A tower crane with double jib sections

A technology of tower cranes and double jibs, applied in cranes, transportation and packaging, etc., can solve the problems of prolonging the construction period, increasing costs, time-consuming installation and disassembly, etc., to reduce installation time, save costs, Effect of reduced transport height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

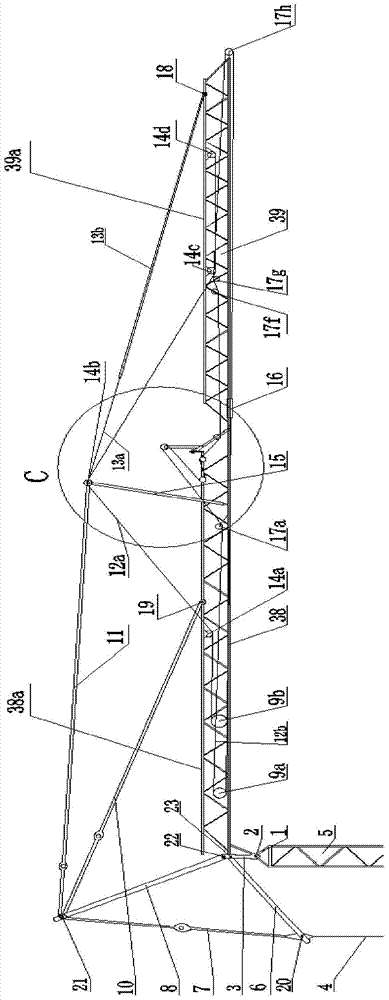

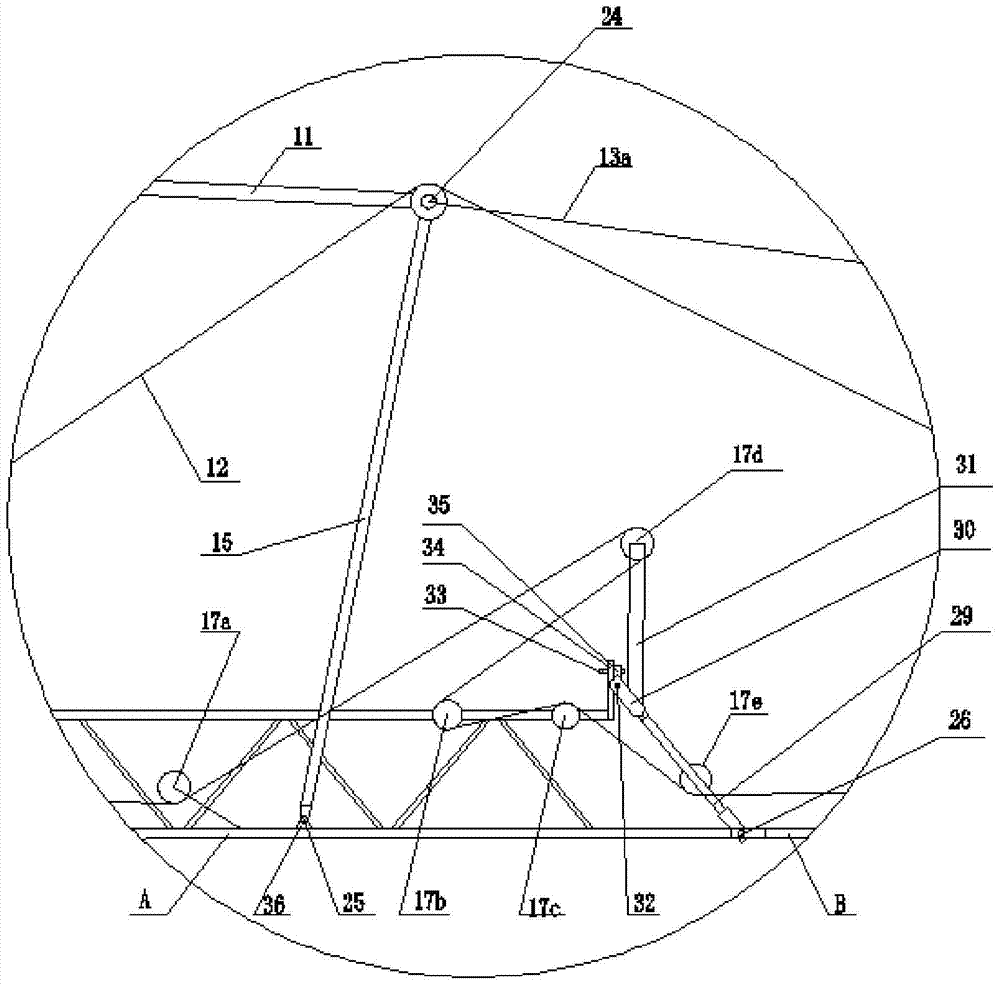

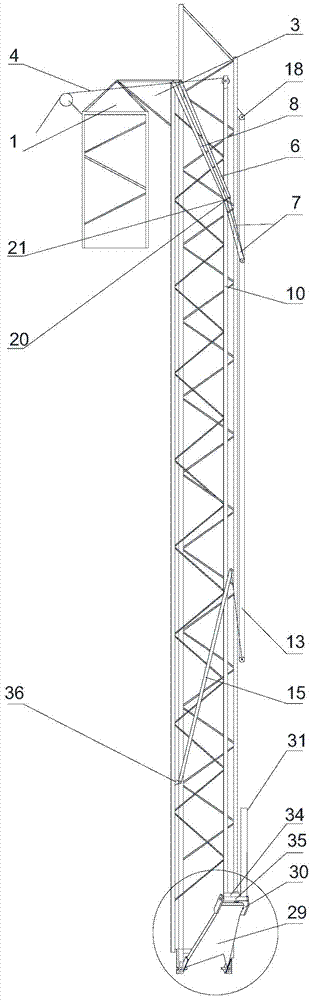

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] like figure 1 and figure 2 As shown, the present invention includes a liftable tower body 5, a first boom section 38, a second boom section 39, a first boom section upper chord 38a, a second boom section 39a, a boom section assembly, a boom section folding assembly , a support rod assembly, a tie rod assembly, a connection assembly and a power assembly. The lower end of the tower body is fixed to the ground, and the other end is movably connected to the boom; the crane folding assembly is respectively connected to the tower body and the boom section for controlling the folding of the boom section. The top of the tower body 5 is fixedly connected with the first ear plate 1 and is hinged with the second ear plate 3 through the first pin shaft 2 .

[0028] The connecting assembly includes a pin shaft part, lug part and pulley part, the pin shaft part includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com