Quick-release modular mooring tower

A mooring tower and modular technology, applied in the field of aerostats, can solve the problems affecting the flight efficiency of the retaining balloon, the complex disassembly and assembly process of the retaining tower, the existence of matching gaps, etc., to achieve convenient transportation, installation and disassembly, and simple structure and operation. , the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

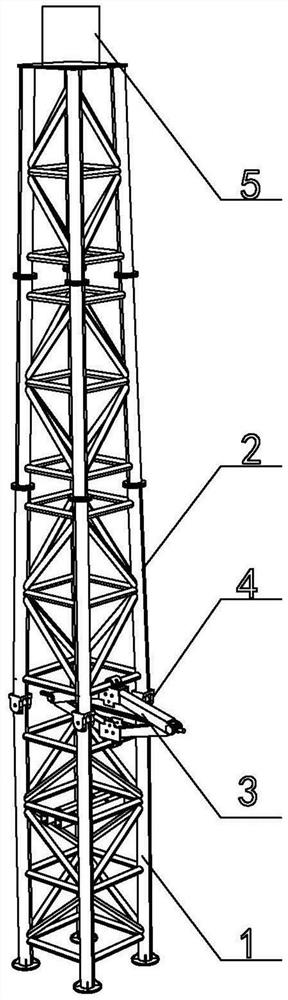

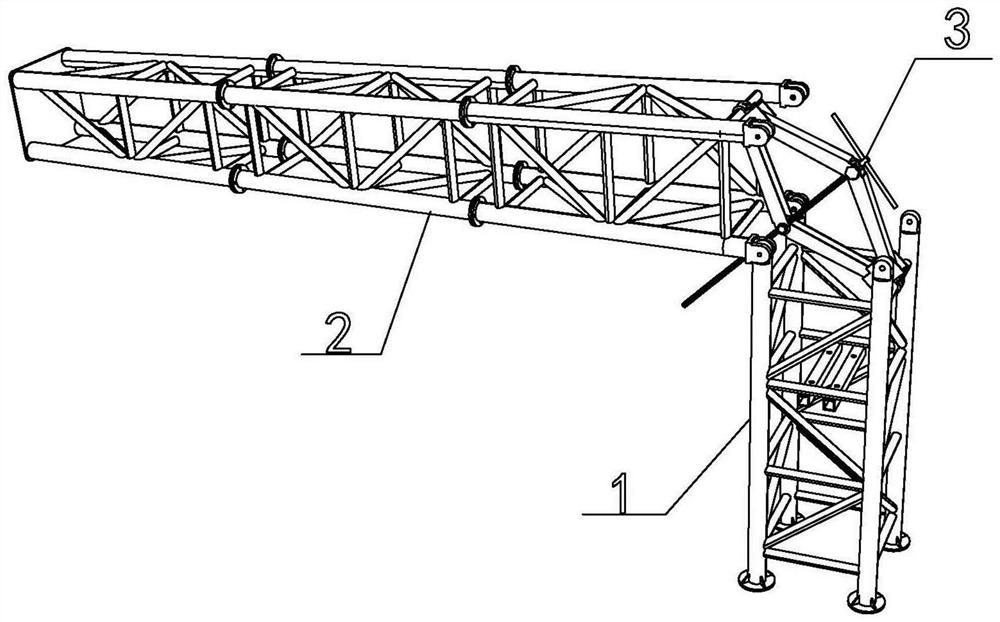

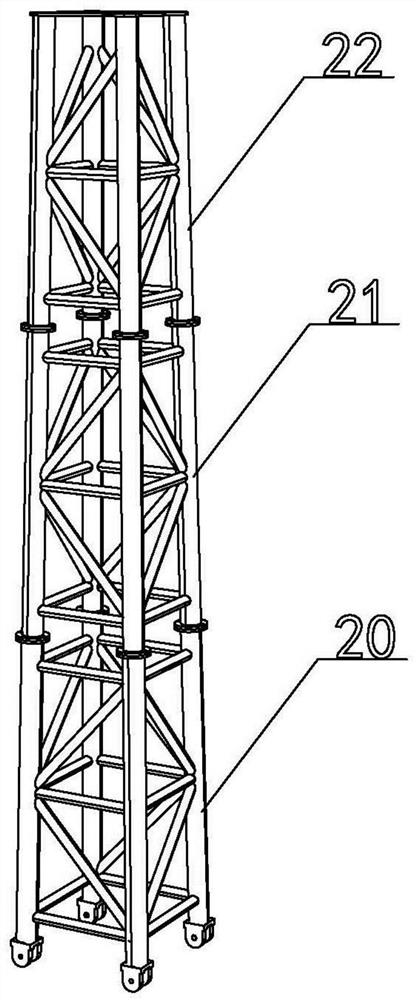

[0045] This embodiment provides a quick-detachable modular mooring tower device, such as Figure 1-2 As shown, it consists of mooring tower fixing module 1, mooring tower rotating module 2, lifting module 3 and tapered fixing device 4.

[0046] The mooring tower fixed module 1 and the mooring tower rotating module 2 are truss structures of composite materials; the four main rods are carbon fiber tubes with a diameter of 80 mm and a wall thickness of 2 mm; the web rods are carbon tubes with a diameter of 40 mm and a wall thickness of 2 mm The reinforcement rods 11 and 201 are carbon tubes with a diameter of 40 mm and a wall thickness of 5 mm; the connection between the main rod and the web rod adopts a molded co-curing method, an integrated structure, and the joint has high structural strength and light weight.

[0047] Table 1 below compares the weight of tethered towers made of different materials:

[0048] Table 1. Weight list of materials with the same strength and differe...

Embodiment 2

[0060]This embodiment illustrates the installation process of the mooring tower in Embodiment 1.

[0061] The mooring tower fixing module 1 is fixed with the mooring platform, and there are four flanges at the lower end, and each flange has bolt holes for fixing, and the bolts of M10 are used for fixing.

[0062] The mooring tower rotation module 2 is first installed on the ground, and the flange piece between the first section of the rotation module, the second section of the rotation module and the third section of the rotation module is connected, and the bolts of M10 are used for fixing.

[0063] The mooring tower rotation module 2 is connected with the tower fixed module 1, the double lug 200 on one side of the lower end of the rotation module is connected with the single lug 12 on one side of the upper end of the fixed module, the lubricating pad 42 is put into the lug hole, and a cone is used to Shaped nut bolts 40, 41 are fixed through the tapered holes on the lugs.

...

Embodiment 3

[0067] This embodiment illustrates the dismantling process of the tethered tower in Embodiment 1.

[0068] The lifting module 3 is installed on the reinforcing rods 11 and 201 of the mooring tower fixed module 1 and the mooring tower rotating module 2 .

[0069] Disassemble the two tapered sub-bolts 40 and 41 on both sides of the lifting module 3, rotate the rocker arm 32 of the lifting module 3 to raise the lifting module 3, and the mooring tower rotating module 2 rotates around one end and one side to turn over. down position.

[0070] Remove the nose cone mooring device 5 installed on the installation platform 221;

[0071] Disassemble the lifting module 3;

[0072] Remove the two conical sub-bolts 40 and 41 connecting the lower end of the mooring tower rotation module 2 to the mooring tower fixed module 1 to complete the disassembly of the mooring tower rotation module 2; dismantle the sub-modules of the mooring tower rotation module 2 on the ground .

[0073] Detach t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com