Patents

Literature

46results about How to "Lower transport height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

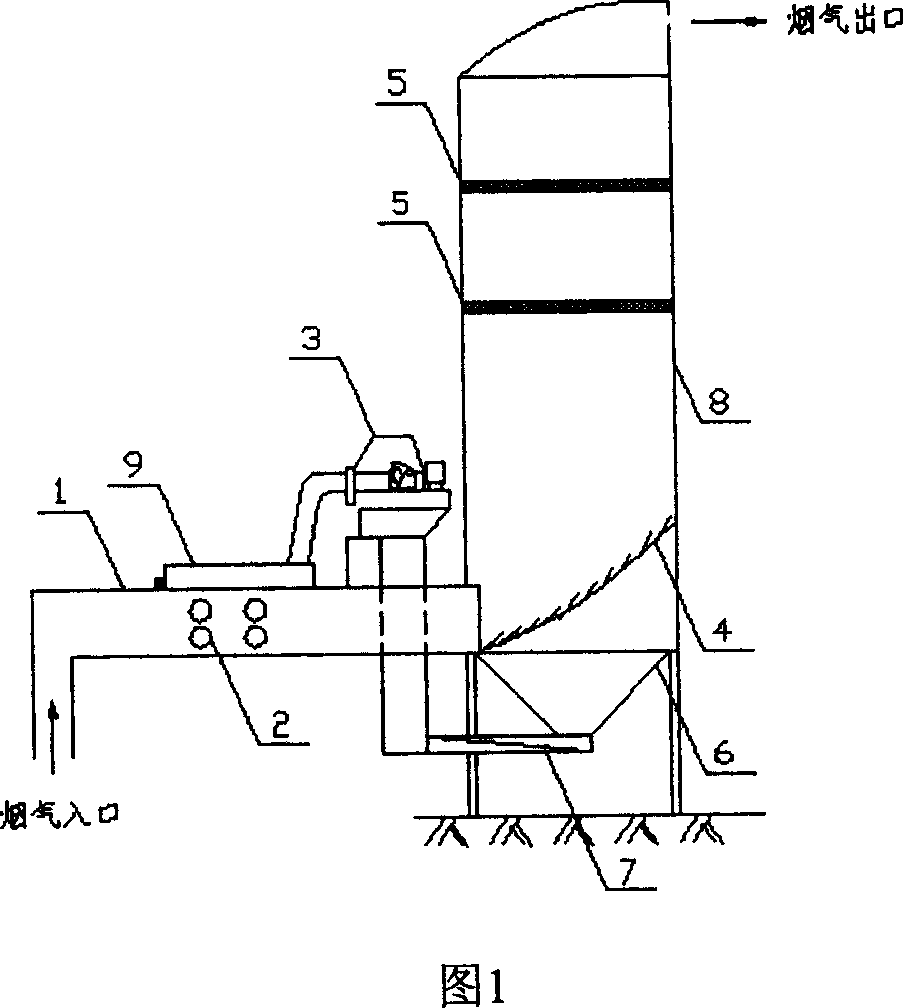

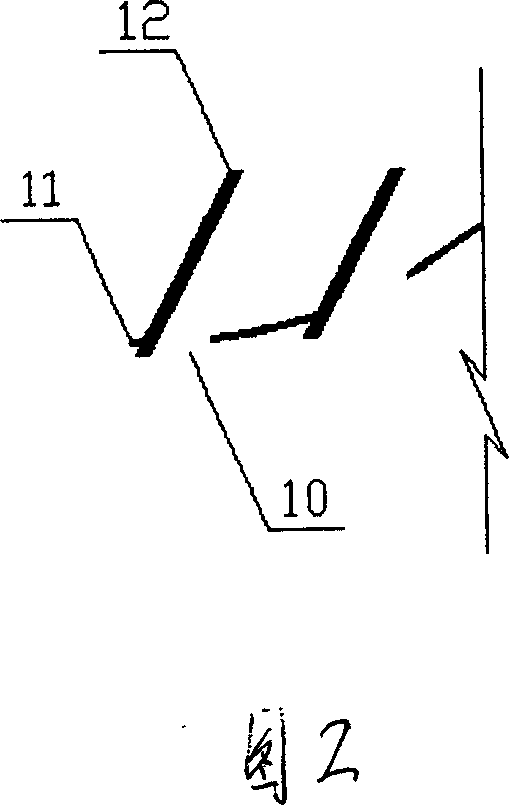

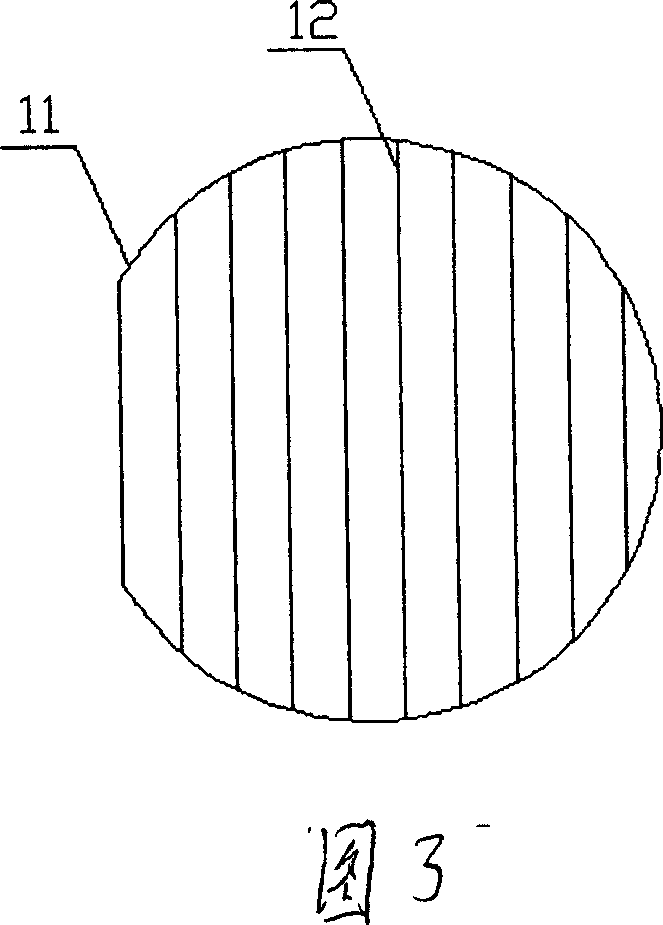

Circular dense phase fluidizing desulfurization apparatus

ActiveCN1973967AImprove utilization efficiencyAdequate responseDispersed particle separationEngineeringDistributor

The circular dense phase fluidizing desulfurization apparatus belongs to the field of environment engineering technology and is one improved fume desulfurizing apparatus. The desulfurizing apparatus includes square Venturi tube, stirrer, elevator, guide unit, web plate, collecting bin, humidifier, reaction region, and material distributor. The guide unit consists of material permeating hole, guide plate skeleton and guide plate. The apparatus of the present invention has smooth running, low power consumption, easy installation and production, light dust collector load lowered by the web plate, and capacity of recovering desulfurizer for reuse.

Owner:BEIJING BEIKE ENVIRONMENTAL ENG CO LTD

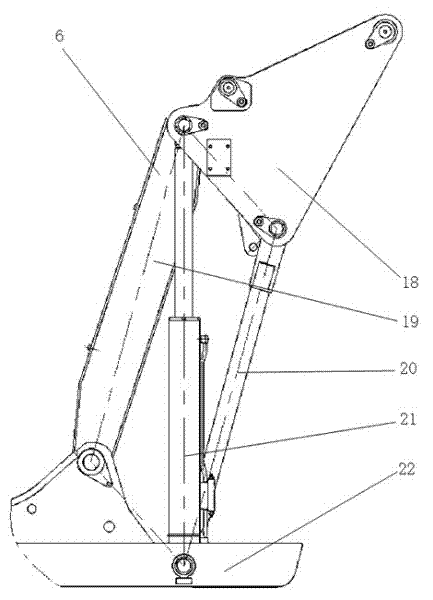

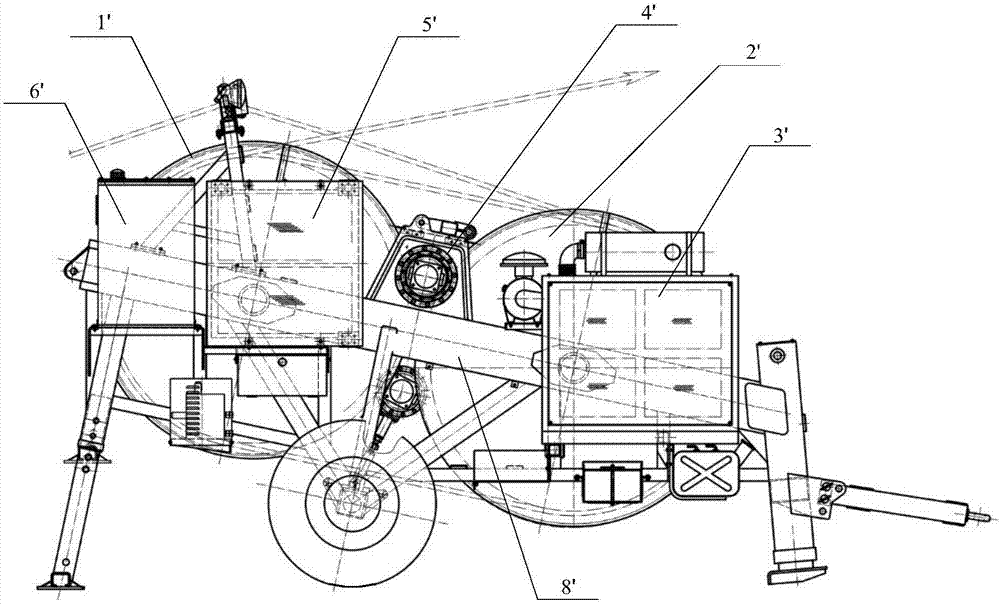

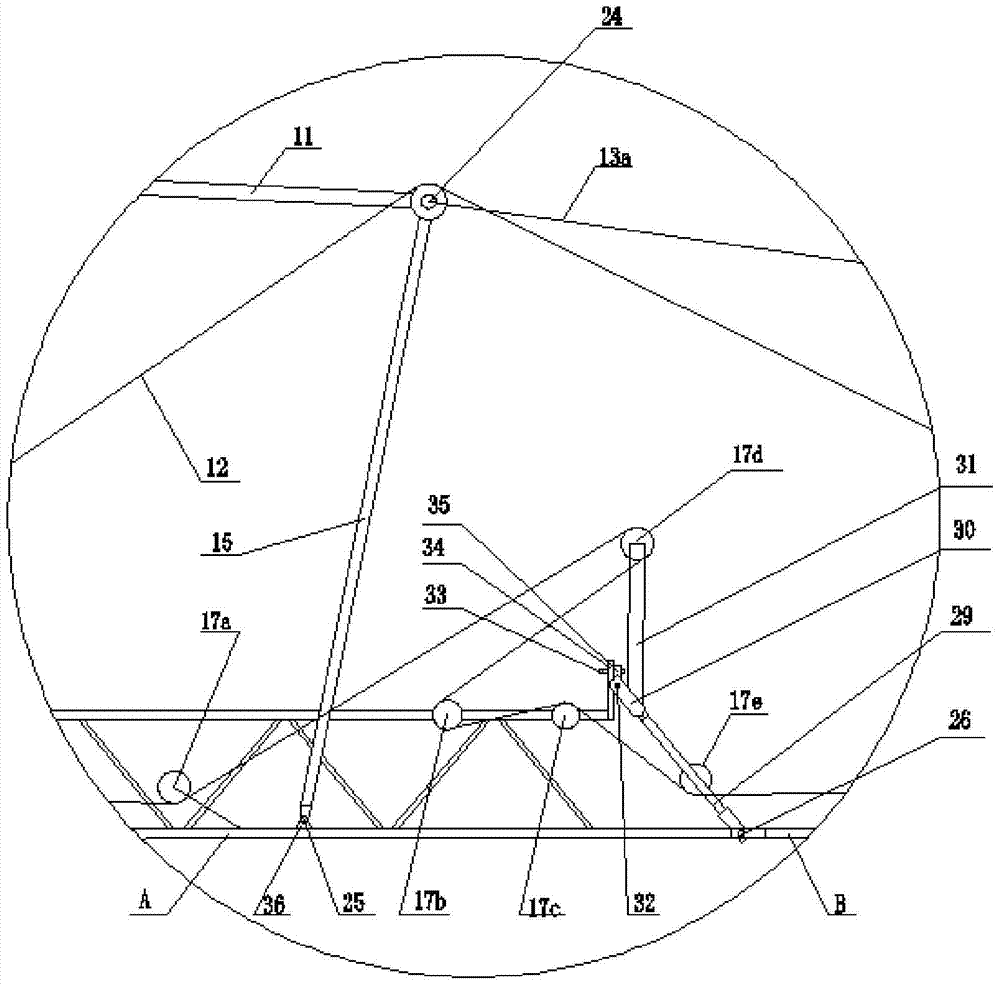

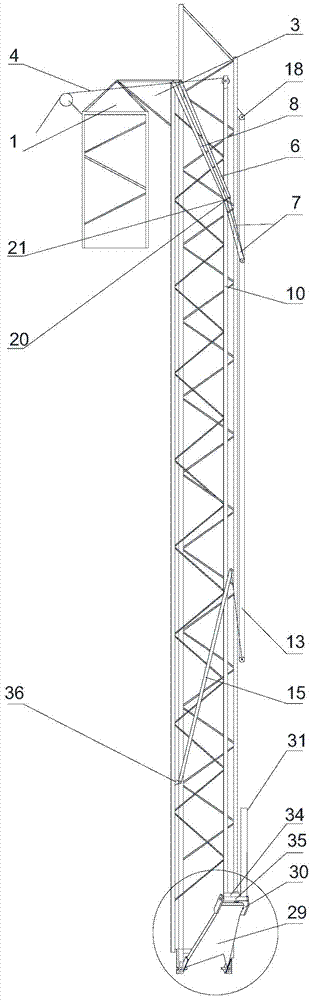

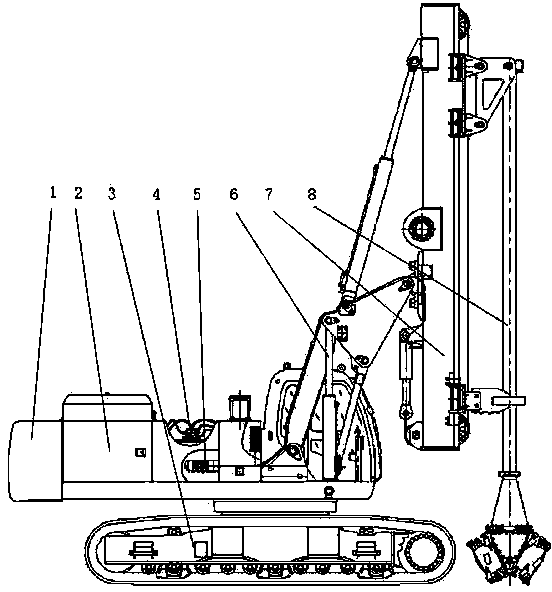

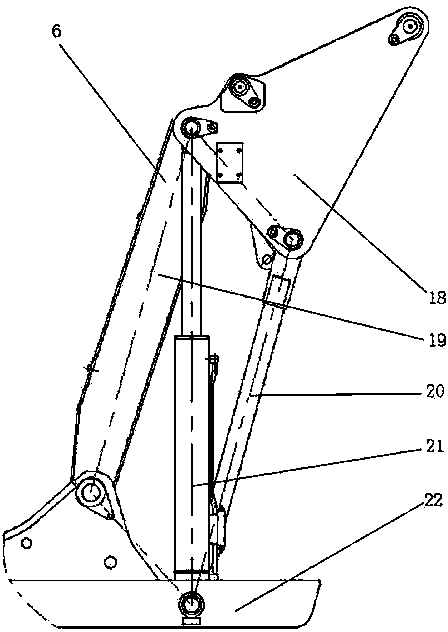

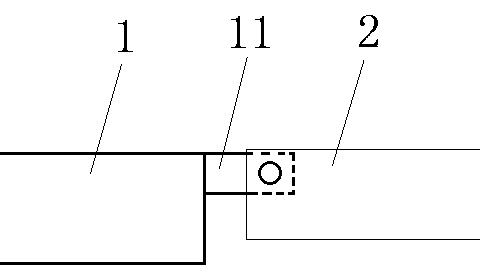

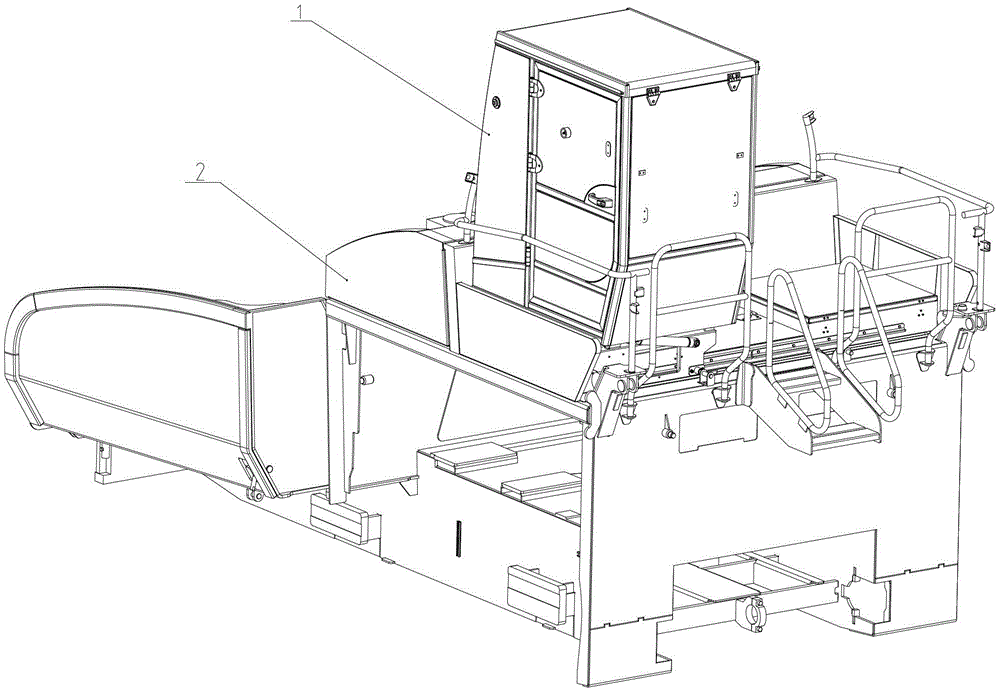

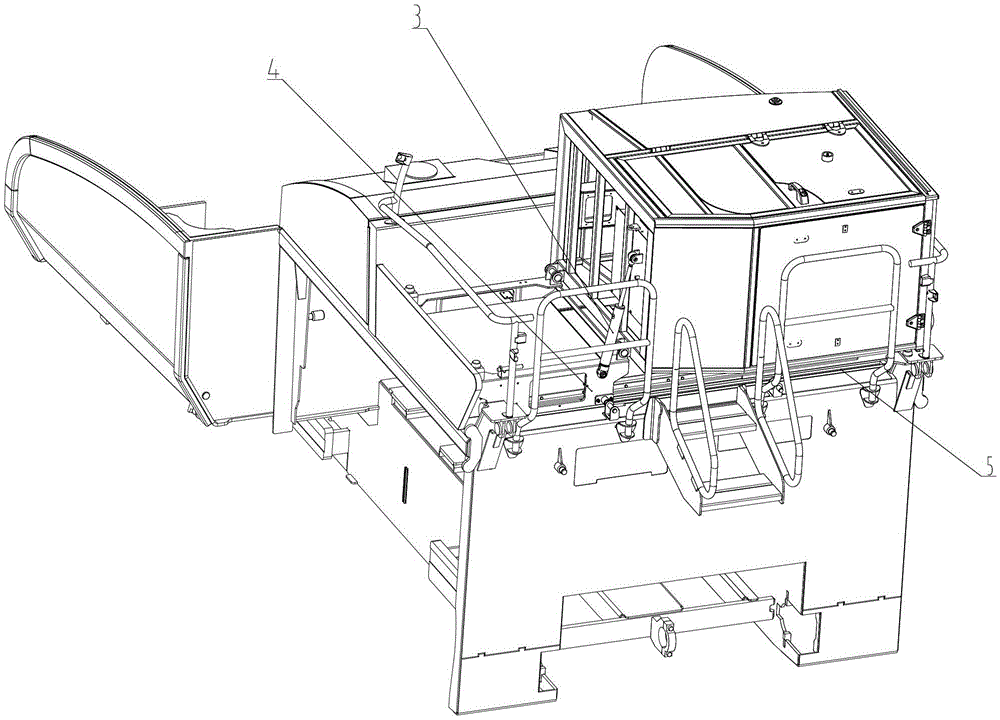

Stirring curing machine

InactiveCN102535437ALower transport heightEasy to transportSoil preservationVehicle frameElectrical control

The invention provides a stirring curing machine. The stirring curing machine comprises an upper vehicle assembly, a lower vehicle assembly connected with the upper vehicle assembly through a rotary support, and a pulp injection system on the upper vehicle assembly. The stirring curing machine is characterized in that one end of a derricking mechanism is connected with the frame of the upper vehicle assembly, and the other end is connected with an upright mast system; an operation device is arranged on the mast system, and can be controlled by a hydraulic system to move on the mast system up and down; a stirring head on the front end of the operation device is driven by the hydraulic system to rotate; and the hydraulic system and an electrical control system are arranged in the upper vehicle assembly. The stirring curing machine provided by the invention has the advantages that the stirring curing machine is specifically used for foundation stabilization, and can reduce stirring dead corners, thereby achieving more uniform stirring. Furthermore, the stirring device in the invention has an enough torque, so that the stirring head can descend into the ground easily when encountering denser soil.

