Patents

Literature

35results about How to "Easy to control operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

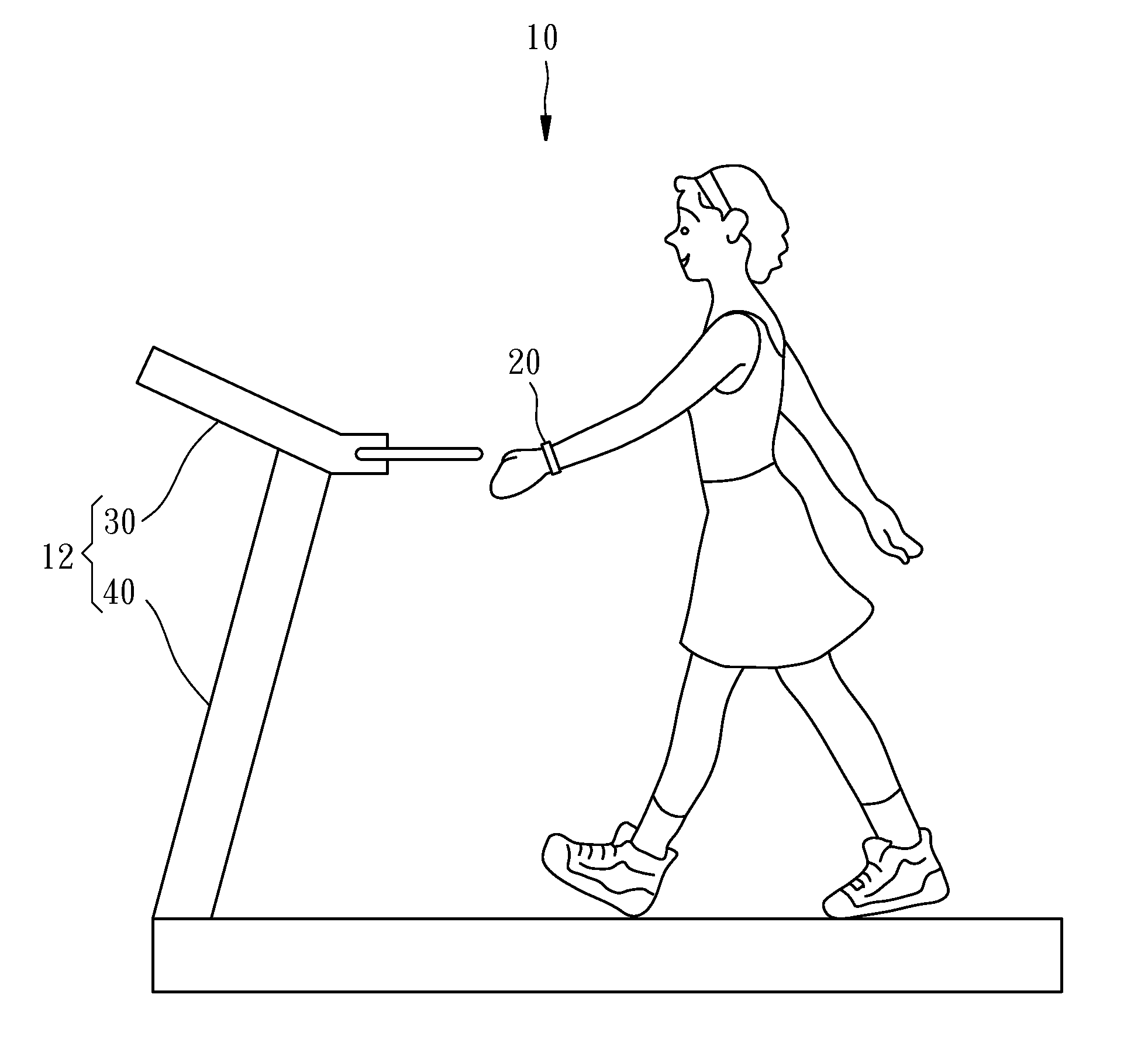

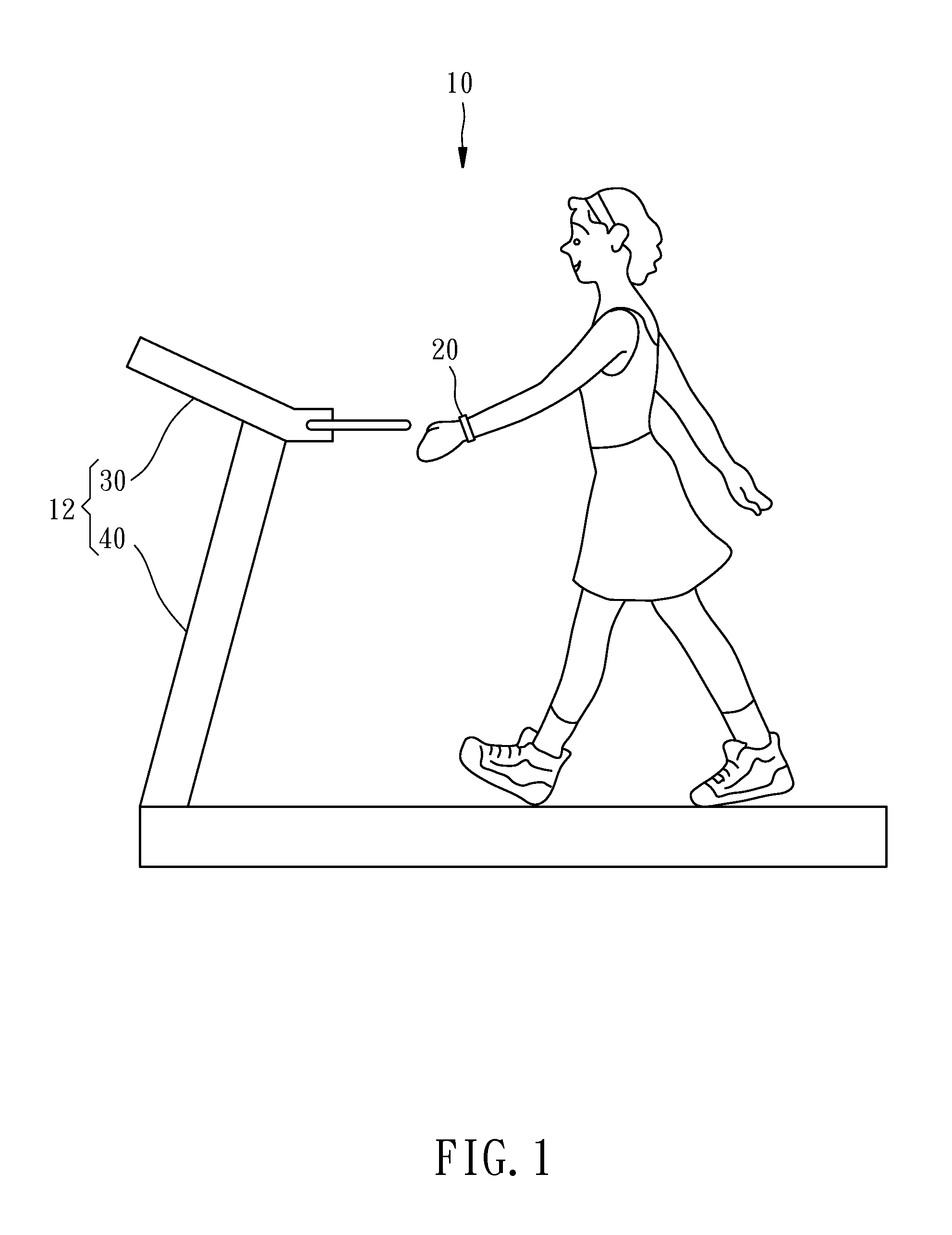

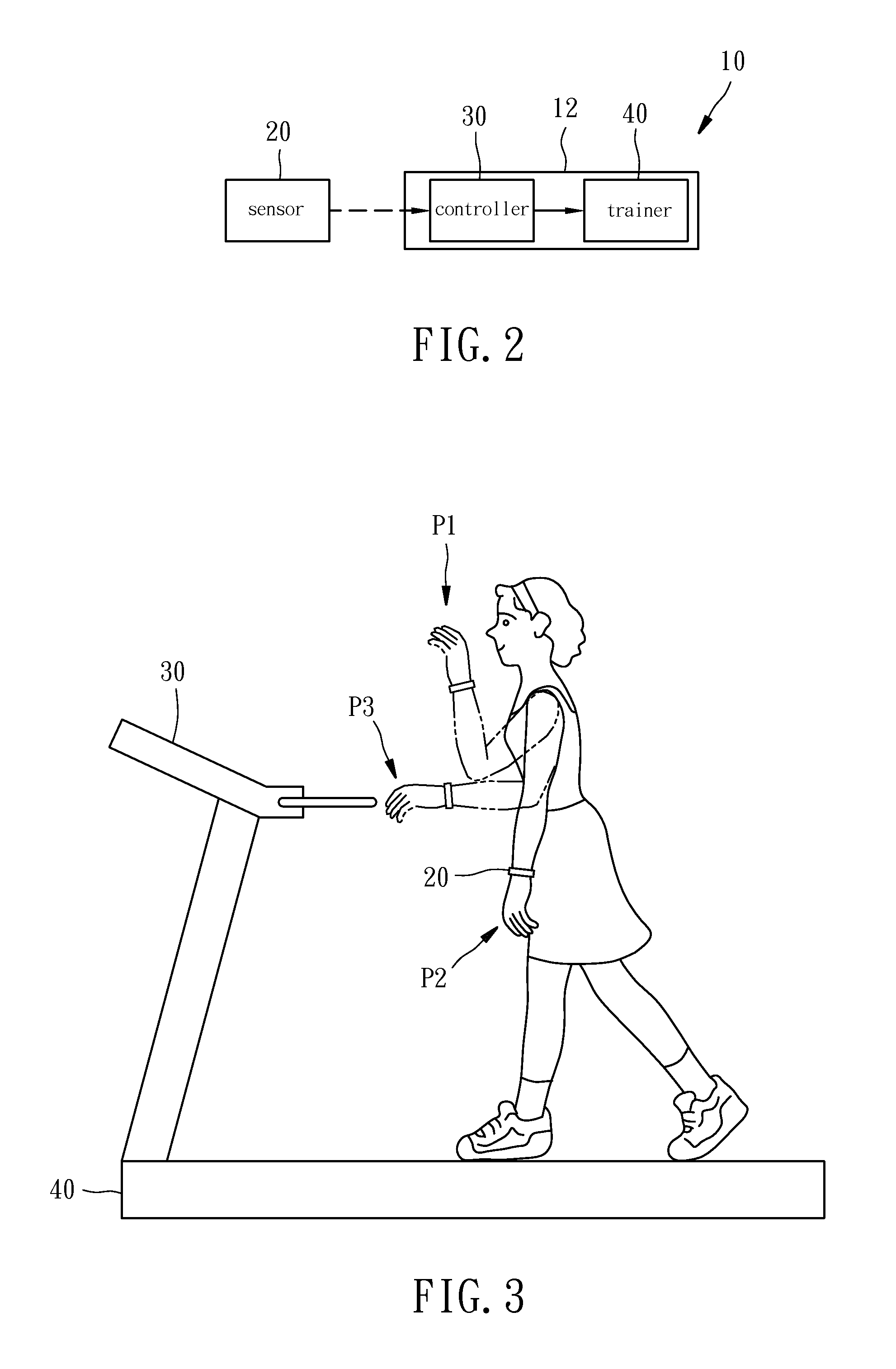

Trainer control method and fitness device using the same

InactiveUS20150105220A1Easy to operate and controlEasy to control operationInertial sensorsCharacter and pattern recognitionControl theoryOperating speed

A trainer control method is provided and includes mounting a sensor at a user's upper extremity, sending from the sensor a sensing signal variable with the position or motion of the upper extremity, and controlling the operating speed of a trainer by the user according to the upper extremity, wherein the sensing signal causes the trainer operating speed to increase and decrease whenever the upper extremity is in first and second states for predetermined duration, respectively. Accordingly, riot only does the user control the operating speed and state of the trainer easily, but user safety is also enhanced.

Owner:HEALTHSTREAM TAIWAN INC

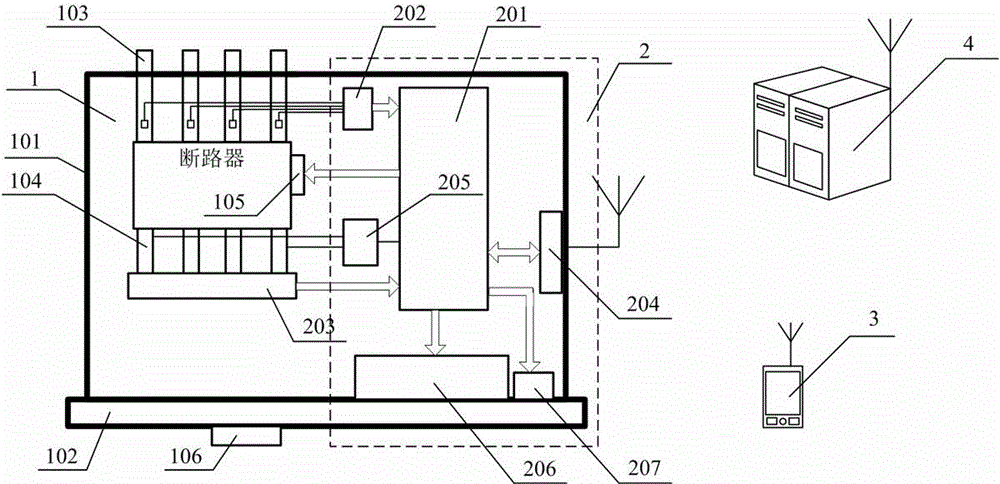

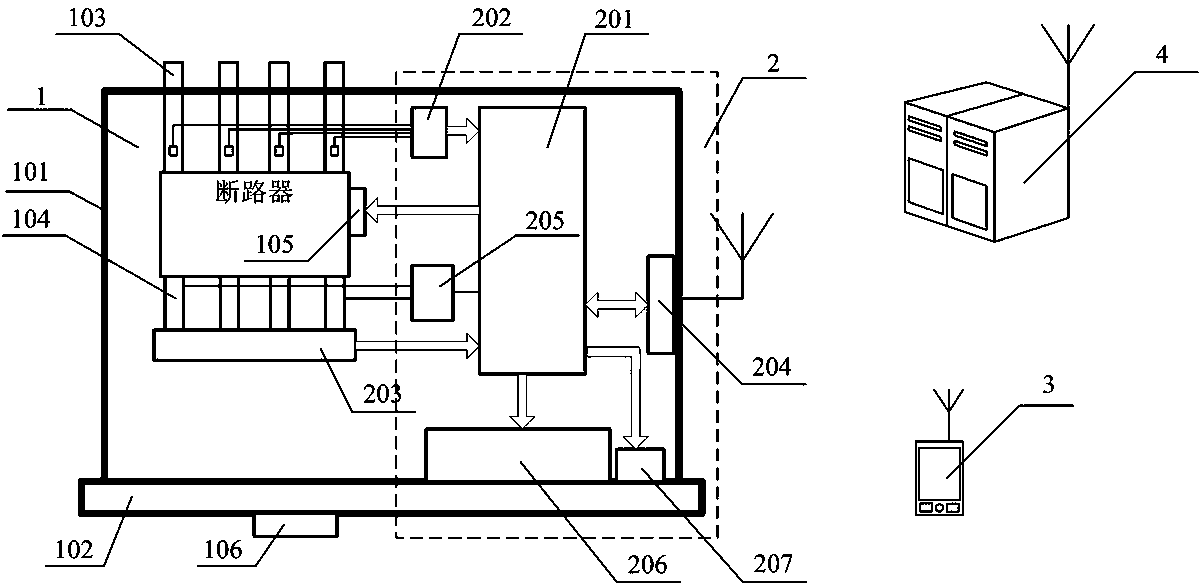

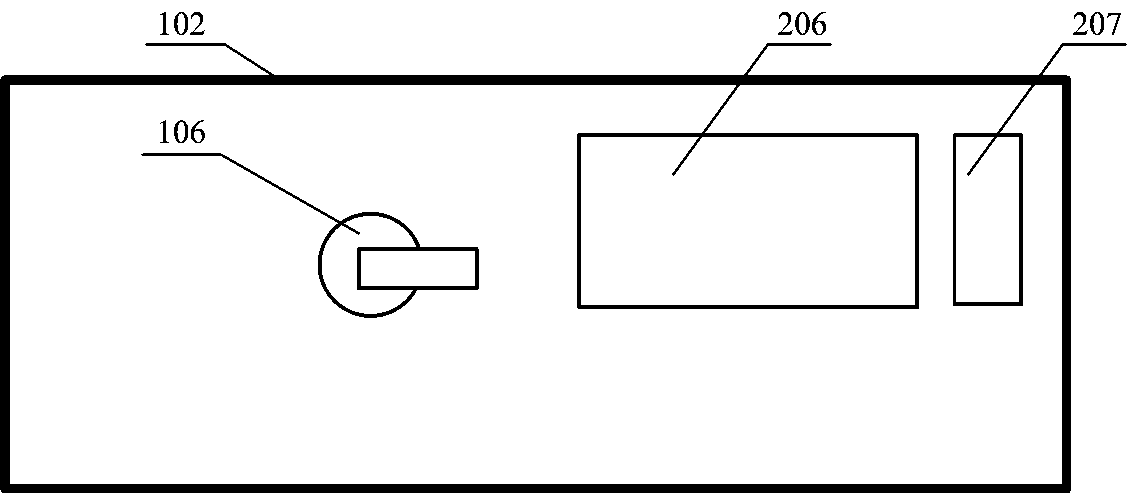

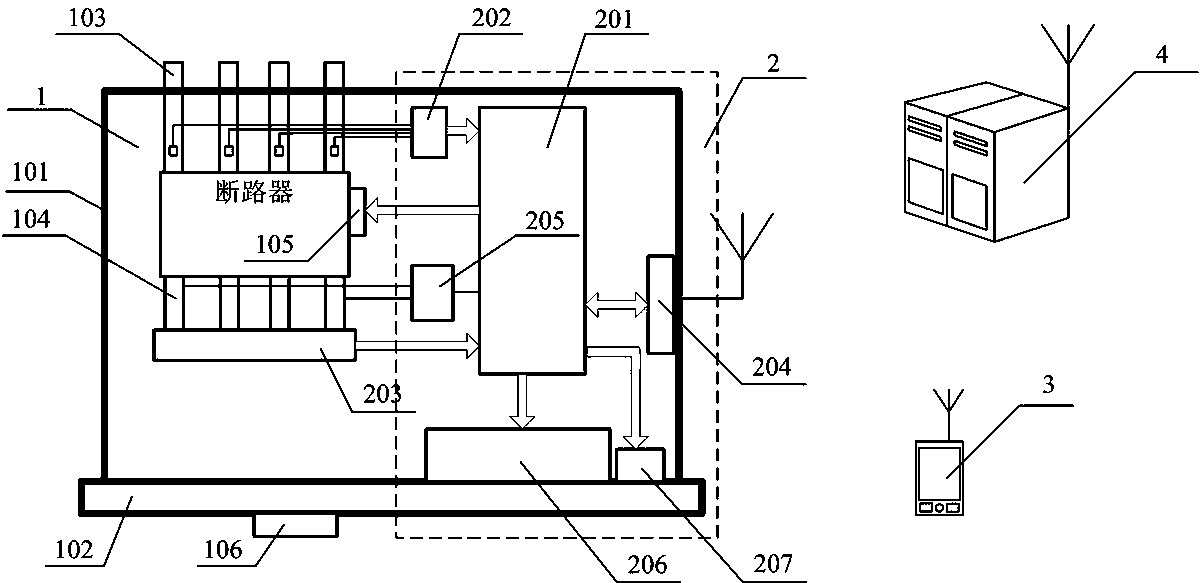

Intelligent pluggable circuit breaker and monitoring and pre-warning system thereof

InactiveCN104597398ASimple structureEasy to installThermometer detailsTransmission systemsEmbedded systemServer

The invention provides an intelligent pluggable circuit breaker and a monitoring and pre-warning system of the intelligent pluggable circuit breaker. The monitoring and pre-warning system is composed of the pluggable circuit breaker, a monitoring and pre-warning device, a portable terminal and a monitoring central server. The monitoring and pre-warning device comprises a measurement and control module, a temperature collection module, a voltage and current collection module, a communication module, a display module and an audible and visual alarm module. Pre-warning is achieved by measuring the temperature of all contacts in real time, measuring and calculating various electric parameters and comprehensively analyzing and judging the working state especially the unhealthy or abnormal state of the pluggable circuit breaker. In addition, the temperature warning function and the temperature protection function are achieved. The pluggable circuit and the monitoring and pre-warning device are highly integrated, the structure is simple, installation is convenient, safety and reliability are achieved, the intelligent running of the pluggable break circuit is achieved, the real-time running monitoring and production management of the field are facilitated, the low cost, production and refitting can be easily achieved, the fault rate and the damage rate of devices are effectively decreased, and the power supply reliability is improved.

