Stirring curing machine

A curing machine and mixing head technology, applied in soil protection, construction, infrastructure engineering, etc., can solve problems such as large dead angle, vertical up and down, and difficulty in achieving uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

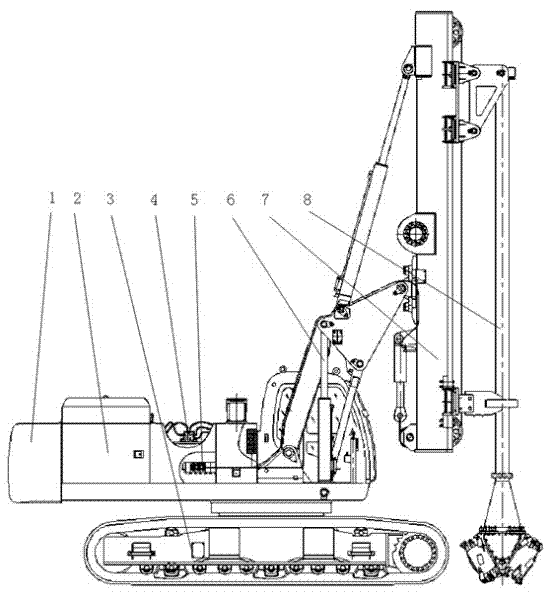

[0026] Such as figure 1 As shown, it is a stirring and curing machine provided by the present invention, including the upper car assembly 2, the lower car assembly 3 is connected with the lower car assembly 3 through the slewing support, and the luffing mechanism 6 is connected with the upper car assembly 2 through the pin shaft. The vehicle frame 22 is connected, the mast system 7 is connected with the luffing mechanism 6 through the pin shaft, and the working device 8 is installed on the mast system 7 . The spraying system 1 is installed at the tail of the boarding assembly 2, and the hydraulic system 4 and the electric control system 5 are both placed inside the boarding assembly 2.

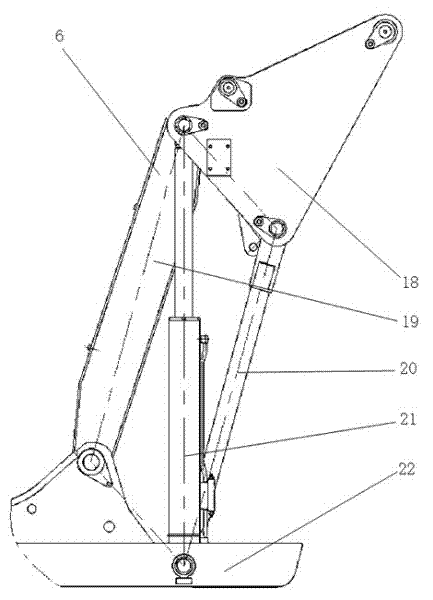

[0027] Such as figure 2 As shown, the luffing mechanism 6 includes a connecting body 18 and a boom 19, the two ends of the boom 19 are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com