Patents

Literature

35results about How to "Solve the bearer problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

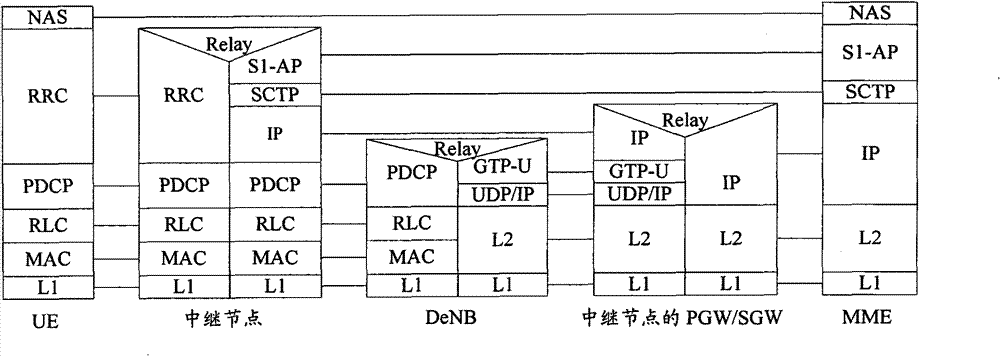

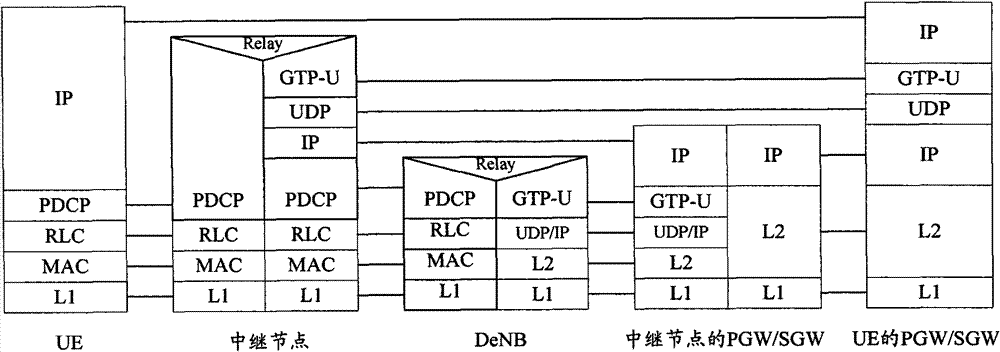

Method and device for realizing packet data convergence protocol of LTE relay system

ActiveCN102026398ASolve the bearer problemReduce processingConnection managementWireless network protocolsProtocol for Carrying Authentication for Network AccessWireless

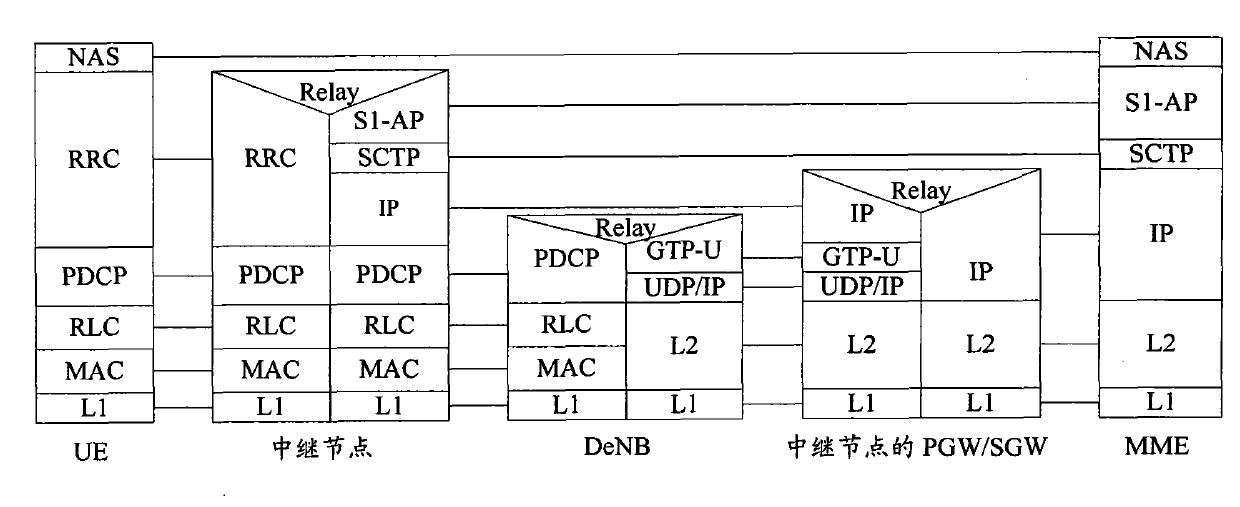

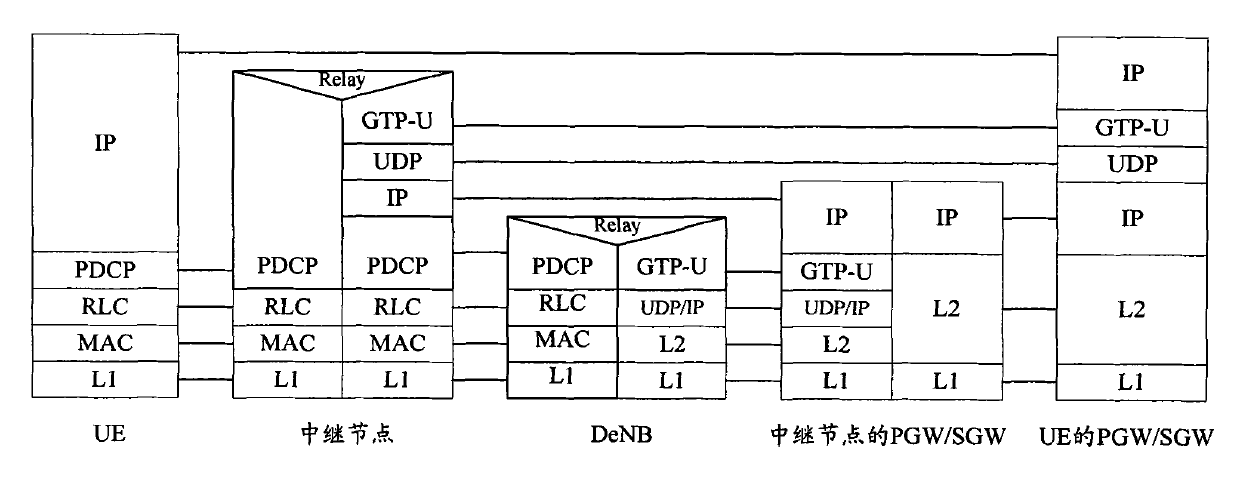

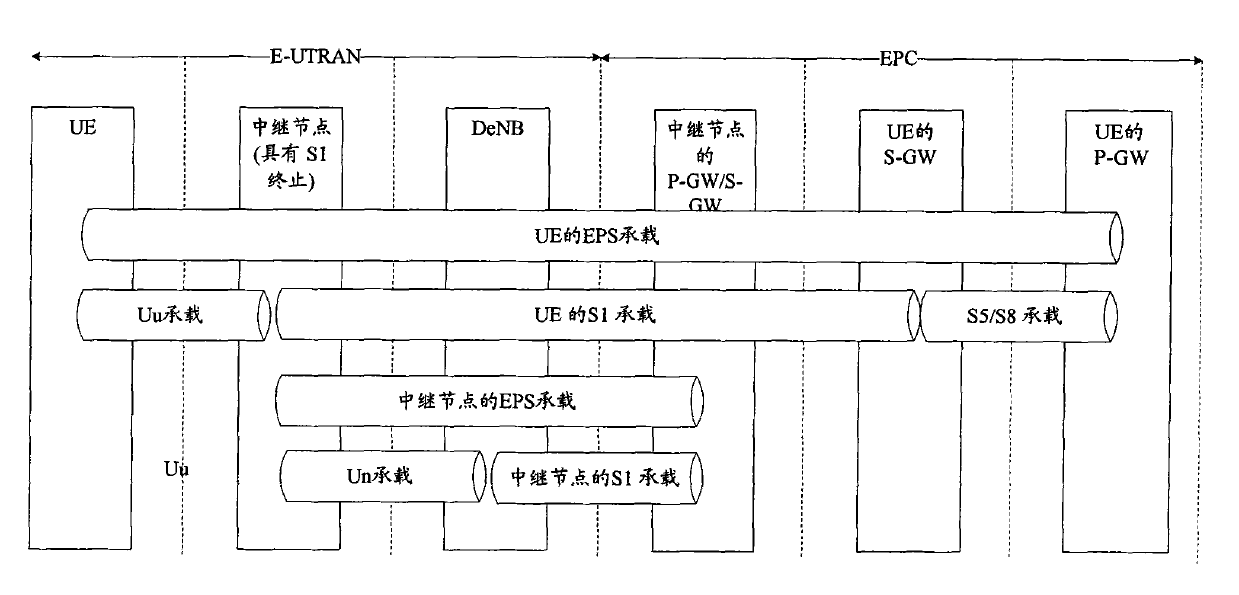

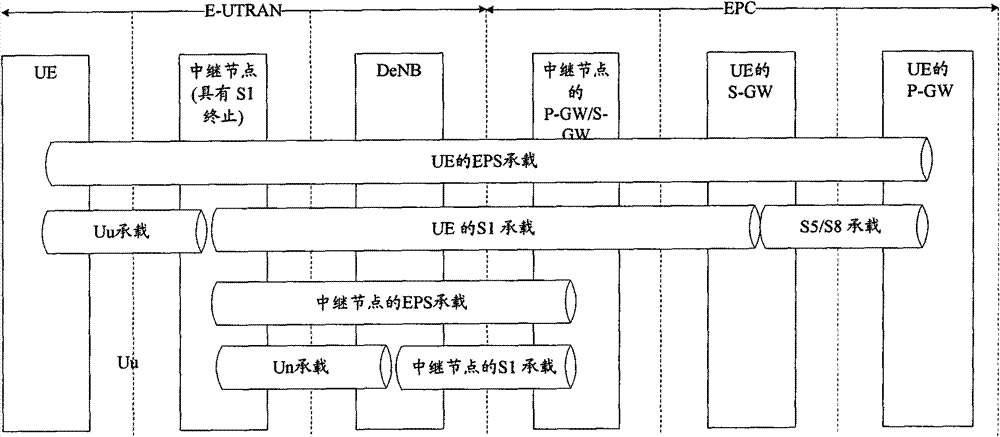

The present invention discloses a method for realizing packet data convergence protocol (PDCP) of LTE wireless relay system, characterized in that: an identification aiming at user equipment radio bearing is introduced at a PDCP layer of Un port, therefore multiplexing of different user equipment data is supported by the PDCP layer of Un port; in the process that user equipment UE produces business and establishes S1 bearing, the following steps are comprised: the relay node Un radio bearing reconfiguration process of the Un port between the relay node and evolution base station equipment is triggered; in the process of the relay node Un radio bearing reconfiguration, the evolution base station equipment and the relay node complete the many-to-one mapping between radio bearing of Un port user equipments and data radio bearing DRB of Un port relay, then establish the corresponding relationship between user equipment radio bearing identification and tunnel identification of GPRS tunnel protocol GTP which is borne by user equipment S1. In addition, the present invention also discloses a relay node and evolution base station equipment.

Owner:POTEVIO INFORMATION TECH

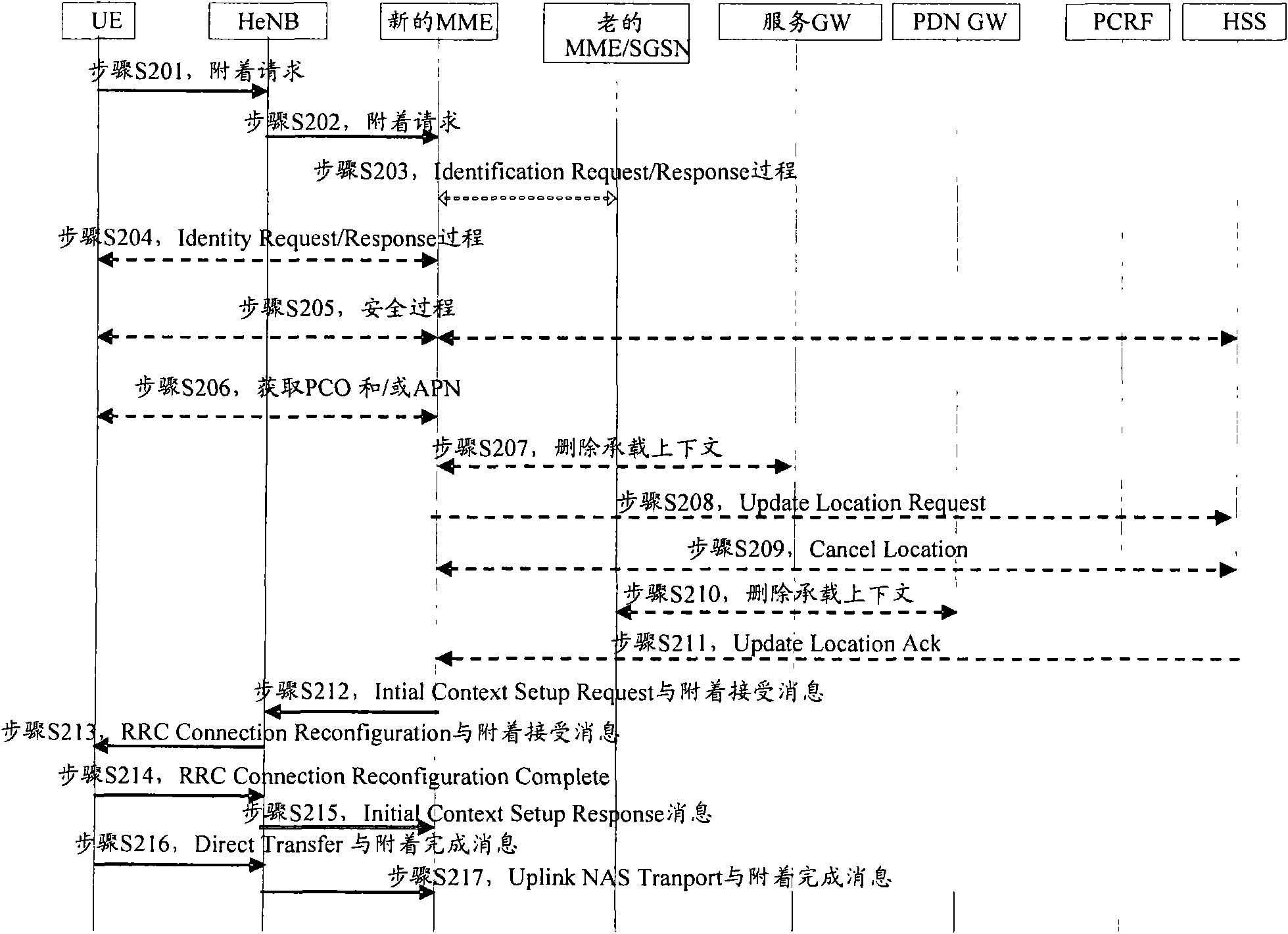

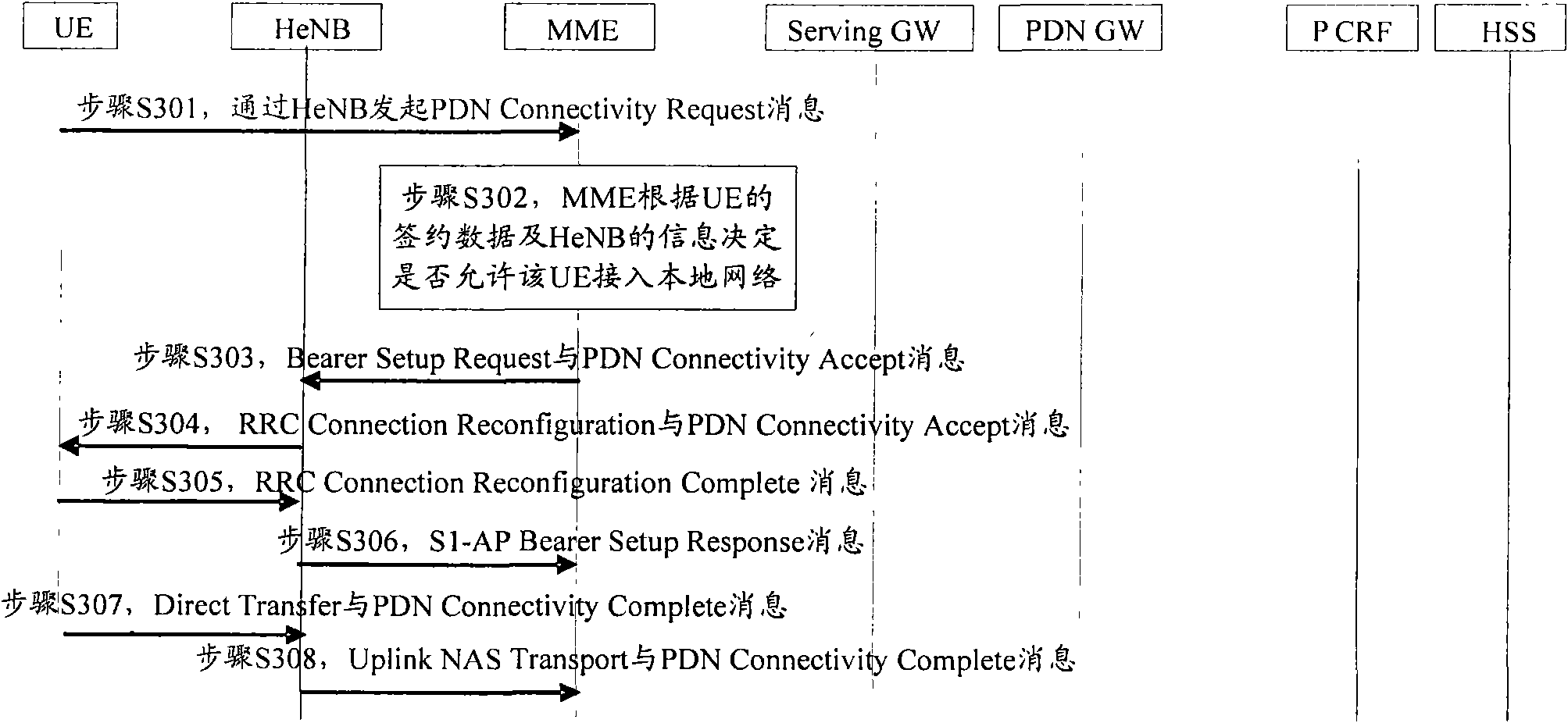

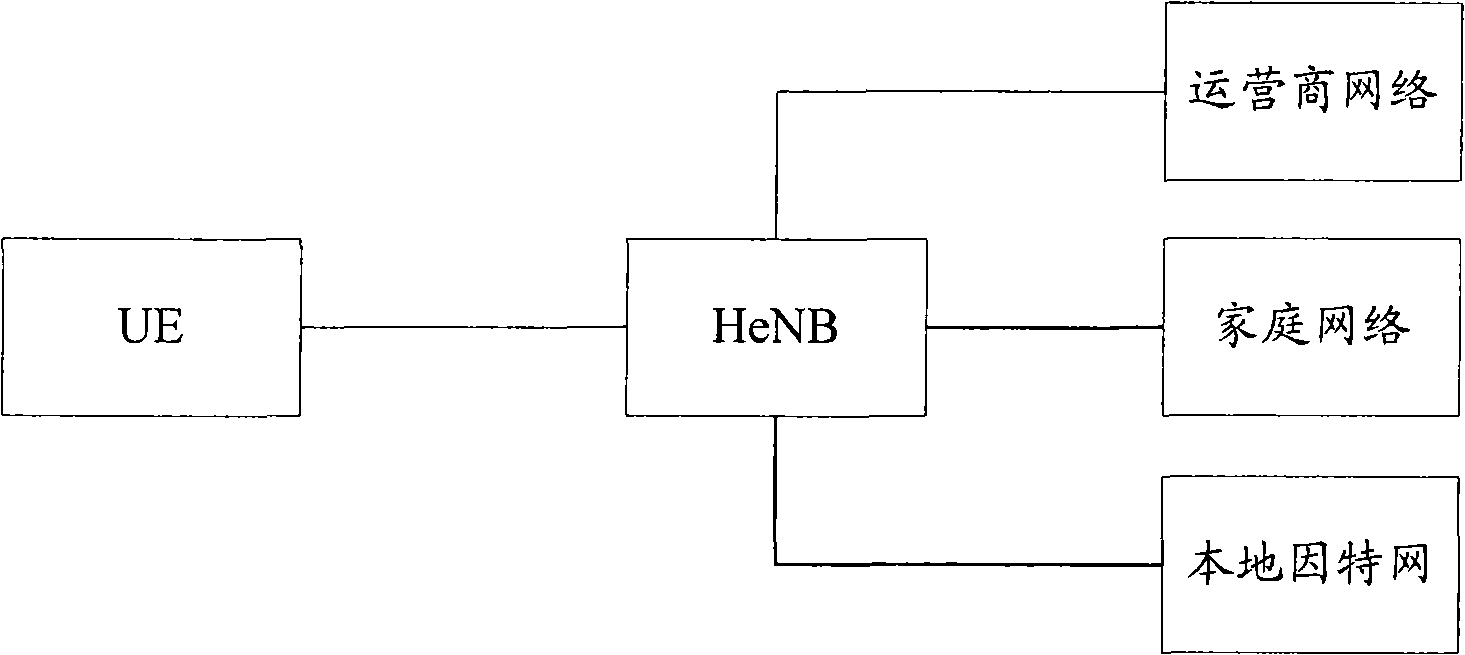

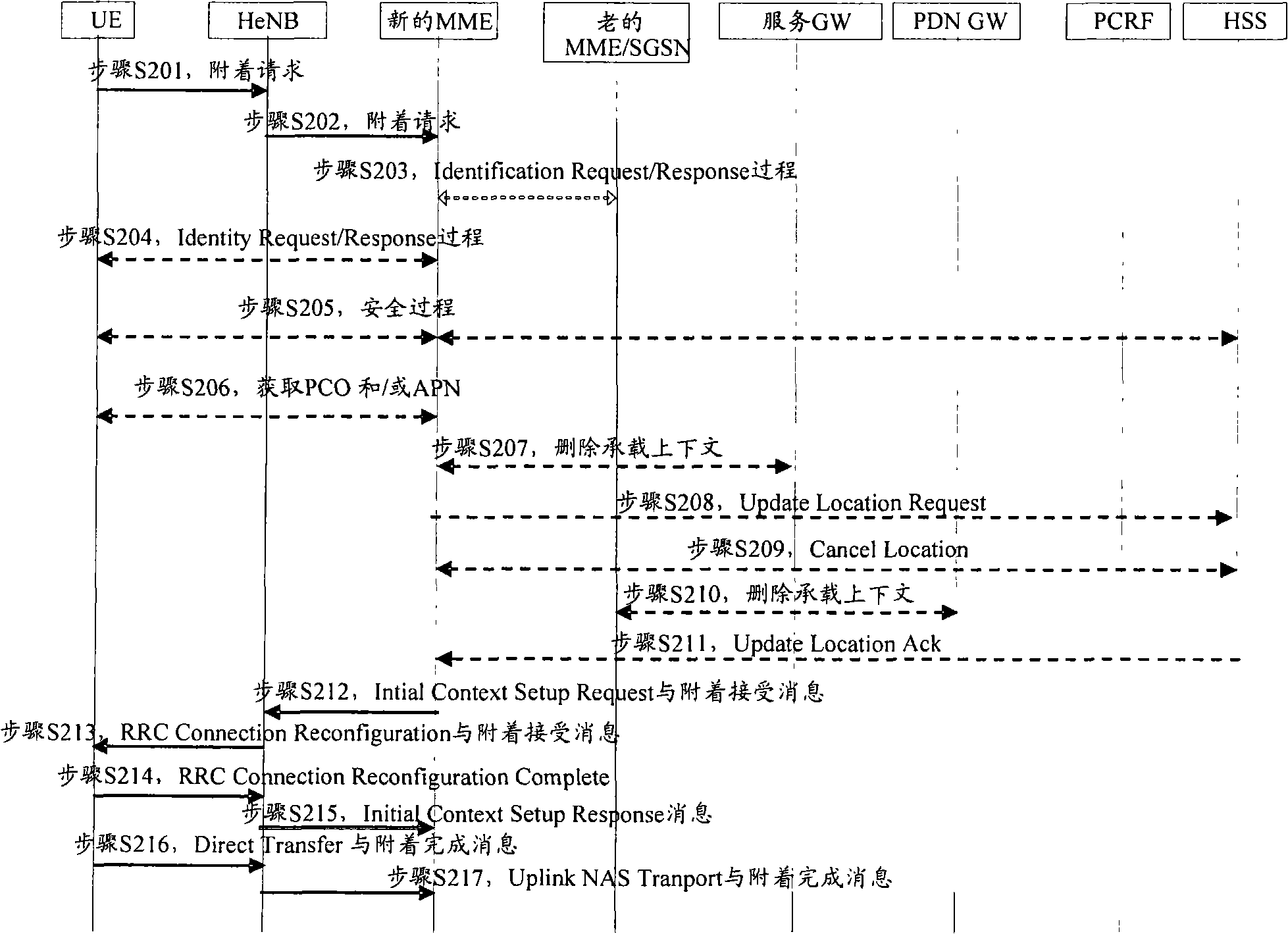

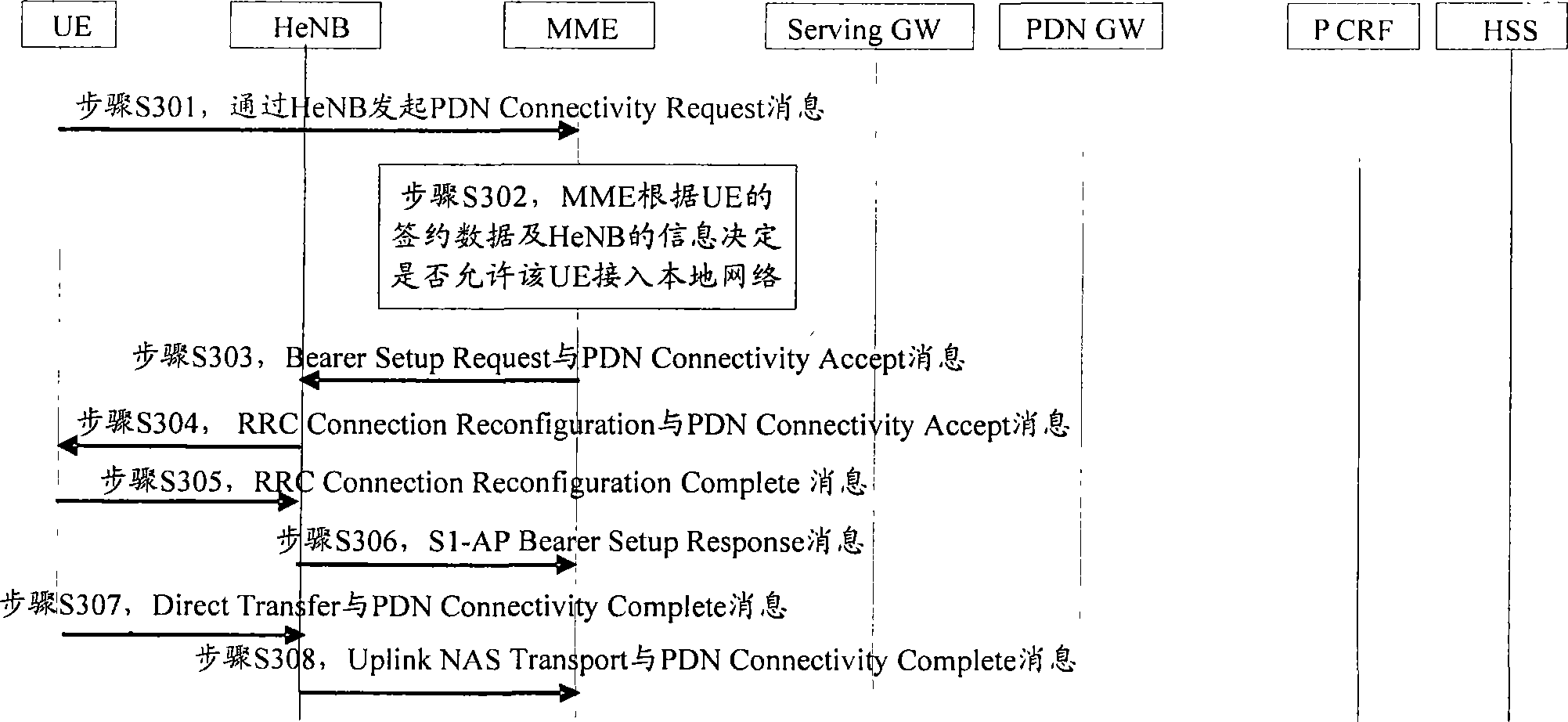

Bearer establishing method, system and device of local network

ActiveCN101860910ASolve the bearer problemEasy accessNetwork traffic/resource managementData transmissionMobility management