Owner:龙工(上海)机械制造有限公司 +1

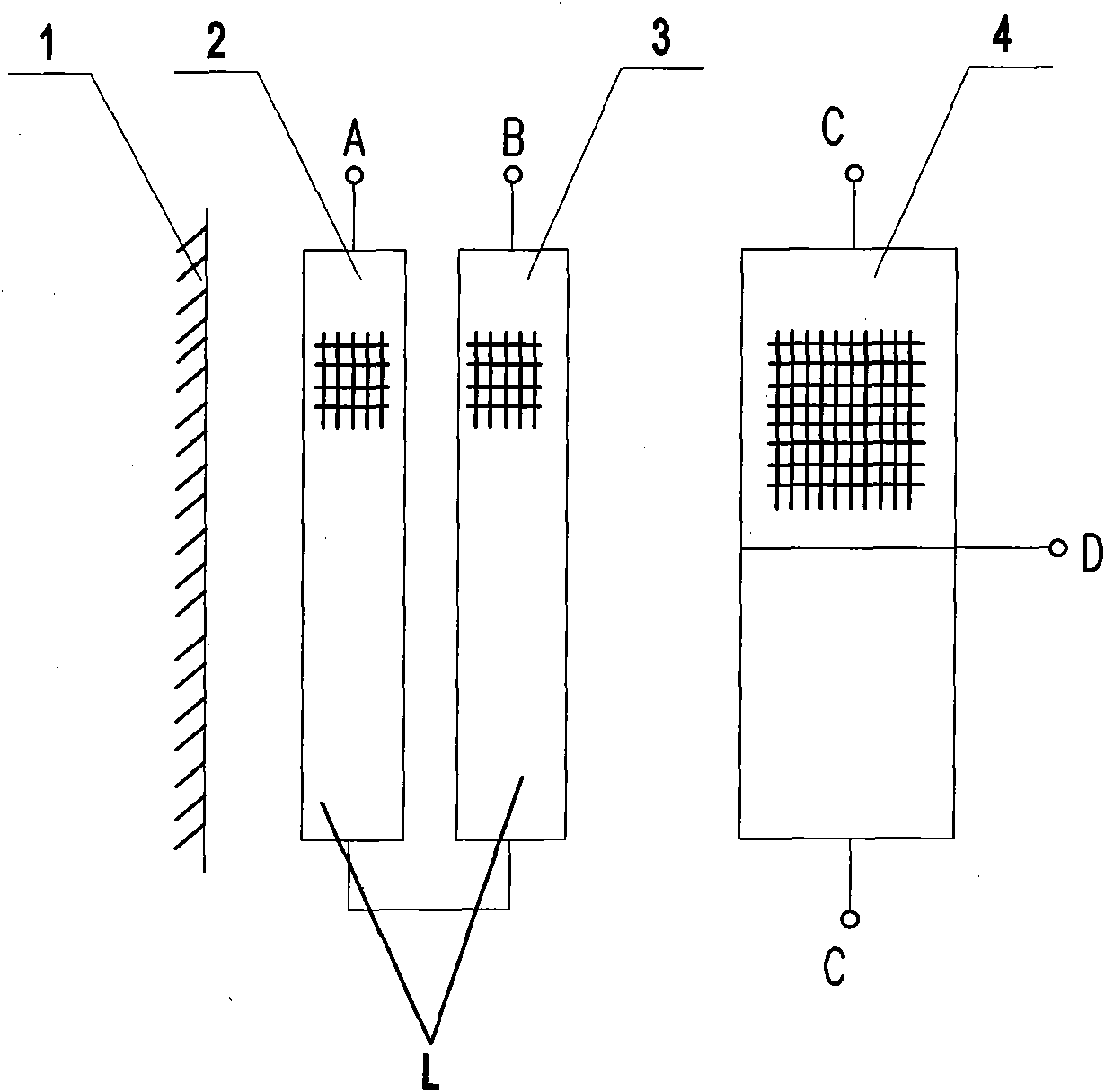

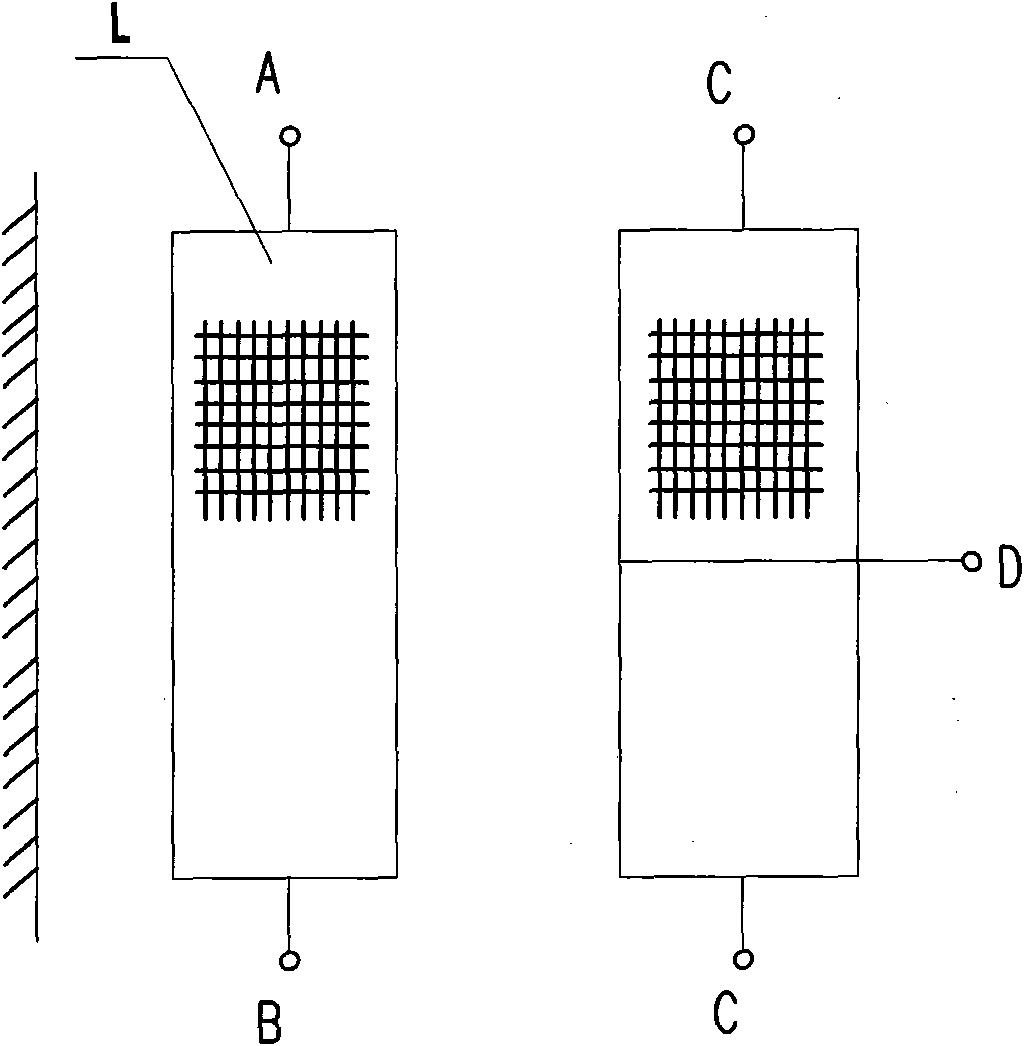

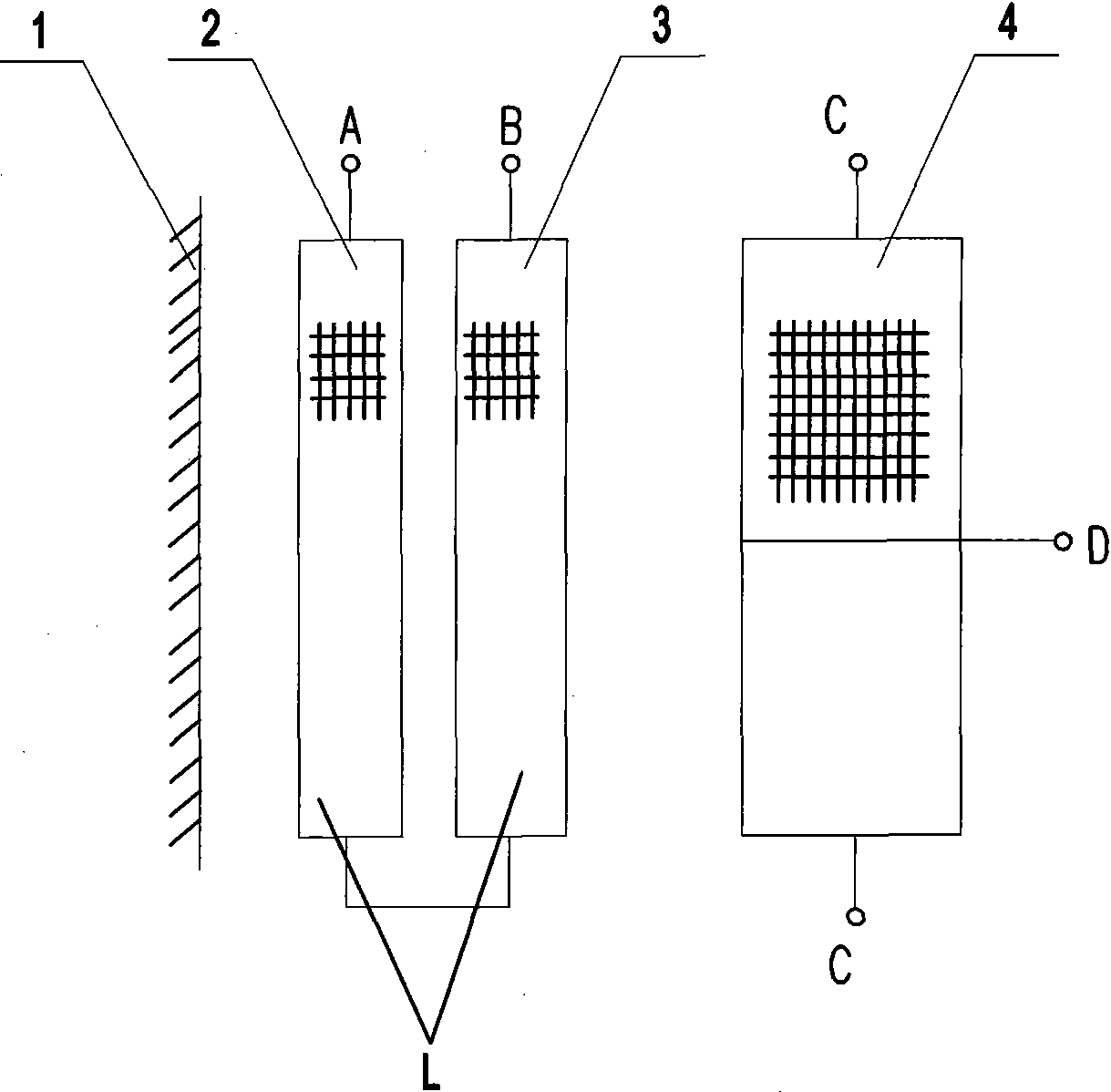

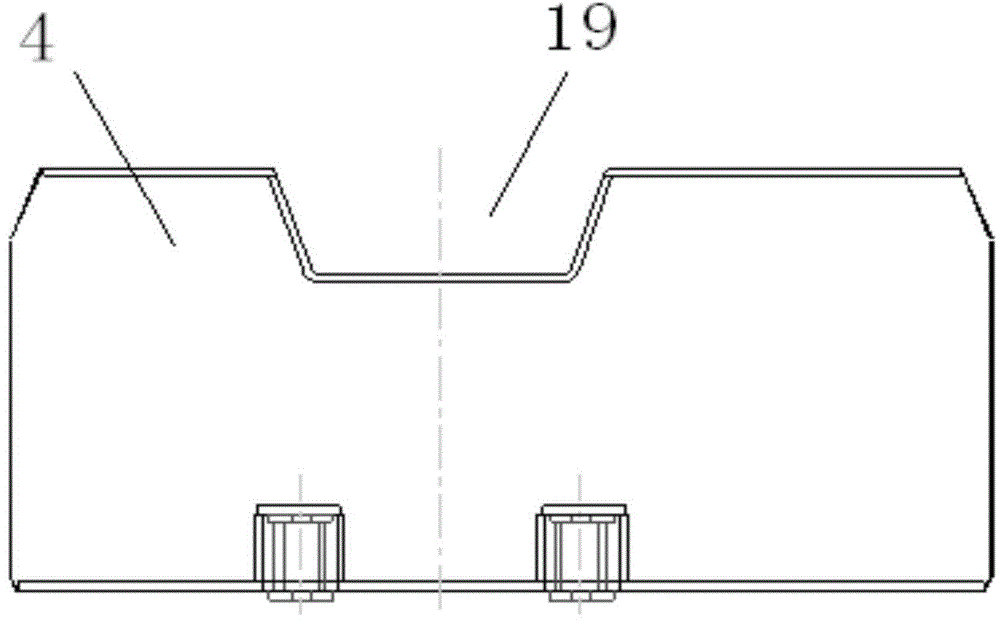

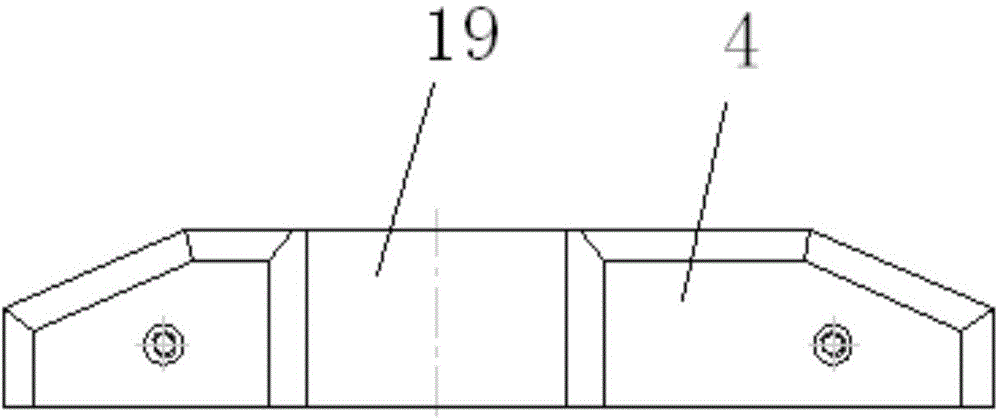

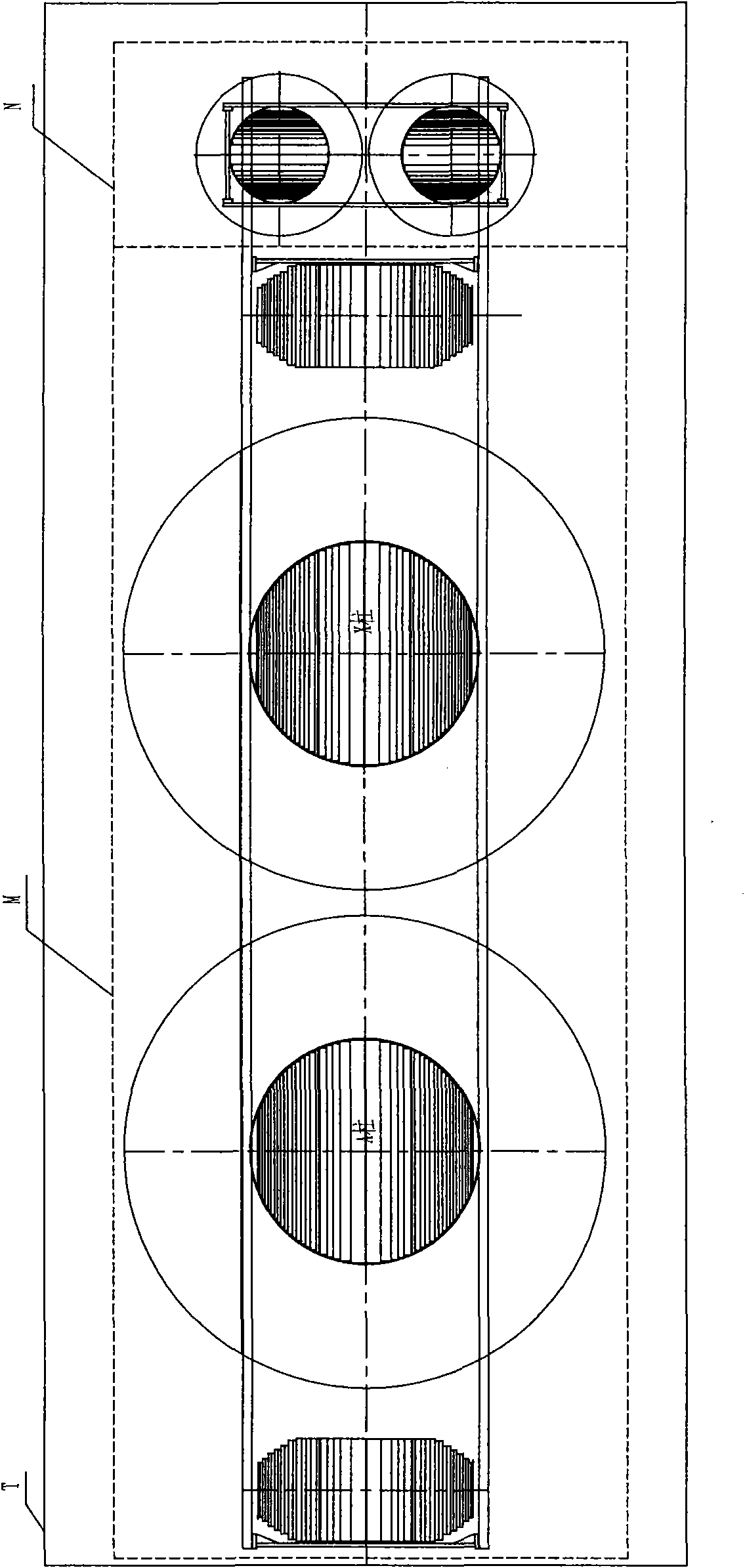

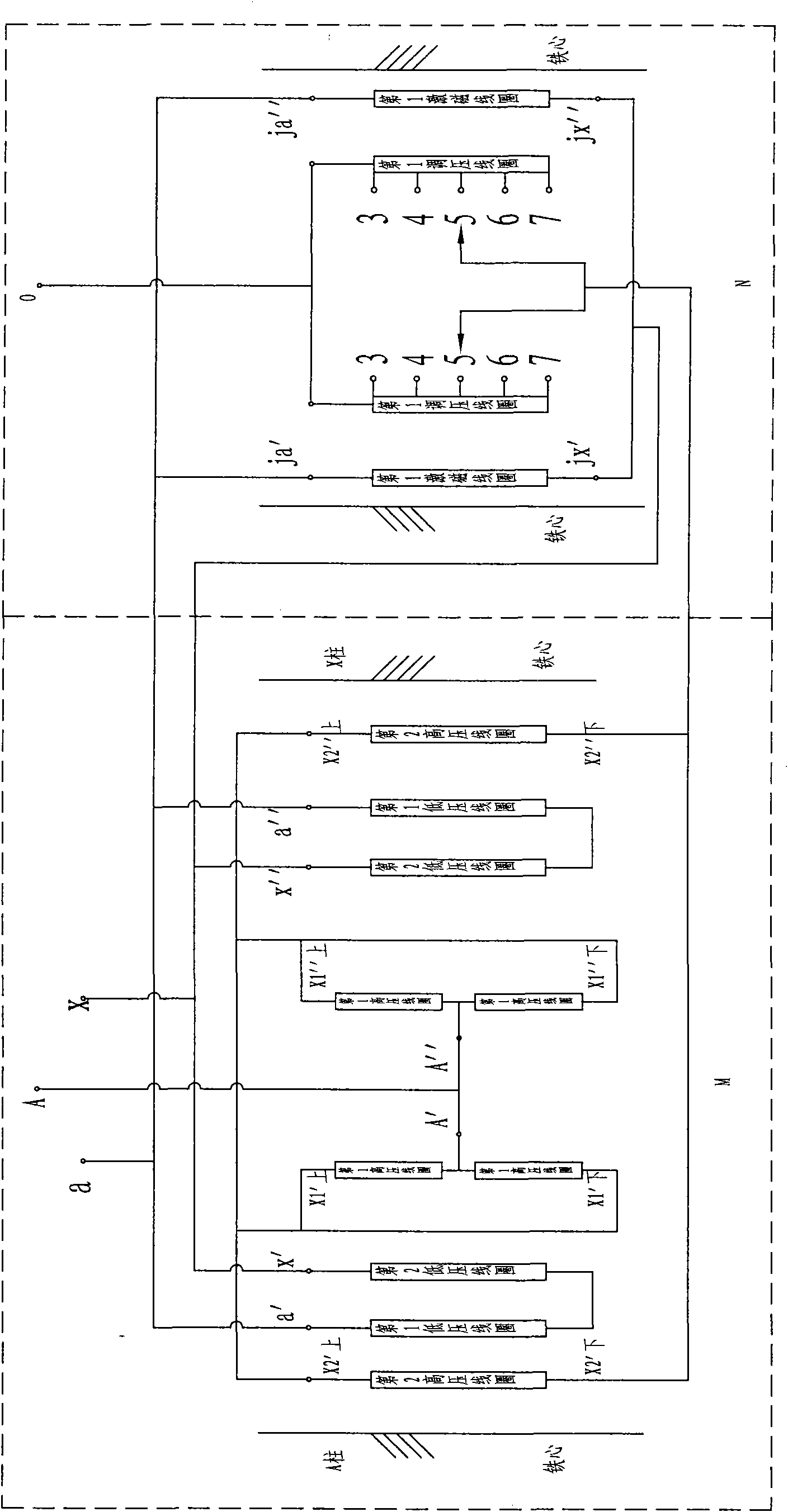

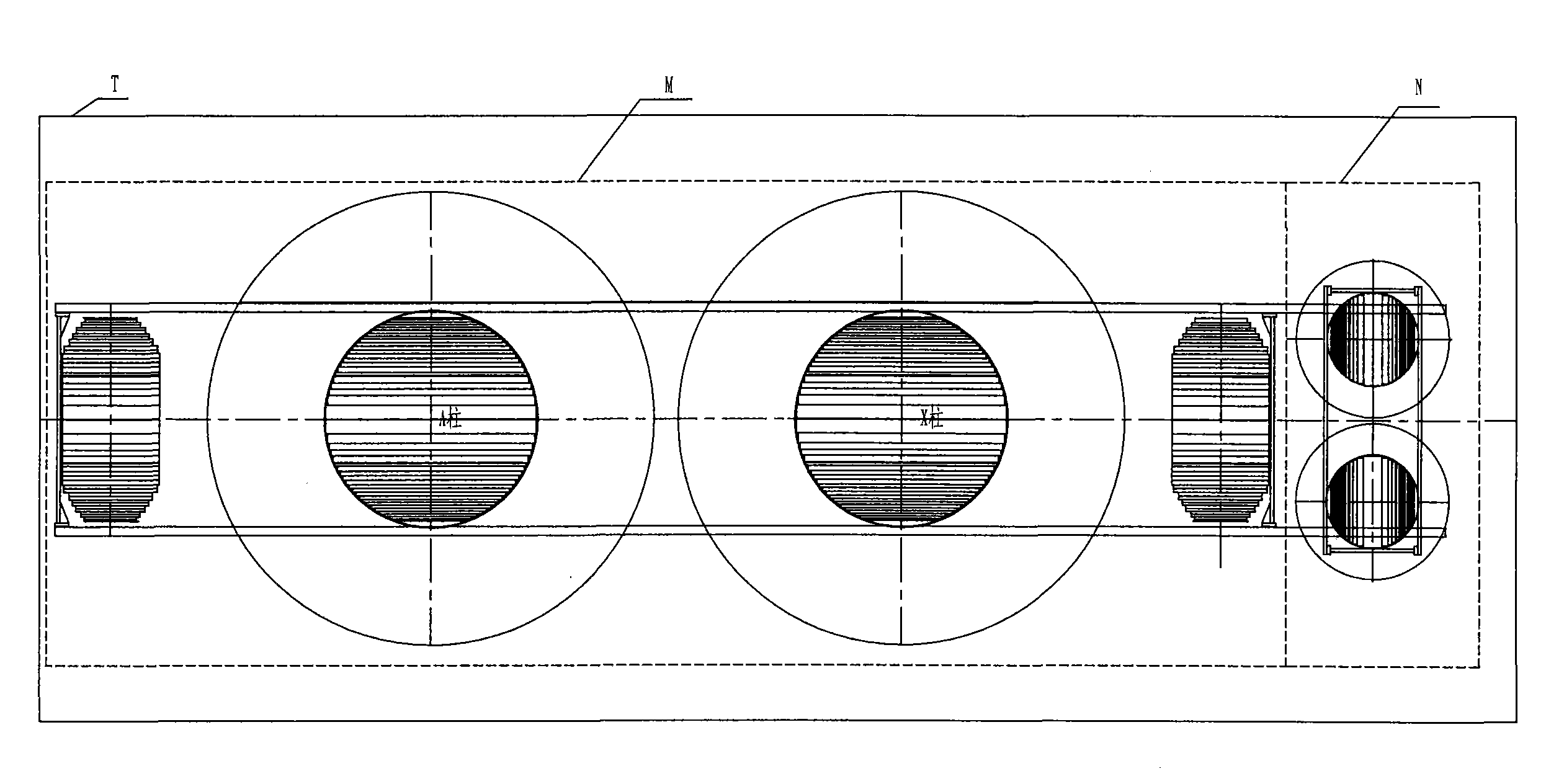

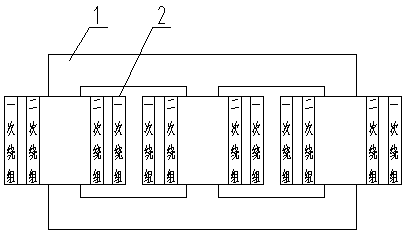

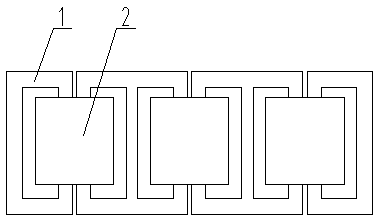

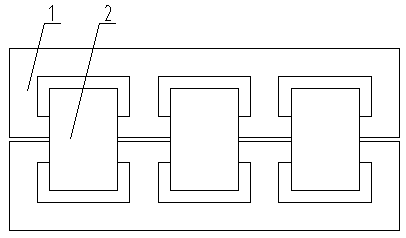

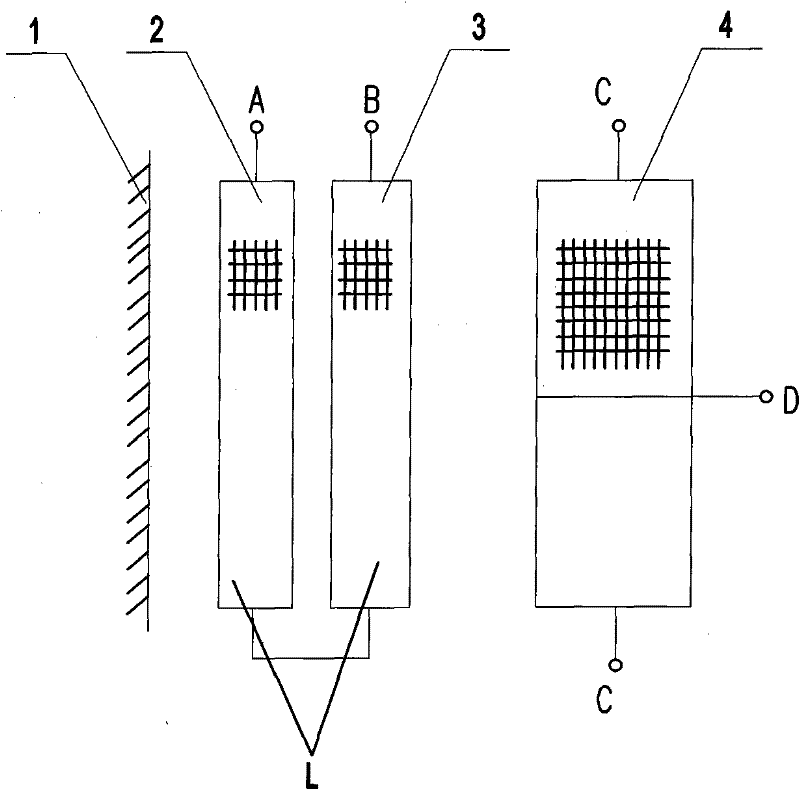

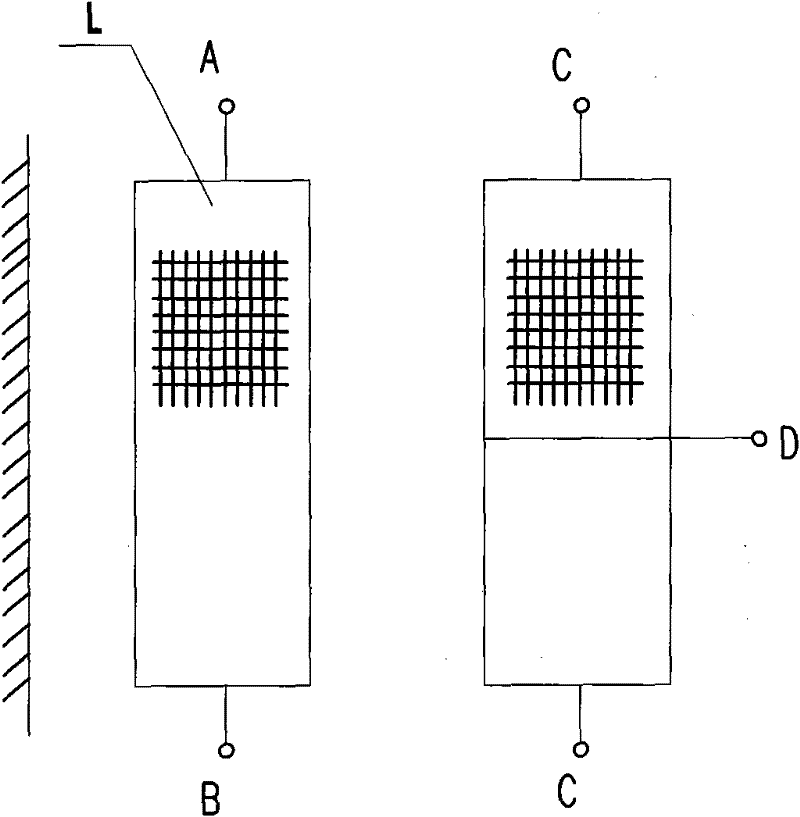

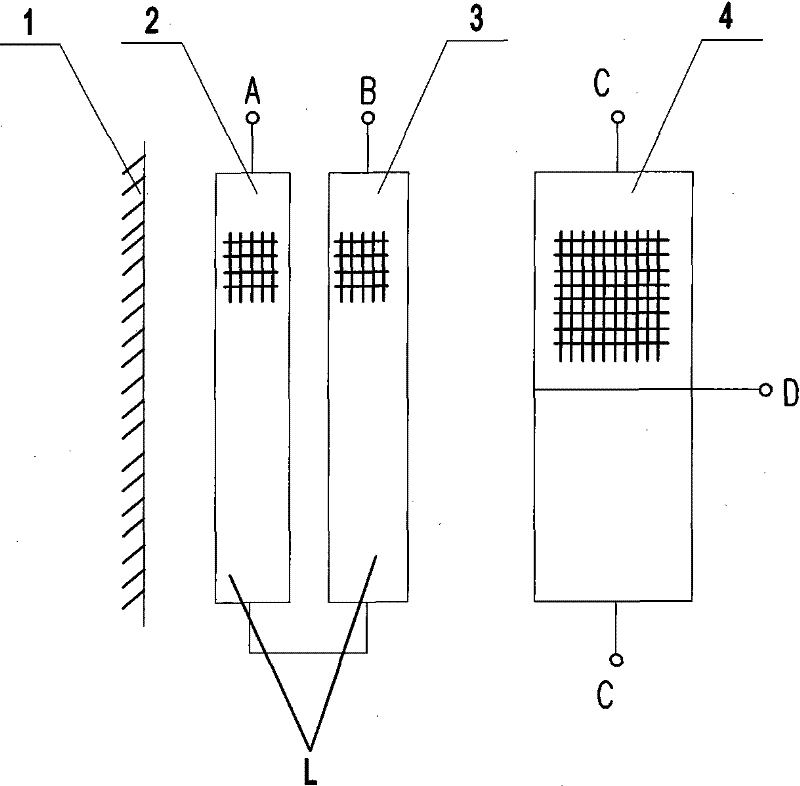

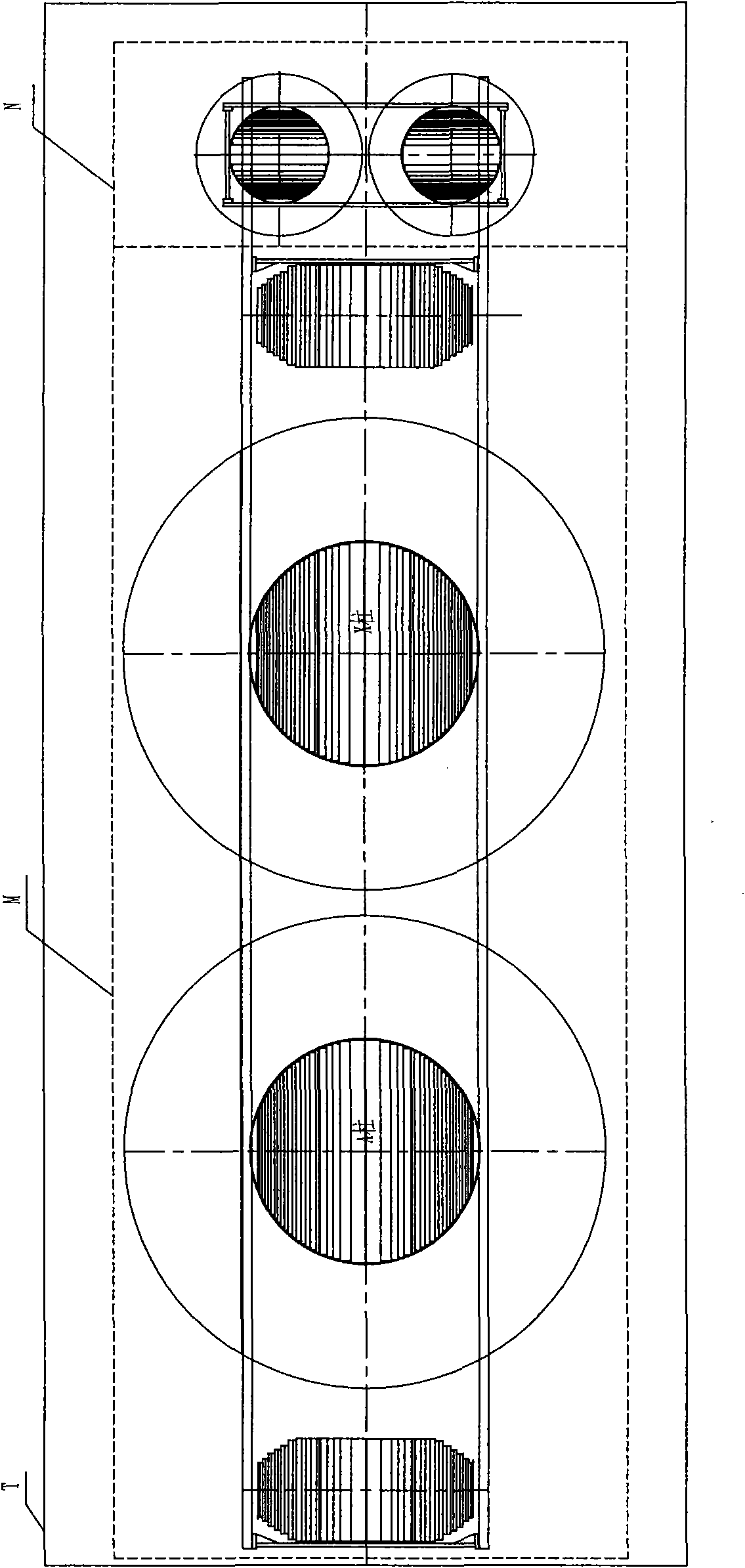

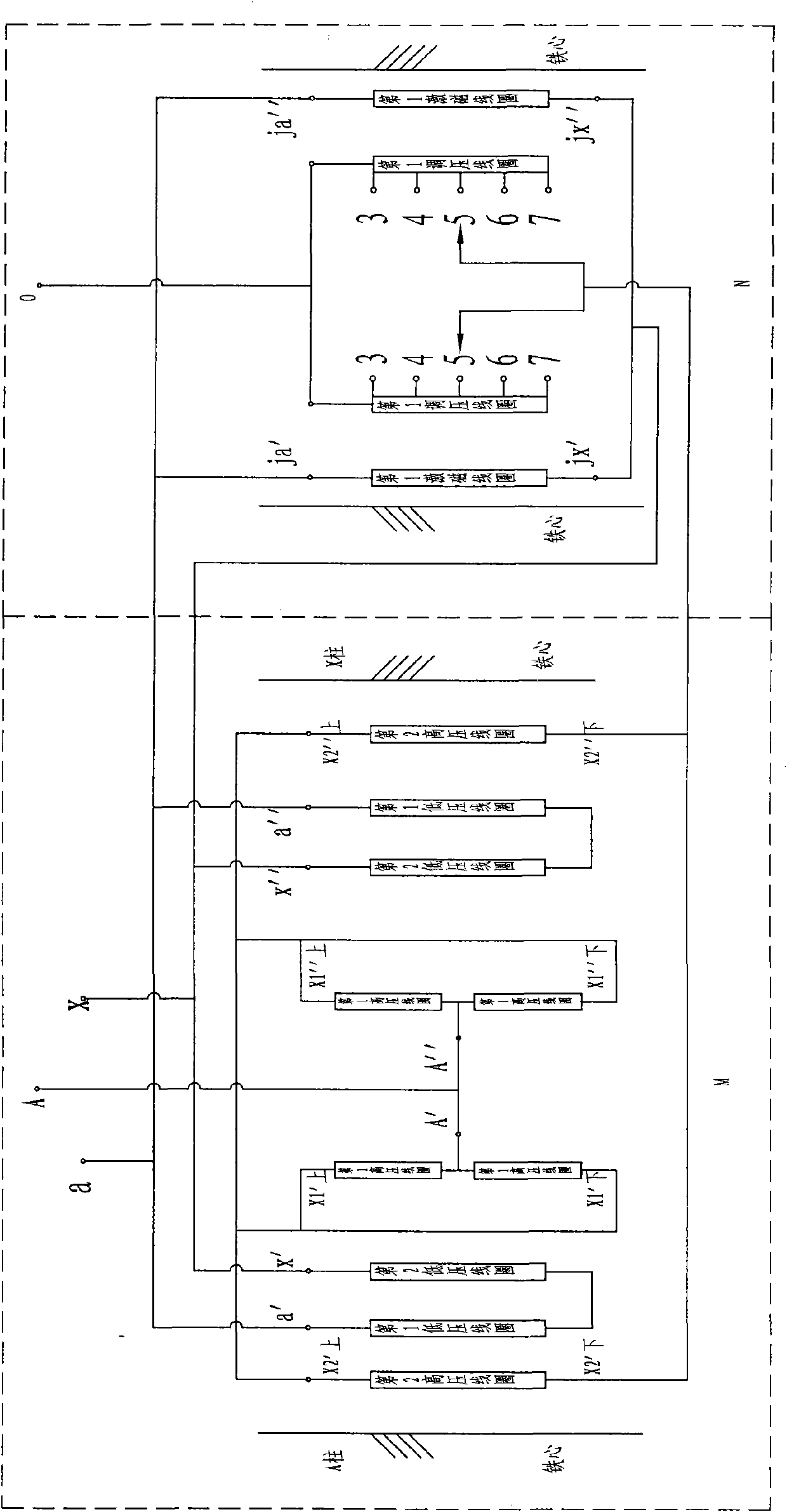

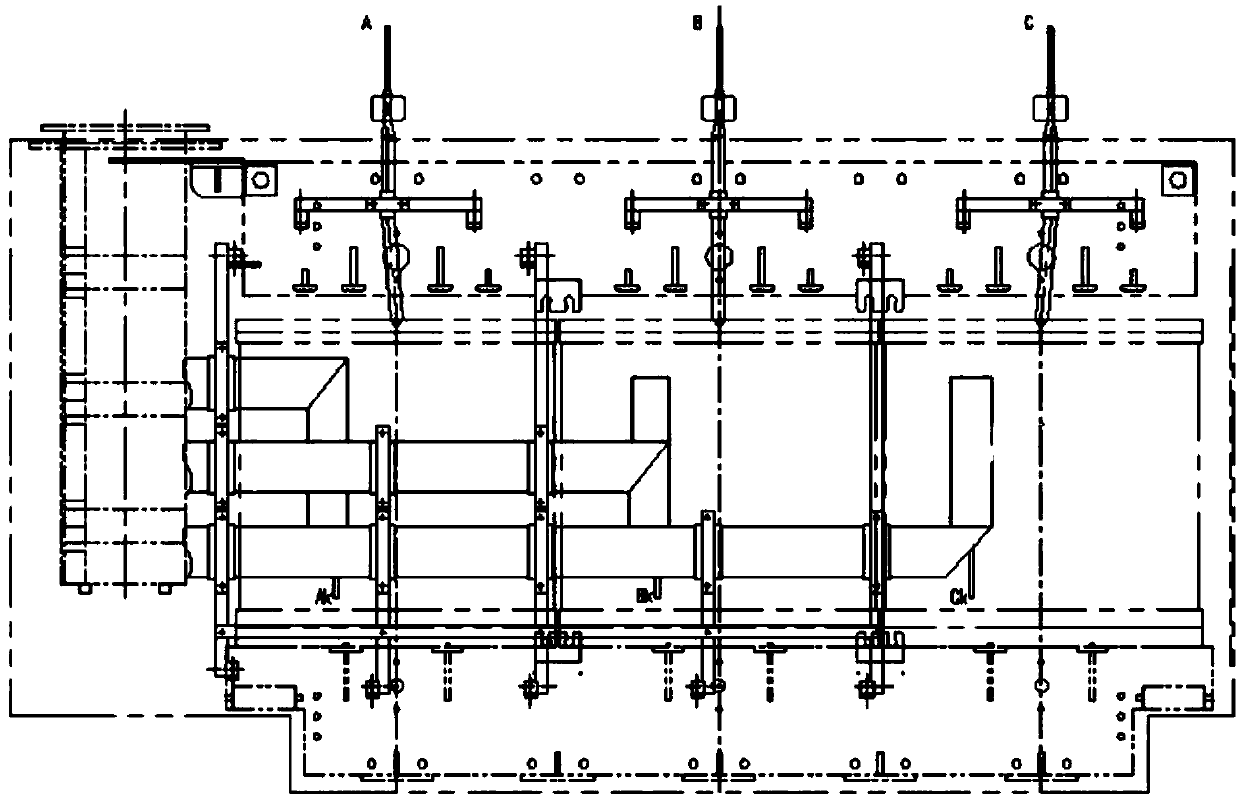

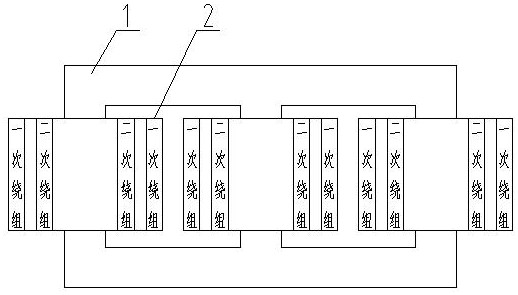

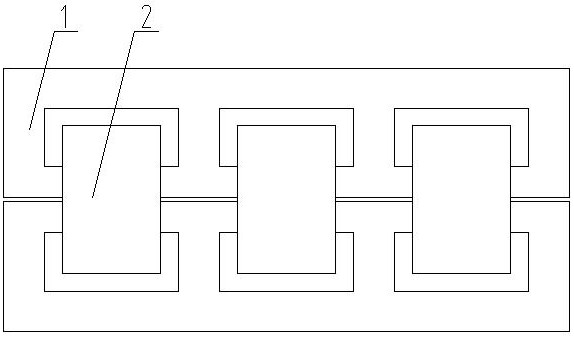

Three-phase generator transformer with super-large capacity

InactiveCN101984499ALower transport heightSolving Flux Leakage Suppression ProblemsTransformers/inductances coils/windings/connectionsTransformerLow voltage

The invention discloses a three-phase generator transformer with super-large capacity, which comprises an iron core, a low-voltage coil and a high-voltage coil and is characterized in that the low-voltage coil is divided into a first low-voltage coil branch and a second low-voltage coil branch which are connected in series, and the number of turns of the first low-voltage coil branch is equal to the number of turns of the second low-voltage coil branch; the iron core, the first low-voltage coil branch, the second low-voltage coil branch and the high-voltage coil are sequentially arranged from the inside to the outside; the two series branches namely the first low-voltage coil branch and the second low-voltage coil branch of the low-voltage coil