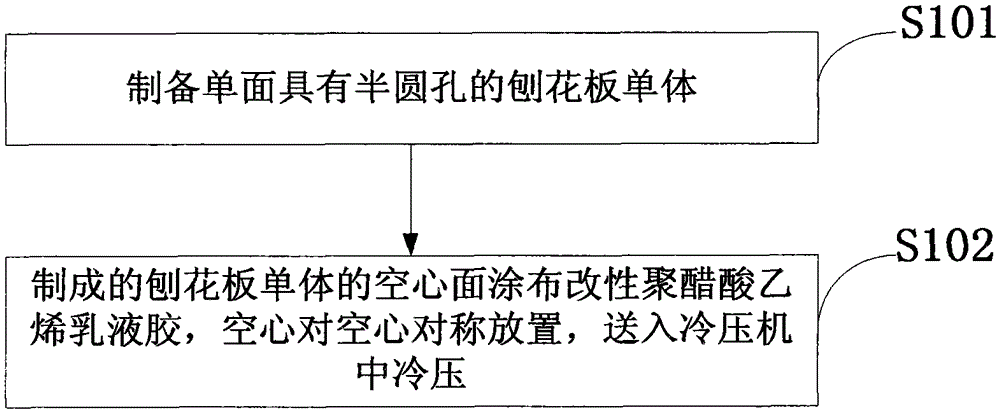

[0063]Select poplar wood shavings, after drying, the moisture content is 3.5%, select phenolic resin adhesive (solid content 45%, viscosity 120s), and add liquid paraffin water repellent with a solid mass ratio of 1.2%, and mix them evenly. Glue sizing, the glue spraying method is selected, the pre-pressing pressure is 1.5MPa for 3 minutes, the single-layer press is used, the hot-pressing time is 190°C and the time is 12 minutes, and the hot-pressing pressure is the unit pressure of 3MPa. One side of the hole is coated with modified polyvinyl acetate emulsion glue, and sent to a press for cold pressing to obtain the final product. The specific process steps are as follows:

[0064] Step 1: Place the semi-circular mold on the backing board at equal intervals along the length o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com