Owner:HARBIN UNIV OF SCI & TECH +1

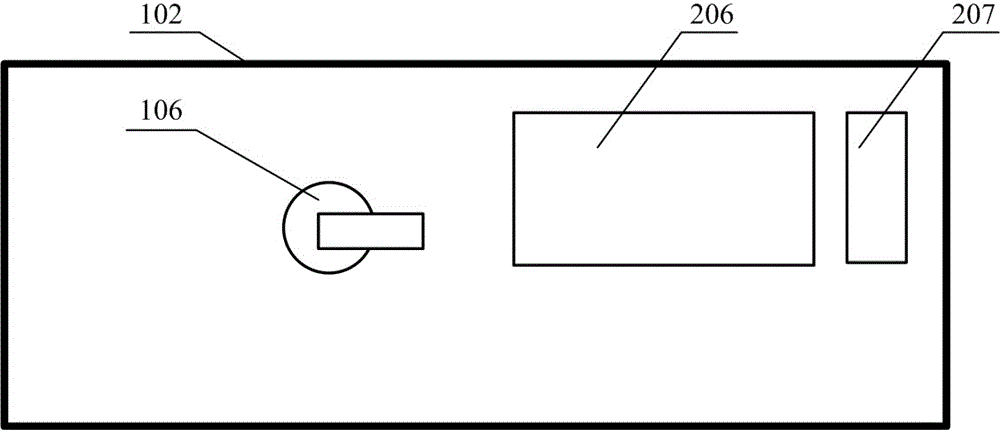

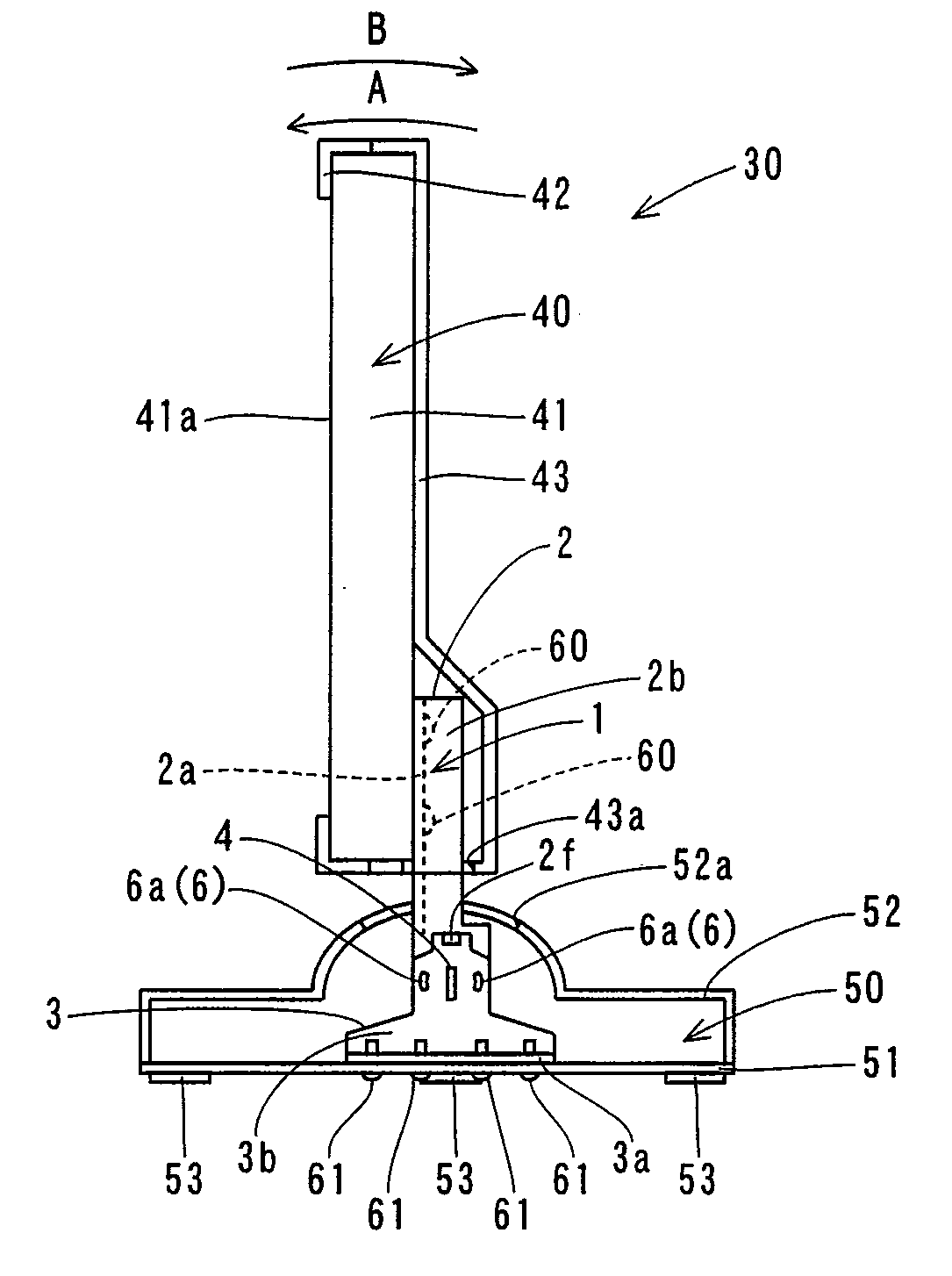

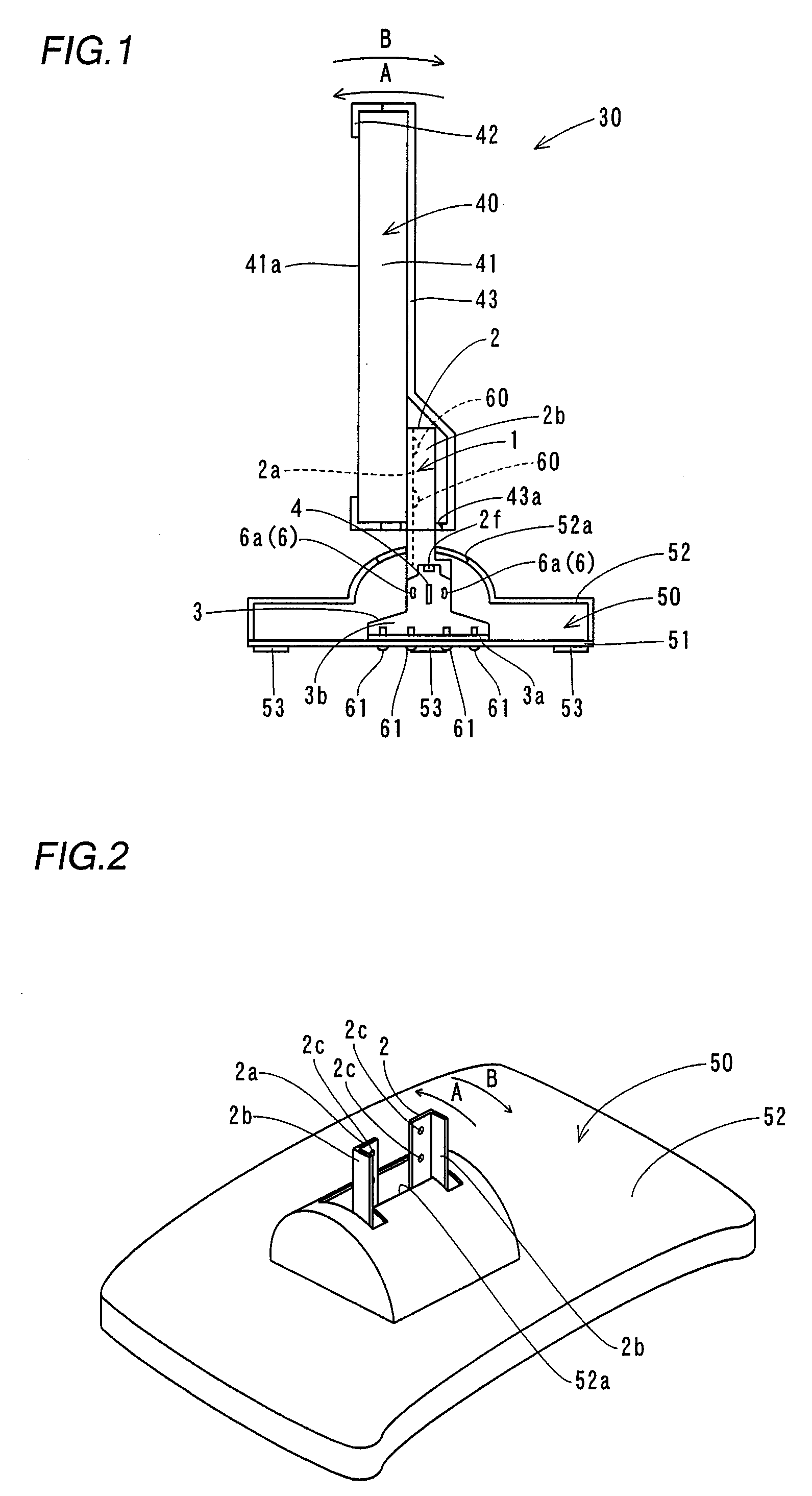

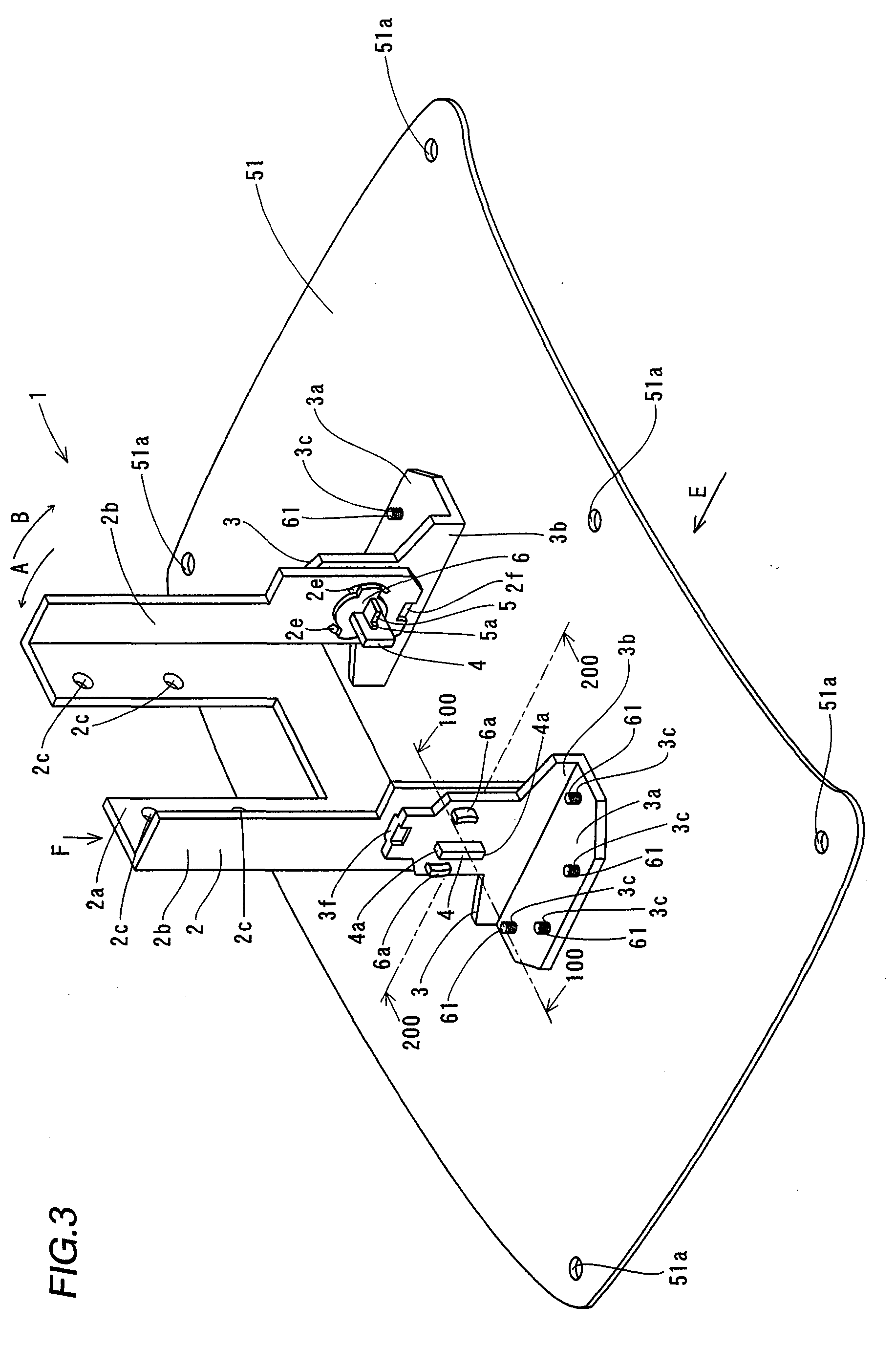

Display Support Mechanism

InactiveUS20070210220A1Easy to control operationEasy to operateStands/trestlesKitchen equipmentRotational axisEngineering

A display support mechanism allowing an easy operation of controlling the angle of a display screen with no requirement for a round shaft serving as an axis of rotation is obtained. This display support mechanism comprises a support shaft provided in the form of a plate, a display screen support member, having a first hole receiving the platelike support shaft, rotatable about the support shaft serving as an axis of rotation and a base support member having a second hole receiving the platelike support shaft, while at least either the display screen support member or the base support member is provided with a projecting portion brought into pressure contact with opposed surfaces of the display screen support member and the base support member for developing frictional resistance.

Owner:FUNAI ELECTRIC CO LTD

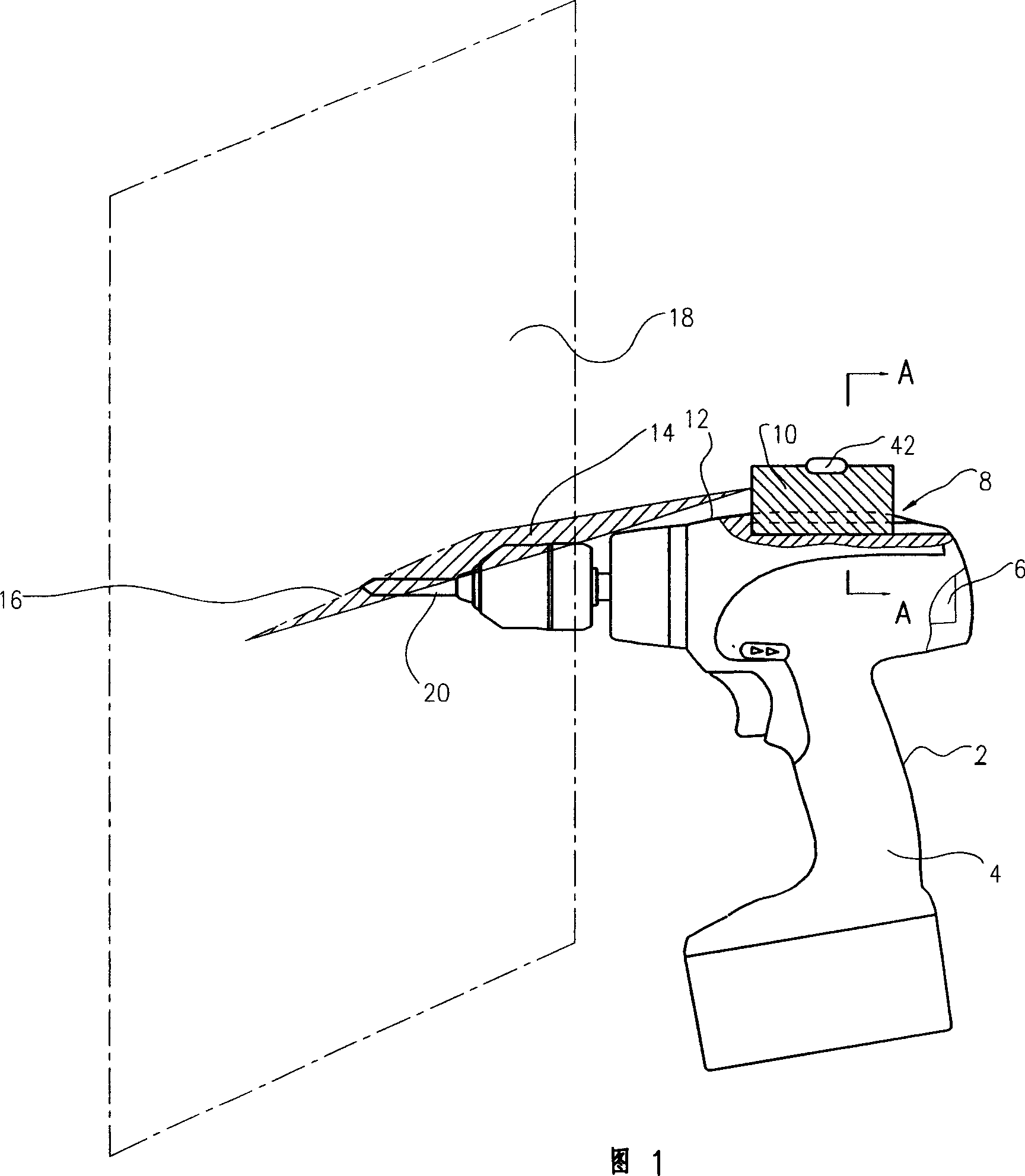

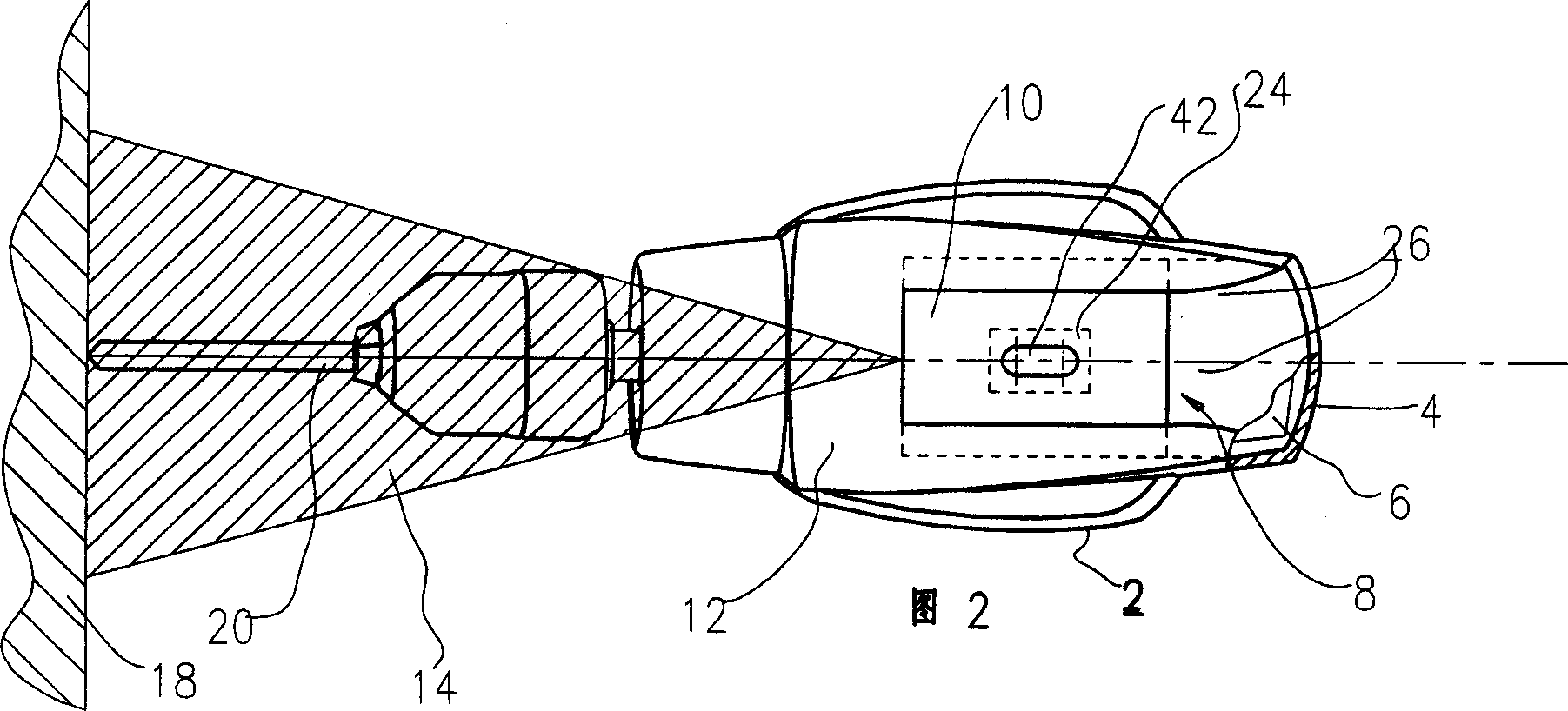

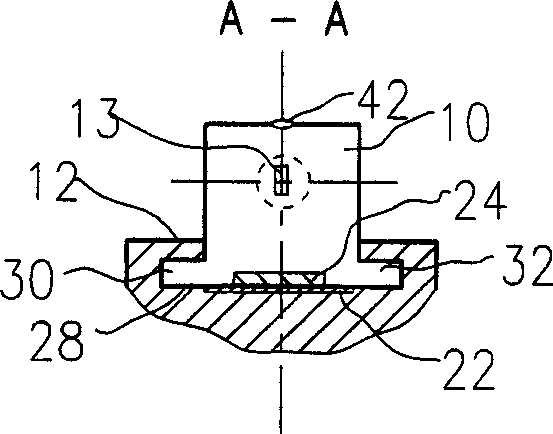

Drill kind electric tool

InactiveCN1597267AEasy to control operationOperation controlPortable power-driven toolsPortable drilling machinesElectric machineryEngineering

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

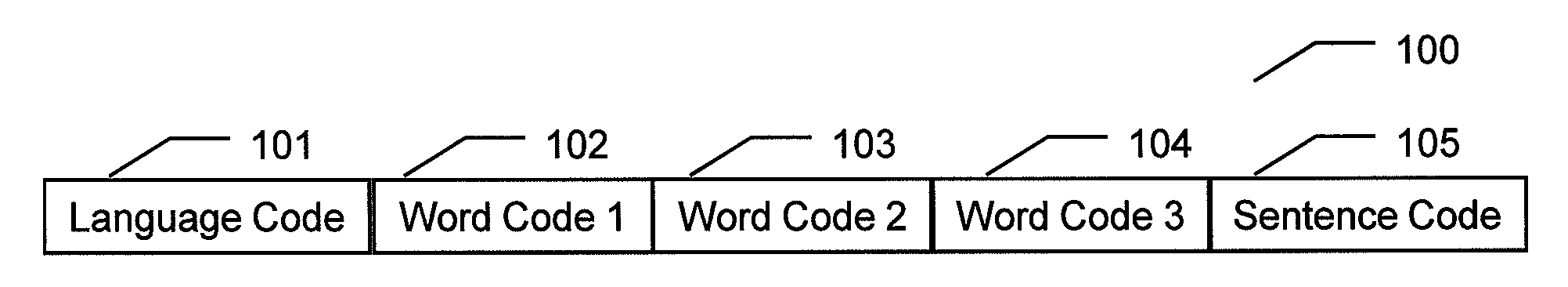

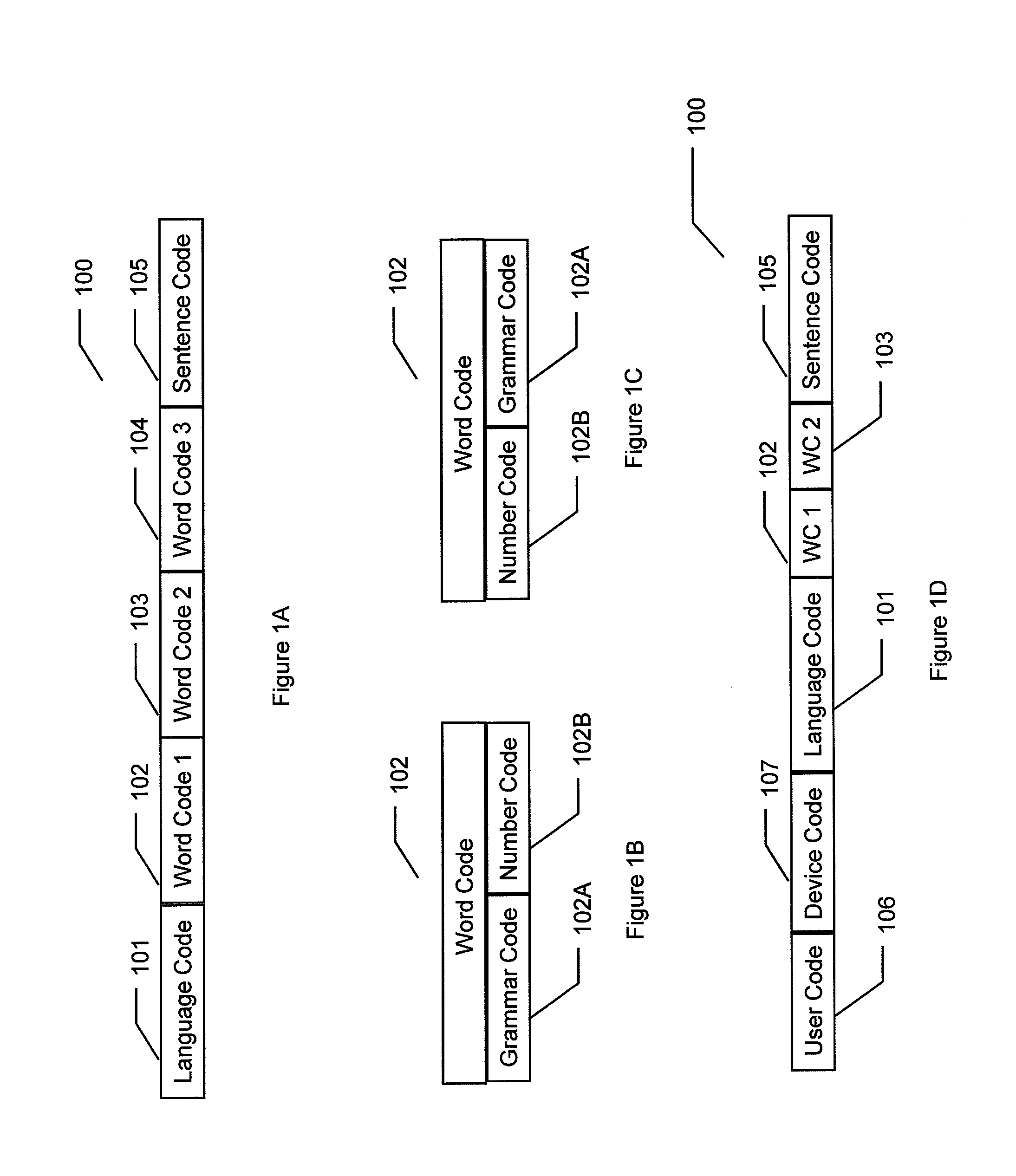

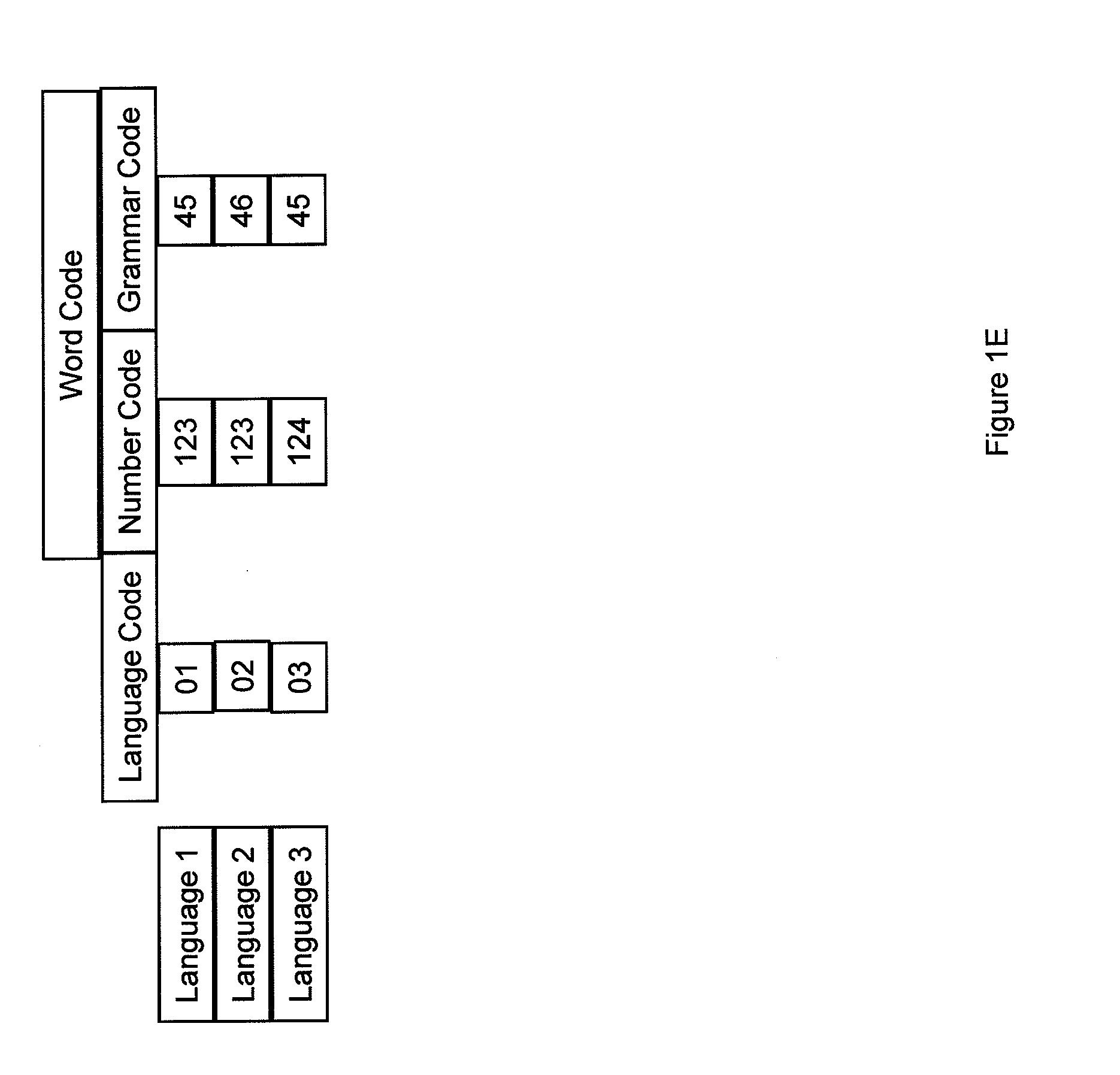

Communication device for multiple language translation system

ActiveUS20120245920A1Easy to control operationEasy to set upNatural language translationSpecial data processing applicationsMultiple languageTranslation system

A communication device for a multiple language translation system is disclosed. The communication device allows users to communicate with others using their own preferred language and the communication device provides a translation for each user in their preferred language. The communication device comprises a wireless transceiver for communicating with other users, networks, and the Internet. Operation switches are provided for controlling operation of the communication device. Signal indicators visually show status or conditions. A user hears the translation via an earphone or sees the translation on a display. A remote control allows the communication device to be controlled remotely.