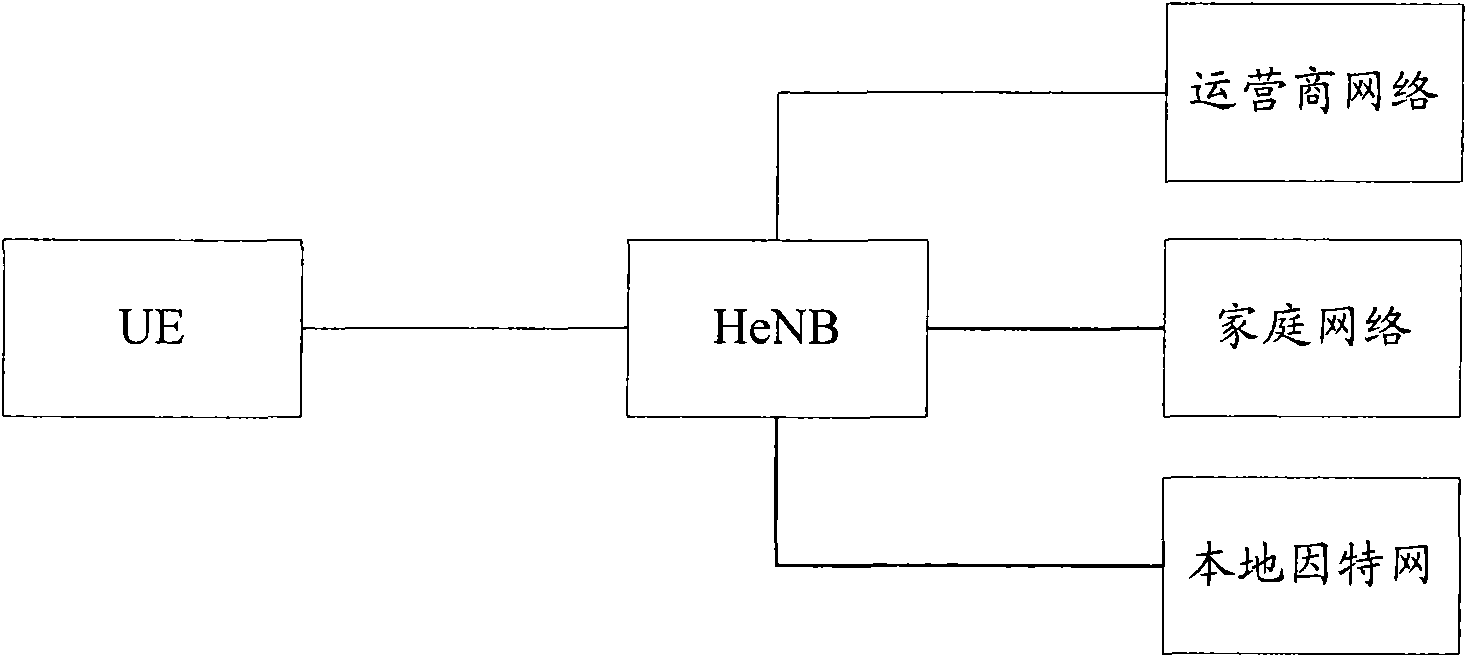

The invention provides a bearer establishing method of a local network. User equipment (UE) sends a packet data network (PDN) connection request through a home enhanced node B (HeNB) and indicates that PDN connection requested to be established by a mobility management entity (MME) is to connect the local network; the MME sends the bearer for establishing the local network to the UE according to the indication and inhibits information borne by the bearer for the local network to the HeNB; and the HeNB establishes the radio bearer of the local network for the UE according to the indication andthe data transmission between the UE and the local network according to the radio bearer. The invention solves the problem that the UE establishes the radio bearer of the local network through the HeNB, thereby enabling the UE to be smoothly accessed to the local network through the HeNB.

Owner:DATANG MOBILE COMM EQUIP CO LTD

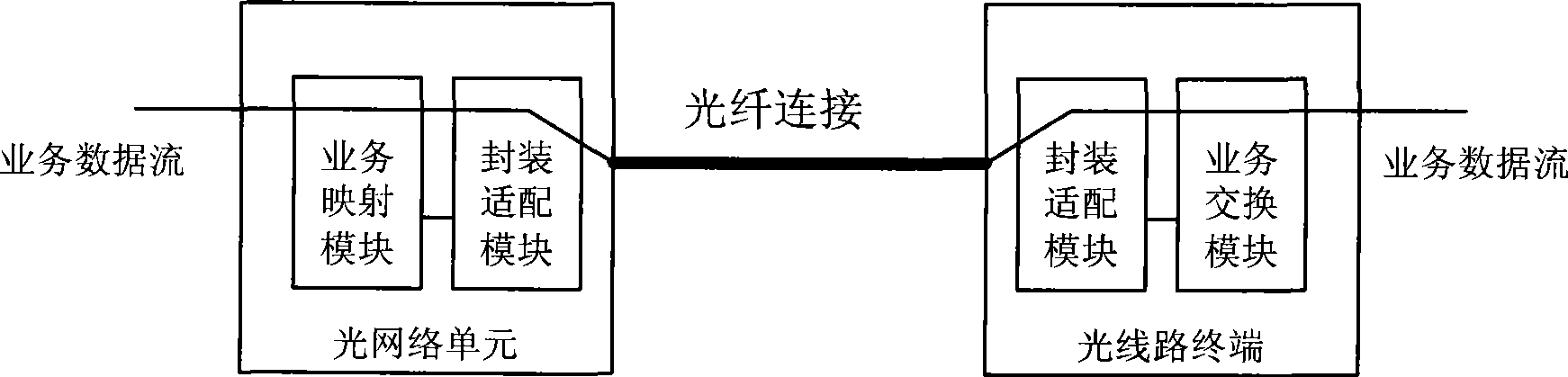

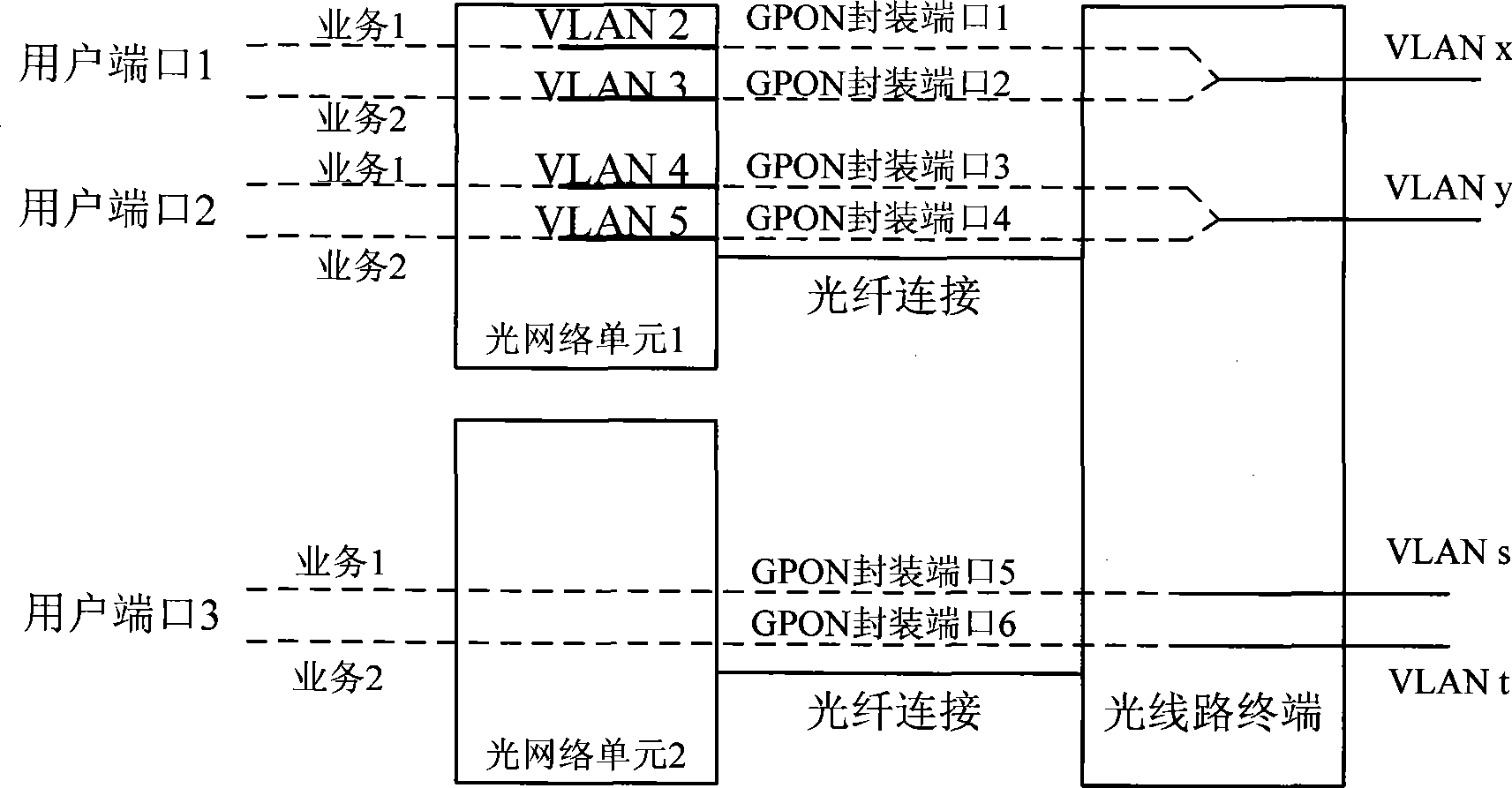

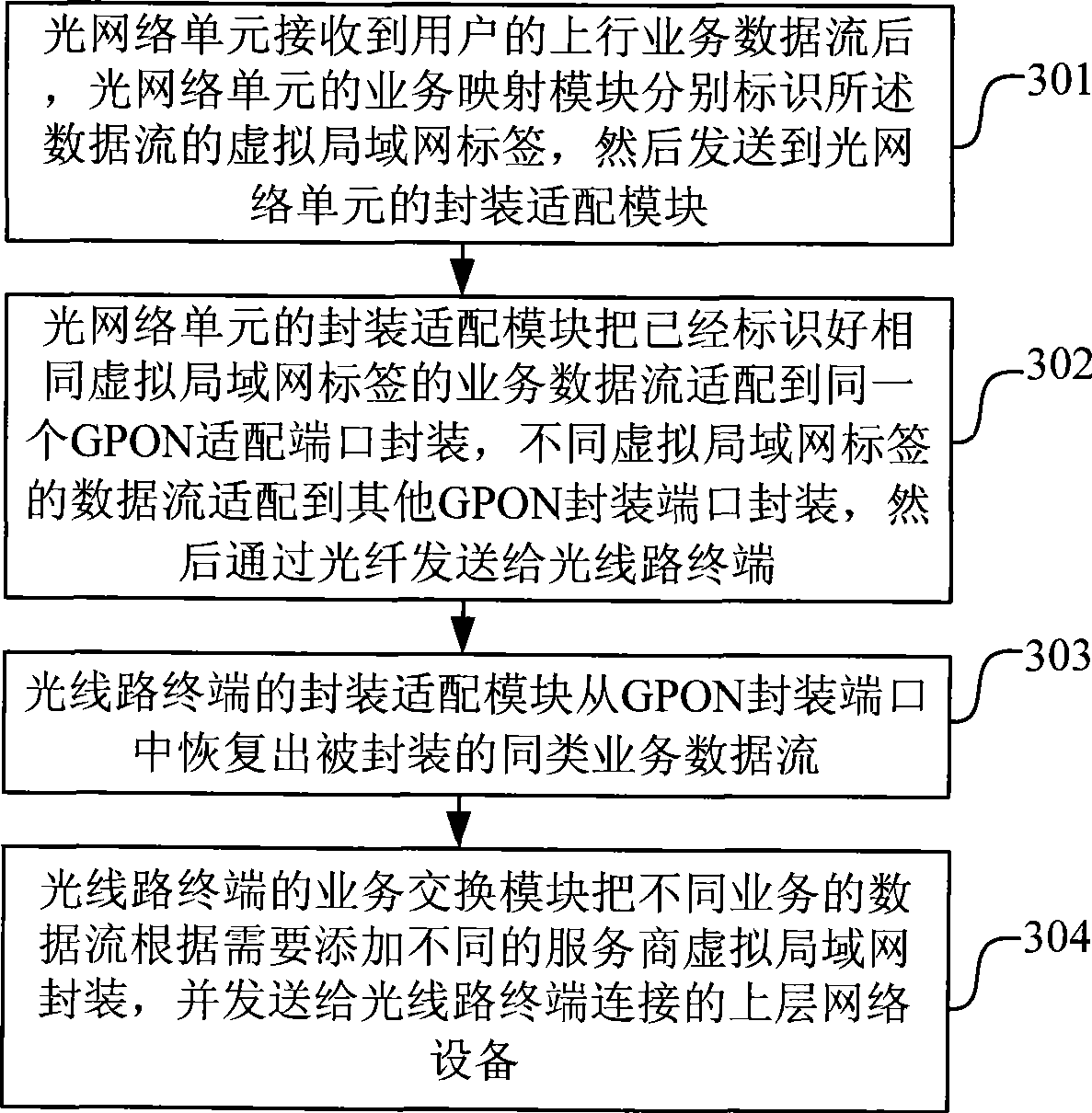

Method for service bearing in G bit passive optical network system

InactiveCN101425944ASolve the bearer problemMultiplex system selection arrangementsElectromagnetic transmissionVirtual LANData stream

The invention discloses a service bearing method for G bit passive optical network system comprising following steps: 1) when optical network unit receives uplink service data stream from user side, separately marking virtual LAN label of the data stream, adapting the service data stream of different virtual LAN label to adapting port of G bit passive optical network GPON, transmitting to optical line terminal; 2) the optical line terminal restores packaged data stream of different virtual LAN label from the GPON package port, mapping the data stream of different virtual LAN label to virtual LAN of different HSP for package to implements service bearing of G bit passive optical network system. The invention provides a method for solving service bearing in GPON access technology.

Owner:ZTE CORP

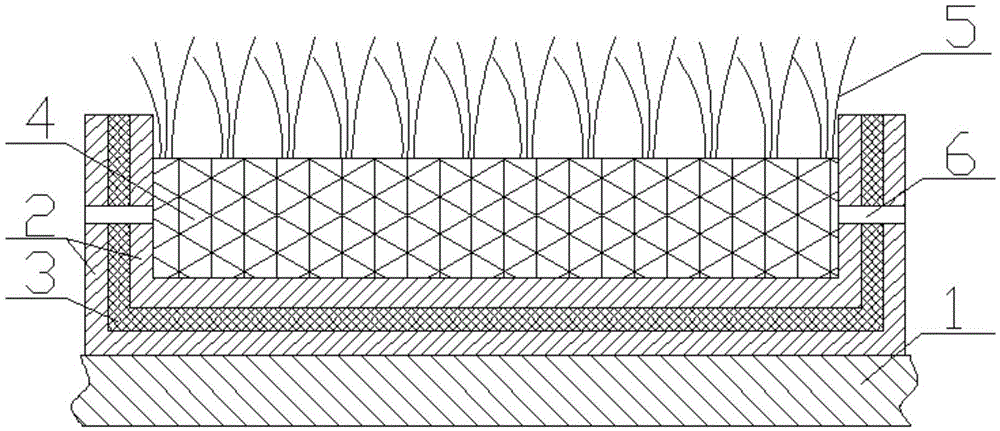

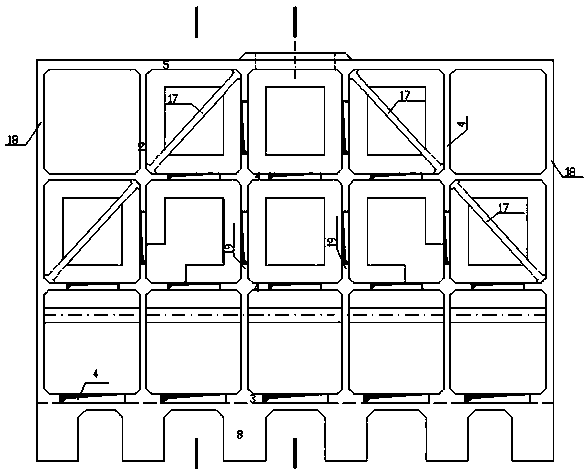

Light roof planting system

InactiveCN105557494AImprove water absorptionReduce weightGrowth substratesCulture mediaBlock layerBlocking layer

The invention relates to a light roof planting system and belongs to the technical field of roof greening. The planting system is fixedly arranged on an upper end surface of a roof and comprises a bearing body and a planting structure arranged in the bearing body, wherein the planting structure comprises a growth matrix layer and a plant layer growing above the growth matrix layer, the growth matrix layer is formed by basalt rock wool boards, the bearing body is felt with a root blocking layer, the root blocking layer is the middle layer, the inner side and the outer side of the root blocking layer are both covered with felt layers, a group of horizontally through overflow holes are uniformly formed in the outer side surface of the bearing body and are on the same horizontal plane, the overflow holes are used for allowing water to overflow, and the bearing body is higher than the growth matrix layer and used for shielding irradiation of sunlight on roots. The weight of the light roof planting system in a unit area is remarkably reduced, the system can be used for a roof of a common house structure, greening operation can be performed on roofs of a city on a large scale, and the basalt rock wool boards can prevent secondary diseases and insect pests, can be recycled and can perform thermal-insulation and consumption-reduction functions.