are respectively in a double-layer multi-spiral structure formed by integrally winding self-adhesive transposed conductors; and the first low-voltage coil branch and the second low-voltage coil branch are separated by an oil clearance brace and an insulating cylinder. The invention not only can obviously lower the transport height of the transformer but also can well solve the problem of magnetic leakage inhibition of low-voltage super-large current leads, thereby improving the economy and the practicability of the three-phase generator transformer with super-large capacity.

Owner:JIANGSU SUNEL TRANSFORMER

Cutting machine

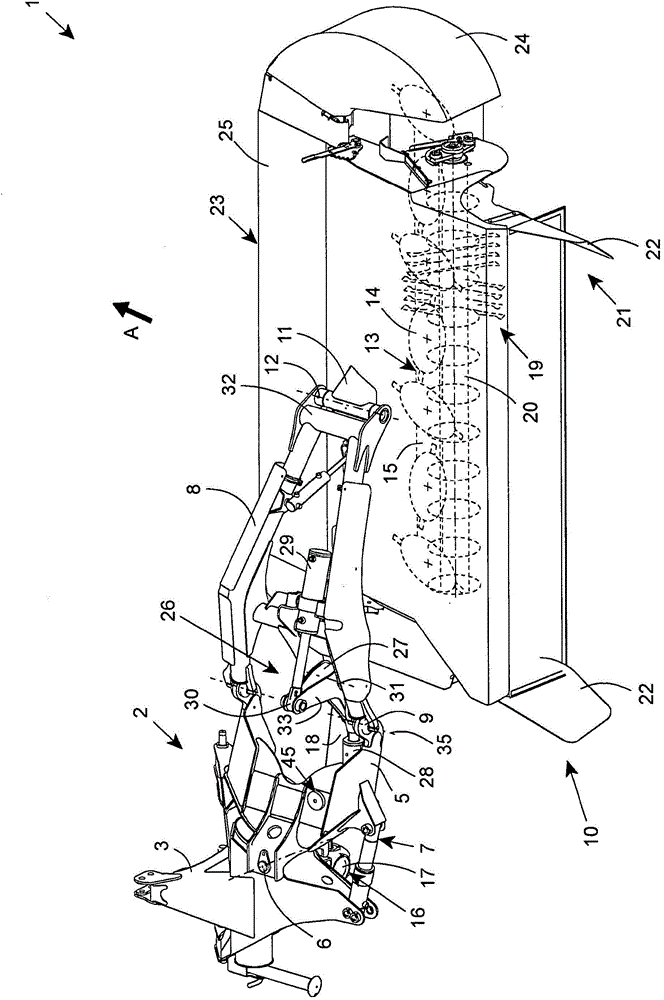

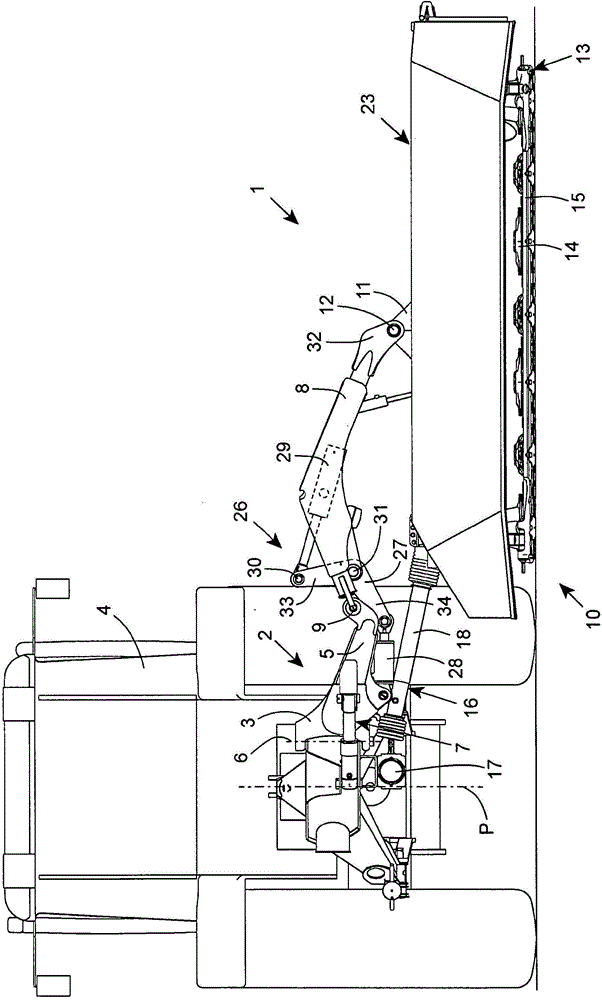

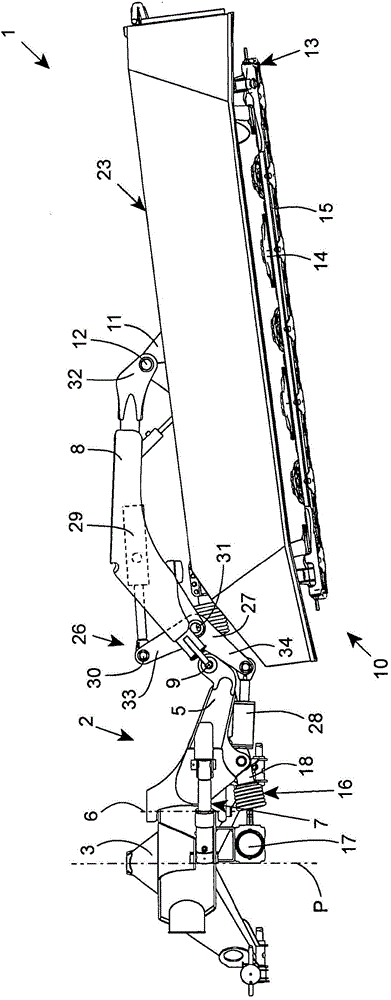

The present invention relates to a cutting machine (1) having a chassis (2) comprising a frame (5) and a hitch bracket (3) designed to be mounted on a three-point hitch of a tractor (4), and having an arm (8) connected directly to the frame (5) by a first joint (9) and extending, at least while operational, sideways relative to the frame (5), the arm (8) supporting a working member (10) and being capable, by means of a movement system (26), of being pivoted relative to the frame (5) between a working position, a manoeuvring position and a transport position, the movement system (26) comprising a connecting rod (27) and at least one first cylinder (28) pivotably connected between the frame (5) and the connecting rod (27) and a second cylinder (29) pivotably connected to the arm (8) and connected to the connecting rod (27) by means of a pivot (30). According to the invention, the connecting rod (27) is connected directly to the arm (8) by a second joint (31), and the second joint (31) is separate from the first joint (9).