Owner:WU MING YUAN

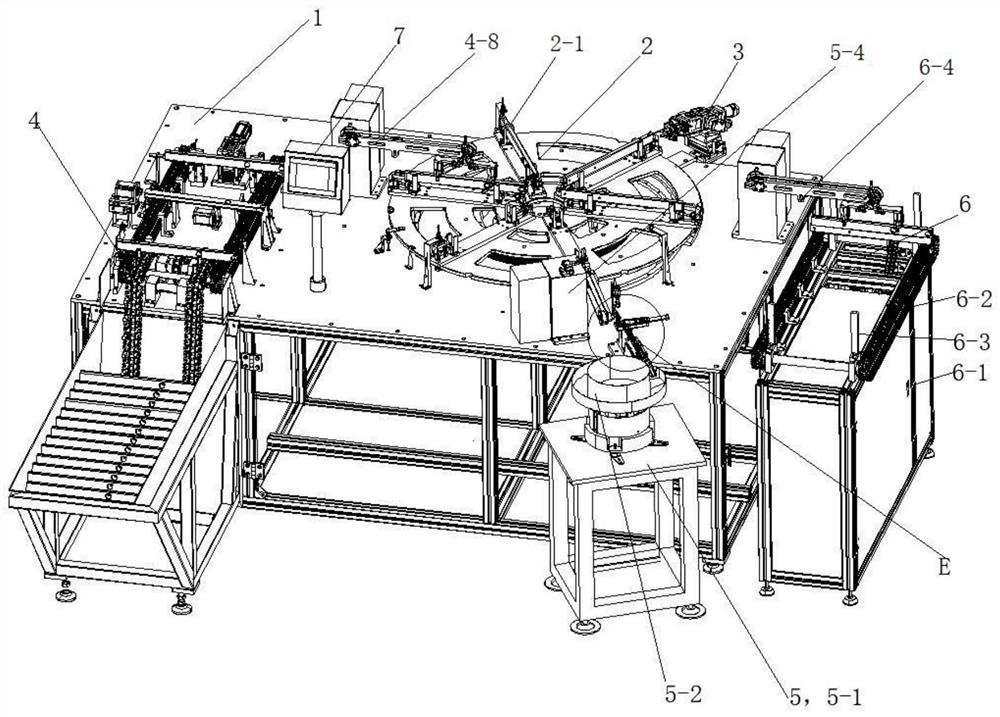

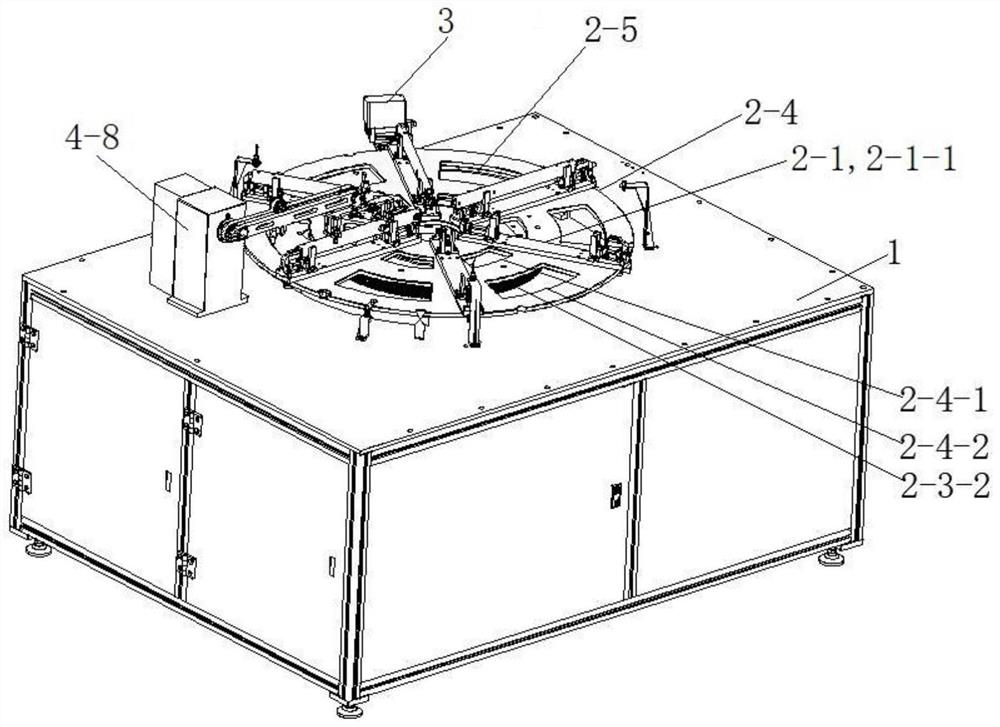

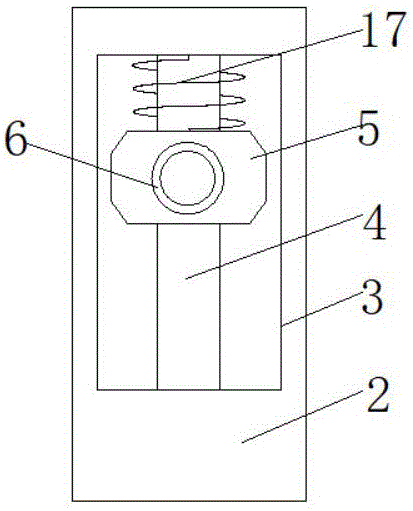

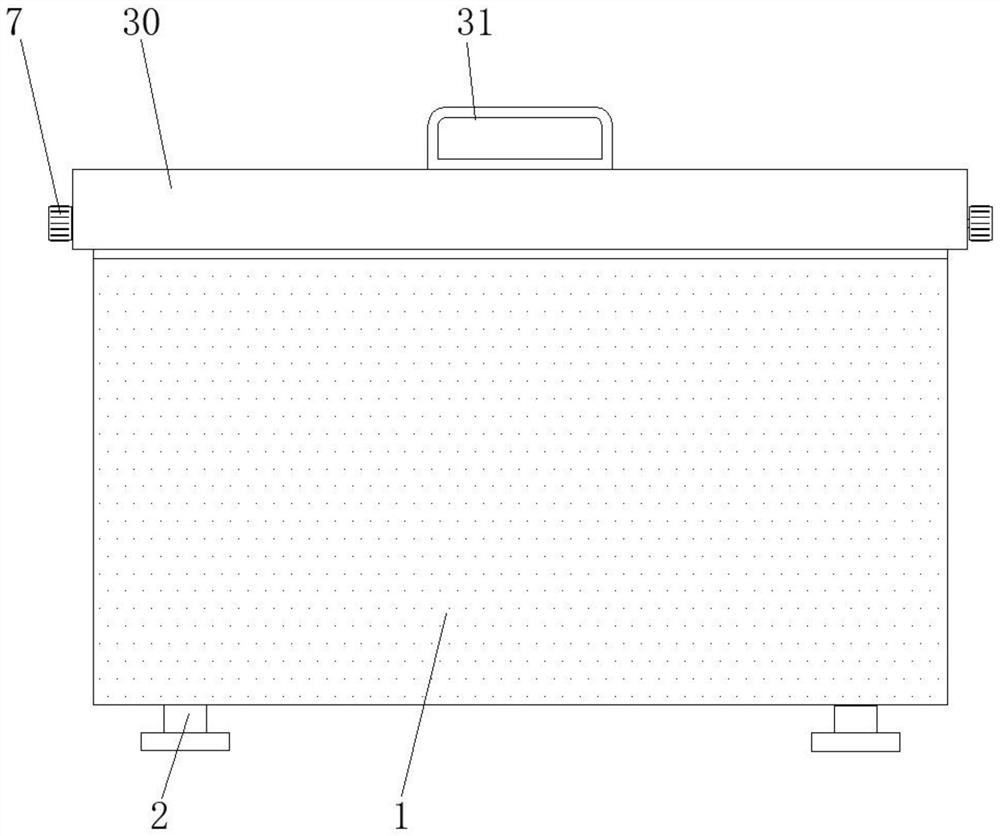

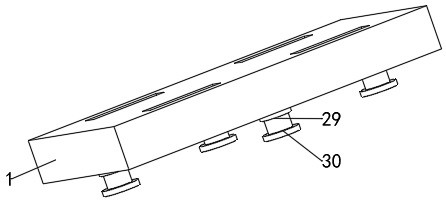

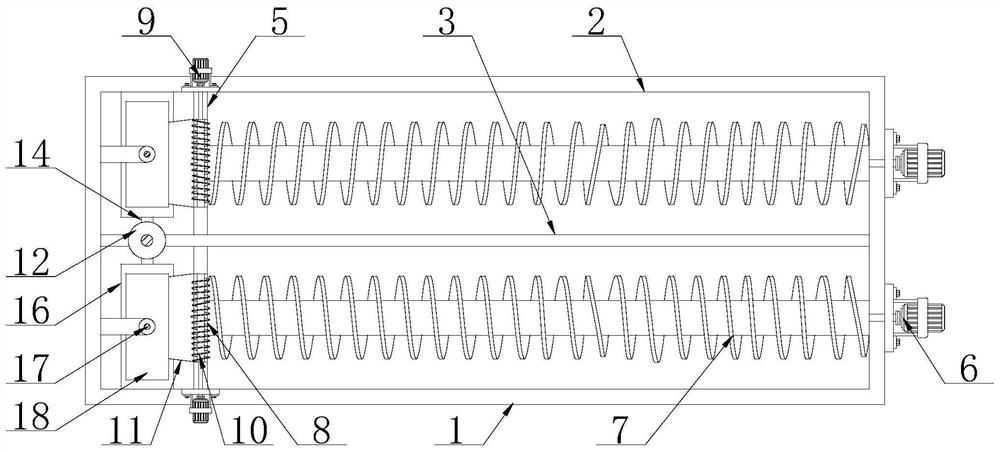

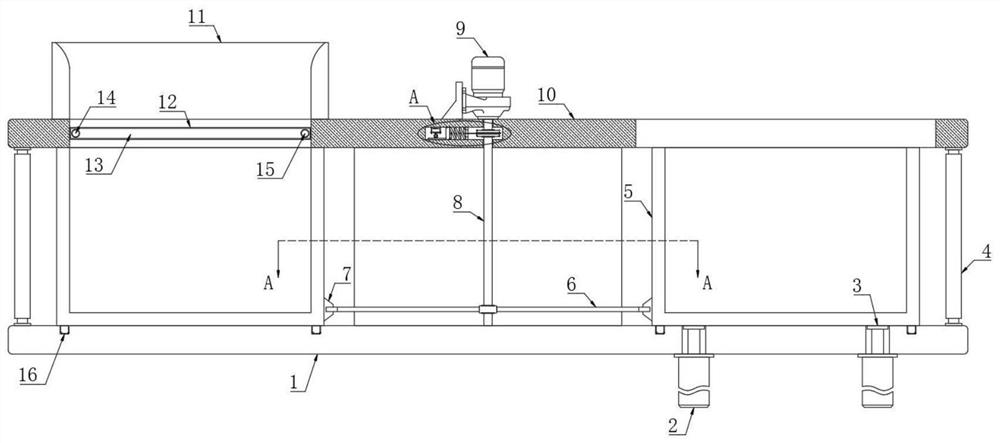

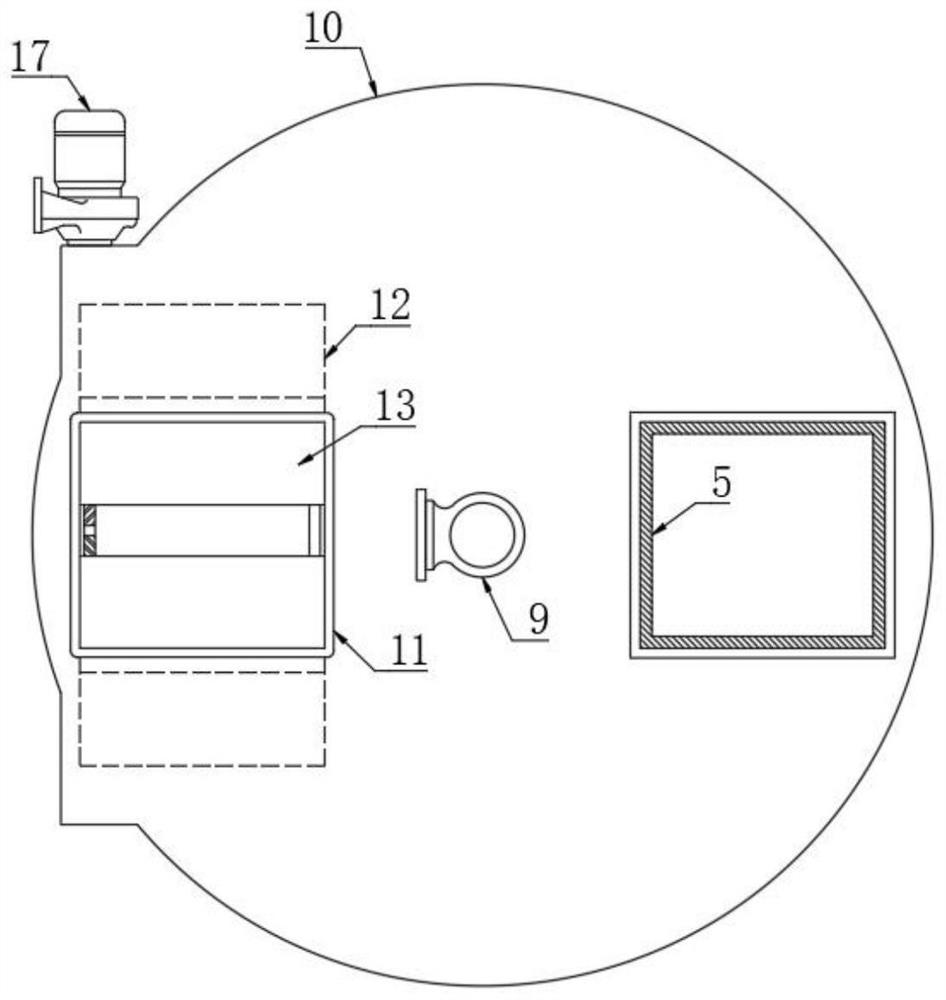

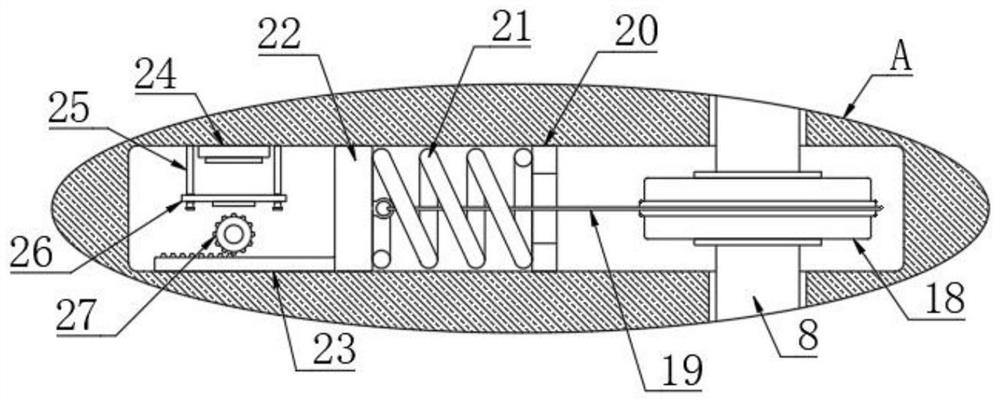

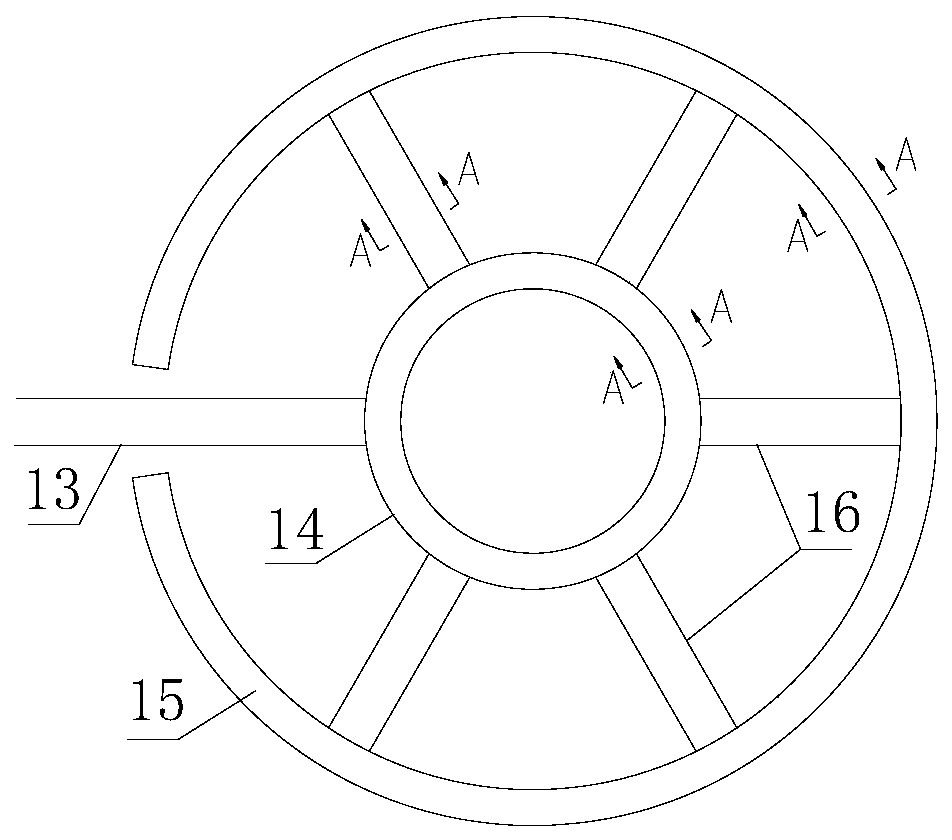

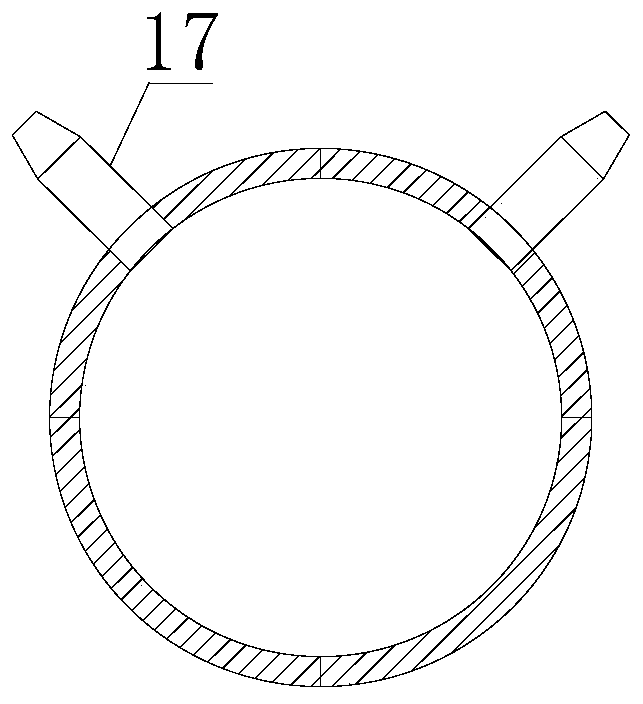

Automatic welding machine for square pipes and gaskets

PendingCN111958141AReduce human inputImprove welding accuracy andWelding/cutting auxillary devicesAuxillary welding devicesSmall footprintManufacturing engineering

The invention discloses an automatic welding machine for square pipes and gaskets. The welding machine comprises an operating table, a rotary worktable fixedly installed on the operating table, and anautomatic gasket feeding device, an automatic square pipe feeding device, a welding device and an automatic discharging device which are arranged around the rotary worktable sequentially. A welding assembly mechanism is arranged on the rotary worktable; the rotary worktable drives the welding assembly mechanism to circulate and operate among the automatic gasket feeding device, the automatic square pipe feeding device, the welding device and the automatic discharging device; and the welding assembly mechanism receives gaskets at the automatic gasket feeding device and square pipes at the automatic square pipe feeding device, and assembly of the gaskets and the square pipes is completed before movement to the welding device. According to the automatic welding machine, automatic feeding, automatic assembly and welding of the square pipes and the gaskets can be achieved, welded parts are conveyed to a discharging area, manual operation is not needed in the whole process, manpower input is reduced, the welding accuracy and the production safety are improved, the floor area is small, and the production cost is greatly reduced.

Owner:常州三拓焊接设备有限公司

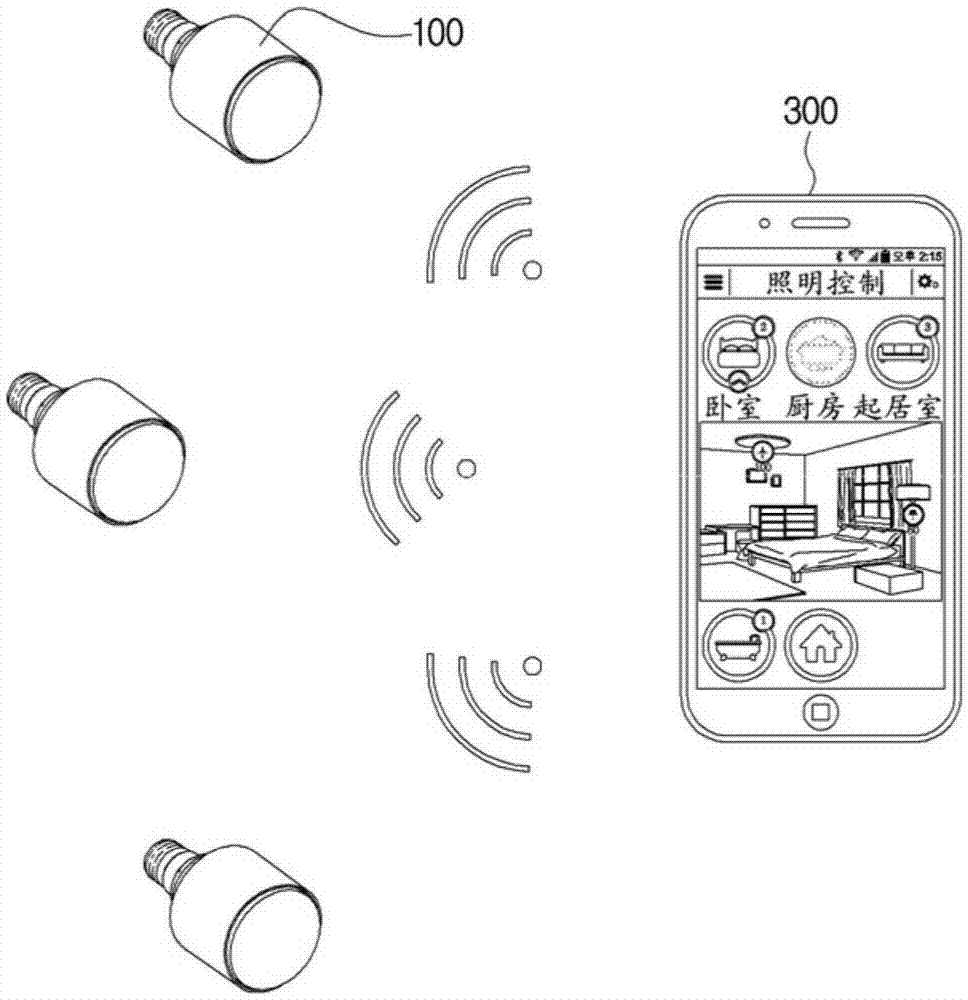

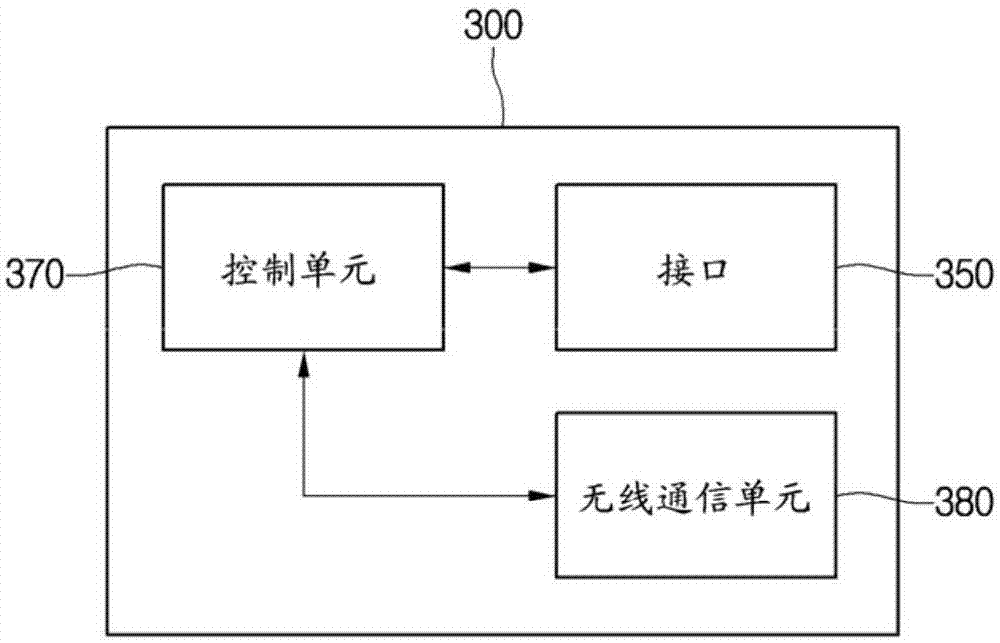

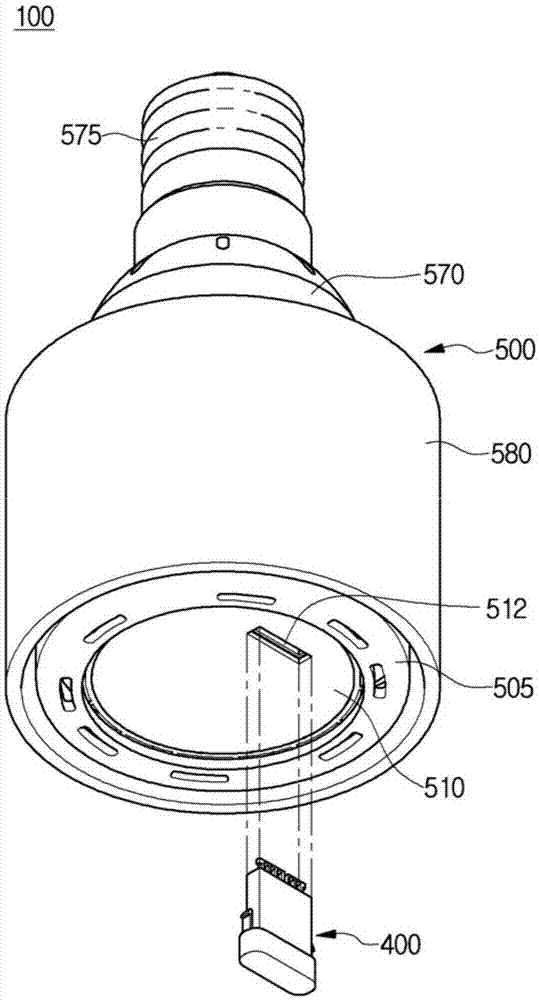

Light Control Apparatus and Method of Controlling Light Thereof

ActiveCN105451412AEasy to control operationOperation controlElectrical apparatusElectric light circuit arrangementGraphicsGraphical user interface

The invention provides a light control apparatus and a method of controlling light thereof. Disclosed is a light control apparatus. The light control apparatus includes: a touch screen to display a first graphical user interface for registering a light; and a control unit to store register information about the light set through the first graphical user interface and to control the registered light by using the stored register information, wherein the first graphical user interface includes: a first area on which information about a light to be registered is displayed; and a second area on which location information for setting an installed location of a first light selected from lights displayed on the first area is displayed, wherein the location information displayed on the second area includes working field information about an actual installation place of the first light, and wherein the working field information includes a photo photographed at the actual installation place of the first light.