Owner:盛和深

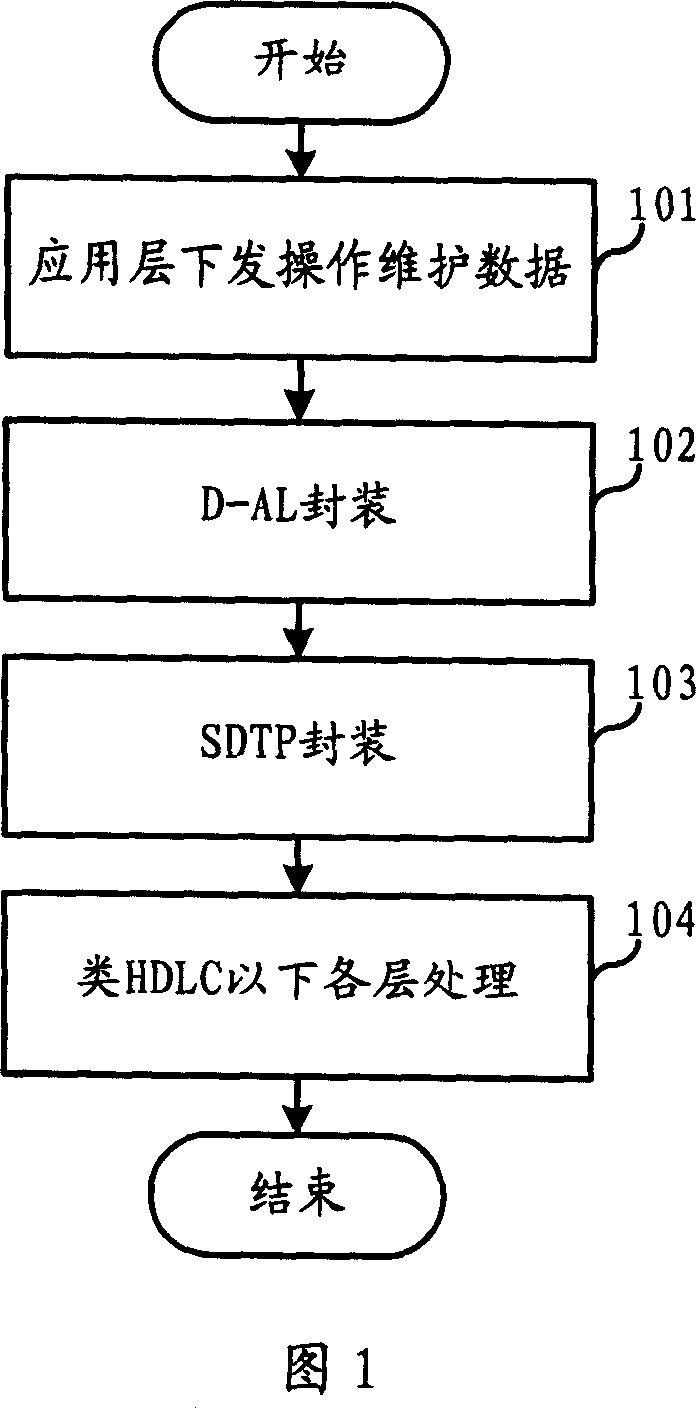

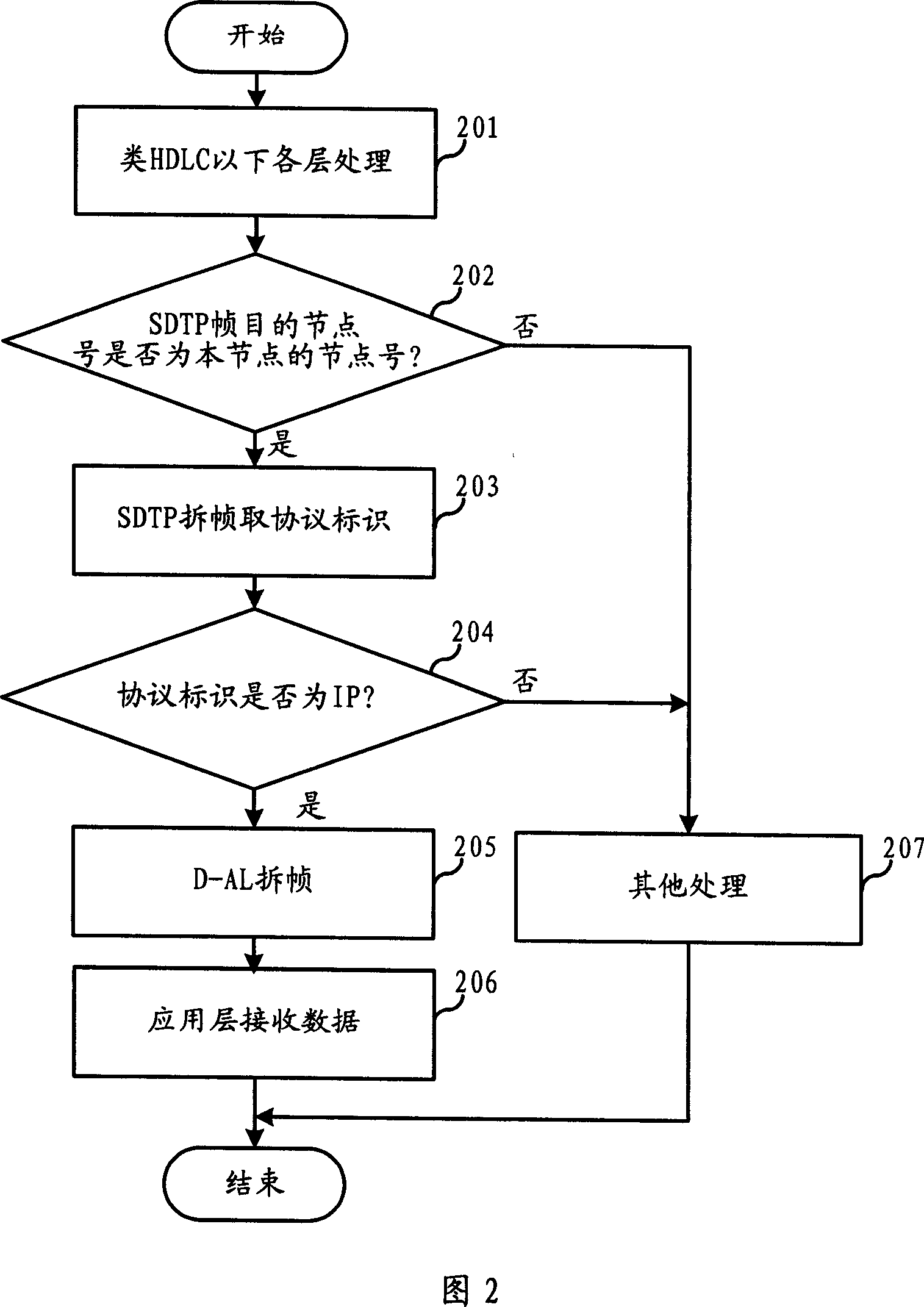

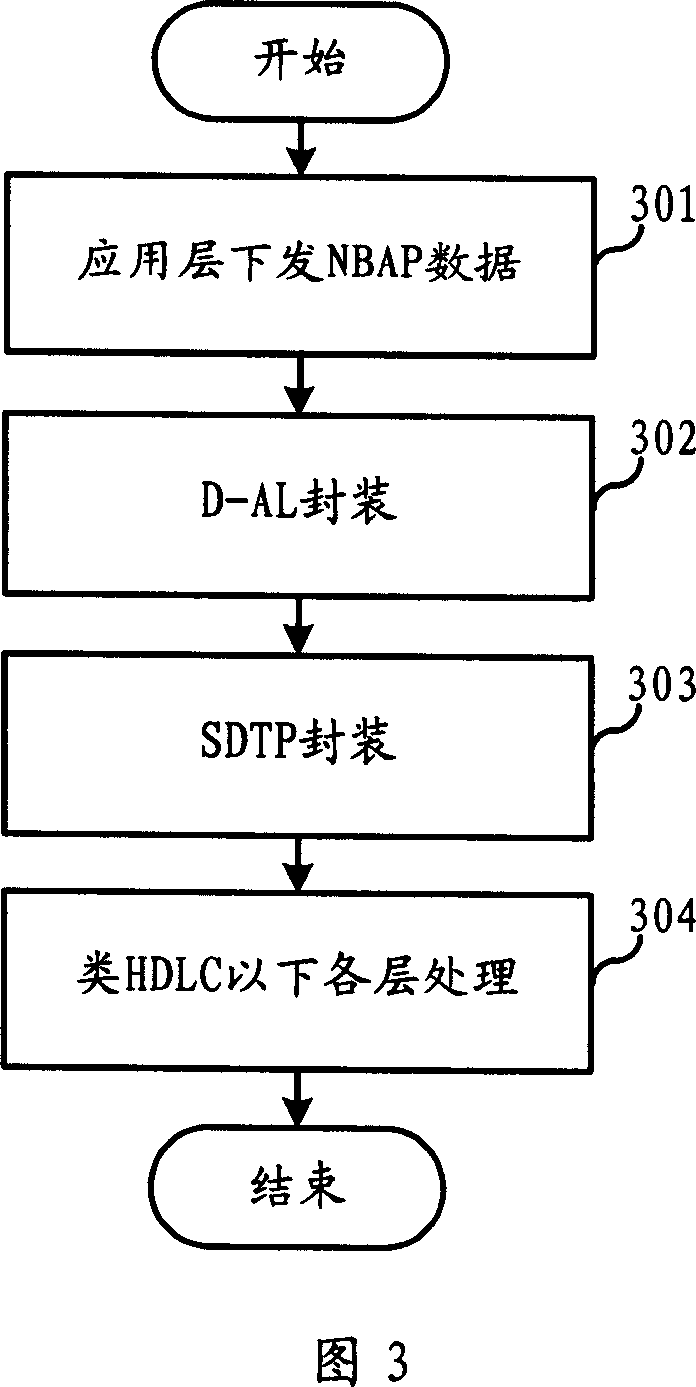

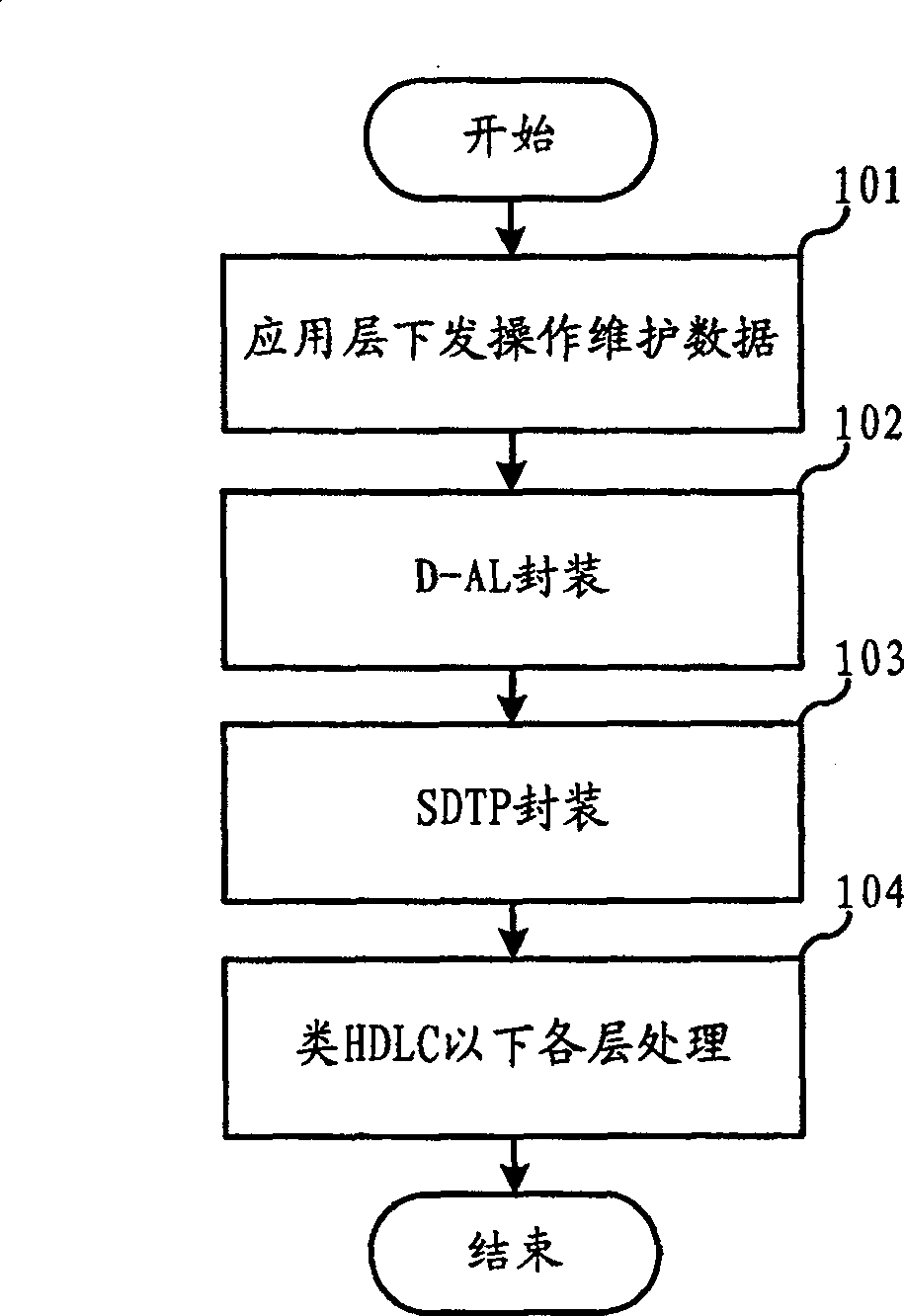

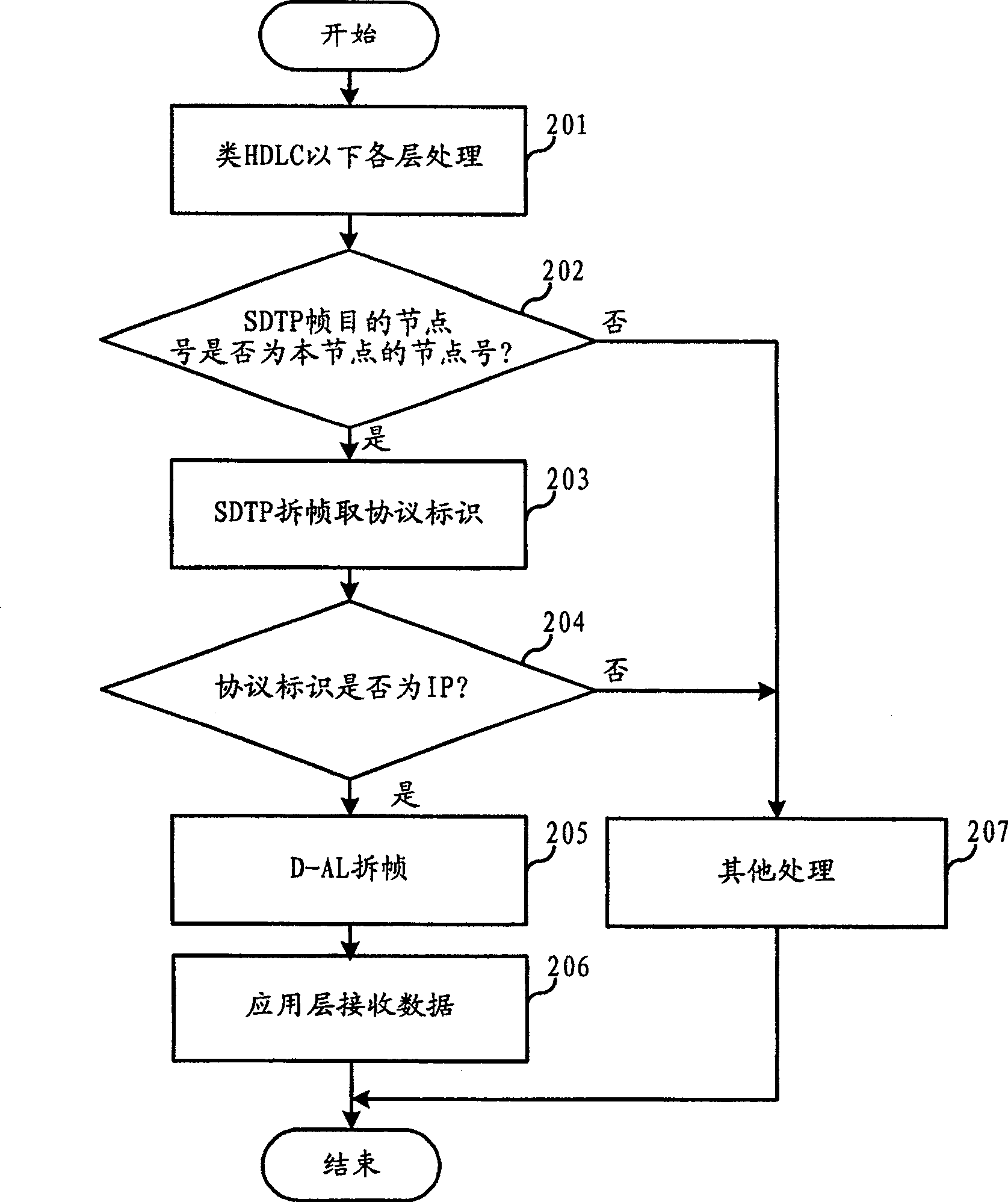

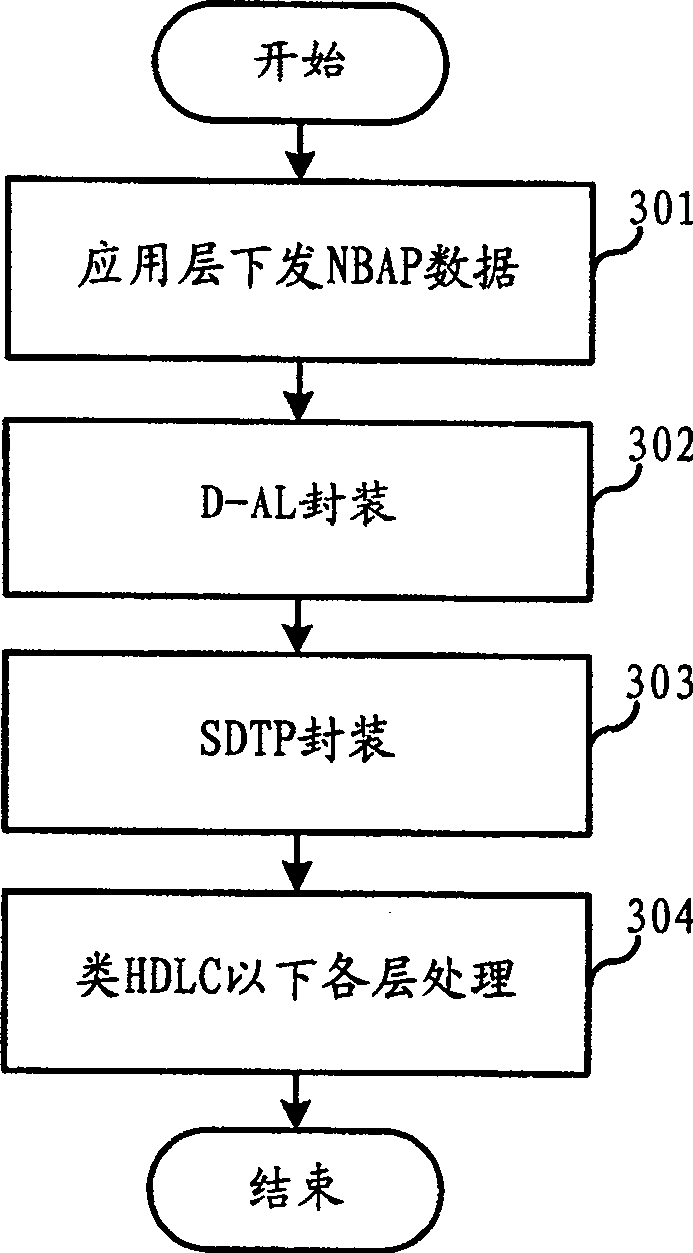

Iub interface data transmission method and system in mobile communication network

ActiveCN1960340ASolve the bearer problemImprove transmission efficiencyData representation error detection/correctionPulse modulation television signal transmissionIp addressData transmission

The invention is used for improving the transmission efficiency of Iub interface and uses SDTP protocol to make data transmission of Iub interface. For each FP layer connection, the bottom layer needs to provide two links; when the length of FP frame is less than M bytes, one of said links maps the IP address and UDP port number to the SDTP node number and MUX-AL port number; when the length of FP frame is more than M bytes, another link directly uses IP address and UDP to package and adopt D-AL to bear.

Owner:XFUSION DIGITAL TECH CO LTD

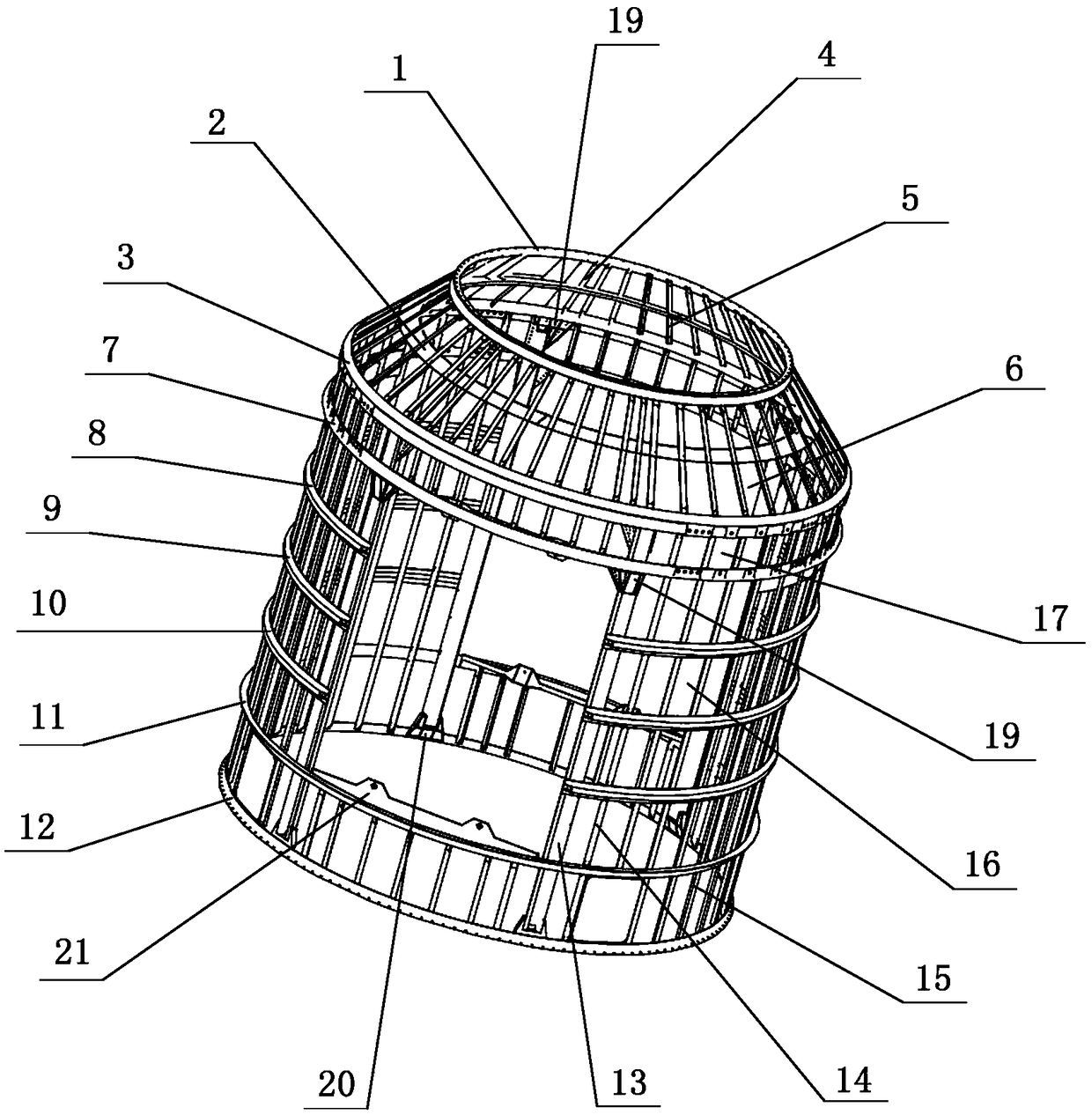

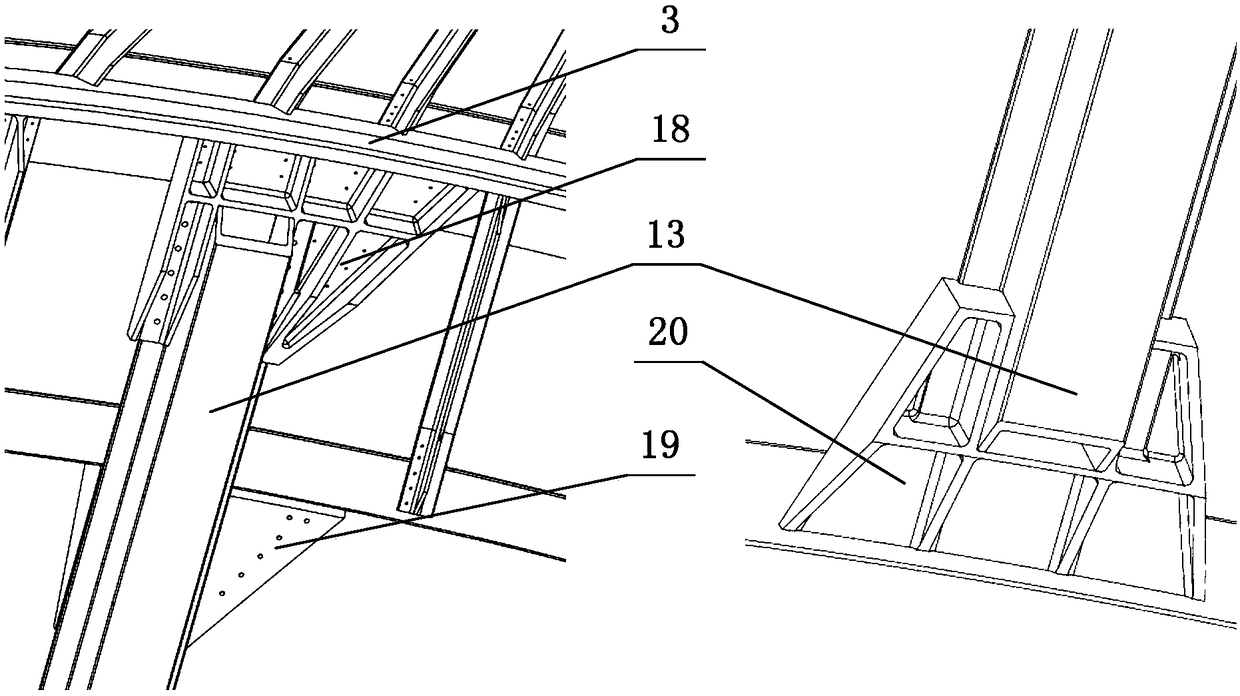

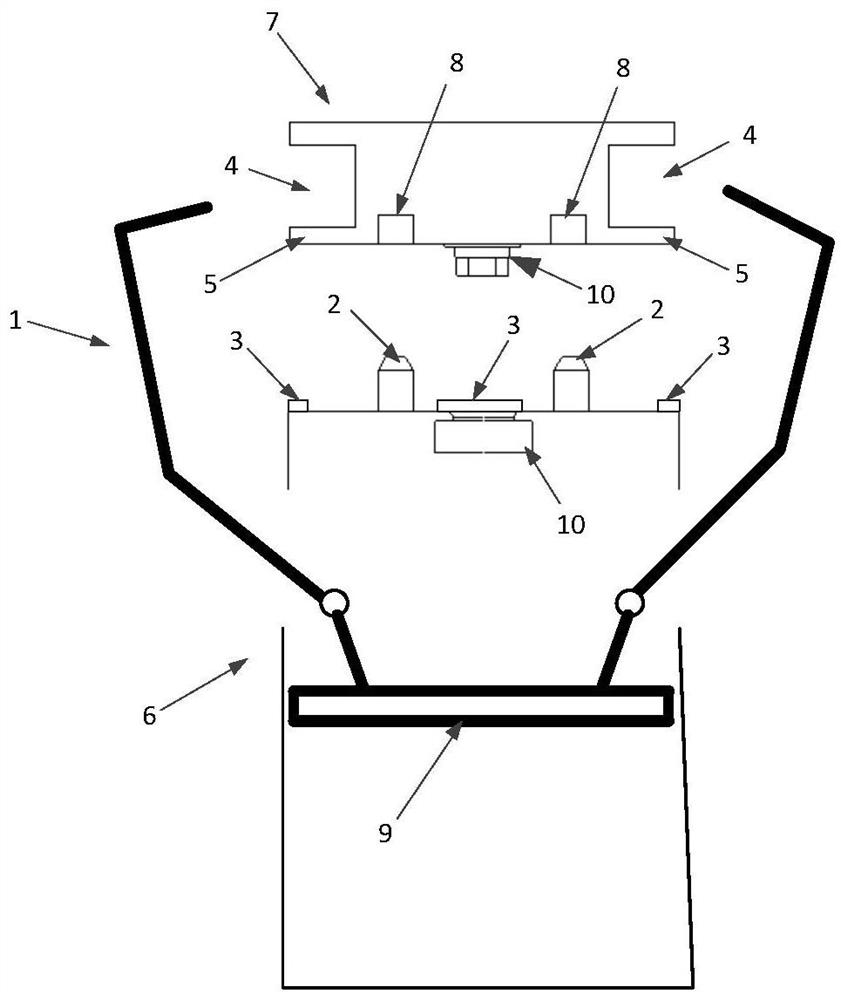

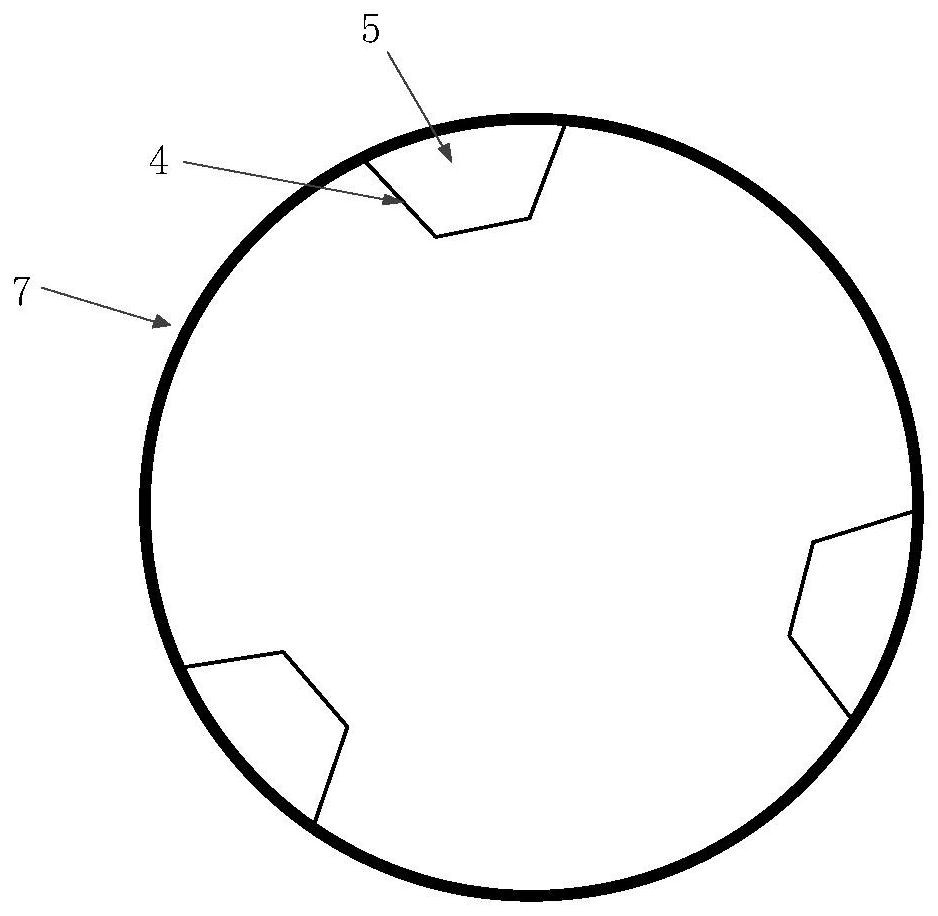

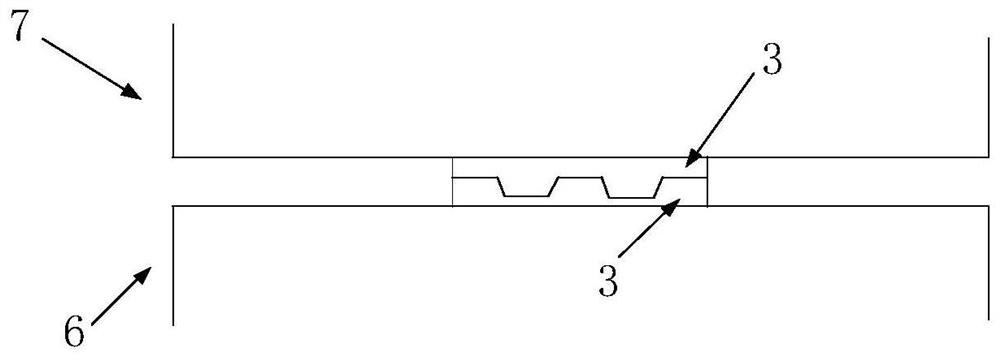

An aircraft cabin structure with large openings

The invention discloses an aircraft cabin structure with a large opening, which is a conical-cylindrical riveted structure, the upper part is a conical section, the lower part is a cylindrical section, and the opening is located in the cylindrical section; The structure comprises a skin, a plurality of frame rings arranged horizontally and a plurality of stringers arranged vertically, the plurality of frame rings sequentially comprise a conical segment front end frame from the top to the bottom, The middle frame of the cone section, the connecting frame of the cylinder cone, several middle frames of the cylinder section, and the rear end frame of the cylinder section are respectively provided with a cone section reinforcing stringer, a front joint, a beam of the cylinder section, and a rear joint on each side of the left and right sides of the opening from the top to the bottom. The middle frames of the cylinder section on the upper and lower sides of the opening are respectively arranged as the middle frame I of the cylinder section and the middle frame V of the cylinder section. Various reinforcing structures are arranged around the large-scale opening of the cabin body to realize the transmission and diffusion of concentrated forces on both sides of the opening.

