Patents

Literature

31results about How to "Expand the operating horizon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

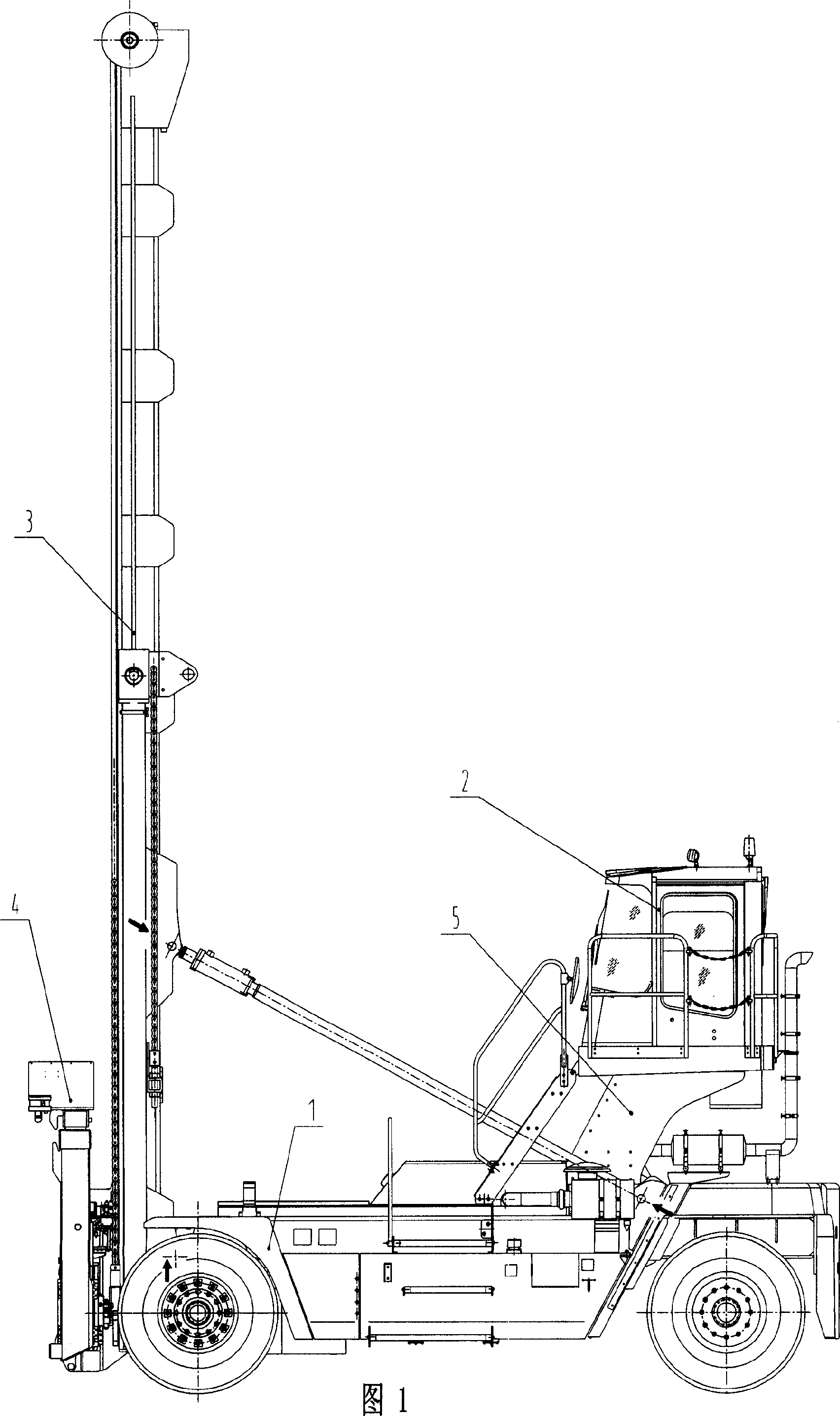

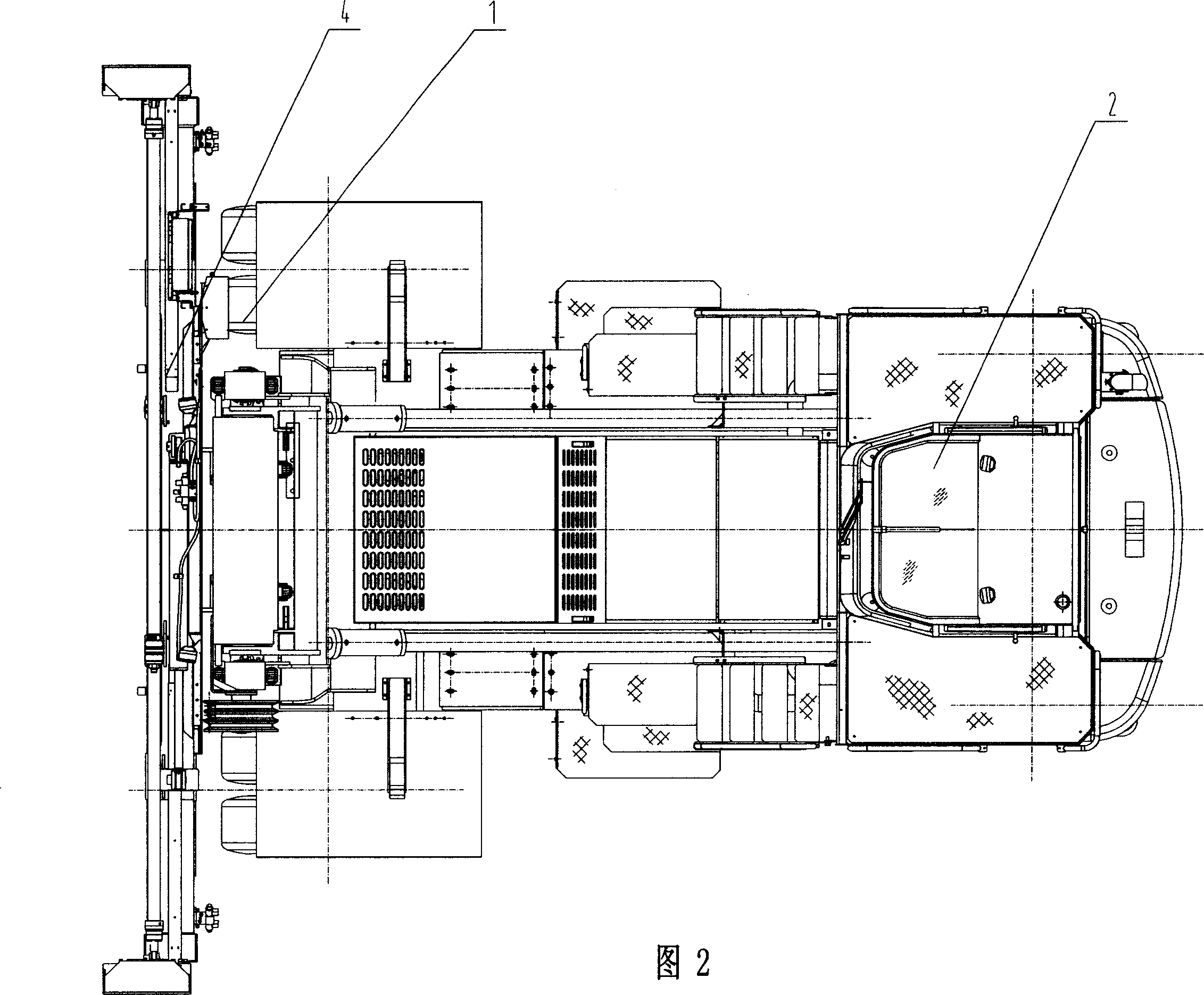

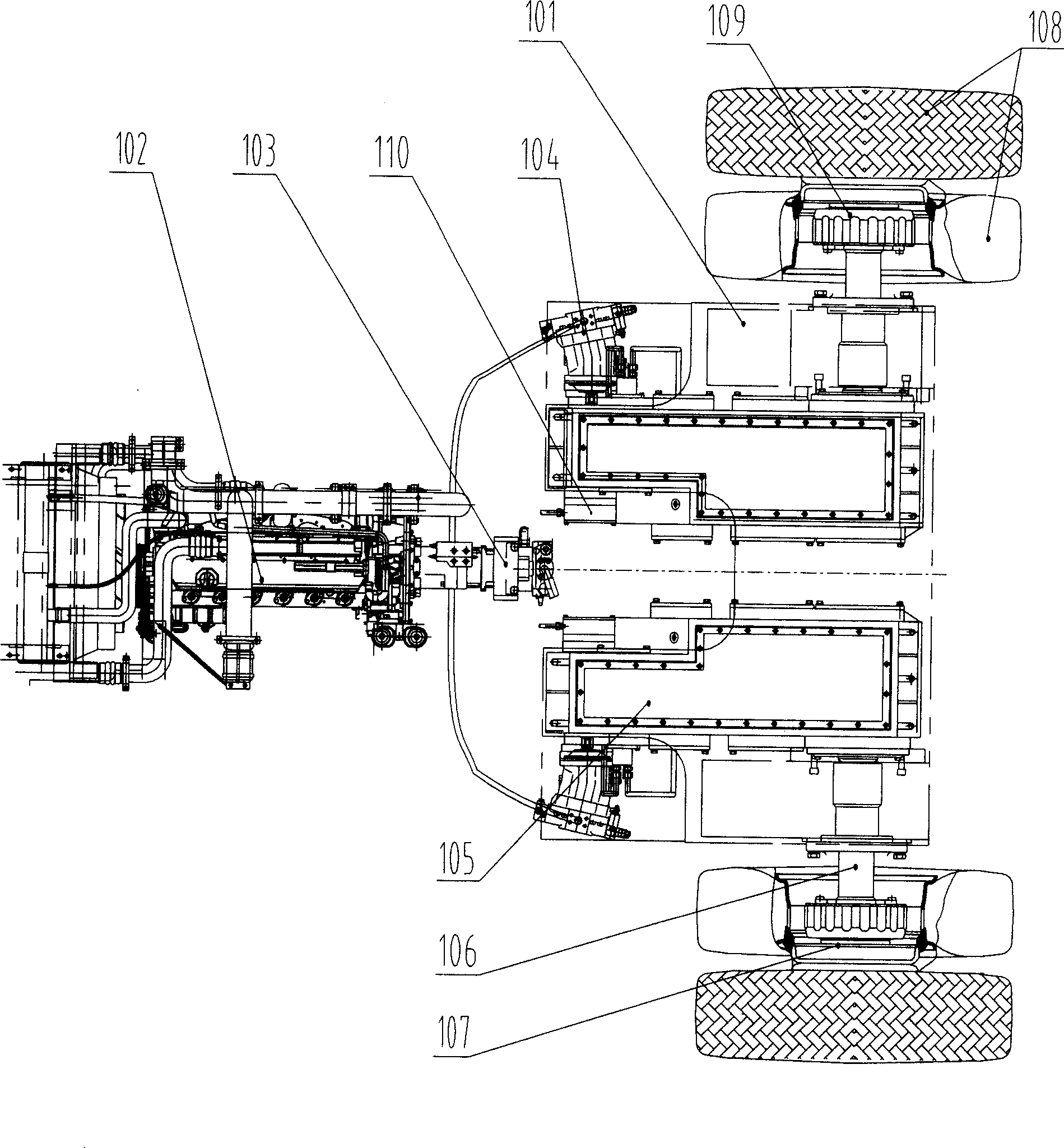

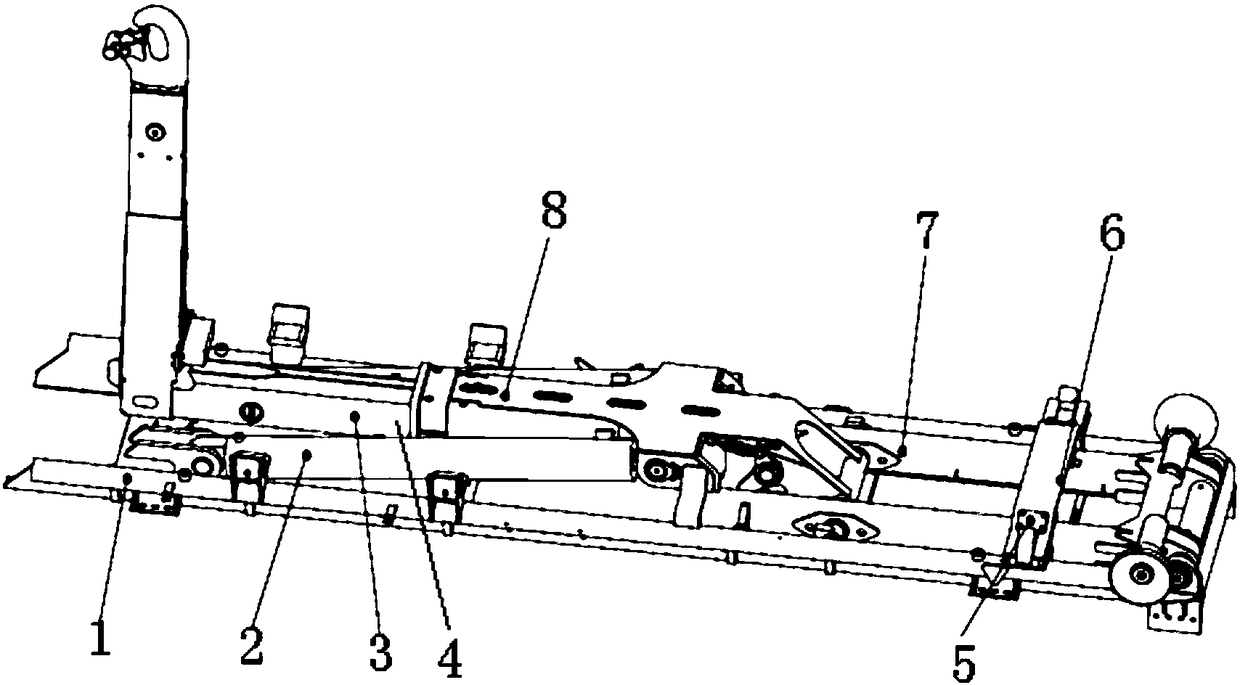

Hydraulic empty container piling crane

InactiveCN1887683AImprove transmission efficiencyReduce energy consumptionLifting devicesHydraulic motorVehicle frame

The hydraulic empty container piling crane includes walking chassis, operator's cab, gantry and sling. The operator's cab and the gantry are installed on the walking chassis, and the sling is installed onto the gantry. The walking chassis includes chassis frame, engine, hydraulic pump, hydraulic motor, speed reducer, half shaft, wheel mechanism and tyre assembly. The hydraulic pump is connected to the output of the engine and connected via pipeline to at least two hydraulic motors, the hydraulic motor has output connected via the speed reducer to the half shaft, the half shaft is connected via the wheel mechanism to the tyre assembly, and the speed reducer is installed on the chassis frame. The present invention has high work efficiency, convenient operation, low use cost and other advantages.

Owner:SANY HEAVY IND CO LTD (CN)

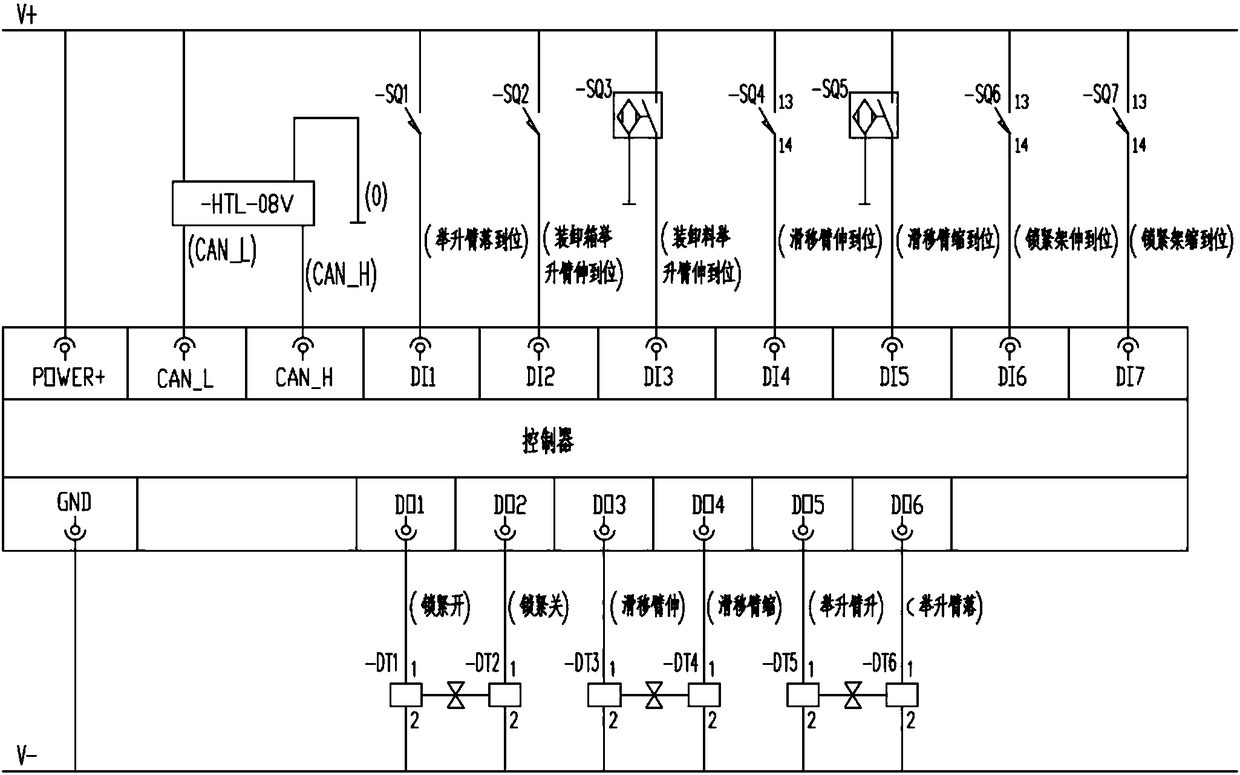

Intelligent control system of detachable container type garbage truck

The invention discloses an intelligent control system of a detachable container type garbage truck. The intelligent control system of the detachable container type garbage truck comprises an manual operation box, a controller, a sliding arm appropriate extension travel switch, a lifting arm appropriate fall travel switch, a sliding arm appropriate retraction proximity switch, a loading and unloading container state lifting arm appropriate extension travel switch, a locking frame appropriate extension travel switch, a loading and unloading state lifting arm appropriate extension proximity switch and a locking frame appropriate retraction travel switch. The controller controls a lifting arm oil cylinder, a sliding arm oil cylinder and a locking frame oil cylinder to complete sequential actions of the overall truck. The controller receives a detection signal of a detection switch and judges the positions of a sliding arm, a locking frame and a lifting arm, the manual operation box sends instructions to control the lifting arm oil cylinder, the sliding arm oil cylinder and the locking frame oil cylinder to sequentially act, and the intelligent control effect is achieved.

Owner:XUZHOU XUGONG ENVIRONMENTAL TECH CO LTD

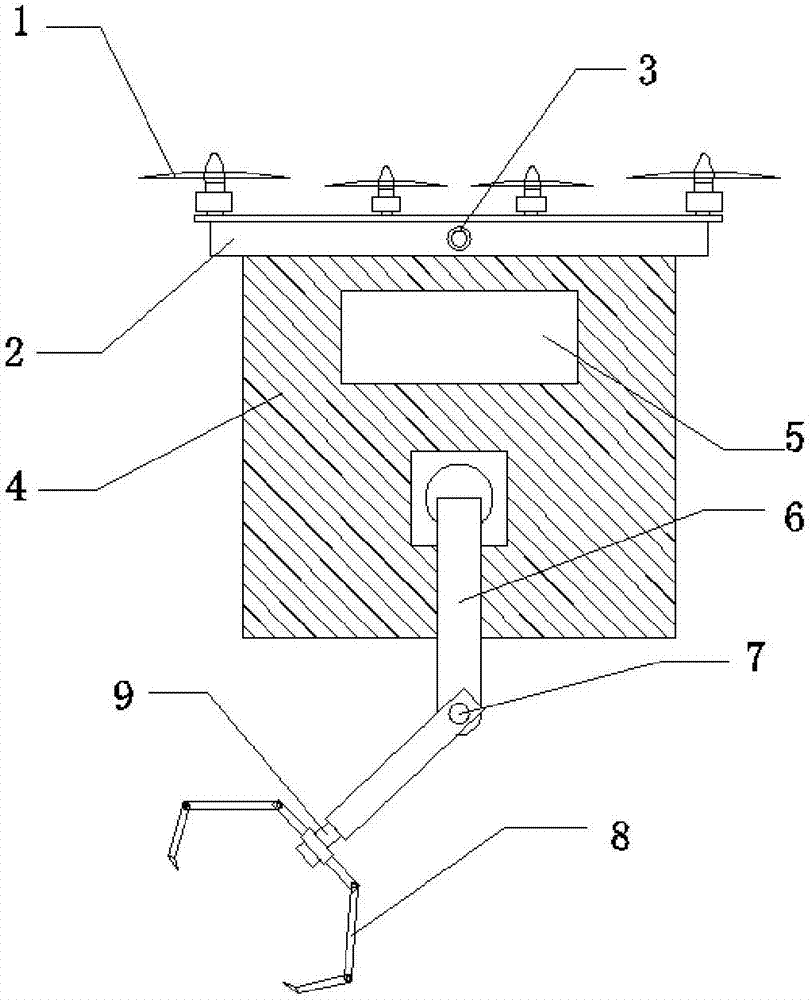

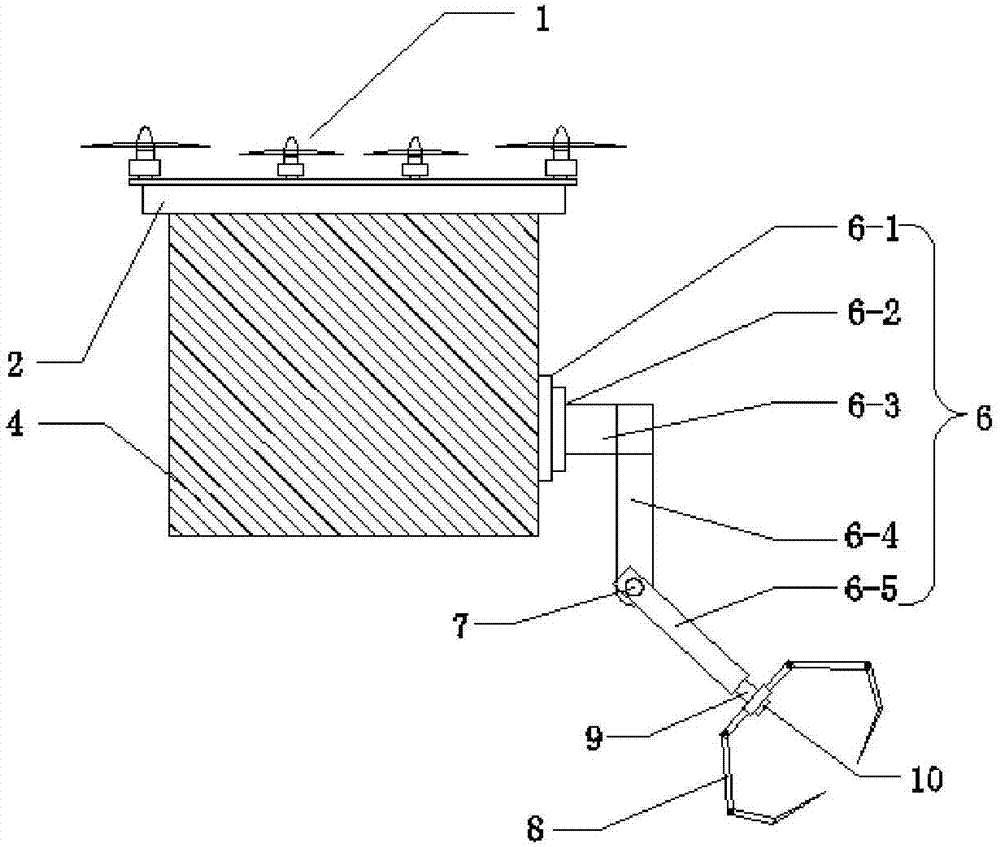

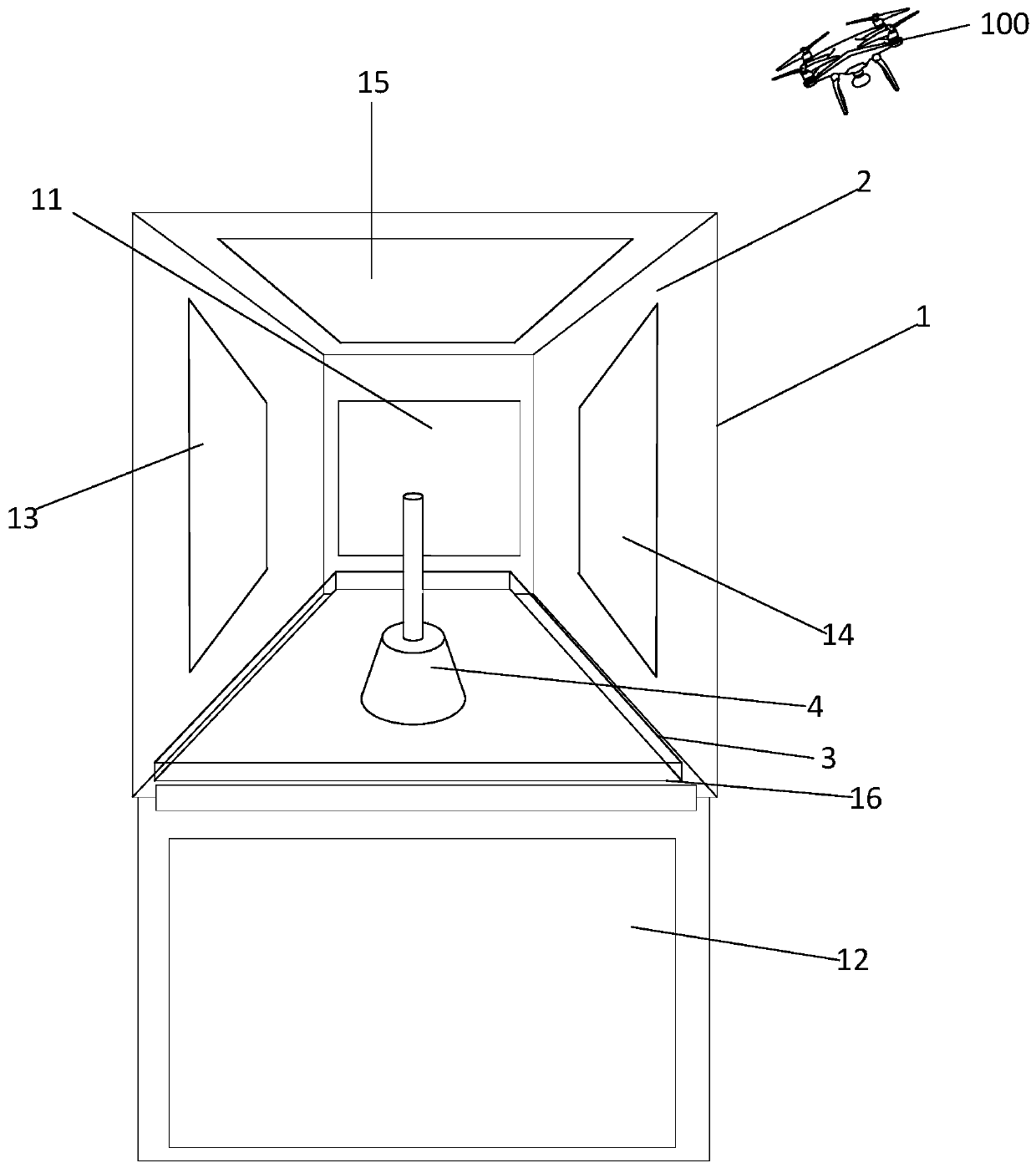

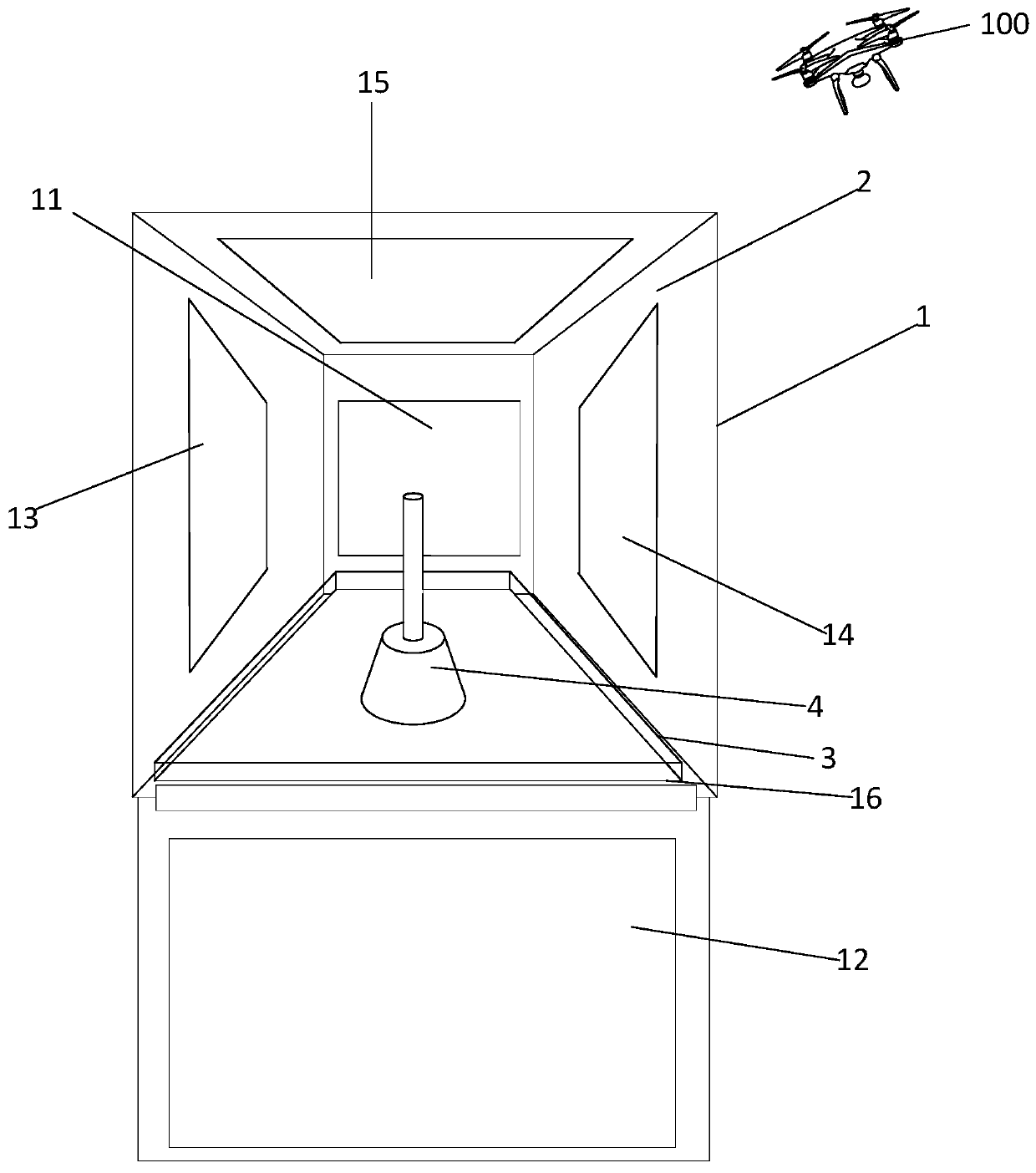

Garbage picking-up unmanned aerial vehicle integrated with garbage can

InactiveCN107881980AIncrease the amount of garbage picked upRealize controllable operationAircraft componentsWay cleaningUncrewed vehiclePropeller