Owner:LG INNOTEK CO LTD

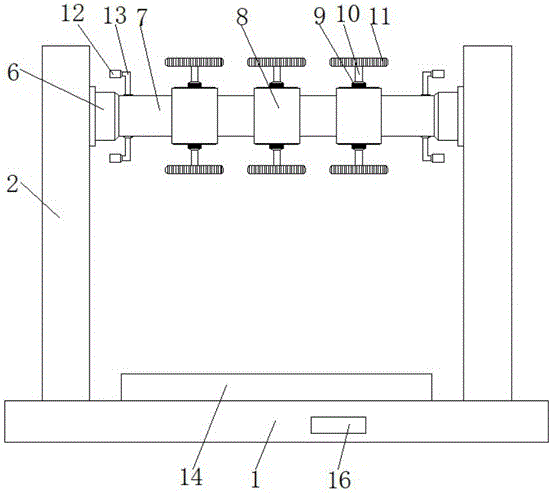

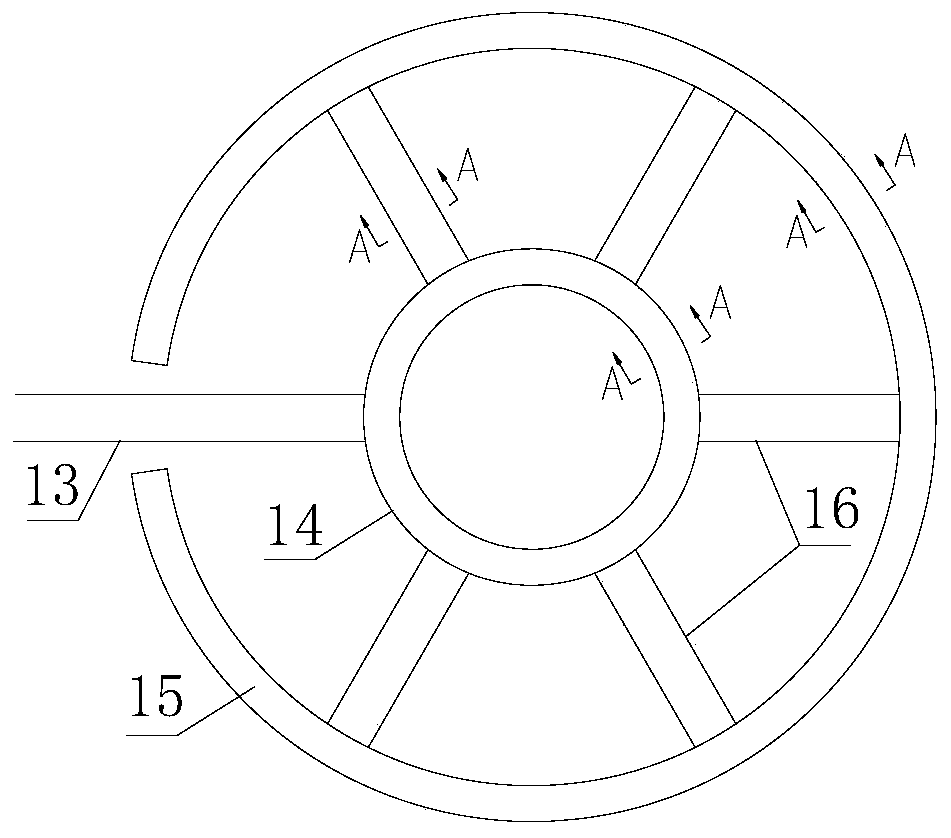

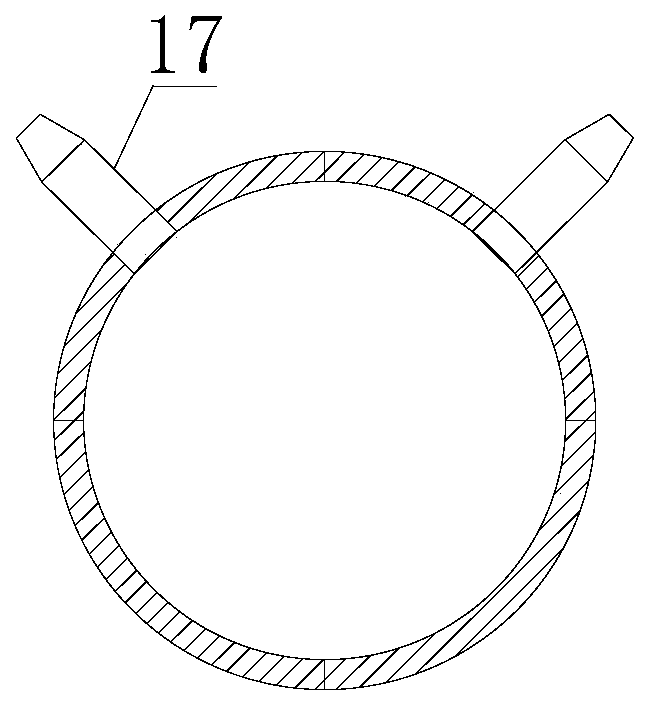

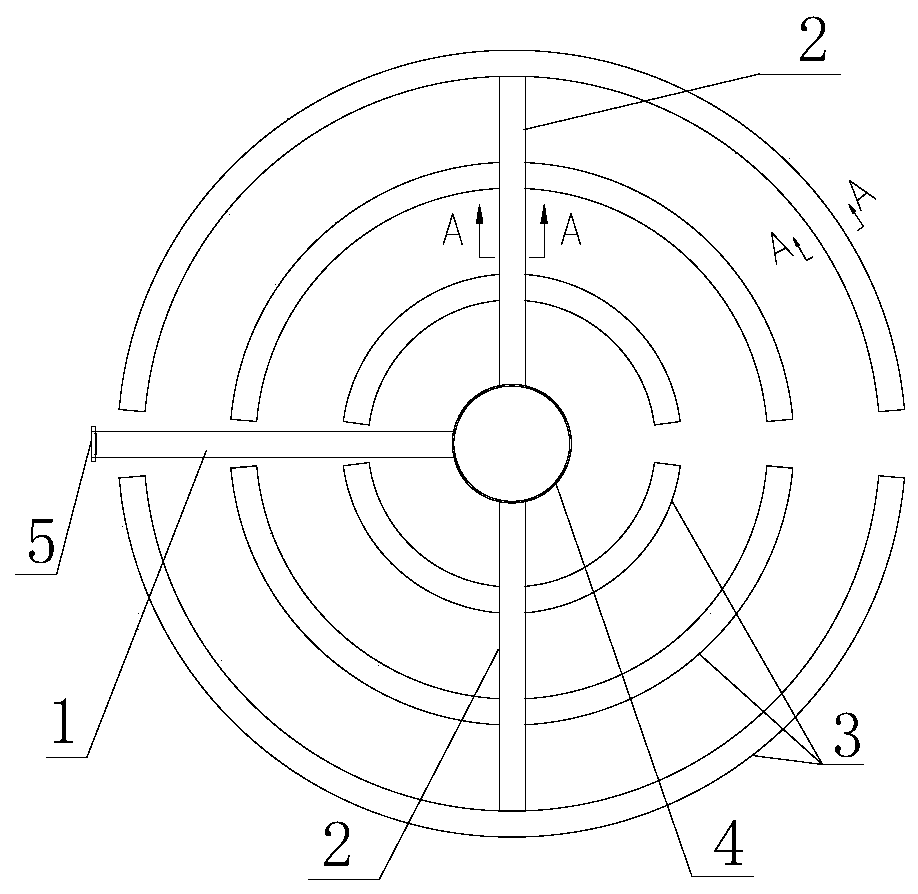

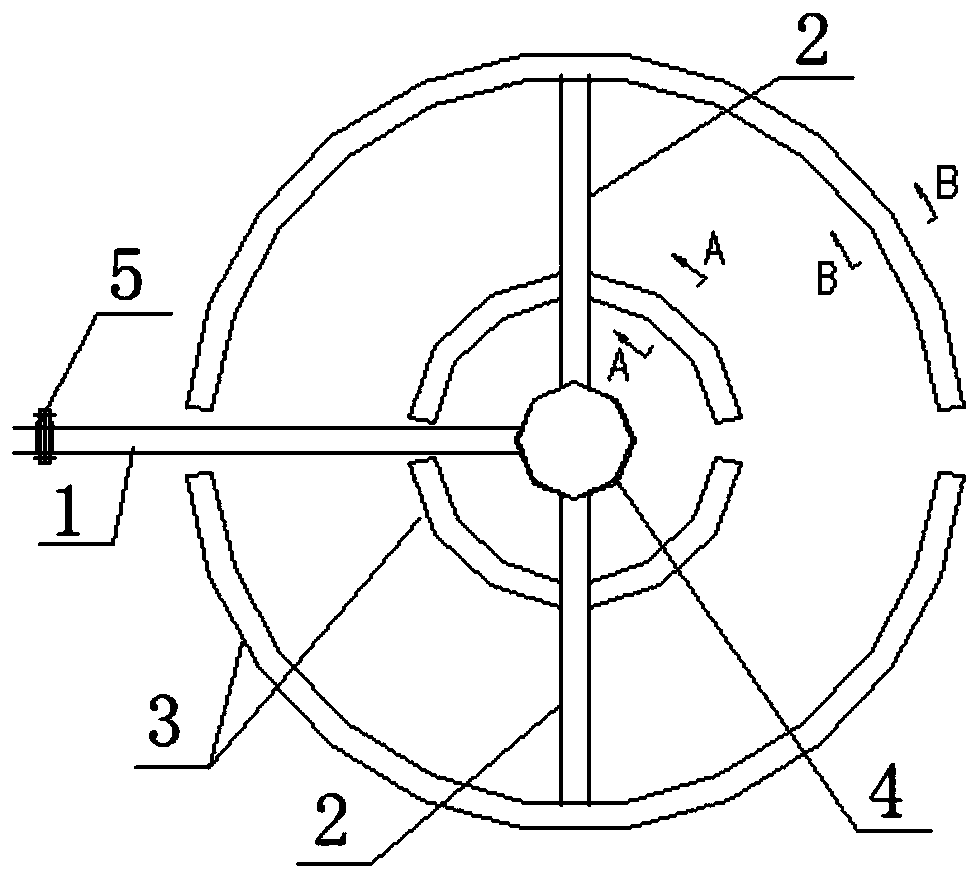

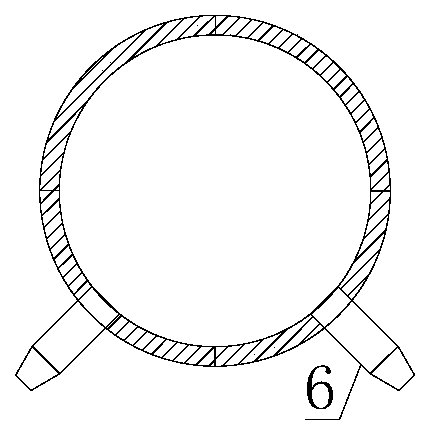

Multi-station grinding tool facilitating grinding wheel replacement

PendingCN107520726AEasy to replaceDoes not affect workGrinding carriagesGrinding drivesRubber ringGrinding wheel

The invention discloses a multi-station grinding tool facilitating grinding wheel replacement. The multi-station grinding tool comprises a work plate. The left side and the right side of the top of the work plate are fixedly connected with connecting plates. Through sliding grooves are formed in the side faces of the connecting plates. A sliding rod is fixedly connected between the top and the bottom of the inner wall of each sliding groove. A sliding block is movably connected to the surface of each sliding rod, and plummer blocks are fixedly connected to the sides, close to each other, of the sliding blocks on the two sides. Through the arrangement of L-shaped fixing plates, rubber rings, a rotation rod and fixing blocks, the L-shaped fixing plates are held and rotate by 180 degrees, the rotation rod rotates, the fixing blocks rotate, grinding wheel bodies located on the tops of the fixing blocks rotate, the upper grinding wheel bodies are located at the lower portions, the lower grinding wheel bodies are located at the upper portion, meanwhile, upper grinding wheel body replacement is convenient, or work stops, and meanwhile normal grinding tool work is not influenced.

Owner:郑州博尔德磨料磨具有限公司

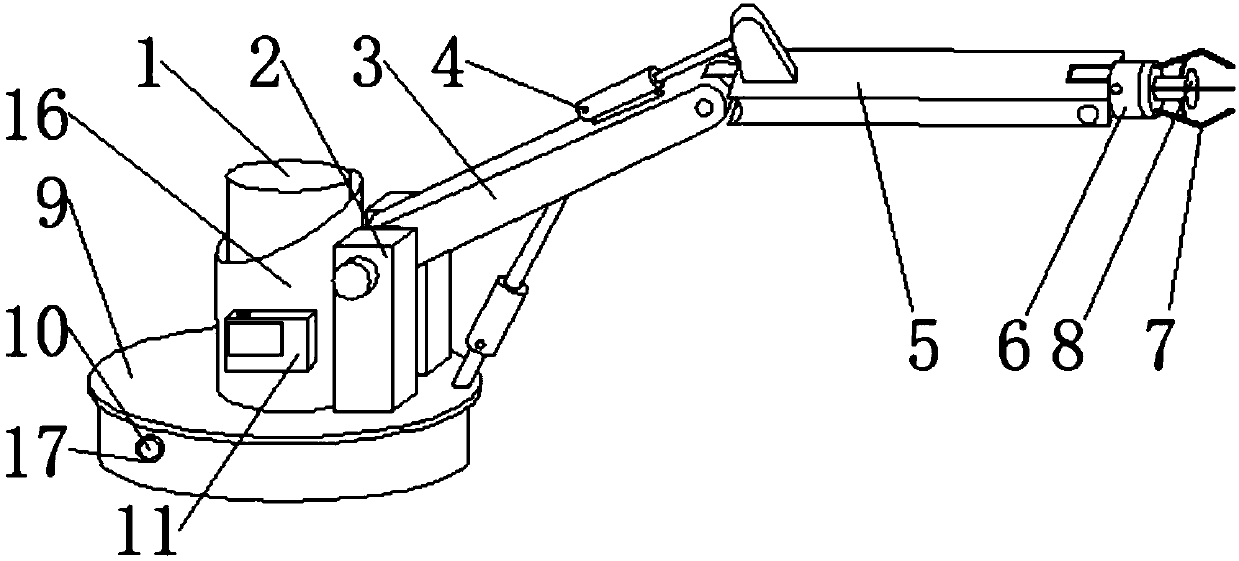

Industrial mechanical arm device

InactiveCN107584481AIncrease flexibilityEasy to control operationProgramme-controlled manipulatorHydraulic pumpControl engineering

The invention discloses an industrial mechanical arm device. The industrial mechanical arm device comprises a fixed pile, wherein a sleeve cover is arranged at the periphery of the fixed pile; a box cover is arranged at the lower end of the sleeve cover; a box body is arranged at the lower end of the box cover; the right end of the sleeve cover is provided with fore-and-aft symmetrical vertical columns; a hydraulic pump is arranged at the right end of the vertical column; a mechanical rear arm is arranged at the upper end between the vertical columns; a hydraulic pump is arranged at the rightend of the upper surface of the mechanical rear arm and is tightly welded with the mechanical rear arm; a mechanical front arm is arranged at the right end of the mechanical rear arm, and the mechanical rear arm is rotatably connected with the mechanical front arm; a rotator is arranged at the right end of the mechanical front arm; and a mechanical claw is arranged at the right end of the rotator.The industrial mechanical arm device disclosed by the invention has the advantages that the box cover can rotate by 360 degrees by adopting the fixed pile as an axle, the mechanical front arm and themechanical rear arm also can move under the power of the hydraulic pump, can work on a working platform surface farther from main power, and the power is much larger than that of the existing mechanical arm, the rotator can provide rotation, and the hydraulic pump at the right end also can provide pressure.

Owner:CHENGDU HONGYUE TECH CO LTD

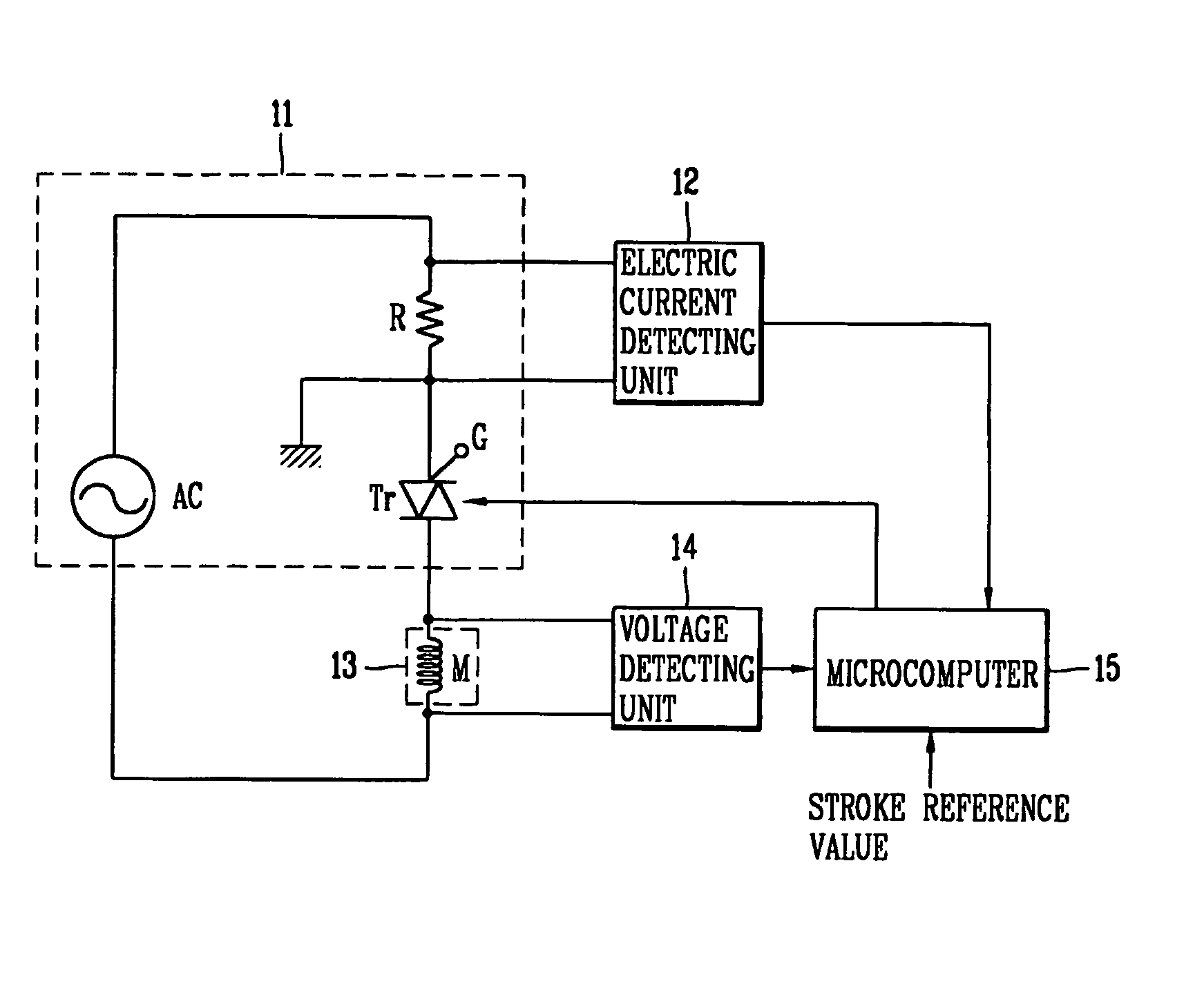

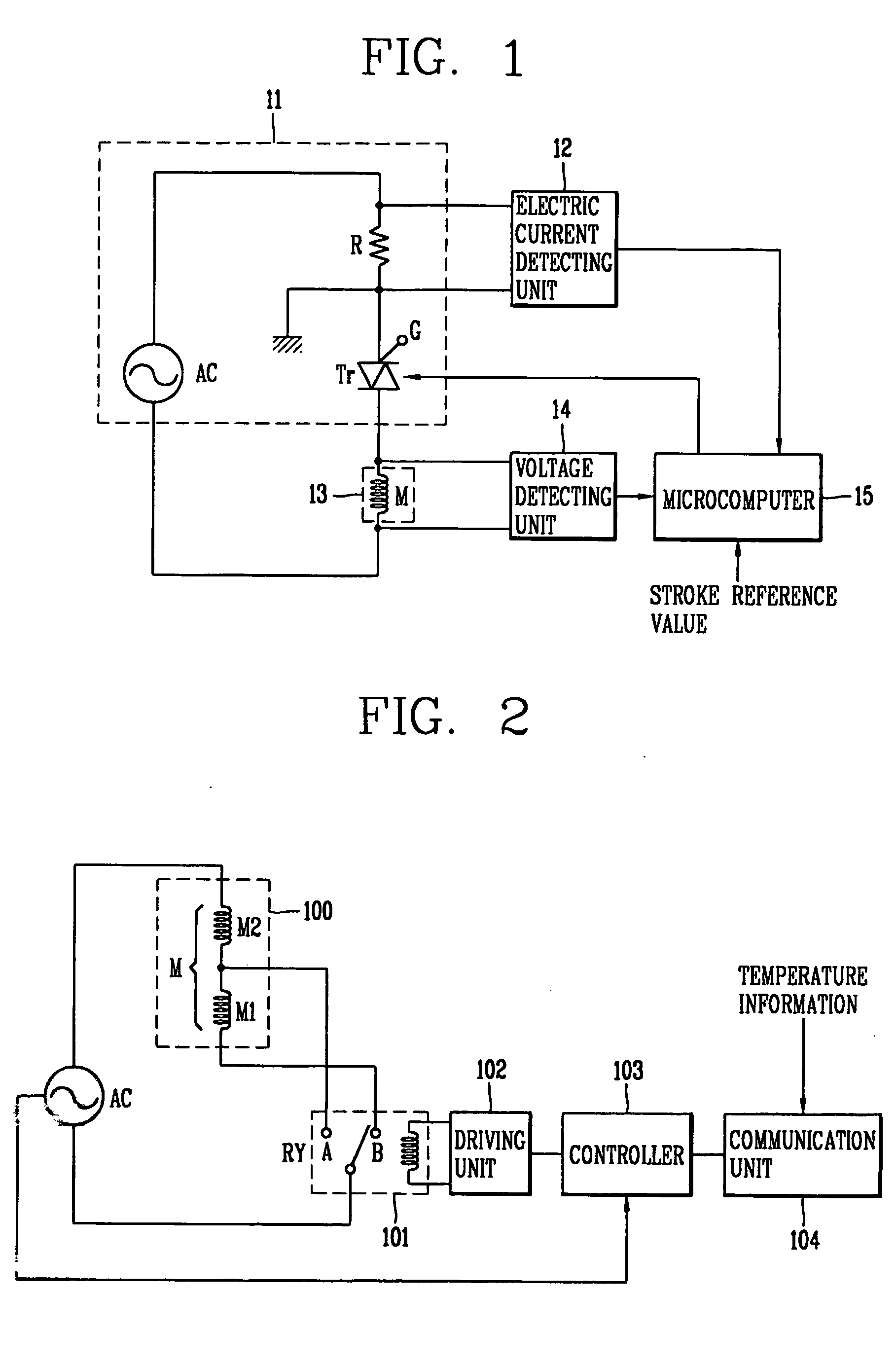

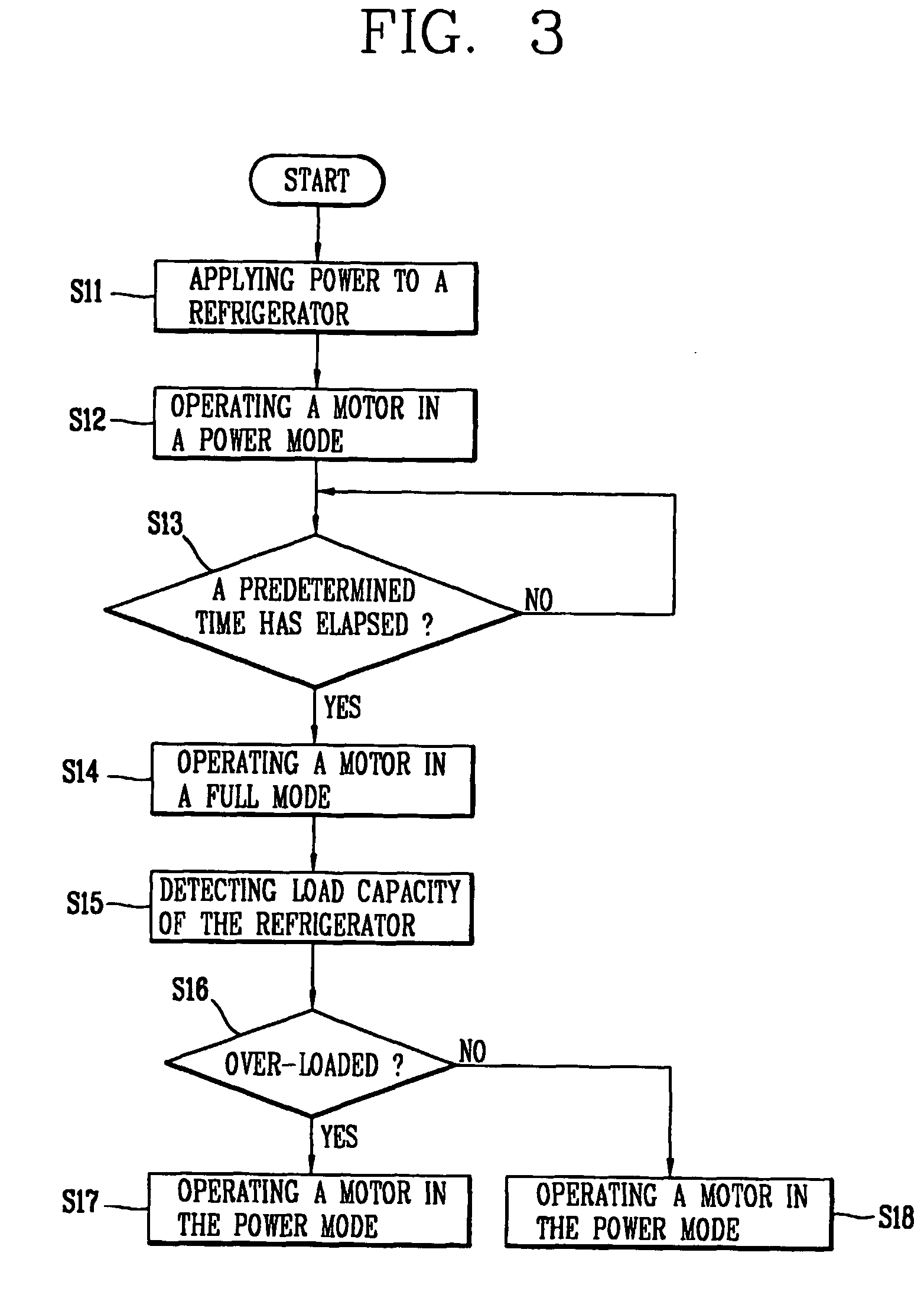

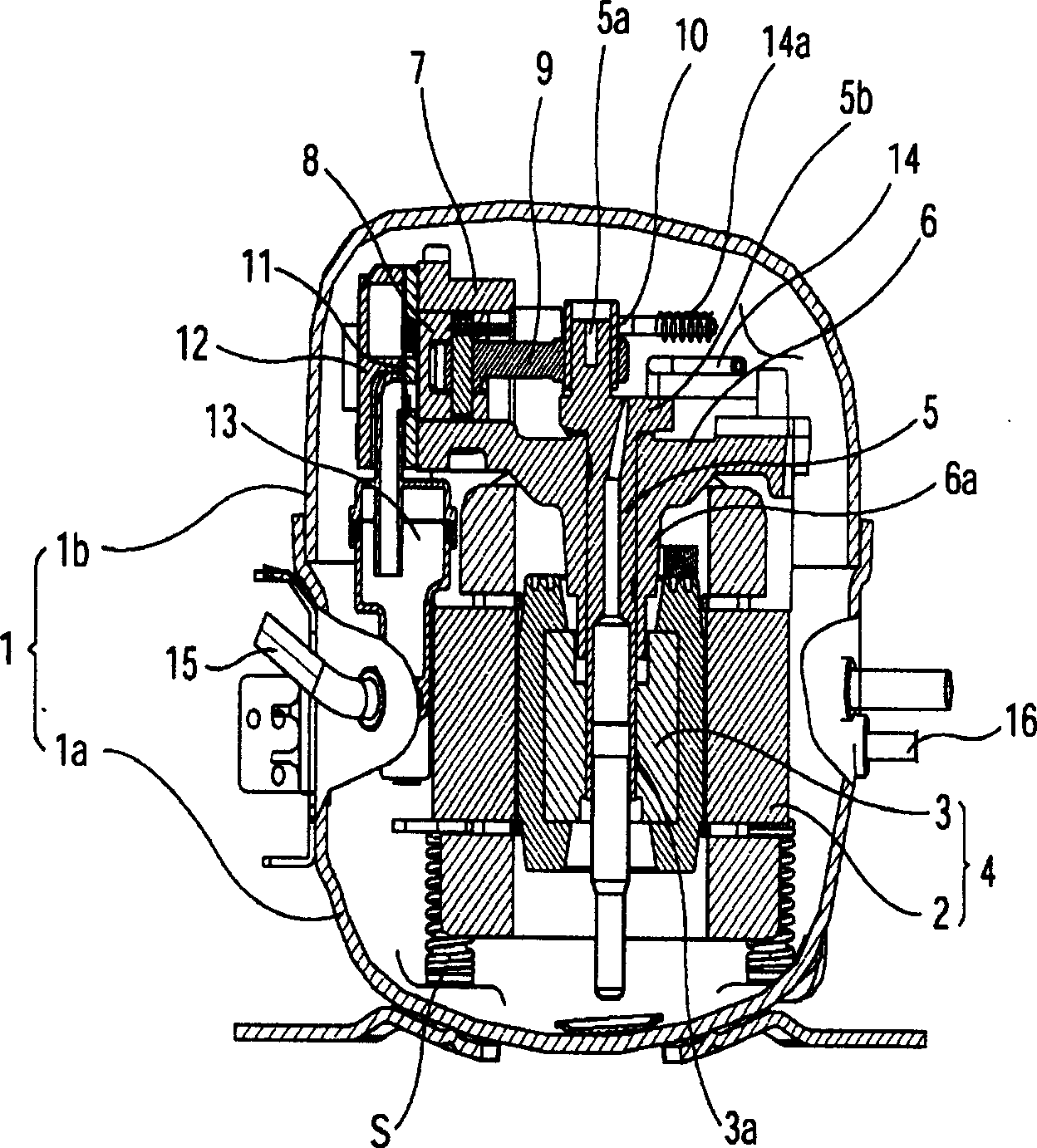

Method for controlling operation of compressor and apparatus thereof

ActiveUS20060115366A1Easy to control operationLimit operation of compressorMotor/generator/converter stoppersAC motor controlEngineeringRefrigerated temperature

A method for controlling an operation of a compressor and its apparatus can easily control an operation of the compressor without a request for a high-priced operation control apparatus by operating the compressor with controlling the amount of currents flowing into a winding coil of a motor (100) of the compressor according to load capacity of the refrigerator. The apparatus includes a control unit (103) for generating a control signal for selecting a main winding coil (M) of a linear motor (100) of a compressor or an auxiliary winding coil (M2) on the basis of the load capacity of a refrigerator, and a switching unit (101) for selecting the main winding coil (M) of the linear motor (100) or the auxiliary winding coil (M2) on the basis of the control signal. Herein, the main winding coil of the linear motor (100) is divided into a plurality of auxiliary winding coils (M2).

