Stacked corrugated annular stretching furniture structure and process thereof

A tensile structure and corrugated technology, which is applied in home appliances, furniture parts, machining/deformation, etc., can solve problems such as difficult transportation, product damage, honeycomb structure crushing, etc., and achieve simple process, easy industrialization, and good load-bearing strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

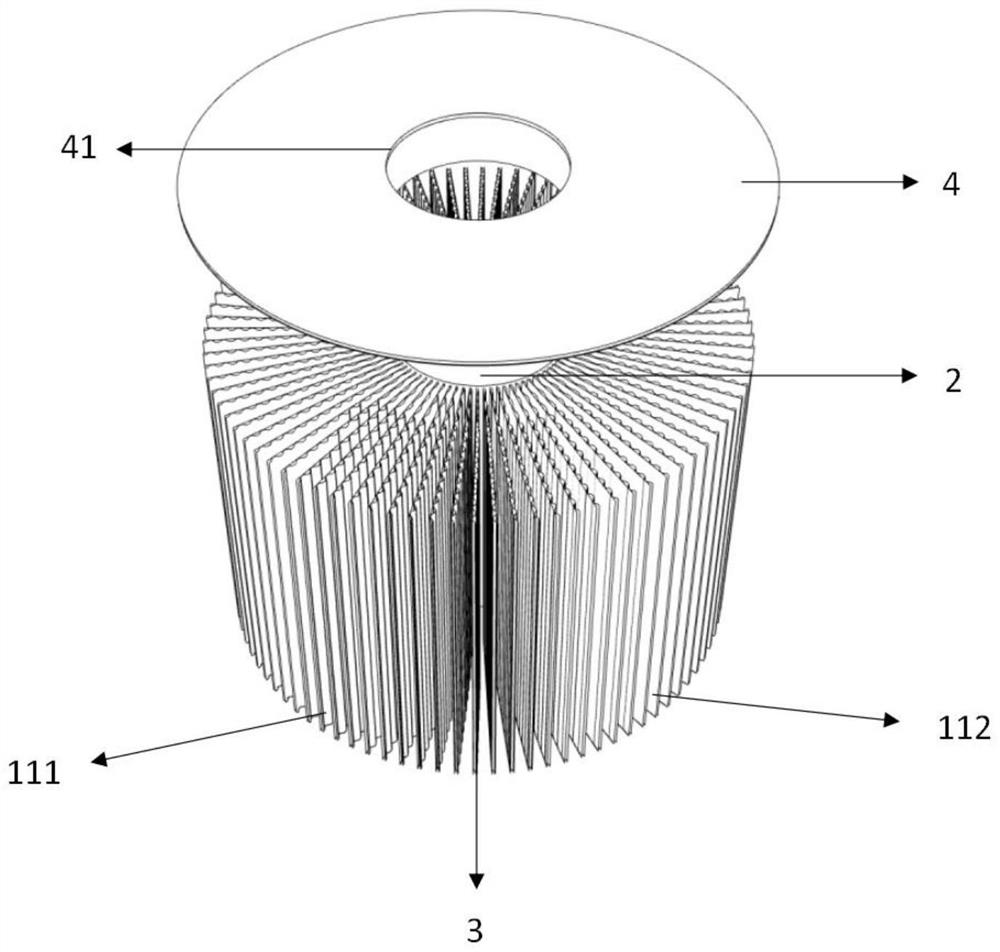

[0019] like figure 1 As shown, the multi-layer stacked corrugated annular tensile structure of this embodiment includes a corrugated unit (1), a covering film (2), and 126 corrugated units (1) are pasted on a covering film (2), and the materials are Kraft paper, the thickness is preferably 0.1-0.4mm, the present embodiment adopts 0.1mm, the corrugated shape is U-shaped corrugated, the size is A-type, the corrugated spacing is 9.0mm, and the corrugated height is 4.8mm, that is, the thickness of the entire single corrugated structure corrugated unit (11) is 5.0mm, the corrugated corrugated extrusion direction is perpendicular to the ground. The cover film is 200πmm long, and the auxiliary plate (3) has a size of 100*403*3mm, and is stretched and unfolded along the cover film (2) in a ring shape and the structure is fixed. The panel (4) is a circle with a radius of 20mm, and a middle groove type plug-in structure (41) with a radius of 100mm is provided on the panel, the recessed...