Owner:KUHN SA

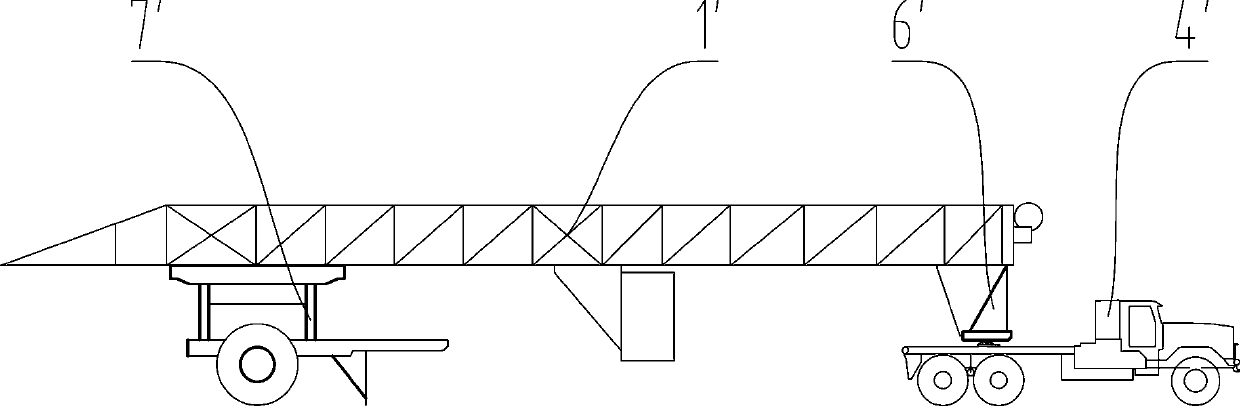

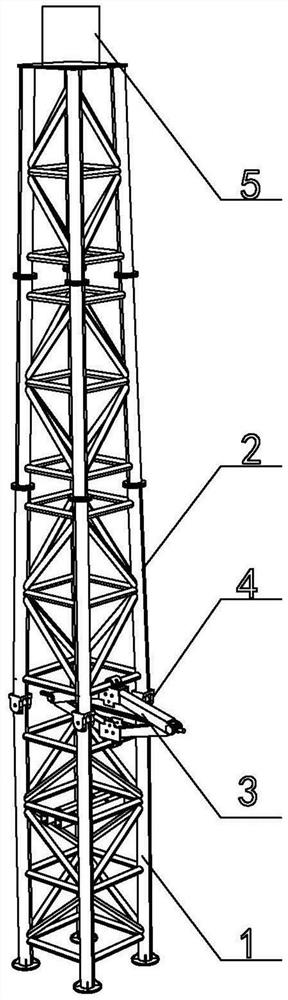

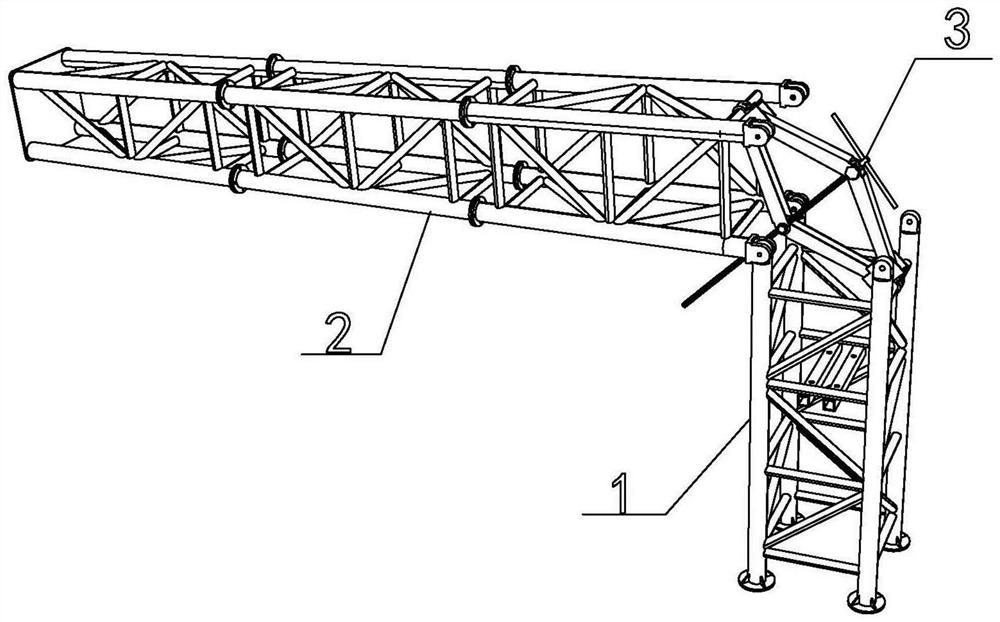

Tower type crane with double hoisting arm sections

The invention provides a tower type crane with double hoisting arm sections. The tower type crane comprises a tower body, a first arm section and a second arm section, wherein the first arm section is connected with the tower body, the second arm section is connected with the first arm section, and a folding mechanism is arranged between the first arm section and the second arm section; after being folded, the first arm section and the second arm section are in a level adjacent state under the effect of the folding mechanism. Compared with an old fixed hoisting arm tower machine, hoisting arms are mutually hinged and folded together through the folding mechanism, so that the transporting height is reduced, and the tower type crane is convenient to transport; the hoisting arm can be orderly unfolded from a folded state to the level state under the effect of a power system, the mounting time of the tower machine is greatly shortened, and the cost of a low-rise building and a plant building is reduced.

Owner:NANJING UNIV OF TECH +1

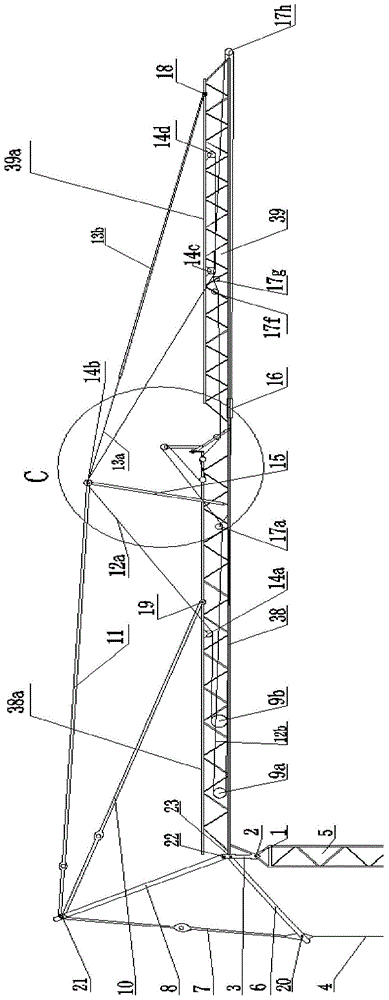

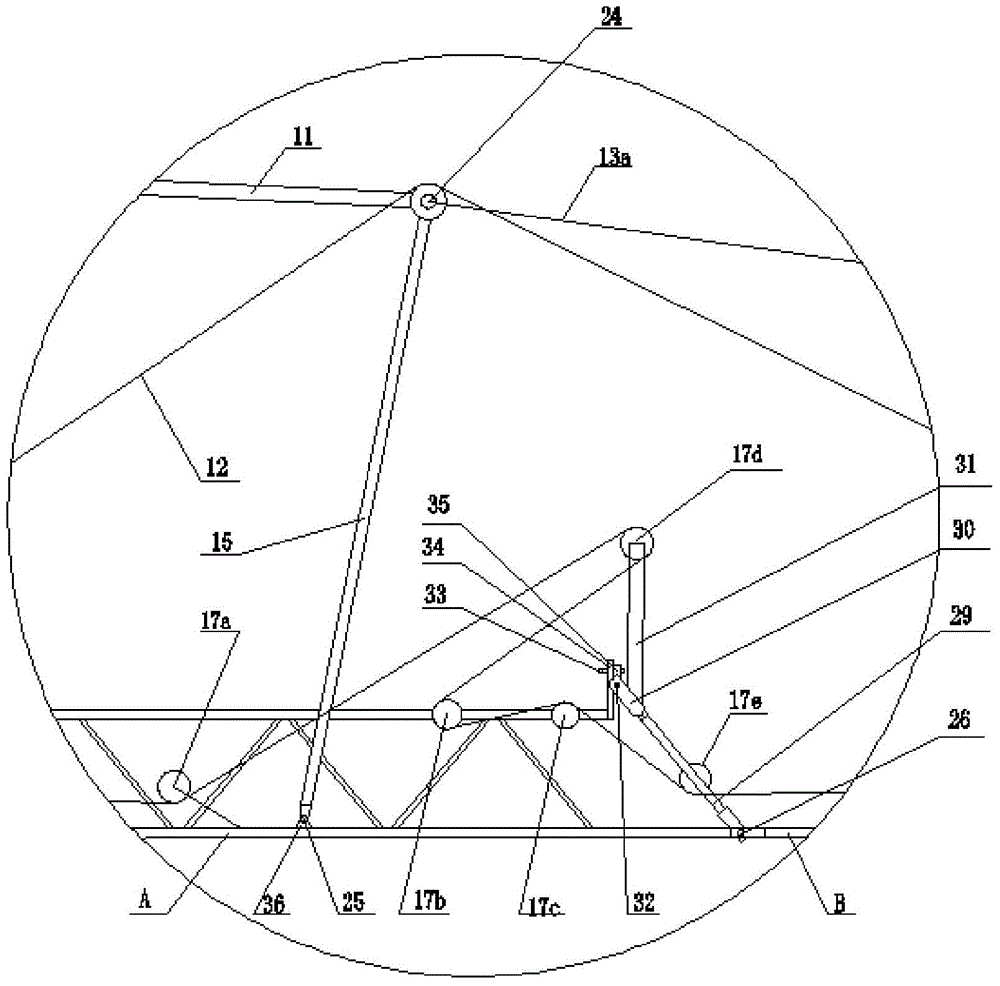

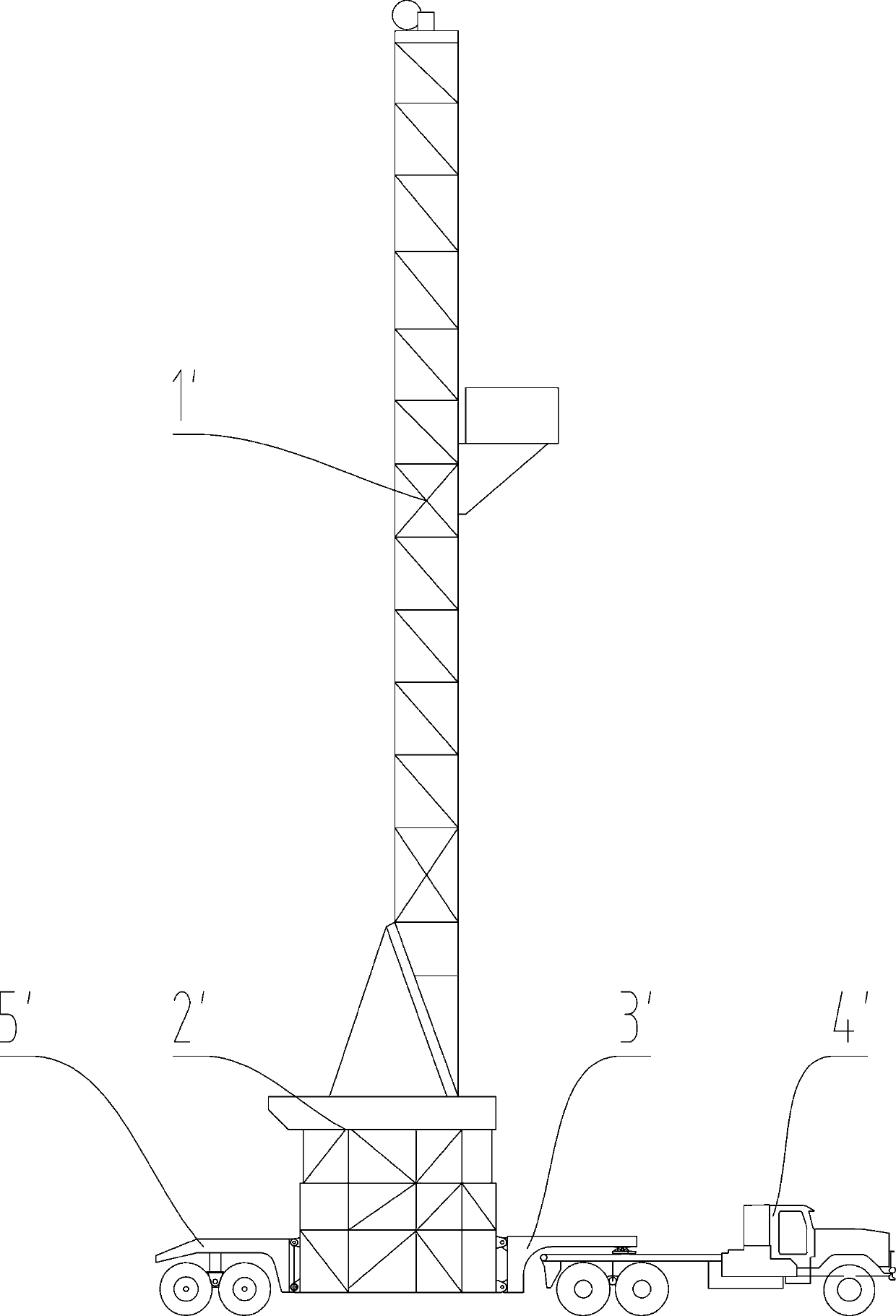

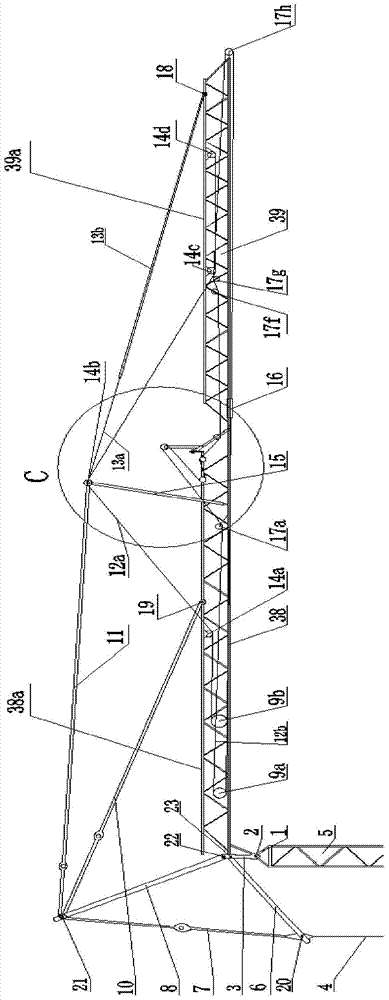

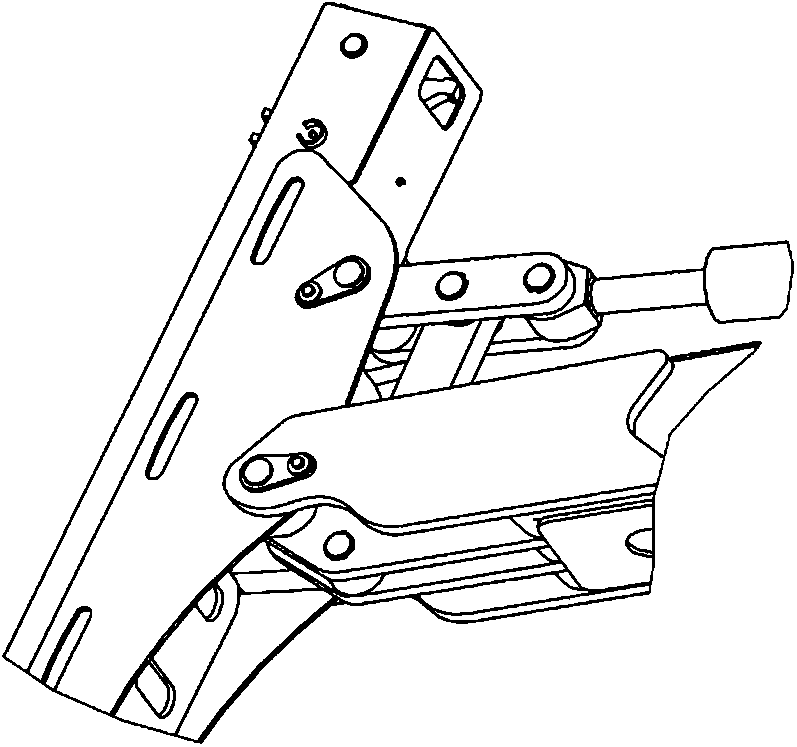

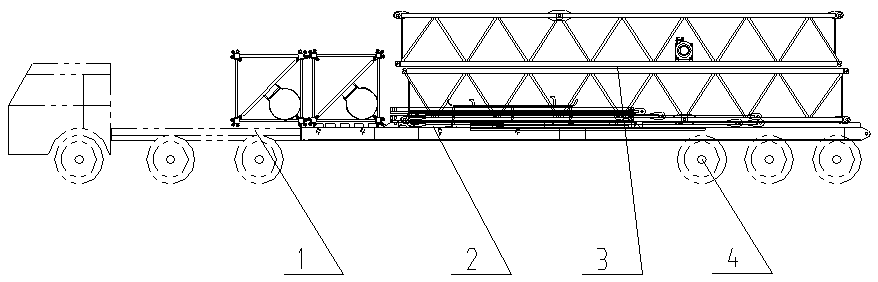

Pull-type drilling rig derrick base structure

PendingCN110185387AAvoid deformationLower transport heightDerricks/mastsDrilling machines and methodsHydraulic cylinderVehicle frame

The invention relates to the field of petroleum drilling and production equipment, in particular to an automated and modular pull-type drilling rig derrick base structure. The pull-type drilling rig derrick base structure comprises a base assembly connected with a foundation, a derrick assembly movably connected with the base assembly, and a trailer frame assembly movably connected with the base assembly and the derrick assembly, and further comprises connection fasteners movably connected with the base assembly, the derrick assembly and the trailer frame assembly correspondingly, jacking hydraulic cylinders fixedly connected with the trailer frame assembly or the base assembly, and supporting rods fixedly connected with the connection fasteners or the base assembly. The pull-type drillingrig derrick base structure has the beneficial effects that the turning radius is small, a using area is not limited, transferring can be conducted at a time, the mounting and carrying time is reduced, and automation and modularization are achieved.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

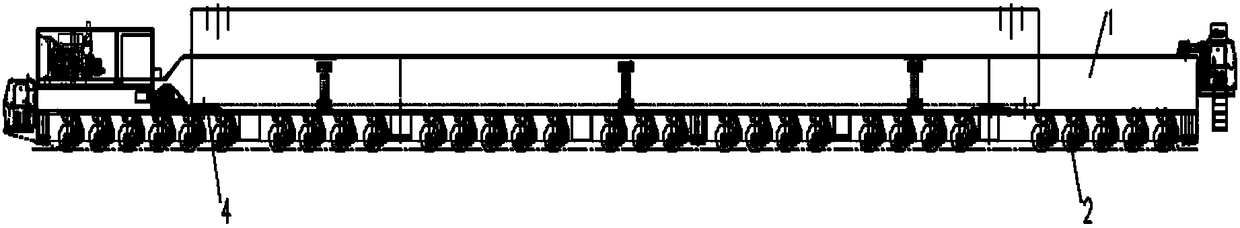

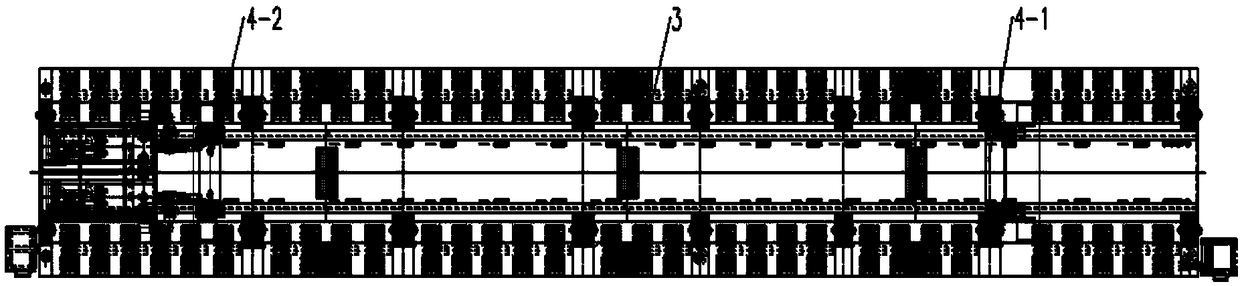

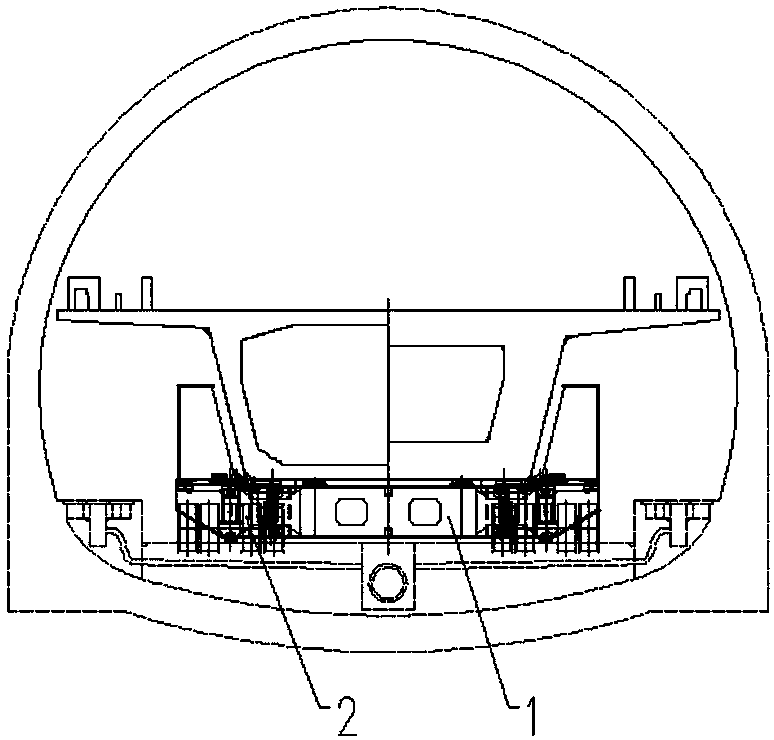

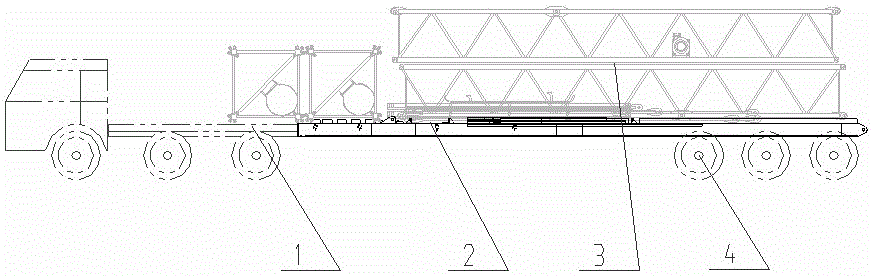

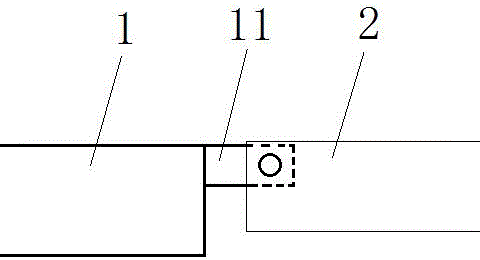

U-shaped tunnel-crossing beam transporting vehicle with adjustable wheel track and beam-feeding method of U-shaped tunnel-crossing beam transporting vehicle

The invention provides a U-shaped tunnel-crossing beam transporting vehicle with an adjustable wheel track and a beam-feeding method of the U-shaped tunnel-crossing beam transporting vehicle. The beamtransporting vehicle at least comprises a vehicle body, traveling wheel sets and a beam carrying trolley; the vehicle body comprises a middle beam located in the middle and two side beams located onthe two sides; a plurality of cross beams are arranged in the longitudinal direction of the middle beam in a penetrating mode at intervals; the two ends of the outer sides of the multiple cross beamsare connected to the lower ends of the side beams correspondingly, so that the U-shaped structure of the vehicle body is formed; the traveling wheel sets are located at the lower ends of the side beams of the vehicle body and detachably connected with the side beams of the vehicle body, and the lower ends of the side beams are provided with two supporting positions of the traveling wheel sets; andthe beam carrying trolley comprises a front beam carrying trolley body and a rear beam carrying trolley body which are detachably connected. Therefore, according to the U-shaped tunnel-crossing beamtransporting vehicle with the adjustable wheel track and the beam-feeding method of the U-shaped tunnel-crossing beam transporting vehicle, the space below the flanges of box girders is utilized to the greatest extent, the transporting height is decreased, the transporting requirement of the large-span large-tonnage box girders can be met, especially the requirements for tunnel-crossing transporting of the box girders can be achieved, the forward travelling range of the front trolley body is further expanded, and longitudinal stability when a front cart of a bridge erecting machine takes the girders is improved.