Owner:LG ELECTRONICS INC

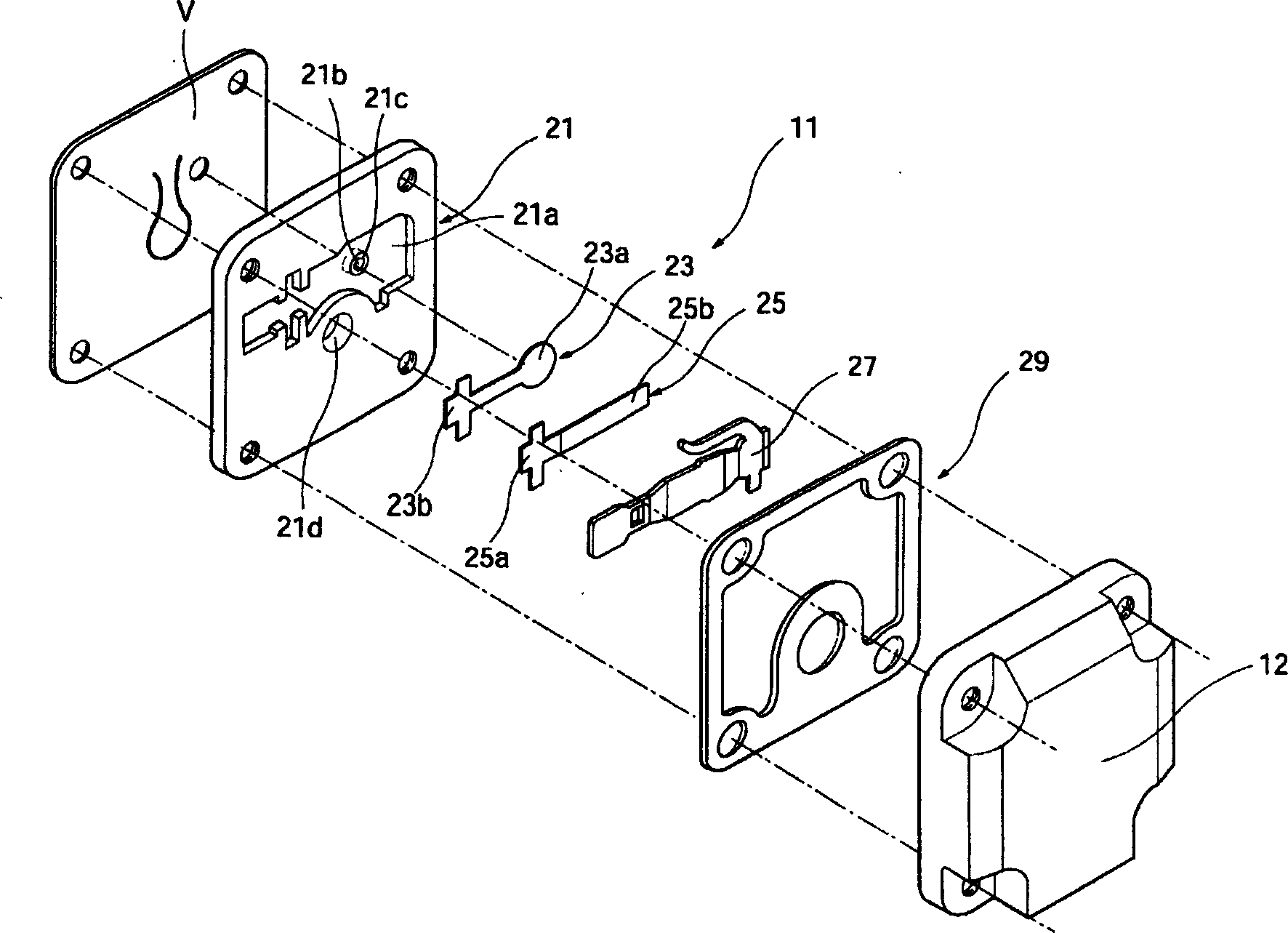

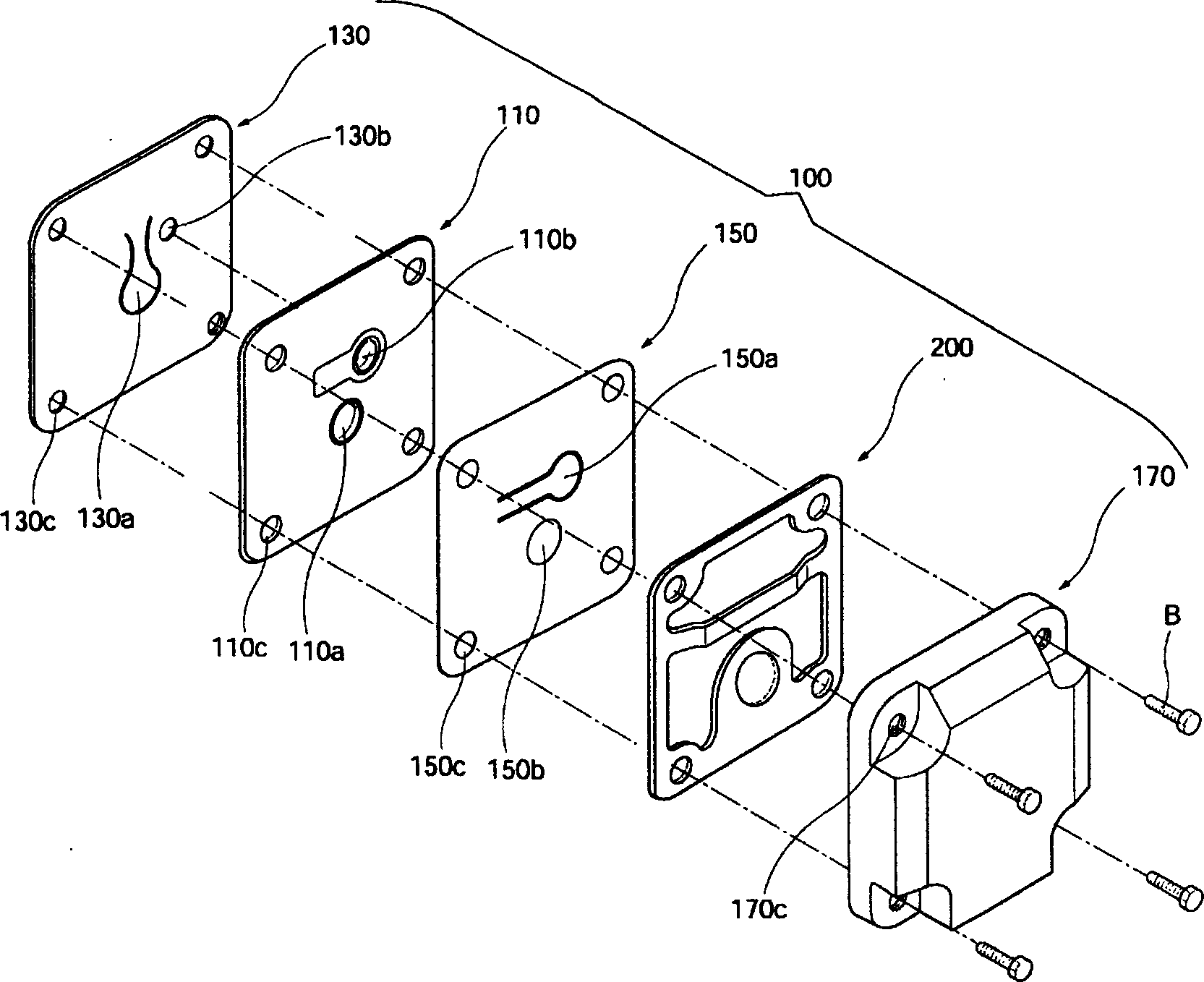

Valve device of hermetic compressor

InactiveCN1769702ASimple structureSimplify the assembly processPositive displacement pump componentsMulti-stage pumpsEngineeringCoolant

The invention discloses a valve device of closed-type compressor, which consists of drainage valve 150a and coat pad 220, wherein the drainage valve 150a covers the outlet 110b of valve board 110, which switches the outlet 110b selectively; the coat pad 220 is set between the drainage side of valve board 110 and covered valve board 110 and roof plate 170 to separate the sucked coolant and drained coolant, which forms the stop 300 on one side to control the starting degree of drainage valve 150a. The invention reduces the assemblage procedure of closed-type compressor valve device, which improves the production efficiency and reduces the making cost of compressor.

Owner:TAIZHOU LG ELECTRONICS REFRIGERATOR CO LTD

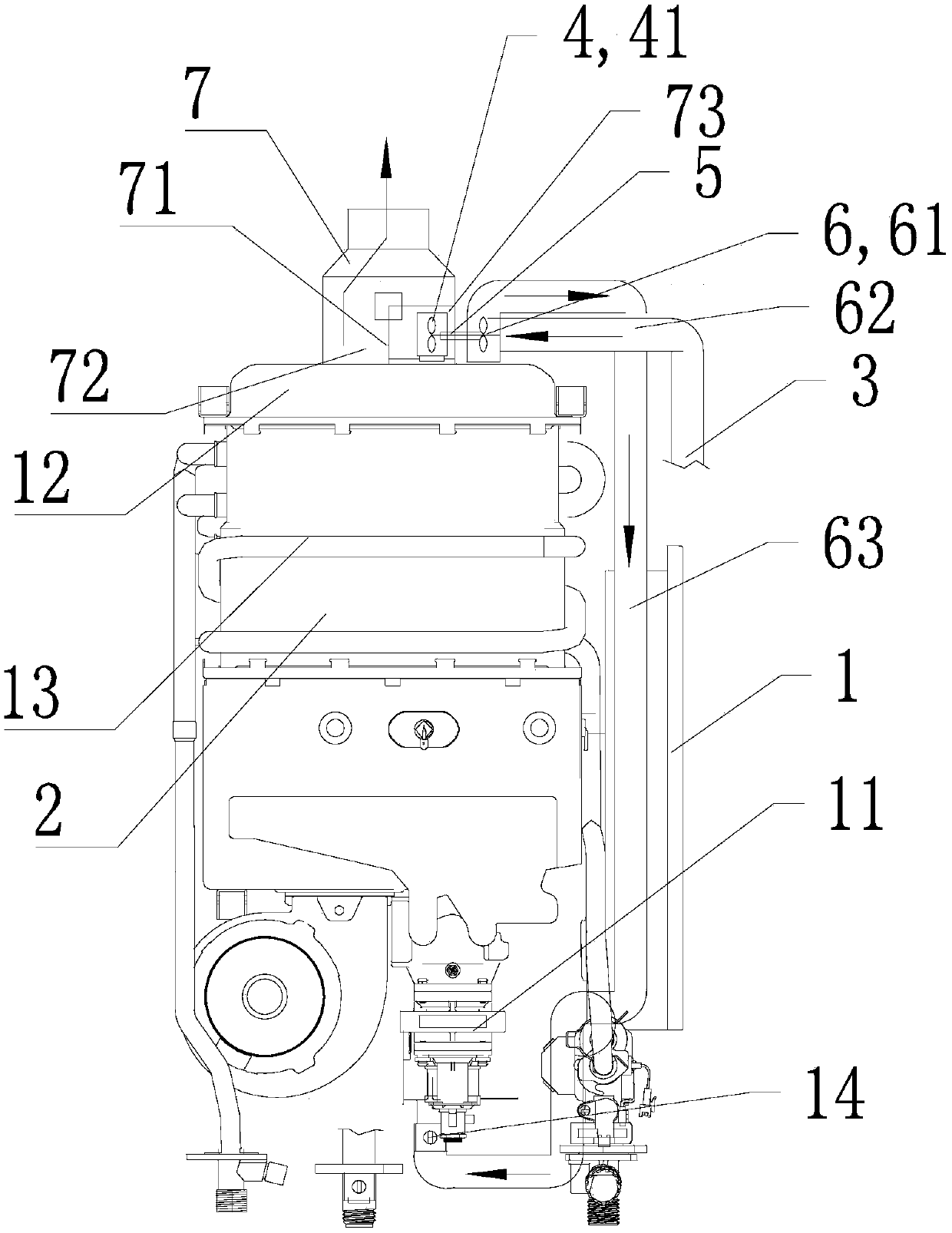

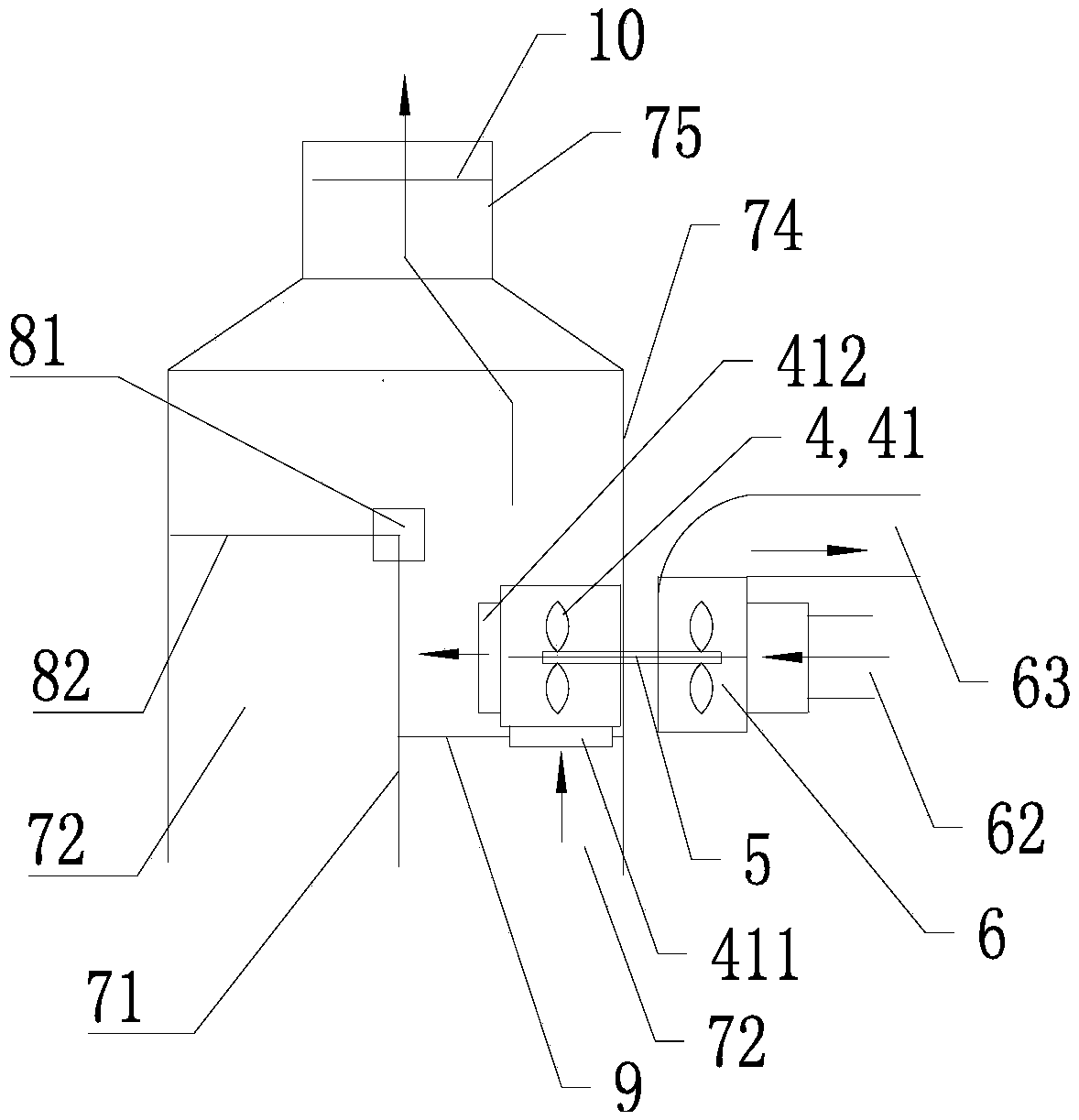

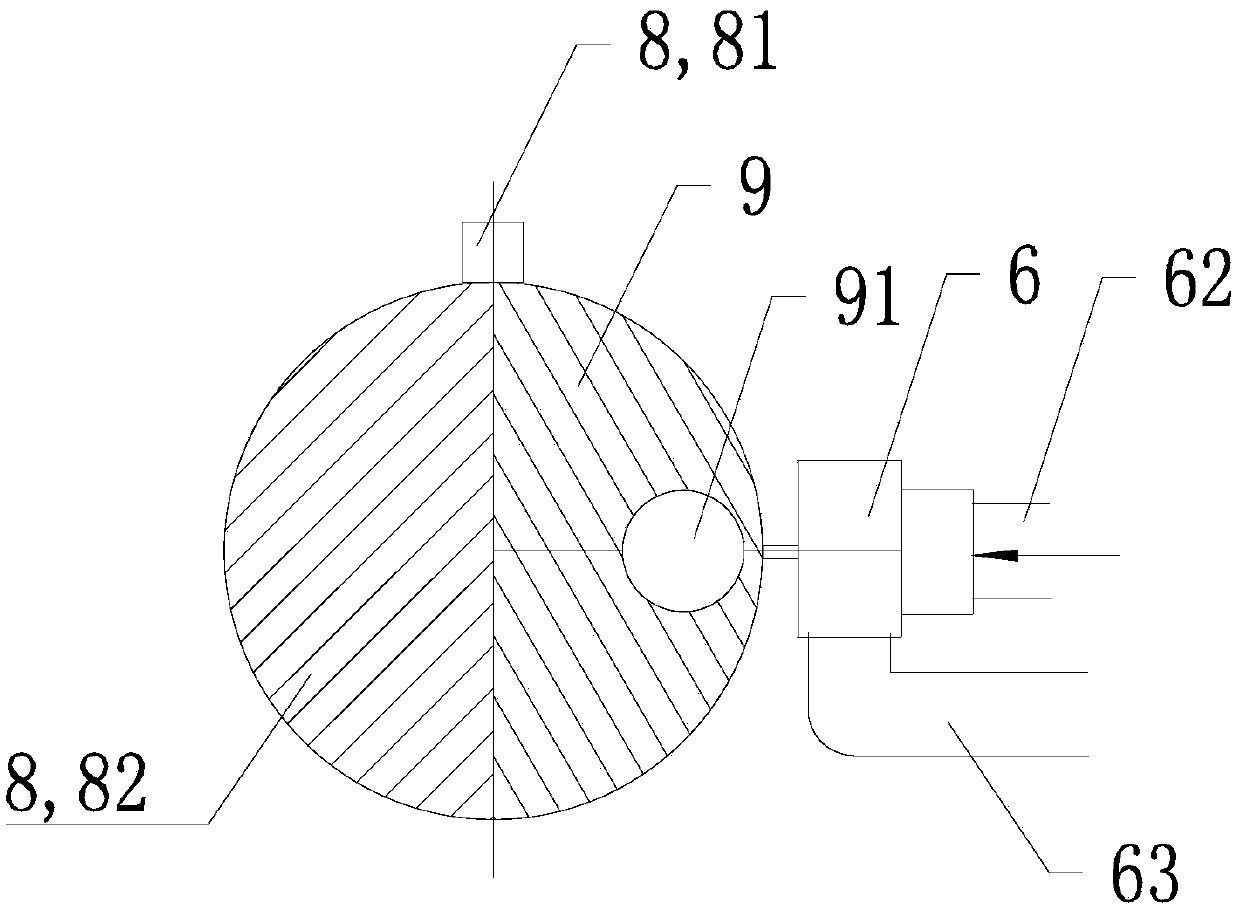

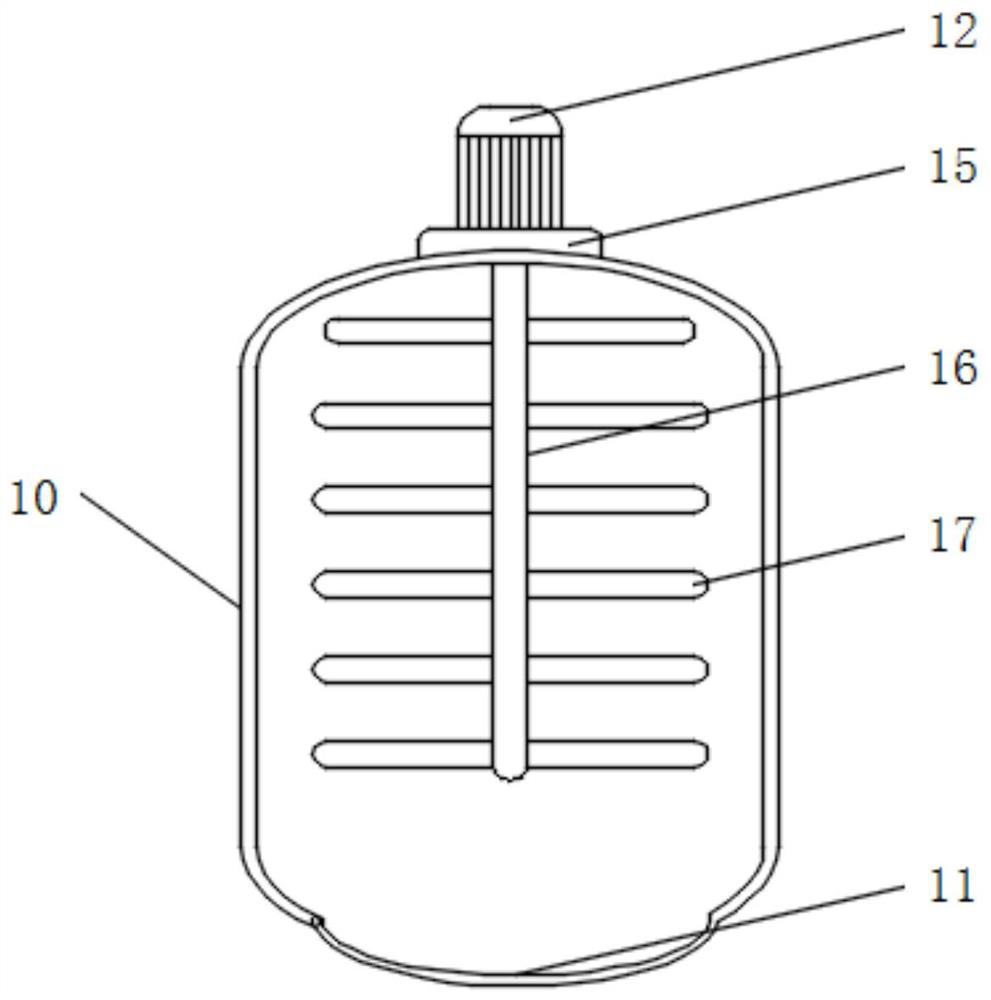

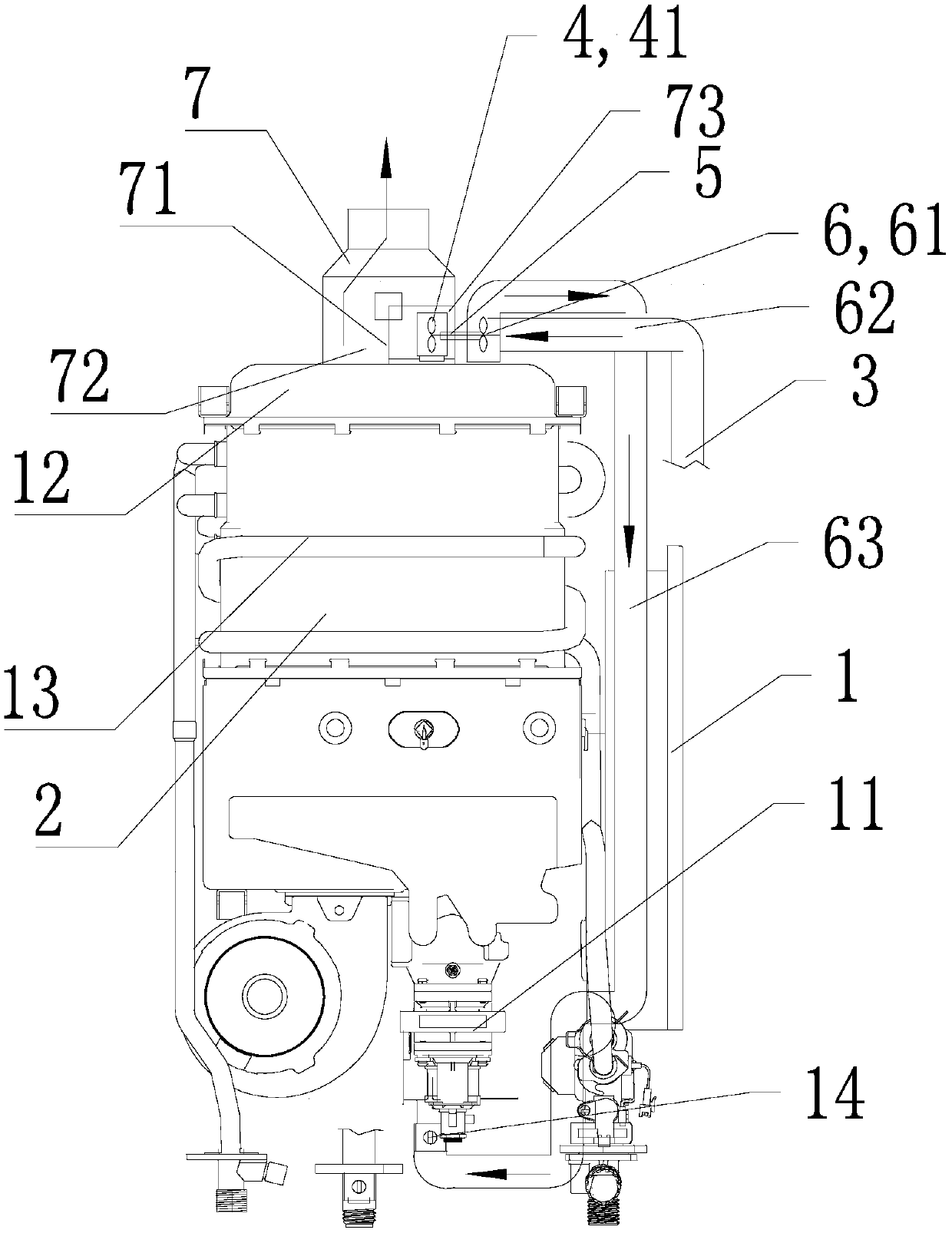

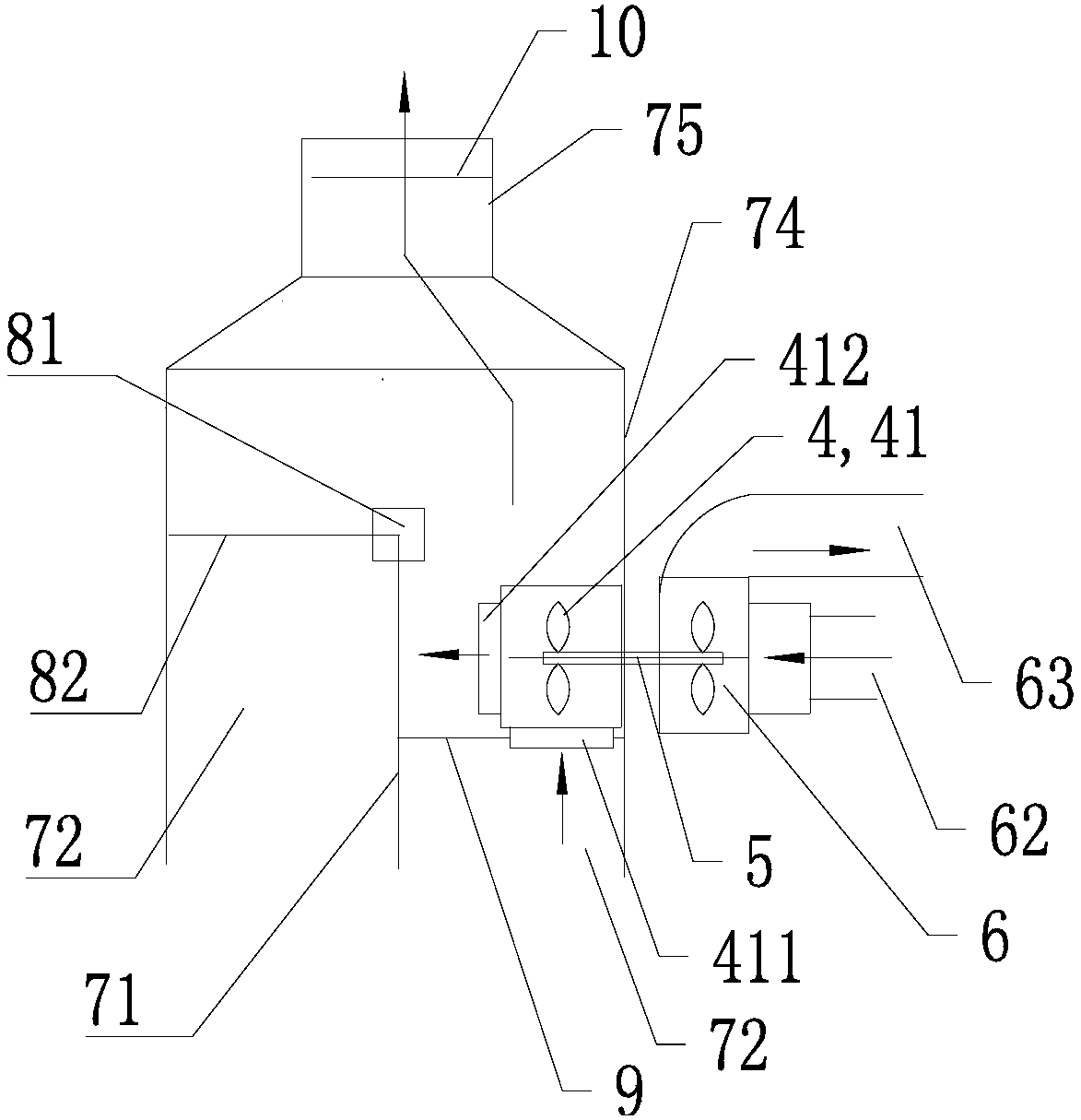

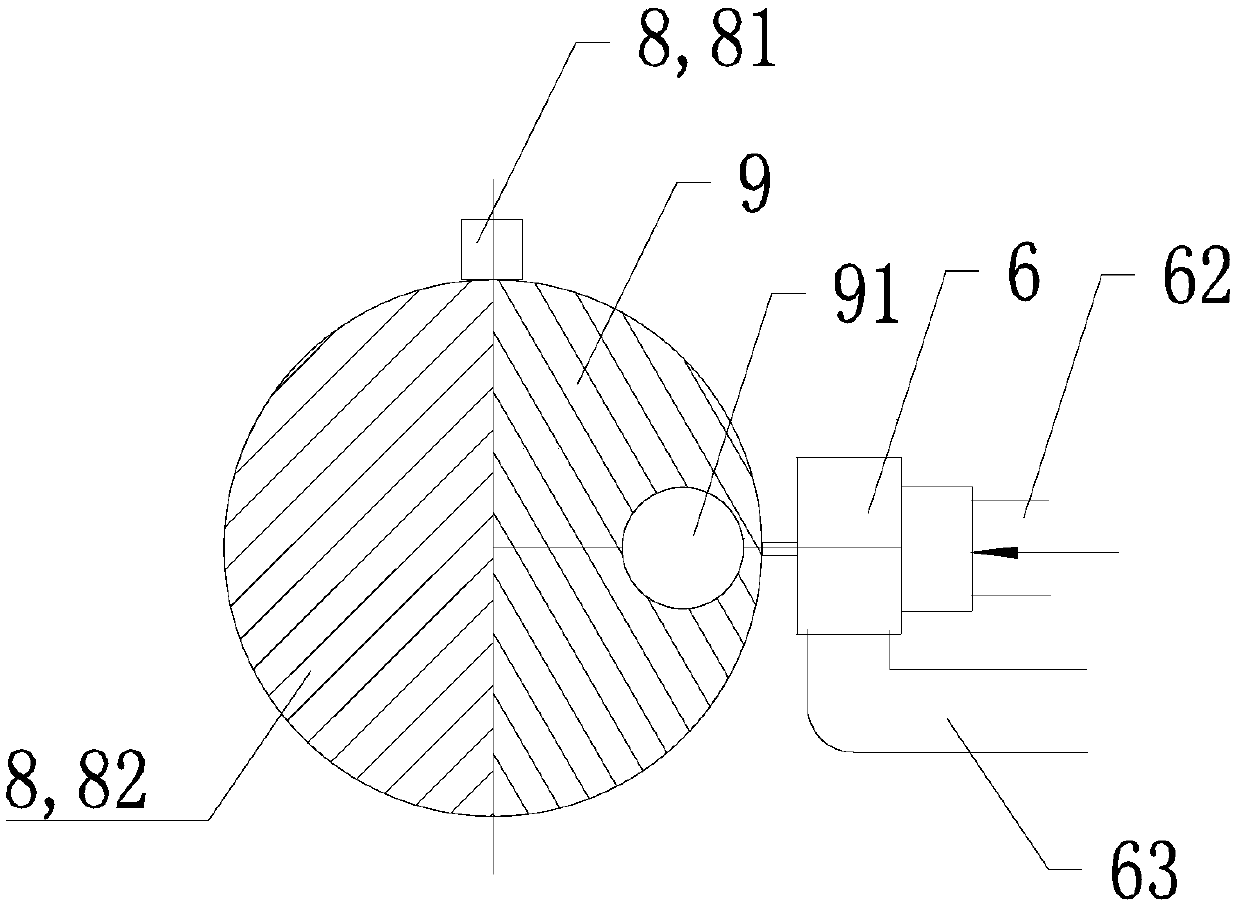

Control method of supercharged gas water heater and gas water heater

PendingCN110966768AGuaranteed intake pressureGuaranteed stabilityWater heatersExhaust gas emissionsEngineering

