U-shaped tunnel-crossing beam transporting vehicle with adjustable wheel track and beam-feeding method of U-shaped tunnel-crossing beam transporting vehicle

A technology for tunnel beam trucks and beam trucks, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., and can solve problems such as difficult design of supporting low-level tunnel beam trucks, inability to transport beams in tunnels, and large spans , to achieve safe and reliable segmental connection, improve the passability of beam transportation, and reduce the transportation height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

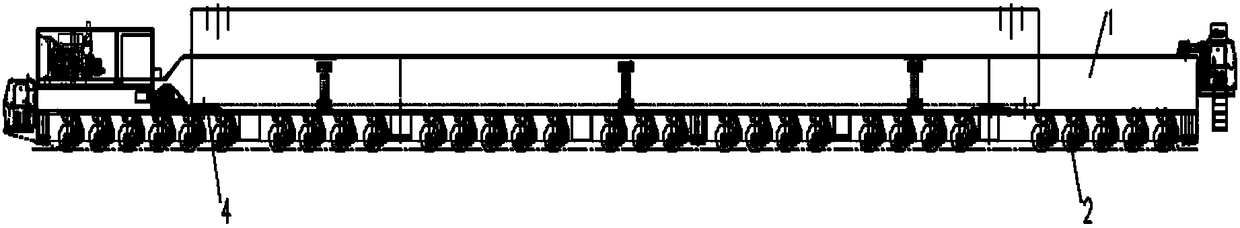

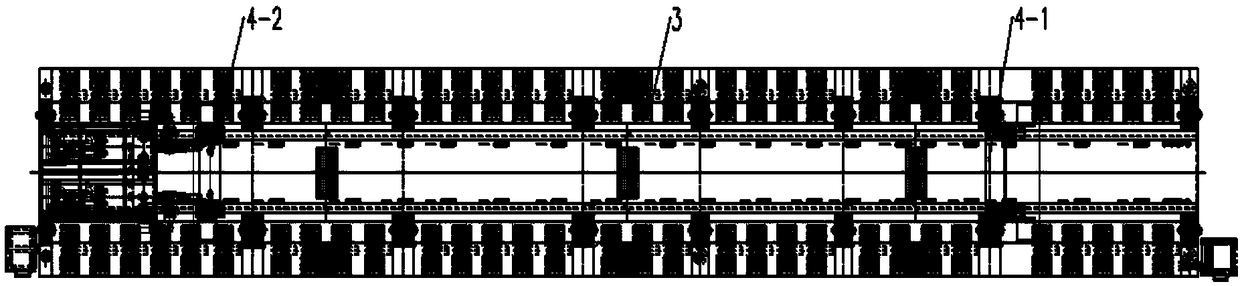

[0042] see Figure 1 to Figure 9, shows the U-shaped tunnel beam transport vehicle with adjustable wheelbase of the present invention.

[0043] See 10A to Figure 10E , shows a schematic diagram of the steps of the beam feeding method of the beam transport vehicle of the present invention.

[0044] The U-shaped tunnel beam transport vehicle with adjustable wheelbase at least includes a vehicle body 1 , a walking wheel set 2 , a steering system 3 and a beam trolley 4 . Among them, see Figure 4-6 , the car body 1 is a U-shaped structure, the walking wheel set 2 and the steering system 3 are located under the car body, and form a detachable connection with the car body, and a plurality of hydraulic legs can also be provided under the car body , the beam trolley 4 is located on the car body 1.

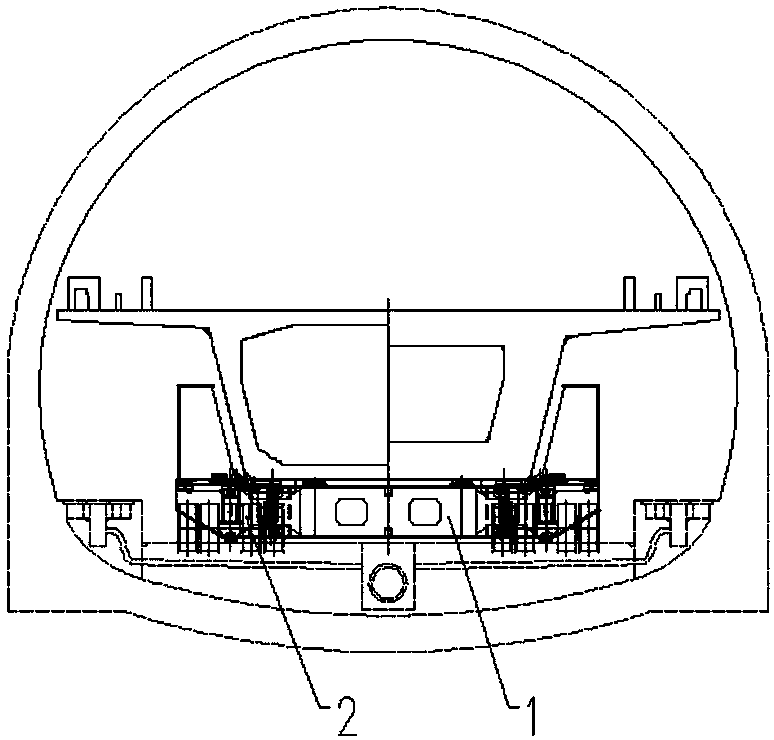

[0045] see image 3 , shows the end view of the U-shaped tunnel beam transport vehicle with adjustable wheelbase of the present invention carrying the box girder through the tunnel. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com