Embodiment 2

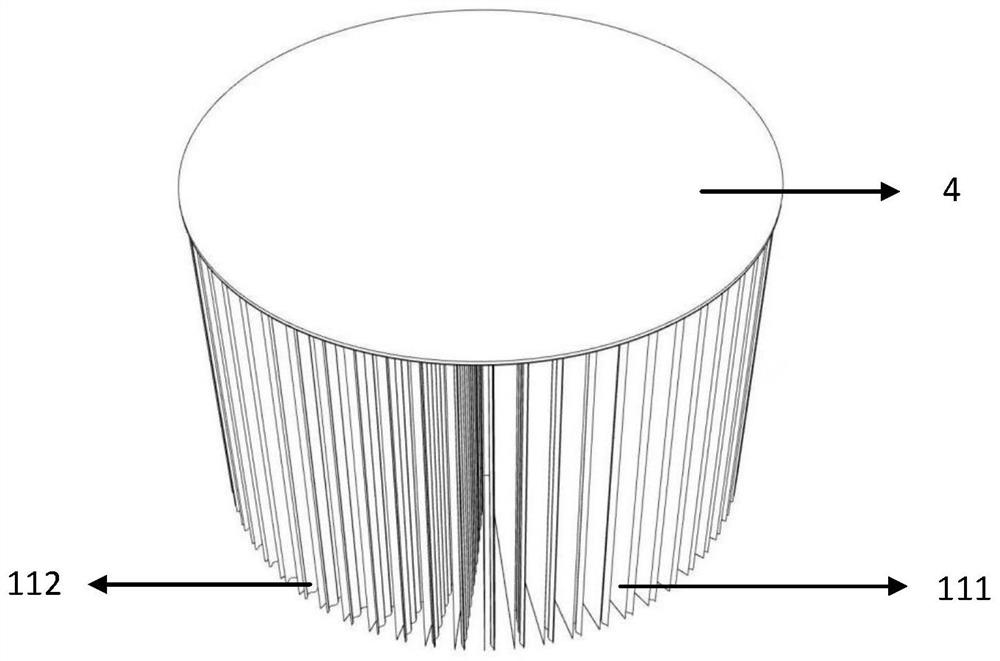

[0023] like figure 2 As shown, the multi-layer stacked corrugated annular tensile structure of this embodiment includes a corrugated unit (1), a covering film (2), and 126 corrugated units (1) are pasted on a covering film (2), and the materials are Kraft paper, the thickness is preferably 0.1-0.4mm, the present embodiment adopts 0.1mm, the corrugated shape is U-shaped corrugated, the size is A-type, the corrugated spacing is 9.0mm, and the corrugated height is 4.8mm, that is, the thickness of the entire single corrugated structure corrugated unit (11) is 5.0mm, the corrugated corrugated extrusion direction is perpendicular to the ground. The cover film is 200πmm long, and the auxiliary plate (3) has a size of 100*403*3mm, and is stretched and unfolded along the cover film (2) in a ring shape and the structure is fixed. The panel (4) is a circle with a radius of 200mm, and there is no plug-in structure (41) on the panel (4). In this example, a connecting bar (5) needs to be ...