The invention discloses a control method of a supercharged gas water heater and the gas water heater. The gas water heater comprises a combustion cavity and a gas inlet pipeline communicating with thecombustion cavity, a waste gas discharge pipeline is arranged on the combustion cavity, a turbine device is arranged in the waste gas discharge pipeline, a supercharging device and a gas pressure detection device are arranged on the gas inlet pipeline, the turbine device is connected with the supercharging device, the gas water heater controls the waste gas flow direction according to pressure value, detected by the gas pressure detection device, of gas, through the turbine device, the supercharging device is driven / closed, and the gas is supercharged / stopped supercharging. According to the gas water heater, kinetic energy and thermal energy of waste gas can be recycled, when it is detected that gas pressure is low, gas is supercharged, the gas inlet pressure and stability are ensured, itis ensured that the optimal combustion working condition is matched, the water outlet temperature and stability are ensured, energy consumption and cost are reduced, and the user bathing experience can be greatly improved.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER +1

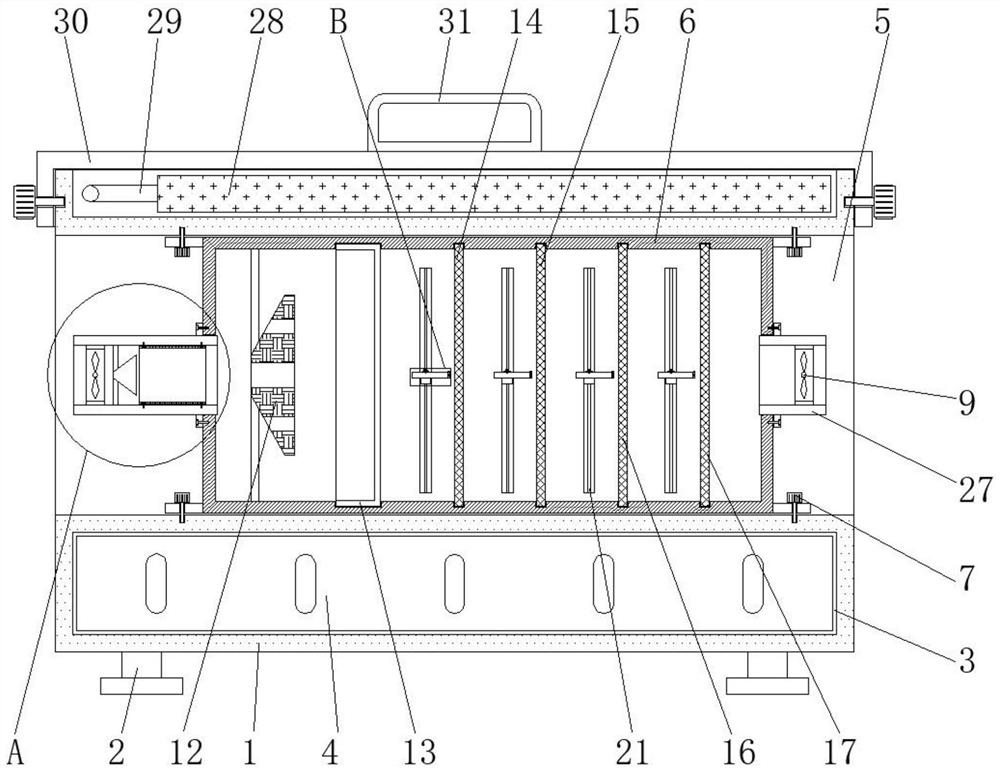

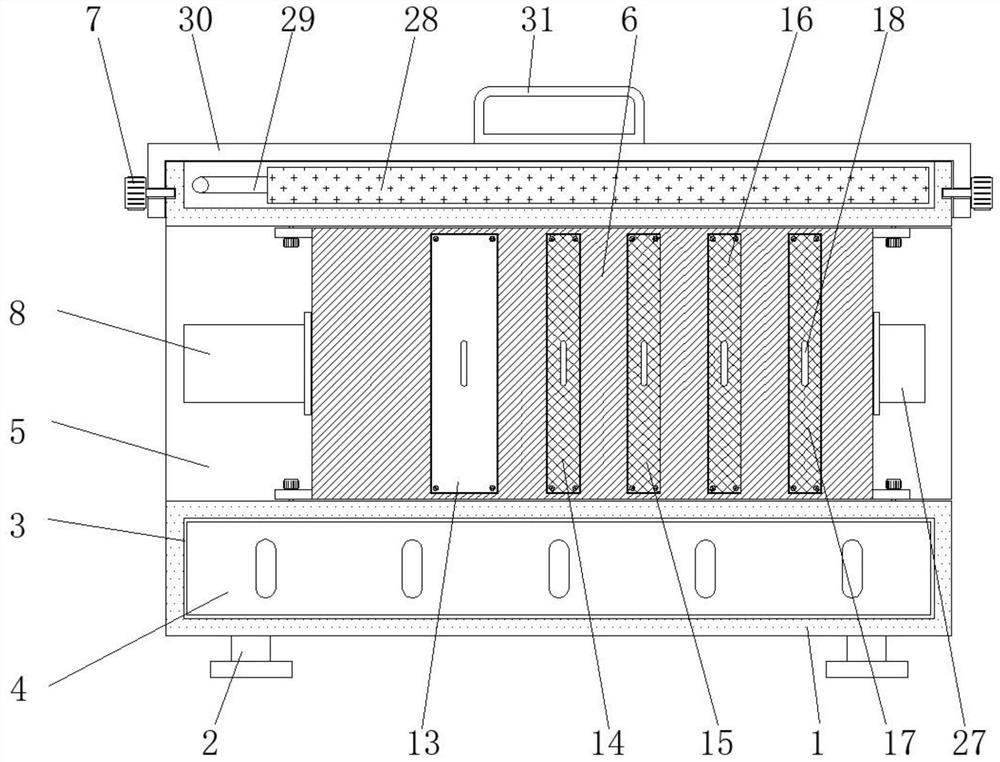

Detection device and detection method for air particulate matters

PendingCN111855507AEasy to control operationFully contactedPreparing sample for investigationParticulatesEngineering

The invention discloses a detection device and a detection method for air particulate matters. The device comprises a bearing box, a motor and a microscope, wherein a fluid director is fixed in the bearing box; a dust collection frame and a second filter screen are respectively arranged on the left side and the right side of a first filter screen; bearing seats are arranged between the dust collection frame and the first filter screen, between the first filter screen and the second filter screen, between the second filter screen and the third filter screen, and between the third filter screenand the fourth filter screen; and the microscope penetrates through the top of the bearing seat and is in threaded connection with a sleeve, an air outlet pipeline penetrates through the right side ofthe bearing box, and a control panel is placed in the top of the bearing box. According to the detection device and the detection method for the air particulate matters, the microscope and the control panel, the microscope can move up and down along with the bearing seat, suspended solids attached to the first filter screen, the second filter screen, the third filter screen and the fourth filterscreen can be observed and detected conveniently, observed and detected results are fed back to the control panel, and analysis is facilitated.

Owner:BEIFANG UNIV OF NATITIES

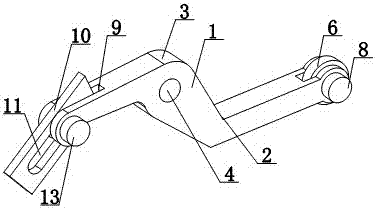

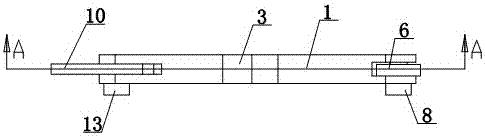

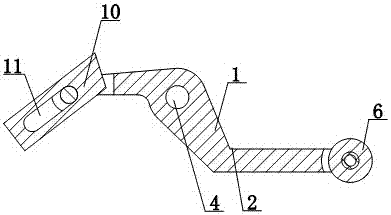

Rubber-covered roller stop mechanism of conveying system in belt conveying mode

InactiveCN107399558AEasy to control operationIncrease contactConveyorsPackagingMechanical engineering

The invention discloses a rubber-coated drum stopper mechanism of a belt conveying transportation system, comprising a mechanical arm, the mechanical arm is provided with a bending part and a bending part; a middle position of the mechanical arm is provided with a mounting hole; one end of the mechanical arm is provided with a first An installation groove, the first installation groove is provided with a guide wheel, the axial position of the guide wheel is provided with a first connecting shaft, the end of the first connecting shaft is provided with a first retaining ring, and the first connecting shaft is installed at one end of the mechanical arm , the first buckle is buckled on the outer side wall of one end of the mechanical arm; the other end of the mechanical arm is provided with a second installation groove, and the second installation groove is provided with a stop block, and the stop block is connected to the other end of the mechanical arm through the second connecting shaft connection; the end of the second connecting shaft is provided with a second buckle, and the second buckle is buckled on the outer side wall of the other end of the mechanical arm. The invention can contact the guide wheel with the rubber-coated drum; the stop block can be rotated around the second connecting shaft, so as to be convenient to contact or separate from the rubber-coated drum and to control the operation of the rubber-coated drum.

Owner:陈沛

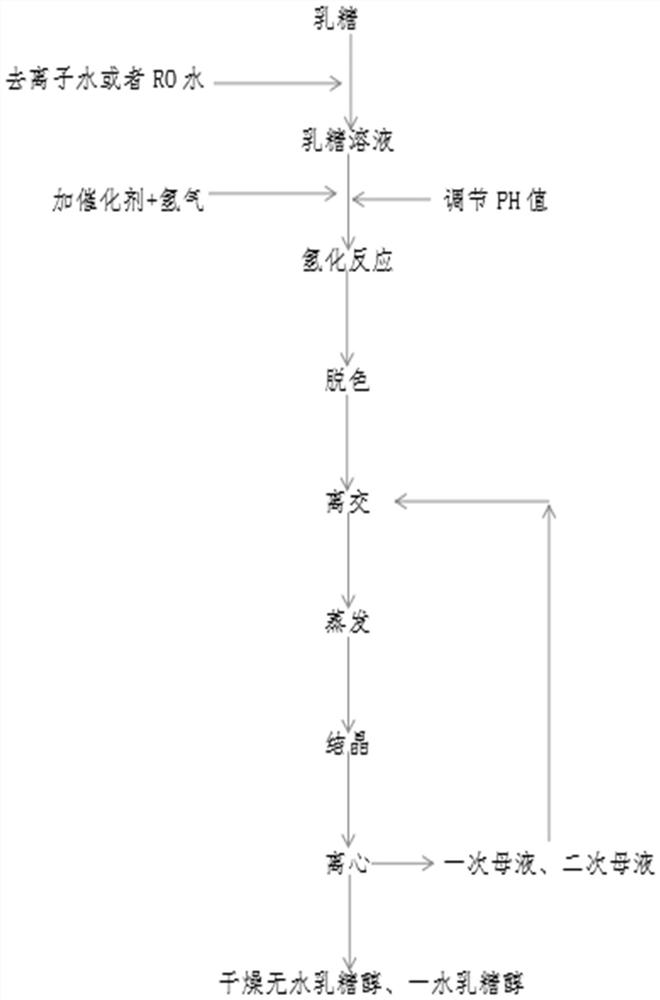

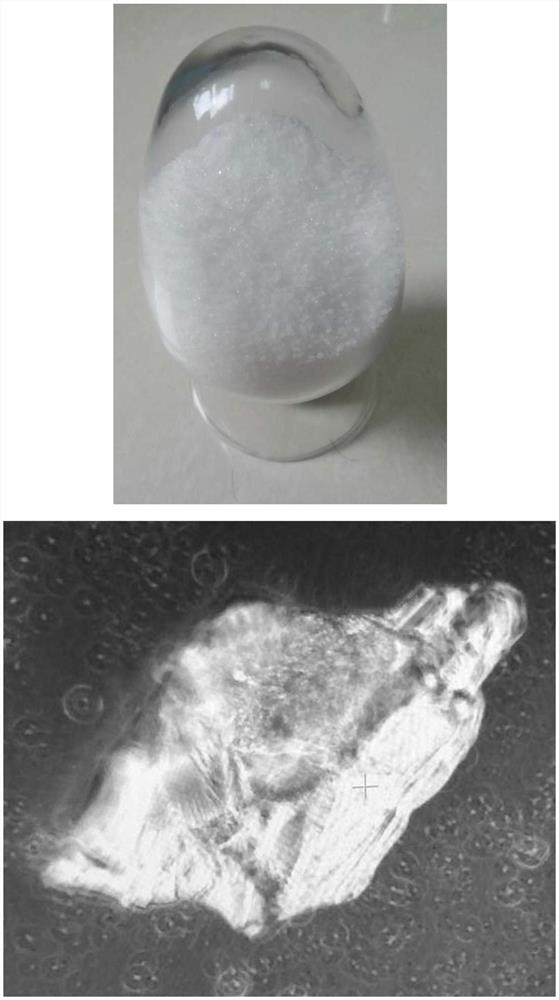

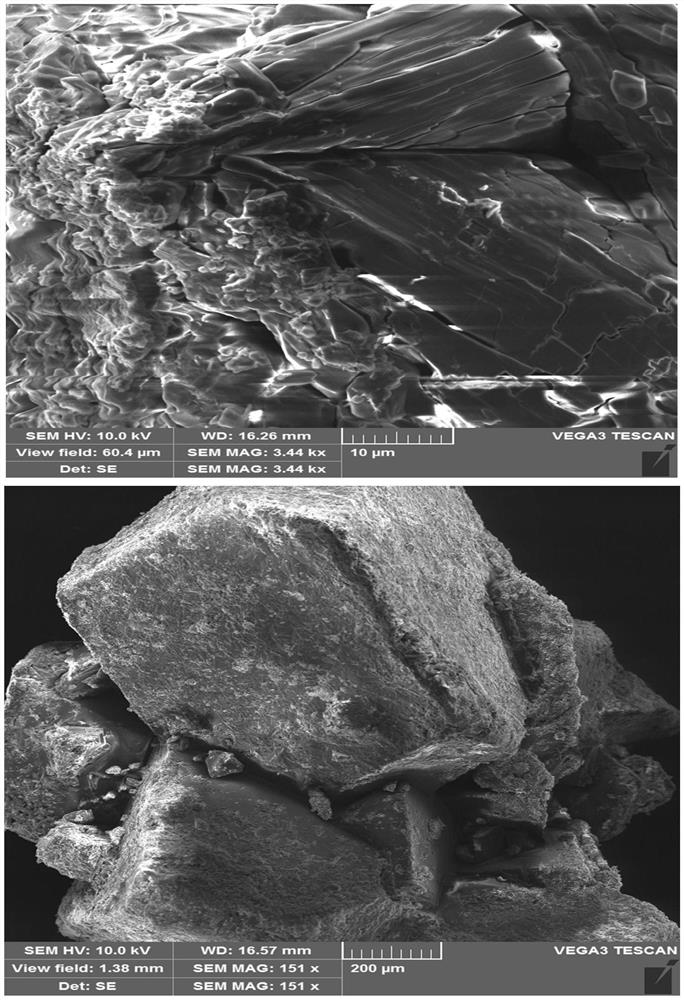

Production process of lactitol crystals

ActiveCN112250722ASimple processEasy to operateSugar derivativesSugar derivatives preparationCrystallographyLACTITOL MONOHYDRATE

The invention discloses a production process of lactitol crystals. The process comprises the following steps of (1) carrying out a hydrogenation reaction on a lactose aqueous solution under the actionof a catalyst to obtain lactose hydrogenation liquid; and (2) removing the catalyst in the lactose hydrogenation liquid to obtain a lactitol solution, and carrying out ion exchange, concentration andcrystallization to obtain anhydrous lactitol crystals or lactitol monohydrate crystals, wherein the crystallization is evaporative crystallization at 78-98 DEG C under the negative pressure not higher than -0.08 MPa in the step (2). Through the process, the first crystallization yield of lactitol relative to a lactose raw material reaches 50.0%-65%, and the total yield of anhydrous lactitol relative to the dry basis mass of the lactose raw material reaches 90% or above; and meanwhile, the process is simplified, the production operation is easy, the production cost is relatively low, and lactitol monohydrate can be obtained only by changing the temperature through the same operation.

Owner:何定兵

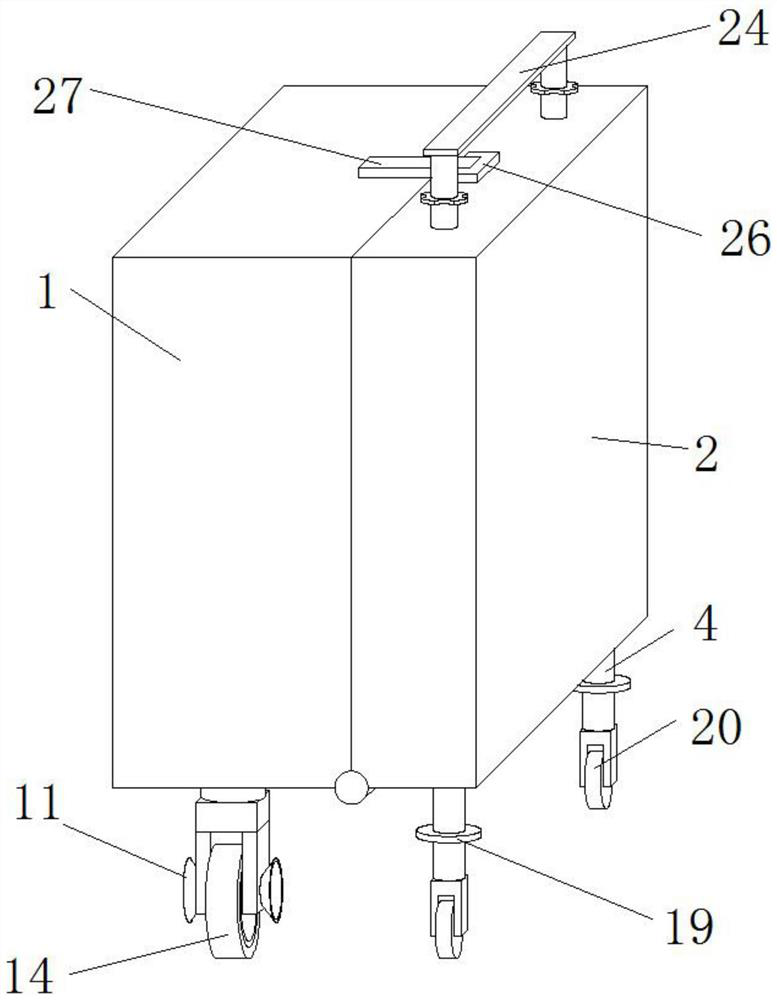

Recorder narrow space walking device for wind driven generator detection

InactiveCN112230141AEasy to moveReduce coefficient of frictionMeasurement instrument housingDynamo-electric machine testingWind drivenClassical mechanics

The invention belongs to the technical field of wave recorders, and particularly relates to a wave recorder narrow space walking device for wind driven generator detection, which comprises a wave recorder body. According to the recorder narrow space walking device for wind driven generator detection, the anti-skid device with the rollers is installed on the lower surface of the recorder, sliding friction between the lower surface of the recorder body and the ground is replaced with rolling friction between the rollers and the ground, then the friction coefficient is reduced, movement of the recorder body is facilitated, and meanwhile the recorder body is prevented from falling off. The sealing cover is supported at the lower end of the sealing cover through the universal wheels, sliding friction between the lower surface of the sealing cover and the ground is replaced with rolling friction between the universal wheels and the ground, then the friction coefficient is reduced, movement of the sealing cover is facilitated, and through mutual supporting between the sealing cover and the recorder body, the sealing performance is improved. The sealing cover is pulled by the handle to drive the wave recorder to move together, so the wave recorder can move in a narrow space conveniently.

Owner:NANJING RUIQI ELECTRONICS TECH CO LTD

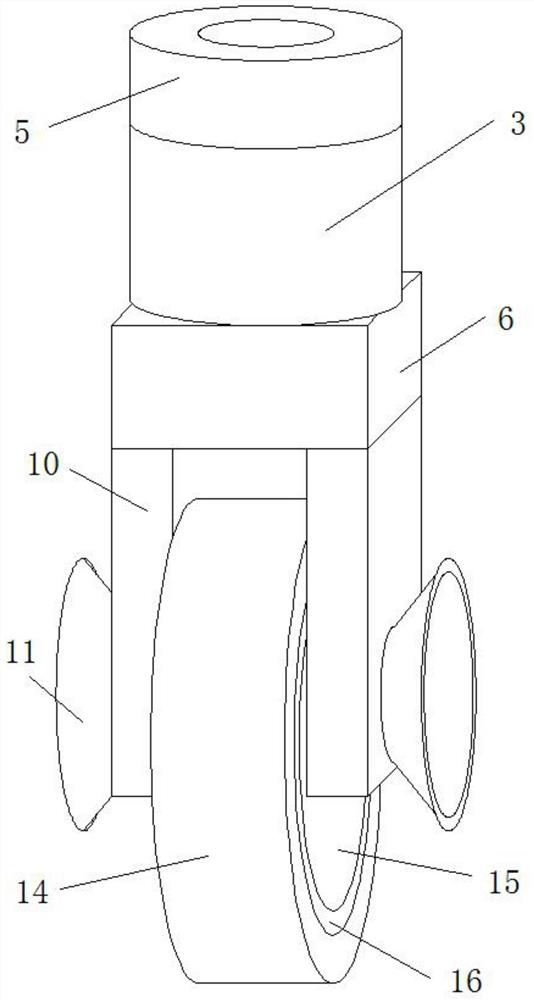

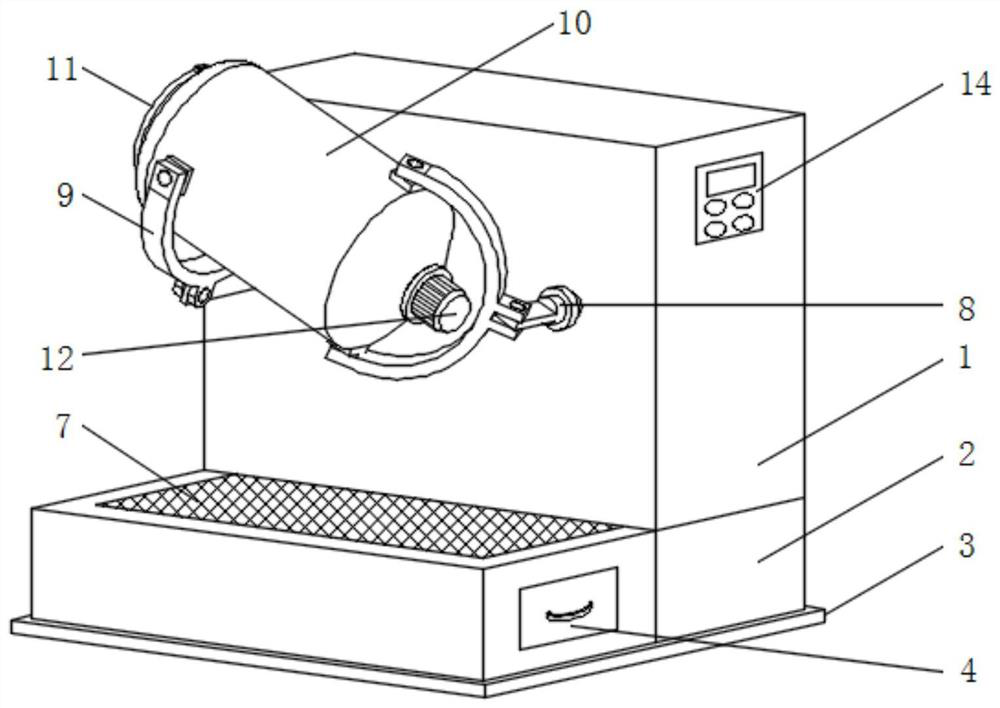

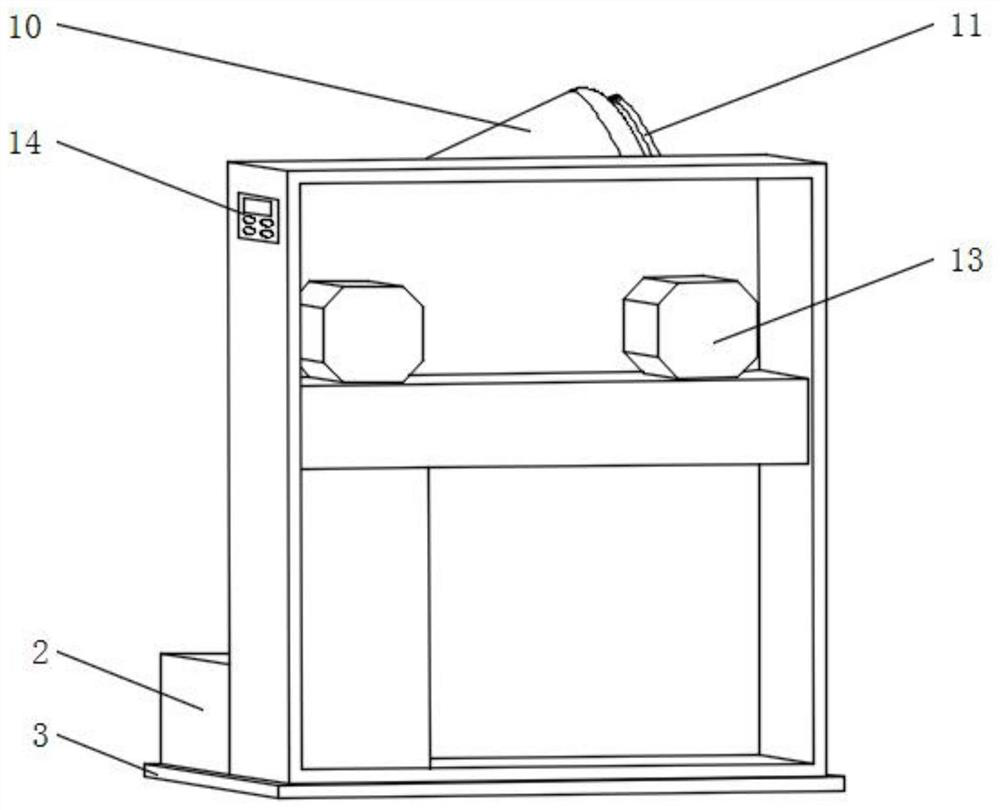

Single-arm type three-dimensional motion mixing machine

PendingCN113952867AStir wellWell mixedRotating receptacle mixersTransportation and packagingUniversal jointElectric machinery

The invention discloses a single-arm three-dimensional motion mixing machine, which comprises an equipment main body, a base is arranged at the lower end of the equipment main body, a bottom plate is arranged at the lower end of the base, a collecting drawer is arranged on the inner side of the bottom plate, sliding rails are arranged on the two sides of the collecting drawer, and a supporting plate is arranged at the position, close to the front end of the equipment main body, of the upper end of the base. A universal joint is arranged at the front end of the equipment main body, a clamping frame is arranged on the surface of the universal joint, a material mixing barrel is arranged on the inner side of the clamping frame, a sealing cover is arranged at one end of the material mixing barrel, a first motor is arranged at the other end of the material mixing barrel, and a connecting rod is arranged at one end of the first motor; and a material mixing rod is arranged on the surface of the connecting rod. According to the single-arm type three-dimensional motion mixing machine, the first motor is matched with the material mixing rod, materials in the material mixing barrel can be mixed more sufficiently, and scattered materials can be collected in the discharging process in cooperation with the collecting drawer at the lower end .