The invention discloses a garbage picking unmanned aerial vehicle integrating a garbage bin, which relates to the field of unmanned aerial vehicles and includes a propeller, a control room, a garbage bin, a mechanical arm assembly and a mechanical claw. The control room is arranged under the propeller. A storage battery and a camera electrically connected to the storage battery are provided in the control room, the dustbin is fixed at the bottom of the control room, an opening is opened on one side of the dustbin below the camera, and the mechanical arm assembly is fixed below the opening, The mechanical claw is arranged at the end of the third mechanical arm. The invention solves the problem that it is difficult and dangerous to clean up the garbage in the mountains, and the garbage bin is arranged under the drone, so that the invention can realize multiple pickups of garbage by the drone within the same flight distance.

Owner:ZHENGZHOU QISHUO ELECTRONICS TECH CO LTD

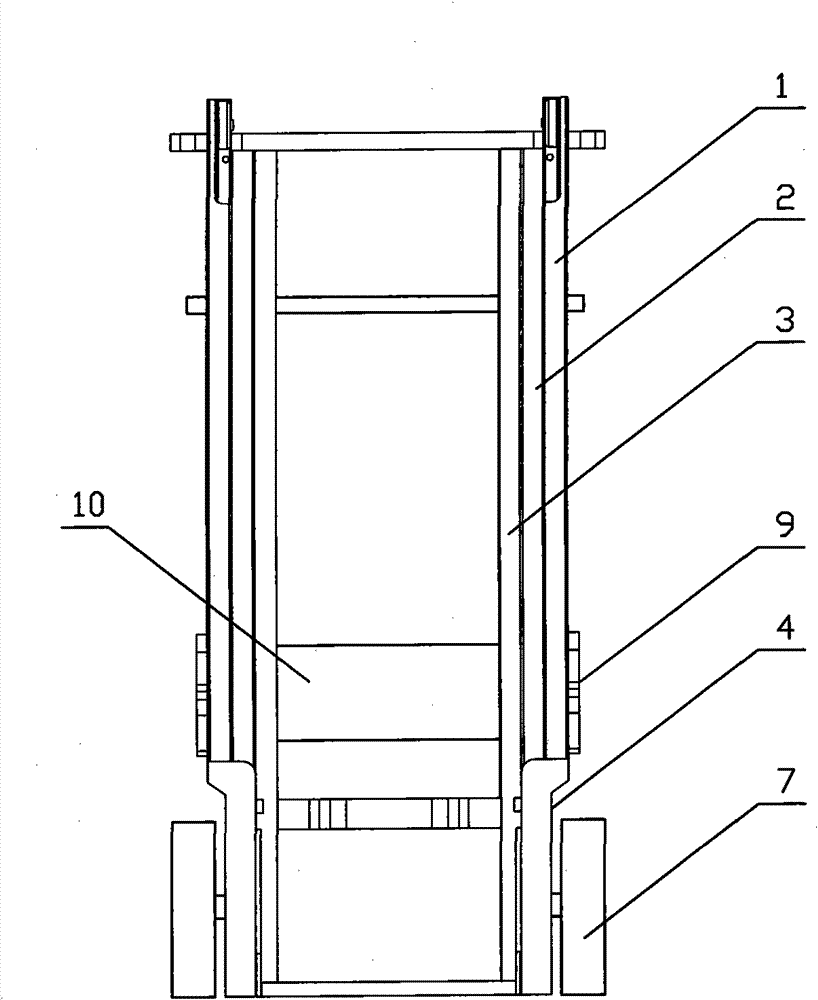

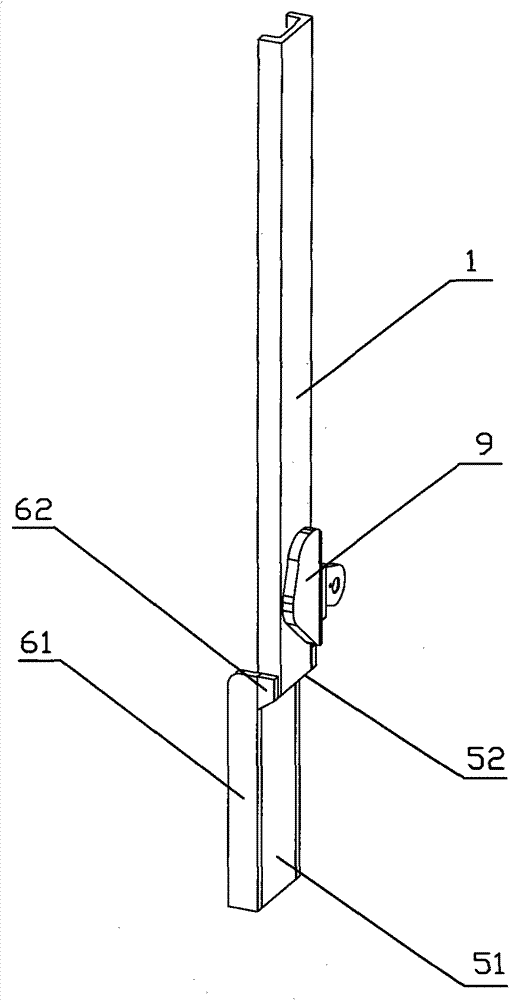

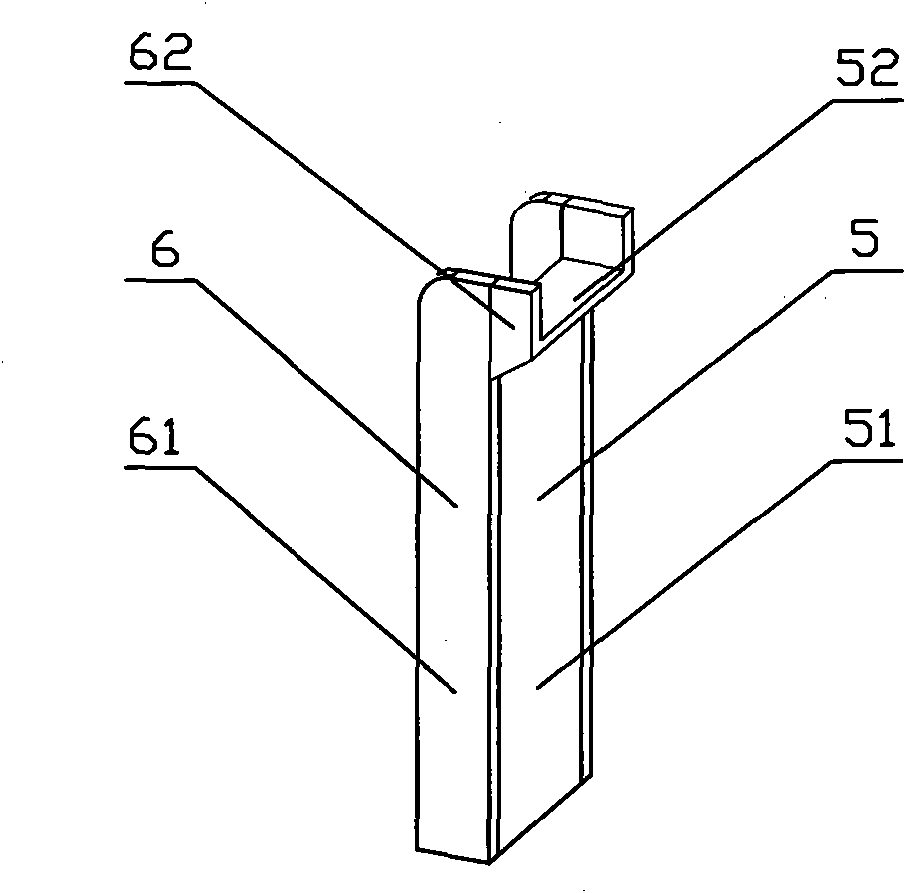

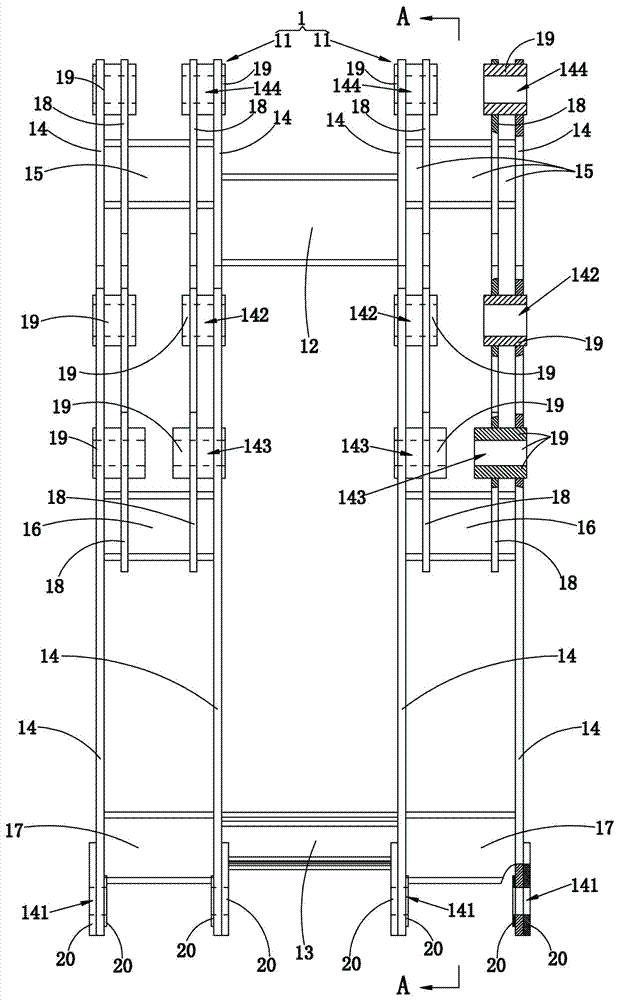

Outer portal frame of forklift truck, triple portal frame of forklift truck and forklift truck

ActiveCN101717058BIncrease distanceExpand the operating horizonLifting devicesPortal frameAerospace engineering

The invention relates to a carrying vehicle device and discloses an outer portal frame of a forklift truck, comprising an outer portal frame supporting column and a portal frame supporting device, wherein the outer portal frame supporting column is arranged on the portal frame supporting device comprising a supporting piece and wing plates which are symmetrically arranged at two ends of the supporting piece front and back; the wing plates are mutually vertical to the supporting piece consisting of a supporting piece web plate and a supporting tabletop on the outer wall of the supporting pieceweb plate; the supporting tabletop is arranged above tires of the forklift truck; the outer portal frame supporting column is arranged on the supporting tabletop; and the supporting piece web plate, the front wing plate and the rear wing plate form a cavity for inserting a middle portal frame. The invention effectively broadens the operation view of drivers and can reduce the economic loss causedby goods damage due to view blind area while improving the safety and the working efficiency.

Owner:ZHEJIANG MAXIMAL FORKELEVATOR

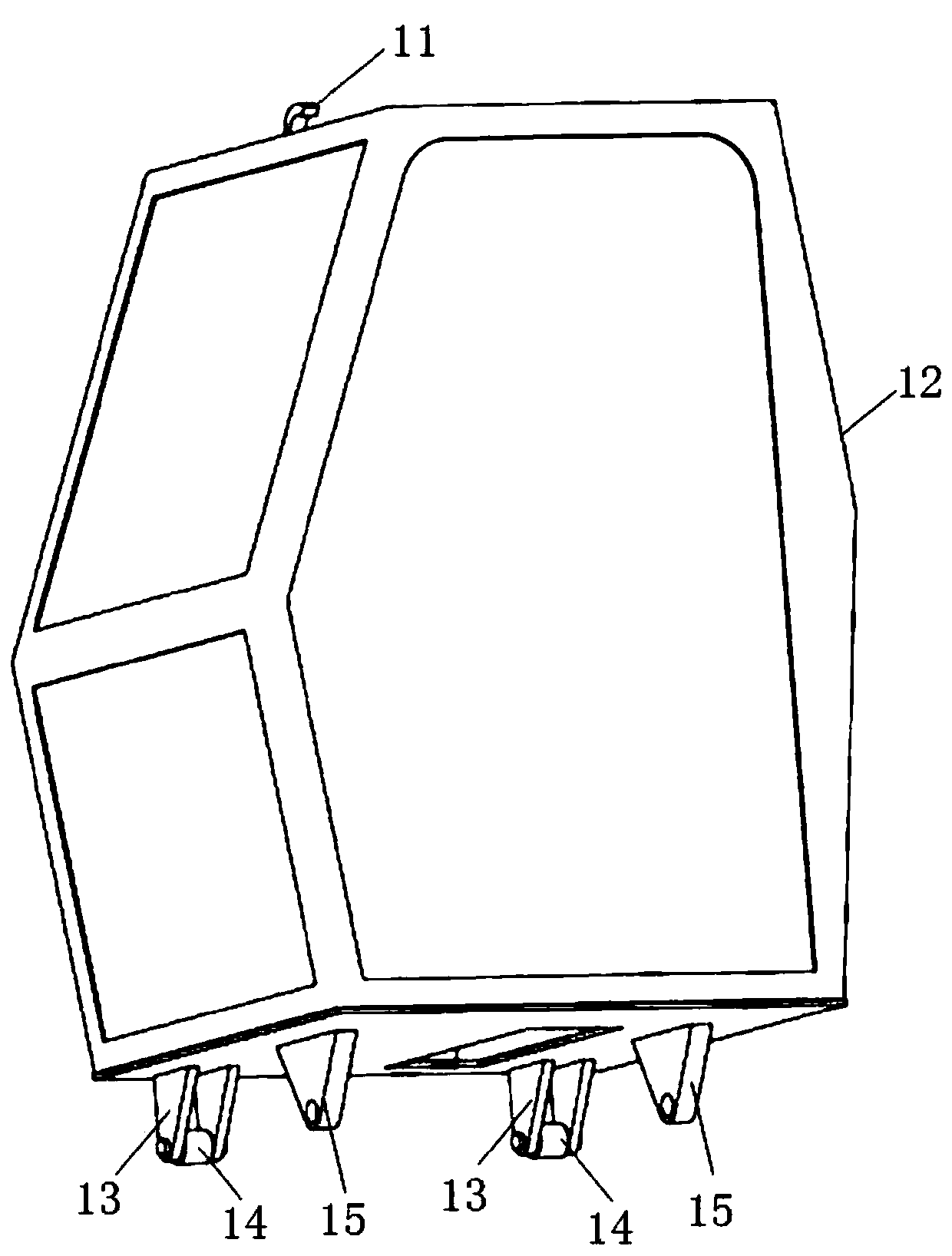

Foldable sliding driver cab and engineering machine with same

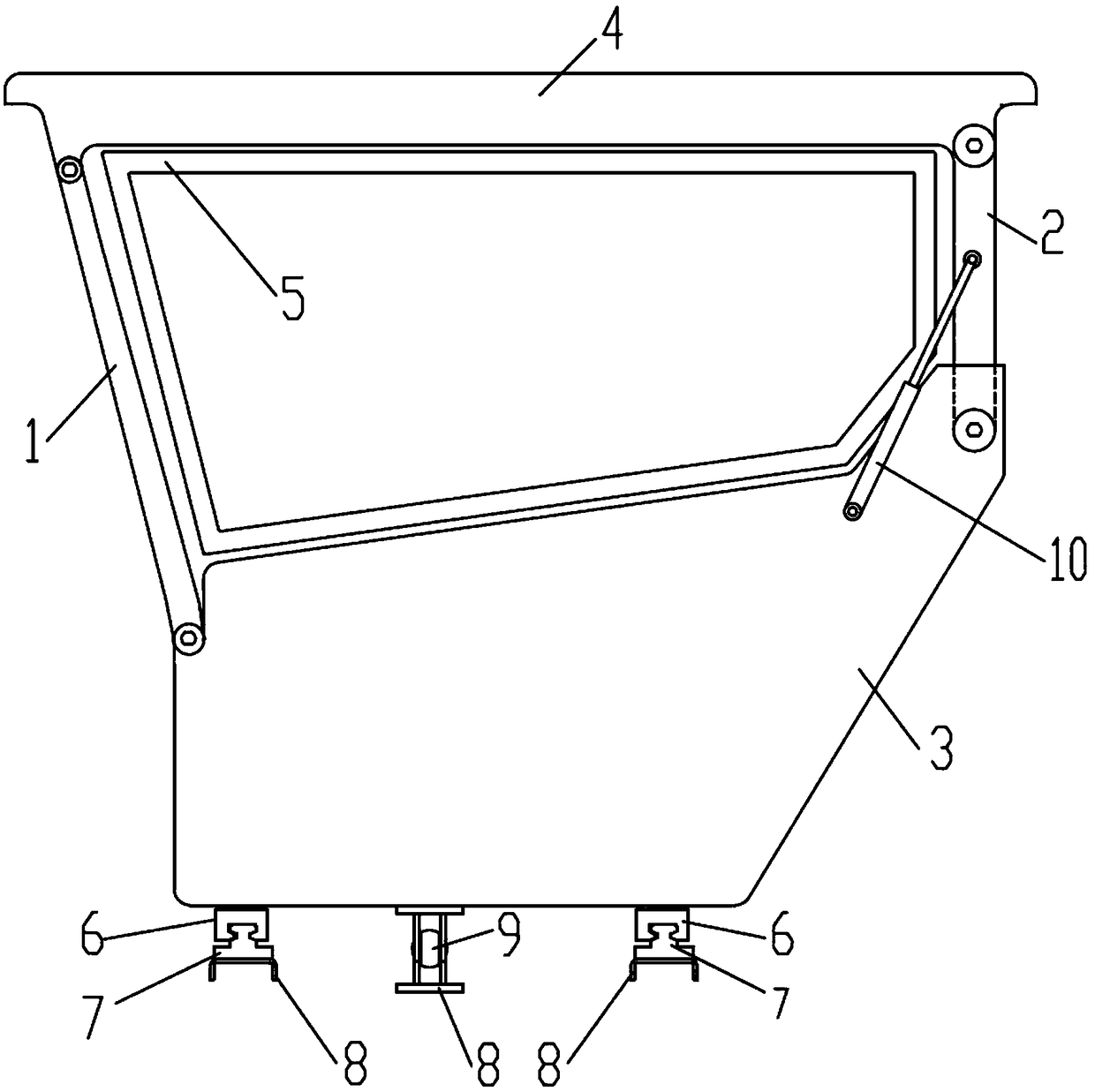

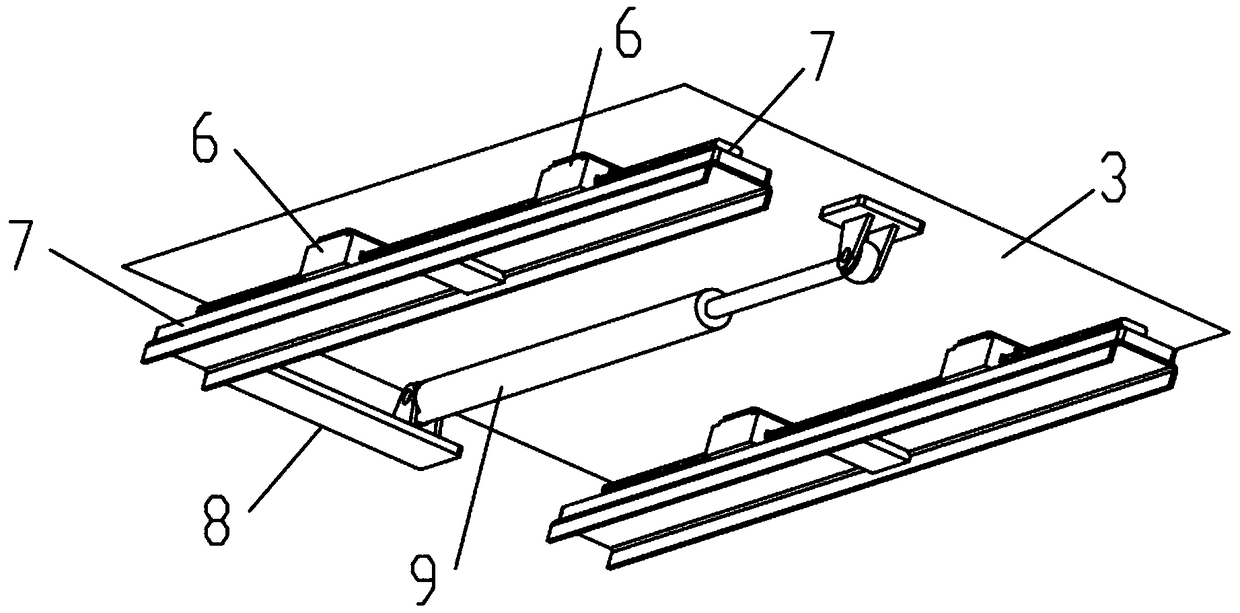

PendingCN109353416ALower transport heightExpand the operating horizonLoading-carrying vehicle superstructuresVehicle frameEngineering

The invention discloses a foldable sliding driver cab. The foldable sliding driver cab comprises a driver cab body mounted on a vehicle frame in a sliding mode; the driver cab body comprises a front frame, a rear frame, a lower frame and a top frame, wherein the top frame is hinged to the upper ends of the front frame and the rear frame, the lower ends of the front frame and the rear frame are hinged to the lower frame, and the front frame, the rear frame, the lower frame and the top frame form a four-bar linkage mechanism; the bottom of the lower frame is provided with a slider, the vehicle frame is provided with a sliding rail matched with the slider, and an oil cylinder I is arranged between the vehicle frame and the lower frame. The four-bar linkage mechanism composed of the front frame, the rear frame, the lower frame and the top frame can achieve folding and adjustment of overall transportation height of the foldable sliding driver cab; the driver cab body is provided with the slider, the vehicle frame is provided with the sliding rail, and sliding of the driver cab can be achieved through movement of the slider on the sliding rail to enlarge the operating view and improve the transportation convenience and operating comfort of an engineering machine.