Embodiment 3

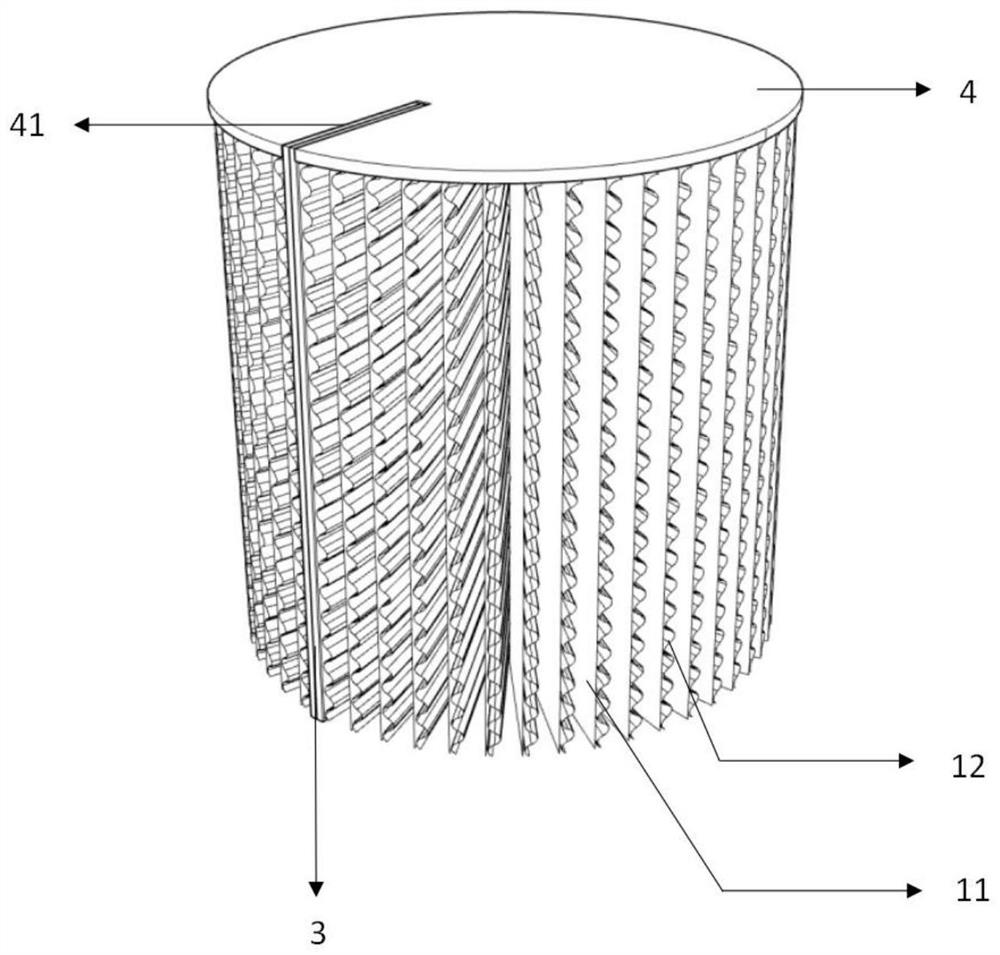

[0026] like image 3 As shown, the multi-layer stacked corrugated annular tensile structure of the present embodiment includes a corrugated unit (1), a covering film (2), and 125 corrugated units (1) are pasted on a covering film (2), and the materials are Kraft paper, the thickness is preferably 0.1-0.4mm, the present embodiment adopts 0.1mm, the corrugated shape is V-shaped corrugated, the size is B-type, the corrugated spacing is 10 mm, and the corrugated height is 4.8 mm, that is, the thickness of the entire single corrugated structure corrugated unit (11) is 5.0 mm. The cover film has a length of 140πmm, and the auxiliary plate (3) has a size of 140*405*5mm. The panel (4) is a circle with a radius of 210 mm, and a plug-in structure (41) is provided on a track of any radius. The connecting bar (5) may not be provided.

[0027] The forming method includes the following steps: S1: Prepare stacked corrugations: in this embodiment, a flat base tape (111) and a corrugated ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com