Owner:CHINA RAILWAY ENG MASCH RES & DESIGN INST CO LTD

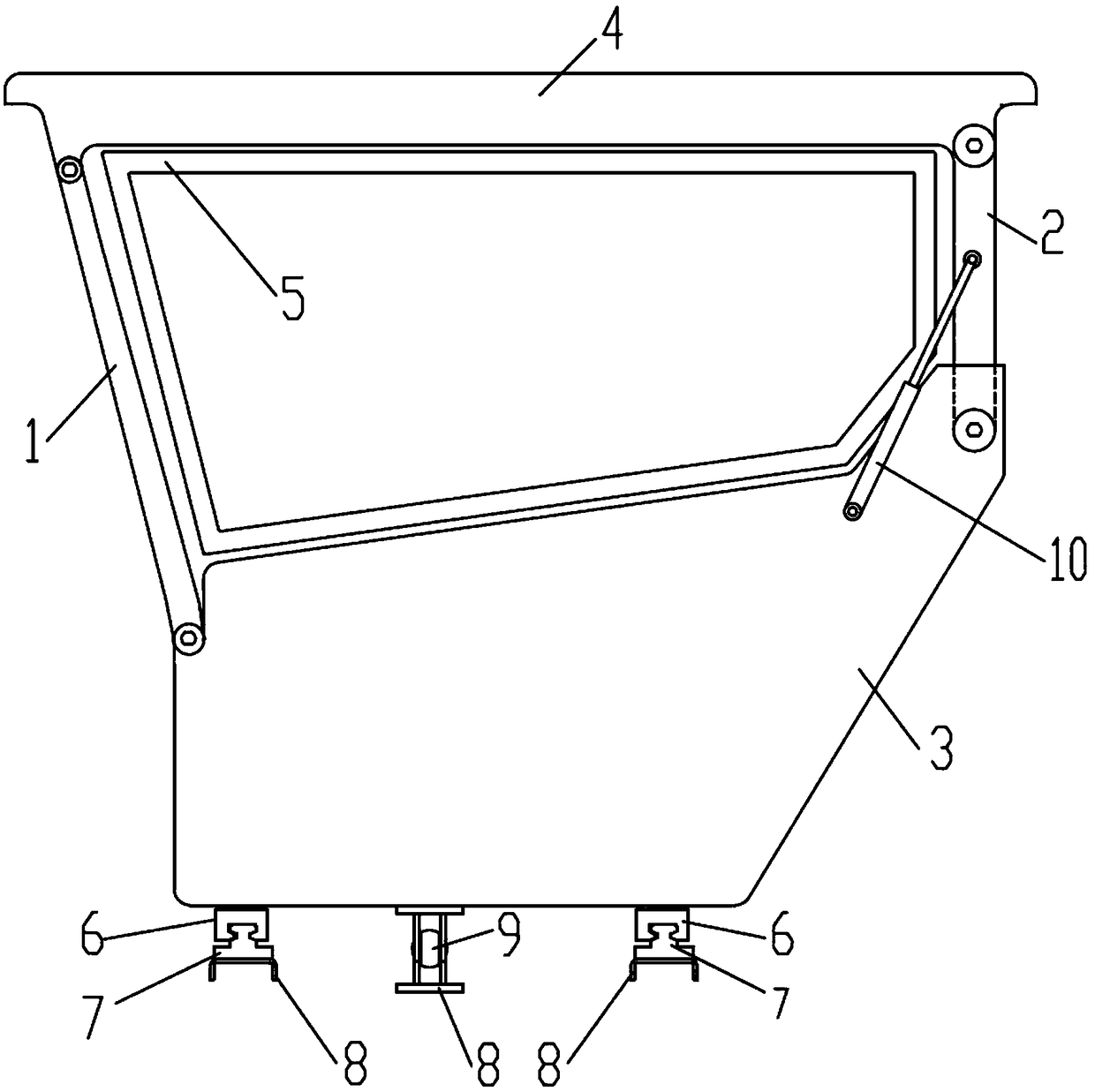

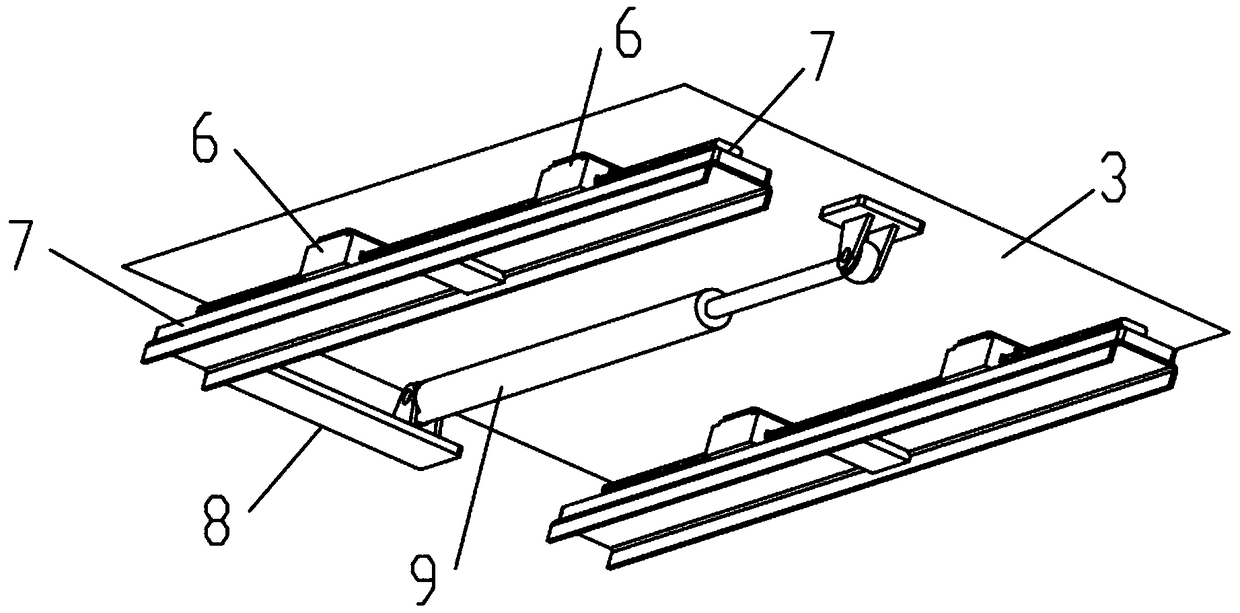

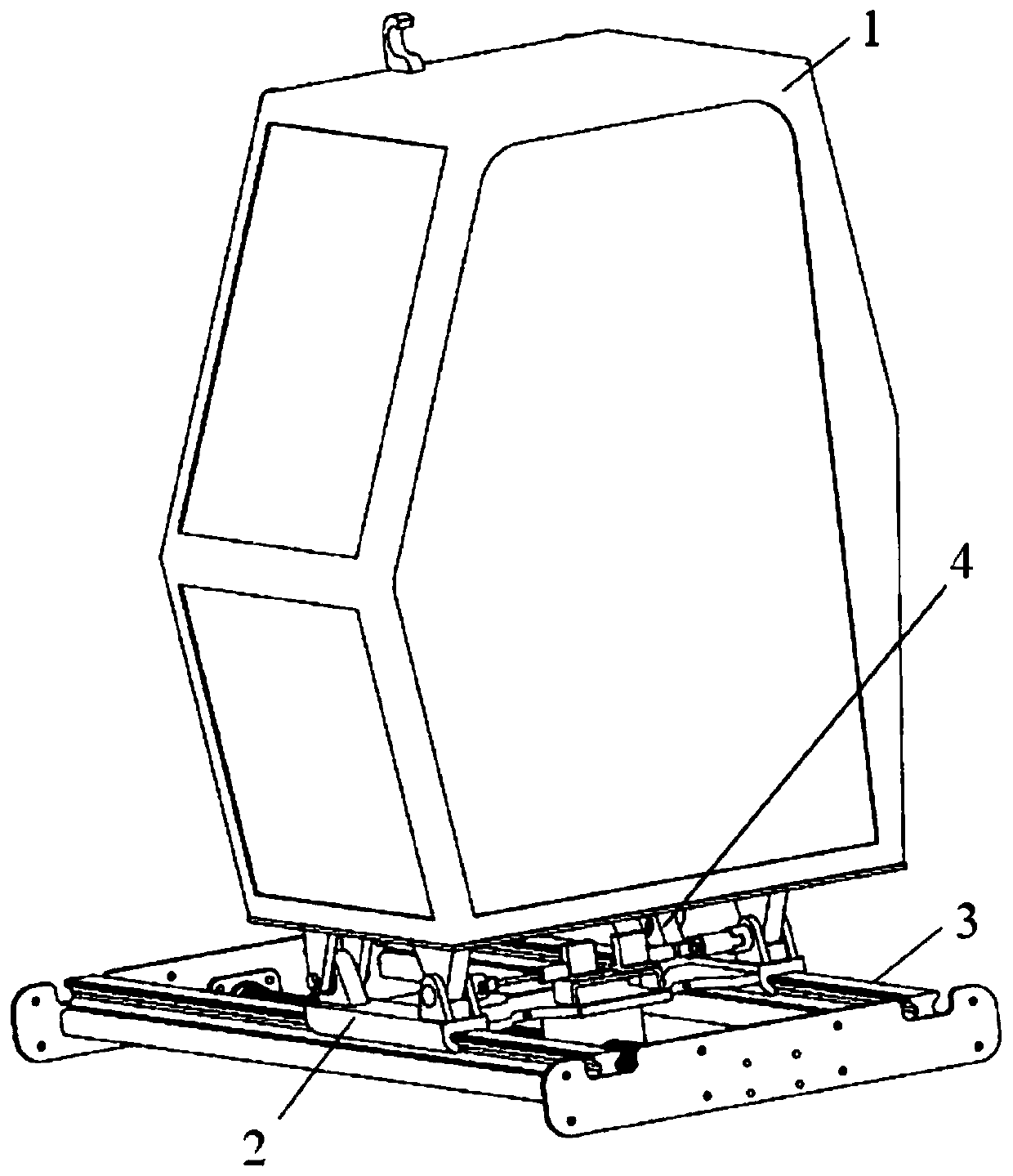

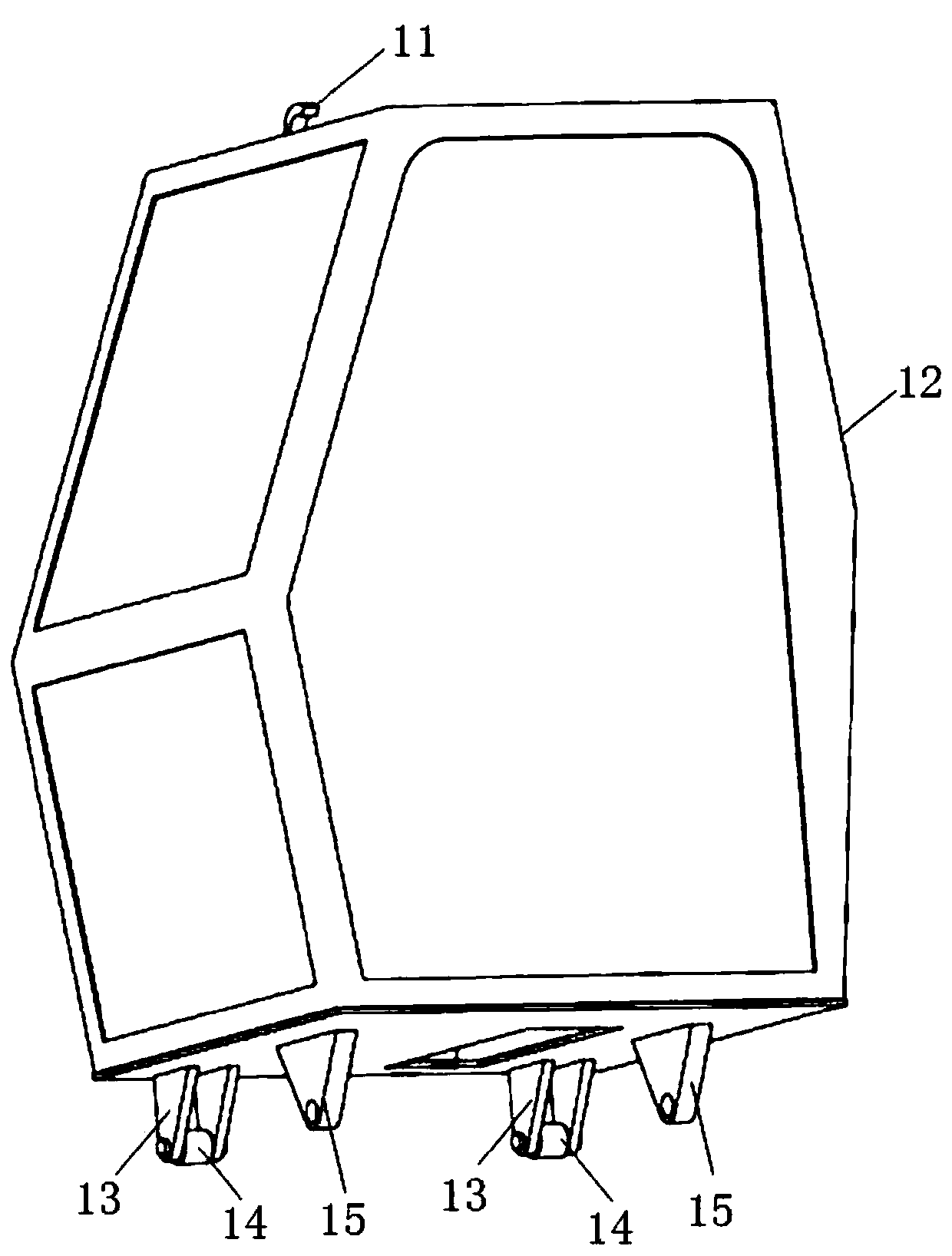

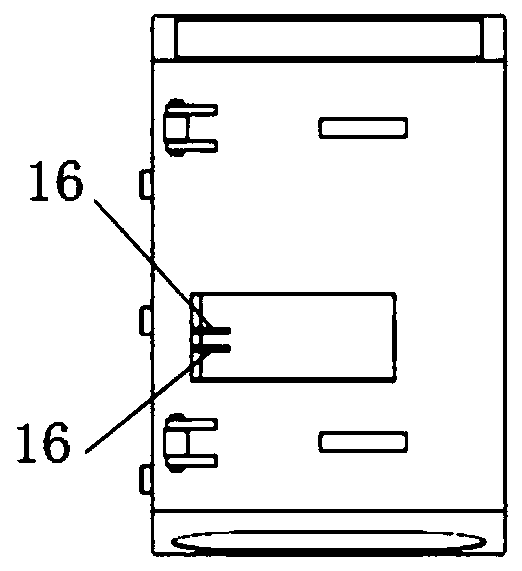

Foldable sliding driver cab and engineering machine with same

PendingCN109353416ALower transport heightExpand the operating horizonLoading-carrying vehicle superstructuresVehicle frameEngineering

The invention discloses a foldable sliding driver cab. The foldable sliding driver cab comprises a driver cab body mounted on a vehicle frame in a sliding mode; the driver cab body comprises a front frame, a rear frame, a lower frame and a top frame, wherein the top frame is hinged to the upper ends of the front frame and the rear frame, the lower ends of the front frame and the rear frame are hinged to the lower frame, and the front frame, the rear frame, the lower frame and the top frame form a four-bar linkage mechanism; the bottom of the lower frame is provided with a slider, the vehicle frame is provided with a sliding rail matched with the slider, and an oil cylinder I is arranged between the vehicle frame and the lower frame. The four-bar linkage mechanism composed of the front frame, the rear frame, the lower frame and the top frame can achieve folding and adjustment of overall transportation height of the foldable sliding driver cab; the driver cab body is provided with the slider, the vehicle frame is provided with the sliding rail, and sliding of the driver cab can be achieved through movement of the slider on the sliding rail to enlarge the operating view and improve the transportation convenience and operating comfort of an engineering machine.

Owner:XCMG CONSTR MACHINERY

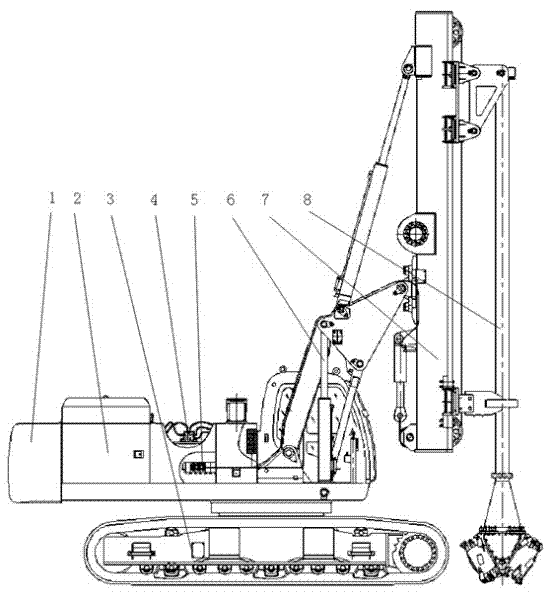

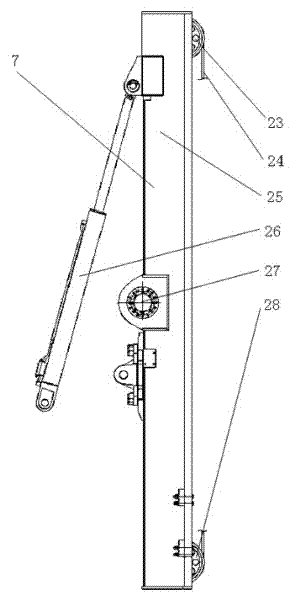

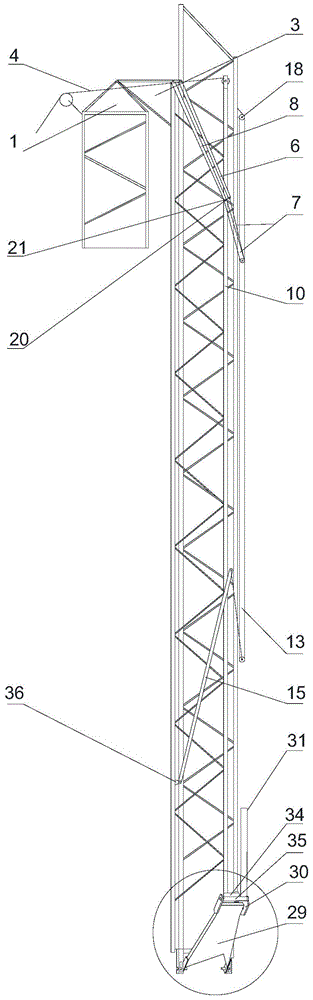

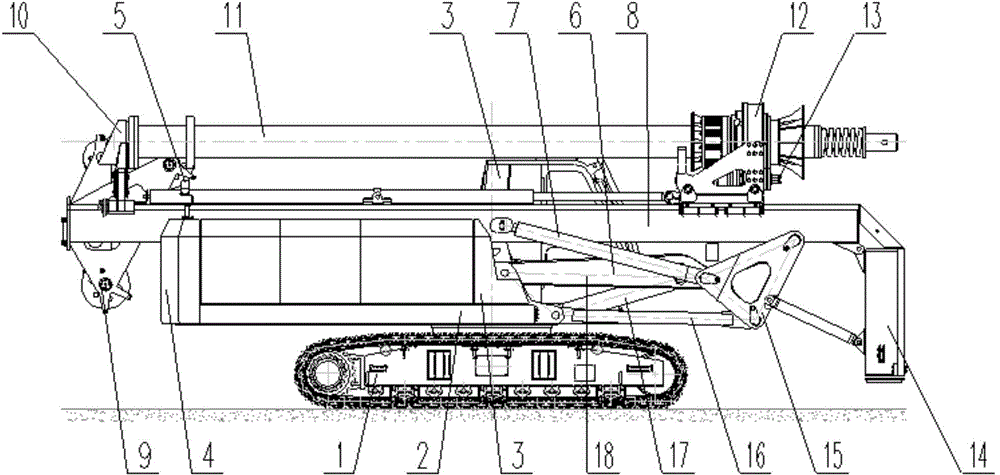

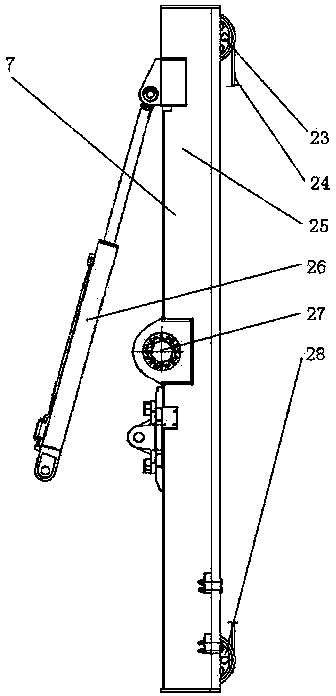

Rotary drilling rig capable of being fully transported with drill pipe

InactiveCN104153709ALabor savingShorten the timeDrilling rodsDerricks/mastsPetroleum engineeringBuilding construction

The invention discloses a rotary drilling rig capable of being fully transported with a drill pipe. The rotary drilling rig comprises a revolving platform (2), a weight (4), a jib luffing mechanism (6), a vertical mast cylinder (7), a mast (8), a follow frame (10), the drill pipe (11), a power head (12) and a lower mast (14); the follow frame (10) is fixedly connected with the mast (8) in transportation, and the drill pipe (11) is fixedly connected with the follow frame (10) and the power head (12) with no need of disassembling. By the arrangement, the drill pipe does not need to be disassembled when the rotary drilling rig is to be transported to other site, the masts can be directly erected for construction when the rotary drilling rig is transported to the construction site, hoisting equipment is not needed for assistance during the whole process, manpower is reduced, time is saved, construction efficiency is greatly improved, and construction cost is lowered.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

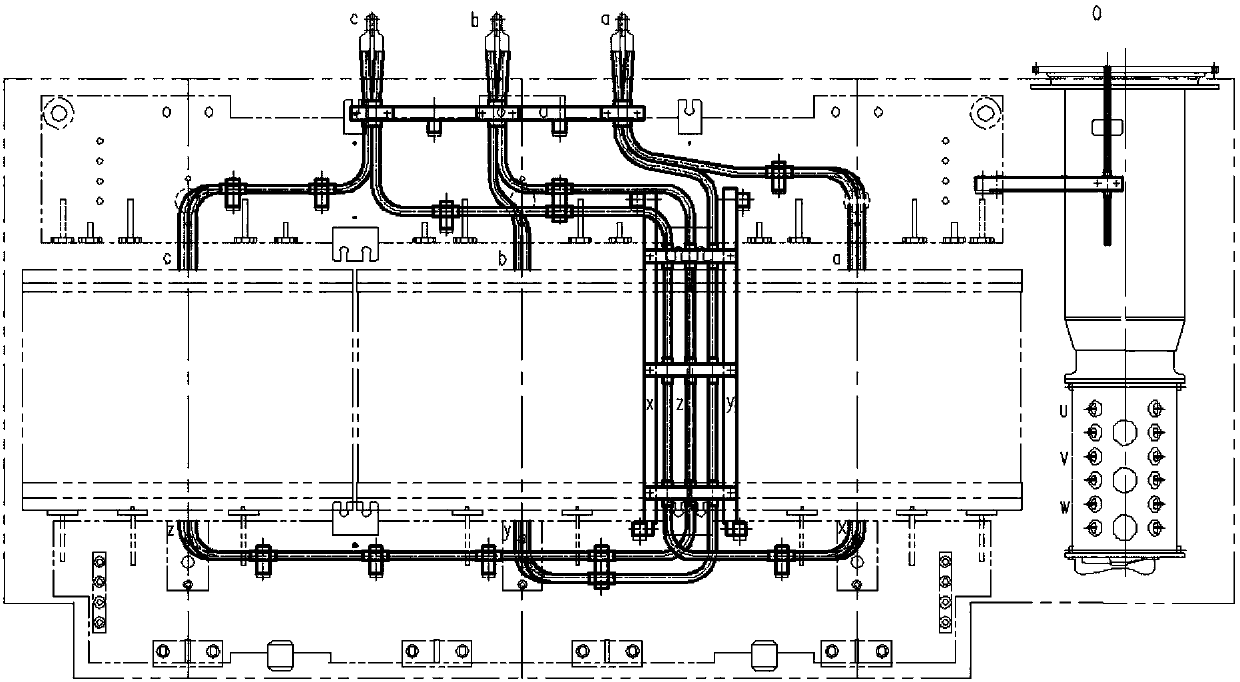

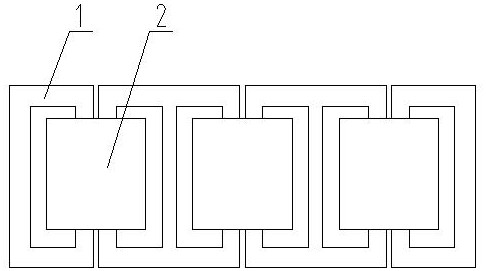

Step-up transformer with dual-body structure for ultra-high-voltage generator

ActiveCN102315005AImprove potential distributionImprove short circuit resistanceTransformers/inductances coils/windings/connectionsFixed transformersLow voltageUltra high voltage

The invention relates to a step-up transformer with a dual-body structure for an ultra-high-voltage generator. The transformer comprises a main body and a voltage regulating body which are arranged in the same oil tank of the transformer, wherein the iron core of the voltage regulating body is of a double-core-column structure; a first exciting coil and a first voltage regulating coil are sheathed on one core column; a second exciting coil and a second voltage regulating coil are sheathed on the other core column; the first exciting coil and the second exciting coil are connected in parallel to form an exciting coil which is in parallel connection with a low-voltage coil in the main body and is led out. According to the invention, a branching section of a high-voltage coil is not used, a voltage-regulating coil is arranged separately and is arranged on the other body; based on low-voltage exciting, the transformer does not regulates voltage in rated branching operation and regulates voltage only in the limit branching operation, therefore the electric potential distribution of the coil is improved, and the short-circuit resistant capability of the transformer is improved.

Owner:TBEA SHENYANG TRANSFORMER GRP CO LTD +1

Rollover sliding type cab and engineering machinery provided with the same

PendingCN111017046ALower transport heightExpand the operating horizonLoading-carrying vehicle superstructuresRolloverControl theory

The invention discloses a rollover sliding type cab which comprises a cab body, a sliding base, a guide rail seat and a rollover oil cylinder. One end of the cab body is hinged to the sliding base, the other end of the cab body is connected with the sliding base through the rollover oil cylinder; the cab body is driven by the rollover oil cylinder to rotate along the hinge point, so that rolloverof the cab body on the sliding base is achieved. The sliding base is installed on the guide rail seat in a sliding mode and drives the cab body to slide along the guide rail seat. According to the invention, when the whole cab is transported, the transportation height of the whole cab can be reduced, the cab can slide according to needs, and the operation view of an operator is enlarged. Accordingto the cab, the transportation convenience and the operation comfort of engineering machinery are improved.