Owner:XCMG CONSTR MACHINERY

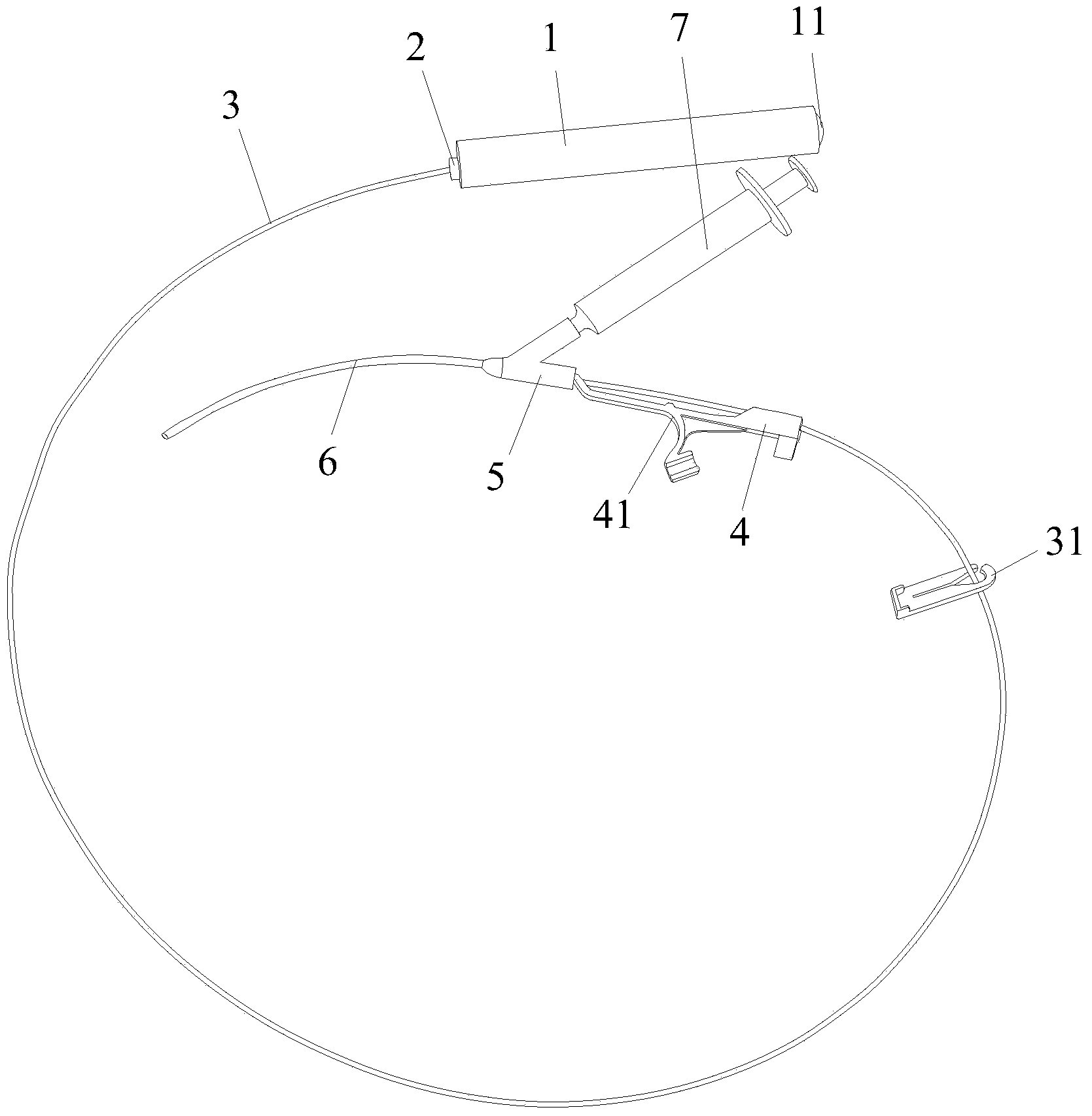

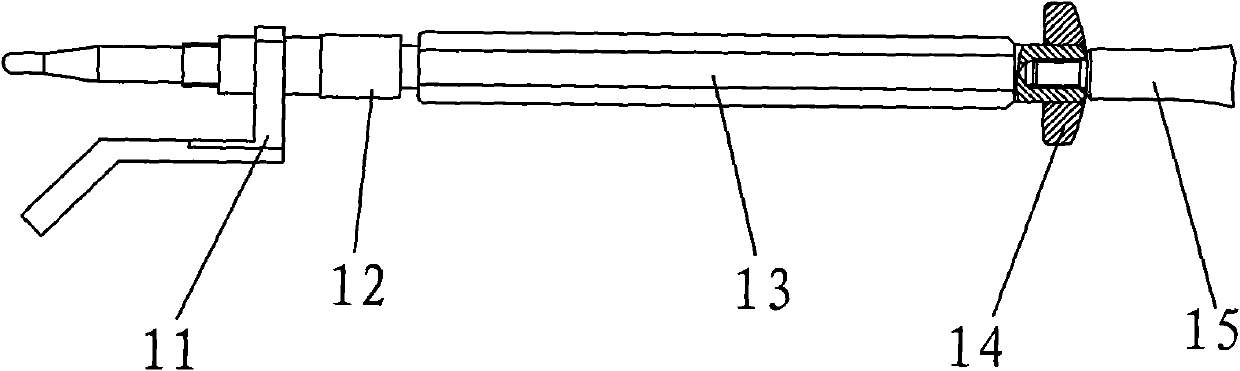

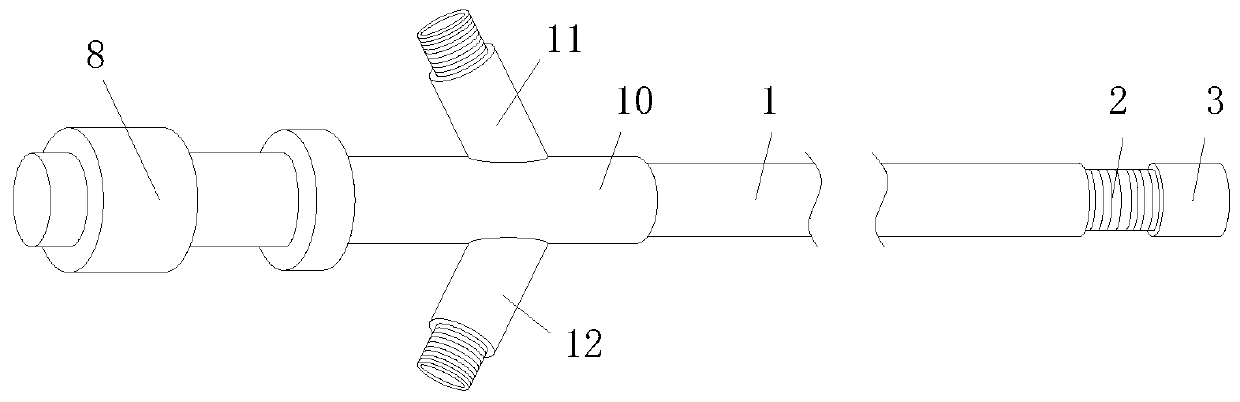

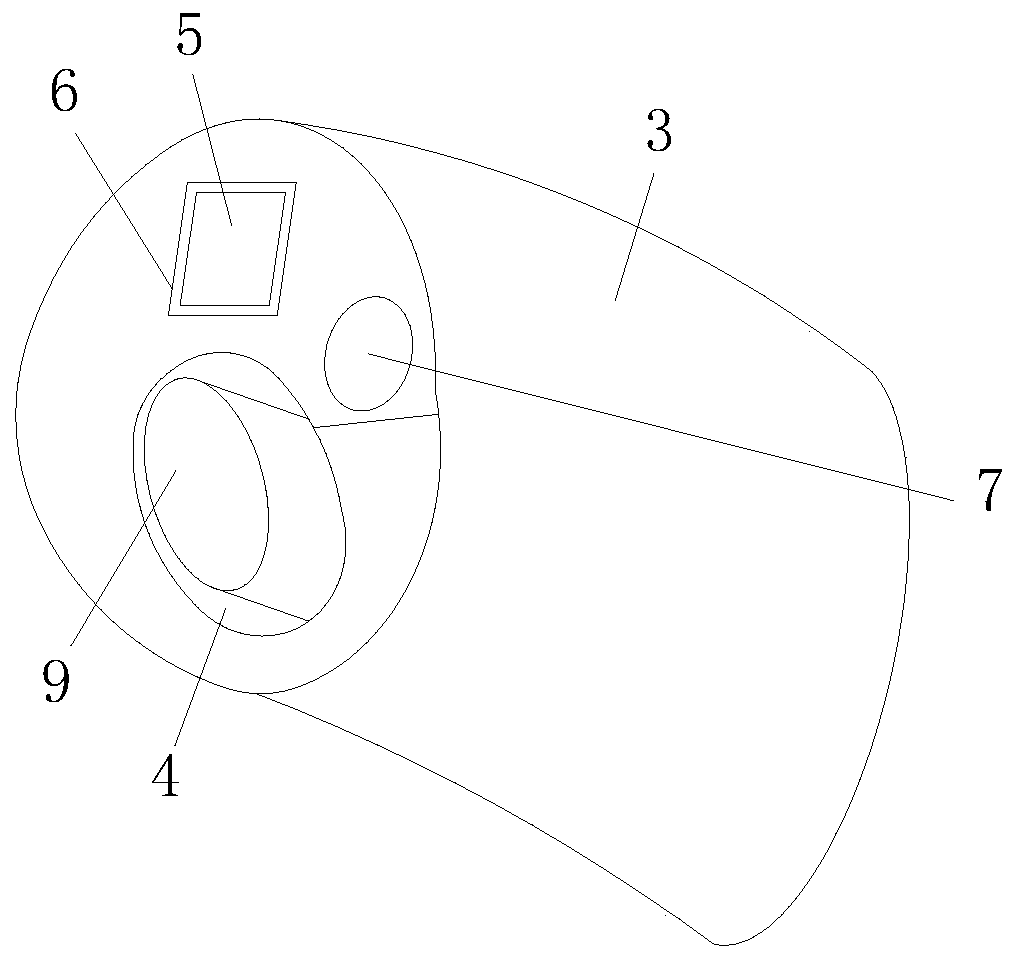

Illumination cannula device for small animal

The invention discloses an illumination cannula device for a small animal, which comprises an LED (Light-Emitting Diode) light source, wherein the front end of the LED light source is connected with a light-guide fiber joint; the front end of the light-guide fiber joint is connected with a light-guide fiber; an optical fiber stabilizing device, a three-way tube and a trachea cannula which are connected with one another are sleeved in sequence at positions close to the front tail end of the light-guide fiber from back to front; the three-way tube is laterally connected with an injector which is communicated with the trachea cannula; and the front tail end of the light-guide fiber is accommodated in the trachea cannula. The illumination cannula device for the small animal disclosed by the invention has the advantages of smaller damages to the tracheae of animals, realization of high animal survival rate, wide view field, sufficient light rays and higher accuracy of insertion of the hose into the trachea cannula.

Owner:陈鸣宇

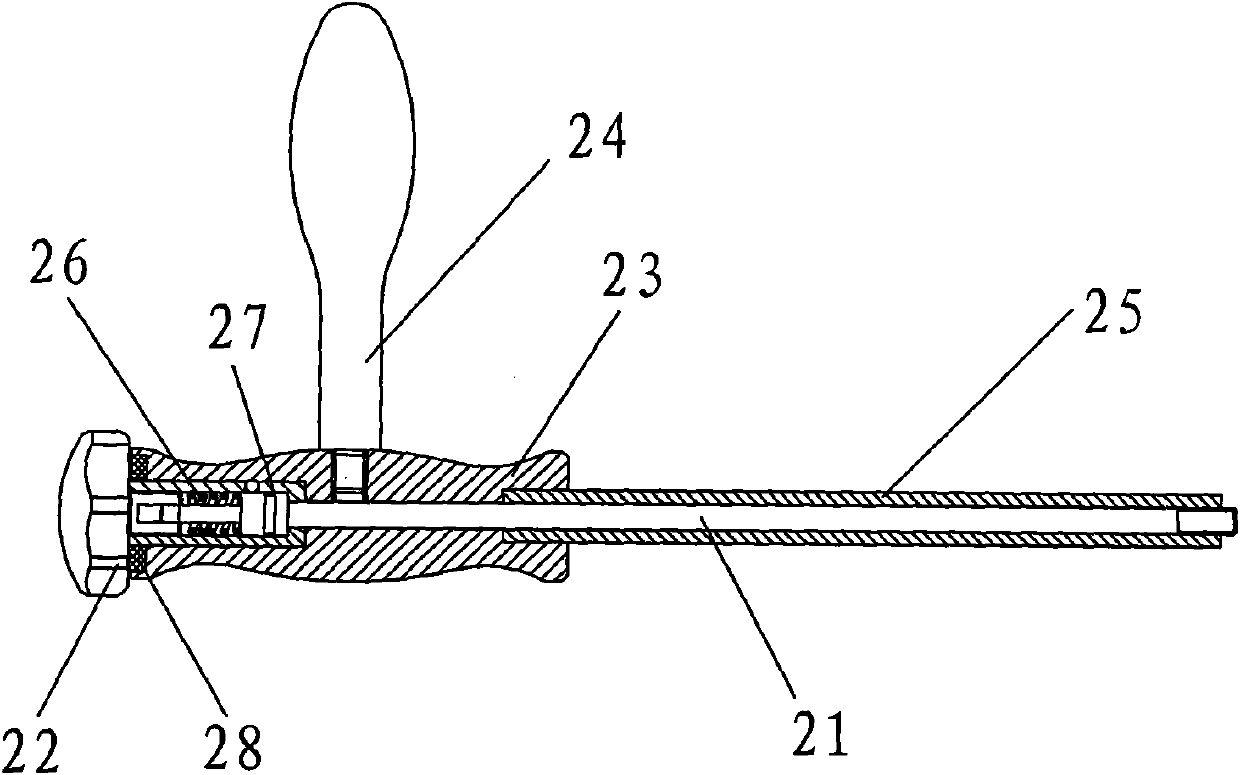

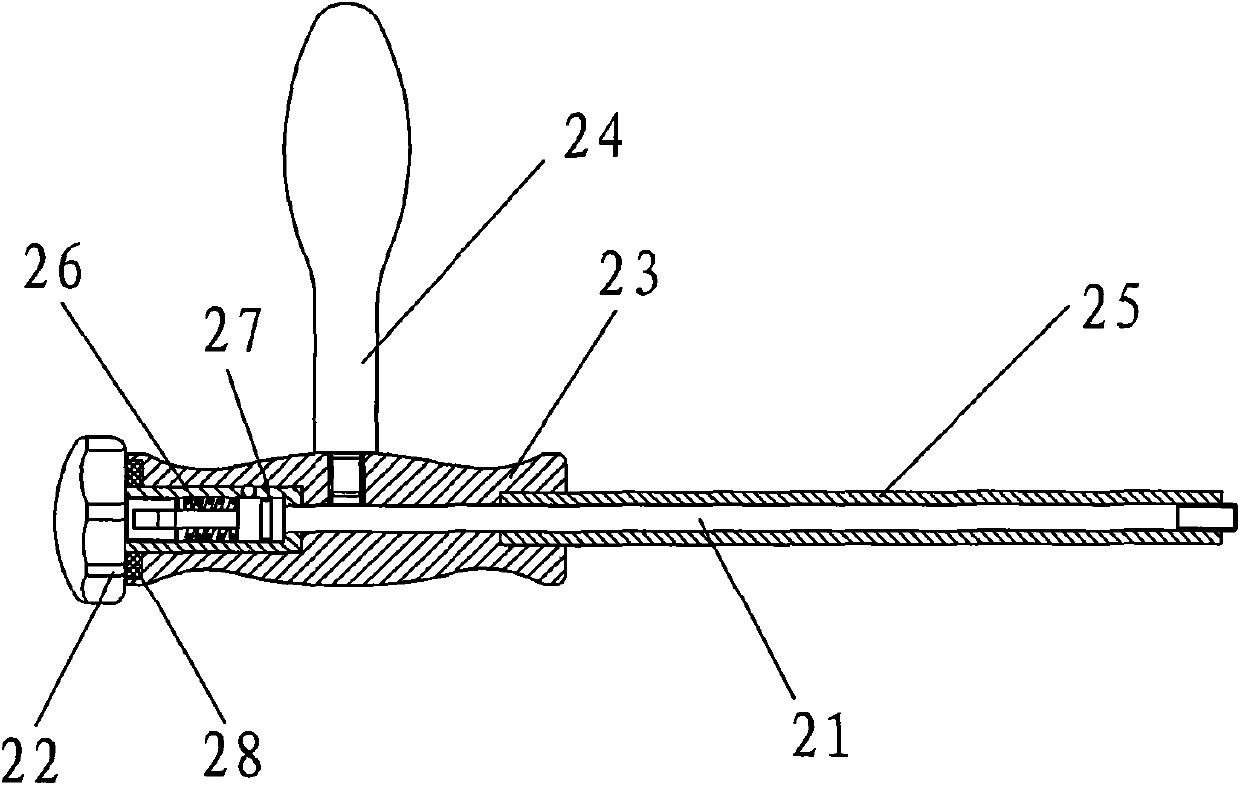

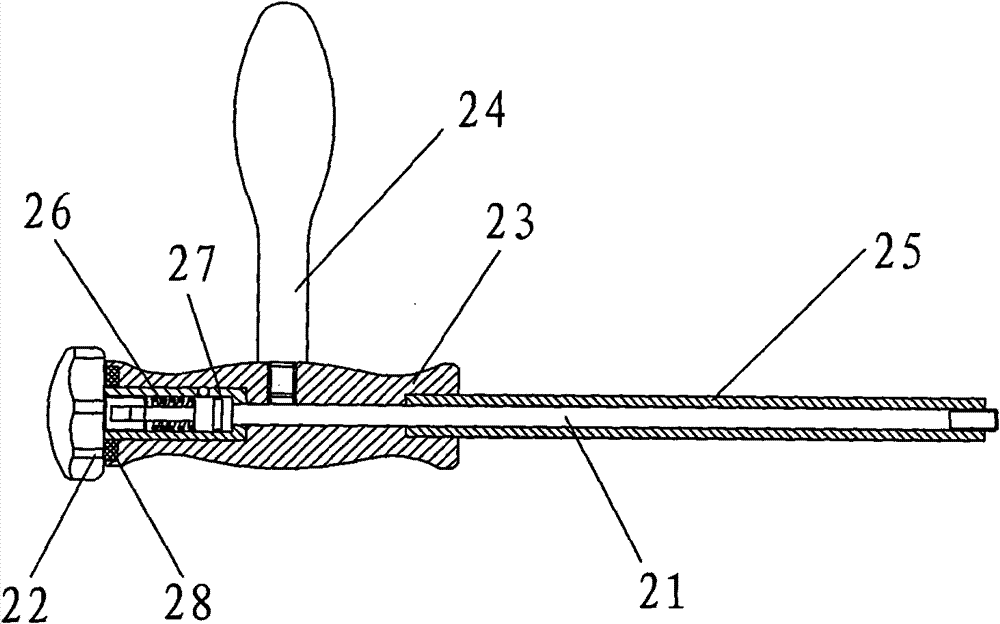

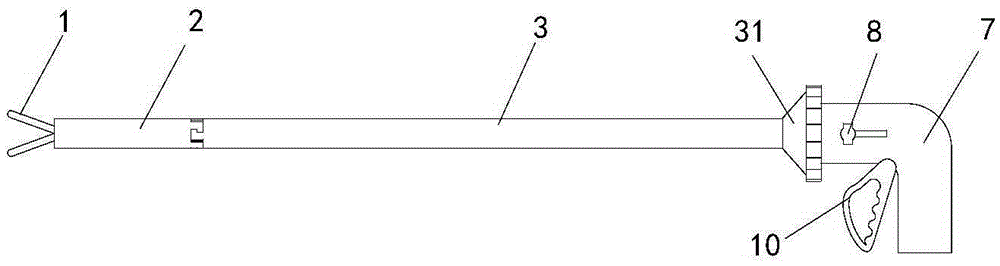

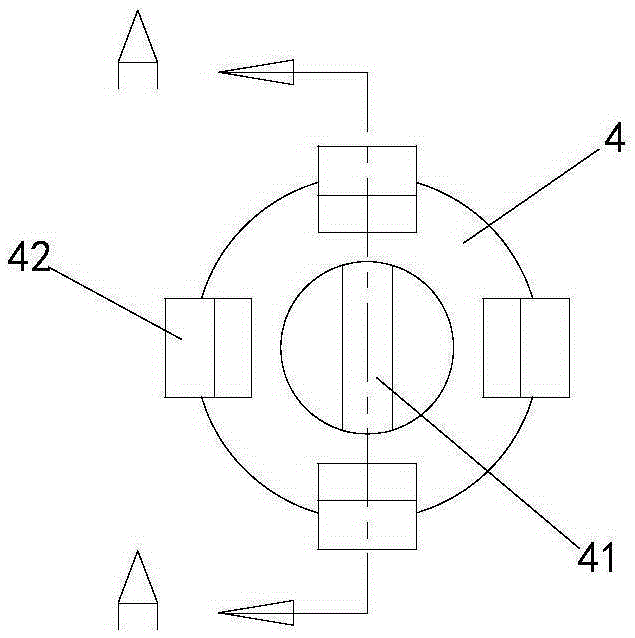

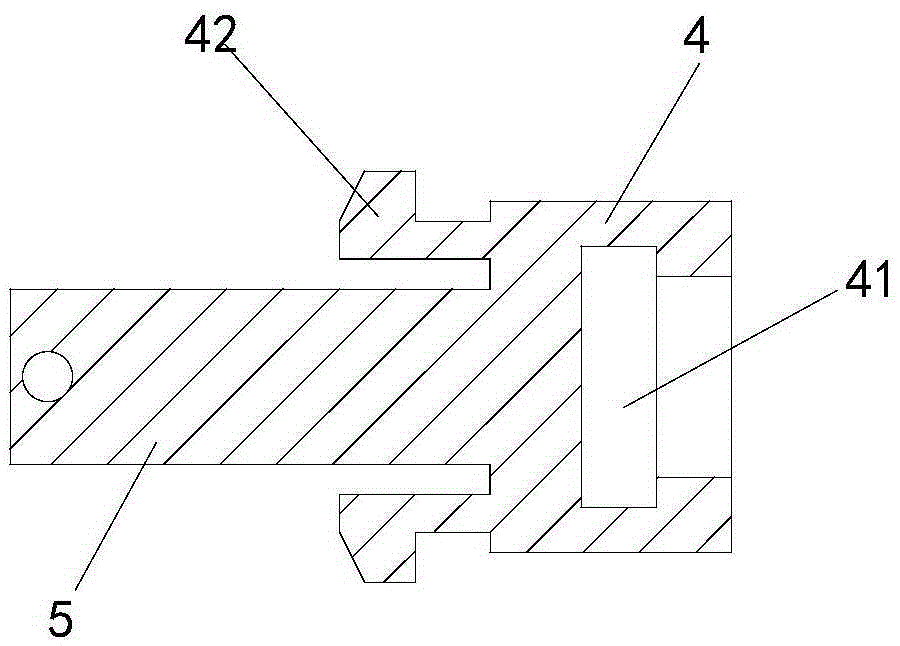

Femoral hip joint stem holder

The invention relates to a femoral hip joint stem holder. The holder comprises a threaded rod, a screwing end cap, a handle and a movable handle, wherein the head of the threaded rod is provided with threads which are matched with a femoral stem; the screwing end cap is connected with the tail end of the threaded rod; the handle is rotatably sleeved at the periphery of the rear part of the threaded rod; and the movable handle is vertically fixed on the handle. The femoral hip joint stem holder can be used conveniently and fast, is rational in torque transfer and has a broad operating range, so that the success rate of surgery is improved.