Owner:SHANGHAI AEROSPACE SYST ENG INST

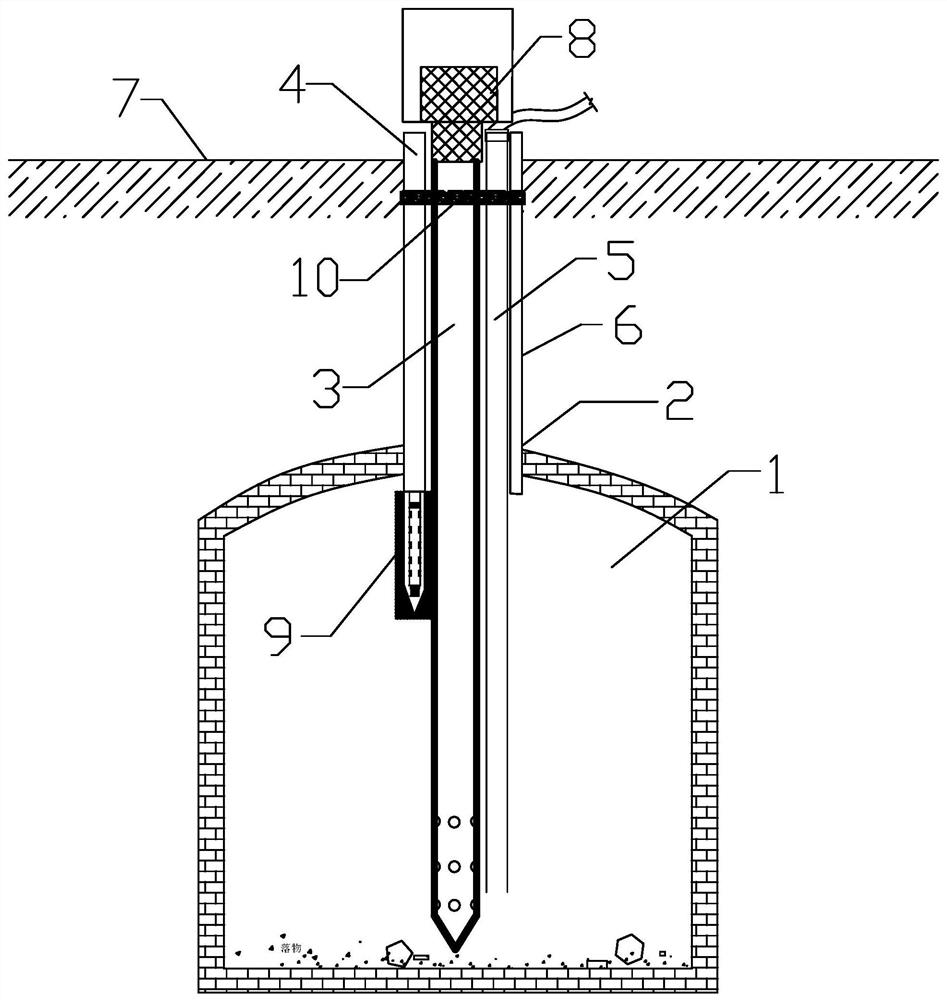

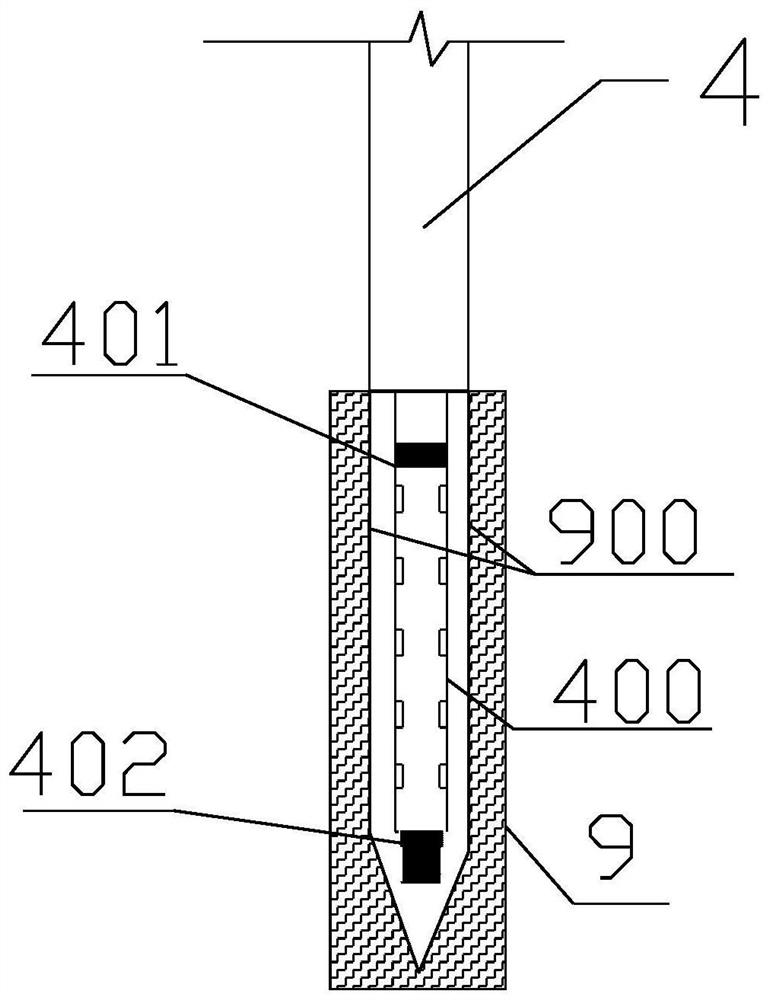

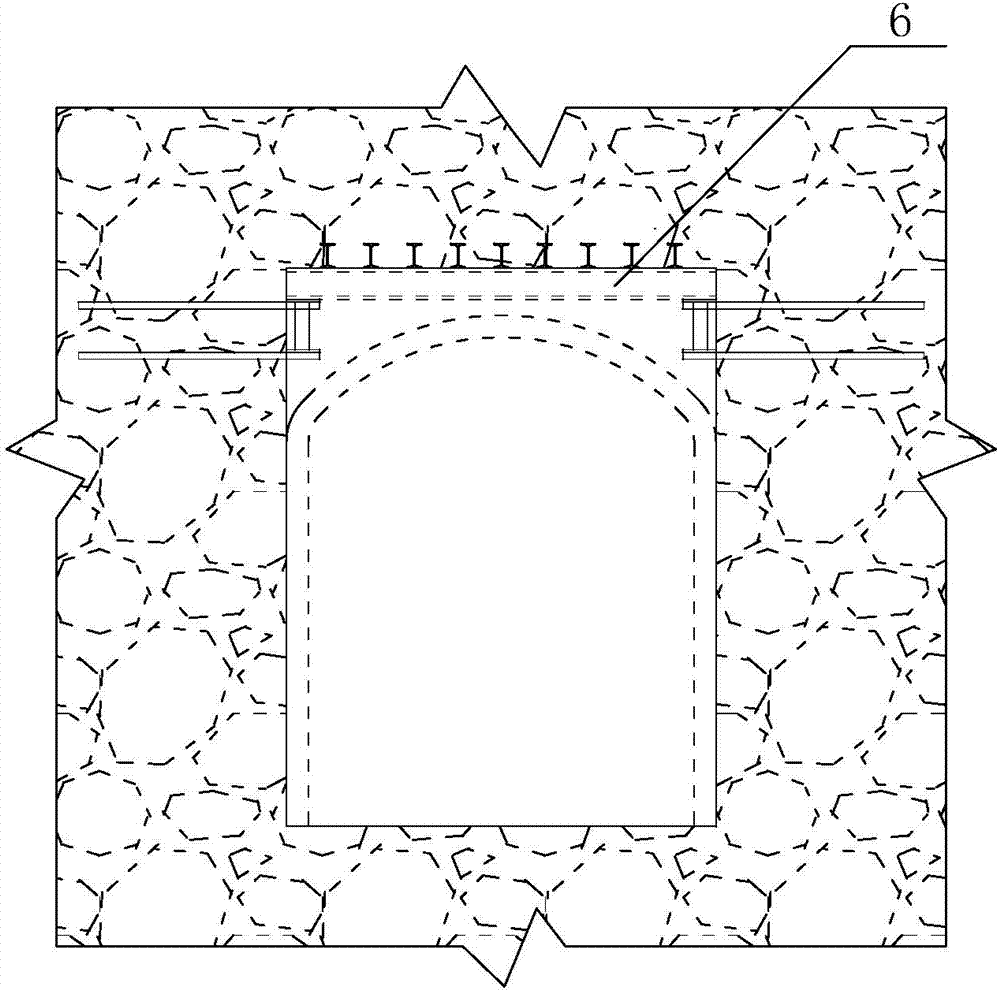

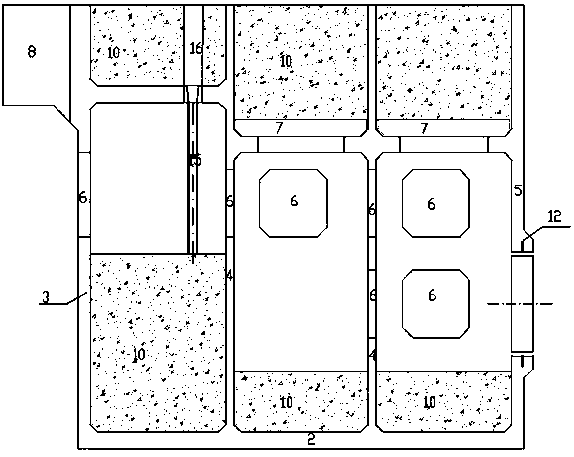

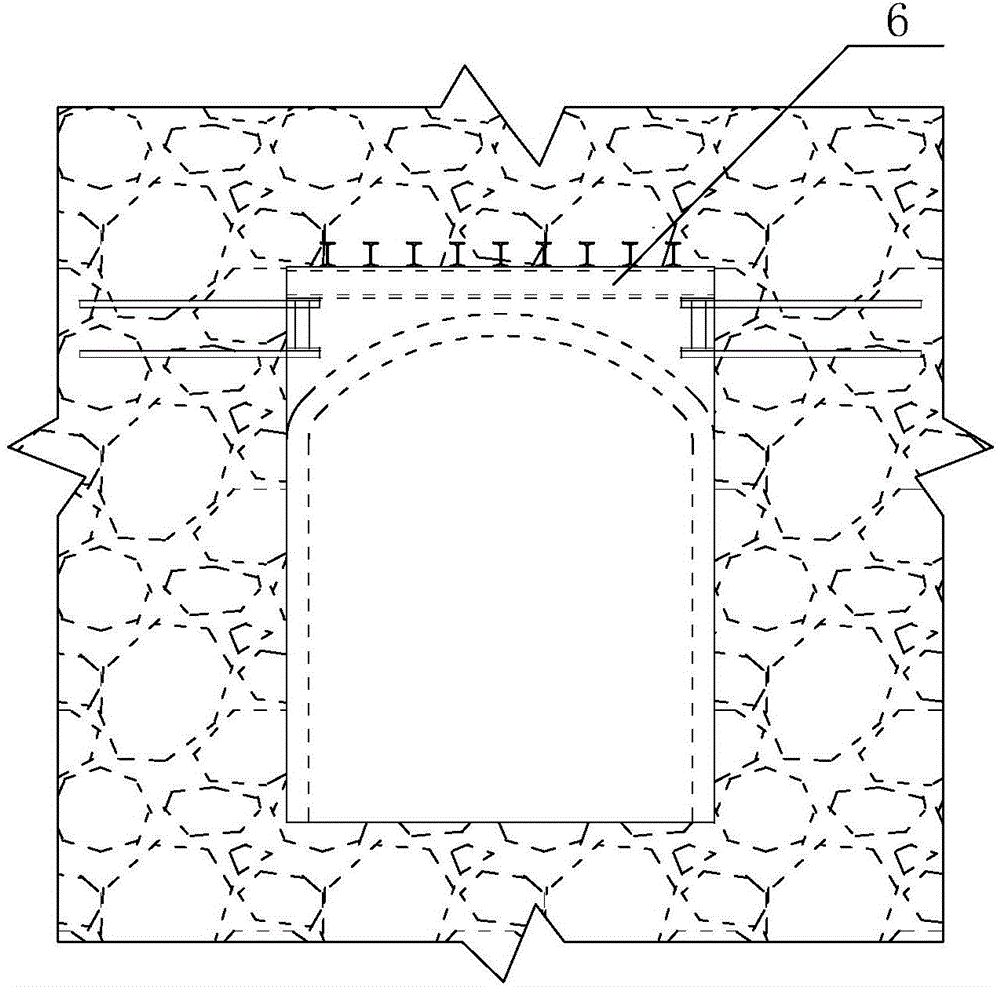

Filling device and method for waste air-raid shelter of pile foundation construction site

ActiveCN112323823ASmooth Construction MeasuresGuaranteed cycleEmbankmentsFoam concreteArchitectural engineering

The invention provides a filling device and method for a waste air-raid shelter of a pile foundation construction site. The filling method comprises the steps that a grouting drill hole is drilled above a waste air-raid shelter to be filled, a primary grouting pipe, a secondary grouting pipe, an air supply pipe and an air exhaust pipe are installed in the drill hole, the primary grouting pipe andthe air supply pipe vertically extend into the bottom of the air-raid shelter, the secondary grouting pipe and the air exhaust pipe vertically extend to the top of the air-raid shelter, firstly, the primary grouting pipe is connected with a grouting pump, the air supply pipe is connected with an air compressor, foam concrete grouting slurry is injected in a layered mode, the primary grouting pipeand the air supply pipe are pulled up all the way to the top of the air-raid shelter after grouting of each layer is completed, then the secondary grouting pipe is connected to inject the foam concrete grouting slurry for the second time, and air is not supplied during secondary grouting. The filling problem of the deep-buried air-raid shelter can be solved under the condition that excavation is not conducted, normal construction of a cast-in-situ bored pile can be guaranteed on a filled construction site, and the problems that when a rotary drilling rig constructs a cast-in-situ pile foundation, normal construction cannot be conducted on the deep-buried air-raid shelter, the site collapses and the like are solved.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