Owner:南京厚威机电设备有限公司

Supercharged gas water heater

PendingCN110966748AGuaranteed intake pressureGuaranteed stabilityWater heatersExhaust gas emissionsInlet pressure

The invention discloses a supercharged gas water heater. The supercharged gas water heater comprises a combustion cavity and a gas inlet pipeline, wherein the gas inlet pipeline is connected with thecombustion cavity; gas enters the combustion cavity to combust; a waste gas exhaust pipeline is arranged on the combustion cavity; a turbine device is arranged in the waste gas exhaust pipeline; a supercharging device is arranged on the gas inlet pipeline; the turbine device is connected to the supercharging device; and while the turbine device rotates, the supercharging device is driven to perform supercharging on gas. The gas water heater disclosed by the invention can recycle kinetic energy and heat energy of waste gas to supercharge gas, so that gas inlet pressure and stability can be guaranteed, the optimal combustion working condition can be guaranteed to be matched, outlet water temperature and stability are guaranteed, energy consumption and cost further can be reduced, and user bathing experience is greatly improved.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER +1

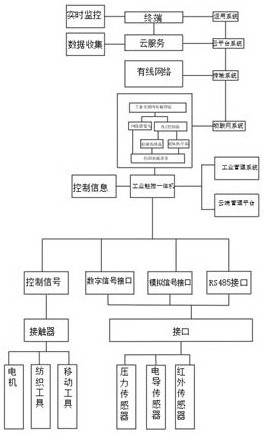

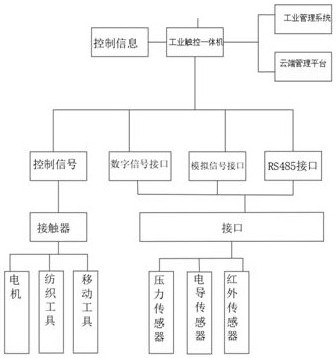

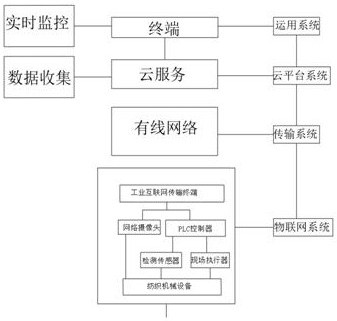

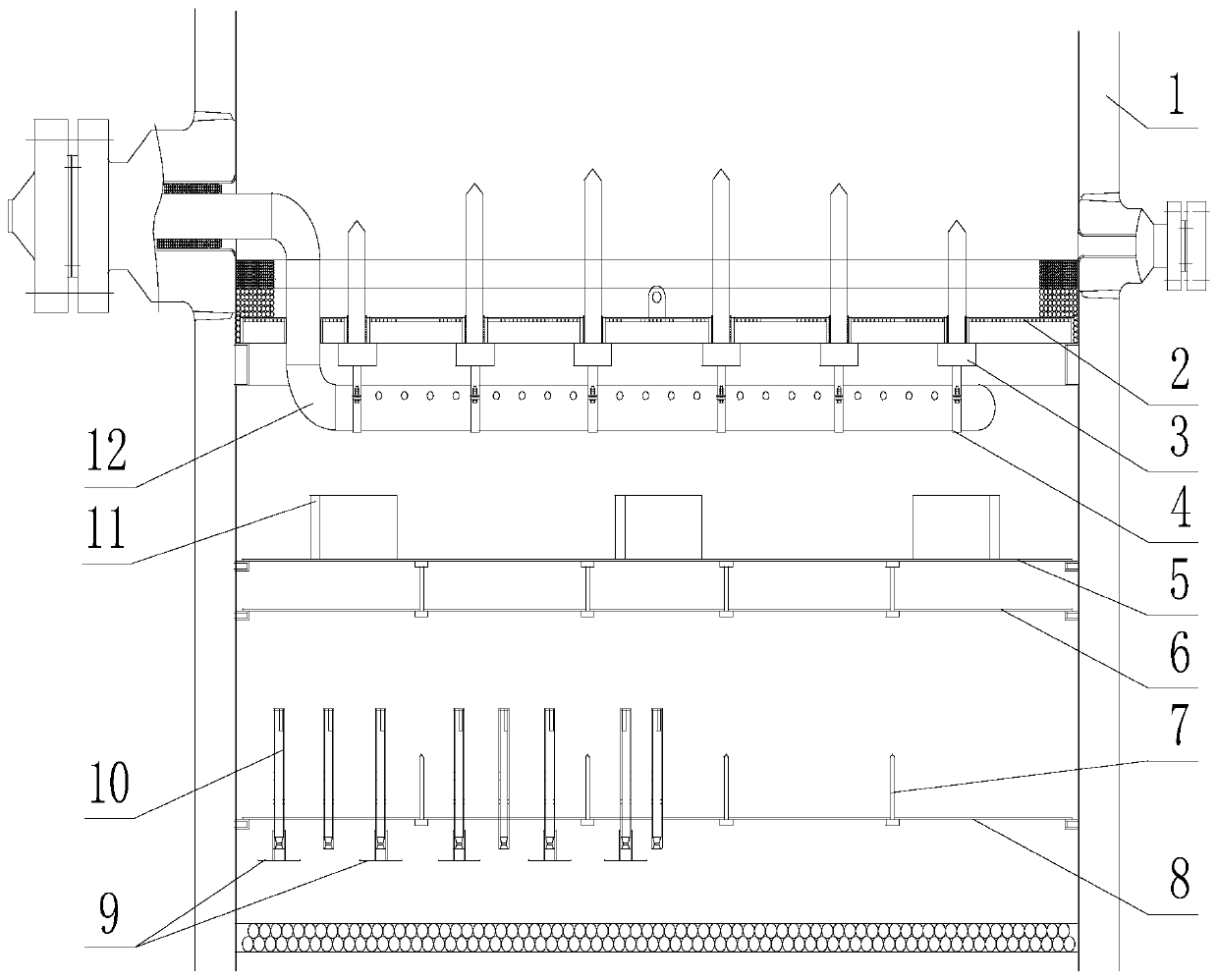

Textile machinery remote operation and maintenance system and realization method thereof

PendingCN113110154ARealize controllable operationEasy to control operationProgramme controlComputer controlControl signalMechanical equipment

The invention discloses a textile machinery remote operation and maintenance system and a realization method thereof. The textile machinery remote operation and maintenance system comprises an industrial touch control all-in-one machine and textile machinery equipment, the industrial touch control all-in-one machine comprises control information, an industrial management system, a cloud management system, a control signal, a digital signal interface, an analog signal interface and an RS485 interface, and the output end of the industrial touch all-in-one machine is electrically connected with the input end of the control information. According to the remote operation and maintenance system and the realization method thereof, the industrial management system and the cloud management system in the industrial touch all-in-one machine are controlled through an application system, a cloud platform system, a transmission system and an Internet of Things system, so that the industrial touch all-in-one machine conveniently controls start and stop of a motor through a control signal and a touch controller, detection is facilitated, and the safety performance is improved; visual operation of the textile machinery equipment can be realized through the control information, the industrial management system and the digital signal interface, operation of workers is facilitated, and fatigue of manual operation is reduced.

Owner:HUAYI ADORNMENT NINGBO

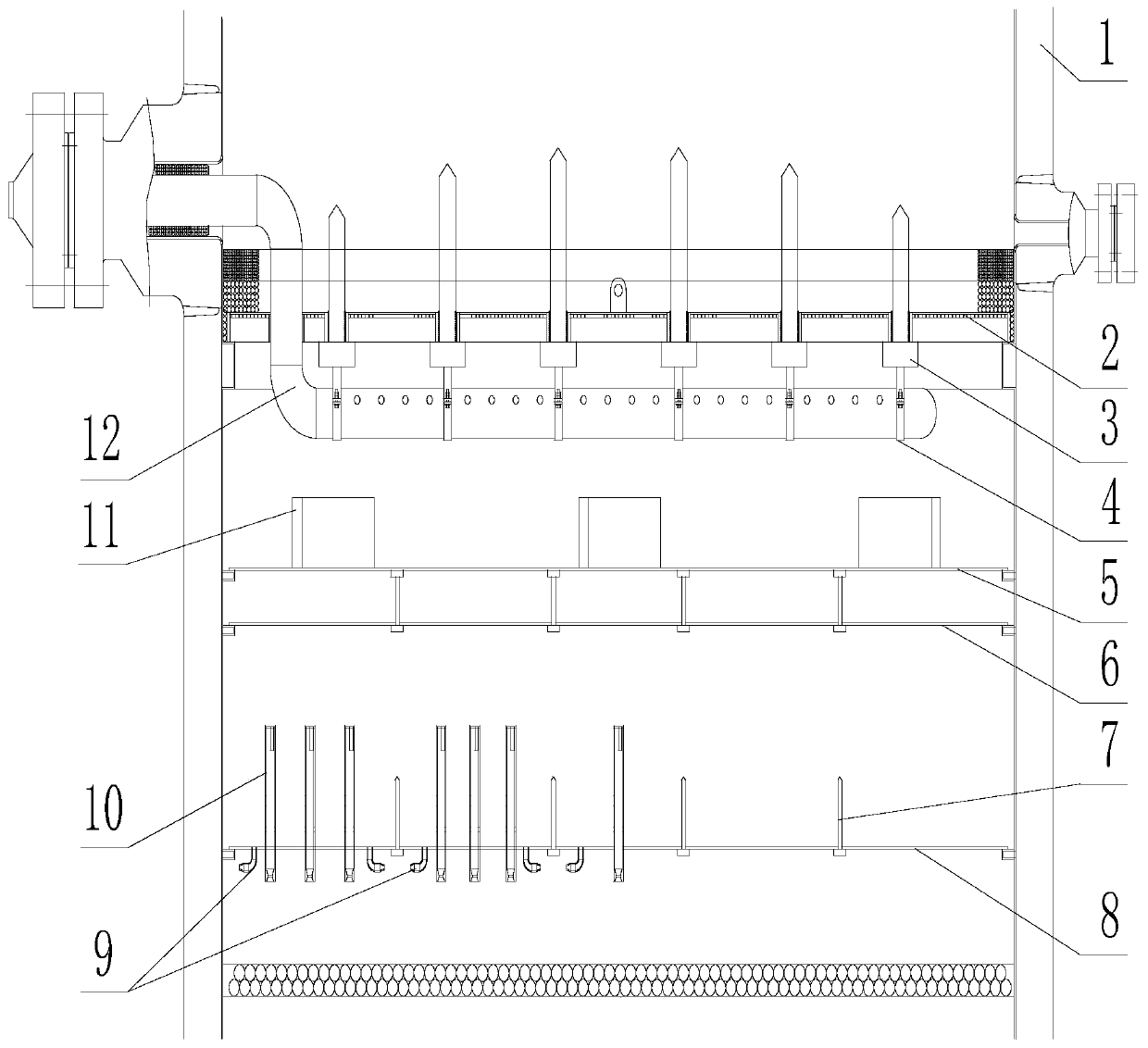

Gas-liquid mixing distribution system

PendingCN111558343AEvenly distributedImprove heat transfer efficiencyHydrocarbon oil crackingHydrocarbon oils refiningPtru catalystDistribution system

The invention discloses a gas-liquid mixing distribution system. The system comprises a shell, and a catalyst grid, a cold hydrogen distributor, a collecting disc, gas-liquid distributors and a distribution disc which are arranged in the shell from top to bottom; mixing chambers are uniformly arranged on the collecting disc; and the distribution disc is fixedly connected with distribution disc supporting beams and the inner wall of the shell, the gas-liquid distributors are vertically fixed to the distribution disc, and flow crushing plates are arranged on the distribution disc and located onthe two sides of the distribution disc supporting beams and at the lower end of the gas-liquid distributor located on the inner wall of the shell. Cold hydrogen can be more uniformly distributed on the total cross section of a reactor, dead zones on the inner wall of the shell and the distribution disc supporting beams are reduced, and the uniform distribution of gas and liquid on the total crosssection of the reactor is fully guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +2

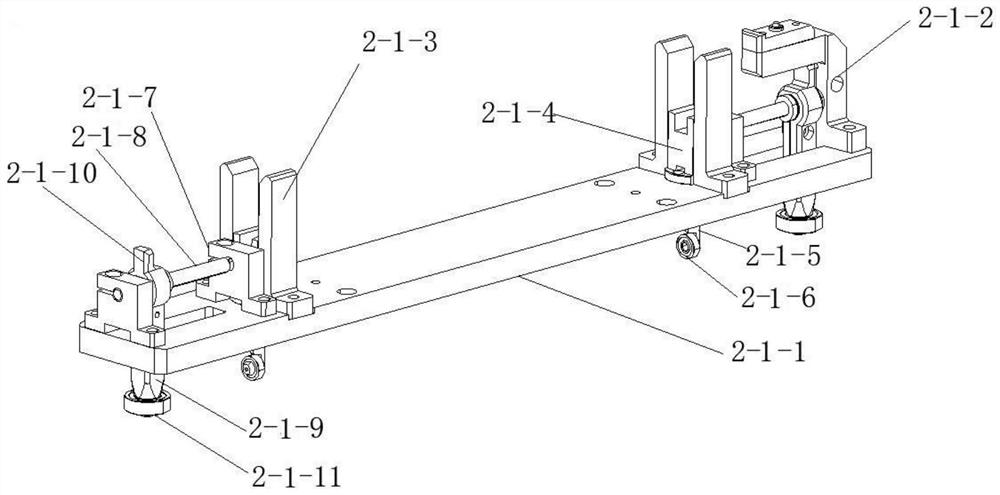

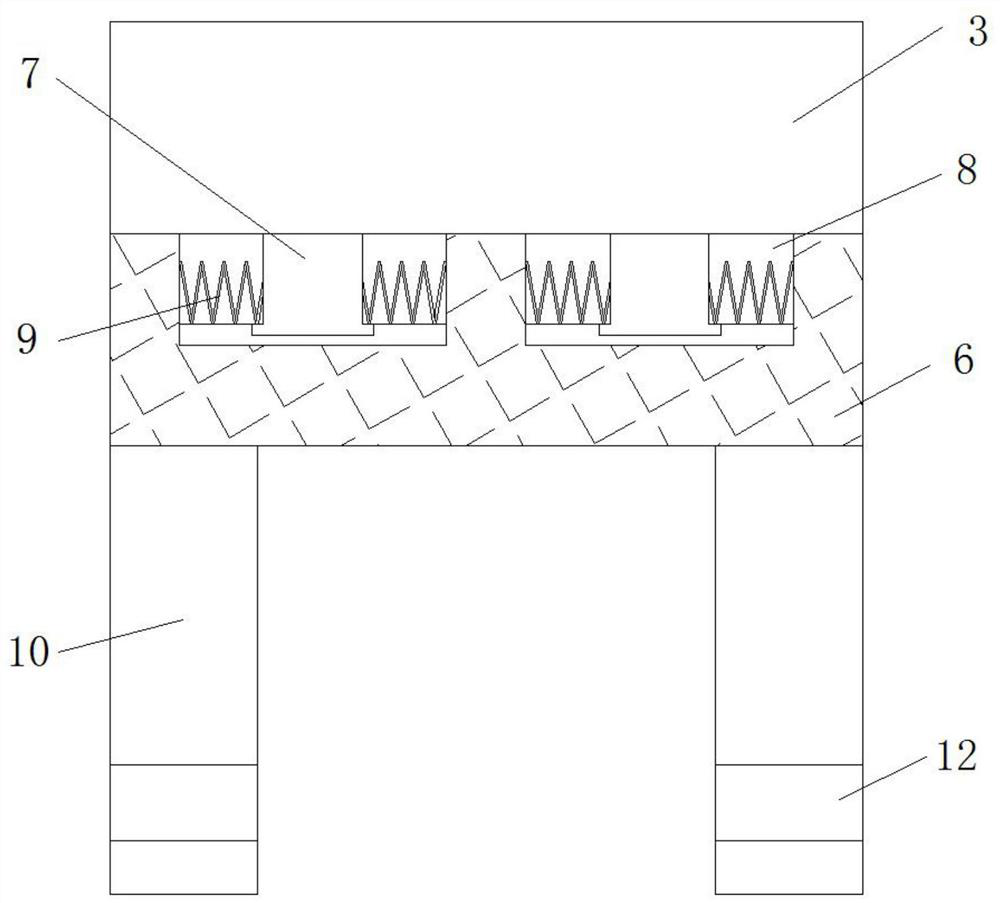

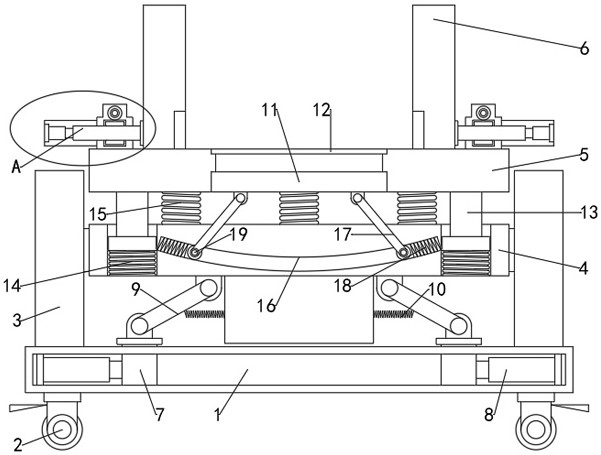

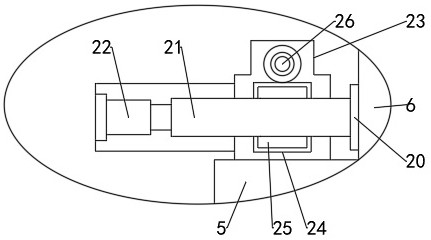

A support chassis for a multifunctional numerical control machine tool

ActiveCN112097069BEasy to clamp and fixAvoid damageStands/trestlesLarge fixed membersNumerical controlHydraulic cylinder

The invention discloses a supporting chassis for a multifunctional numerical control machine tool, which comprises a base, a lifting platform is movably installed on the upper end of the base, a supporting seat is mounted on the lifting platform, and a limit mechanism is arranged on the supporting seat; the numerical control machine tool Use the support chassis to control the movement of the limit plate through the operation of the worm, which is convenient for clamping and fixing CNC machine tools of different specifications. The board is equipped with a pressure sensor, which can control the clamping force of the limit plate; through the arrangement of a shock-absorbing structure between the support seat and the limit plate, the vibration during the assembly and operation of the CNC machine tool can be effectively reduced; There is a cooling fan, which can cool the machine tool to ensure the long-term effective operation of the machine tool; the telescopic hydraulic cylinder controls the movement of the lifting platform along the fixed frame, making the height of the CNC machine tool easy to adjust and the lifting more stable.

Owner:苏州泰中意五金科技有限公司

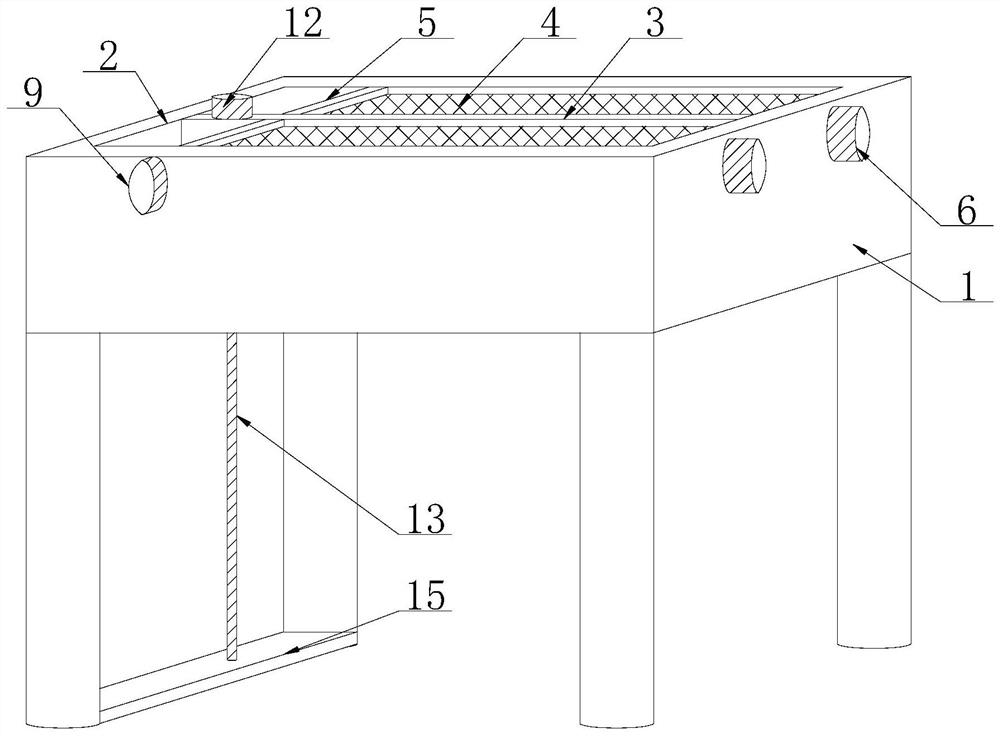

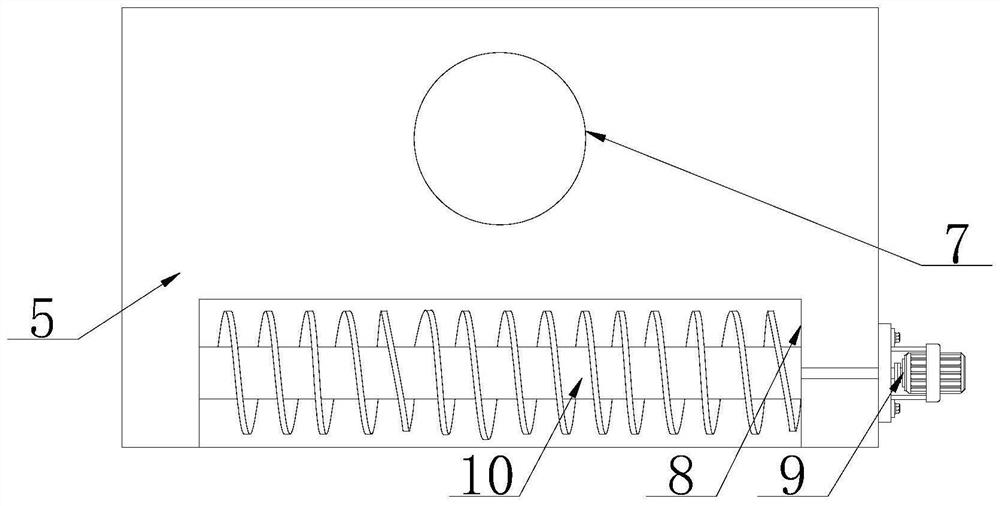

Manufacturing device of pervious concrete baking-free brick

ActiveCN114311260AEasy controlled fillingImprove delivery efficiencySolid waste managementPreparing sample for investigationBrickElectric machinery

A pervious concrete baking-free brick manufacturing device comprises a fixing frame, supporting columns are fixedly connected to the four corners of the bottom of the fixing frame, a groove is formed in the middle of the fixing frame, a partition plate is fixedly connected to the middle of the groove, two first motors are fixedly connected to the side wall of one end of the fixing frame, and baffles are fixedly connected to the two sides of one end of the partition plate in the groove. Compared with the prior art, the raw material conveying device has the beneficial effects that by means of the filter screen fixedly connected to the interior of the groove, raw materials are filtered when conveyed, and it is avoided that some miscellaneous blocks enter the raw materials to affect subsequent machining and manufacturing; through the first motor fixedly connected to the side wall of one end of the fixing frame, operation of the spiral feeding rod is conveniently controlled, raw materials conveyed into the groove are stirred and conveyed, conveying and filling of the raw materials are facilitated, the production efficiency is improved, and the situation that the raw materials are solidified in the conveying process, and follow-up conveying and production efficiency are affected is avoided.

Owner:GUANGDONG UNIV OF TECH

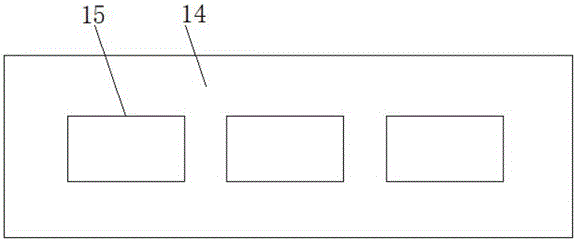

Intelligent plug-in circuit breaker and its monitoring and early warning system

InactiveCN104597398BSimple structureEasy to installThermometer detailsTransmission systemsElectricityEarly warning system

The invention provides an intelligent plug-in circuit breaker and its monitoring and early warning system, which is composed of a plug-in circuit breaker, a monitoring and early warning device, a portable terminal and a monitoring center server. The monitoring and early warning device includes a measurement and control module, a temperature acquisition module, a voltage and current acquisition module, a communication module, a display module and an audible and visual alarm module. By measuring the real-time temperature of each contact, measuring and calculating various electrical parameters, comprehensively analyzing and judging the working status of the plug-in circuit breaker, especially analyzing and judging its unhealthy or abnormal status, so as to realize early warning. In addition, the temperature alarm and temperature protection functions are realized. The plug-in circuit breaker is highly integrated with the monitoring and early warning device, with simple structure, convenient installation, safety and reliability. The transformation is easy to implement, which effectively reduces the failure rate and damage rate of equipment and improves the reliability of power supply.