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

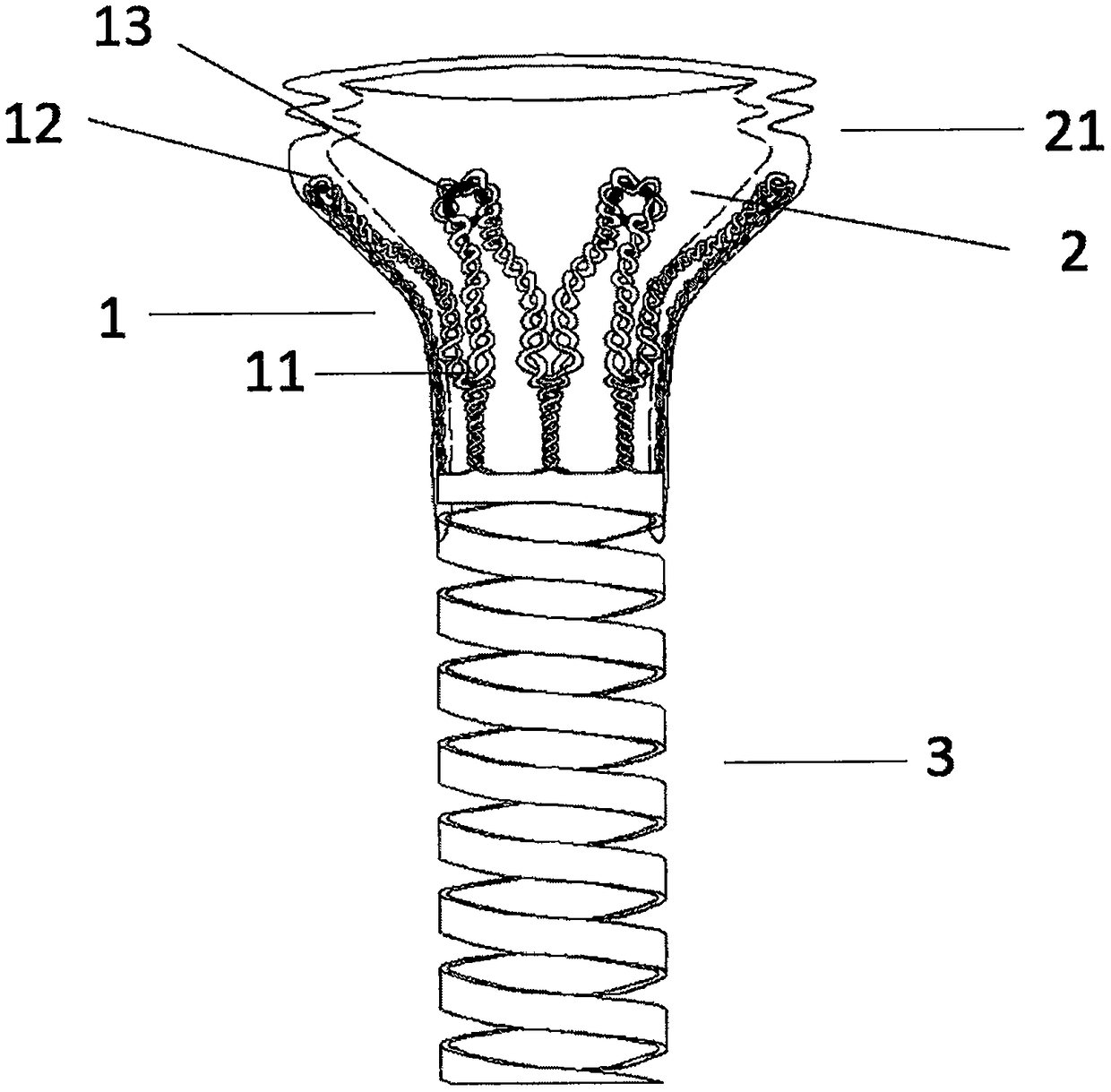

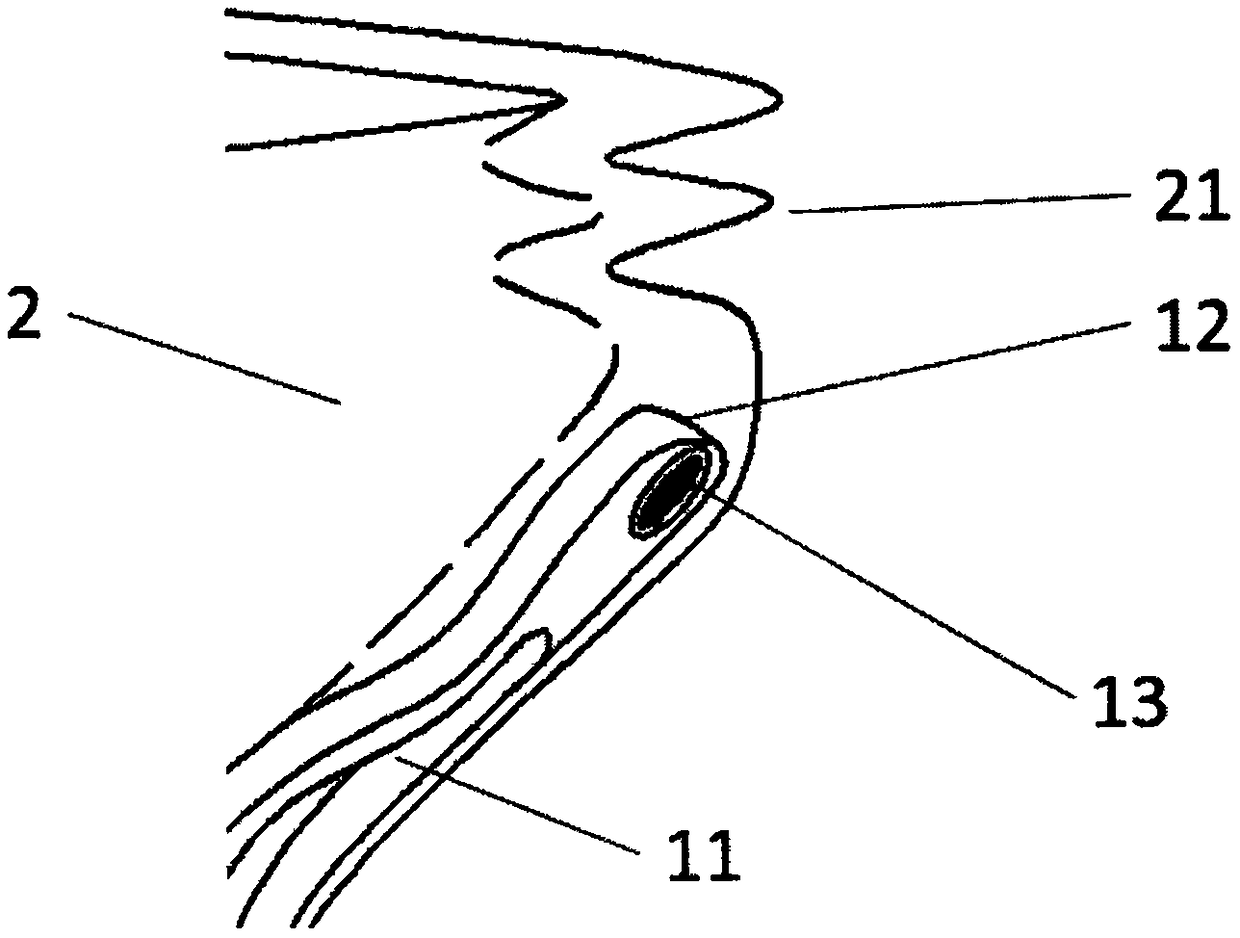

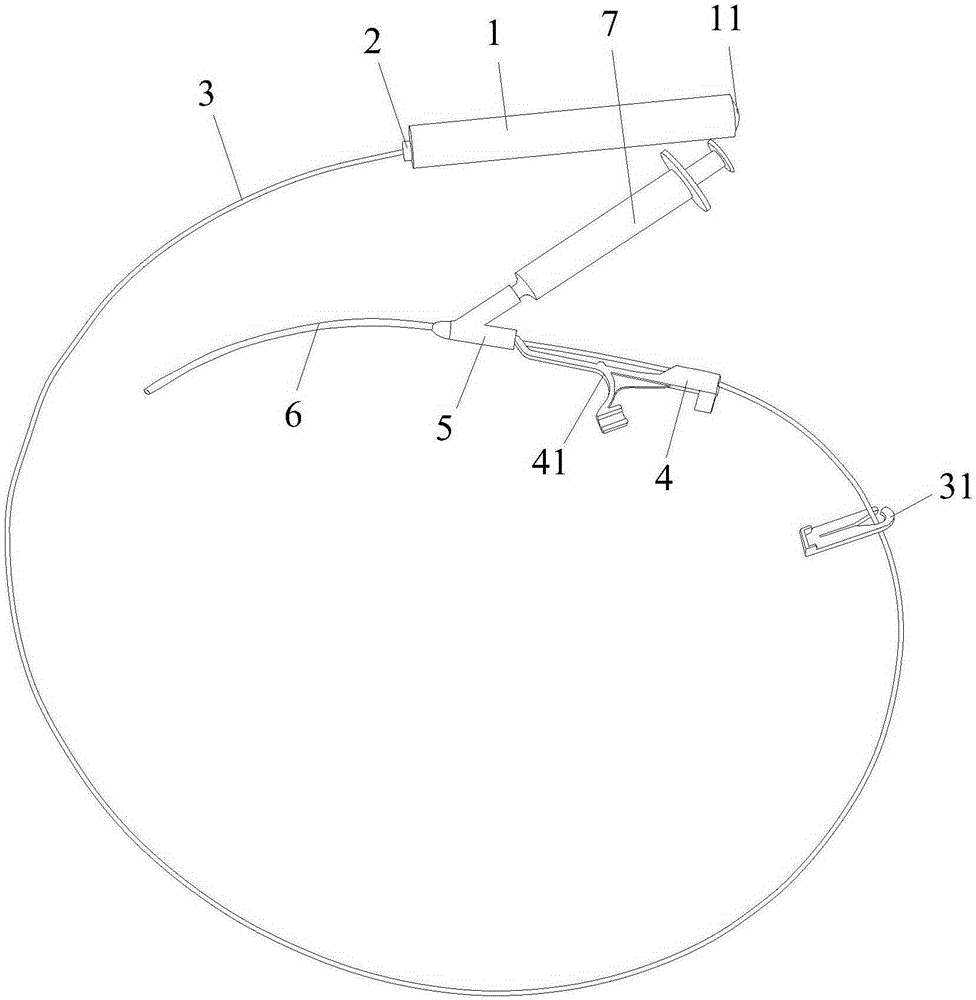

Device for auxiliary fixing

The invention relates to a device for auxiliary fixing. The device comprises a supporting frame (1), a membrane structure (2) and a connecting piece (3). The far end of the supporting frame (1) is inan opening state, the supporting frame (1) is composed of a plurality of supporting rods (11). The far ends of the supporting rods are provided with anti-puncture structures (12), the membrane structure (2) is fixedly connected to the supporting frame (1), the gar end of the membrane structure (2) is provided with a reinforcing structure (21), the connecting piece (3) is fixedly connected to the near end of the supporting frame (1), and the connecting piece (3) is hollow. The problems that in the prior art, due to heart beating, an injection needle and a conveying pipe are likely to slide, aninjection point is not accurate, an injectant is likely to be disengaged, and the myocardium is abraded and punctured are solved.

Owner:NINGBO DIOCHANGE MEDICAL TECH CO LTD

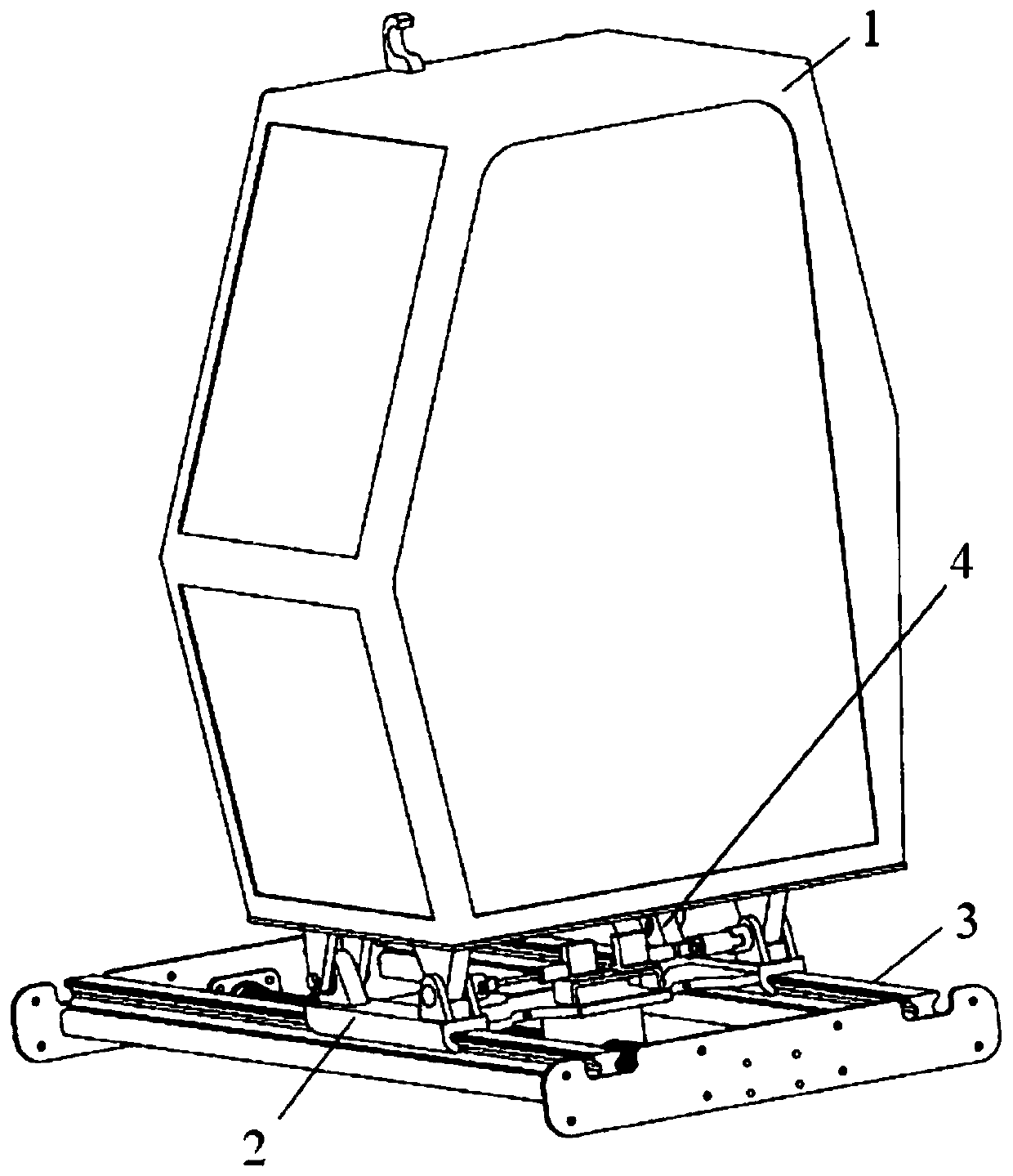

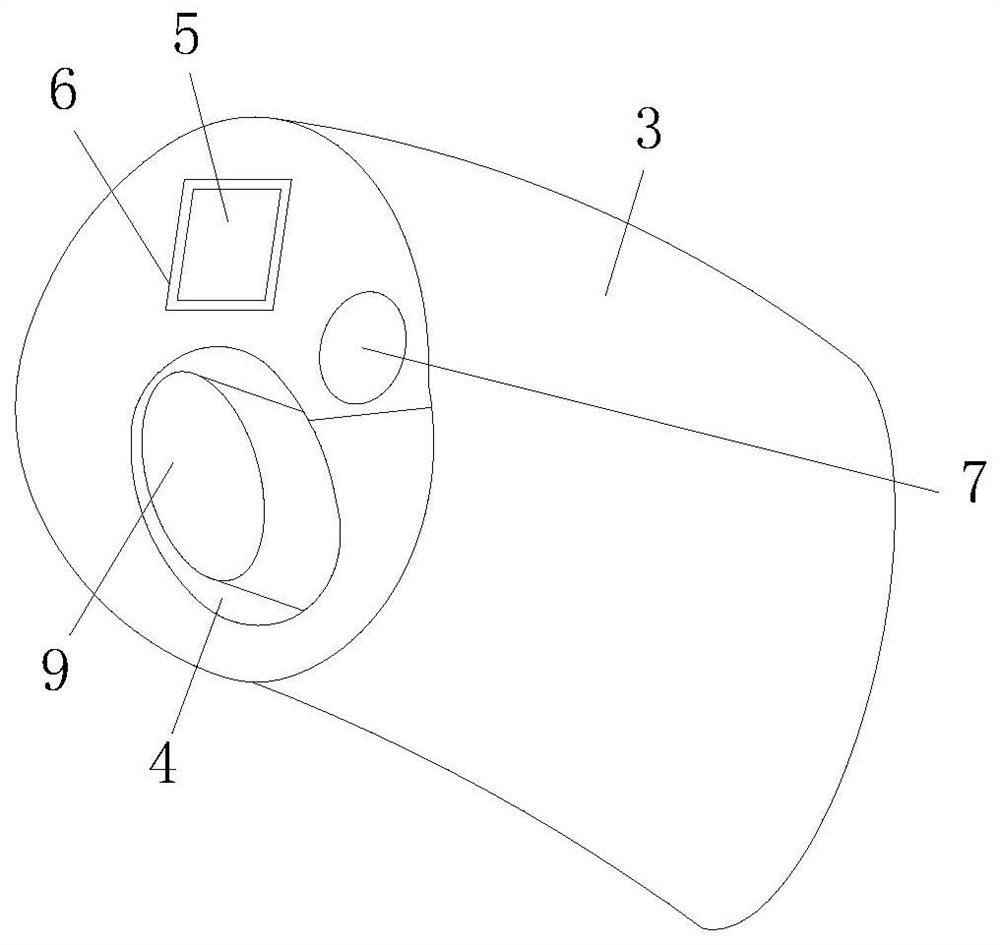

Rollover sliding type cab and engineering machinery provided with the same

PendingCN111017046ALower transport heightExpand the operating horizonLoading-carrying vehicle superstructuresRolloverControl theory

The invention discloses a rollover sliding type cab which comprises a cab body, a sliding base, a guide rail seat and a rollover oil cylinder. One end of the cab body is hinged to the sliding base, the other end of the cab body is connected with the sliding base through the rollover oil cylinder; the cab body is driven by the rollover oil cylinder to rotate along the hinge point, so that rolloverof the cab body on the sliding base is achieved. The sliding base is installed on the guide rail seat in a sliding mode and drives the cab body to slide along the guide rail seat. According to the invention, when the whole cab is transported, the transportation height of the whole cab can be reduced, the cab can slide according to needs, and the operation view of an operator is enlarged. Accordingto the cab, the transportation convenience and the operation comfort of engineering machinery are improved.

Owner:XCMG CONSTR MACHINERY

A system and method for self-inspection remote control detachment of a large unmanned aerial vehicle

ActiveCN106184804BHigh strength requirementsExquisite and beautiful structureLaunching/towing gearElectricityControl signal

The invention discloses a disengagement device for a large unmanned aerial vehicle. The disengagement device comprises a body, a push rod motor, a feedback module and a receiving module. The body comprises a lock arranged at one end and a connecting mechanism located at the other end, and the lock and the connecting mechanism are used for being connected with the unmanned aerial vehicle and a launching cradle respectively. The push rod motor is contained in a cavity of the body and provided with a telescopic push rod and can stretch into the lock of the body or retract from the lock. The feedback module is arranged in the cavity of the body and used for detecting the locked or disengaged connecting state of the push rod motor and the lock in real time and feeding the connecting state to an external control platform. The receiving module is arranged in the cavity of the body, electrically connected with the push rod motor and used for receiving an external control signal and sending the external control signal to the push rod motor to drive the push rod motor to stretch into the lock or retract from the lock so as to control the connecting state of the push rod motor and the lock. The invention further discloses a corresponding disengagement take-off method. By means of the disengagement device and the disengagement take-off method, stable and reliable connection in the unmanned aerial vehicle loading and transporting and lunching processes can be effectively guaranteed; besides, effective and reliable disengagement in lunching can be guaranteed.

Owner:XIANGYANG HONGWEI AIRCRAFT

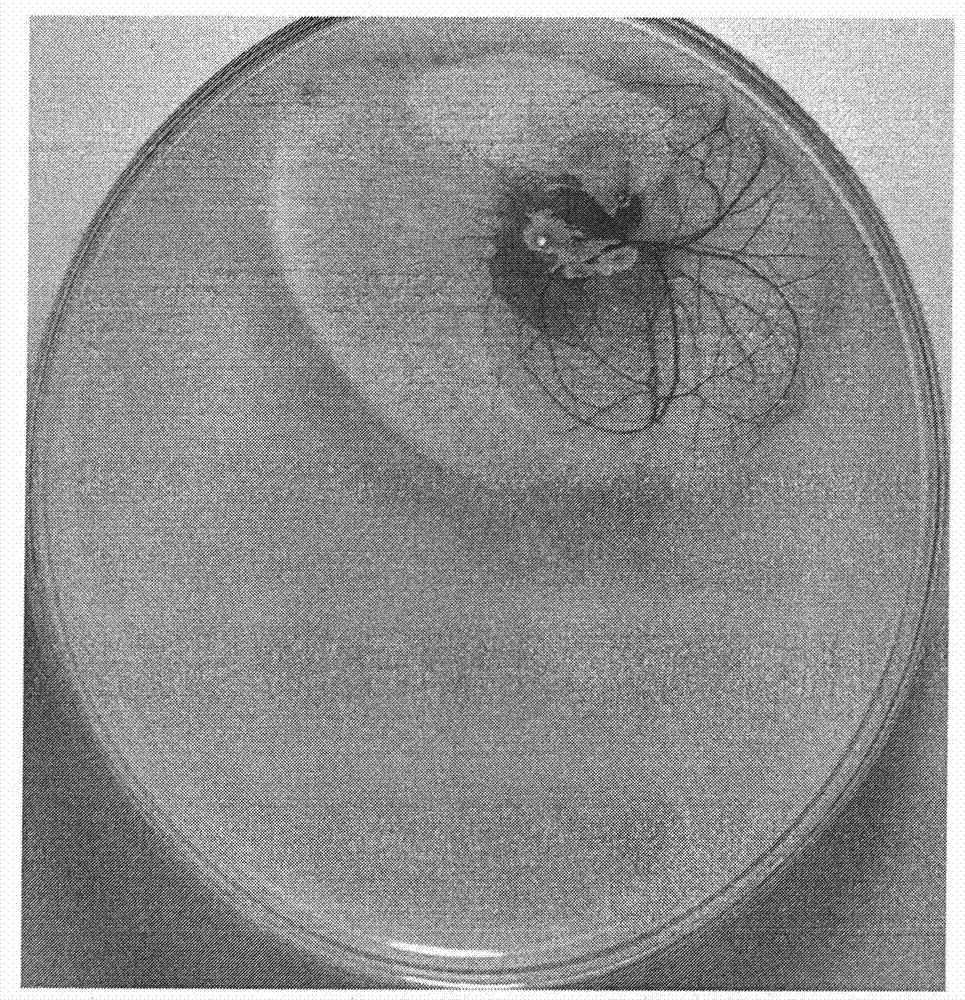

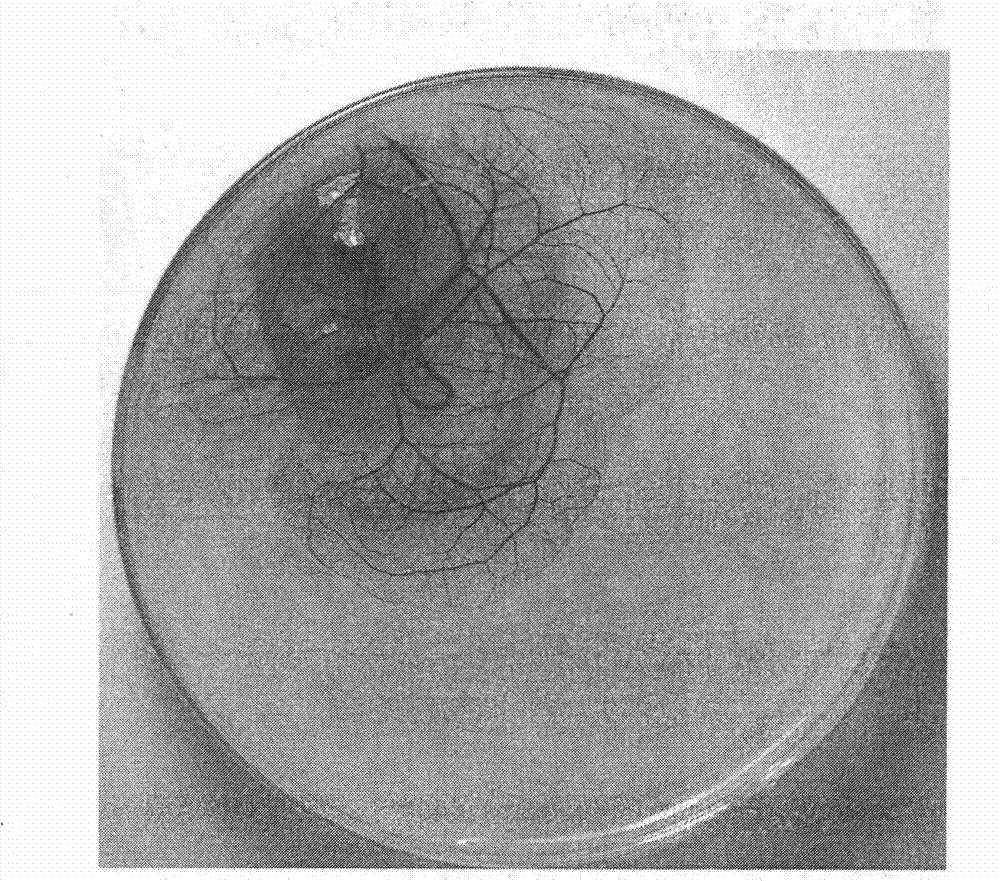

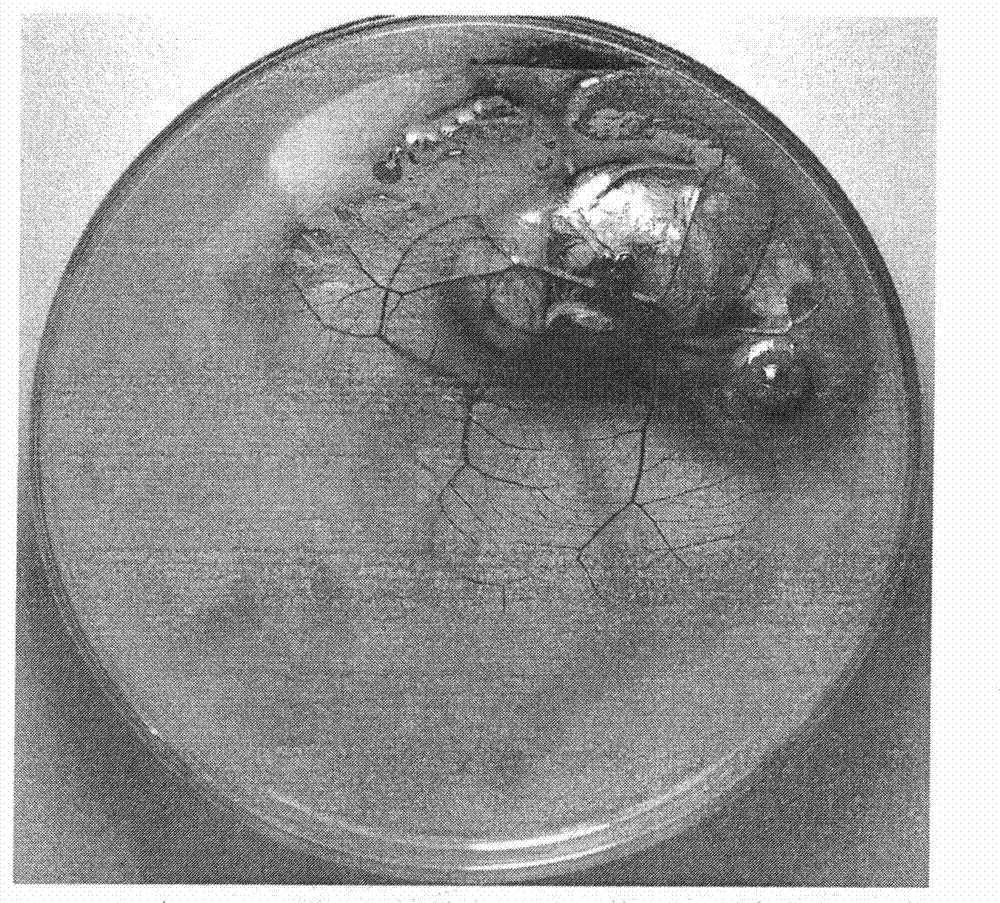

Method for detecting anti-anaphylaxis function of compound

InactiveCN101487839BImprove survival rateEasy to determineBiological testingAllergic antiAnimal science

A method for detecting antiallergic effect of compounds comprises the following steps: placing fertilized chicken eggs, which are sterilized by 75% alcohol in an incubator with humidified water pond to incubate the fertilized chicken eggs for 75-100h; opening egg shells; moving chick embryos into a sterile glass plate with diameter of 75-90mm; pre-adding buffer solution pre-heated to 37 DEG C foropening shells into the plate; selecting and placing chick embryos with un-damaged vitelline membrane into a constant-temperature incubator at 37.5 DEG C to continuously incubate the chick embryos tothe 8th to 15th day; grouping the chick embryos randomly; placing the chick embryos into the constant-temperature incubator to continuously incubate the chick embryos after adding compounds to be tested; when the chick embryos is incubated for 1h or 12h or 24h or 48h, adding materials which have stimulation to chick embryo allantoid vitelline membrane veins; assessing the changes of veins according to simulating factors; and calculating the suppression ratio of antiallergic compounds with different concentration. The method is simple, cheap and clear in observed index.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

Femoral hip joint stem holder

The invention relates to a femoral hip joint stem holder. The holder comprises a threaded rod, a screwing end cap, a handle and a movable handle, wherein the head of the threaded rod is provided with threads which are matched with a femoral stem; the screwing end cap is connected with the tail end of the threaded rod; the handle is rotatably sleeved at the periphery of the rear part of the threaded rod; and the movable handle is vertically fixed on the handle. The femoral hip joint stem holder can be used conveniently and fast, is rational in torque transfer and has a broad operating range, so that the success rate of surgery is improved.

