Preparation and application of cement material self-repairing molecular self-assembled microspheres

A cement material, self-healing technology, used in the preparation of microspheres, microcapsule preparations, etc., to achieve the effect of improving compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

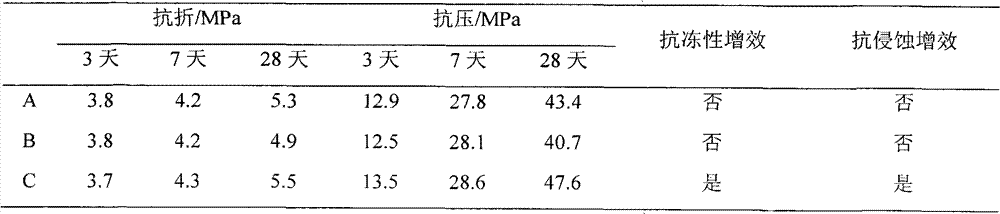

[0034] Embodiment 1 (general cement)

[0035] A kind of preparation method that has self-healing function microsphere to universal cement, comprises the following steps:

[0036] (1) select the repairing liquid epoxy resin that can have repairing function to general cement material, active diluent is dilute with benzyl alcohol;

[0037] (2) add surfactant sodium dodecylbenzenesulfonate to the solution that step (1) obtains, stir 35min, form the emulsion of O / W;

[0038] (3) in the solution that step (2) obtains, add functional monomer polyethylene, divinylbenzene to be spherical wall;

[0039] (4) Add cross-linking agent methacrylamide and porogen toluene to the solution obtained in step (3), feed nitrogen to replace the air inside;

[0040] (5) Slowly heat up to 70°C, and react continuously for 4 hours at a stirring speed of 300r / min;

[0041] (6) Add 0.4% initiator potassium persulfate, continue to react for 2 hours, and vacuum dry;

[0042] (7) The product obtained in t...

Embodiment 2

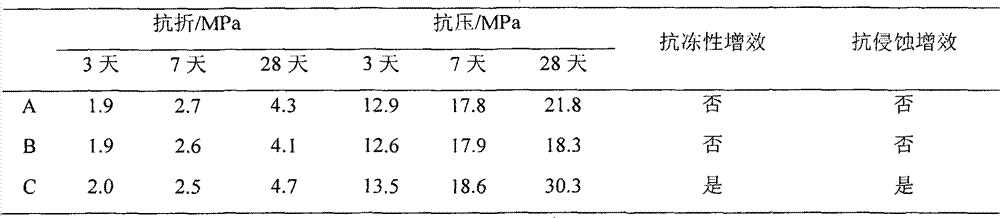

[0048] Embodiment 2 (masonry cement)

[0049] A method for preparing microspheres with self-repairing function for masonry cement, comprising the following steps:

[0050] (1) select the repair fluid polysulfide rubber and butyl rubber that can repair the masonry cement material, and the reactive diluent is dilute with n-butanol;

[0051] (2) add surfactant cetyltrimethylammonium bromide in the solution that step (1) obtains, stir 50min, form the emulsion of O / W;

[0052] (3) in the solution that step (2) obtains, add functional monomer polystyrene, polybutadiene to be spherical wall;

[0053](4) Add crosslinking agent methacrylamide and porogen n-heptane to the solution obtained in step (3), feed nitrogen to replace the air inside;

[0054] (5) Slowly heat up to 75°C, and react continuously for 5 hours at a stirring speed of 250r / min;

[0055] (6) Add 0.3% initiator potassium persulfate, continue to react for 3 hours, and vacuum dry;

[0056] (7) The product obtained in t...

Embodiment 3

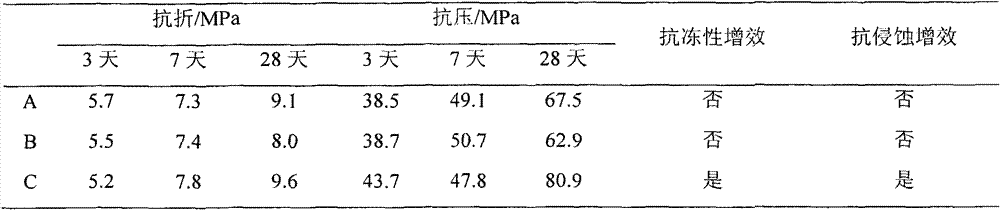

[0062] Embodiment 3 (road portland cement)

[0063] A preparation method for road Portland cement with self-repairing functional microspheres, comprising the following steps:

[0064] (1) Select suitable road Portland cement repair fluid polyurethane and α-cyanoacrylate, active diluent xylene to dilute;

[0065] (2) add surfactant Tween in the solution that step (1) obtains, stir 35min, form the emulsion of O / W;

[0066] (3) adding functional monomer polyamide and polyacrylamide to the solution obtained in step (2) are spherical walls;

[0067] (4) Add crosslinking agent methacrylamide and porogen liquid paraffin to the solution obtained in step (3), feed nitrogen to replace the air inside;

[0068] (5) Slowly heat up to 65°C, and react continuously for 4 hours at a stirring speed of 250r / min;

[0069] (6) Add 0.4% initiator ammonium persulfate, continue to react for 2 hours, and dry in vacuum;

[0070] (7) The product obtained in step (6) is mixed into cement with a conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com