Owner:XCMG CONSTR MACHINERY

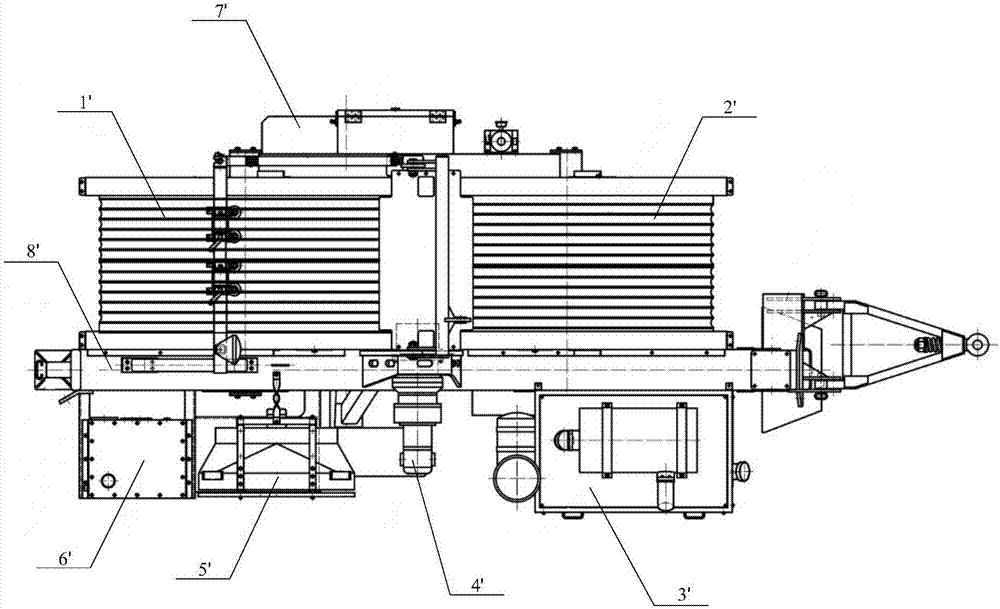

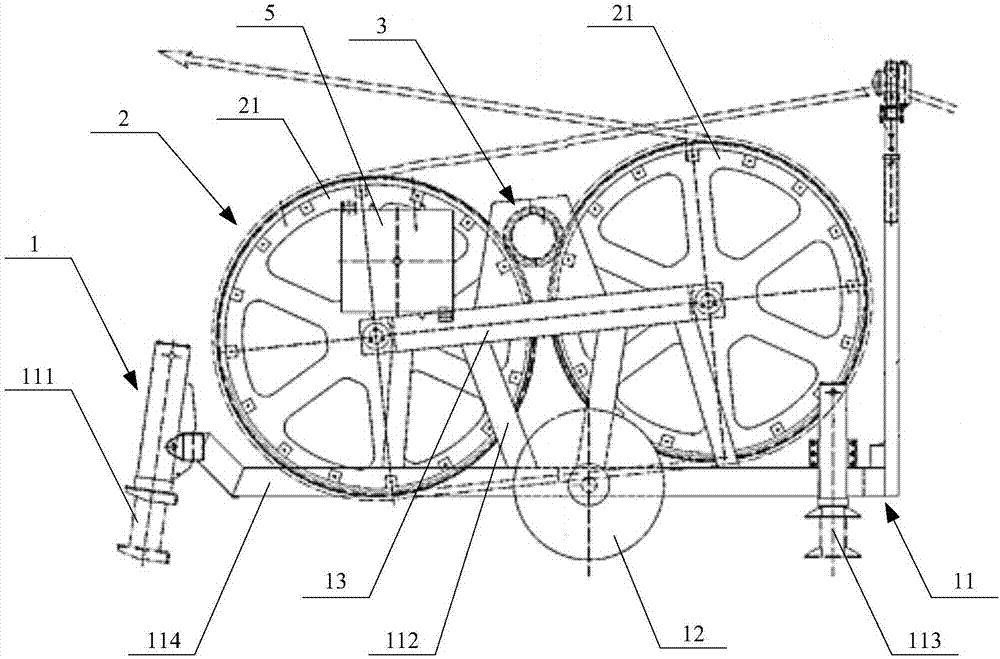

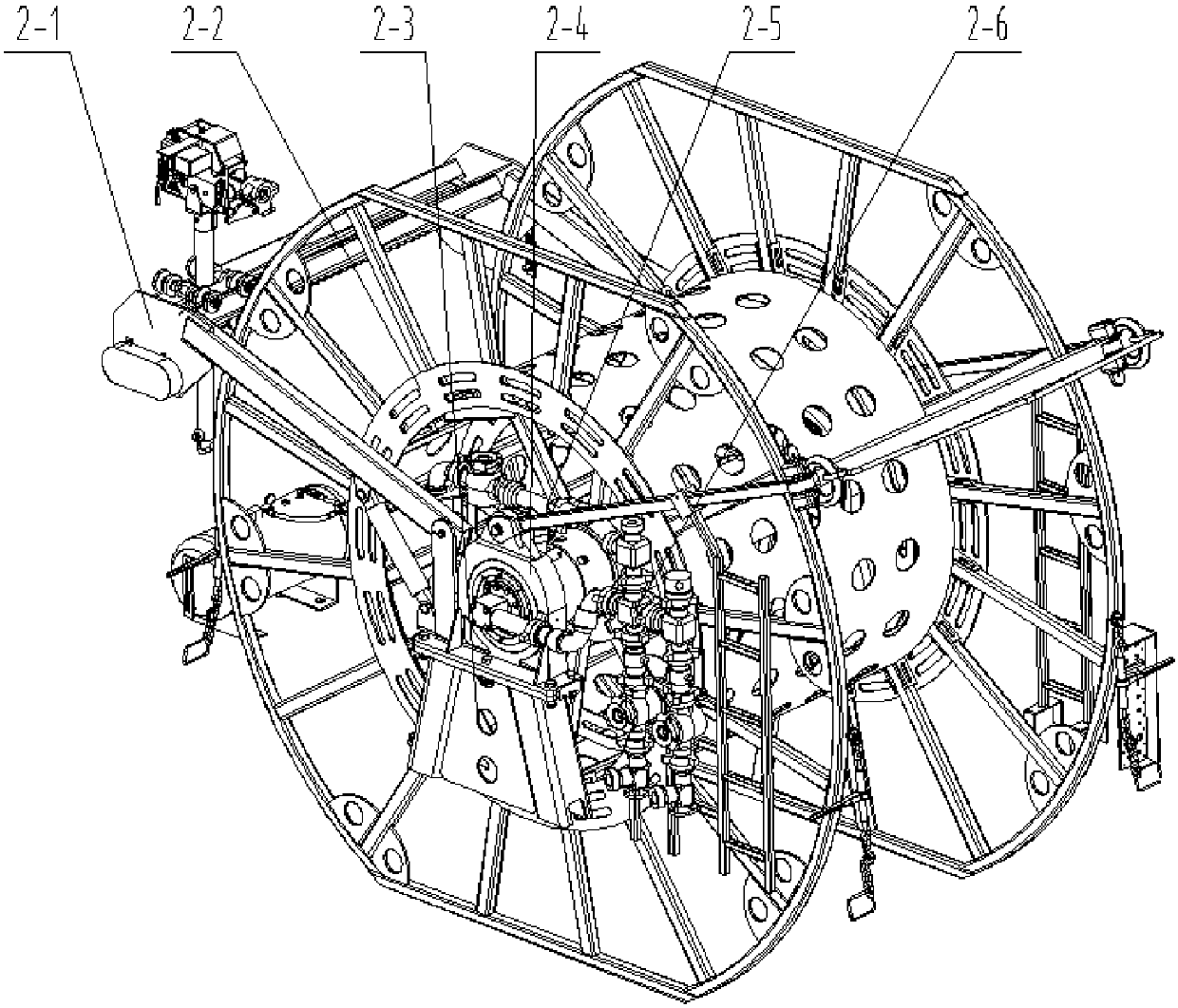

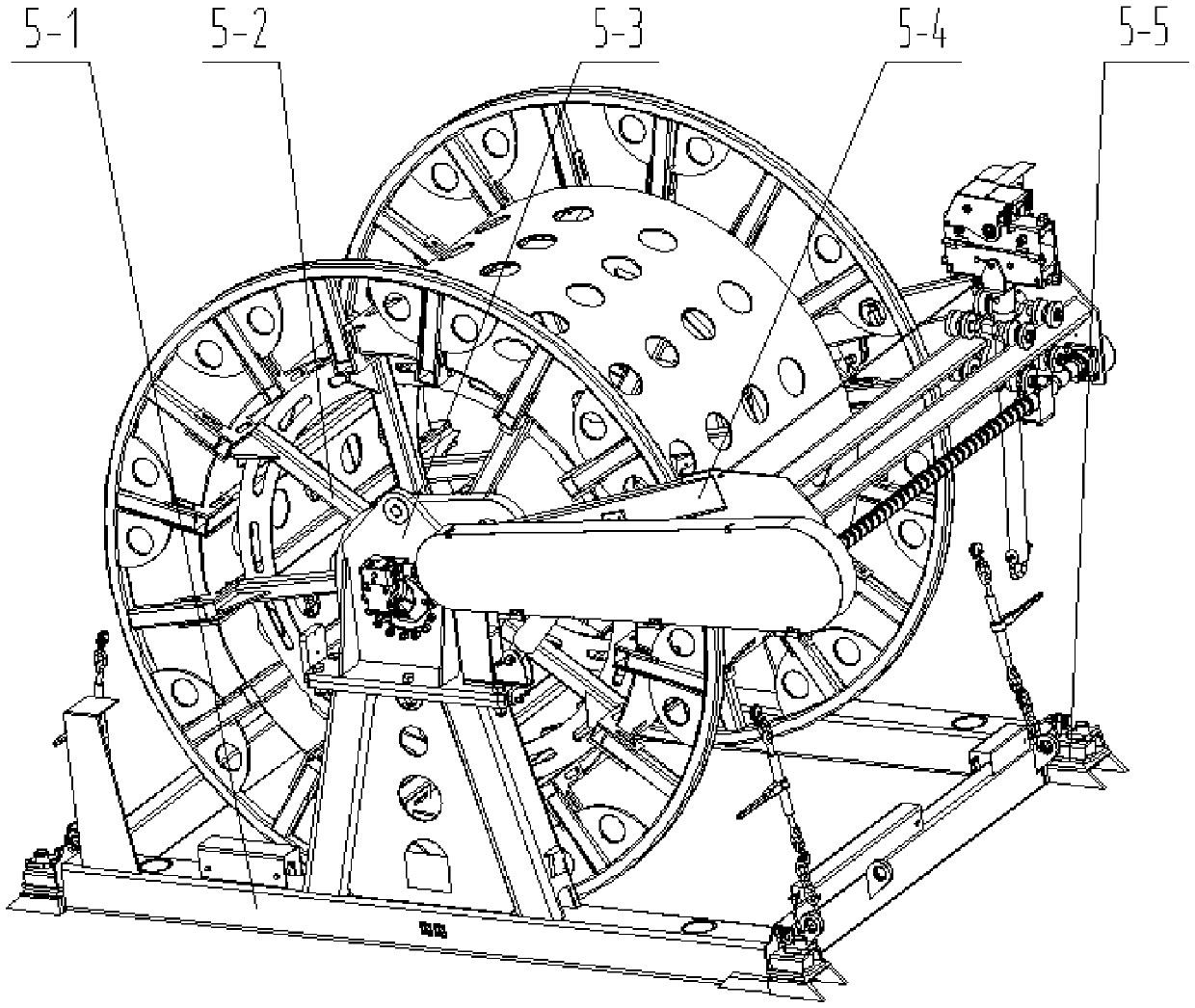

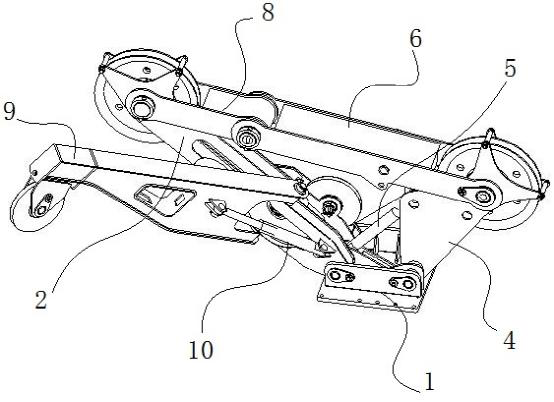

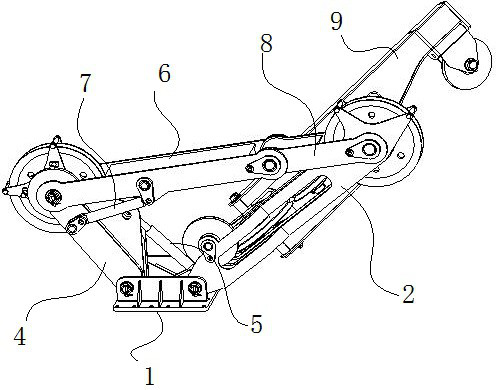

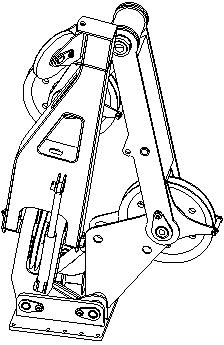

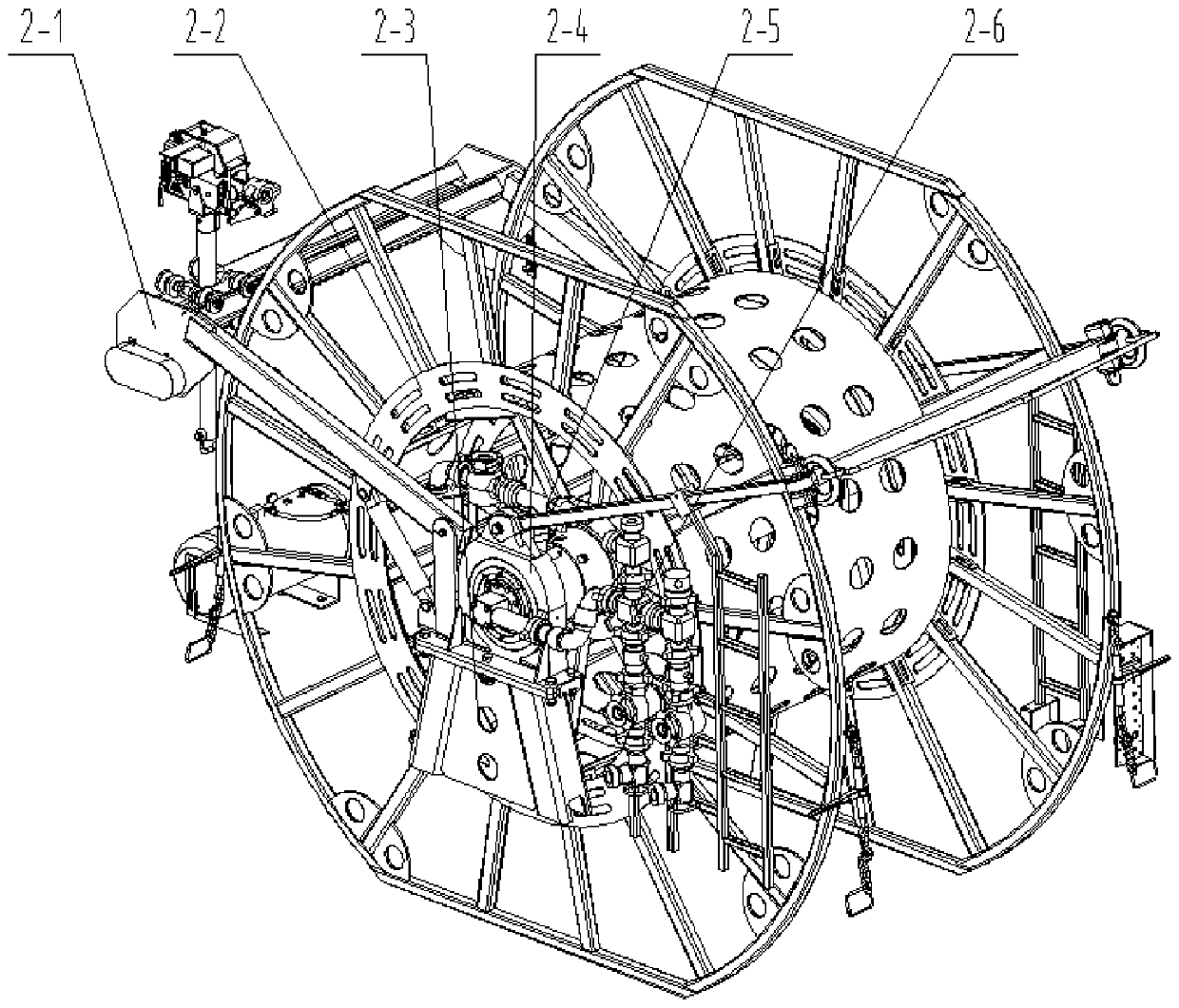

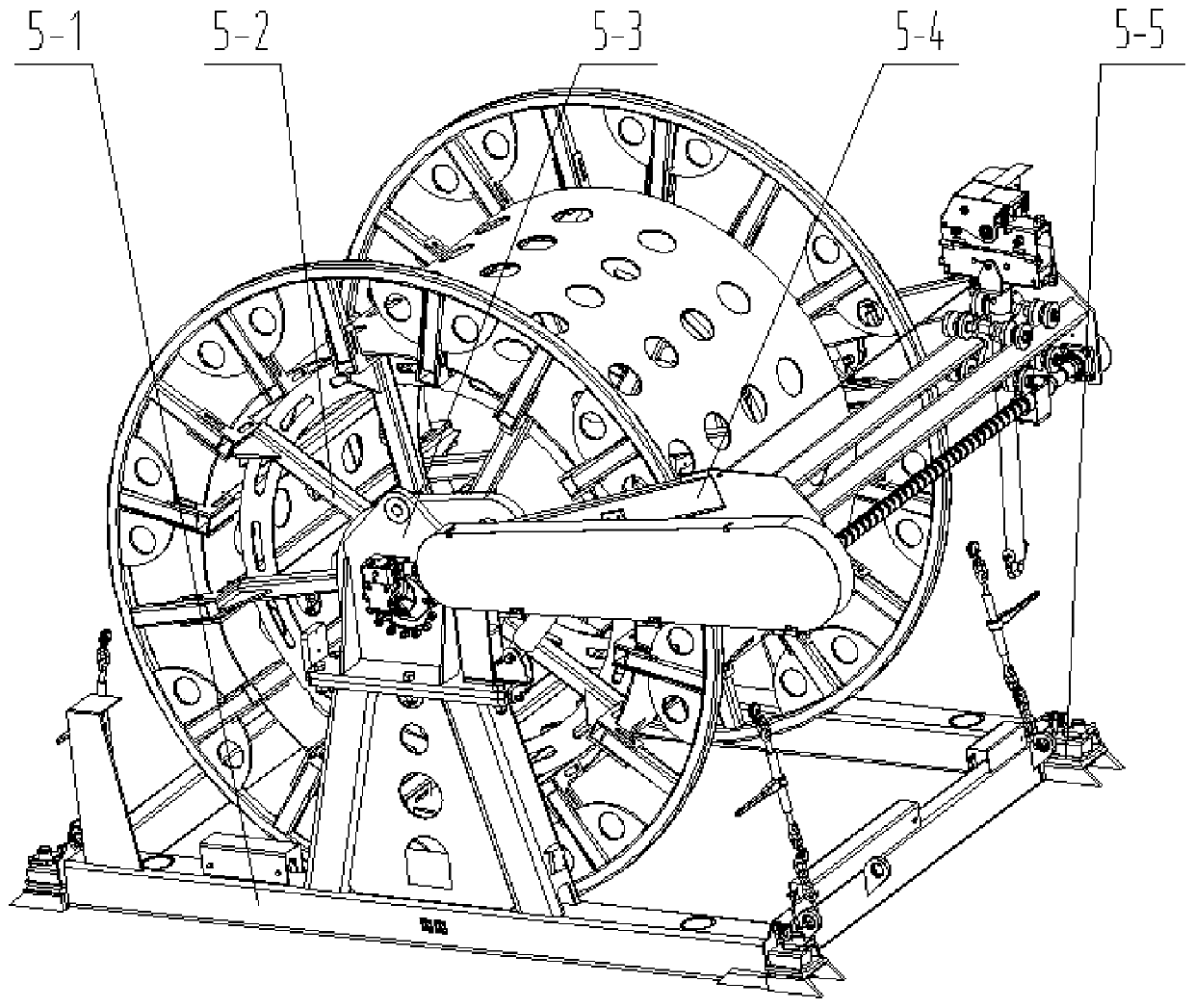

Split type tension machine of tension stringing for power transmission line

ActiveCN107394679ASave spaceLower transport heightApparatus for overhead lines/cablesTransmission lineEngineering

The invention discloses a split type tension machine for tension stringing for a power transmission line. The tension machine comprises a support device, a tension wheel component, a tightening mechanism and a power mechanism, wherein the tension wheel component is rotatably connected with the support device for twisting a conductor line; the tightening mechanism is connected with the support device and rotatably connected with the tension wheel component and used for enabling the conductor line to maintain the tightening state under the external traction effect; the power mechanism is detachably connected with the tightening mechanism and used for enabling the tightening mechanism to generate the tightening force. In the split type tension machine disclosed by the invention, the power mechanism is detachably connected with the tightening mechanism so that the power mechanism and the tightening mechanism are in split structure; when the tension machine is placed on a tension vehicle, the power mechanism and the tightening mechanism can be respectively placed, the space is greatly saved, the position of the tension machine on the tension vehicle can be reduced as required, the transportation height of the tension vehicle can be effectively reduced especially in carbon fiber conductor line twisting; furthermore, the whole weight of the tension machine is reduced.

Owner:CHINA ELECTRIC POWER RES INST +2

Novel core-type transformer with windings arranged in staggered mode

PendingCN111145984AIncreased sudden short-circuit pass rateImprove pass rateTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresCapacitanceStructural engineering

The invention relates to a novel transformer. Structural advantages of an existing shell-type transformer and an existing core-type transformer are integrated, so a shell-type transformer and a core-type transformer can be completely replaced. The cost is greatly reduced, and the percent of pass of sudden short circuit tests is theoretically 100%. A transformer winding is good in cooling effect, high in overload capacity, large in limit capacity and convenient to transport, and the limit capacity is superior to that of a shell type transformer. When vertical transportation is inconvenient, thetransformer body can be transported horizontally, and the transportation height is reduced. The capacitor is compact in structure, small in appearance size, light in overall weight, uniform in capacitor distribution, reliable in insulation and high in lightning stroke resistance and operation overvoltage resistance, and leads are convenient to install.

Owner:孙崇山

Quick-release modular mooring tower

PendingCN111942608AEasy to disassembleEasy to transportAnchoring installationsMarine engineeringTower

The invention belongs to the field of aerostats, and particularly discloses a quick-release modular mooring tower device which can be used for anchoring, flying and recycling of a mooring balloon, anda mooring tower comprises a mooring tower fixing module, a mooring tower rotating module, a lifting module and an optional conical fixing device. The mooring tower main body is divided into two modules, the modules are manufactured by adopting a carbon fiber composite material co-curing molding technology, the weight is light, the rigidity is high, and the mooring tower modules are convenient toassemble and disassemble. The conical fixing device can be composed of tapered primary and secondary bolts, has a guiding function, is accurate in positioning, and is beneficial to disassembly, assembly and transportation.