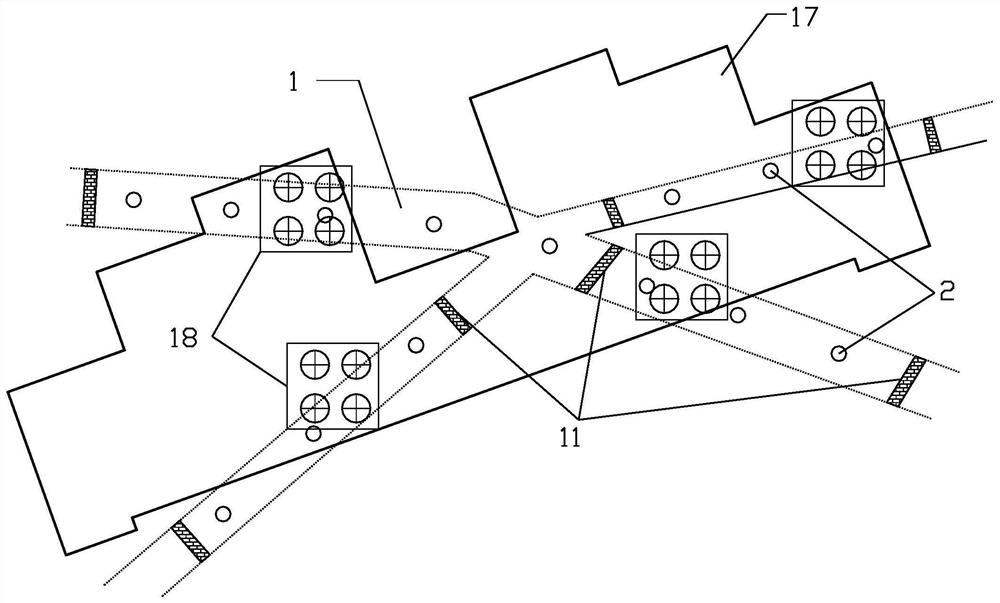

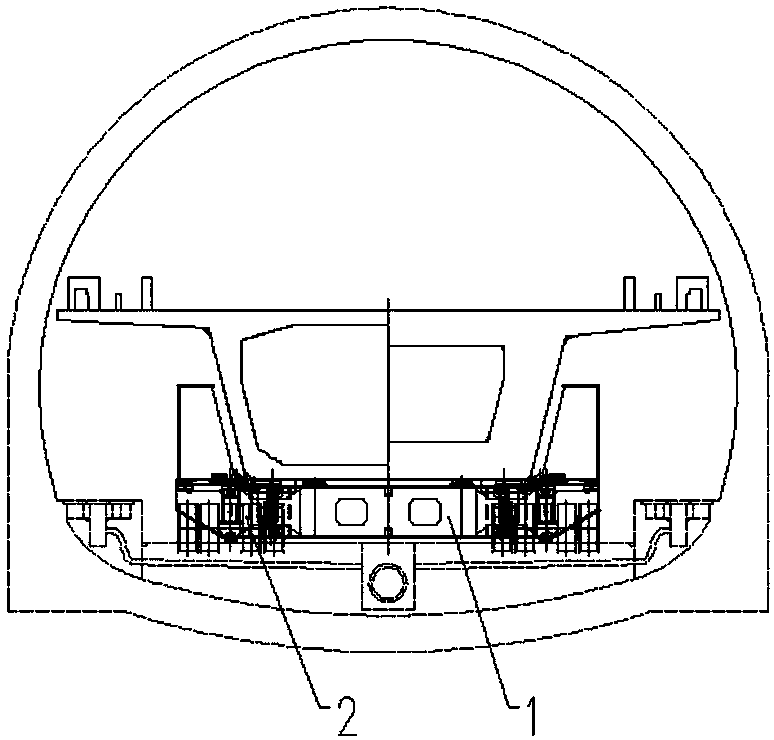

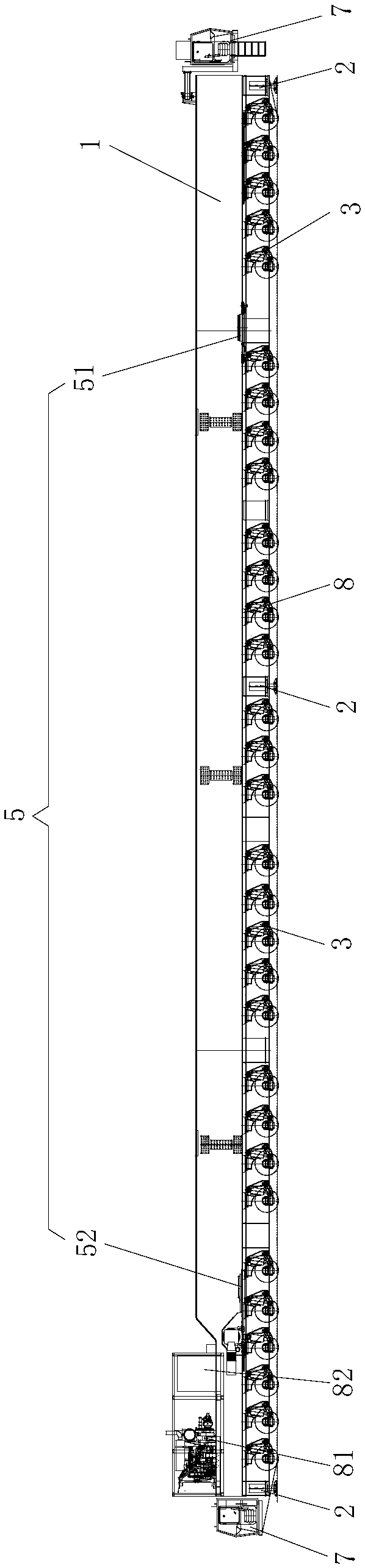

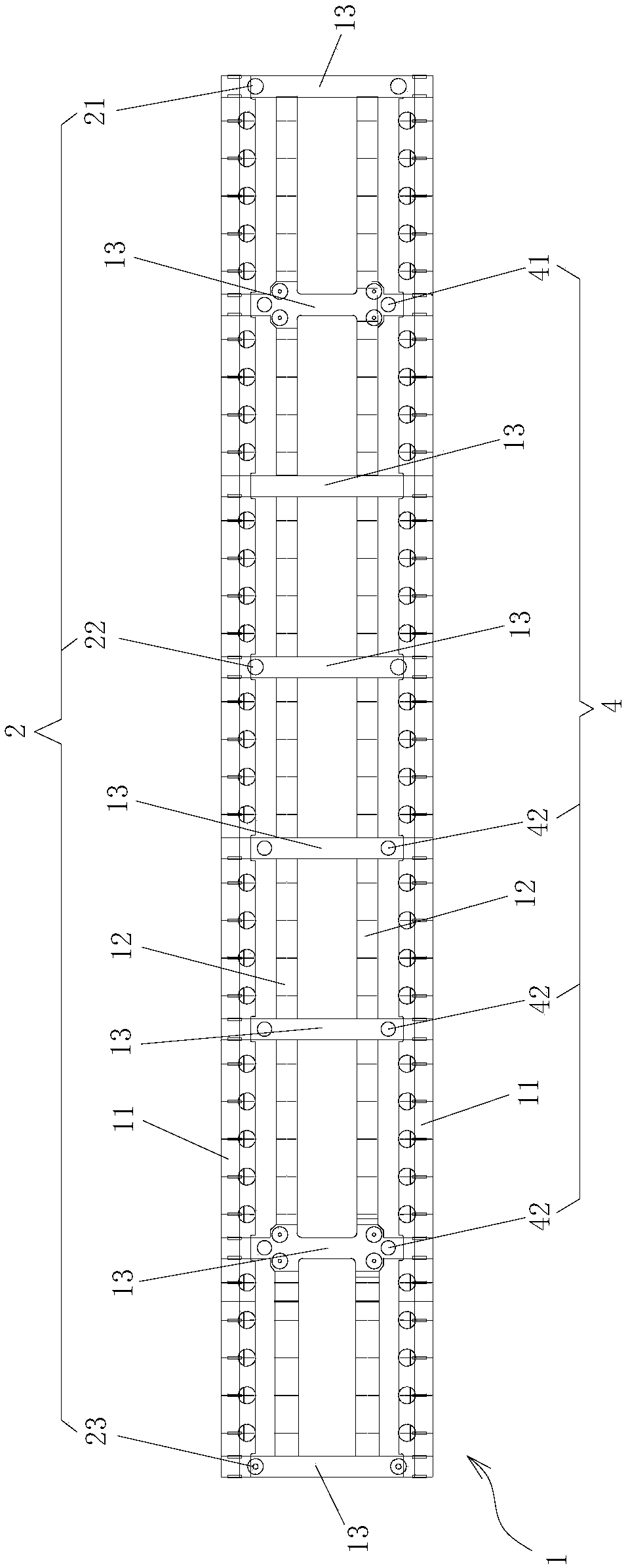

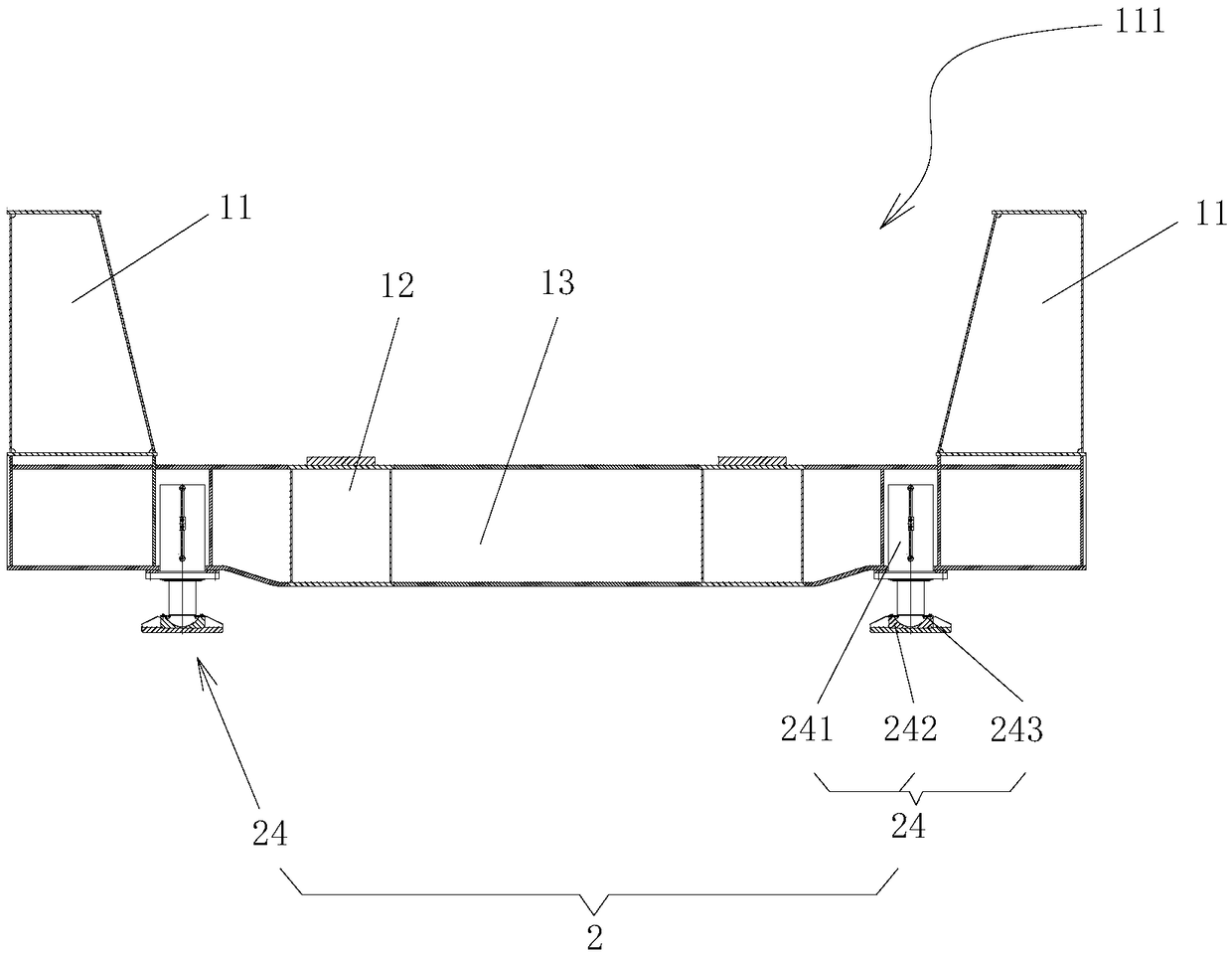

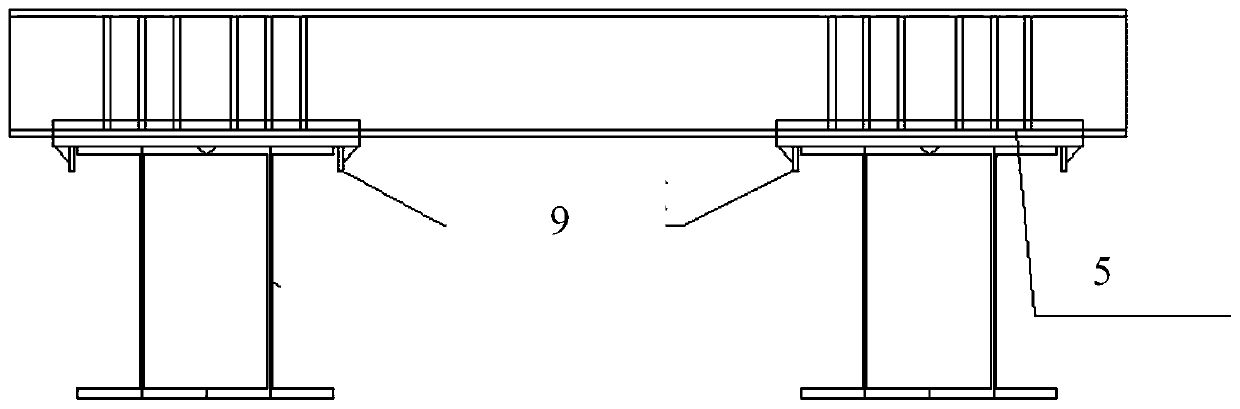

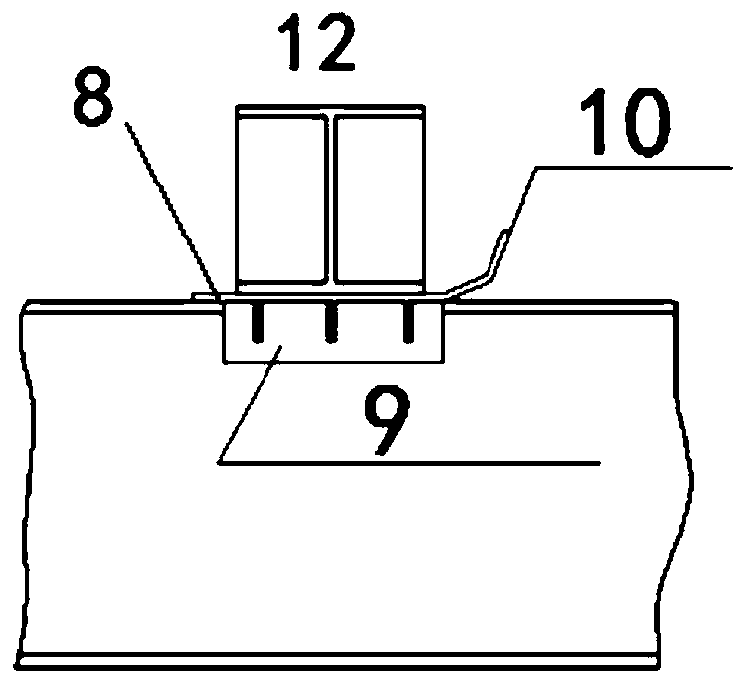

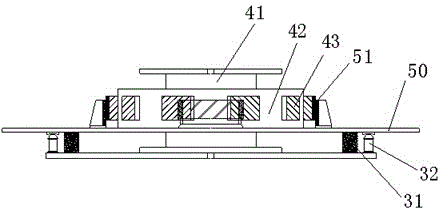

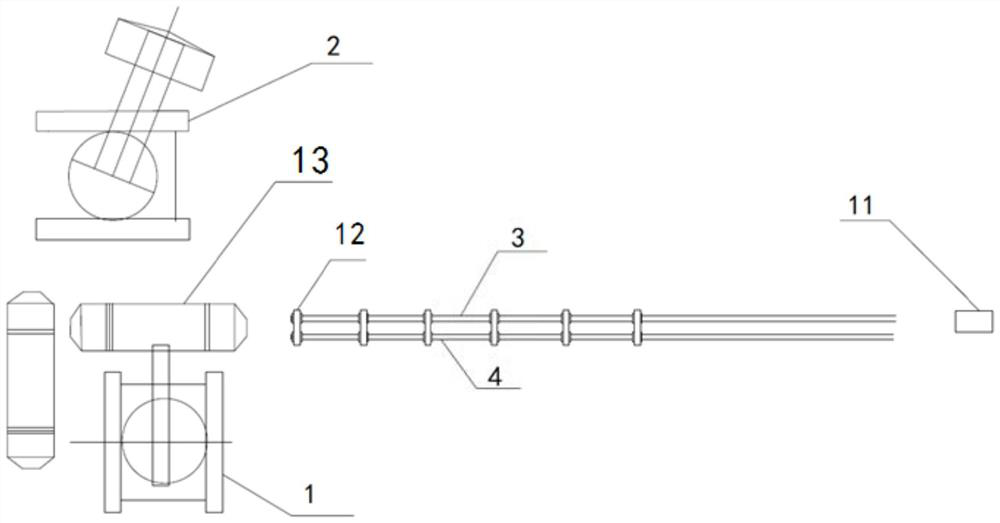

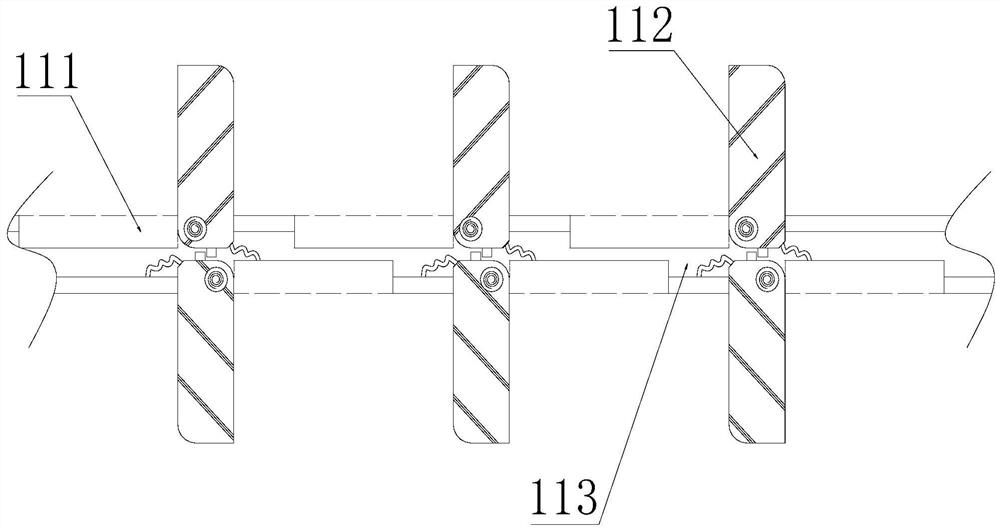

U-shaped tunnel-crossing beam transporting vehicle with adjustable wheel track and beam-feeding method of U-shaped tunnel-crossing beam transporting vehicle

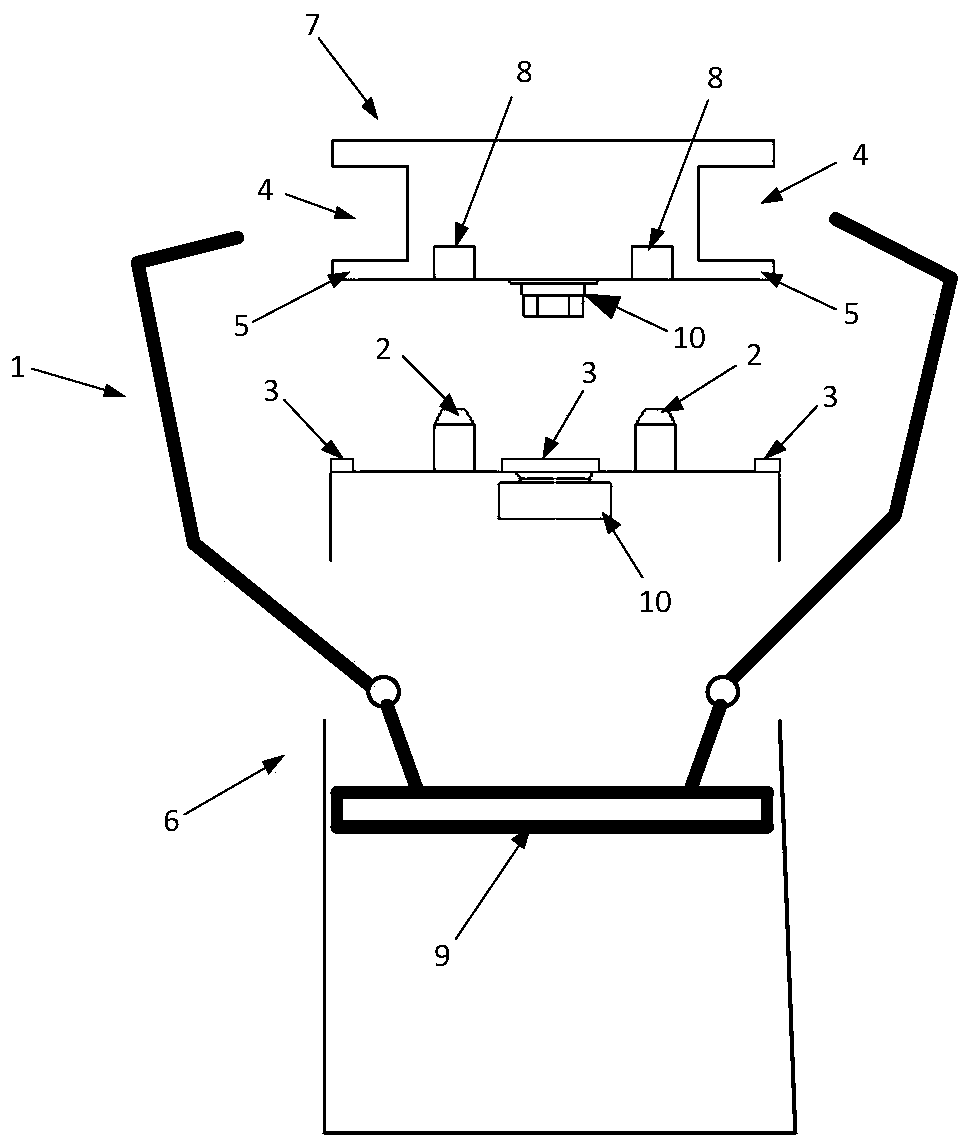

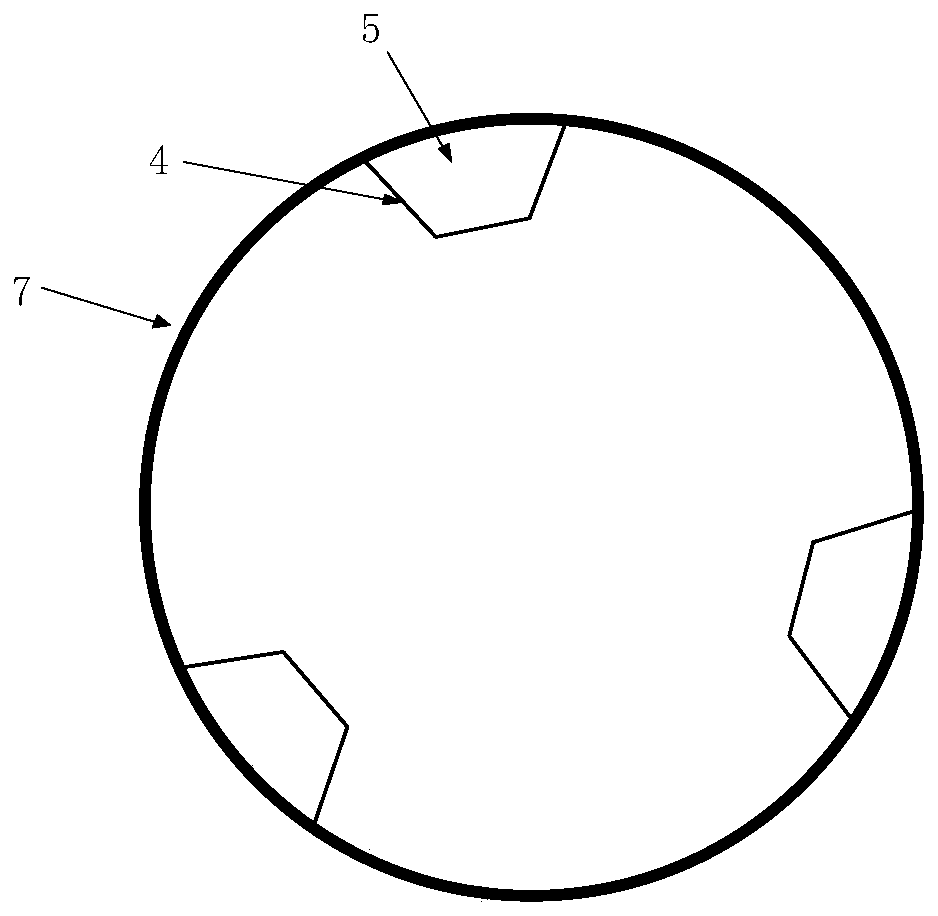

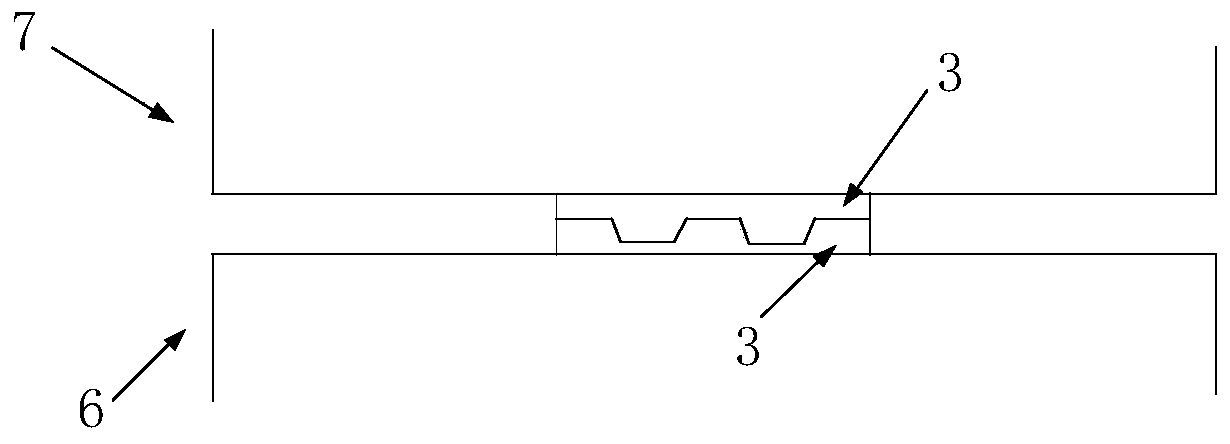

The invention provides a U-shaped tunnel-crossing beam transporting vehicle with an adjustable wheel track and a beam-feeding method of the U-shaped tunnel-crossing beam transporting vehicle. The beamtransporting vehicle at least comprises a vehicle body, traveling wheel sets and a beam carrying trolley; the vehicle body comprises a middle beam located in the middle and two side beams located onthe two sides; a plurality of cross beams are arranged in the longitudinal direction of the middle beam in a penetrating mode at intervals; the two ends of the outer sides of the multiple cross beamsare connected to the lower ends of the side beams correspondingly, so that the U-shaped structure of the vehicle body is formed; the traveling wheel sets are located at the lower ends of the side beams of the vehicle body and detachably connected with the side beams of the vehicle body, and the lower ends of the side beams are provided with two supporting positions of the traveling wheel sets; andthe beam carrying trolley comprises a front beam carrying trolley body and a rear beam carrying trolley body which are detachably connected. Therefore, according to the U-shaped tunnel-crossing beamtransporting vehicle with the adjustable wheel track and the beam-feeding method of the U-shaped tunnel-crossing beam transporting vehicle, the space below the flanges of box girders is utilized to the greatest extent, the transporting height is decreased, the transporting requirement of the large-span large-tonnage box girders can be met, especially the requirements for tunnel-crossing transporting of the box girders can be achieved, the forward travelling range of the front trolley body is further expanded, and longitudinal stability when a front cart of a bridge erecting machine takes the girders is improved.

Owner:CHINA RAILWAY ENG MASCH RES & DESIGN INST CO LTD

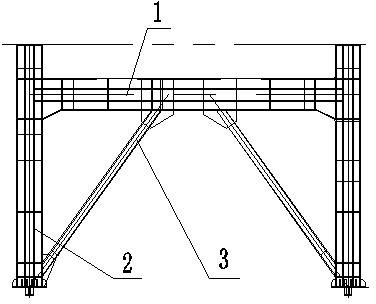

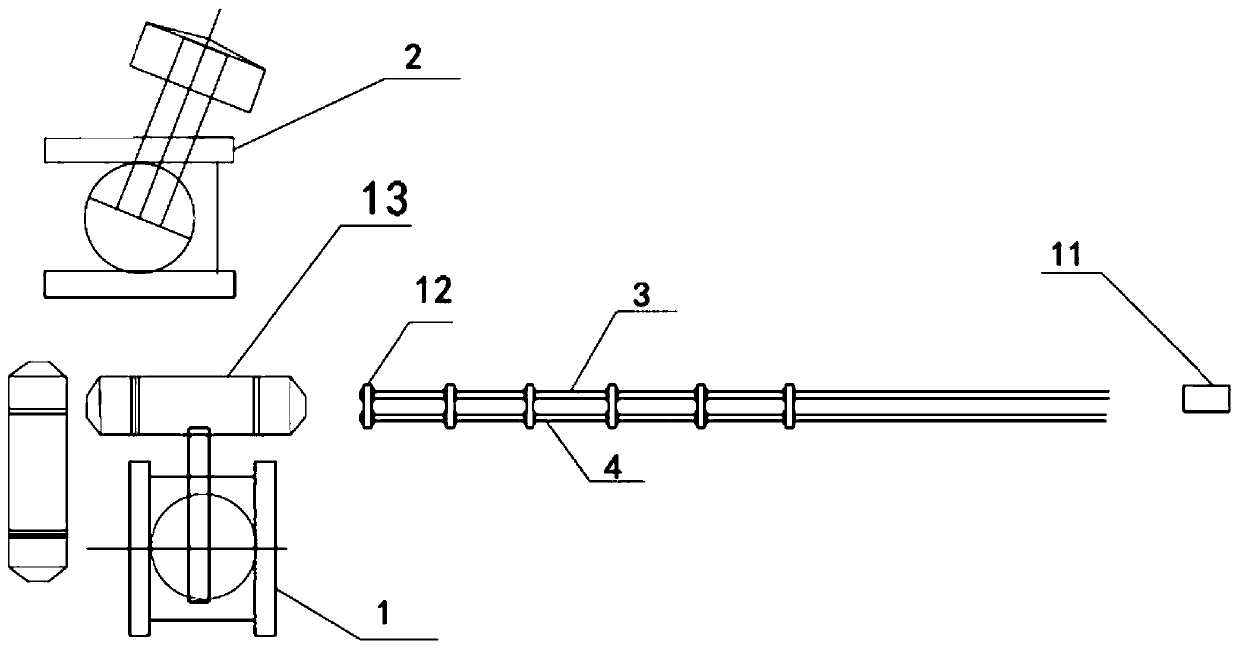

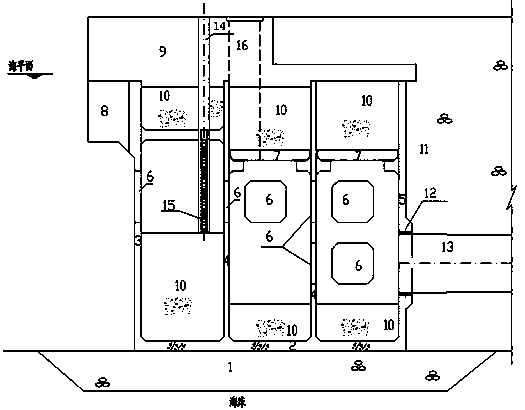

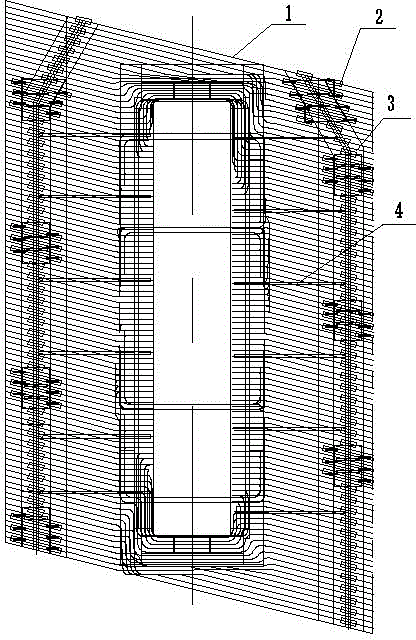

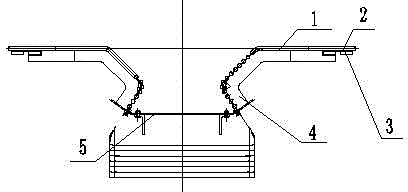

Main steel frame node device of tower type supercritical boiler and connecting method

ActiveCN102162637AImprove stabilitySection form economyFluid heatersBoiler supporting/setting arrangementsSupercritical steam generatorSteel frame

The invention relates to a main steel frame node device of a tower type supercritical boiler and a connecting method. The stress of a traditional column is lower than 4000 tons; and as the stress of a tower type boiler is characterized in that the stress of a single rod is great, the length is great. The product comprises a beam (1), wherein assembly columns (2) are connected at two ends of the beam respectively, the lower end of the beam is connected with the lower parts of the assembly columns through a vertical support (3), each assembly column comprises a lower-section column, each lower-section column is connected with an end plate of the lower-section column, each end plate of the lower-section column is connected with an end plate of an upper-section column through a bolt, each end plate of the upper-section column is connected with the upper-section column, the lower-section columns and the upper-section columns are connected with annular stiffening ribs, the lower-section columns and the upper-section columns are connected with the end plates, the end plates are connected with box-shaped transition pieces through bolts, the box-shaped transition pieces are connected with a connecting plate, and the box-shaped transition pieces and the connecting plate constitute the vertical support. The invention is used for tower type supercritical boilers.