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

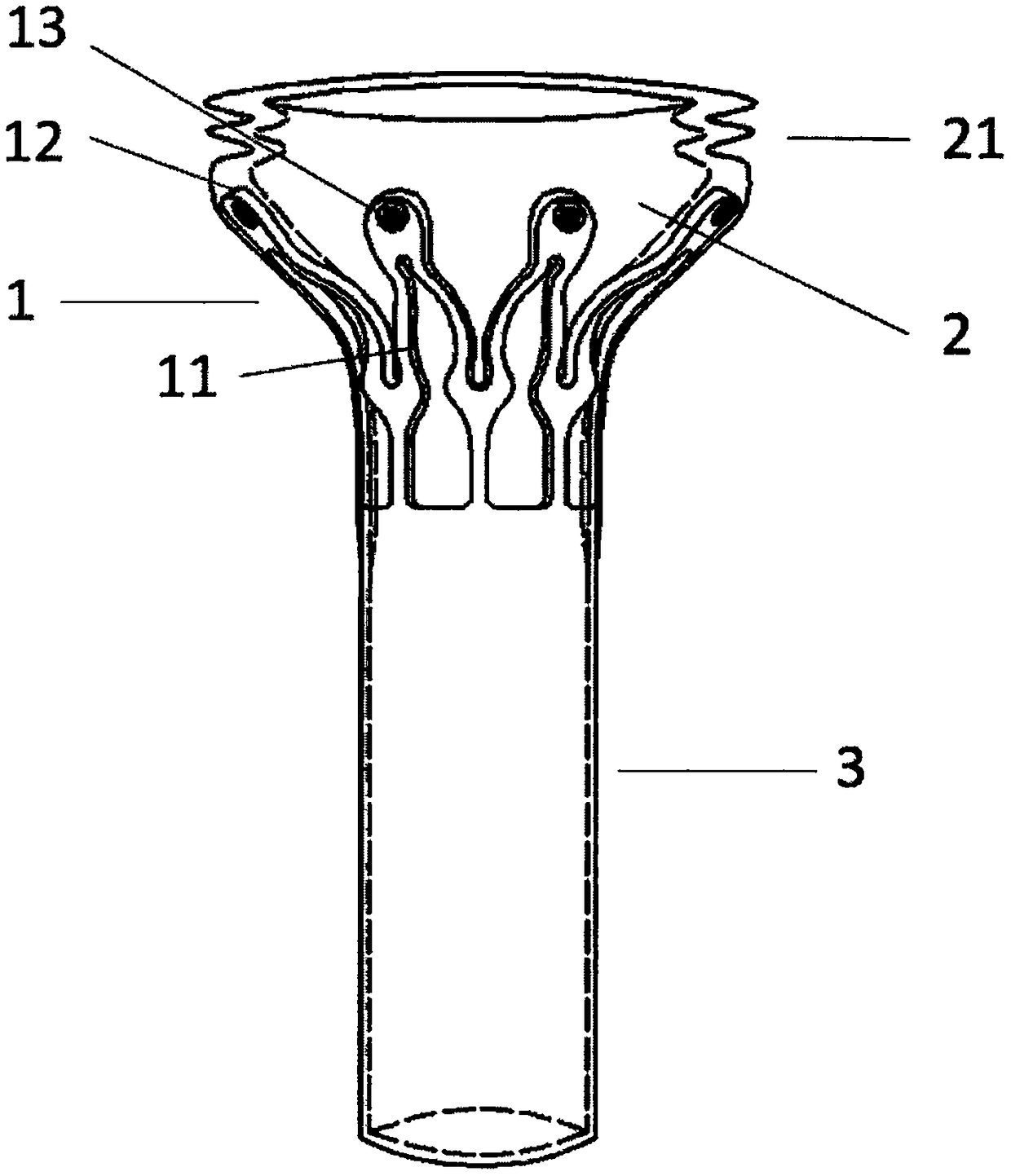

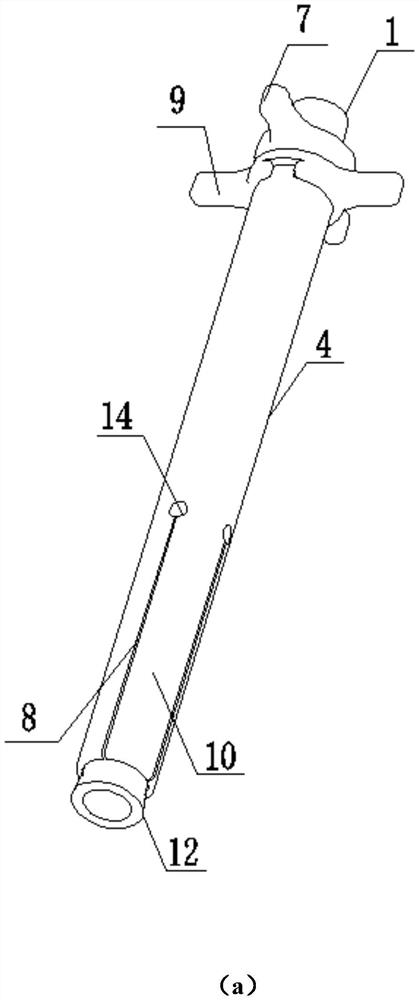

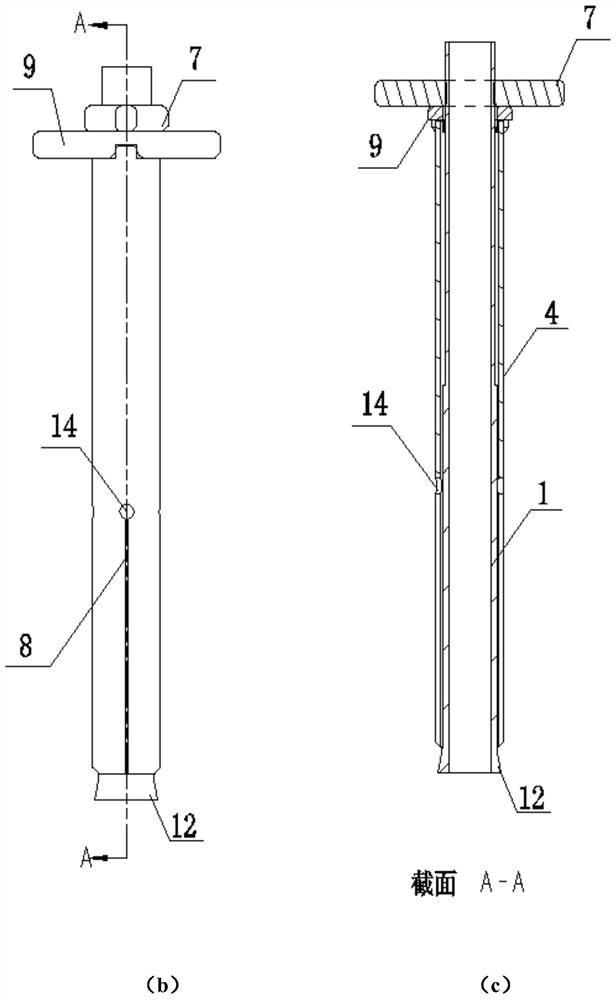

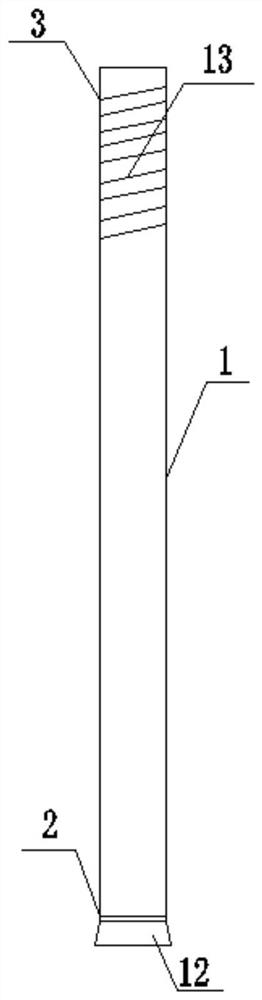

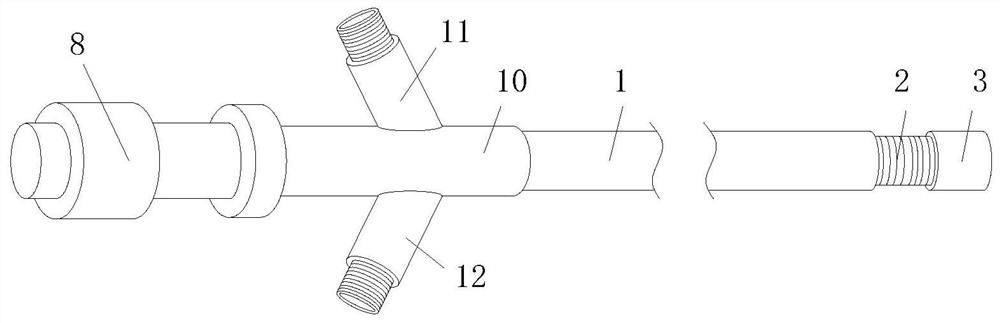

Inner expansion cannula

PendingCN112754553AExpand the operating horizonSufficient operating spaceSurgeryAnatomyOuter Cannula

The invention relates to an inner expansion cannula, and belongs to the field of medical instruments. The inner expansion cannula comprises an inner cannula, an outer cannula and a power-assisted nut, wherein the inner cannula and the outer cannula are each provided with a cannula head end and a cannula tail end; the interior of the inner cannula is hollow; the cannula head end of the inner cannula is of a horn mouth structure expanding outwards; external threads are formed in the outer wall of the cannula tail end of the inner cannula; the power-assisted nut is provided with internal threads matched with the external threads; the interior of the outer cannula is hollow; the outer cannula sleeves the inner cannula; a side hole is formed in the outer cannula; longitudinal incisions are arranged in a manner of extending towards the cannula head end of the outer cannula along the side hole; the cannula wall between the adjacent longitudinal incisions forms an expansion blade; and the inner cannula is driven by rotating the power-assisted nut to move, so that the expansion blade can be expanded or closed in the radial direction. In the operation process of an endoscope, on the premise that the skin incision is not expanded, soft tissue around the operation space is expanded from the body through the inner expansion cannula, so that the operation visual field of the endoscope can be expanded, and shielding of the soft tissue under the endoscope is reduced.

Owner:王振海

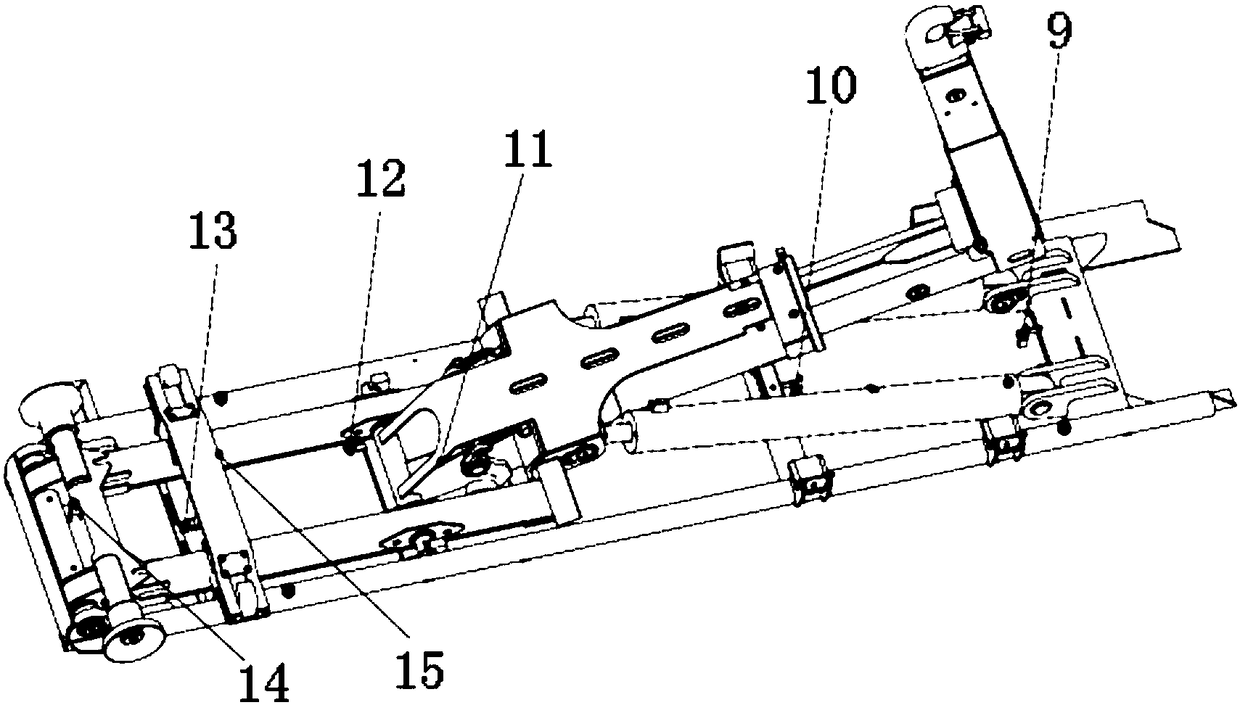

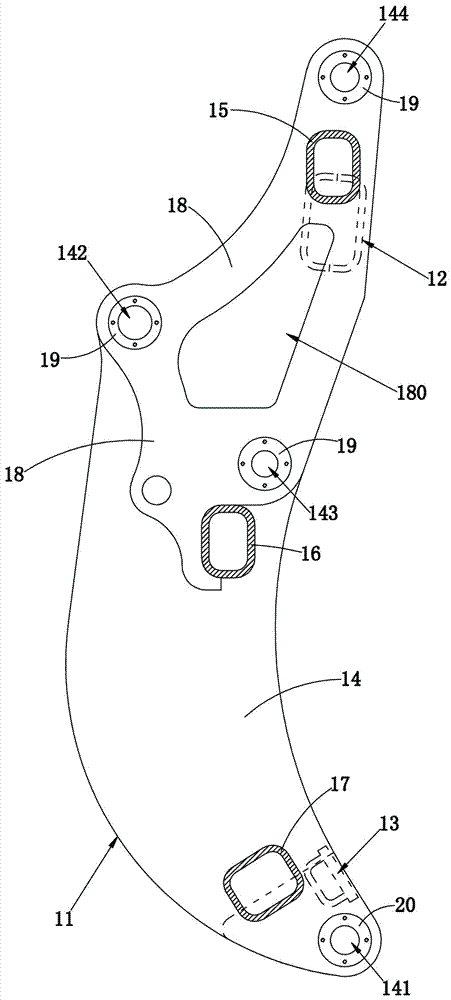

Booms for large tonnage forklifts/loaders

ActiveCN105220721BReduce weightReduce the difficulty of productionMechanical machines/dredgersVehicle frameEngineering

The invention relates to a movable arm for a large-tonnage forklift / loader. The movable arm comprises a movable arm main body; and the movable arm main body is formed by two movable arm units, the two movable arm units are integrally connected through a front beam and a rear beam, and the front beam and the rear beam are distributed at the two ends of the movable arm units. Each movable arm unit is formed by at least two movable arm plates which are integrally connected through a connecting beam; vehicle frame connecting holes, rocker connecting holes, oil cylinder connecting holes and accessory connecting holes are formed in the movable arm plates; and the vehicle frame connecting holes, the rocker connecting holes, the oil cylinder connecting holes and the accessory connecting holes of the movable arm plates are respectively distributed coaxially. The movable arm is suitable for the large-tonnage forklift / loader. According to the movable arm, movable arm main plates with heavy weights and large thicknesses can be replaced through a method that a plurality of movable arm plates are combined to form the movable arm units. Thus, the loading requirement can be met, the weight of the movable arm is effectively reduced, and the producing difficulty of the movable arm is reduced.

Owner:QUANZHOU WEISHENG MECHINE DEV

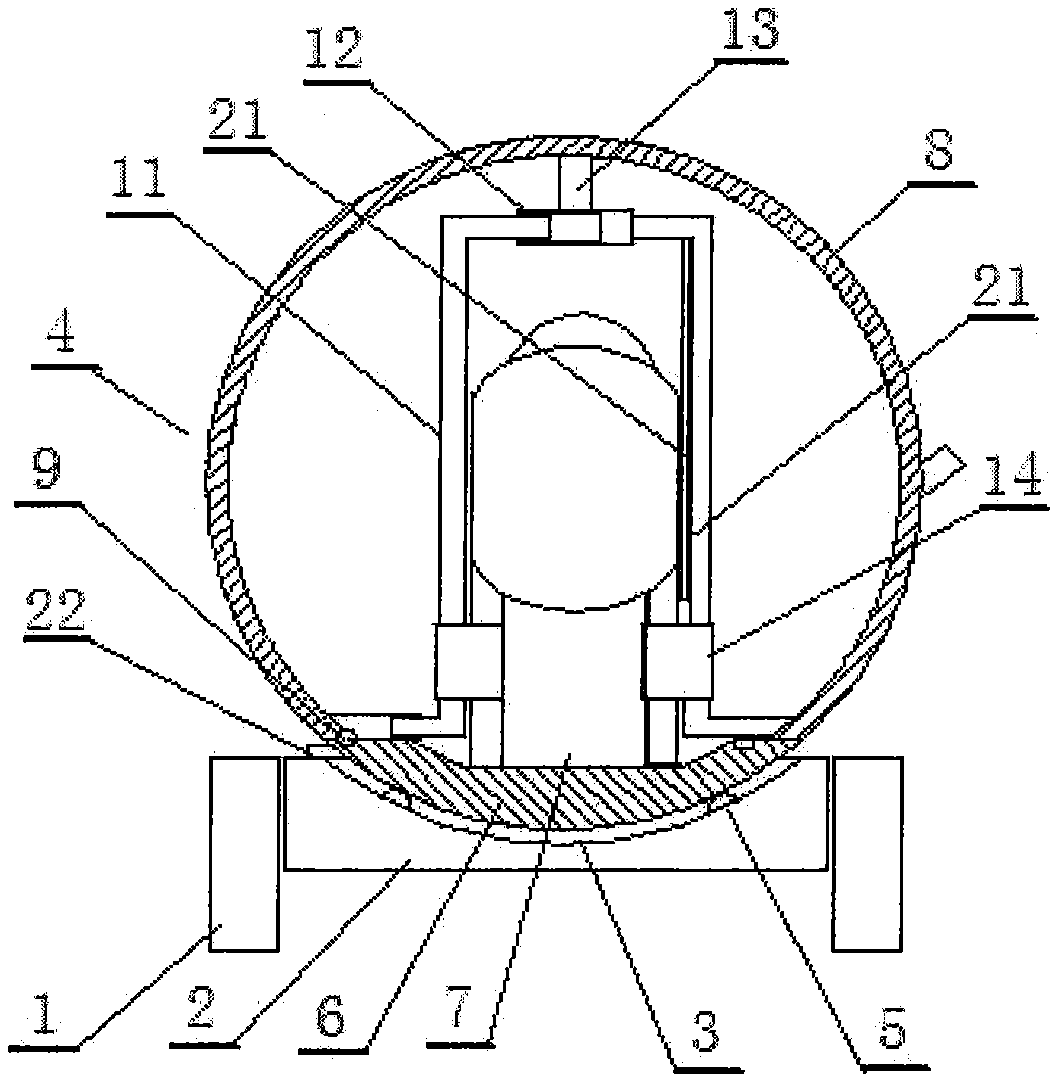

A special vehicle for hoof repairing of dairy cows

InactiveCN105232175BRealize transformationAvoid provocationAnimal fetteringSurgical veterinaryBody shapeSide lying

The invention discloses a trolley special for cow hoof trimming. The trolley comprises wheels and a trolley base plate. A roller-shaped trolley box rack is arranged in an arc-shaped groove of the center area of the trolley base plate, a crescent-shaped movable supporting plate on the bottom section of the trolley box rack is provided with a trapezoidal groove in the front-rear direction, and the movable supporting plate and an upper section trolley box rack are movably connected; n-shaped binding racks are arranged in the upper section trolley box rack side by side front and back, and binding belts are arranged on the bottom sections of four side stand columns of each n-shaped binding rack. The two ends of the trolley box rack are opened, an annular gear ring is arranged on the front-end side wall of the trolley box rack, and the trolley base plate is provided with a motor and a transmission gear which is engaged with the annular gear ring. The trolley special for cow hoof trimming has the advantages that by the adoption of the roller-shaped trolley box rack, various body positions of cows can be switched stably, and width adjusting sleeves on the n-shaped binding racks can meet the needs of the cows with different body shapes; due to the arrangement of the movable supporting plate, the hoof areas of the cows can be fully exposed, and the operating field of view is widened; backing plates are attached to the inner sides of the stand columns on the right side so that the cows can feel more comfortable in a side-lying state.

Owner:黑龙江省兽医科学研究所

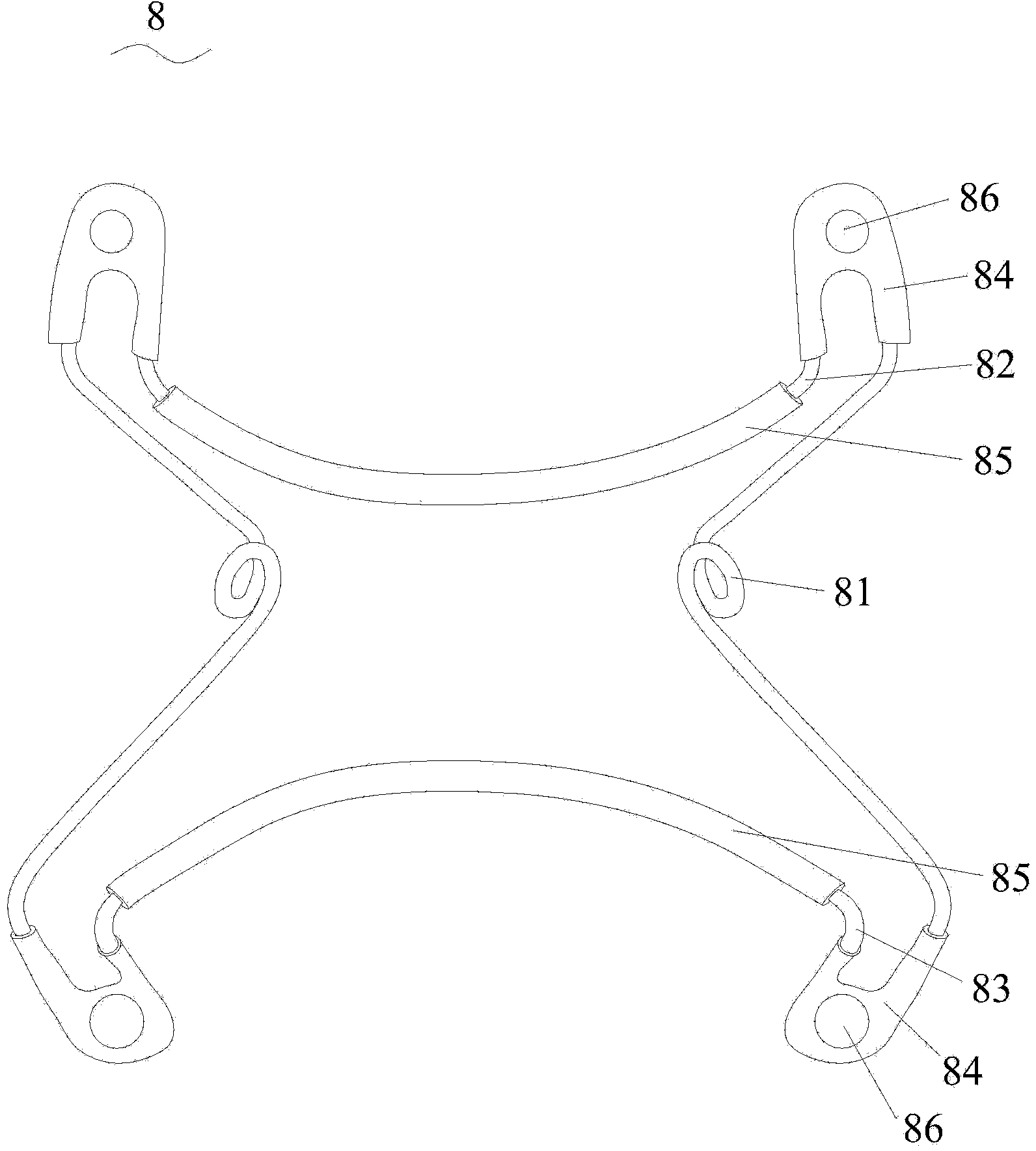

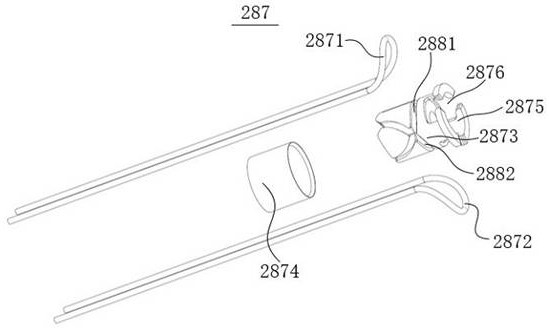

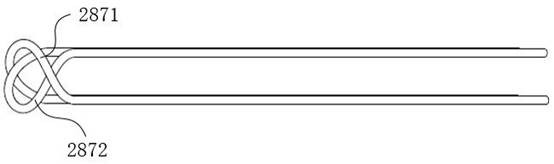

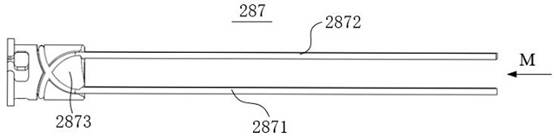

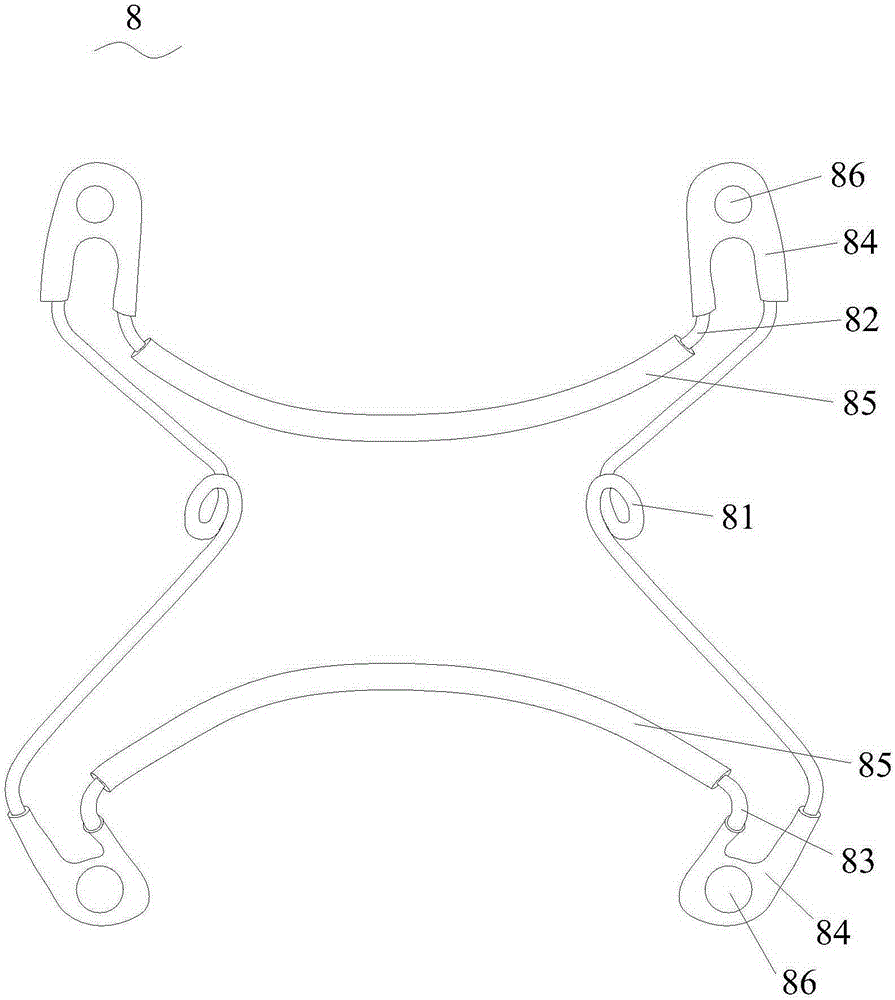

Rope fixing structure, surgical instrument, split surgical device and robot

ActiveCN114305541AExpand the operating horizonSimple fixed structureComputer-aided surgeryInterference fitPhysical medicine and rehabilitation

The invention discloses a rope fixing structure, a surgical instrument, a split surgical device and a robot. The rope fixing structure comprises a first traction rope, a second traction rope, a rigid connecting piece and a locking sleeve. The rigid connecting piece is provided with a first rope groove and a second rope groove, and the first rope groove and the second rope groove intersect to form at least one intersection point. The first pulling rope is embedded in the first rope groove and extends out of the first end of the rigid connecting piece, and the second pulling rope is embedded in the second rope groove and extends out of the first end of the rigid connecting piece. At the intersection point, the first pulling rope or the second pulling rope protrudes out of the surface of the rigid connecting piece, the locking sleeve is arranged on the surface of the rigid connecting piece in a sleeving mode, and at the intersection point, the locking sleeve is in interference fit with the first pulling rope or the second pulling rope. The two traction ropes are crossed and overlapped to form the convex block so as to form a fixing mode of an interference fit connection relation, more other accessories do not need to be additionally used, the fixing structure is simple, the size is small, and the operation visual field of surgical instruments can be expanded.