Owner:丹阳昊天飞行器技术有限公司

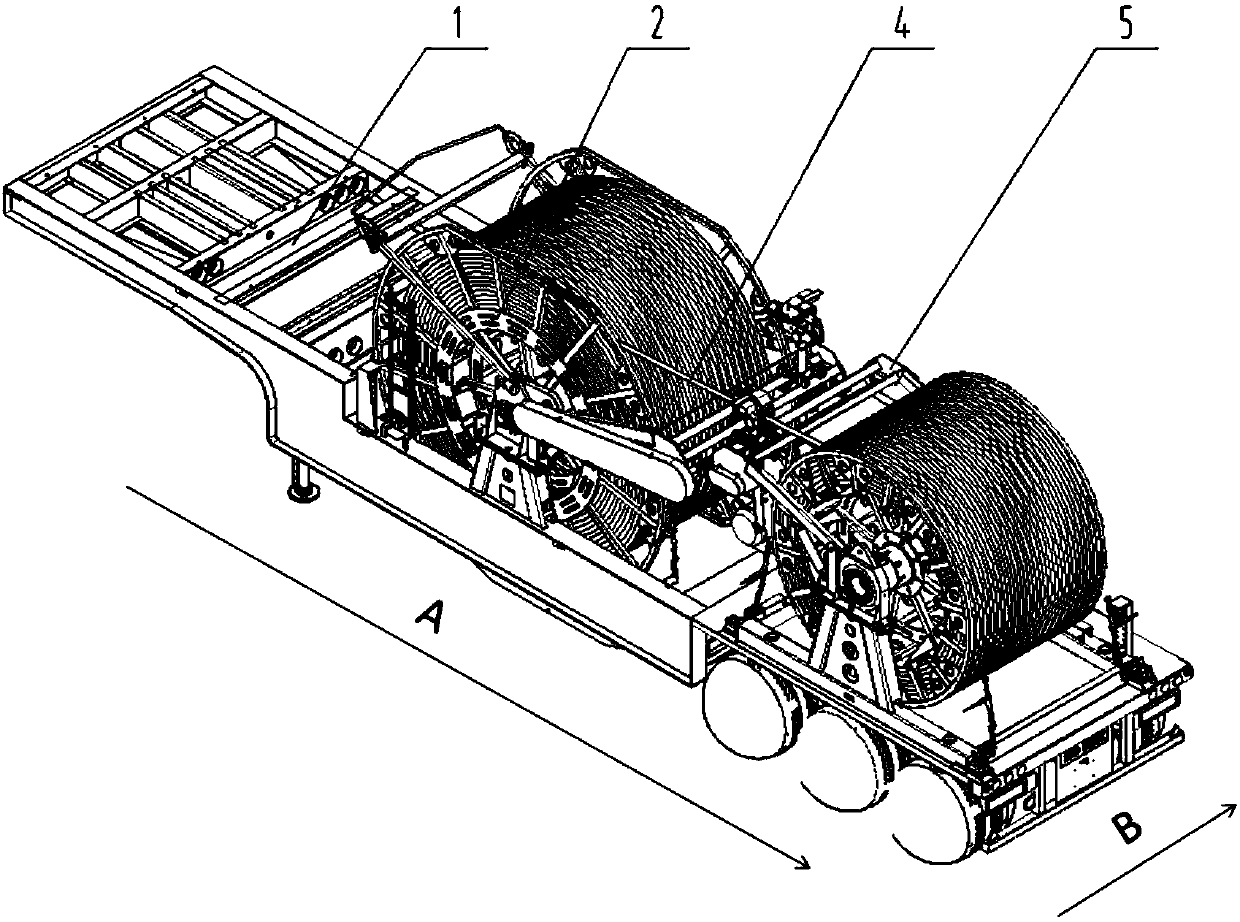

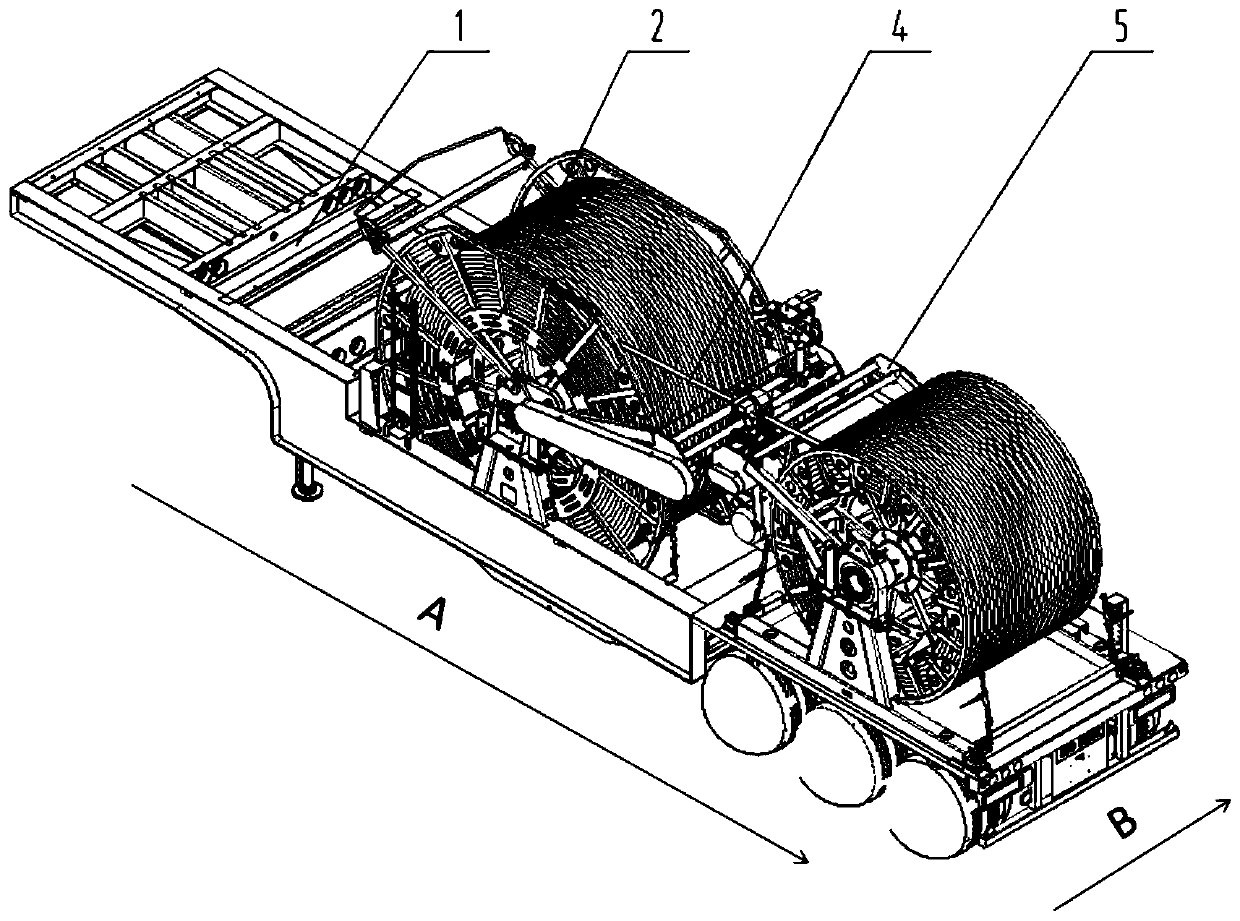

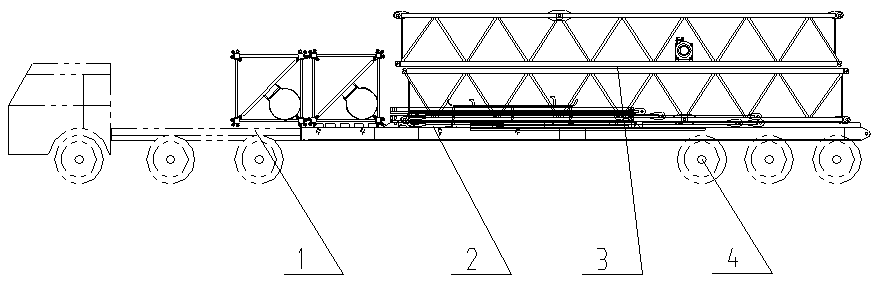

Car-mounted continuous pipe working equipment

ActiveCN107905744AExtended shipping lengthLower transport heightDrilling rodsDrilling casingsEngineering

The invention discloses car-mounted continuous pipe working equipment. The car-mounted continuous pipe working equipment includes a car chassis and a plurality of rollers, wherein the car chassis is provided with the length direction and the width direction; the multiple rollers are arranged on the car chassis and distributed in the length direction of the car chassis, the axis of each roller is parallel to the width direction of the car chassis, and a coil of continuous pipe is arranged on the multiple rollers. The car-mounted continuous pipe working equipment has the following beneficial effects that the transportation length of the continuous pipe is improved, the height of the roller transporting is reduced, and the requirement of the road transportation is met; the continuous pipe isin a disconnected state on the rollers, and the advantage of the continuous pipe is effectively exerted, that is, the continuous pipe can has no coupling and can work in a whole mode; a base column ofa main roller is directly welded to the car chassis, so that the weight of the car chassis is reduced; one of the rollers is in an oval shape, the transport height of the car-mounted continuous pipeworking equipment can be reduced, and the capacity capable of winding the continuous pipe is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +3

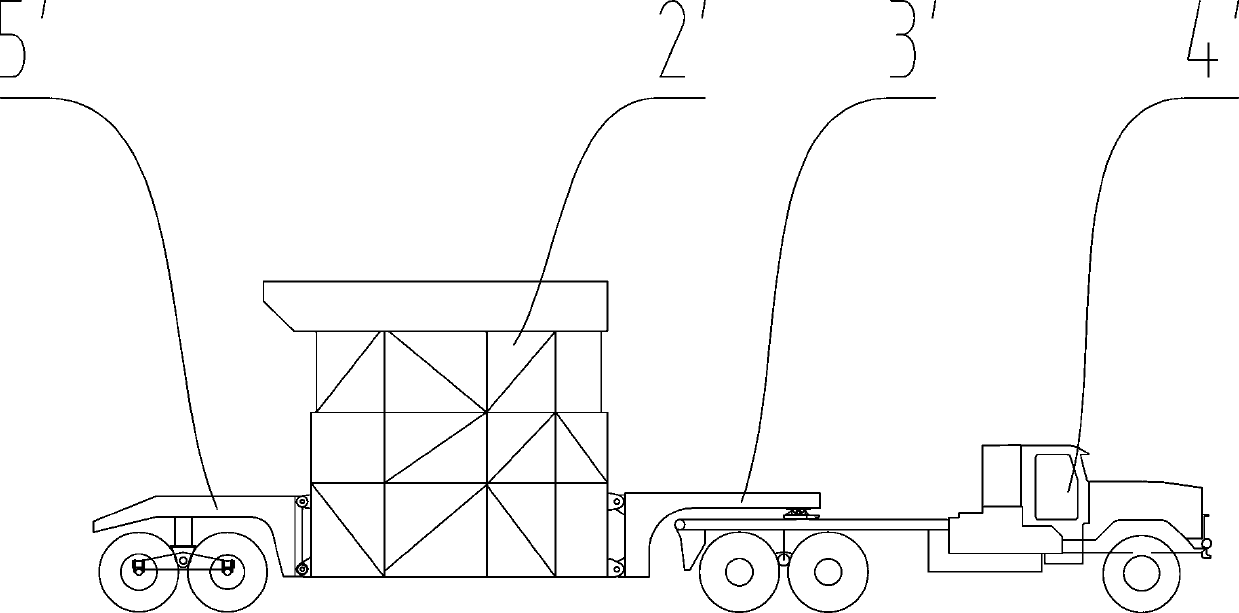

Crane arm and balance arm overall transport device

ActiveCN106428262AImprove passabilityReduce shipping costsTractor-trailer combinationsEngineeringTrafficability

The invention discloses a crane arm and balance arm overall transport device. The device comprises a transport vehicle head, wherein the transport vehicle head is connected with a balance arm module; a transport wheel module is placed at the bottom of the other end of the balance arm module; a crane arm module is fixed at the upper part of the balance arm module. The device is obvious in effect, convenient and practical, and can realize overall transport of the crane arm and the balance arm through the balance arm module and the transport wheel module, a whole vehicle is not needed, the transport cost is reduced, the transport height can be decreased and the trafficability of the vehicle is improved.

Owner:XUZHOU CONSTR MACHINERY

Three-phase generator transformer with super-large capacity

InactiveCN101984499BLower transport heightSolving Flux Leakage Suppression ProblemsTransformers/inductances coils/windings/connectionsTransformerLow voltage

The invention discloses a three-phase generator transformer with super-large capacity, which comprises an iron core, a low-voltage coil and a high-voltage coil and is characterized in that the low-voltage coil is divided into a first low-voltage coil branch and a second low-voltage coil branch which are connected in series, and the number of turns of the first low-voltage coil branch is equal to the number of turns of the second low-voltage coil branch; the iron core, the first low-voltage coil branch, the second low-voltage coil branch and the high-voltage coil are sequentially arranged fromthe inside to the outside; the two series branches namely the first low-voltage coil branch and the second low-voltage coil branch of the low-voltage coil are respectively in a double-layer multi-spiral structure formed by integrally winding self-adhesive transposed conductors; and the first low-voltage coil branch and the second low-voltage coil branch are separated by an oil clearance brace andan insulating cylinder. The invention not only can obviously lower the transport height of the transformer but also can well solve the problem of magnetic leakage inhibition of low-voltage super-large current leads, thereby improving the economy and the practicability of the three-phase generator transformer with super-large capacity.

Owner:JIANGSU SUNEL TRANSFORMER

Foldable goose head structure with infinitely adjustable drilling center distance

ActiveCN113107397BSave shipping spaceLower transport heightDrilling rodsDrilling casingsControl theoryPulley

The invention discloses a foldable goose head structure with infinitely adjustable drilling center distance, belonging to the technical field of rotary drilling rigs. The proximal end of the main pulley frame I is rotatably mounted on the base, and the distal end of the main pulley frame I is hinged with a connecting rod I; II is hinged with connecting rod I; a variable center distance oil cylinder is hinged between the main pulley frame II and the base, and a posture maintaining cylinder is hinged between the main pulley frame II and the connecting rod II; the proximal end of the auxiliary pulley frame I is rotated and installed on the main pulley frame II. On the pulley frame I, a swinging oil cylinder of the auxiliary goose head frame is hinged between the auxiliary pulley frame I and the main pulley frame I. The invention finally realizes the stepless adjustment of the drilling center distance of the rotary drilling rig through the telescopic driving of the main pulley frame II of the variable center distance oil cylinder to swing back and forth. The goose head structure reaches the minimum in the front, rear, left and right directions, reducing the occupied space and meeting the transportation requirements.

Owner:XUZHOU XUGONG FOUND CONSTR MACHINERY

Step-up transformer with dual-body structure for ultra-high-voltage generator

ActiveCN102315005BImprove potential distributionImprove short circuit resistanceTransformers/inductances coils/windings/connectionsFixed transformersLow voltageTransformer

The invention relates to a step-up transformer with a dual-body structure for an ultra-high-voltage generator. The transformer comprises a main body and a voltage regulating body which are arranged in the same oil tank of the transformer, wherein the iron core of the voltage regulating body is of a double-core-column structure; a first exciting coil and a first voltage regulating coil are sheathed on one core column; a second exciting coil and a second voltage regulating coil are sheathed on the other core column; the first exciting coil and the second exciting coil are connected in parallel to form an exciting coil which is in parallel connection with a low-voltage coil in the main body and is led out. According to the invention, a branching section of a high-voltage coil is not used, a voltage-regulating coil is arranged separately and is arranged on the other body; based on low-voltage exciting, the transformer does not regulates voltage in rated branching operation and regulates voltage only in the limit branching operation, therefore the electric potential distribution of the coil is improved, and the short-circuit resistant capability of the transformer is improved.

Owner:TBEA SHENYANG TRANSFORMER GRP CO LTD +1

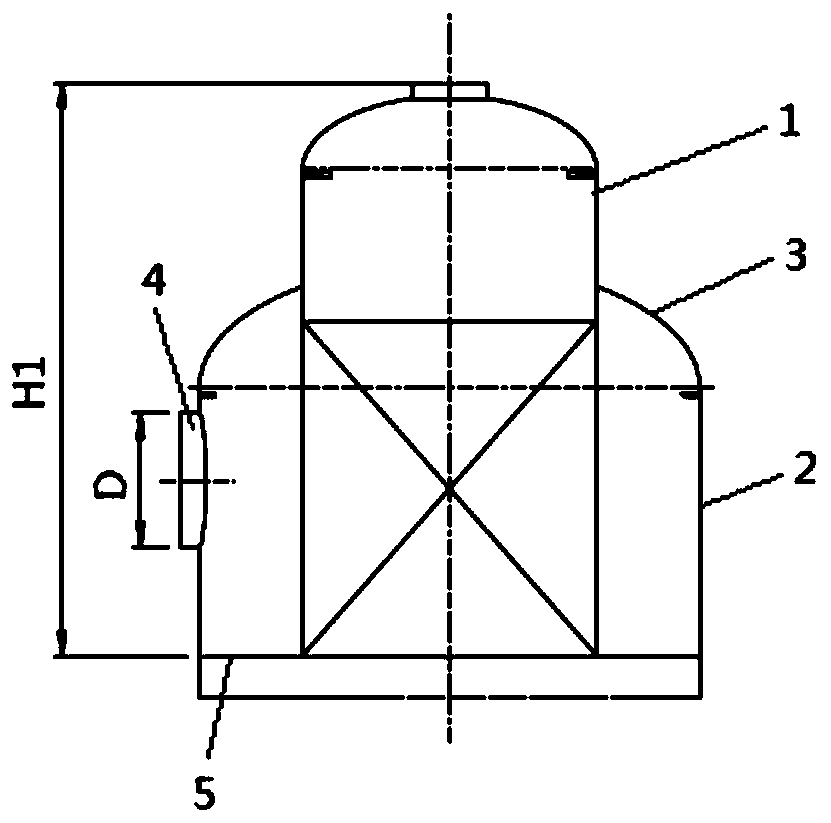

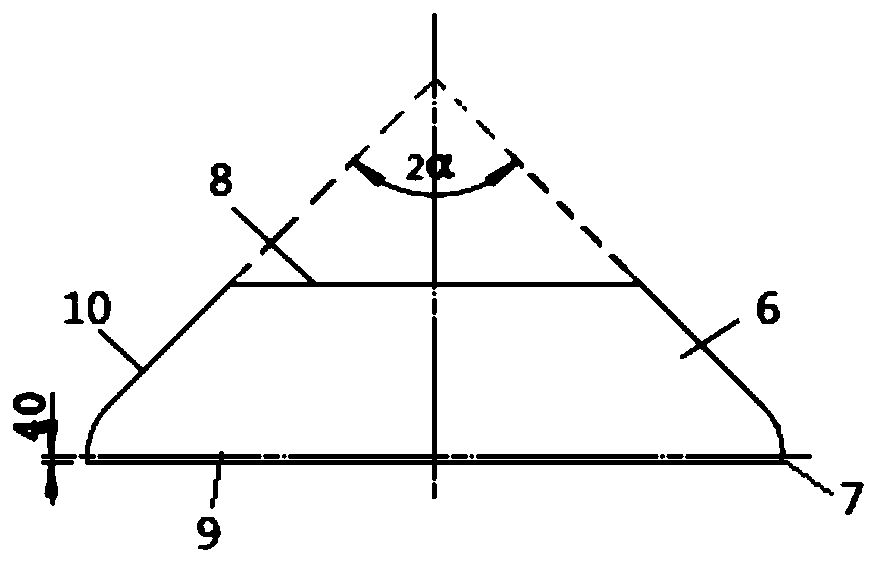

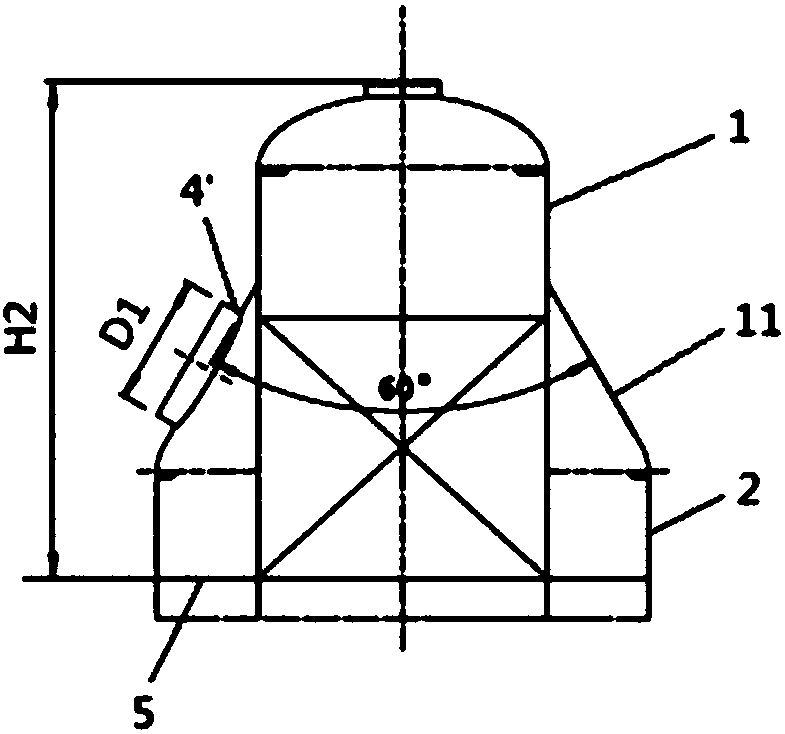

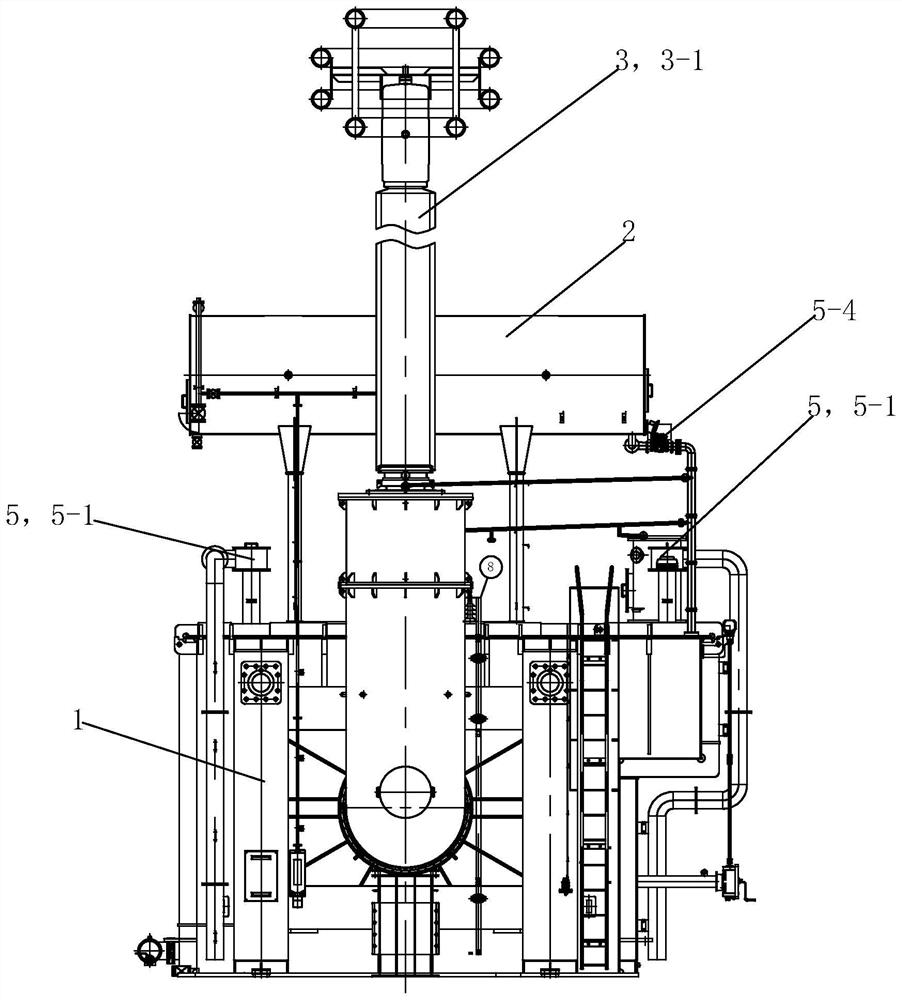

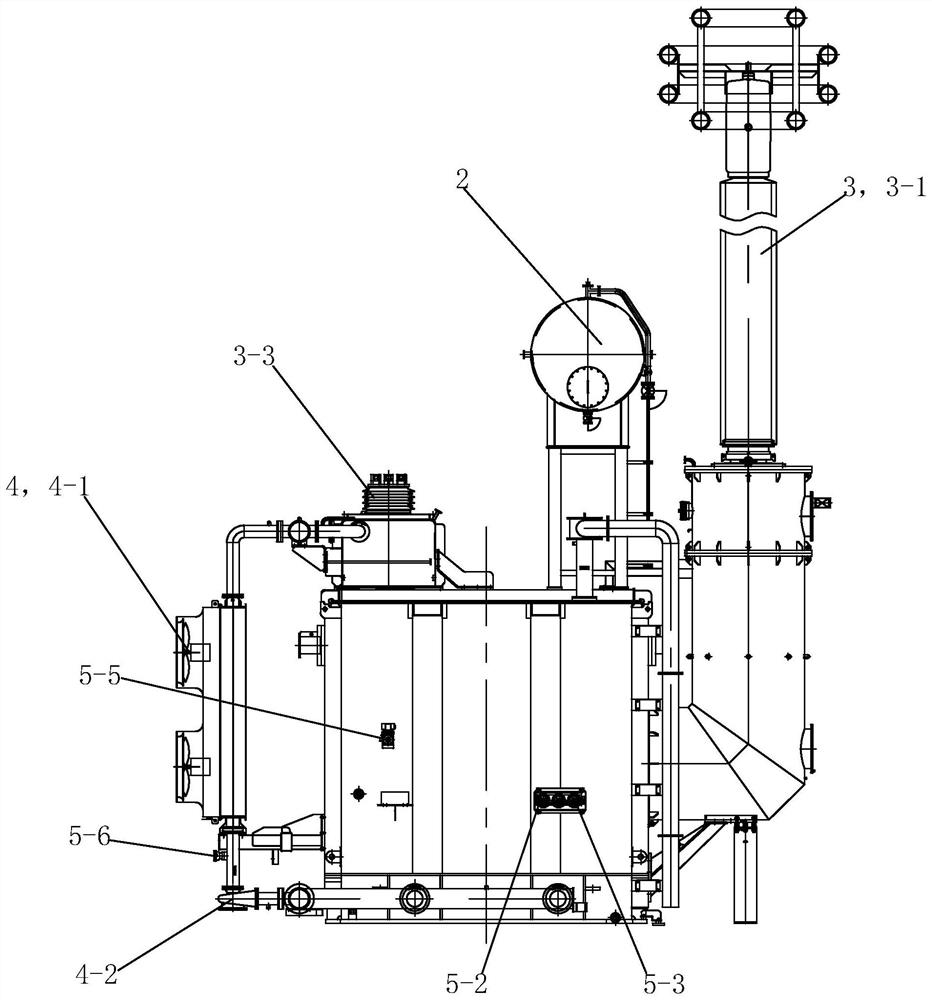

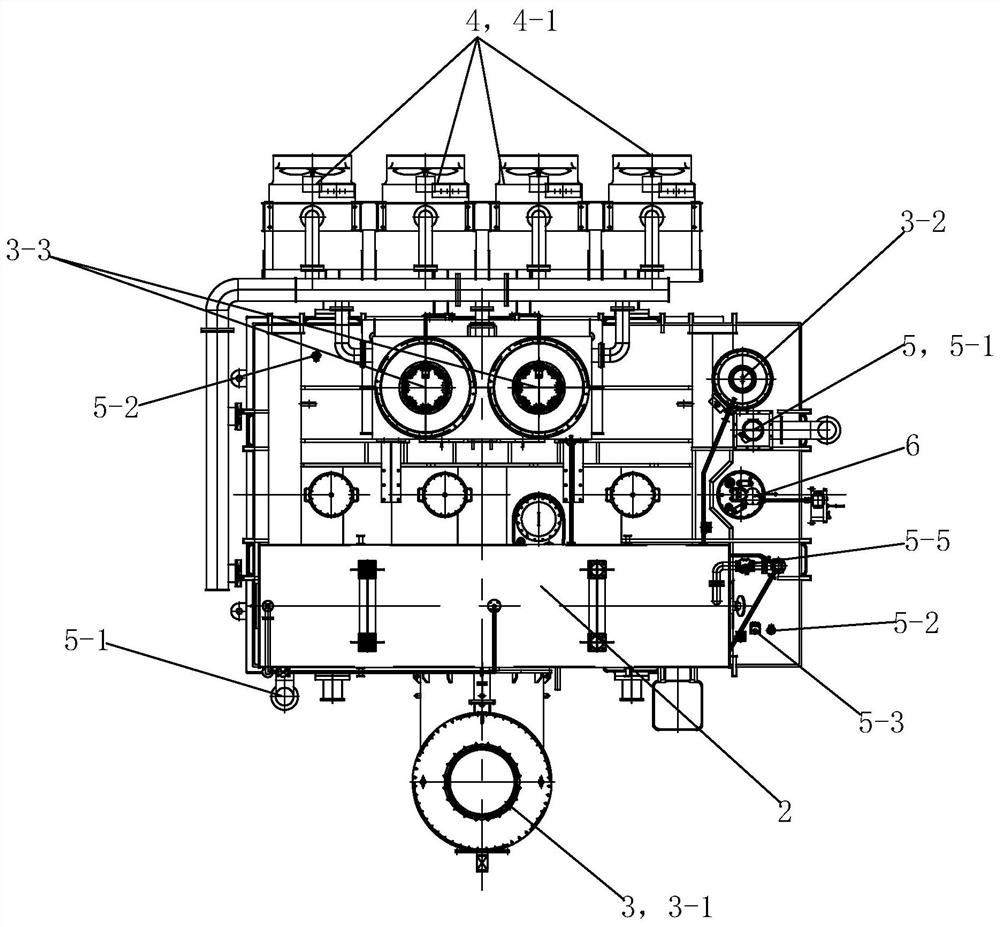

Air separation device

InactiveCN110487025AThe case of increasing the height of the upper towerLower transport heightSolidificationLiquefactionBiochemical engineeringAir separation