Owner:HARBIN UNIV OF SCI & TECH +1

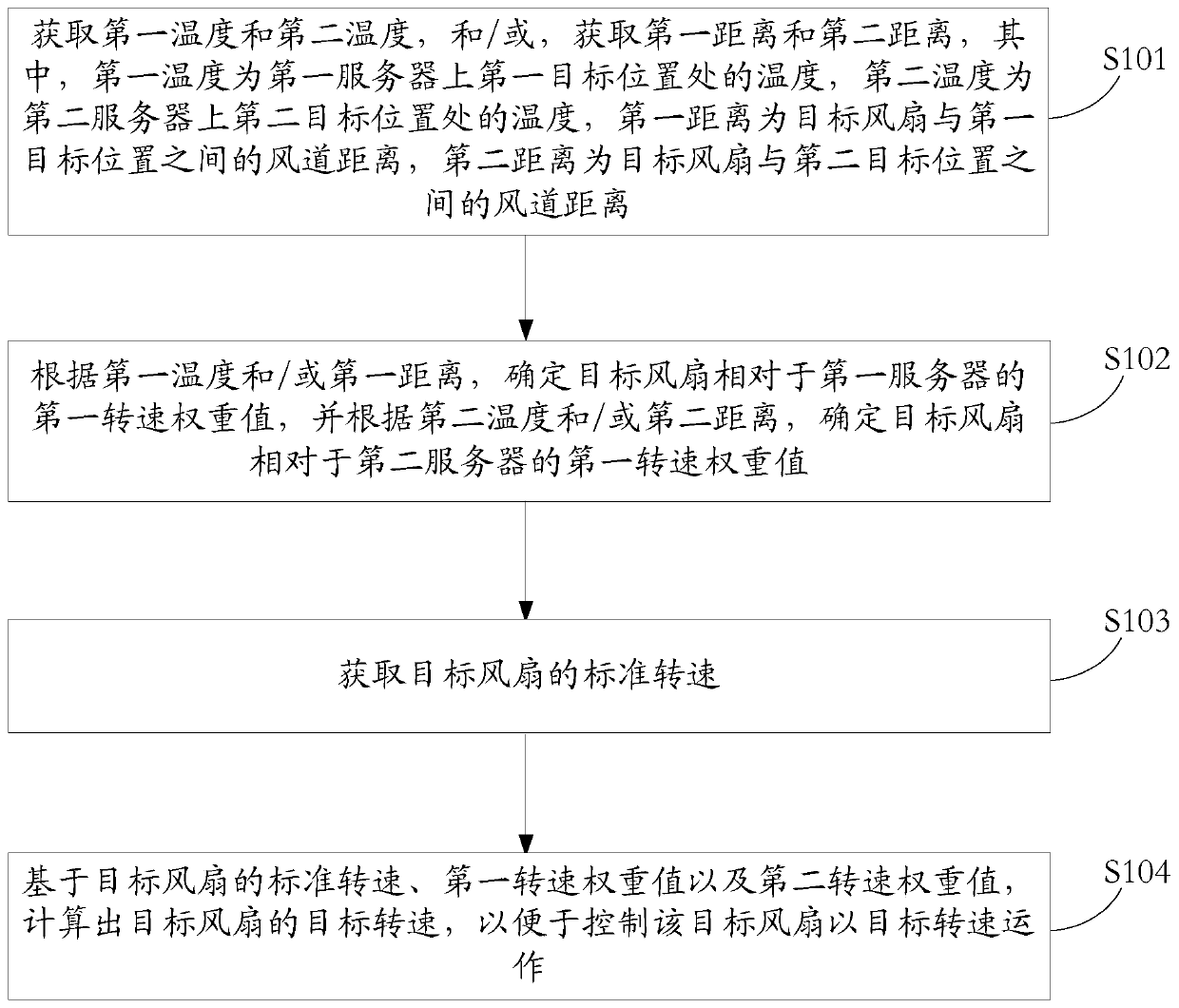

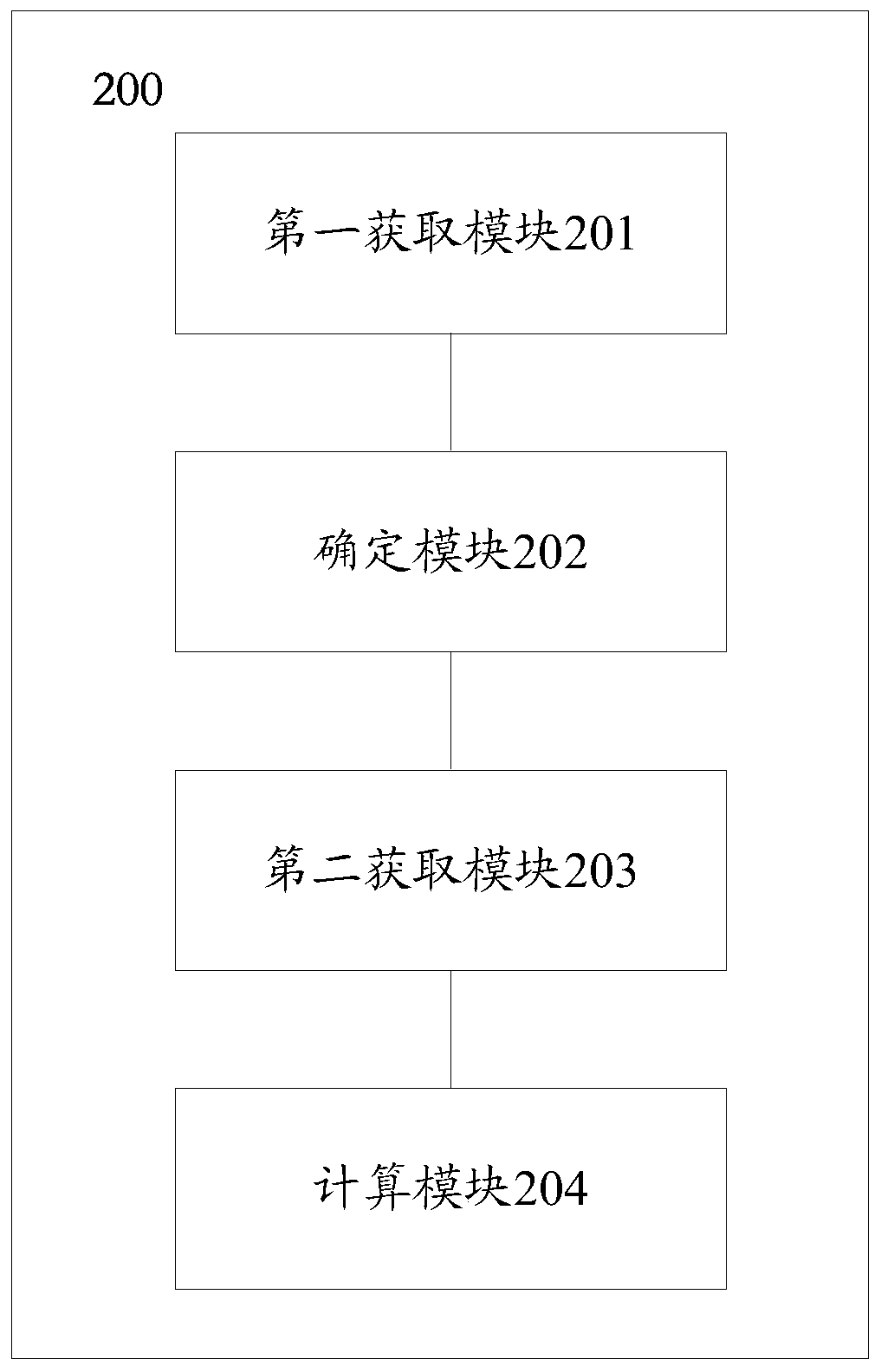

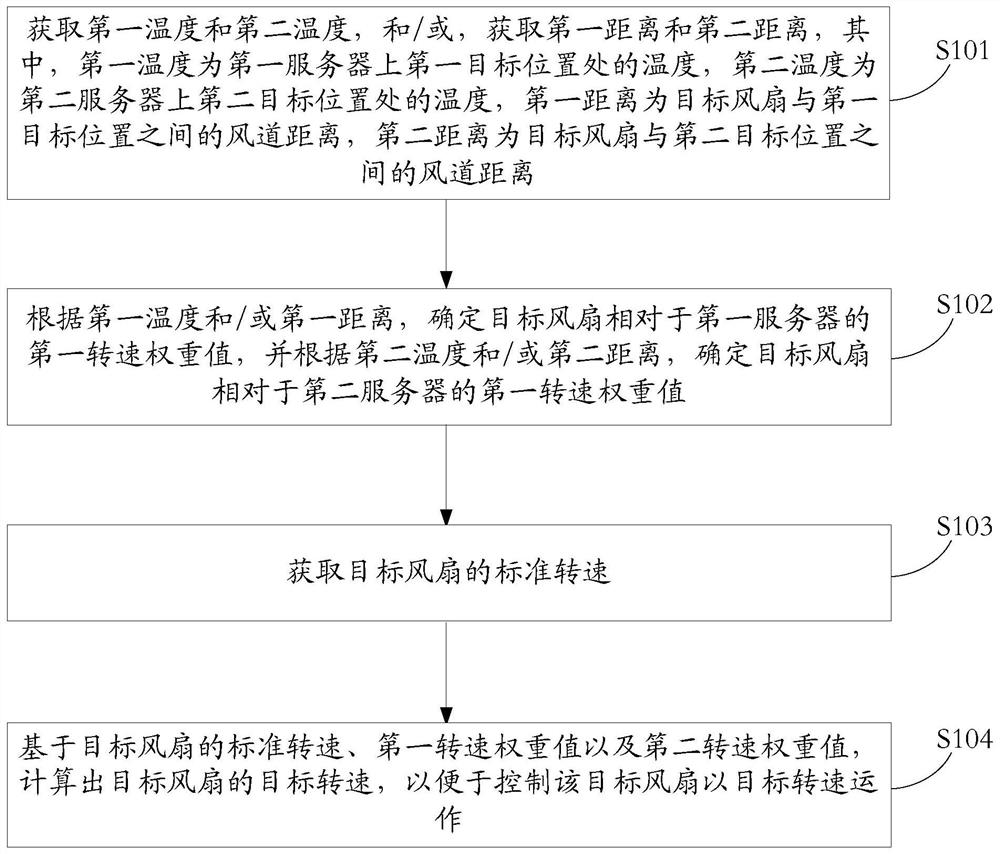

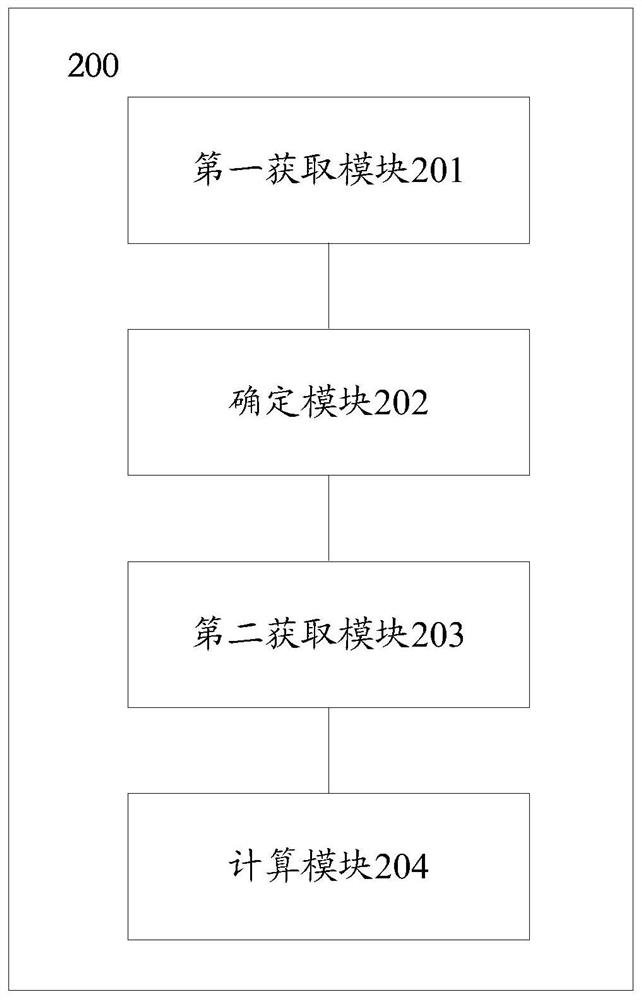

Control method and device for rotational speed of fan

ActiveCN109854525AReduce power consumptionEasy to control operationDigital data processing detailsPump controlComputer sciencePower consumption

The invention discloses a control method and device for a rotational speed of a fan. The control method for the rotational speed of the fan comprises the following steps: obtaining a first temperatureand a second temperature, and / or, obtaining a first distance and a second distance; obtaining a standard rotational speed of the target fan; determining a first rotational speed weight value of the target fan relative to a first server according to the obtained first temperature and / or first distance, and determining a second rotational speed weight value of the target fan relative to a second server according to the obtained second temperature and / or second distance; and calculating a target rotational speed of the target fan on the basis of the standard rotational speed of the target fan, the first rotational speed weight value and the second rotational speed weight value, so as to control the target fan to run at the target rotational speed. Thus, different fans are enabled to realizeheat dissipation for the servers on the basis of different rotational speeds by controlling the rotational speed weight values, so that the effect of reducing the power consumption of the fan while ensuring the heat dissipation effect on the servers.

Owner:INSPUR BUSINESS MACHINE CO LTD

Gas-liquid mixing device

PendingCN111558342AHigh heat transfer efficiencySimple structureHydrocarbon oil crackingHydrocarbon oils refiningHeat transfer efficiencyMixing chamber

The invention discloses a gas-liquid mixing device. The device comprises a shell, and a catalyst grid, a collecting disc, a cold hydrogen distributor, a bubble cap, a coarse distribution disc, gas-liquid distributors, a distribution disc and a redistribution disc which are arranged in the shell from top to bottom, wherein the cold hydrogen distributor is fixedly connected with a central hole of the collecting disc through an opening in the upper end of a mixing chamber and mainly comprises a gas inlet pipe, distribution ring pipes, distribution straight pipes, a nozzle and the mixing chamber,the distribution ring pipes are concentrically distributed by taking the mixing chamber as the center, the distribution straight pipes and the distribution ring pipes are crossed and communicated, andthe distribution straight pipes and the gas inlet pipe are communicated with the side wall of the mixing chamber. The device is simple and compact in structure and suitable for being used between catalyst bed layers of a large-diameter down-flow reactor; and cold hydrogen can be more uniformly distributed on the total cross section of the reactor and can be fully mixed with reaction oil gas, so that uniform mass transfer and heat transfer are guaranteed, and the heat transfer efficiency of a medium in the reactor is improved.

Owner:CHINA PETROLEUM & CHEM CORP +2

A kind of fan speed control method and device

ActiveCN109854525BReduce power consumptionEasy to control operationDigital data processing detailsPump controlEngineeringMechanical engineering

Owner:INSPUR BUSINESS MACHINE CO LTD

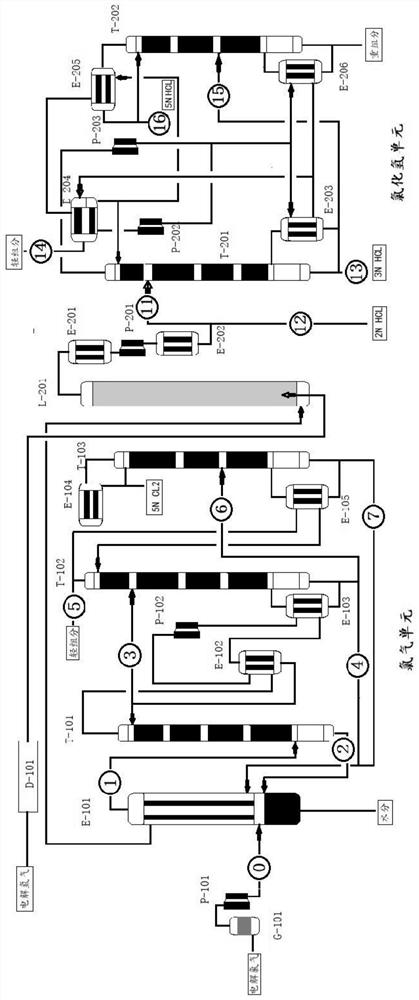

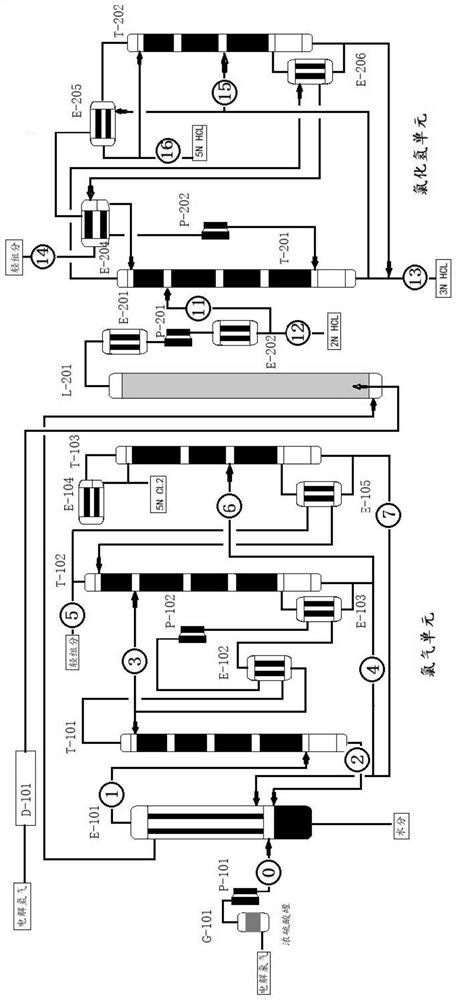

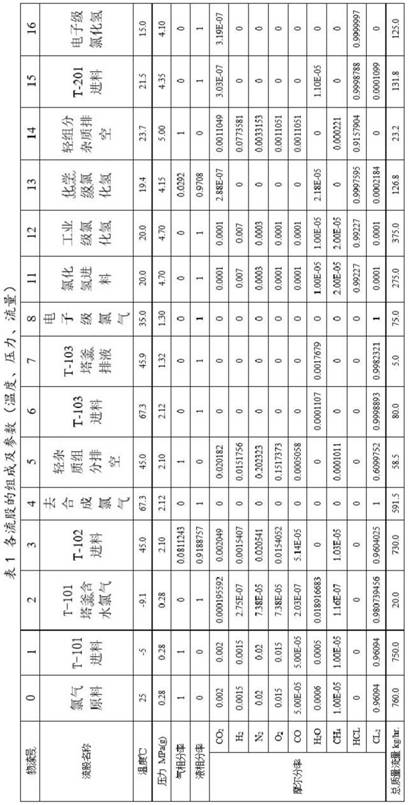

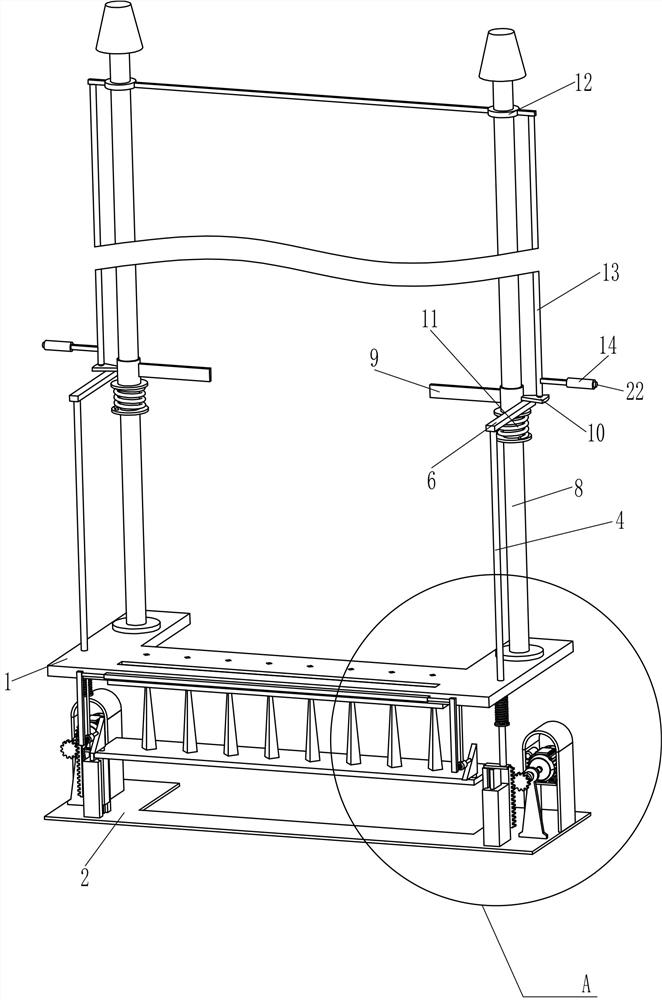

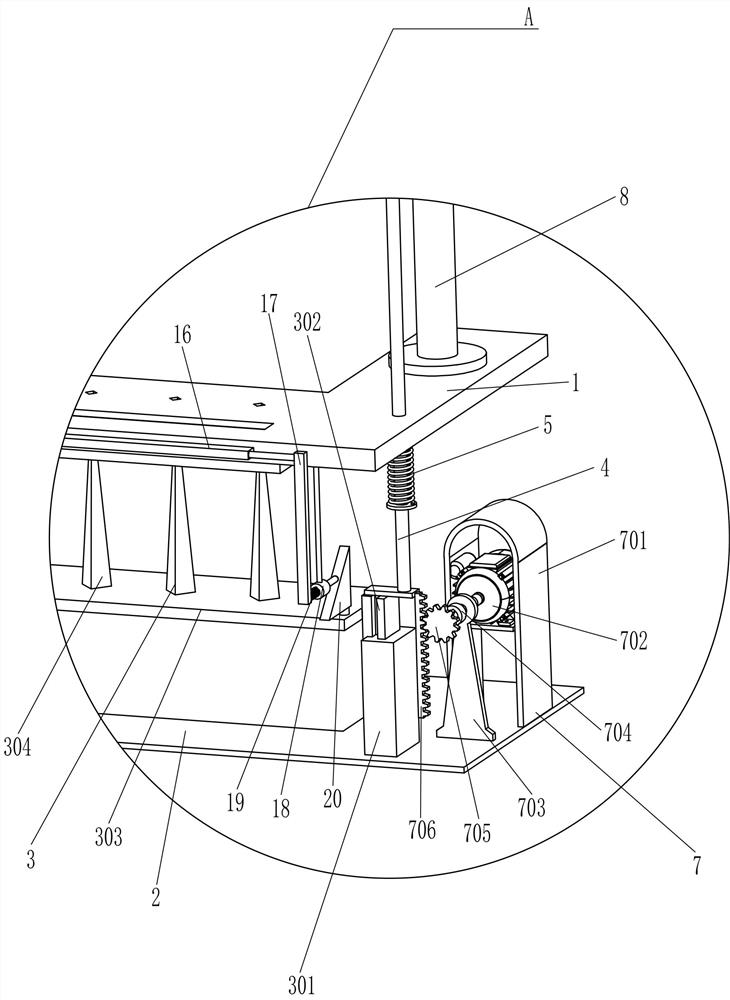

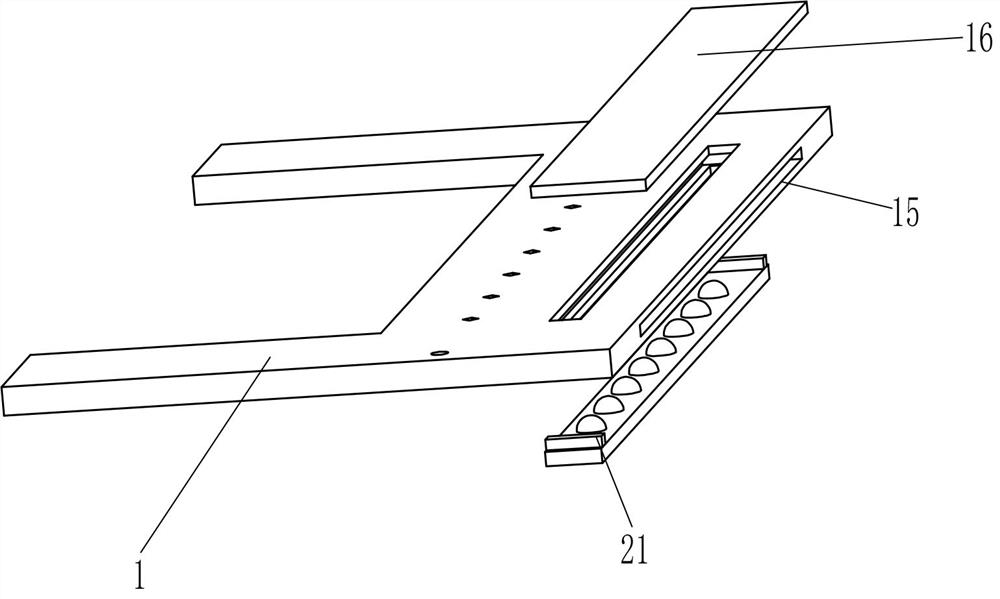

System and method for joint production of electronic chlorine and electronic hydrogen chloride

ActiveCN112777568ALow costReduce manufacturing costChlorine/hydrogen-chloride purificationHydrogen chloride preparationPhysical chemistryHydrogen chloride

The invention provides a system and a method for joint production of electronic chlorine and electronic hydrogen chloride, the system for production of electronic chlorine comprises a condenser, a dehydrating tower, a heat exchanger, a compressor, a chlorine light component removal tower, a chlorine refining tower and the like, and the system for production of hydrogen chloride is based on the system for production of chlorine, and further comprises a hydrogen chloride synthesis furnace, a liquefaction unit, a hydrogen chloride light component removal tower and a hydrogen chloride refining tower. According to the invention, anhydrous and oxygen-free chlorine without water and oxygen in the process of producing the electronic chlorine and external electrolytic hydrogen without water through pressure swing adsorption can be synthesized into hydrogen chloride in the hydrogen chloride synthesis furnace, the hydrogen chloride has extremely low water content,. and corrosion is avoided. By adopting the system and the method disclosed by the invention, the electronic chlorine, the electronic hydrogen chloride and the anhydrous hydrogen chloride can be produced by directly adopting electrolytic chlorine and electrolytic hydrogen, so that the raw material cost is saved; and meanwhile, a heat integration rectification technology is adopted in the process, so that energy is comprehensively utilized.

Owner:北京华宇同方化工科技开发有限公司

A fast measuring device for truck height

ActiveCN111457821BAvoid forced card punchingOrderlyMechanical thickness measurementsAlarmsFast measurementControl theory

The invention relates to a fast measuring device, in particular to a fast measuring device for the vehicle height of a truck. The technical problem of the present invention is how to provide a fast height measuring device for a truck that is convenient for measuring the height of the truck and can effectively prevent the truck from being jammed. A fast measuring device for the vehicle height of a truck, including a first installation board, a second installation board, etc.; the first installation board and the second installation board are installed and fixed by concrete and other supporting objects. Through the cooperation of the inserting rod and the upper device, the invention prevents the driver from forcibly punching the card in order to avoid high-speed tolls when the truck is measuring the height of the truck, and ensures the orderly measurement of the height of the truck.

Owner:HUNAN HAIDEWEI TECH

Sorting device

ActiveCN113844849APrevent fallingGood for fallingWaste collection and transferControl devices for conveyorsCircular discElectric machinery

Owner:ANKANG UNIV

Gas-liquid mixing distribution system

PendingCN111558339AEvenly distributedHigh heat transfer efficiencyHydrocarbon oil crackingHydrocarbon oils refiningDistribution systemEngineering

The invention discloses a gas-liquid mixing distribution system. The system comprises a shell, and a catalyst grid, a cold hydrogen distributor, a collecting disc, a gas-liquid distributor and a distribution disc which are arranged in the shell from top to bottom; mixing chambers are uniformly arranged on the collecting disc; and the distribution disc is fixedly connected with distribution disc supporting beams and the inner wall of the shell respectively, the gas-liquid distributor is vertically fixed on the distribution disc, gas-liquid spray heads are arranged at the positions, located onthe two sides of the distribution disc supporting beams and the inner wall of the shell, of the distribution disc, the gas-liquid spray heads on the two sides of the distribution disc supporting beamsare oppositely arranged in a staggered mode or obliquely arranged in pairs, and the gas-liquid spray heads on the inner wall of the shell are arranged right opposite to the inner wall of the shell orobliquely opposite to the inner wall of the shell. Cold hydrogen can be more uniformly distributed on the total cross section of a reactor, dead zones on the inner wall of the shell and the distribution disc supporting beams are reduced, and the uniform distribution of gas and liquid on the total cross section of the reactor is fully guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com