Garbage picking-up unmanned aerial vehicle integrated with garbage can

A technology of dustbins and drones, which is applied to aircraft parts, construction, transportation and packaging, etc. It can solve the problems of large volume, fixed purpose, and limited range of motion, so as to increase the operating field of vision, prevent secondary pollution, and facilitate cleaning. The effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

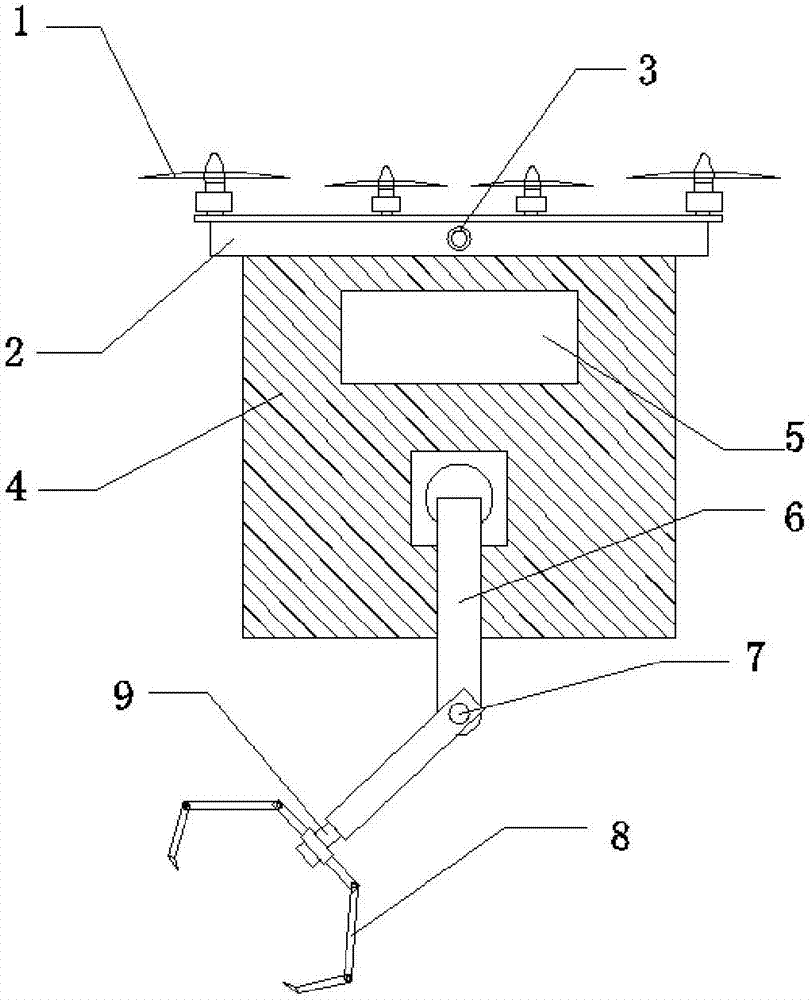

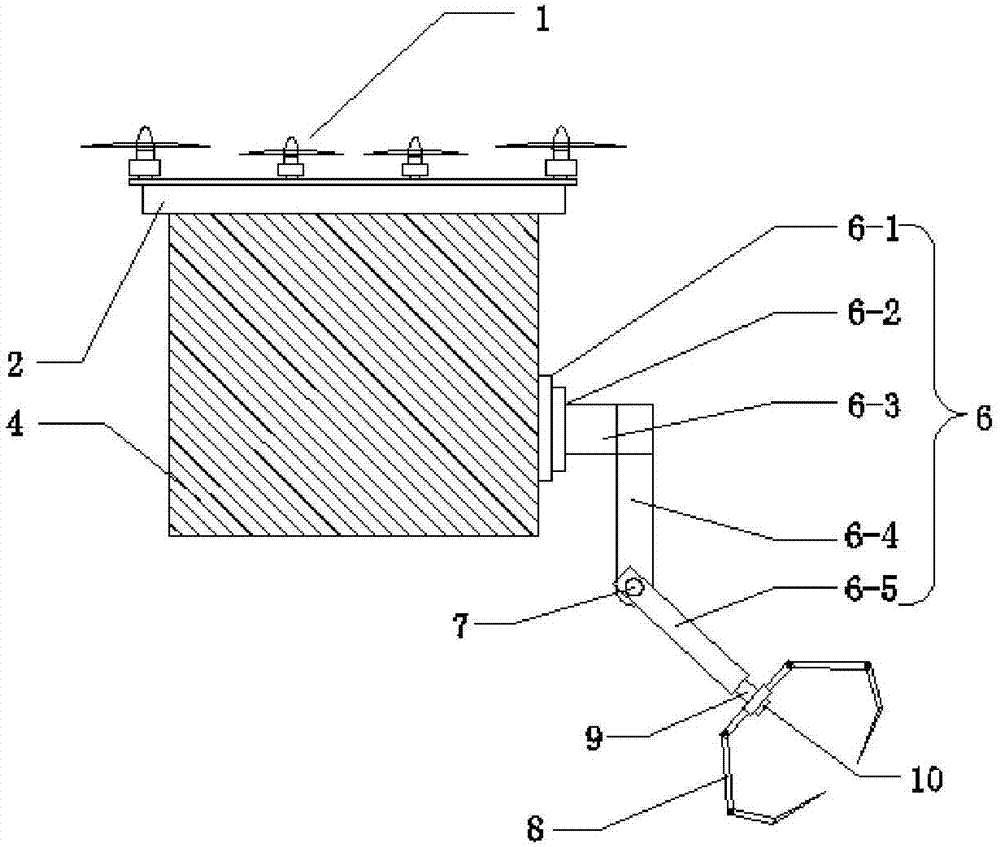

[0024] Such as Figure 1~2 The above provides a garbage picking unmanned aerial vehicle integrating a garbage bin, including a propeller 1, a control room 2, a garbage bin 4, a mechanical arm assembly 6 and a mechanical claw 8, and the control room 2 is arranged under the propeller 1 A storage battery and a camera 3 electrically connected to the storage battery are provided in the control room 2, the dustbin 4 is fixed at the bottom of the control room 2, and an opening 5 is opened on one side of the dustbin 4 below the camera 3, the said The mechanical arm assembly 6 is fixed below the opening 5 , and the mechanical claw 8 is arranged below the mechanical arm assembly 6 .

[0025] The mechanical arm assembly 6 includes a base 6-1, a brushless motor A6-2, a first mechanical arm 6-3, a second mechanical arm 6-4 and a third mechanical arm 6-5 connected in sequence. The seat 6-1 is fixed on the surface of the dustbin 4, the second mechanical arm 6-4 is perpendicular to the first...

Embodiment 2