Owner:APEIRON SURGICAL (BEIJING) CO LTD

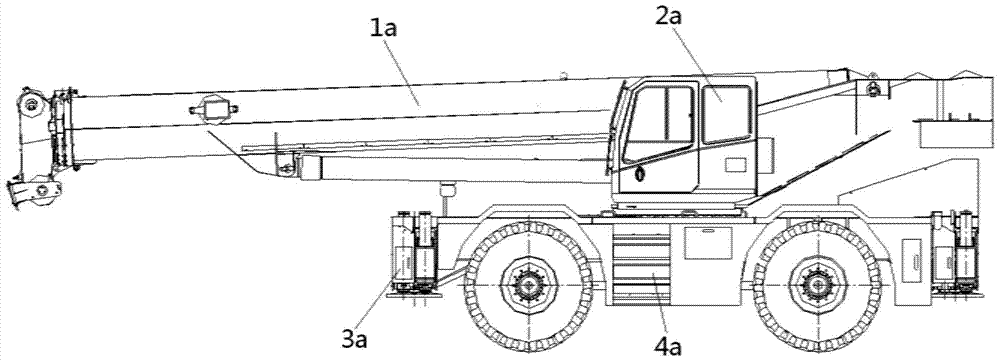

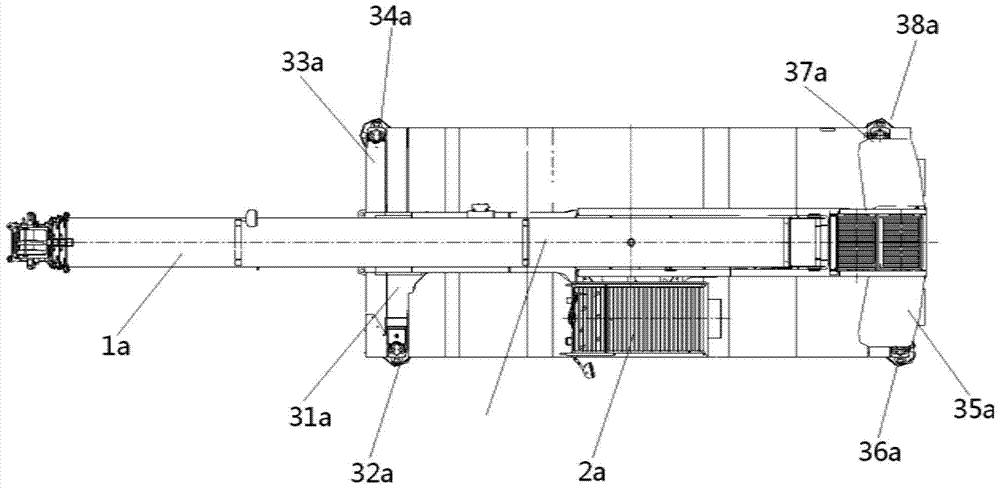

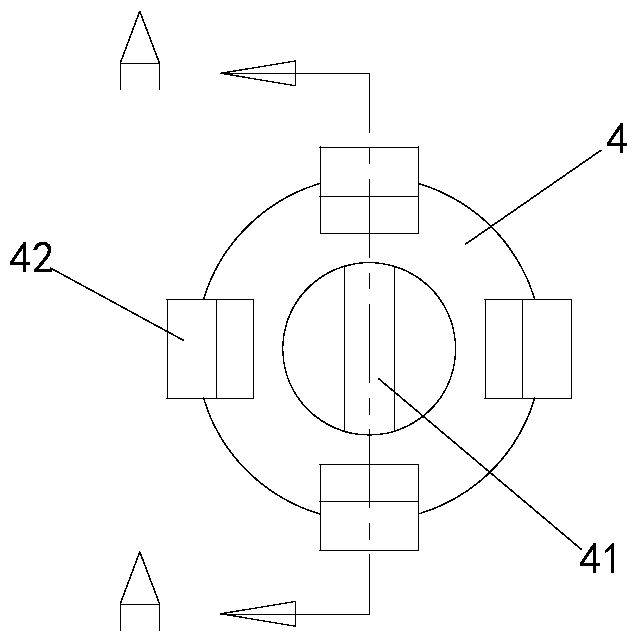

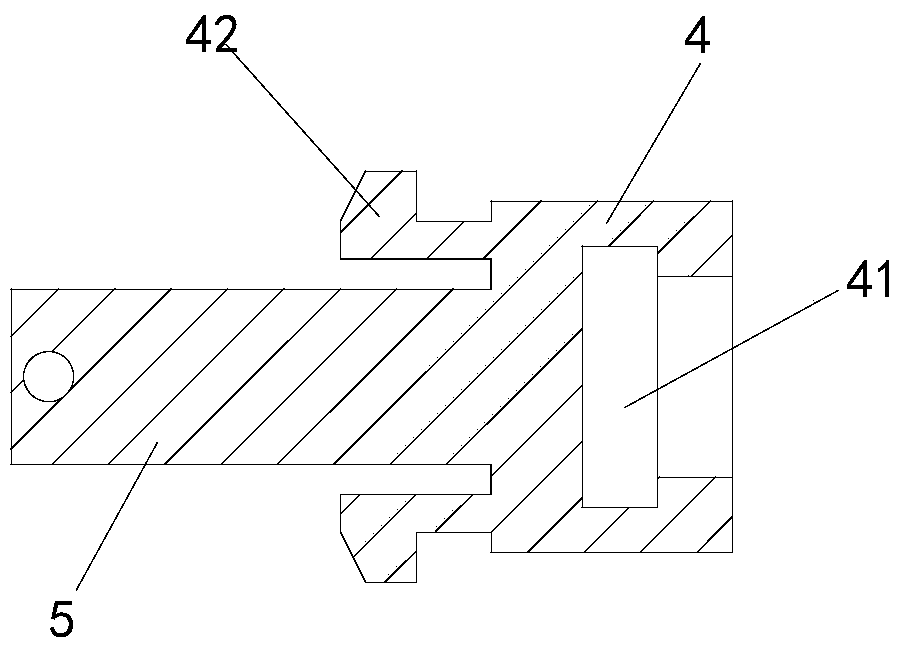

Remote wireless remote control device, crane outrigger control system and method

ActiveCN105293286BSolve the disadvantages of operationAvoid inconvenienceTransmission systemsLoad-engaging elementsRemote controlControl system

The invention relates to a remote wireless remote control device, a crane outrigger control system and a method thereof. The remote wireless remote control device includes: a radio signal for sending a corresponding radio signal corresponding to a crane outrigger control command, including: an encoding circuit (11) and a radio frequency transmitting circuit ( 12), the coding circuit (11) is used to convert the crane outrigger control command into a coded signal; the radio frequency transmitting circuit (12) is used to amplify the coded signal and send it to the receiver. The remote wireless remote control device of the present invention enables personnel to operate freely and effectively at any position near the crane on the ground, solves the disadvantage that the operation can only be performed in the control room, avoids the inconvenience caused by personnel going up and down the control room, and effectively reduces Labor intensity; and the way of operation on the ground can greatly improve the operating field of vision, eliminate blind spots in the field of vision, and can fully observe the movement of the horizontal outriggers and vertical cylinders, thereby improving the operational safety of the crane.

Owner:XUZHOU HEAVY MASCH CO LTD

A kind of ureteral stent taking catheter

The present invention relates to the technical field of medical devices, in particular to a catheter for taking a ureteral stent, including a catheter, an elbow part, an end part, a protective sealing plate, a perfusion channel, grasping forceps, a main pipe, a perfusion tube, an optical fiber access tube and a bladder Mirror, the right end of the catheter is fixedly connected to the left side of the elbow part, the right side of the elbow part is fixedly connected with the left side of the end part, and a working channel is opened in the middle of the lower part of the end part , a fiber channel is opened in the middle of the upper half of the end part. The present invention achieves the purpose of reusable use of the fiberscope in the postoperative shell, without any contact with human tissue without hindering the operation field of view generated by the optical fiber, so it can meet the requirement of one-time use, with low cost and price, no Pollution is generated, so after the operation, the fiberscope does not need to be sterilized and can be operated continuously.

Owner:傅发军

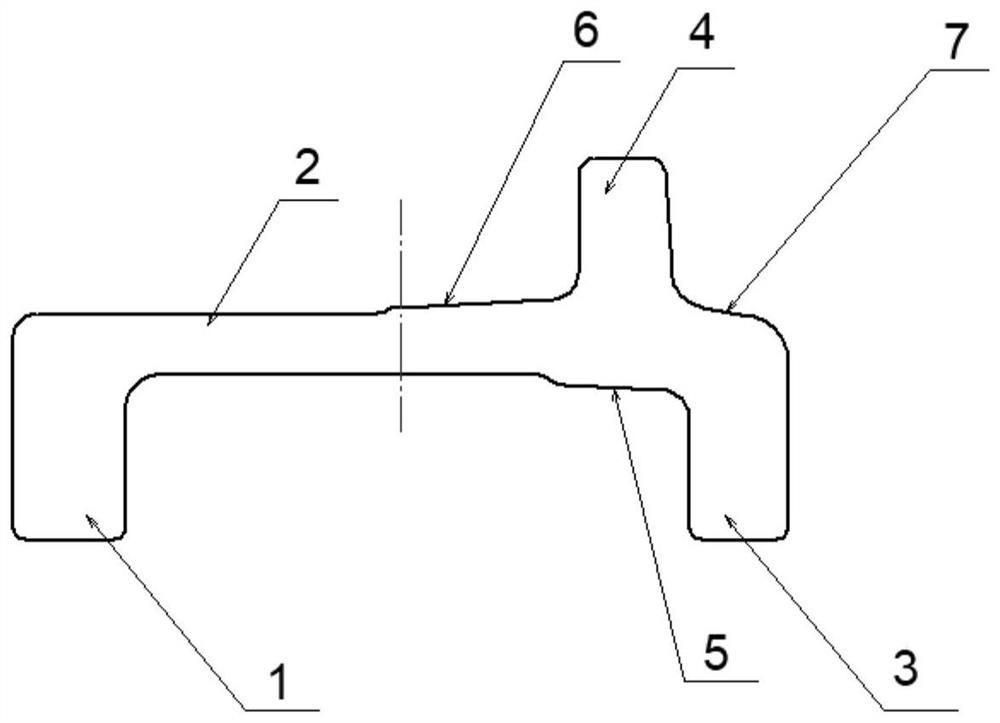

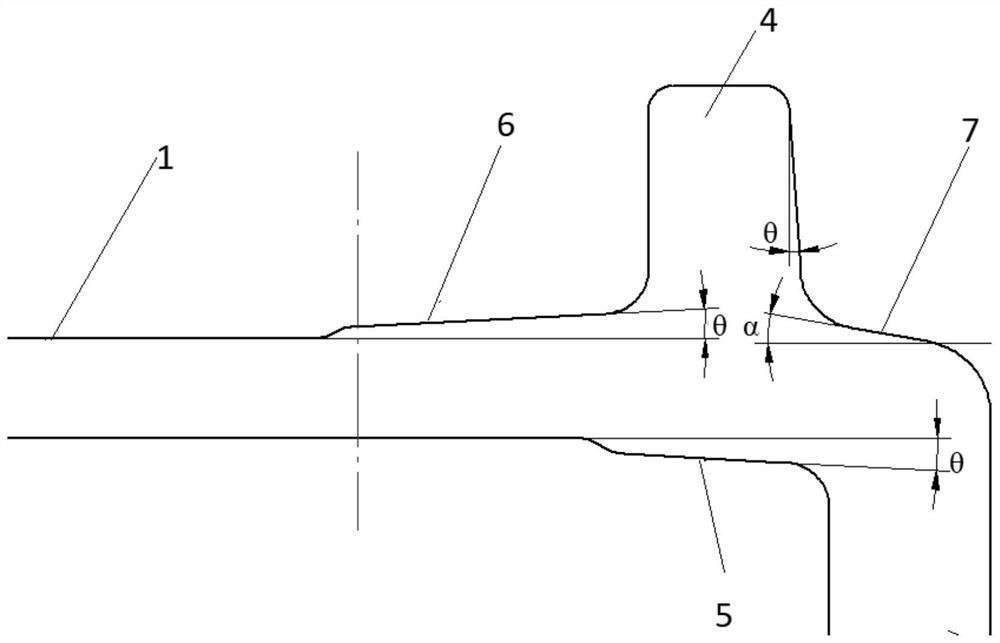

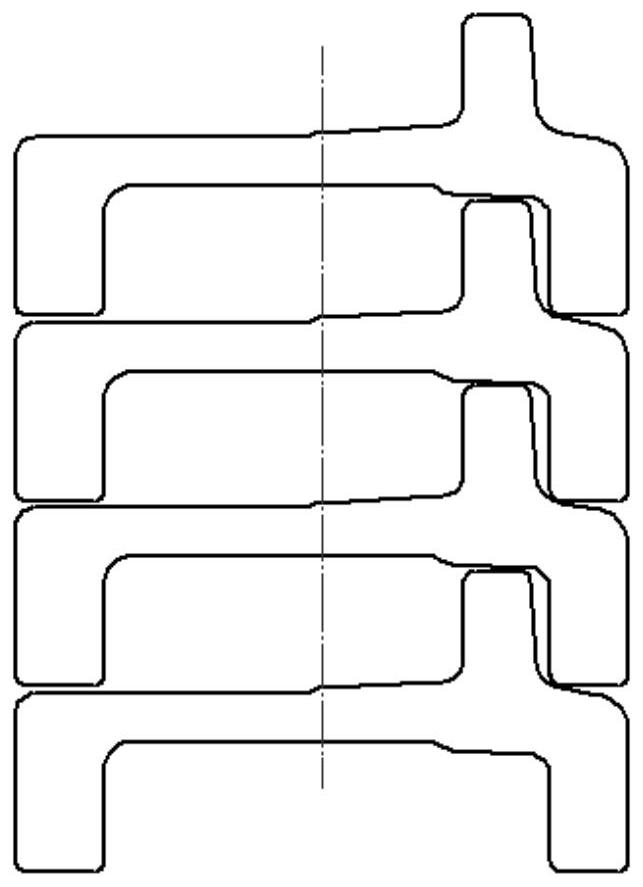

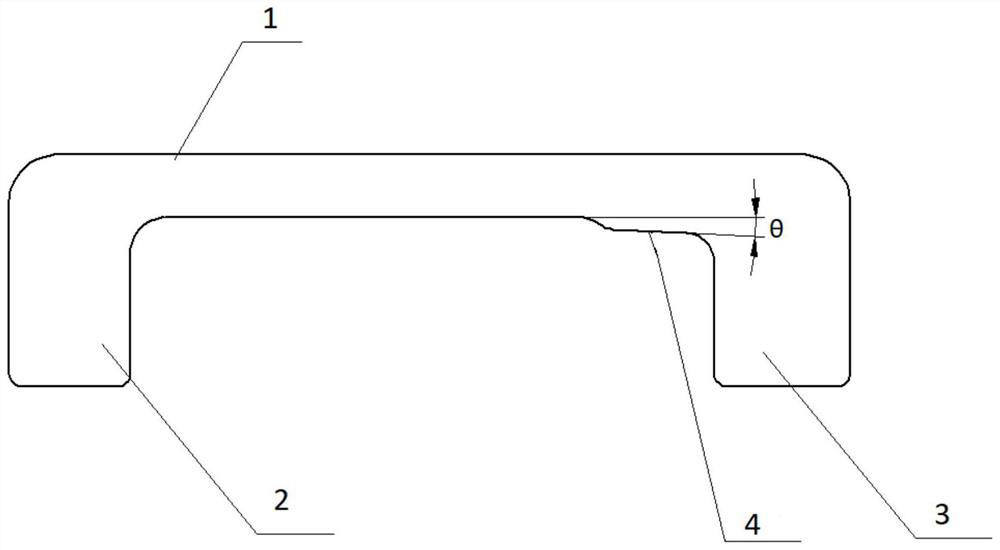

Hot-rolled J-shaped steel for forklift portal

PendingCN112794243AReduced structure widthExpand the operating horizonLifting devicesManufacturing engineeringMaterials processing

The invention relates to the technical field of machinery and material processing, and particularly relates to hot-rolled J-shaped steel for a forklift portal. The hot-rolled J-shaped steel for the forklift portal comprises a web, a first wing plate, a second wing plate and a third wing plate, and further comprises a first boss, a second boss and a wedge-shaped table, wherein the first wing plate and the second wing plate are positioned at the two ends of the lower surface of the web, and form a C-shaped structure with the web; the third wing plate is positioned at the position, far away from one end of the first wing plate, of the upper surface of the web; the first boss is positioned at the joint of the lower surface of the web and the left side surface of the second wing plate; the second boss is positioned at the joint of the upper surface of the web and the left side surface of the third wing plate; and the wedge-shaped table is positioned at the joint of the upper end surface of the second wing plate and the right side surface of the third wing plate. The hot-rolled J-shaped steel is wide in operation view, is high in rigidity, saves materials, and is low in hot-rolling difficulty and production cost.

Owner:SHANDONG IRON & STEEL CO LTD +1

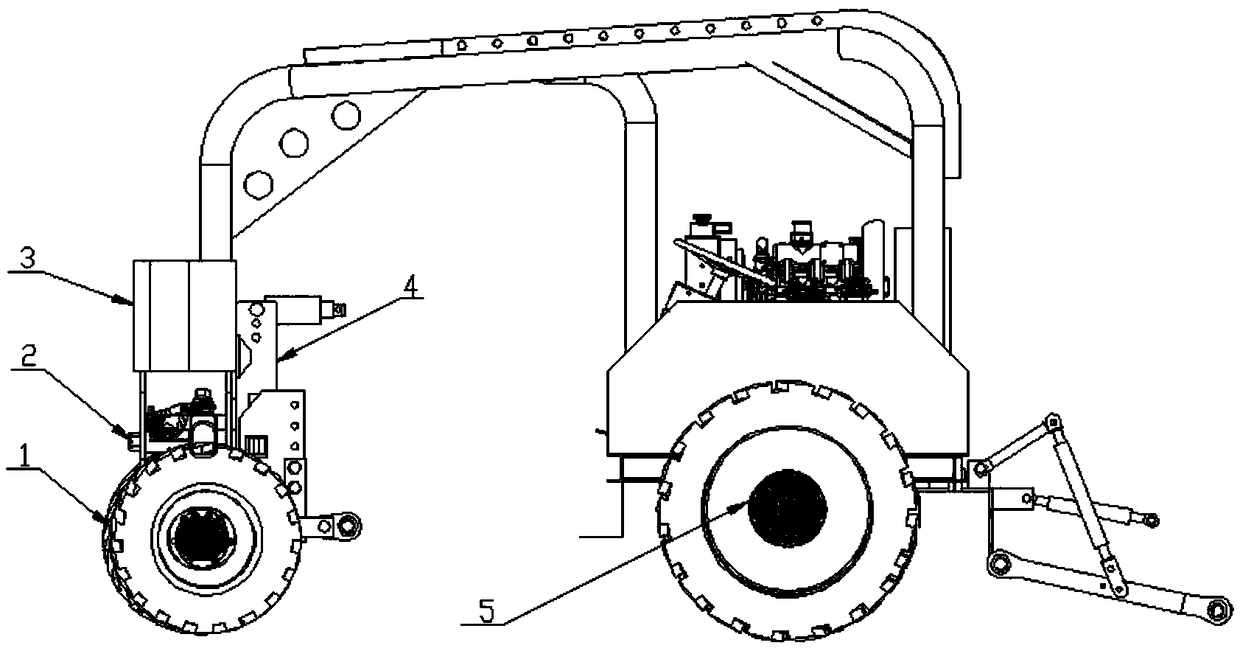

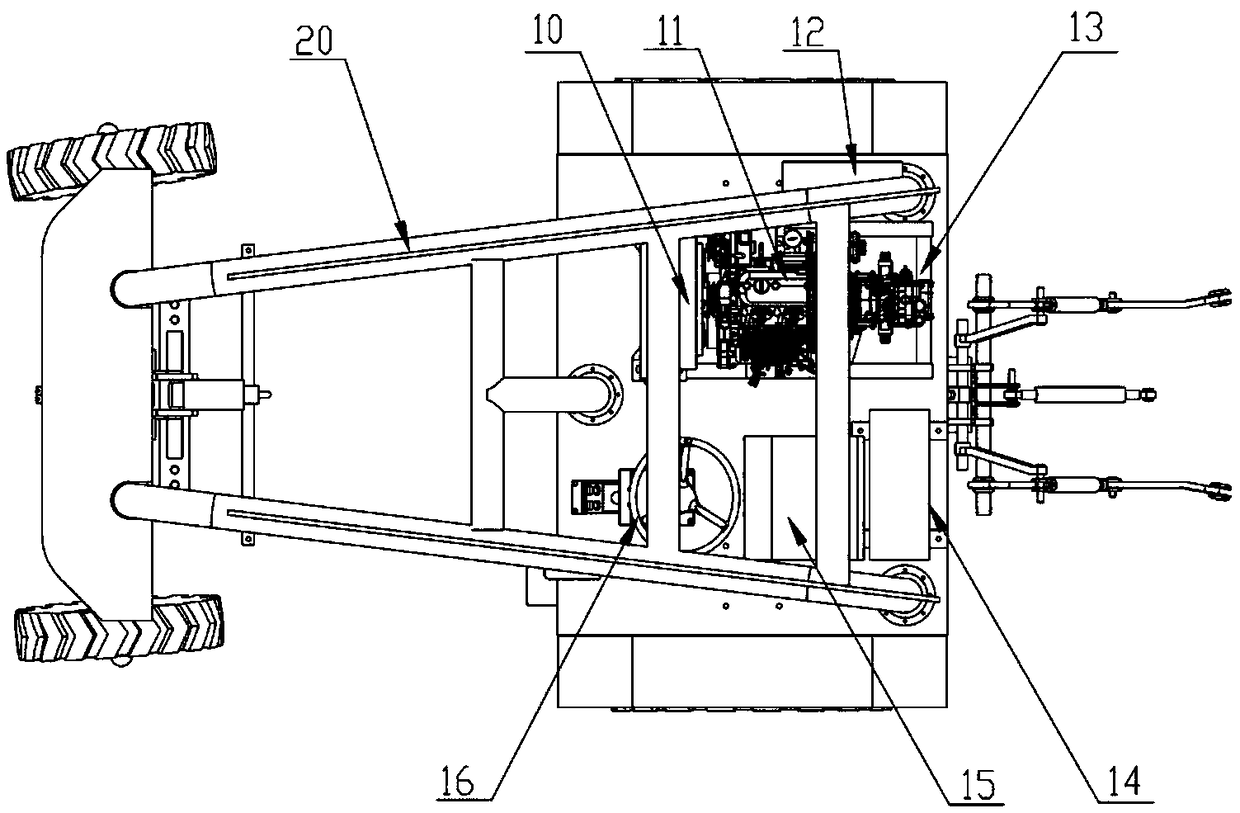

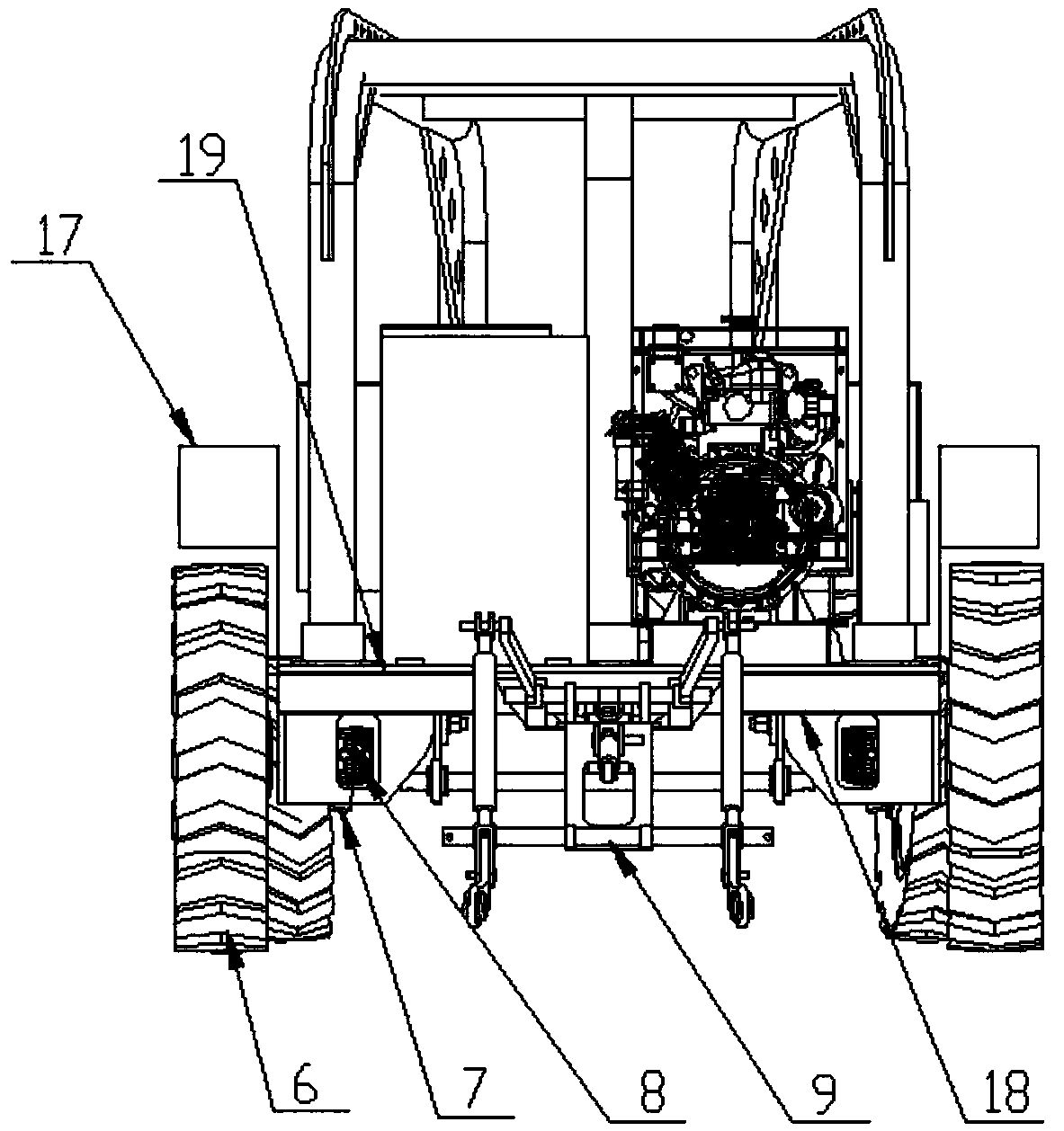

A power machine for vegetable field work

InactiveCN106922233BExpand the operating horizonAchieve multi-functionalityAgricultural undercarriagesHydraulic motorDriver/operator

Owner:CHINA AGRI UNIV

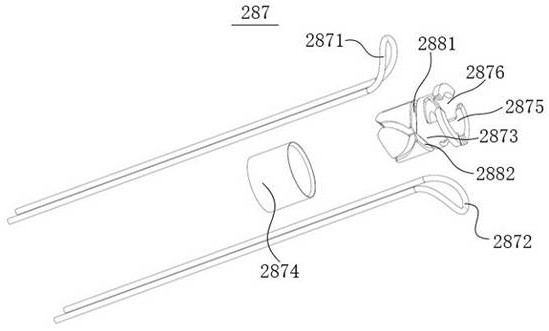

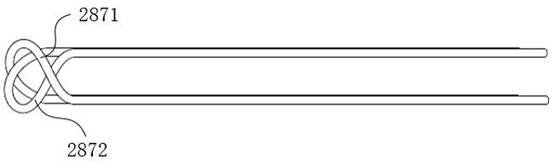

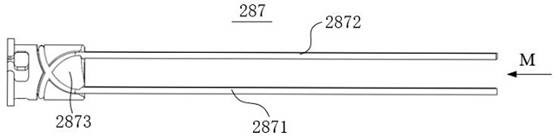

Separable blood vessel blocking forceps under laparoscope

InactiveCN106667540AImprove efficiencyImprove securitySurgical forcepsWound clampsPERITONEOSCOPEDissection forceps

A pair of separable blood vessel blocking forceps under a laparoscope comprises a sleeve, a control mechanism and a blocking forceps clamp, wherein the blocking forceps clamp is arranged in the sleeve, actions of the blocking forceps clamp are controlled through the control mechanism, the sleeve comprises a front sleeve and a rear sleeve, and the front sleeve and the rear sleeve are detachably connected in an embedded mode. The control mechanism comprises a front portion control mechanism and a rear portion control mechanism, the front portion control mechanism is movably connected with the blocking forceps clamp, and the rear portion control mechanism is detachably and movably connected with the front portion control mechanism. The pair of separable blood vessel blocking forceps is reasonable in structural design, a possible biggest operating view field is provided for an operation by adopting the separable structural design to facilitate execution of other operations, the efficiency of a laparoscopic surgery and the safety are greatly improved, and convenience is provided for medical workers.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Vehicle-mounted unmanned aerial vehicle ground control system

PendingCN110045663AExtended flight rangeExpand the operating horizonProgramme controlComputer controlLiquid-crystal displayControl system

The invention discloses a vehicle-mounted unmanned aerial vehicle ground control system. The system comprises a vehicle body, a control room arranged in the vehicle body, and six liquid crystal displays laid on six walls in the control room, wherein transparent glass supporting plates are arranged above the lower liquid crystal display at intervals; unmanned aerial vehicle remote operation equipment is arranged above the transparent glass supporting plates; the six liquid crystal displays are connected to an airborne computer on an unmanned aerial vehicle in order to receive real-time pictureinformation about front, back, upper, lower, left and right positions of the unmanned aerial vehicle; the airborne computer is connected to front, back, upper, lower, left and right image sensors of the unmanned aerial vehicle in order to receive real-time picture information; and the unmanned aerial vehicle remote operation equipment is connected to the airborne computer on the unmanned aerial vehicle in order to control the unmanned aerial vehicle to fly through servo action equipment. The control system is wide in operation view and good in experience.