Owner:HARBIN BOILER

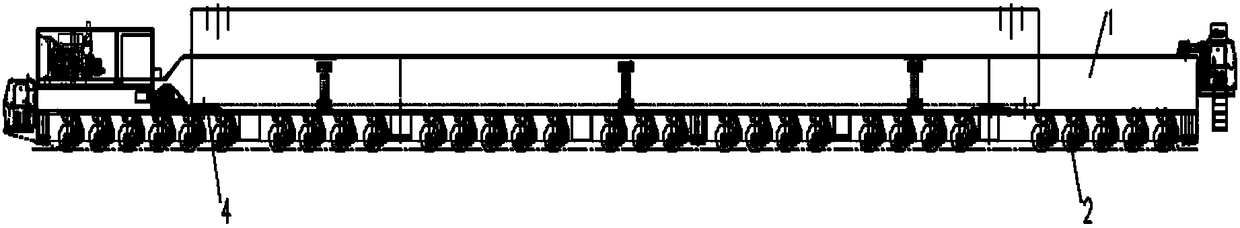

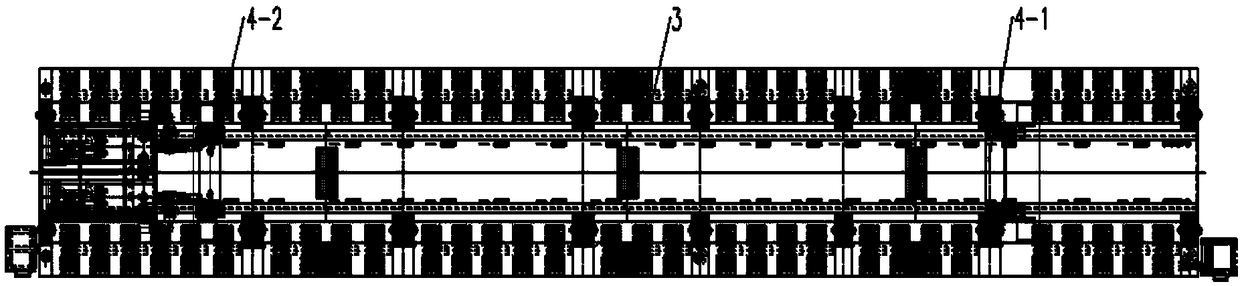

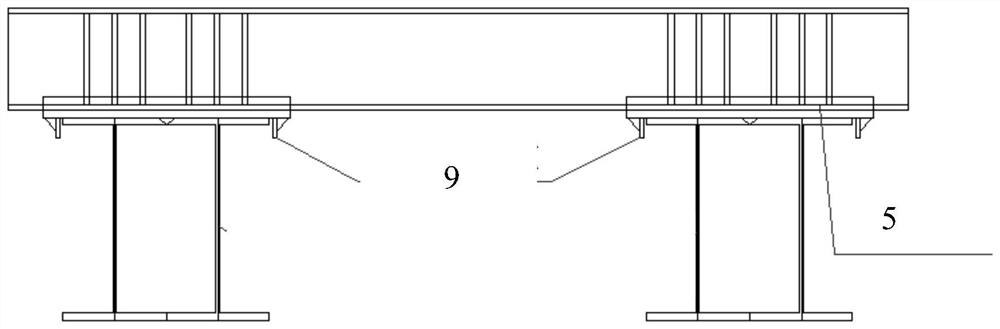

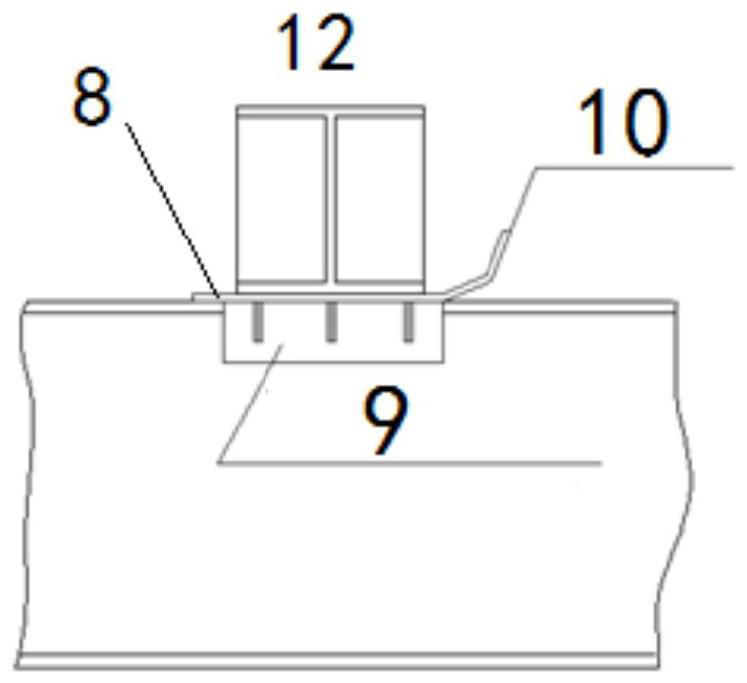

Tunnel passing girder transporting vehicle

PendingCN108130862AReduce the height of beam transport and feed beamSolve tire loading problemsBridge erection/assemblyEngineeringSpandrel

The invention provides a tunnel passing girder transporting vehicle. The tunnel passing girder transporting vehicle comprises a vehicle body, a plurality of hydraulic supporting leg groups, a plurality of travelling wheel groups, a supporting switching structure and a girder carrying trolley; the vehicle body is provided with two outer side supporting girders and two inner side longitudinal girders which are parallel to each other, the two inner side longitudinal girders are located between the lower ends of the two outer side supporting girders, and a plurality of transverse girders are connected to the two outer side supporting girders and the two inner side longitudinal girders at intervals; a groove-shaped structure for storing a box girder is formed between the two outer side supporting girders; the multiple hydraulic supporting leg groups are arranged at the lower ends of the two outer side supporting girders at intervals from front to rear, and the multiple travelling wheel groups are connected to the lower ends of the two outer side supporting girders at intervals from front to rear; the supporting switching structure is provided with a front fixing supporting assembly anda plurality of rear fixing supporting assemblies, the front fixing supporting assembly is arranged on a cross girder at the front end of the vehicle body, and the multiple rear fixing supporting assemblies are arranged on all cross girders at the rear end of the vehicle body; and the girder carrying trolley is provided with a front girder carrying trolley body and a rear girder carrying trolley body, and the front girder carrying trolley body and the rear girder carrying trolley body are movably arranged on the two inner side longitudinal girders. The tunnel passing girder transporting vehiclecan solve the problem of passing a tunnel of a transporting vehicle carrying large-span and large-tonnage box girders.

Owner:CHINA RAILWAYS CORPORATION +3

Overweight horizontal high-pressure heater hoisting system and hoisting method

ActiveCN111377383AAvoid the problem of turning aroundSolve instabilityLifting devicesRunwaysMarine engineeringControl theory

The invention relates to an overweight horizontal high-pressure heater hoisting system and hoisting method. The overweight horizontal high-pressure heater hoisting system comprises a first crawler crane, a second crawler crane and a hauling slide way; the main arm rotating coverage ranges of the first crawler crane and the second crawler crane are partially overlapped, and the hauling sliding wayis located on the outer side of the longitudinal area where the first crawler crane and the second crawler crane are located and is close to the first crawler crane in the transverse direction; the distance between the first crawler crane and the hauling slide way is 3500mm-4500 mm shorter than that between the second crawler crane and the hauling slide way, a to-be-hoisted object enters from theedge of the coverage area of the second crawler crane and one side close to the first crawler crane, and the central axis of the hauling slide way is perpendicular to the longitudinal direction, and the starting point of the to-be-hoisted object and the hauling slide way are positioned on two sides of the first crawler crane respectively. Hoisting in place of large and heavy equipment such as 320-ton equipment is achieved, and the equipment can rotate by 90 degrees.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

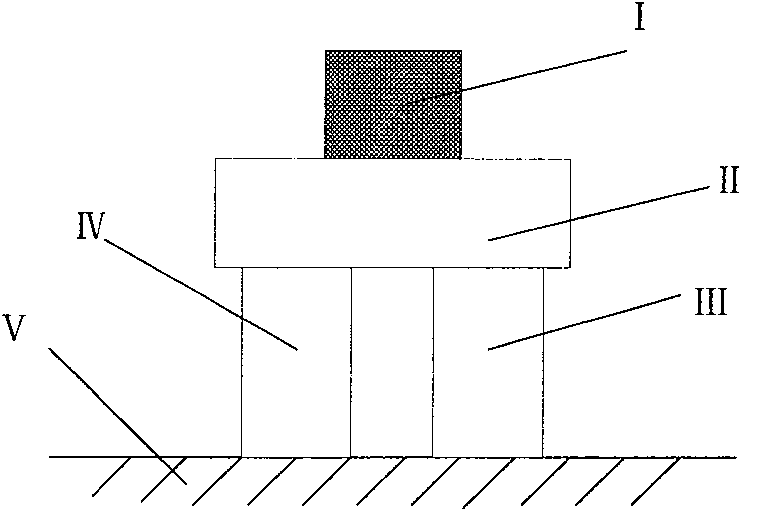

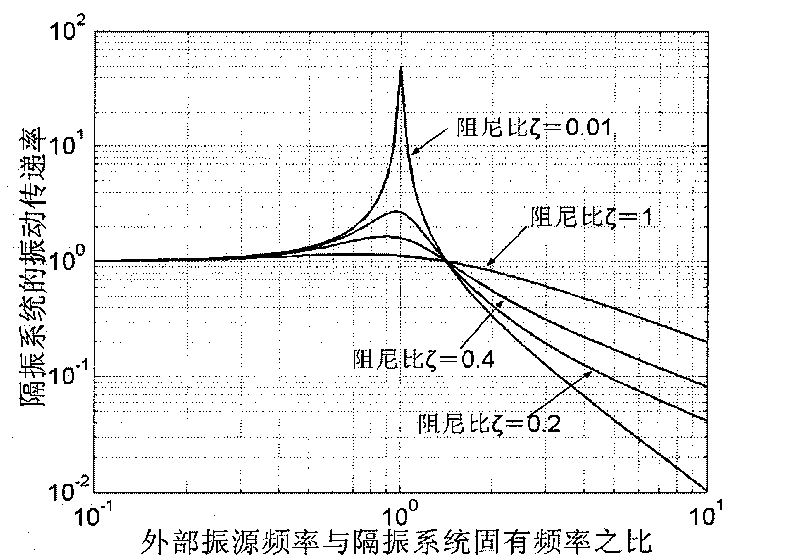

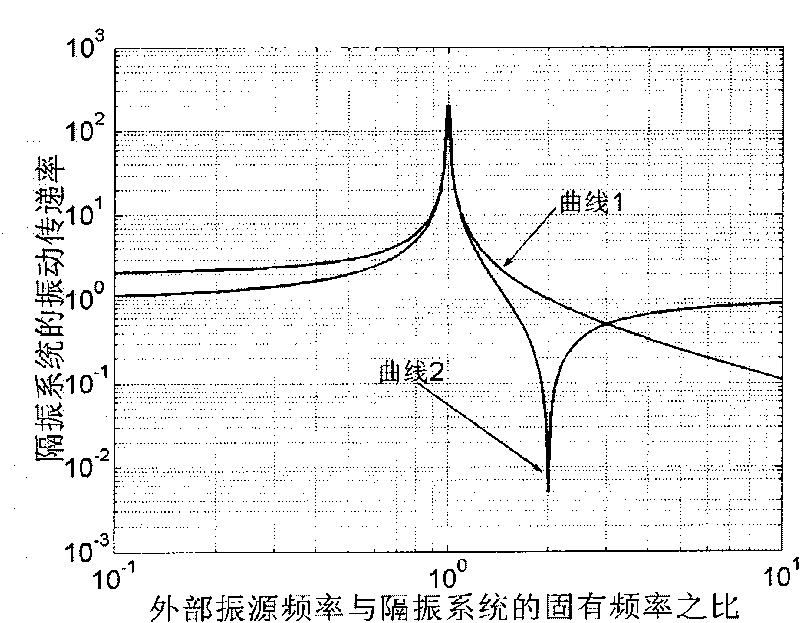

Single-degree-of-freedom ultralow frequency vertical vibration isolation system

InactiveCN101225865BImprove the vibration isolation effectImprove the problem of high vibration transmission rateNon-rotating vibration suppressionVertical vibrationDynamic stiffness

The invention relates to a vertical vibration isolation system of single freedom and ultra-low frequency, comprising a mass block, a middle mass block, a zero point generator, a zero stiffness apparatus and a stiffness base. The zero stiffness apparatus invents the dynamic stiffness values of the system at a low cost, which greatly decreases the natural frequency of the system and realizes the passive vibration isolation within the range of ultra-low frequency. The zero point generator reduces the vibration transmissibility in the range of the ultra-low frequency and improves the efficiency ofvibration isolation; otherwise, the parameters of the zero point generator can be changed to regulate the system vibration transmissibility according to the actual amplitude and frequency requirements of the vibration isolation. The existing relationship between the zero point generator and the zero stiffness apparatus is: the zero stiffness apparatus decreases the dynamic stiffness value and also brings down the zero value of the zero point generator III and realizes zero within the range of ultra-low frequency.

Owner:XI AN JIAOTONG UNIV

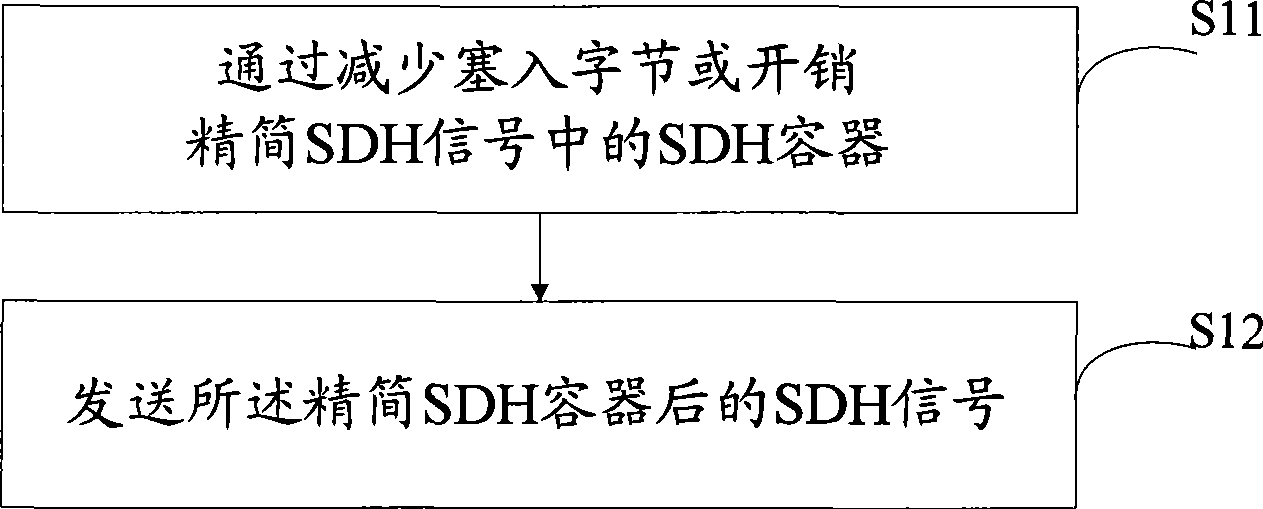

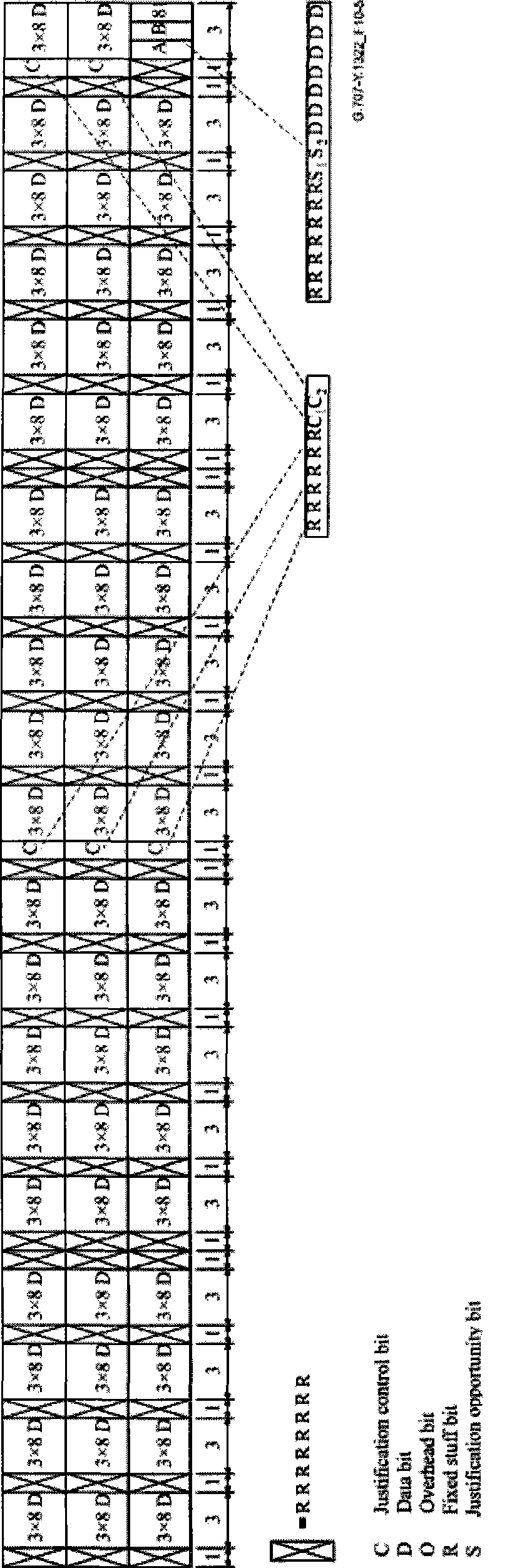

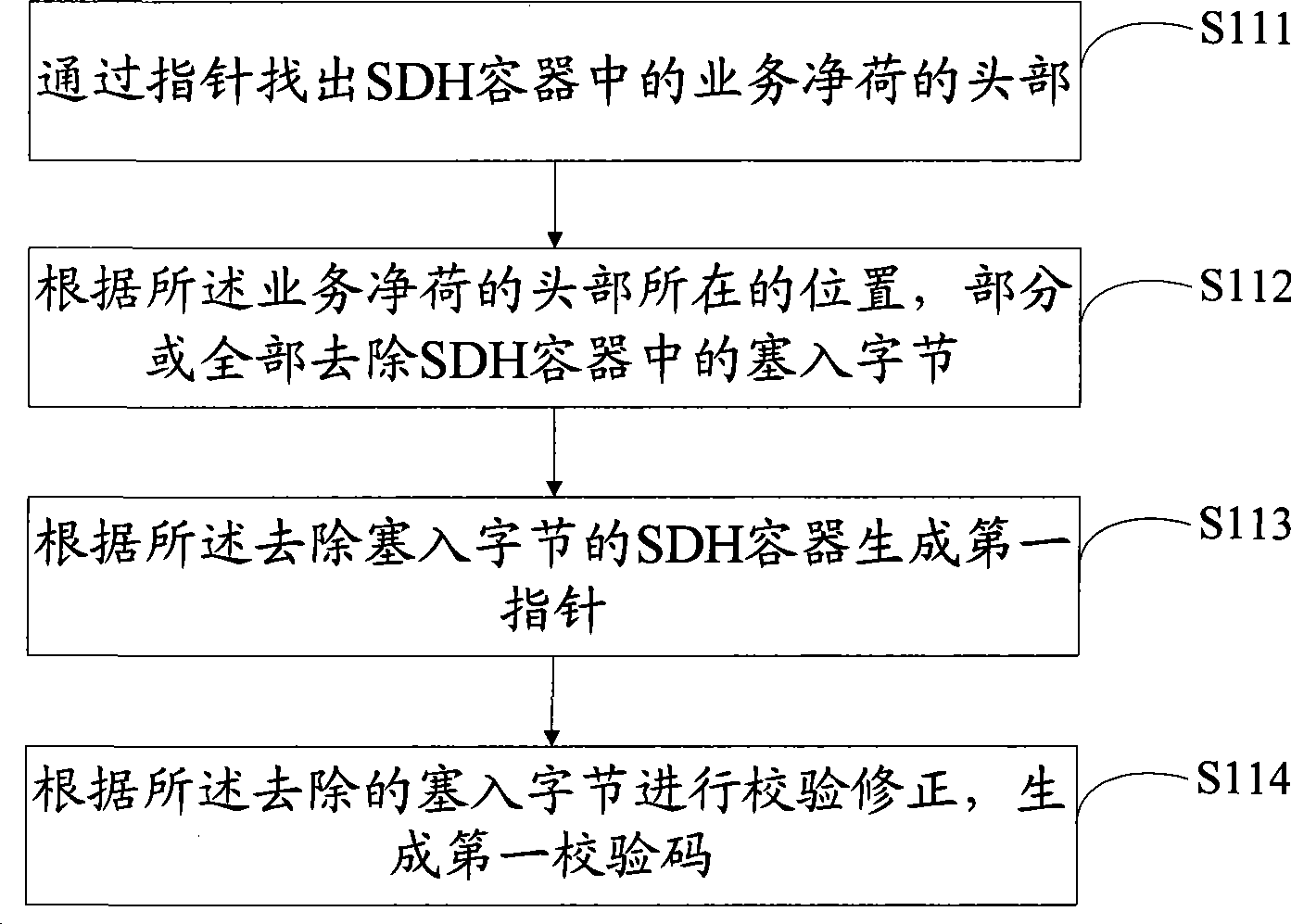

Transmission method, device and system for synchronous numerical sequence signal

InactiveCN101465706ASolve the bearer problemRealize the function of dockingTime-division multiplexSequence signalByte

The embodiment of invention discloses a SDH signal transmission method, a device and a system, which relate to wireless communication field and can solve the problem that when a PDH signal is multiplexed with a SDH signal, the generated bandwidth is insufficient. The SDH signal transmitting method includes that SDH container in SDH signal is simplified through stuffing byte or cost reduction; the SDH signal with simplified SDH container is transmitted. The SDH signal receiving method includes that a SDH signal is received, and the simplified SDH container of the SDH signal is recovered through the recovery of stuffing byte or cost. The embodiment of invention is applicable to SDH transmission in wireless communication field.

Owner:HUAWEI TECH CO LTD

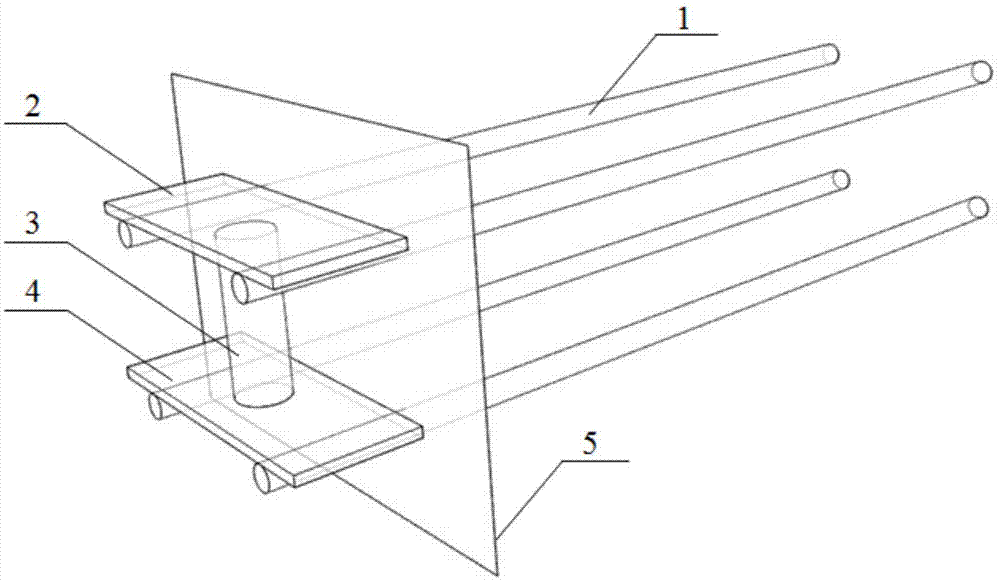

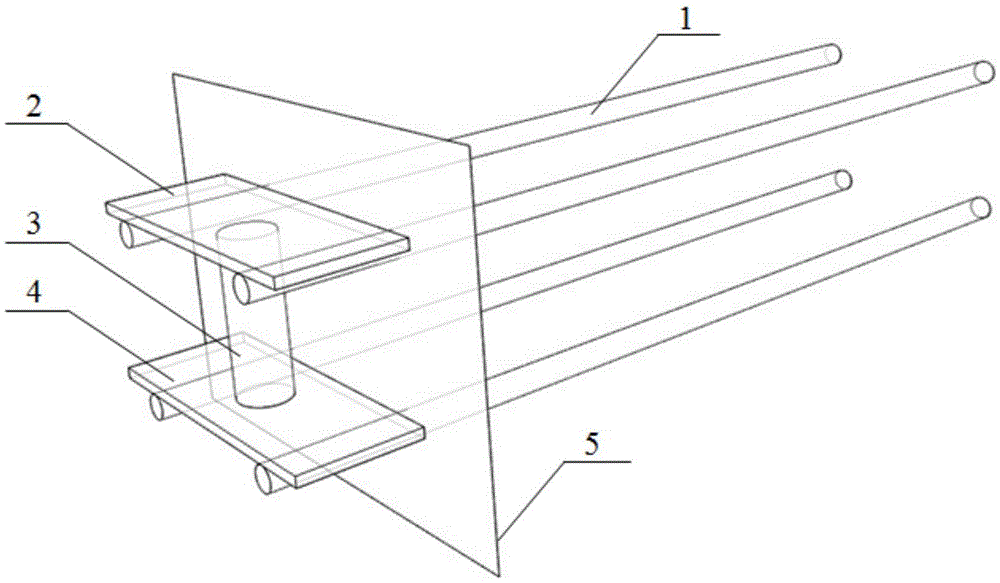

Supporting device for roof advance support in process of tunneling in caving loose rock mass and application of supporting device

The invention discloses a supporting device for a roof advance support in the process of tunneling in caving loose rock mass and application of the supporting device. The device is composed of round tubes, steel plates and a steel tube. The four round tubes are arrayed in a rectangular mode and divided into two sets of round tubes, the steel plates are welded to the ends of both the sets of round tubes, and the steel plates are connected through the steel tube in a supported mode. In the construction process, four horizontal holes are drilled firstly in the two walls of a tunnel according to the distance and the length of the round tubes, the round tubes are inserted into the horizontal holes, the round tubes are exposed out of the lateral walls of the tunnel about 0.2 m, then the steel plates are welded to the exposed parts of the round tubes respectively, and the steel tube is welded between the upper layer steel plate and the lower layer steel plate. In the using process, I-steel or other materials are welded to the upper layer steel plate of the device, so that a roof beam used as the roof advance support is formed. The supporting device is suitable for driving in mine unstable rock mass or tunneling in the loose rock mass after a gob collapse, the roof support problem of the caving loose rock mass is solved, and the supporting device has the advantages of being simple in structure, reliable in performance, convenient for a worker to operate and the like.