The invention discloses an air separation device. The device at least comprises a rectifying tower, the rectifying tower comprises a first tower body and a second tower body, the first tower body is arranged on the second tower body, the diameter of the first tower body is smaller than that of the second tower body, the first tower body and the second tower body are connected through a conical seal head, and at least one open hole is formed in the conical seal head.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

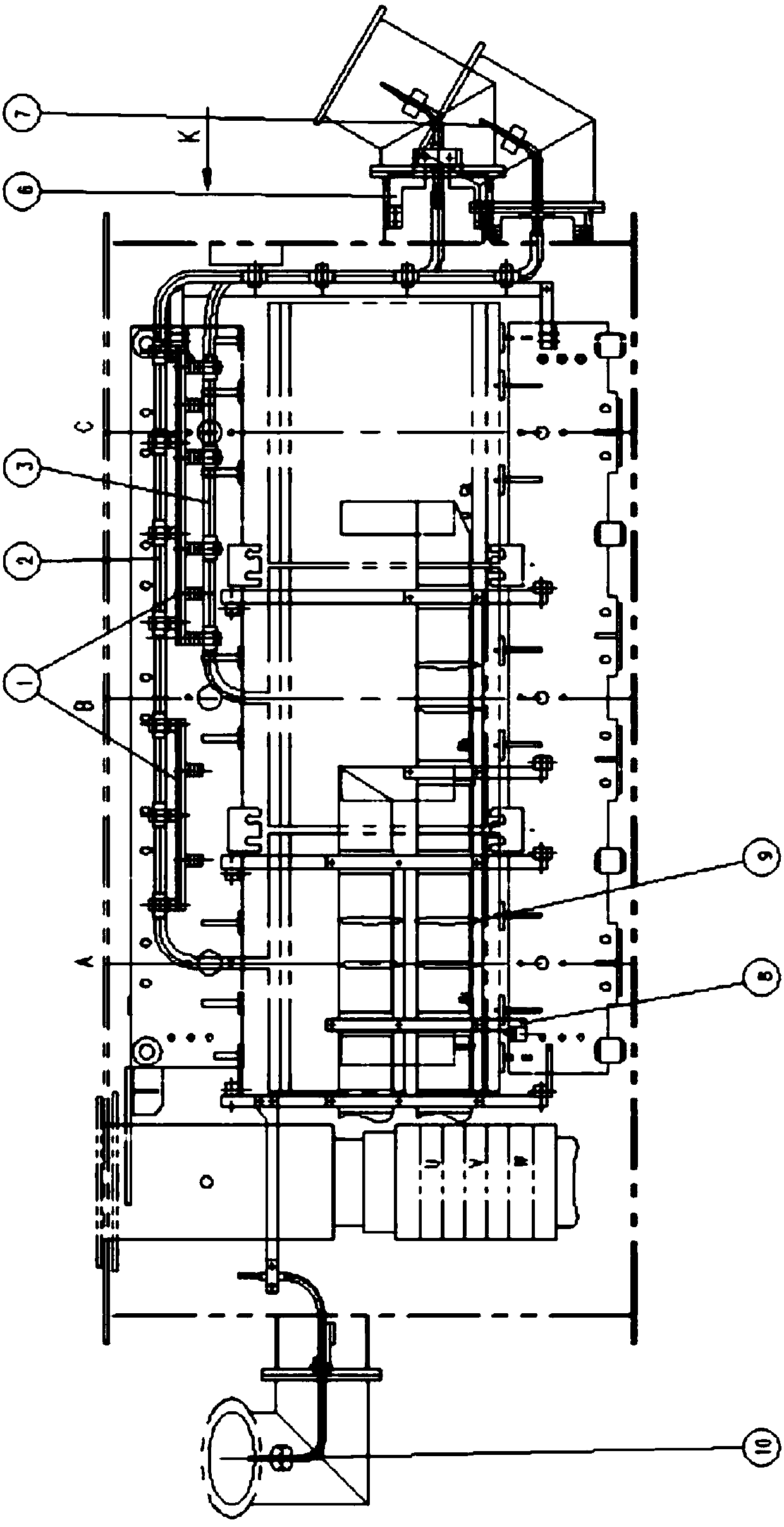

110 kV double-winding vehicle-loaded transformer lead structure

InactiveCN108053983ASmall body sizeMake full use of spaceTransformers/inductances coolingTransformers/inductances coils/windings/connectionsLow voltageFuel tank

The invention relates to a 110 kV double-winding vehicle-loaded transformer lead structure. The 110 kV double-winding vehicle-loaded transformer lead structure comprises a high-voltage lead structureand a low-voltage lead structure, wherein the high-voltage lead structure comprises A-phase, B-phase and C-phase high-voltage phase lines; ends of A-phase and B-phase high-voltage phase lines are discharged in the axial direction; the lines are horizontally distributed along an iron core upper clamping piece and are lead to the end, which is close to a C phase, of a fuel tank; the end of the C-phase high-voltage phase line is discharged in a radial direction on a short axis side of the fuel tank; the A-phase, B-phase and C-phase high-voltage phase lines are fixed and guided to the position ofa lower heightening seat on the short axis side of the fuel tank; and after being fixedly clamped in the heightening seat, the A-phase, B-phase and C-phase high-voltage phase lines are connected witha high-voltage sleeve. On the premise of meeting safe and stable running of a transformer, the size of the transformer is greatly reduced, the space of the fuel tank is utilized fully, the volume of the fuel tank is greatly reduced, the using amount of transformer oil and steel is reduced, the transportation size of the transformer is reduced, the economy of a 110 kilovolt double-winding vehicle-mounted transformer is improved remarkably, and transportation flexibility is also improved.

Owner:SHANDONG POWER EQUIP

Vehicle-mounted coiled tubing equipment

ActiveCN107905744BExtended shipping lengthLower transport heightDrilling rodsDrilling casingsCouplingControl theory

Owner:BC P INC CHINA NAT PETROLEUM CORP +3

A tower crane with double jib sections

The invention provides a tower type crane with double hoisting arm sections. The tower type crane comprises a tower body, a first arm section and a second arm section, wherein the first arm section is connected with the tower body, the second arm section is connected with the first arm section, and a folding mechanism is arranged between the first arm section and the second arm section; after being folded, the first arm section and the second arm section are in a level adjacent state under the effect of the folding mechanism. Compared with an old fixed hoisting arm tower machine, hoisting arms are mutually hinged and folded together through the folding mechanism, so that the transporting height is reduced, and the tower type crane is convenient to transport; the hoisting arm can be orderly unfolded from a folded state to the level state under the effect of a power system, the mounting time of the tower machine is greatly shortened, and the cost of a low-rise building and a plant building is reduced.

Owner:NANJING TECH UNIV +1

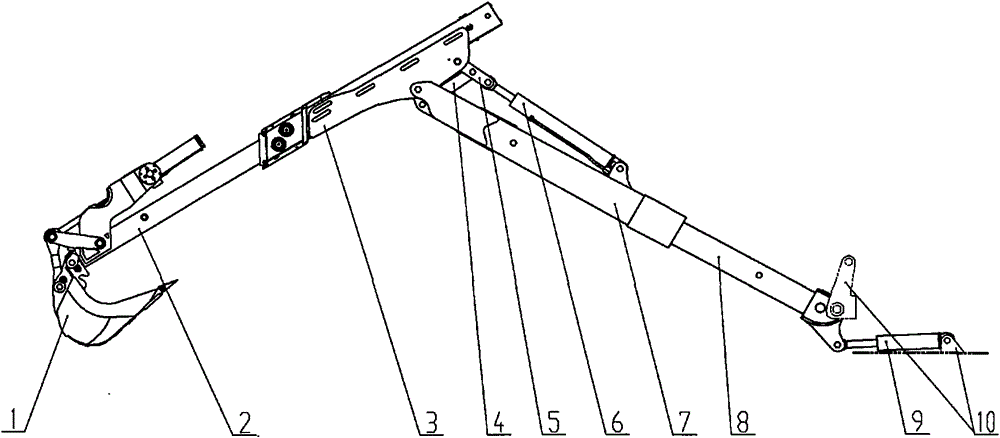

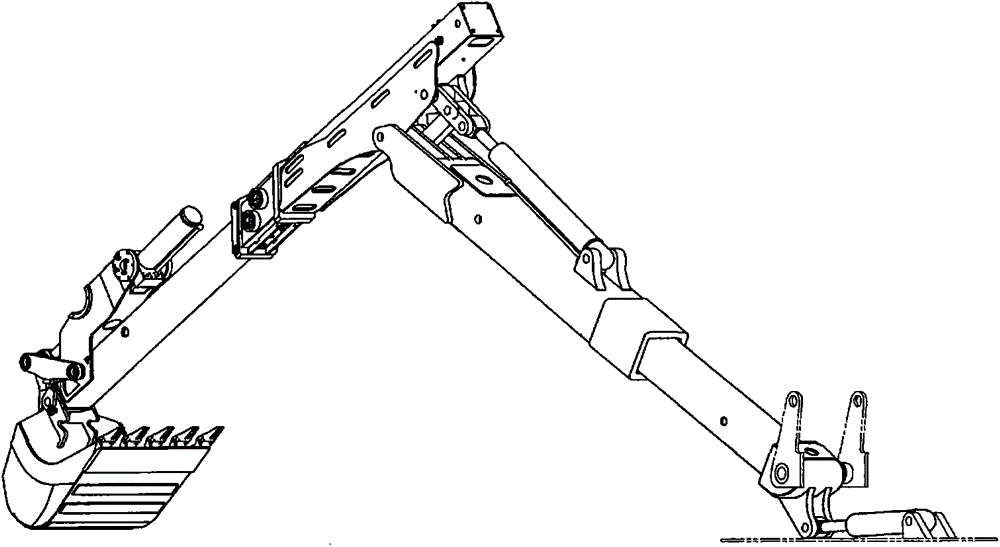

A new working device and excavator

ActiveCN103603386BExpand the scope of workIncrease the rotation angleMechanical machines/dredgersMiniaturizationEngineering

The invention belongs to the field of excavator technology and particularly discloses a working device and an excavator. A telescopic bucket rod and a telescopic moving arm in the working device greatly improve the working range of the working device. A four-connecting-rod mechanism greatly improves the rotatable angle of the bucket rod and the working range of the whole working device. A moving arm oil cylinder is placed in a platform and enables the bucket rod to be possibly restored to the lower surface of the moving arm at a large angle, thus, the restoration angle and the restoration range of the working device are improved, and the condition that an operation machine tool scrapes the moving arm oil cylinder in the restoration state of the bucket rod is avoided. The excavator has the large-range operation capacity which a small excavator does not have, has the characteristics, of being light in weight, small in size and flexible, which a large excavator does not have, and is especially suitable for large-area operation by the small excavator or superlarge-area operation occasions of the large excavator. Meanwhile, when the working device is in a completely restored state, the excavator is small in size, light in weight, low in transportation and driving height, and small in rotary radius, and can be driven and transferred easily.

Owner:XCMG CONSTR MACHINERY

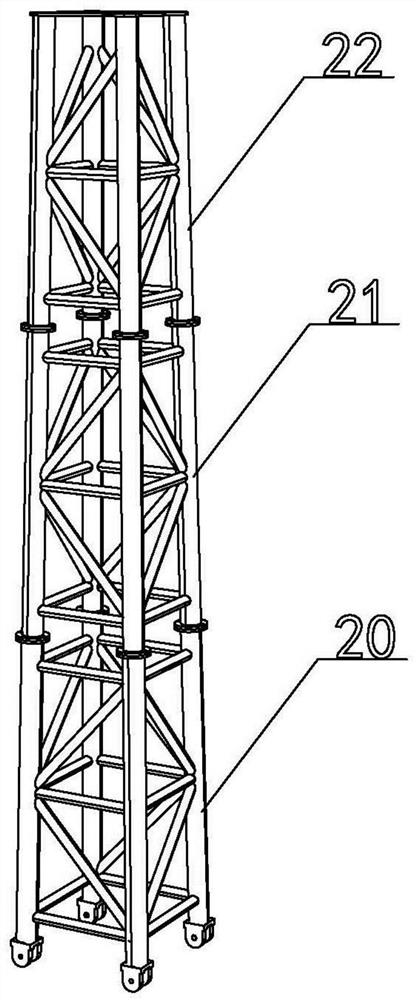

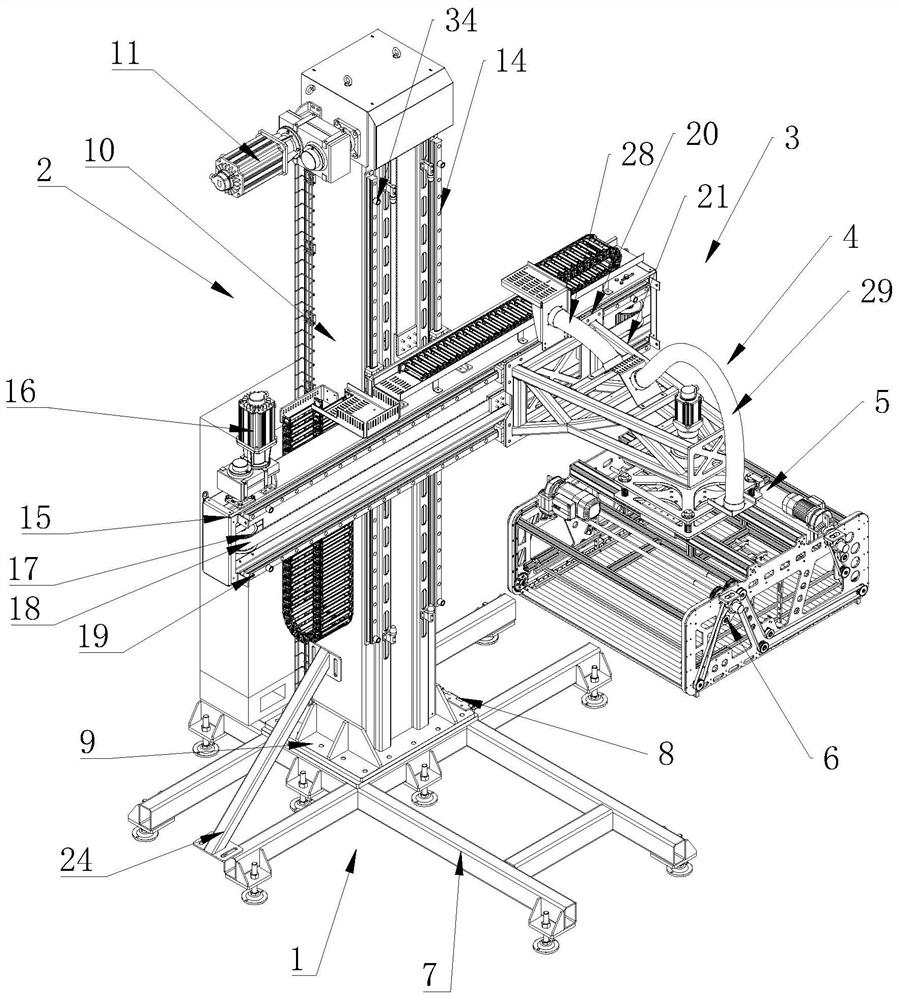

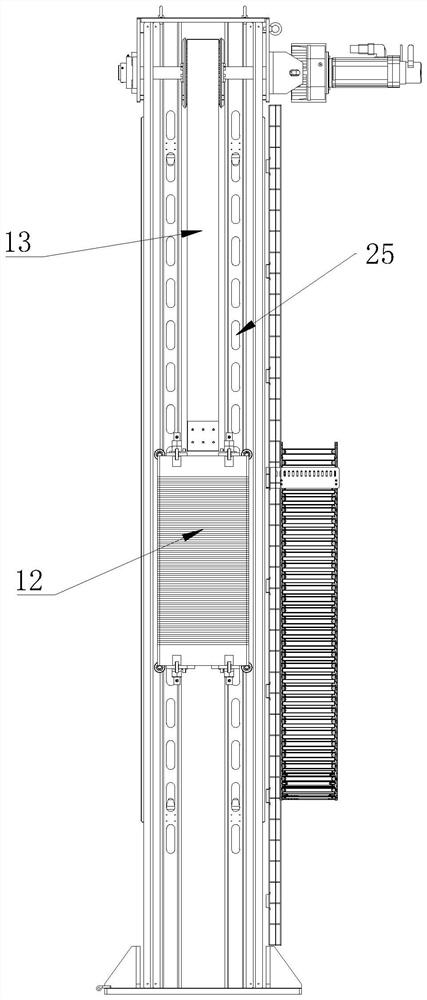

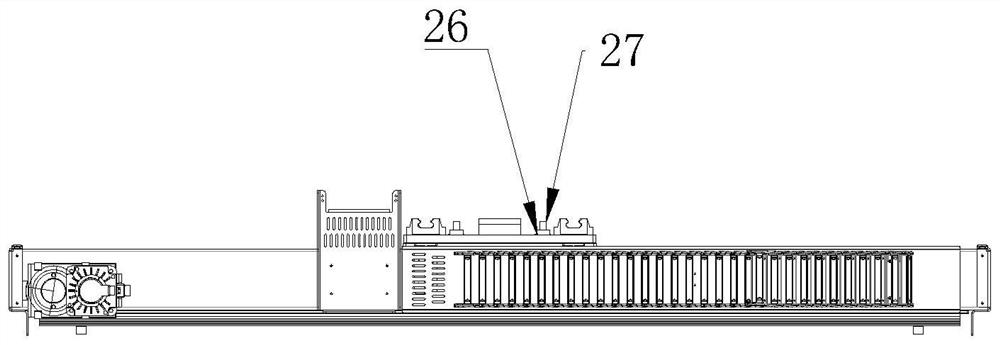

Single-stand-column stacking machine

InactiveCN113443423APrevent weight lossReduce volumeStacking articlesSupporting framesPalletizerGravity center

The invention discloses a single-stand-column stacking machine. According to the technical scheme, the single-stand-column stacking machine comprises a base, a stand column component, a cross beam mechanism, a grabbing arm mechanism, a damping mechanism and a grabbing hand used for fixing a product. The single-stand-column stacking machine has the characteristics that the single-stand-column stacking machine is small in size and convenient to move and convey, and the production space is not occupied while equipment stability can be provided by adopting a single-stand-column form. The stand column component and the base can be put down, a stand column is adopted for supporting, transportation can be facilitated, toppling caused by the unstable gravity center is avoided, and the transportation height can also be reduced.

Owner:太仓全众智能装备有限公司

Stirring curing machine

InactiveCN102535437BLower transport heightEasy to transportSoil preservationElectrical controlEngineering

The invention provides a stirring curing machine. The stirring curing machine comprises an upper vehicle assembly, a lower vehicle assembly connected with the upper vehicle assembly through a rotary support, and a pulp injection system on the upper vehicle assembly. The stirring curing machine is characterized in that one end of a derricking mechanism is connected with the frame of the upper vehicle assembly, and the other end is connected with an upright mast system; an operation device is arranged on the mast system, and can be controlled by a hydraulic system to move on the mast system up and down; a stirring head on the front end of the operation device is driven by the hydraulic system to rotate; and the hydraulic system and an electrical control system are arranged in the upper vehicle assembly. The stirring curing machine provided by the invention has the advantages that the stirring curing machine is specifically used for foundation stabilization, and can reduce stirring dead corners, thereby achieving more uniform stirring. Furthermore, the stirring device in the invention has an enough torque, so that the stirring head can descend into the ground easily when encountering denser soil.

Owner:龙工(上海)机械制造有限公司 +1

An integral transportation device for the balance arm of the lifting arm

ActiveCN106428262BImprove passabilityReduce shipping costsTractor-trailer combinationsEngineeringTrafficability

Owner:XUZHOU CONSTR MACHINERY

Heart-type transformer with interleaved windings

ActiveCN109841394BLow costReduce performance indicatorsTransformers/inductances coolingTransformers/inductances coils/windings/connectionsShort-circuit testOvervoltage

Owner:孙崇山

Double-ring oil-immersed power transformer with 1000kV high-voltage winding split

PendingCN112259327AReduce temperature riseLower transport heightTransformers/inductances coolingTransformers/inductances coils/windings/connectionsTransformerControl theory

The invention provides a double-ring oil-immersed power transformer with 1000kV high-voltage winding split. The double-ring oil-immersed power transformer comprises an oil tank, an oil storage cabinet, a sleeve, cooling equipment, secondary protection equipment, a non-excitation voltage regulating switch, an iron core, a winding assembly and a lead. The winding assembly comprises a voltage regulating winding, a first high-voltage winding, a first low-voltage winding, a second low-voltage winding and a second high-voltage winding which are sequentially arranged from inside to outside; the voltage regulating winding is close to an iron core main column, and insulating cylinders and supporting strips are arranged between the voltage regulating winding and the iron core main column, between the adjacent windings and between the second high-voltage winding and an iron core side column. The voltage regulating winding is connected in series with the first and second high-voltage windings to form a high-voltage winding part of the transformer; the first and second low-voltage windings are connected in series to form a low-voltage winding part of the transformer. Through the overall structural design, the problem that in the prior art, a 1000kV double-ring oil-immersed power transformer is high in transportation height is effectively solved, and the switch is low in insulation level, loss, noise and temperature rise and high in insulation reliability.

Owner:CHANGZHOU TOSHIBA TRANSFORMER

Cab and construction machinery

ActiveCN102991590BLower transport heightPass smoothlyRoads maintainenceLoading-carrying vehicle superstructuresArchitectural engineeringWorking environment

The invention discloses a driver's cab and construction machinery. The driver's cab is arranged on a main engine of the construction machinery. The driver's cab is provided with: a tilting mechanism for tilting the driver's cab. One end is telescopically connected with the bottom plate of the cab, and the other end of the tilting mechanism is connected with the main engine. Therefore, the present invention can provide a healthy working environment and can reduce the transport height of the construction machine.

Owner:SANY HEAVY IND CO LTD (CN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com