[0028] Such as Figure 1~3 As shown, this embodiment is to make further improvements on the basis of embodiment 1, specifically:

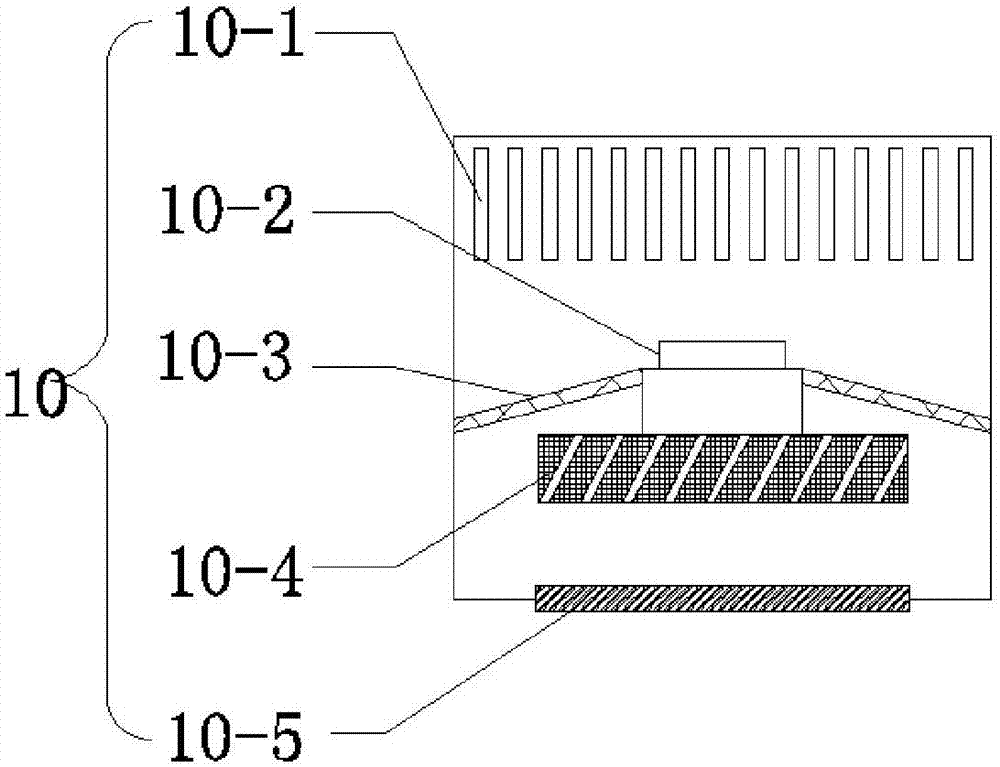

[0029] A vacuum suction device 10 is provided at the bottom of the mechanical arm assembly 6, and the vacuum suction device 10 includes several equidistantly arranged exhaust ports 10-1 arranged on the upper end of the vacuum suction device 10, located at the exhaust port. The fan 10-4 below the mouth 10-1 and the air inlet 10-5 arranged at the bottom of the vacuum suction device 10, the upper part of the fan 10-4 is provided with a motor 10-3, and the fan 10-4 and the motor 10 -3 are connected, and a support structure 10-2 is provided around the motor 10-3, and the support 10-2 is fixed to the inner wall of the vacuum suction device 10.

[0030] In this embodiment, the vacuum suction device at the bottom of the mechanical arm is located directly above the garbage when grabbing the garbage, and can effectively absorb plastic garbage bags and other...

Embodiment 3

[0032] This embodiment makes further improvements on the basis of Embodiments 1 and 2, specifically:

[0033] A brushless motor C9 is arranged on the top of the mechanical claw 10, and the brushless motor C9 is electrically connected to the battery.

[0034] The mechanical claw 10 is provided with sawtooth.

[0035] In this embodiment, the mechanical claw is provided with sawtooth to increase the friction between the mechanical claw and the garbage, which can effectively prevent falling off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com