Owner:CENT SOUTH UNIV

Method and device for realizing packet data convergence protocol of LTE relay system

ActiveCN102026398BSolve the bearer problemReduce processingConnection managementWireless network protocolsPDCPProtocol for Carrying Authentication for Network Access

The present invention discloses a method for realizing packet data convergence protocol (PDCP) of LTE wireless relay system, characterized in that: an identification aiming at user equipment radio bearing is introduced at a PDCP layer of Un port, therefore multiplexing of different user equipment data is supported by the PDCP layer of Un port; in the process that user equipment UE produces business and establishes S1 bearing, the following steps are comprised: the relay node Un radio bearing reconfiguration process of the Un port between the relay node and evolution base station equipment is triggered; in the process of the relay node Un radio bearing reconfiguration, the evolution base station equipment and the relay node complete the many-to-one mapping between radio bearing of Un port user equipments and data radio bearing DRB of Un port relay, then establish the corresponding relationship between user equipment radio bearing identification and tunnel identification of GPRS tunnel protocol GTP which is borne by user equipment S1. In addition, the present invention also discloses a relay node and evolution base station equipment.

Owner:POTEVIO INFORMATION TECH CO LTD

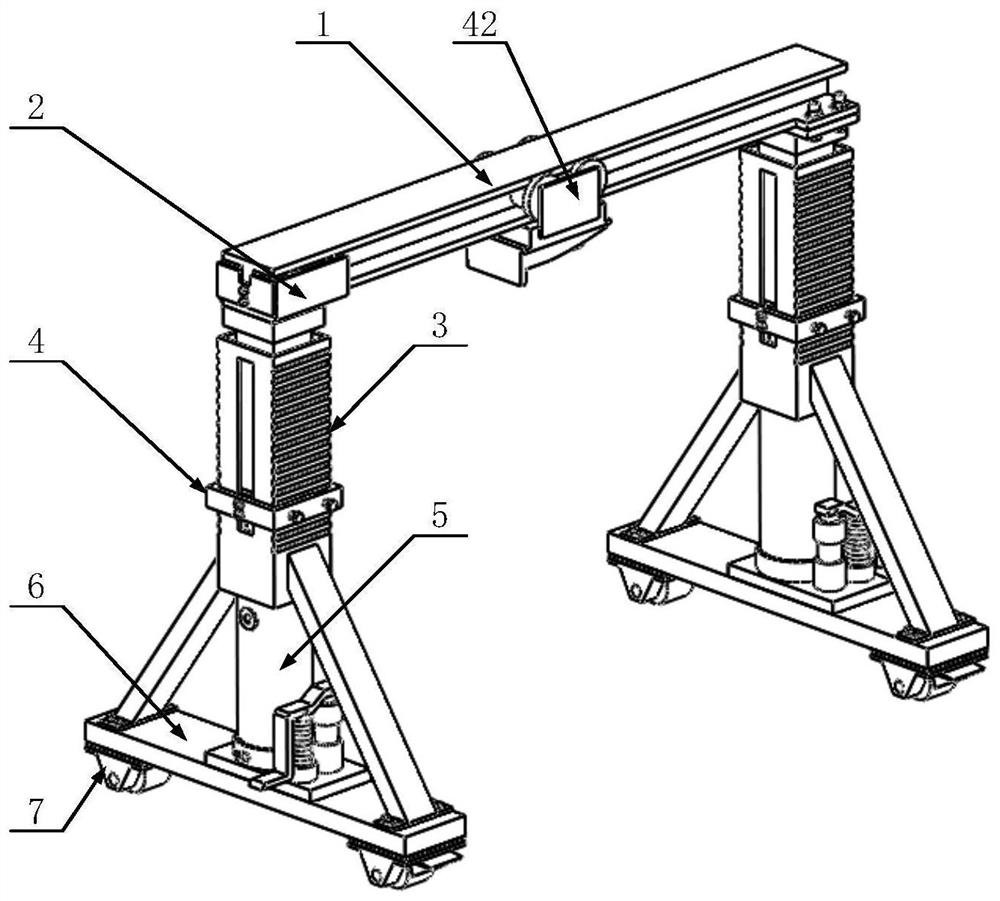

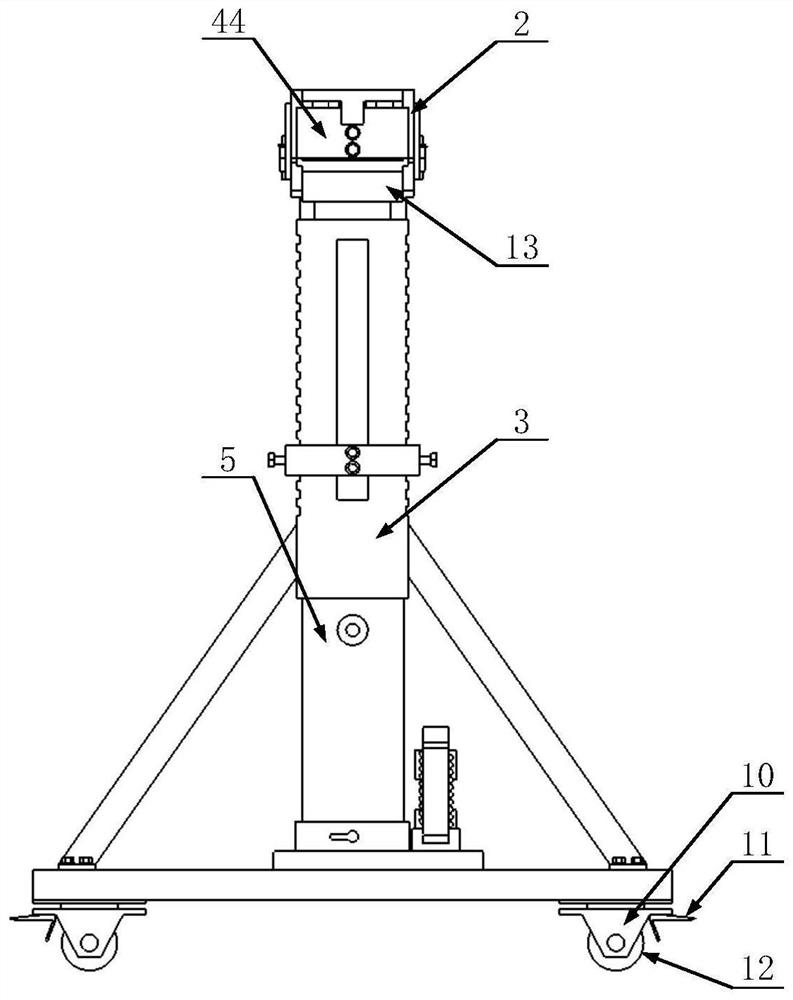

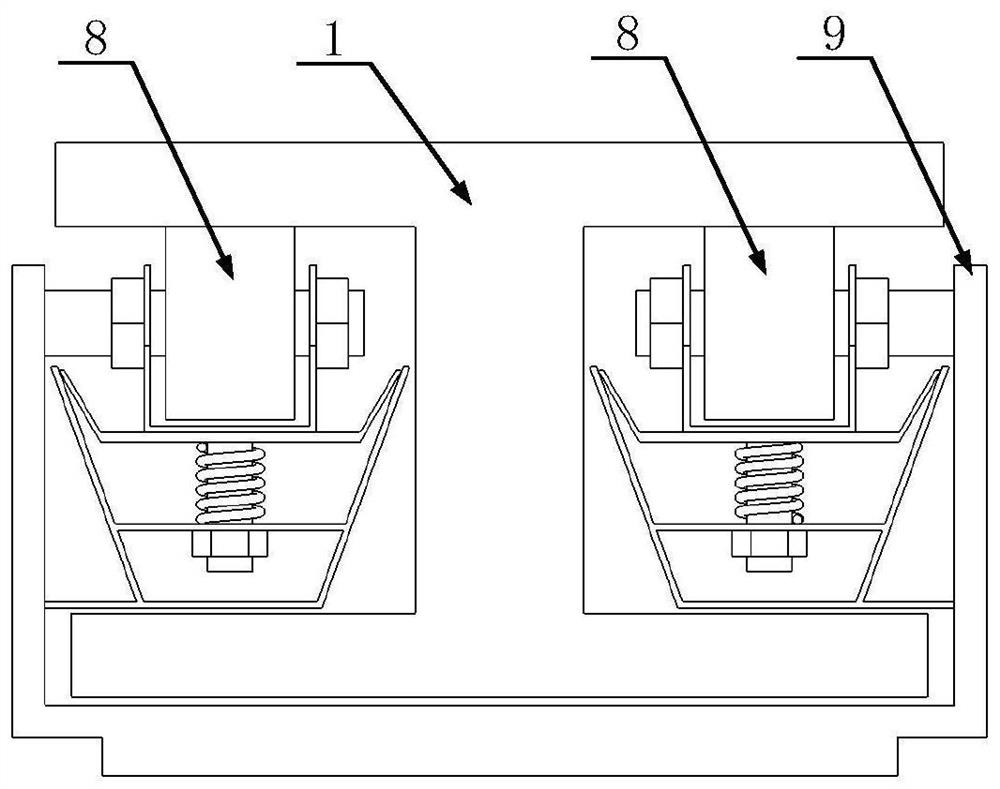

Gantry crane with adjustable span height

ActiveCN113479784AGuaranteed high usabilityIncreased high usabilityBase supporting structuresBraking devices for hoisting equipmentsStructural engineeringControl theory

The invention discloses a gantry crane with the adjustable span height. The gantry crane comprises a transverse moving mechanism and hydraulic lifting devices. One end of an I-shaped cross beam is fixedly connected with one hydraulic lifting device, the other end of the I-shaped cross beam is in sliding connection with the transverse moving mechanism, the transverse moving mechanism is fixedly connected with the other hydraulic lifting device, the transverse moving mechanism is used for transverse movement, and the hydraulic lifting devices are used for adjusting the height of the I-shaped cross beam. The height of the gantry crane is adjusted by designing the hydraulic lifting devices, the problem that the lifting height of a traditional gantry crane cannot be adjusted is solved, and the height applicability of the gantry crane is guaranteed; and furthermore, the single-side transverse free movement of the gantry crane is realized by designing the transverse moving mechanism, the problem that the span of a traditional gantry crane cannot be adjusted is solved, the stability and the span applicability of the gantry crane are ensured, the gantry crane with the adjustable span and height can be adjusted according to different lifting objects, height and span can be freely adjusted, and the application range is wide.

Owner:KUNMING UNIV OF SCI & TECH

Three-level fault-tolerant butt joint mechanism capable of resisting on-orbit impact

ActiveCN111092328ASolve Guidance Issues for Correct MatingSolve the bearer problemCoupling device detailsButt jointElectrical connection

The invention discloses an on-orbit impact resistant three-stage fault-tolerant butt joint mechanism and realizes first-stage fault tolerance between a driving end and a driven end through matching ofa gripper grabbing end mounted at the driving end and a butt joint groove which is circumferentially designed at the driven end and matched with the grabbing end in shape. A guide rod installed on anend face of the driving end and a slot designed in an end face of the driven end are matched and connected in an inserted mode, secondary fault tolerance between the driving end and the driven end isachieved, three-stage fault-tolerant stage on-orbit impact resistance between the driving end and the driven end is achieved through matched insertion connection of tooth-shaped butt joint blocks installed at the driving end and the driven end in the circumferential direction. The mechanism is advantaged in that a guiding problem of correct plugging of an electric connector is solved through first two stages, through third-stage fault tolerance, an electric connector is not stressed after being plugged.

Owner:BEIHANG UNIV +1

Wharf caisson water taking device and construction method

PendingCN108867758AReduce occupancyReduce construction timeCaissonsDrinking water installationRebarReinforced concrete

The invention provides a wharf caisson water taking device and a construction method. A reinforcing bar caisson comprises a caisson compartment which is formed by a front wall, a rear wall, side walls, a longitudinal separating wall and a transverse separating wall and is characterized in that a flow guiding wall is arranged in the reinforcing bar caisson, a water inlet hole is formed in the frontwall, energy dissipation holes are formed in the longitudinal separating wall and the transverse separating wall, a hole is formed in the rear wall, the hole is connected with a large water taking pipe, the large water taking pipe is provided with a water sealing component, and concrete is poured on part of the bottom and top of the caisson compartment to form a dam body of a gravity wharf, the lower portion of the dam body is a block stone bed on the sea floor, the upper portion is a reinforcing bar concrete breast wall, the rear side is a block stone prism, and the top is a surface layer structure. According to the device, a water taking port is combined with a large wharf structure, a sea area is not needed to be selected separately to form the water taking hole, the occupation on thesea area is reduced, a large amount of construction time is saved, and a large amount of engineering cost is saved. The caisson water taking structure is reasonably arranged to protect the safety of facilities in a harbor basin.

Owner:中交天津港湾工程设计院有限公司

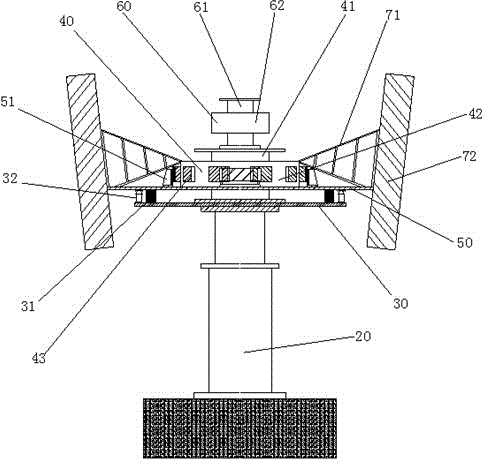

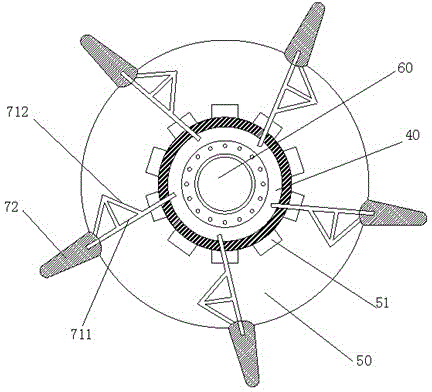

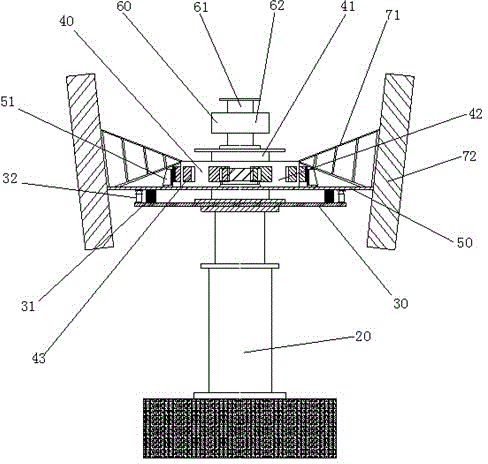

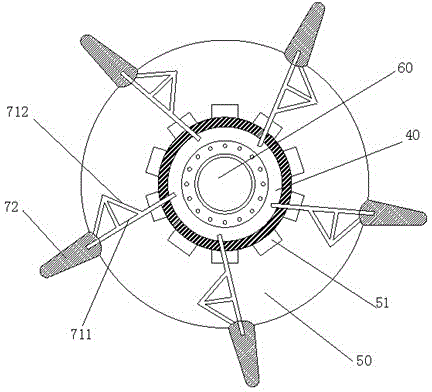

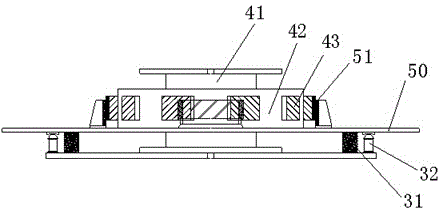

Drag-lift type composite medium-sized magnetic suspension wind driven generator

ActiveCN102748232ASimple structureReduced manufacturing and assembly costsFinal product manufactureWind motor supports/mountsWind forceDynamo

The invention discloses a drag-lift type composite medium-sized magnetic suspension wind driven generator which comprises a column tower, a generator motor and blades. The generator motor comprises a rotating portion, a fixed plate and a rotating plate, wherein the rotating portion is connected with the blades and is driven to rotate by the blades; the fixed plate is fixed on the column tower; the rotating plate is matched with the generator motor and is connected with the blades; a magnetic suspension device is arranged between the fixed plate and the rotating plate; the generator motor comprises a first column and a cylindrical rotating portion, the first column is fixedly carried by the fixed plate, the cylindrical rotating portion rotates around the first column, splines are outwards convexly arranged on the outer surface of the rotating portion, at least one interference portion is fixed on the rotating plate, and each interference portion is inserted between the corresponding two splines and interferes with the two splines; the rotating plate shares the weight carried by the rotating portion; and the rotating portion of the generator motor is provided with the splines which are matched with the interference portions on the rotating plate. The drag-lift type composite medium-sized magnetic suspension wind driven generator is simple and practical in structure, and manufacture and assembly costs are effectively reduced.

Owner:江苏元中直流微电网有限公司

An overweight horizontal high-pressure heater hoisting system and hoisting method

ActiveCN111377383BAvoid the problem of turning aroundSolve instabilityLifting devicesRunwaysMarine engineeringControl theory

The invention relates to a hoisting system and hoisting method for an overweight horizontal high-pressure heater, comprising a first crawler crane, a second crawler crane, and a hauling slide; the main arms of the first crawler crane and the second crawler crane rotate Coverage partially overlaps, the hauling chute is located outside the longitudinal area where the first crawler crane and the second crawler crane are located, close to the first crawler crane, and in the transverse direction, the first crawler crane is compared to the second crawler crane The distance between the crane and the hauling chute is 3500‑4500mm short, and the objects to be hoisted enter from the edge of the area covered by the second crawler crane and the side close to the first crawler crane, the central axis of the hauling chute is perpendicular to the longitudinal direction, The starting point of material entry and the hauling slideway are respectively located on both sides of the first crawler crane. It realizes the hoisting and positioning of relatively heavy and large-scale equipment such as 320-ton equipment, and the equipment can be rotated 90 degrees.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

Iub interface data transmission method and system in mobile communication network

ActiveCN100466630CSolve the bearer problemImprove transmission efficiencyData representation error detection/correctionPulse modulation television signal transmissionIp addressData transmission

The invention is used for improving the transmission efficiency of Iub interface and uses SDTP protocol to make data transmission of Iub interface. For each FP layer connection, the bottom layer needs to provide two links; when the length of FP frame is less than M bytes, one of said links maps the IP address and UDP port number to the SDTP node number and MUX-AL port number; when the length of FP frame is more than M bytes, another link directly uses IP address and UDP to package and adopt D-AL to bear.

Owner:XFUSION DIGITAL TECH CO LTD

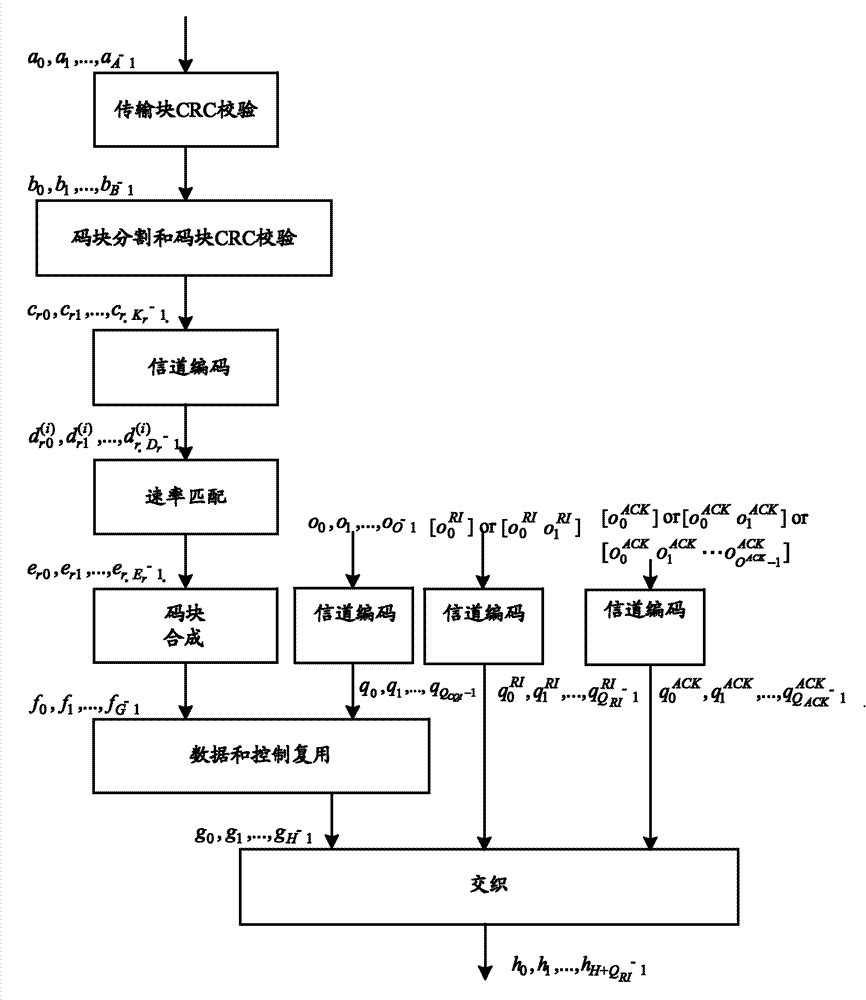

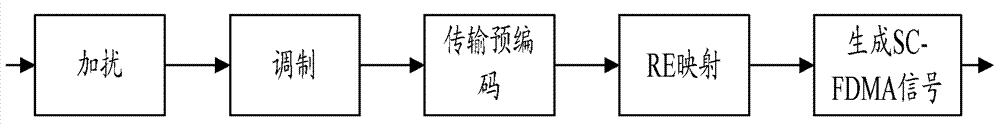

Method and device for transmitting uplink control signaling on physical uplink shared channel

ActiveCN102484872BResolve transmissionGuaranteed transmission qualitySignal allocationChannel coding adaptationData capacityTelecommunications

The present invention discloses a method for transmitting uplink control signaling in a Physical Uplink Shared Channel (PUSCH). The method includes: when two transport blocks / codewords are transmitted in the PUSCH, mapping uplink control signaling to the layer corresponding to one of the two transport blocks / codewords to transmit. The present invention also discloses an apparatus for transmitting uplink control signaling in the PUSCH. The apparatus includes: a mapping unit, used for mapping uplink control signaling to the layer corresponding to one of two transport blocks / codewords when the two transport blocks / codewords are transmitted in the PUSCH; and a transmission unit, used for transmitting the uplink control signaling. The present invention effectively solves the problem of transmitting uplink control signaling in the PUSCH when the PUSCH uses spatial multiplexing in an LTE-A system, and ensures the data capacity. The channel quality corresponding to the transport blocks selected in various ways is relatively good, thereby ensuring the transmission quality of the uplink control signaling.

Owner:ZTE CORP

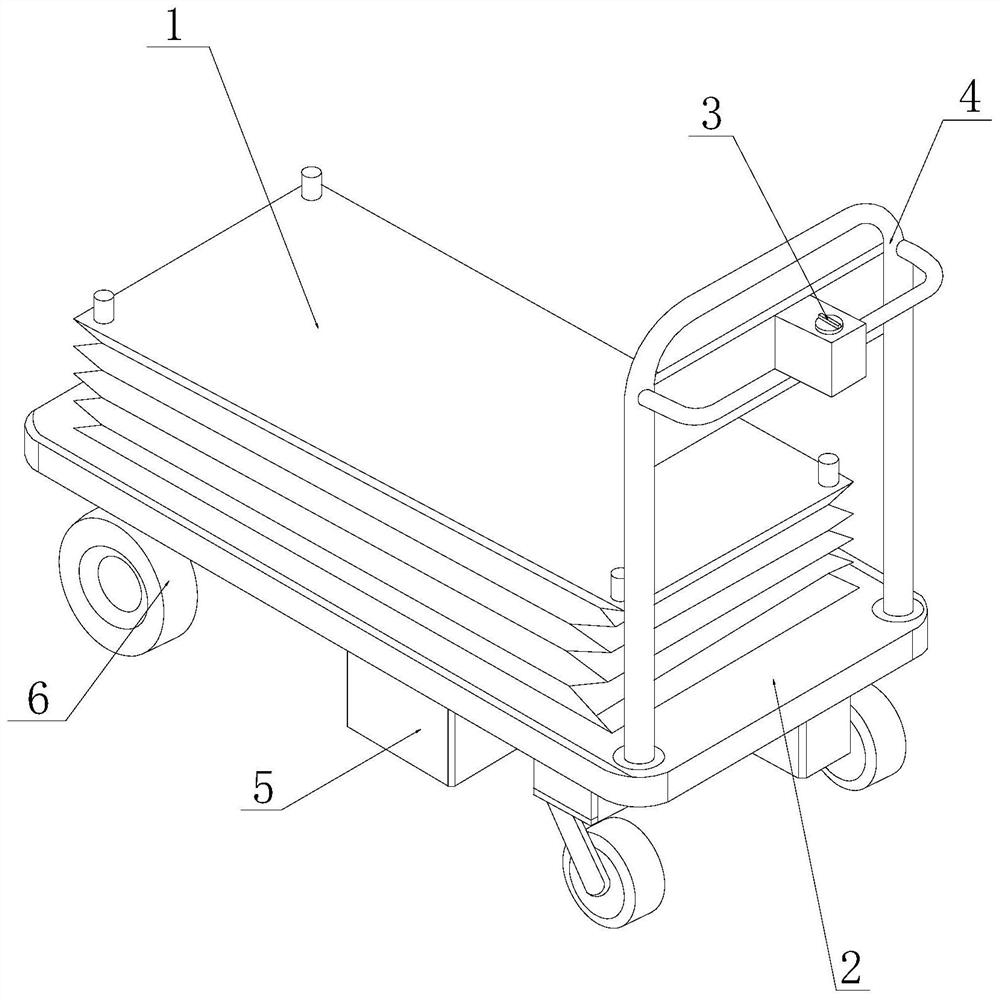

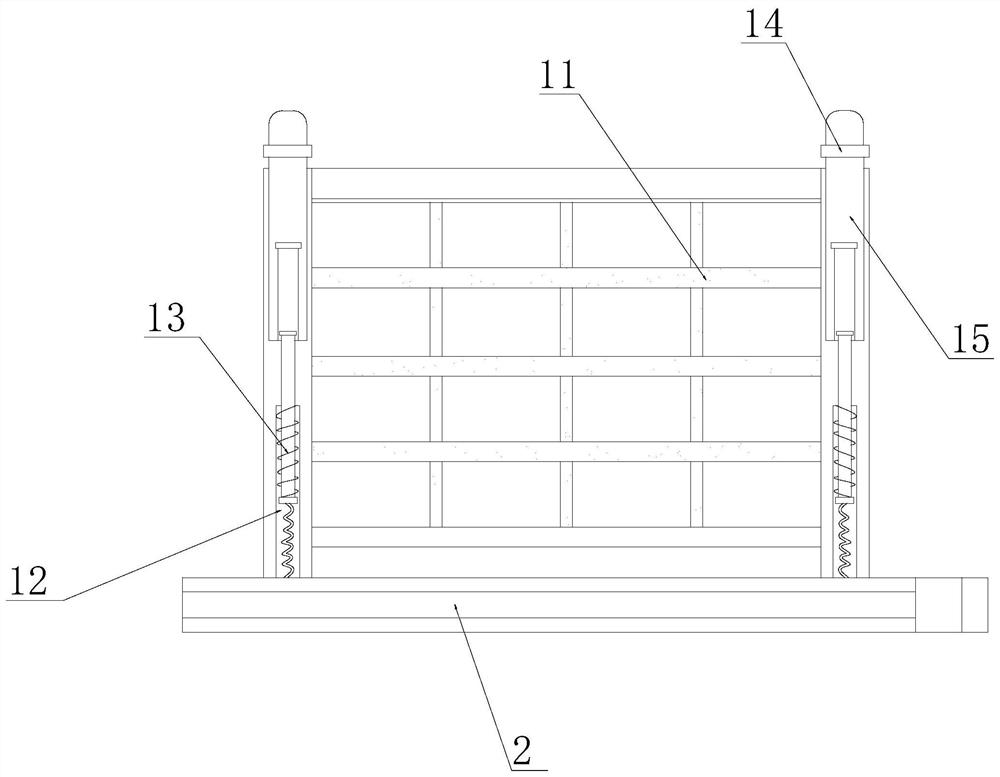

Logistics box-free shell delivery logistics frame

InactiveCN112660217AAvoid stackingSolve the bearer problemHand carts with multiple axesHand cart accessoriesDrive wheelLogistics management

The invention discloses a logistics box-free shell delivery logistics frame which structurally comprises a folding box, an objective table, a controller, a push rod, a storage battery and driving wheels, the lower end of the folding box is fixedly connected with the surface of the objective table in an embedded mode, the right side of the objective table is spirally connected with the push rod, the upper end of the push rod is fixed to the controller through bolts, and the controller is in clearance fit with the interior of the storage battery. The interior of the storage battery is movably matched with the driving wheels, the folding box comprises a folding frame, a supporting rod, a threaded rod, a slip limiting hoop and a sleeve rod, the two sides of the folding frame are movably matched with the sleeve rod, the outer surface of the sleeve rod is movably clamped with the slip limiting hoop, and the slip limiting hoop is in clearance fit with the internal threaded rod. According to the invention, the object carrying frame is unfolded through the opening and closing device, the unfolding frames are matched to form a storage cavity, the delivered shells are loaded in a one-to-one mode, friction between the delivered shells and other shells in the transportation process is effectively avoided, and the problem that the upper ends and the lower ends of the shells are impacted during shaking in the delivery process, and consequently the shells are damaged in the transportation process is effectively solved through cushion blocks and anti-collision blocks on the inner surfaces of the unfolding frames.