Owner:山东蜂巢航空科技有限公司

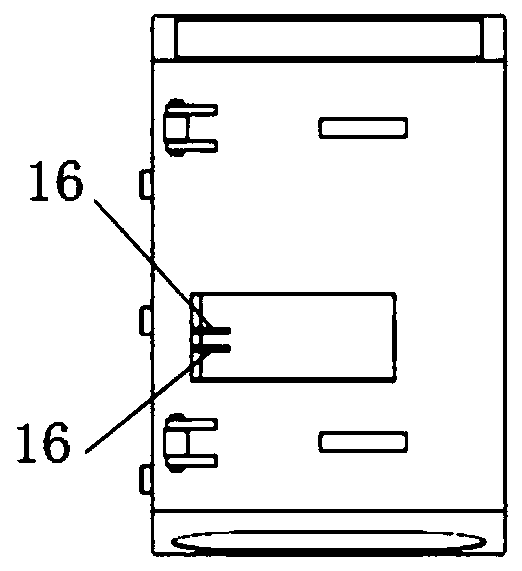

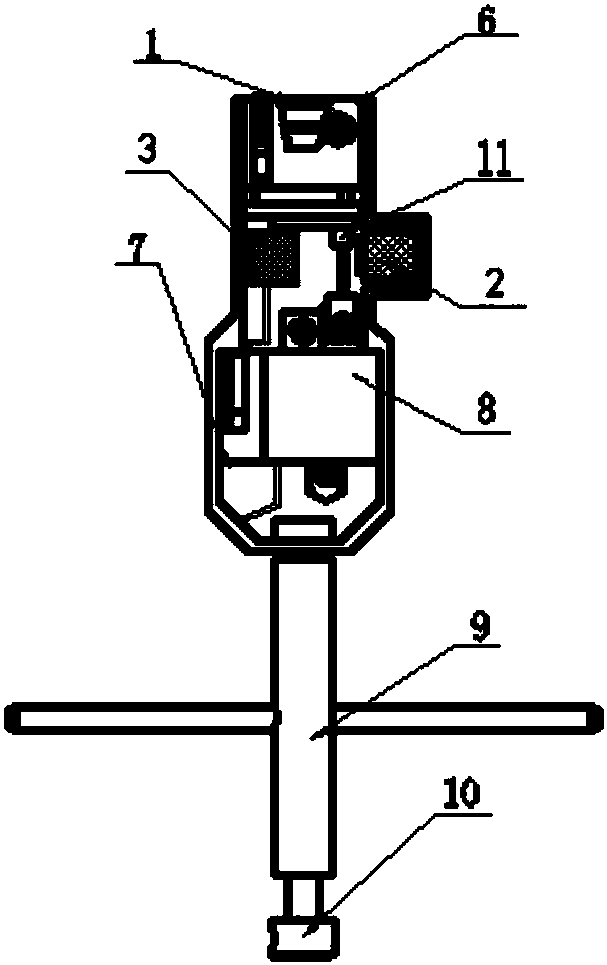

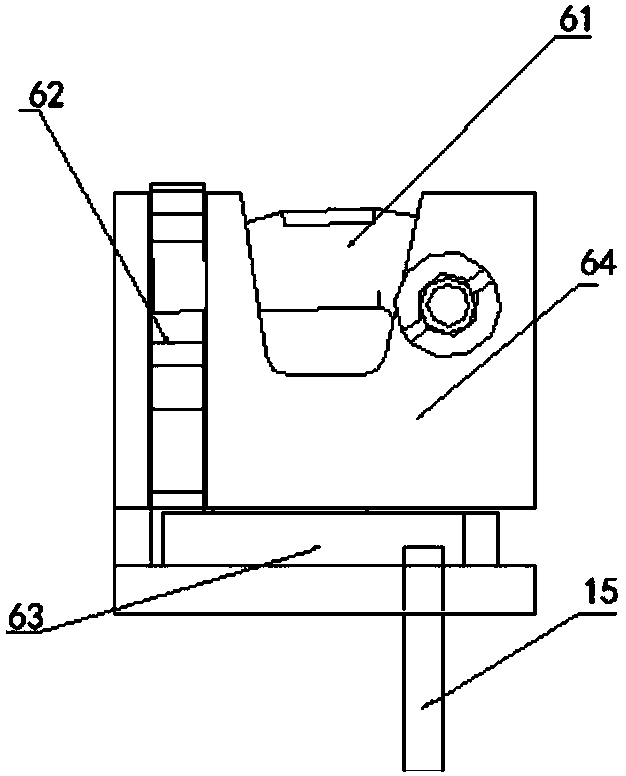

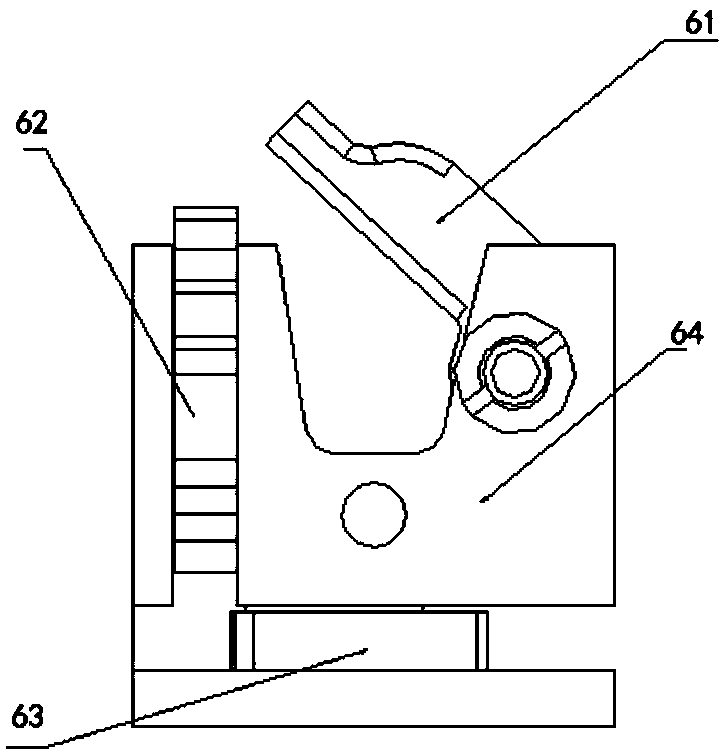

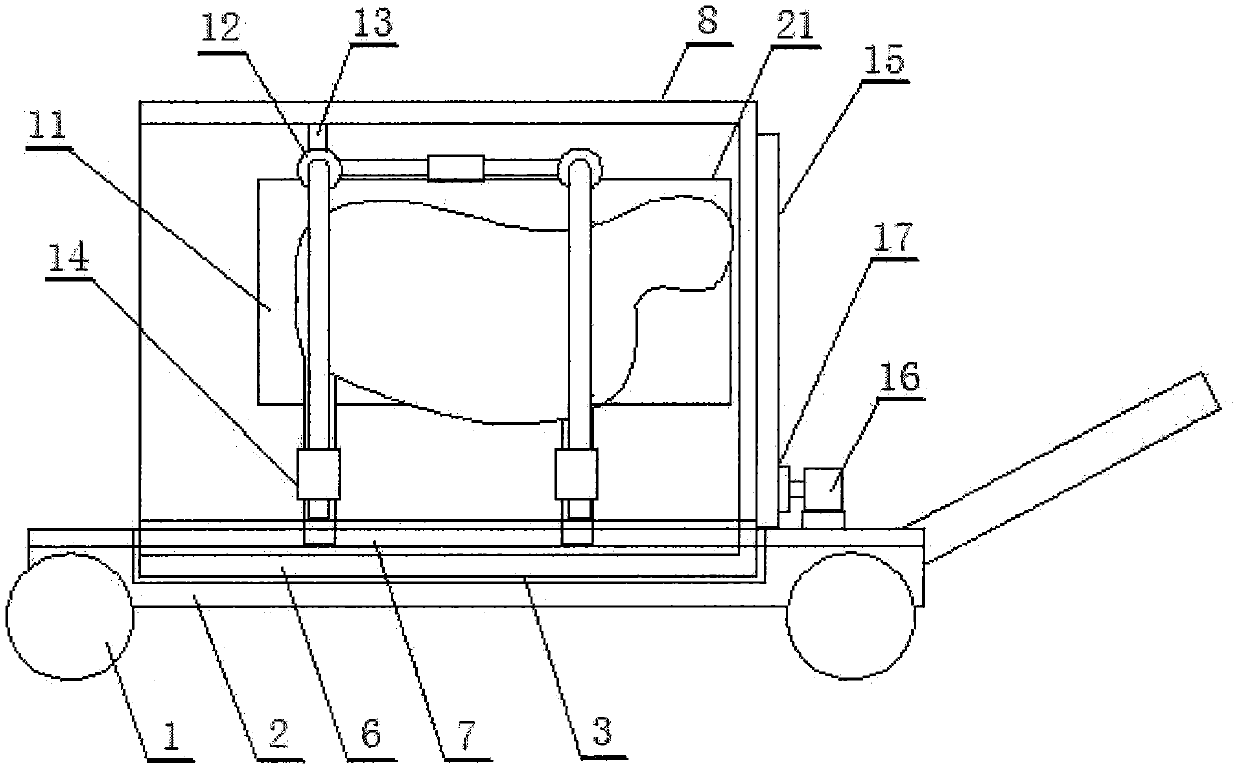

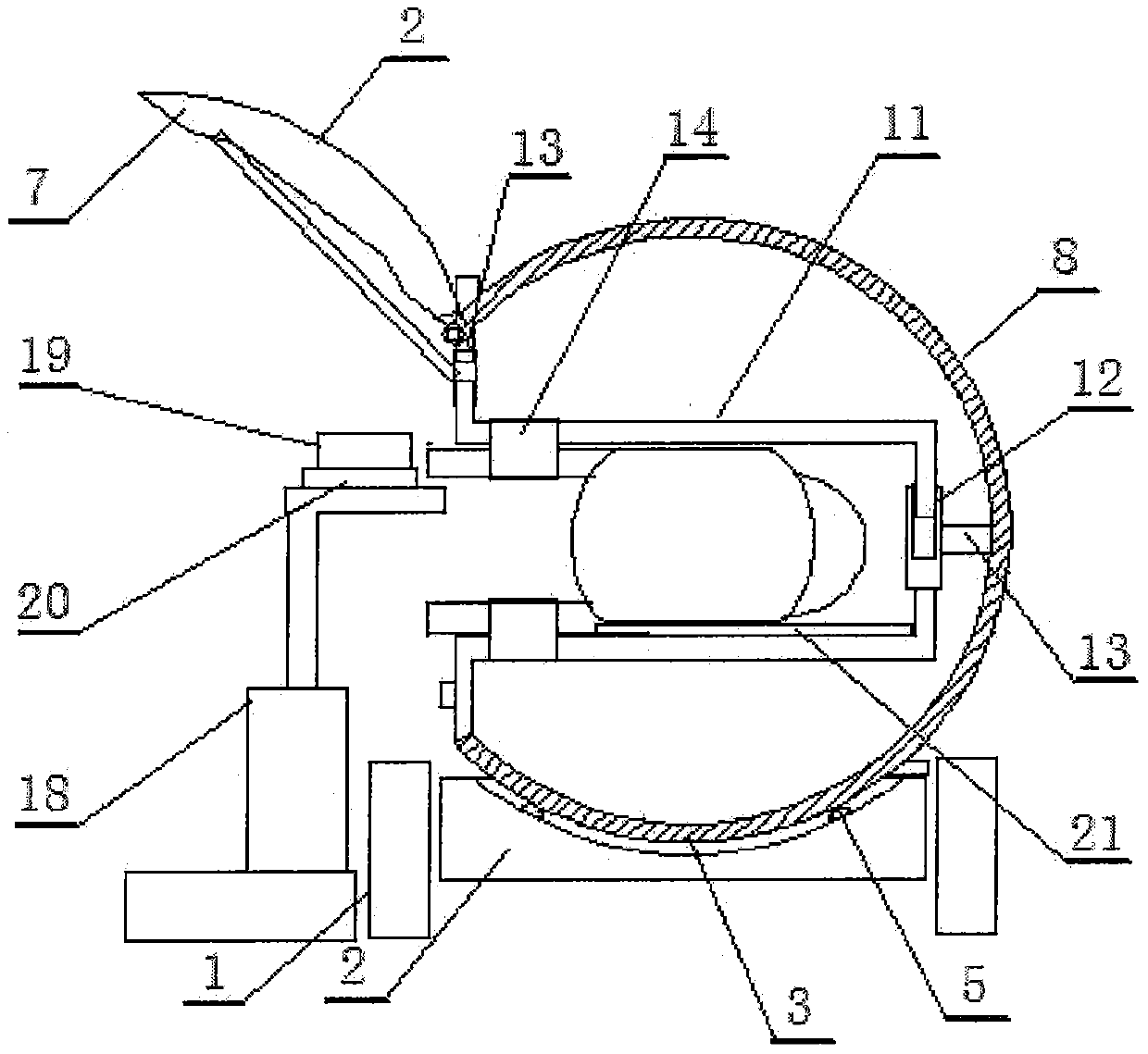

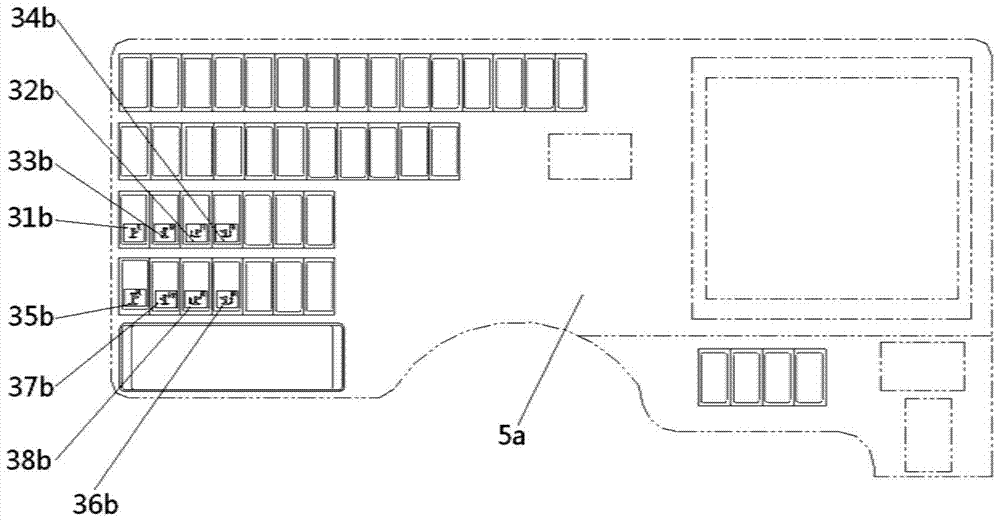

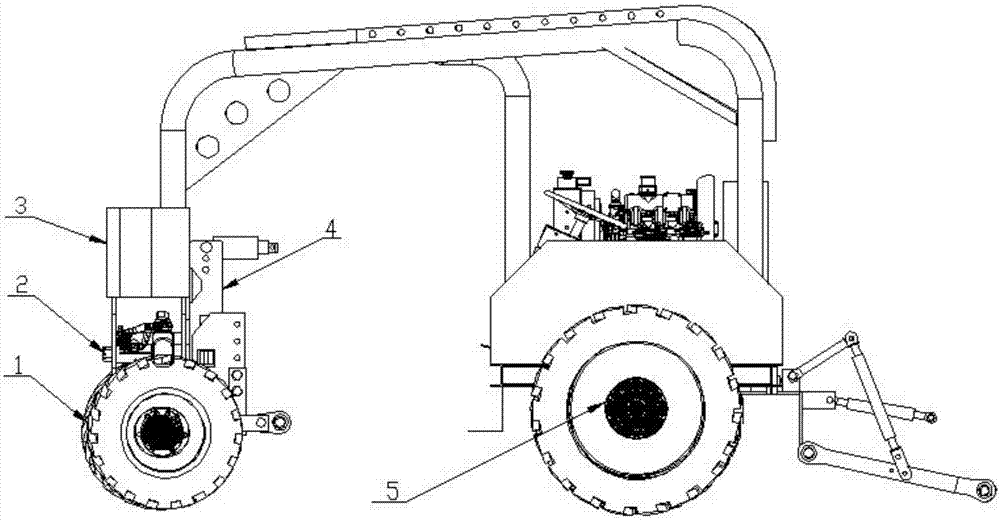

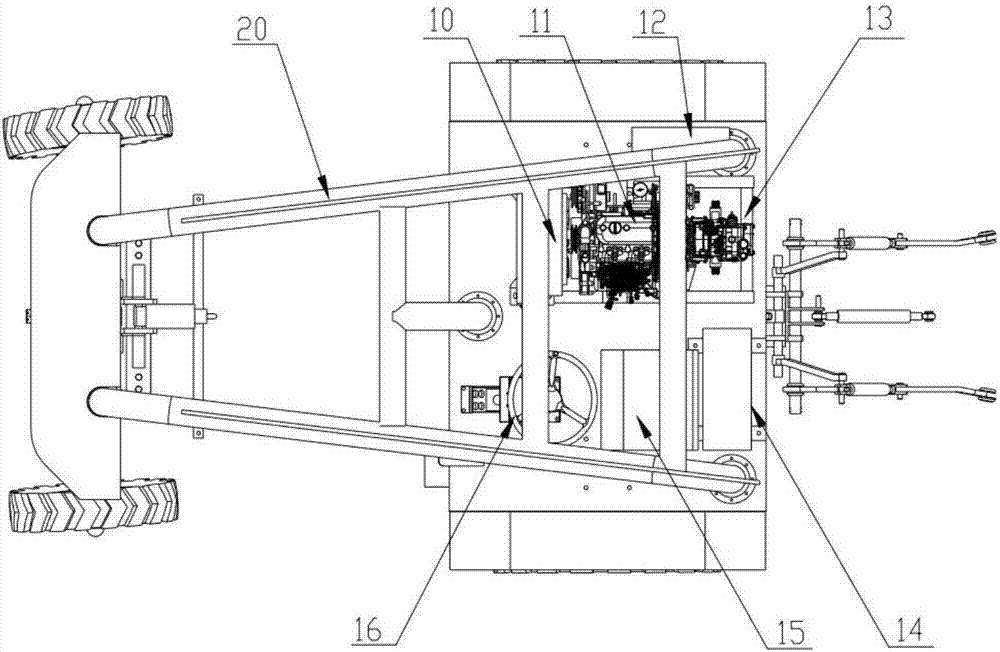

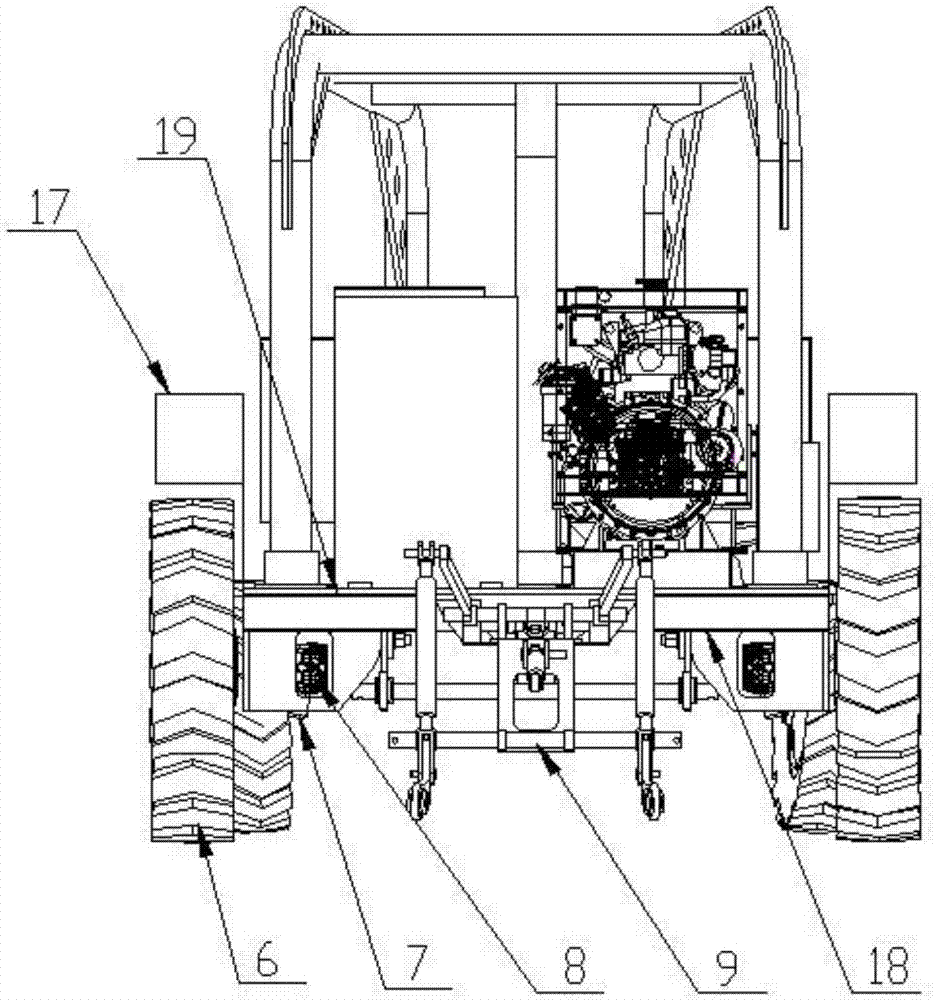

Vegetable field operation power machine

InactiveCN106922233AExpand the operating horizonAchieve multi-functionalityAgricultural undercarriagesHydraulic motorSteering wheel

The invention belongs to the technical field of agricultural machinery and particularly relates to a vegetable field operation power machine which is used for dragging vegetable field operation agricultural machines and implements. The power machine comprises a front wheel (1), a rear wheel (6), a hydraulic motor (8), an engine heat radiator (10), an engine (11), a diesel tank (12), a hydraulic pump (13), a hydraulic oil bulk assembly (14), a seat (15), a steering wheel (16), a supporting frame (19), a frame (20), a swinging bridge (2), a transverse swinging frame (3) and an inter-axis suspension device (4). The vegetable field operation power machine provided by the invention can be used for dragging various types of field operation agricultural machines and implements and can freely walk between narrow-line rows of relatively high crops; and the operation view of a driver is expanded and multifunction of the agricultural machinery is realized.

Owner:CHINA AGRI UNIV

Catheter for taking out ureteral stent

The invention relates to the technical field of medical instruments, in particular to a catheter for taking out a ureteral stent. The catheter for taking out a ureteral stent comprises a guide tube, abent tube part, an end part, a protective sealing plate, a perfusion channel, grasping forceps, a main pipeline, a perfusion tube, an optical fiber introducing tube and a cystoscope, the right end ofthe guide tube is fixedly connected to the left side of the bent tube part, the right side of the bent tube part fixedly communicates with the left side of the end part, a working channel is formed in the middle of the lower half part of the end part, and an optical fiber channel is formed in the middle of the upper half part of the end part. The invention achieves the purpose that an optical fiber scope is repeatedly used after an operation, the optical fiber scope cannot make any contact with human tissue on the premise that the operation view field generated by optical fibers is not hindered, and therefore the optical fiber scope can meet the disposable use requirement and is low in cost and price and free of pollution. Therefore, after the operation, the optical fiber scope does not need sterilization treatment and can perform continuous operation.

Owner:傅发军

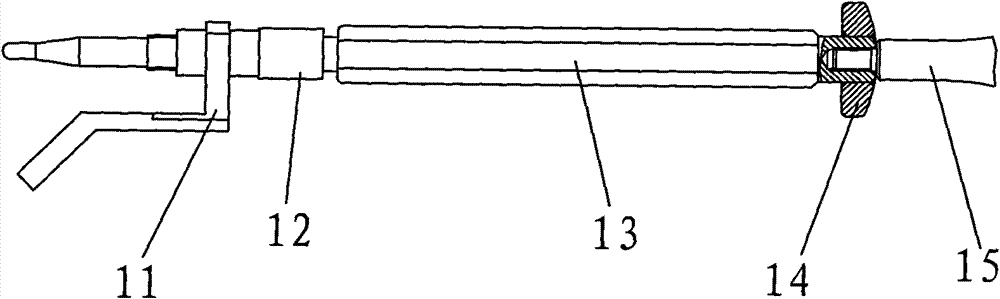

Illuminated intubation device for small animals

The invention discloses an illumination cannula device for a small animal, which comprises an LED (Light-Emitting Diode) light source, wherein the front end of the LED light source is connected with a light-guide fiber joint; the front end of the light-guide fiber joint is connected with a light-guide fiber; an optical fiber stabilizing device, a three-way tube and a trachea cannula which are connected with one another are sleeved in sequence at positions close to the front tail end of the light-guide fiber from back to front; the three-way tube is laterally connected with an injector which is communicated with the trachea cannula; and the front tail end of the light-guide fiber is accommodated in the trachea cannula. The illumination cannula device for the small animal disclosed by the invention has the advantages of smaller damages to the tracheae of animals, realization of high animal survival rate, wide view field, sufficient light rays and higher accuracy of insertion of the hose into the trachea cannula.

Owner:陈鸣宇

Rope fixation structures, surgical instruments, split surgical devices and robots

ActiveCN114305541BExpand the operating horizonSimple fixed structureComputer-aided surgeryInterference fitPhysical medicine and rehabilitation

The invention discloses a rope fixing structure, a surgical instrument, a split surgical device and a robot. The rope fixing structure includes a first traction rope, a second traction rope, a rigid connector and a locking sleeve. The rigid connecting piece is provided with a first rope groove and a second rope groove, and the first rope groove and the second rope groove intersect to form at least one intersection point. The first traction rope is embedded in the first rope groove and extends from the first end of the rigid connector, and the second traction rope is embedded in the second rope groove and extends from the first end of the rigid connector. At the intersection point, the first traction rope or the second traction rope protrudes from the surface of the rigid connector, and the locking sleeve is set on the surface of the rigid connector. At the intersection point, the locking sleeve is connected to the first traction rope or the second traction rope. Interference fit. The present invention uses two traction ropes to cross and overlap to form bumps to form an interference fit connection relationship. It does not require the use of many other accessories. The fixing structure is relatively simple and compact, which is conducive to expanding the operating field of view of surgical instruments.

