Cutting machine

A technology of cutting machines and racks, applied in the directions of cutters, harvesters, agricultural machinery and implements, etc., can solve the problems of large total stroke and total length, expensive, increased volume, quality and cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

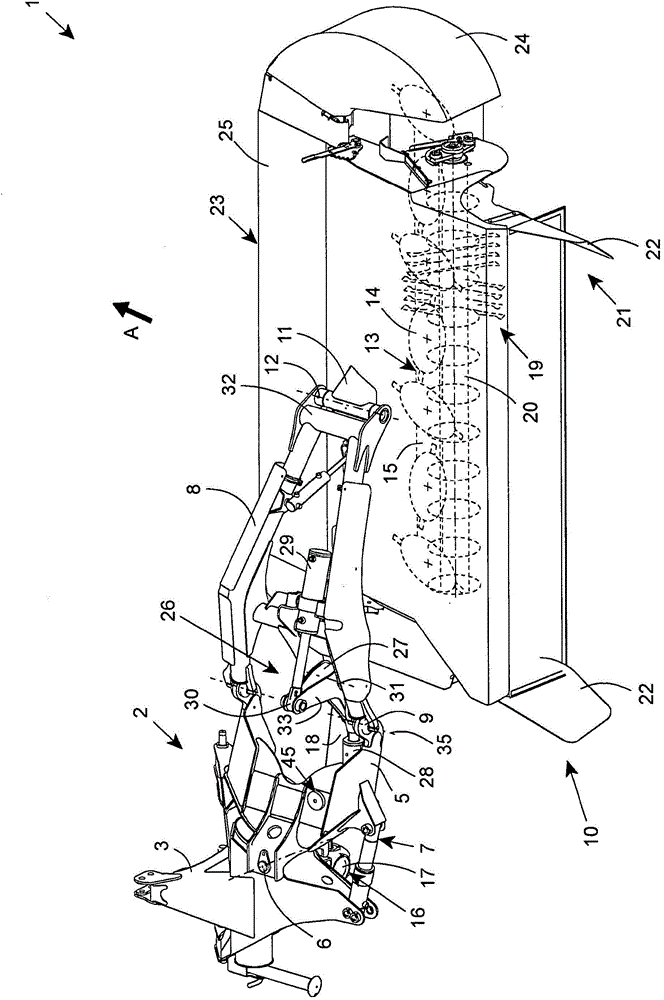

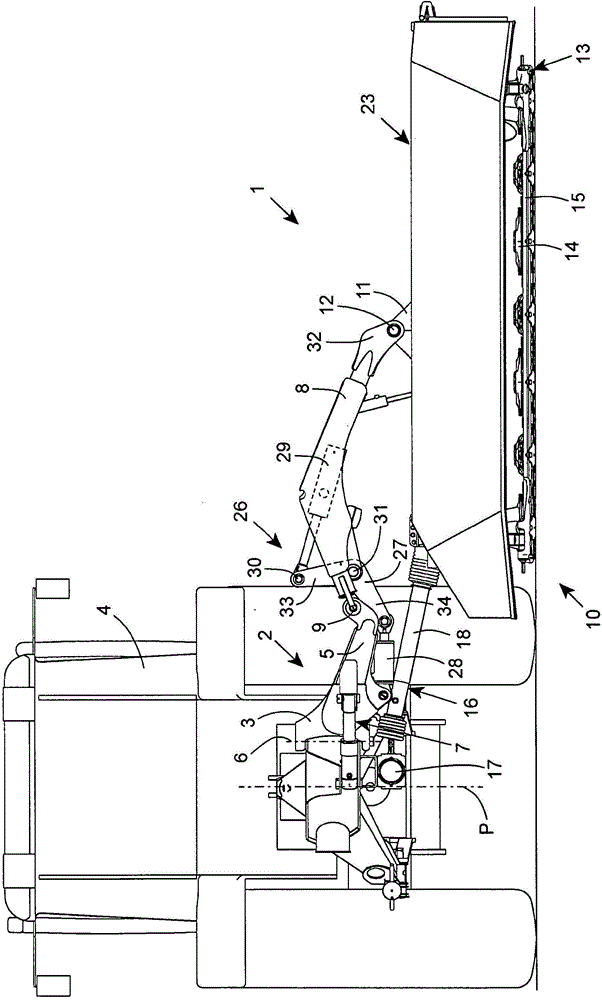

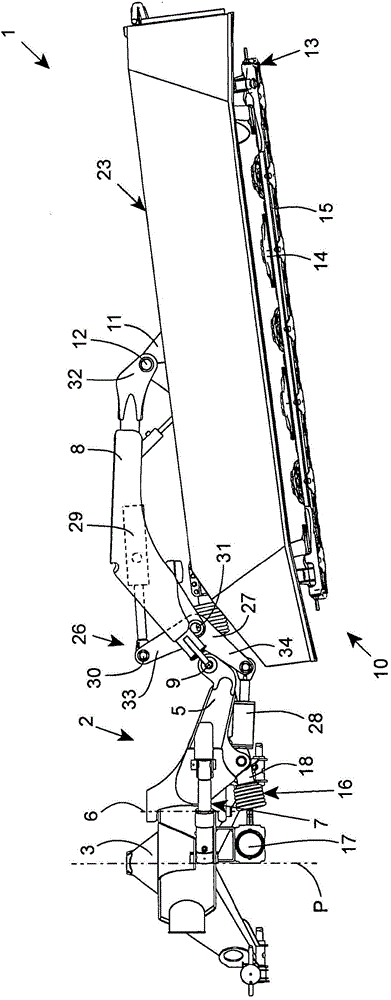

[0016] In the following, concepts such as "above", "below", "lower" and "upper" are defined relative to the ground, and concepts such as "front", "rear", "downstream", "left" and "right" are defined relative to Defined in the forward direction (A).

[0017] Such as figure 1 As shown, the cutting machine (1) of the present invention includes a frame (2). The frame (2) particularly comprises a articulated bracket (3), which can be mounted on figure 2 On the three-point hitch coupler of the tractor (4) which is only partially shown on the top. The articulation bracket ( 3 ) is, for example, in the form of a mechanically welded structure. The hitch bracket comprises in its lower part two journals designed to be hooked on the lower hitch arm of the tractor (4). In its upper part, the hitch bracket comprises one or more eyelets receiving a shaft for connection to the upper hitch link of the tractor (4). Rack (2) also has a frame (5). The frame (5) can be rigidly or hingedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com