Owner:曾丽琼

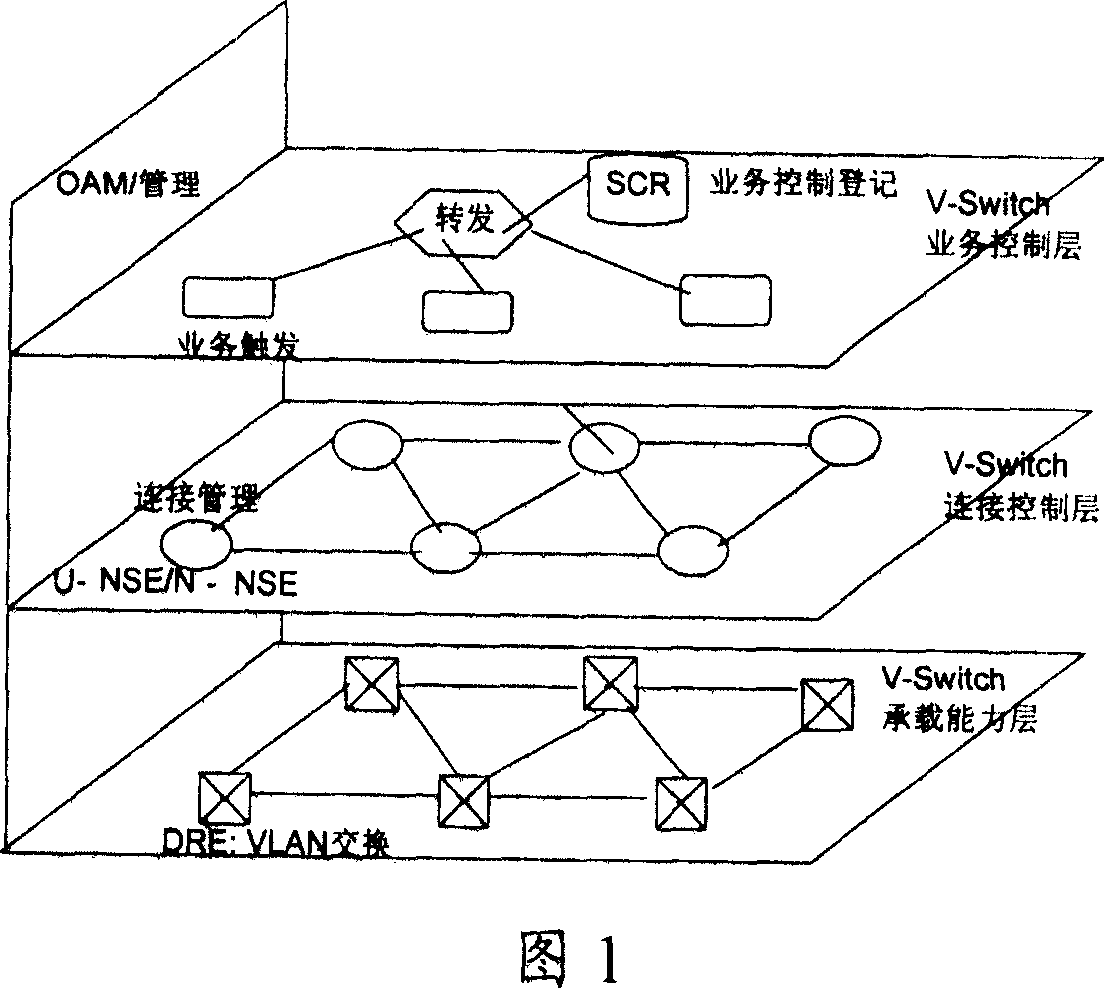

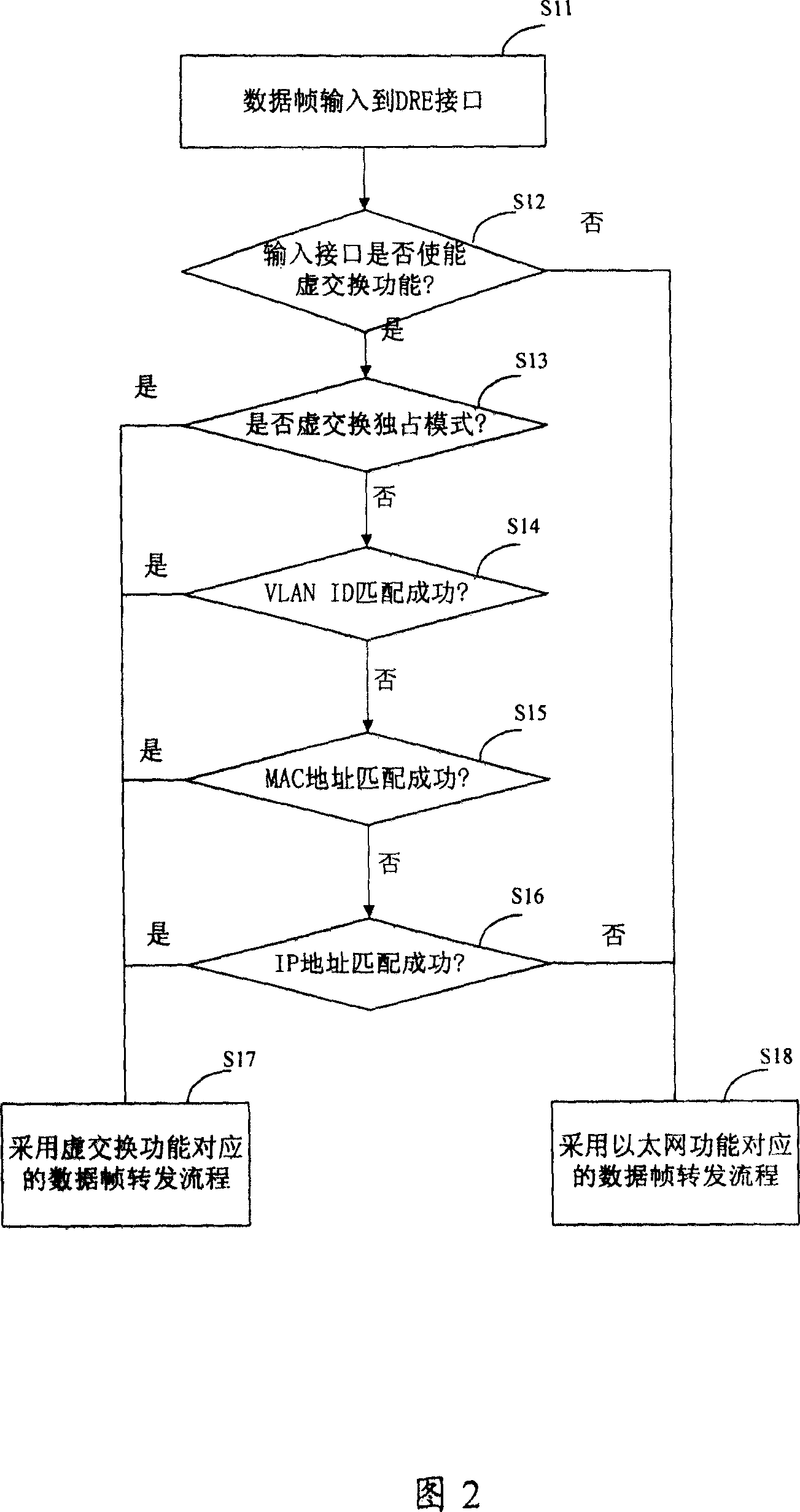

Method for retransmitting data frame by data retransmitting entity

ActiveCN100377549CSimplicity guaranteedSolve the bearer problemData switching networksDecision strategyVirtual switch

Being applicable to Ethernet, the disclosed method for forwarding data frame through data retransmission entity (DRE) includes following procedures: using one or more interfaces of DRE to enable function of virtual Switch (V-Switch); configuring work mode for one or more interfaces of DRE of enabling V-Switch function as share mode between V-Switch and Ethernet; setting up decision strategy for using V-Switch function to forward received data frame under share mode; when DRE interface configured in share mode receives data frame, if tag information carried by data frame is matched to the decision strategy, then forwarding the data frame by using retransmission flow corresponding to V-Switch function; otherwise retransmission flow corresponding to Ethernet function is utilized. The invention makes DRE equipment possess both functions of V-Switch and Ethernet in order to solve load-supporting issues in multicast, broadcast, and point-to-point operations.

Owner:HUAWEI TECH CO LTD

The Supporting Device and Application of Roof Advance Support in Caving and Loose Rock Body when Roadway Forming

The invention discloses a supporting device for a roof advance support in the process of tunneling in caving loose rock mass and application of the supporting device. The device is composed of round tubes, steel plates and a steel tube. The four round tubes are arrayed in a rectangular mode and divided into two sets of round tubes, the steel plates are welded to the ends of both the sets of round tubes, and the steel plates are connected through the steel tube in a supported mode. In the construction process, four horizontal holes are drilled firstly in the two walls of a tunnel according to the distance and the length of the round tubes, the round tubes are inserted into the horizontal holes, the round tubes are exposed out of the lateral walls of the tunnel about 0.2 m, then the steel plates are welded to the exposed parts of the round tubes respectively, and the steel tube is welded between the upper layer steel plate and the lower layer steel plate. In the using process, I-steel or other materials are welded to the upper layer steel plate of the device, so that a roof beam used as the roof advance support is formed. The supporting device is suitable for driving in mine unstable rock mass or tunneling in the loose rock mass after a gob collapse, the roof support problem of the caving loose rock mass is solved, and the supporting device has the advantages of being simple in structure, reliable in performance, convenient for a worker to operate and the like.

Owner:CENT SOUTH UNIV

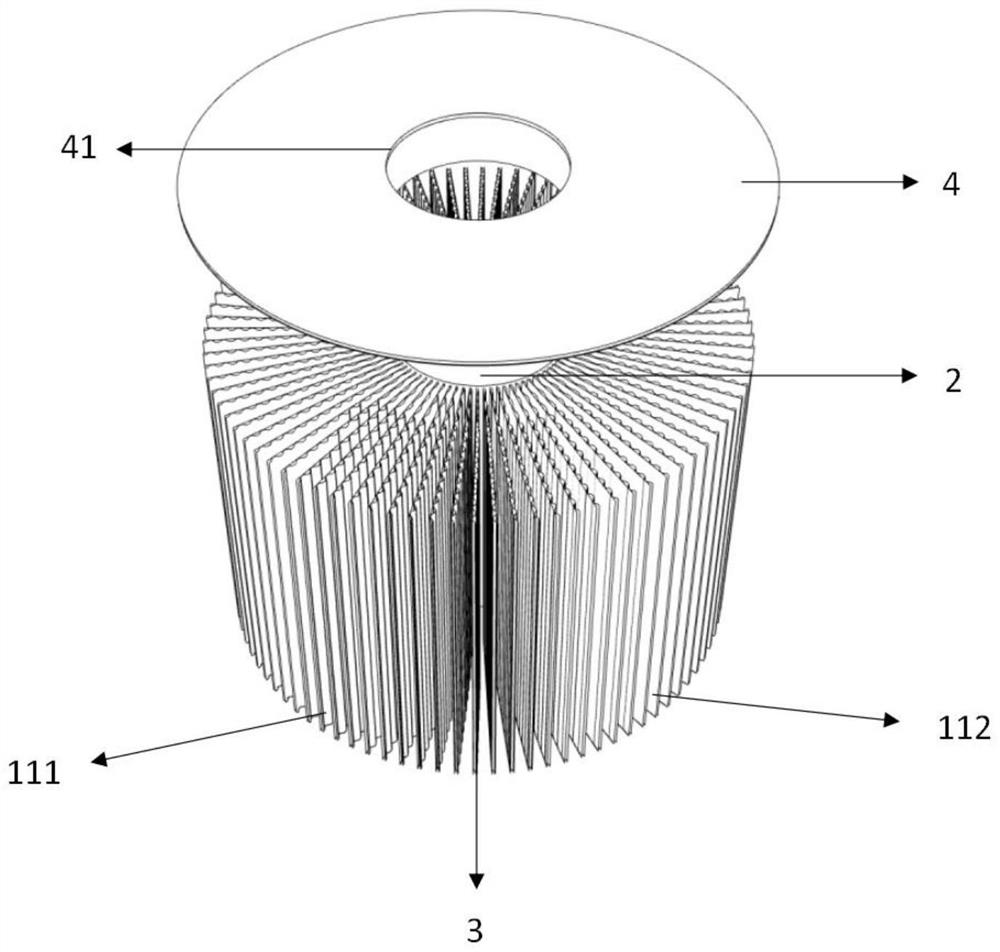

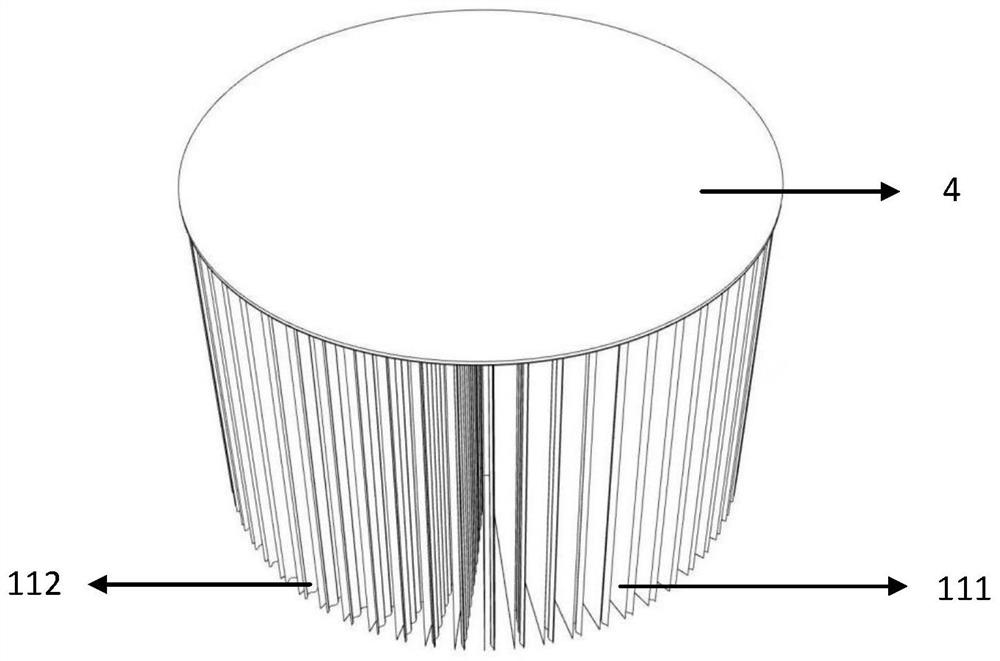

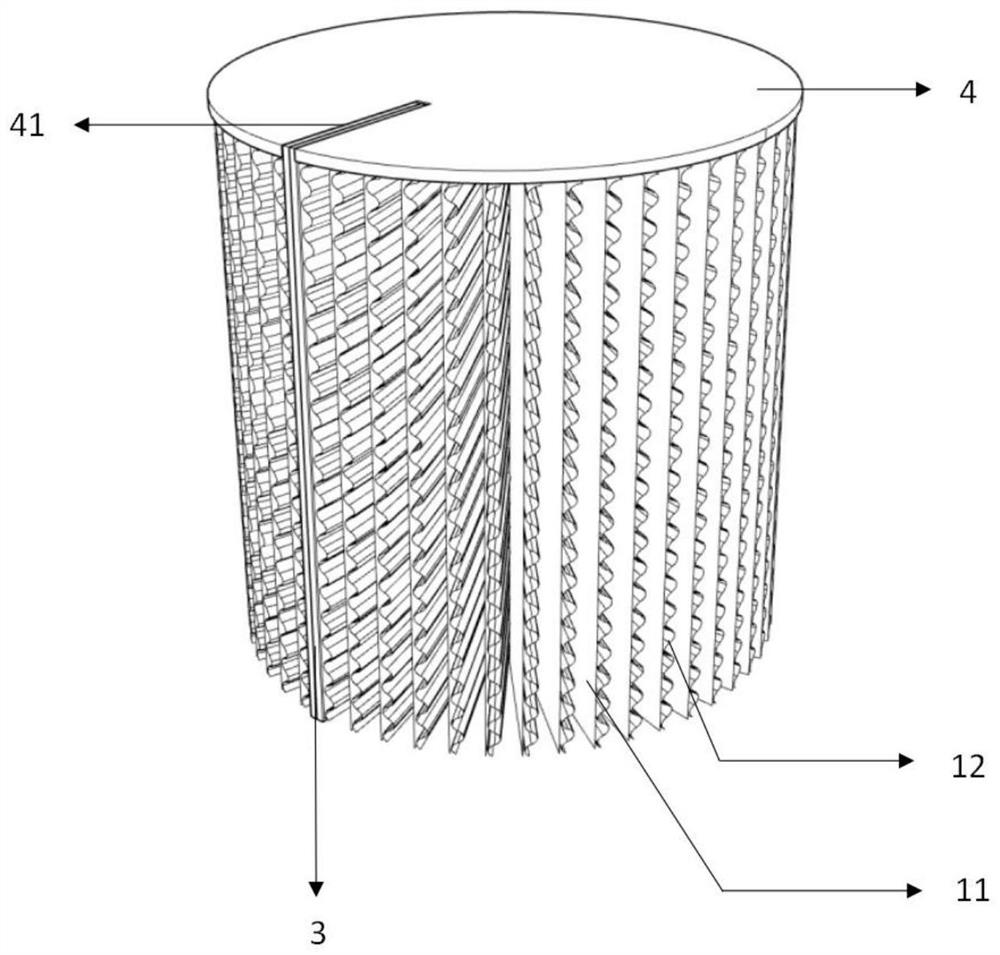

Stacked corrugated annular stretching furniture structure and process thereof

PendingCN114680492AGood load-bearing strengthSimple processMechanical working/deformationFurniture partsComposite materialHollow cylinder

The invention discloses a stacked corrugated annular stretching structure and a process thereof. The stacked corrugated annular stretching structure is formed by annularly unfolding n corrugated units along a covering film, covering a panel and fixing. The hollow corrugated unit is formed by stacking n + 1 plane base bands and n corrugated base bands, an auxiliary plate is glued and pressed on the plane base band on the outermost side of the stacked corrugations, and a covering film is pasted on the surface of only one side. When in use, the auxiliary plate is annularly stretched and unfolded along the covering film and is combined and fixed. The stacked corrugated annular stretching structure is characterized in that the n corrugated units are in a radial shape and are perpendicular to the ground to support the panel, and the middle of each corrugated unit is a hollow cylinder. The forming method comprises the following steps that S1, the stacked corrugations are prepared; s2, glue pressing, drying and shaping; and S3, pasting a side film. The unfolding method comprises the following steps that S1, the auxiliary plate is annularly unfolded, combined and then fixed; s2, fixing the seat surface;

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

A Three-level Fault-tolerant Docking Mechanism Against In-Orbit Shock

ActiveCN111092328BSolve Guidance Issues for Correct MatingSolve the bearer problemCoupling device detailsButt jointElectrical connection

The invention discloses an on-orbit impact resistant three-stage fault-tolerant butt joint mechanism and realizes first-stage fault tolerance between a driving end and a driven end through matching ofa gripper grabbing end mounted at the driving end and a butt joint groove which is circumferentially designed at the driven end and matched with the grabbing end in shape. A guide rod installed on anend face of the driving end and a slot designed in an end face of the driven end are matched and connected in an inserted mode, secondary fault tolerance between the driving end and the driven end isachieved, three-stage fault-tolerant stage on-orbit impact resistance between the driving end and the driven end is achieved through matched insertion connection of tooth-shaped butt joint blocks installed at the driving end and the driven end in the circumferential direction. The mechanism is advantaged in that a guiding problem of correct plugging of an electric connector is solved through first two stages, through third-stage fault tolerance, an electric connector is not stressed after being plugged.

Owner:BEIHANG UNIV +1

Bearer establishing method, system and device of local network

ActiveCN101860910BSolve the bearer problemEasy accessNetwork traffic/resource managementData transmissionMobility management

The invention provides a bearer establishing method of a local network. User equipment (UE) sends a packet data network (PDN) connection request through a home enhanced node B (HeNB) and indicates that PDN connection requested to be established by a mobility management entity (MME) is to connect the local network; the MME sends the bearer for establishing the local network to the UE according to the indication and inhibits information borne by the bearer for the local network to the HeNB; and the HeNB establishes the radio bearer of the local network for the UE according to the indication andthe data transmission between the UE and the local network according to the radio bearer. The invention solves the problem that the UE establishes the radio bearer of the local network through the HeNB, thereby enabling the UE to be smoothly accessed to the local network through the HeNB.

Owner:DATANG MOBILE COMM EQUIP CO LTD

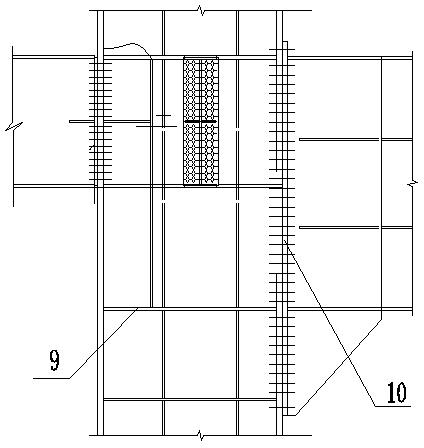

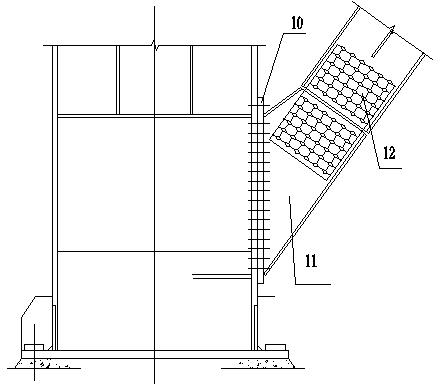

350MW supercritical boiler combustor nozzle tube panel device and method

ActiveCN102261642BSolve the bearer problemSafe and reliable water circulationBoiler supporting/setting arrangementsSteam boilersSupercritical steam generatorThermodynamics

350MW supercritical boiler burner nozzle tube screen device and method. At present, domestic 300MW lignite boilers are all subcritical, and the steam parameters are low, which leads to low operating efficiency of power plants; according to the national "Eleventh Five-Year Plan" energy planning and the requirements of industrial structure adjustment and energy saving and consumption reduction, develop high-parameter, high-efficiency supercritical A boiler is imperative. A 350MW supercritical boiler burner nozzle tube panel device, which consists of a tube panel (1) connected to the pipes. The tubes and the load protruding part of the tube panel are connected to the burner and the water wall of the boiler by connecting pieces, and the burner and the water wall are connected to the frame beam through the tension plate. The invention is used for the nozzle tube screen of the 350MW supercritical boiler burner.

Owner:HARBIN BOILER

Drag-lift type composite medium-sized magnetic suspension wind driven generator

ActiveCN102748232BRotation efficiencyNo wearFinal product manufactureWind motor supports/mountsWind drivenComposite media

Owner:江苏元中直流微电网有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com