Owner:APEIRON SURGICAL (BEIJING) CO LTD

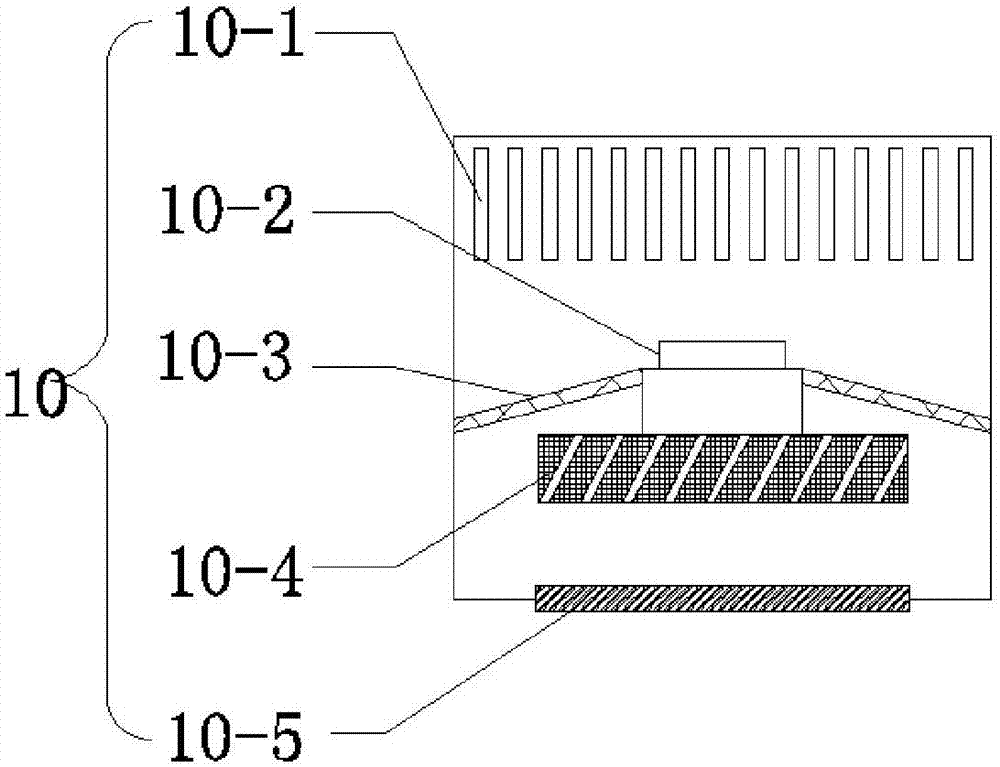

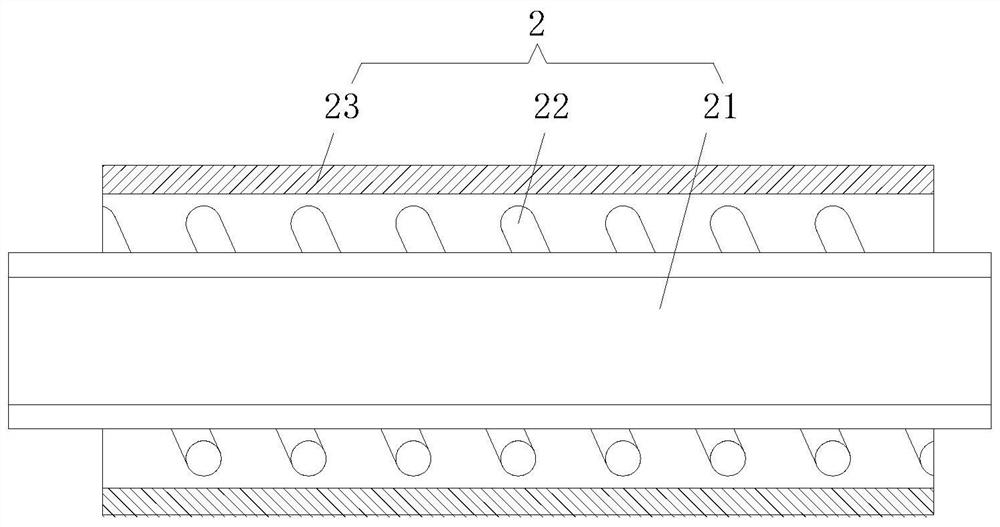

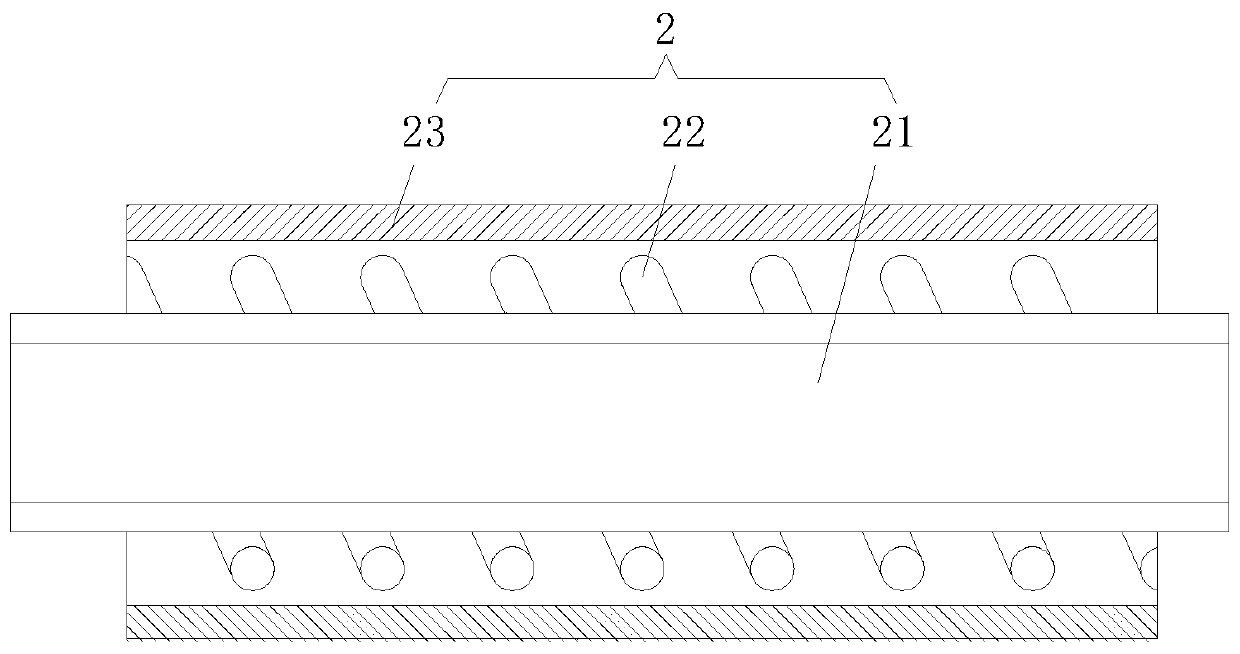

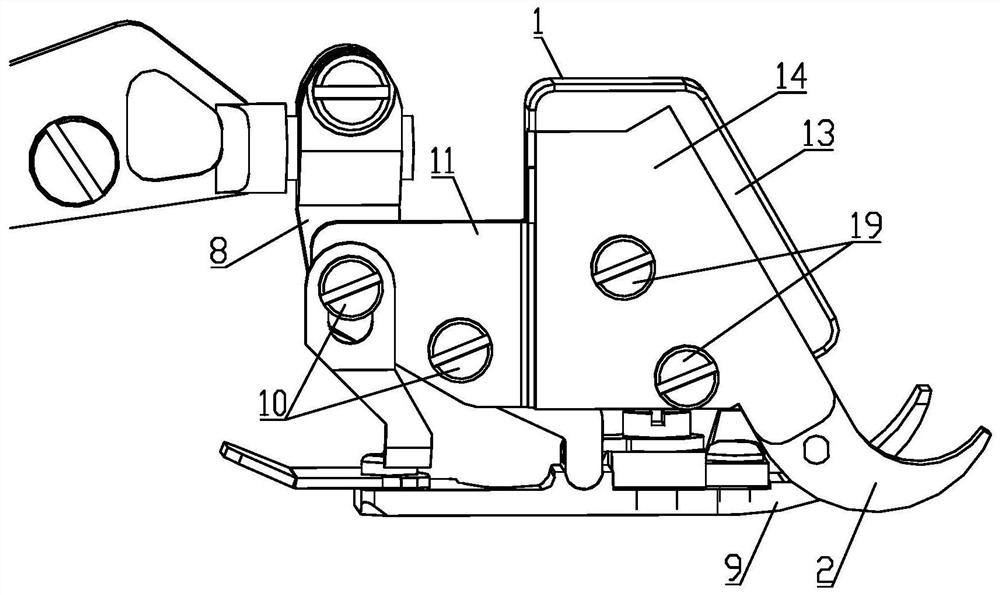

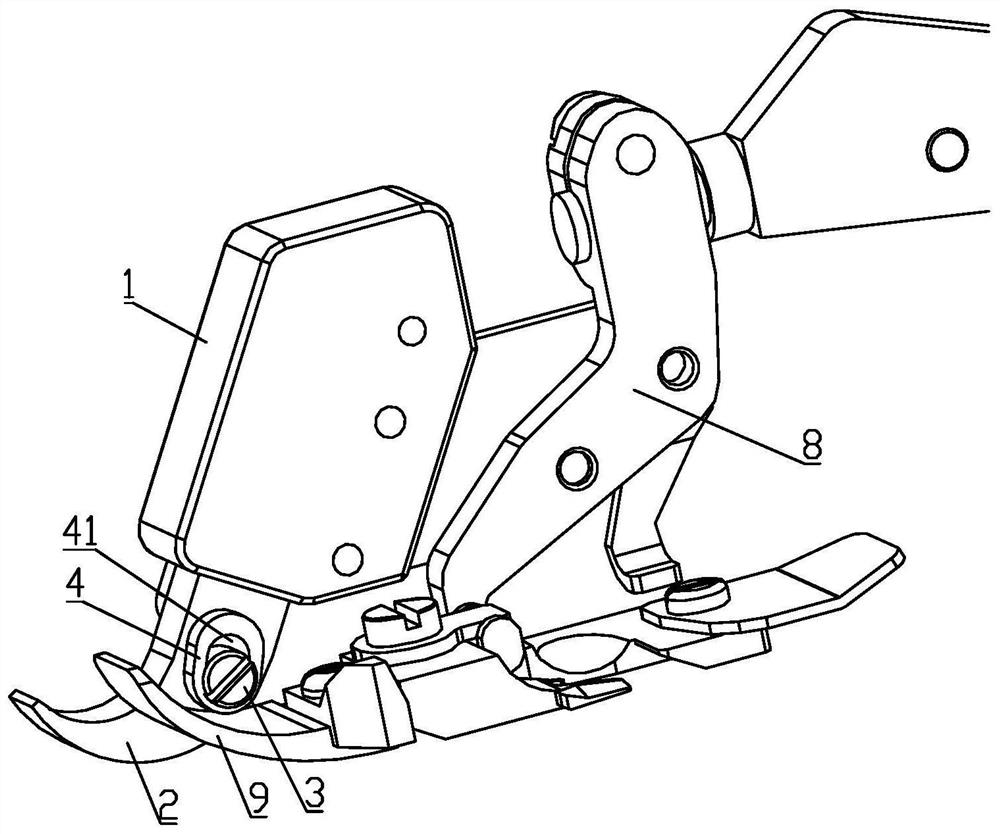

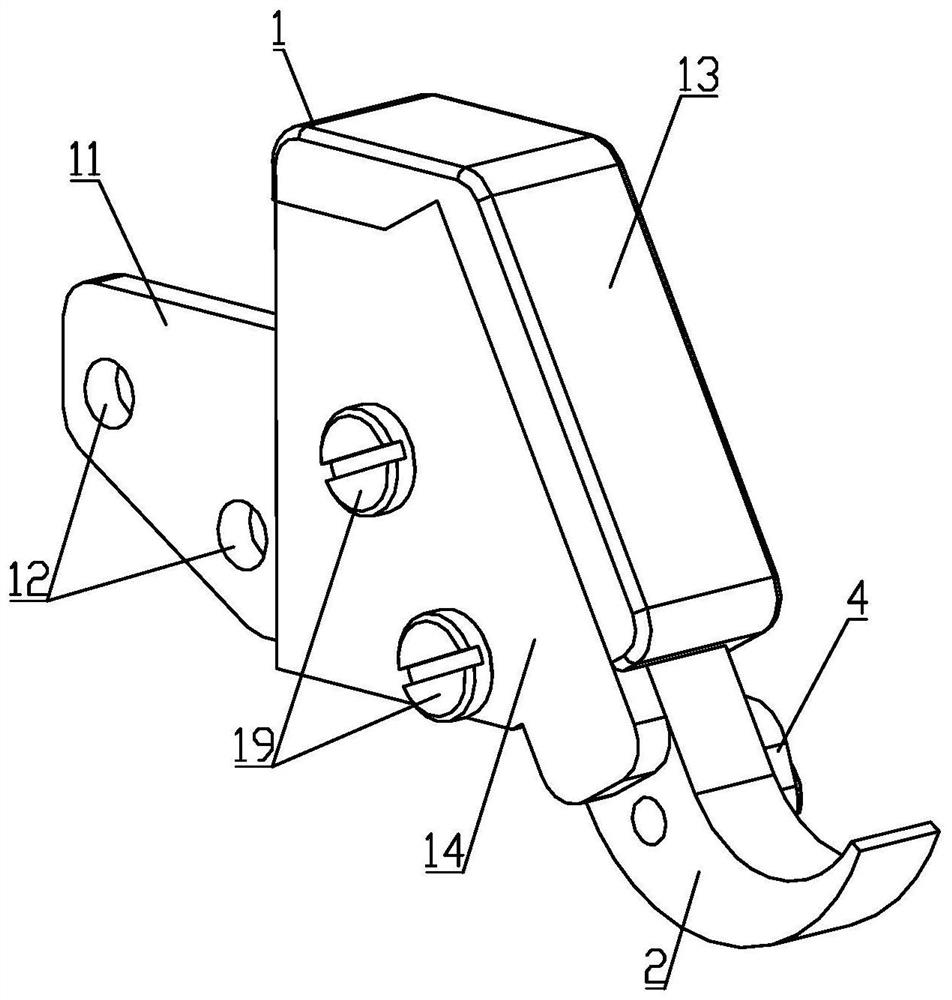

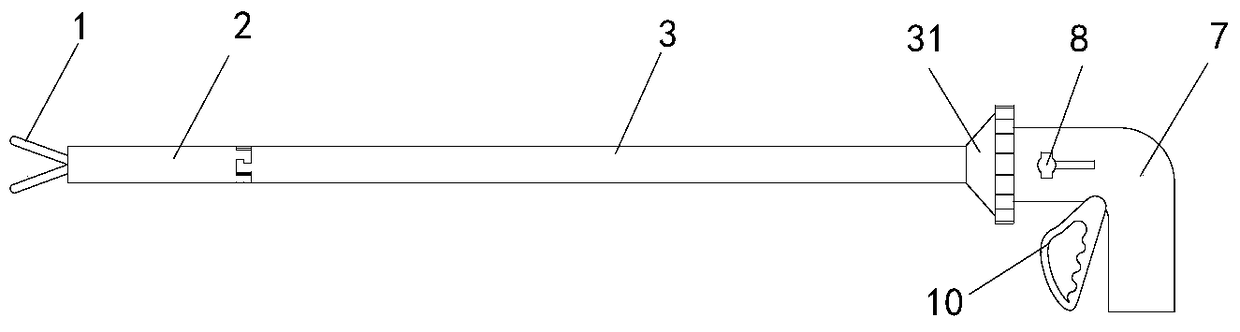

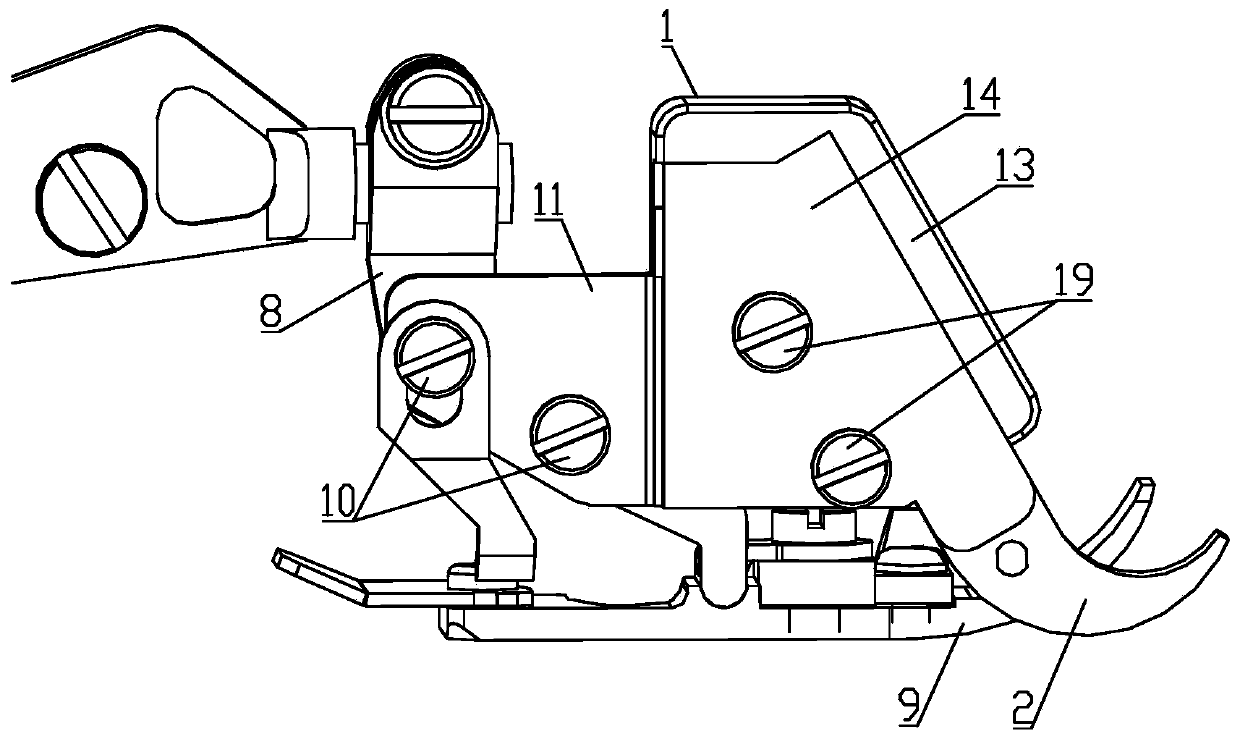

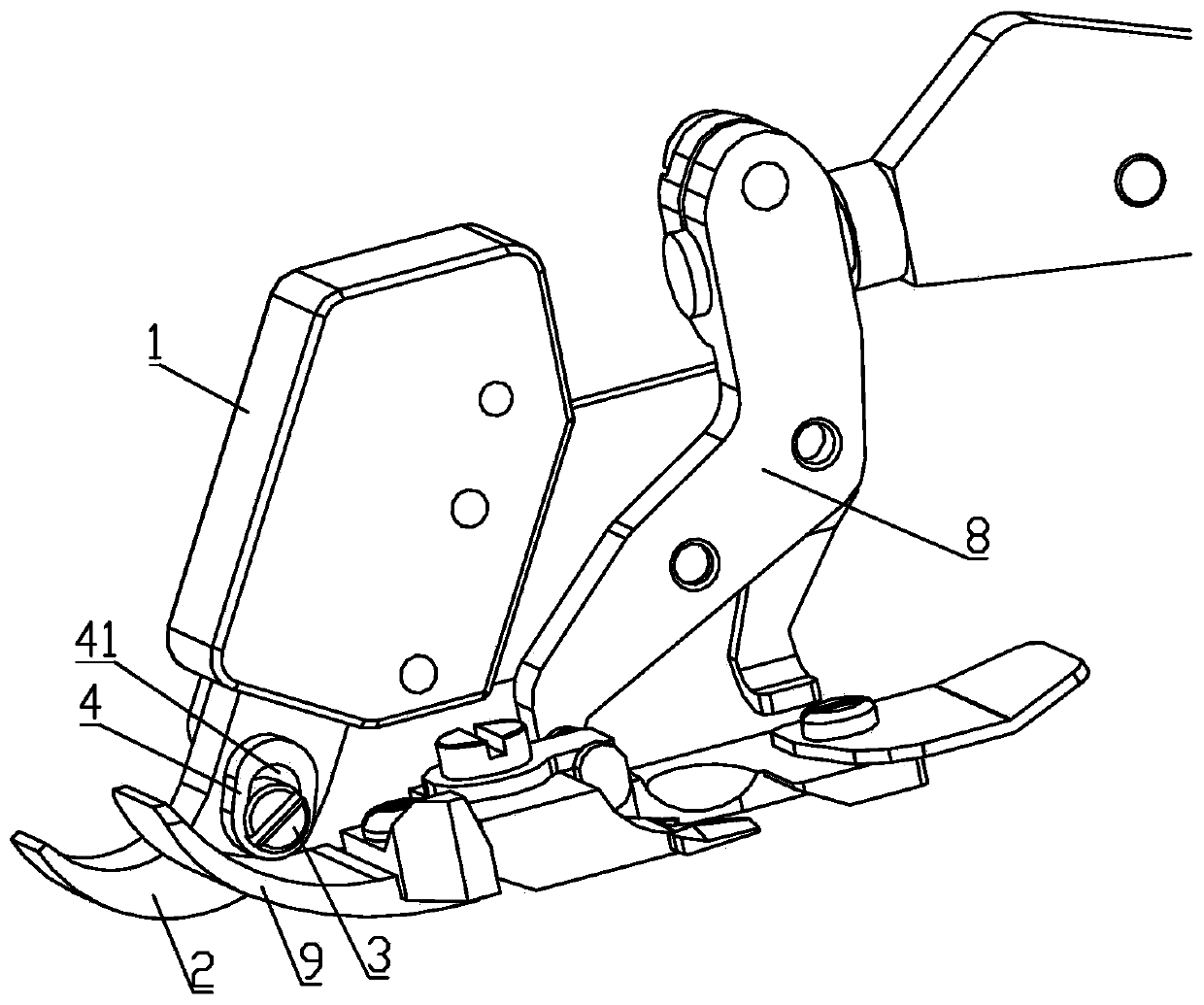

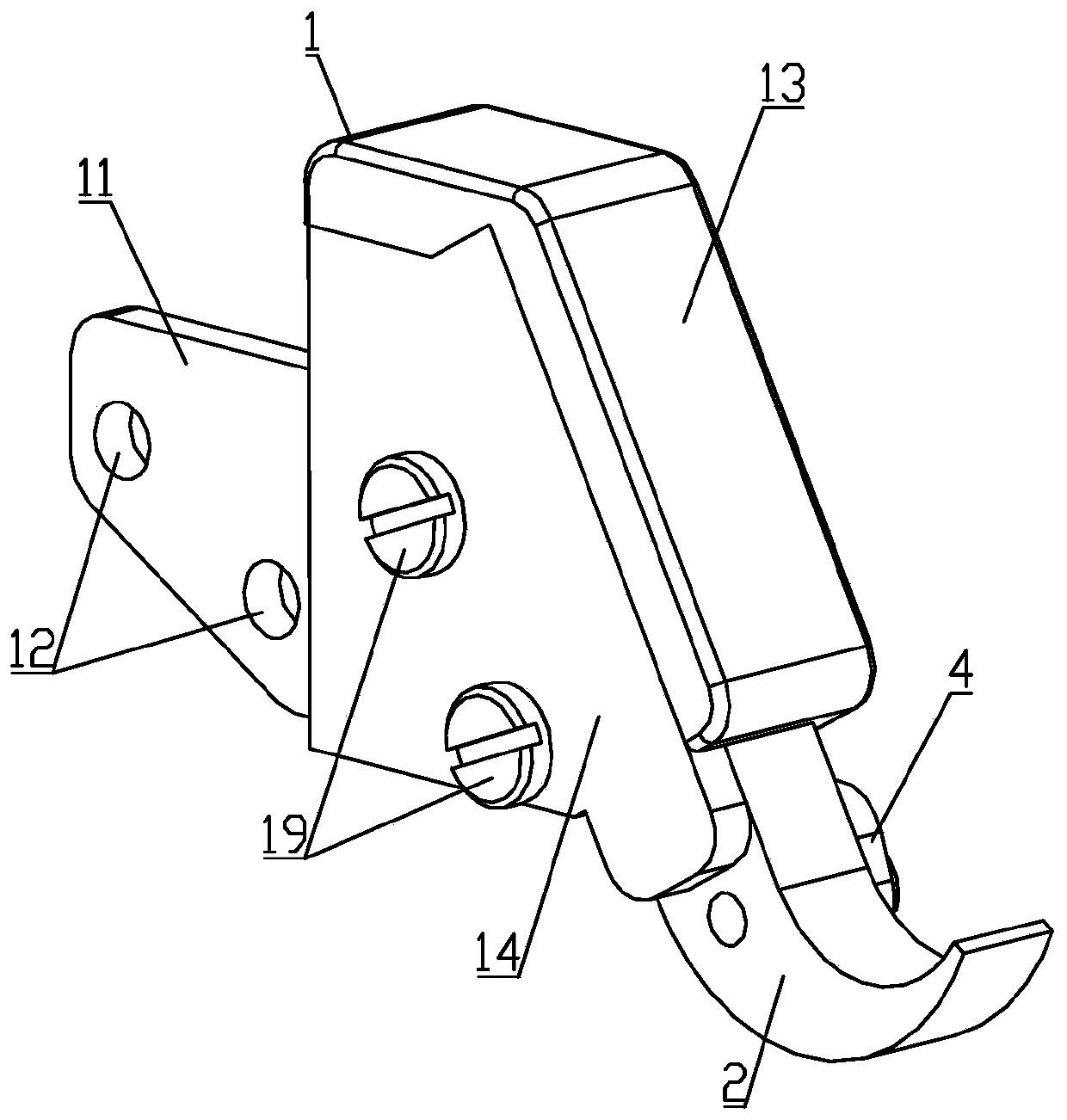

Sewing material thickness modular detection device and sewing machine

ActiveCN110670263BSignificant progressAvoid pollutionSewing-machine elementsEngineeringSewing machine

Owner:JACK SEWING MASCH CO LTD

Laparoscopic Detachable Vascular Blocking Forceps

InactiveCN106667540BImprove efficiencyImprove securitySurgical forcepsWound clampsPERITONEOSCOPEDissection forceps

A pair of separable blood vessel blocking forceps under a laparoscope comprises a sleeve, a control mechanism and a blocking forceps clamp, wherein the blocking forceps clamp is arranged in the sleeve, actions of the blocking forceps clamp are controlled through the control mechanism, the sleeve comprises a front sleeve and a rear sleeve, and the front sleeve and the rear sleeve are detachably connected in an embedded mode. The control mechanism comprises a front portion control mechanism and a rear portion control mechanism, the front portion control mechanism is movably connected with the blocking forceps clamp, and the rear portion control mechanism is detachably and movably connected with the front portion control mechanism. The pair of separable blood vessel blocking forceps is reasonable in structural design, a possible biggest operating view field is provided for an operation by adopting the separable structural design to facilitate execution of other operations, the efficiency of a laparoscopic surgery and the safety are greatly improved, and convenience is provided for medical workers.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Modular detection device for sewing material thickness and sewing machine

The invention relates to the technical field of sewing machines, in particular to a modular detection device for sewing material thickness and a sewing machine comprising the same. The modular detection device for sewing material thickness comprises: a support body, wherein the support body and a sewing machine body are separate which are independent of each other, the support body is provided with a mounting part which is detachably connected with the sewing machine body, and a closed accommodating space is formed in the support body; a moving part, movably arranged in the accommodating space, wherein one end of the moving part extends out of the accommodating space and is positioned above a sewing material, and when the thickness of the sewing material changes, the moving part moves through the contact of the sewing material with the moving part; and a detection mechanism, arranged in the accommodating space and used for detecting the movement amplitude of the moving part and transmitting detection information to a control module of the sewing machine body. Both the moving part and the detection mechanism are arranged in the accommodating space of the support body to form an independent modular device, a closed integral structure is formed, the dustproof effect is good, and disassembly and assembly are convenient.

Owner:JACK SEWING MASCH CO LTD

Hot-rolled C-shaped steel for forklift gantry

PendingCN112777528AReduced structure widthReduce stiffnessLifting devicesStructural engineeringMaterials processing

The invention relates to the technical field of machinery and material machining, in particular to hot-rolled C-shaped steel for a forklift gantry. The hot-rolled C-shaped steel for the forklift gantry comprises a web plate, a first wing plate and a second wing plate and further comprises a boss, the first wing plate and the second wing plate are located at the two ends of the lower surface of the web and form a C-shaped structure with the web, and the boss is located at the joint of the lower surface of the web plate and the left side surface of the second wing plate. The steel has the advantages of wide operation field, light weight, good rigidity, low hot rolling difficulty and low production cost.

Owner:SHANDONG IRON & STEEL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com