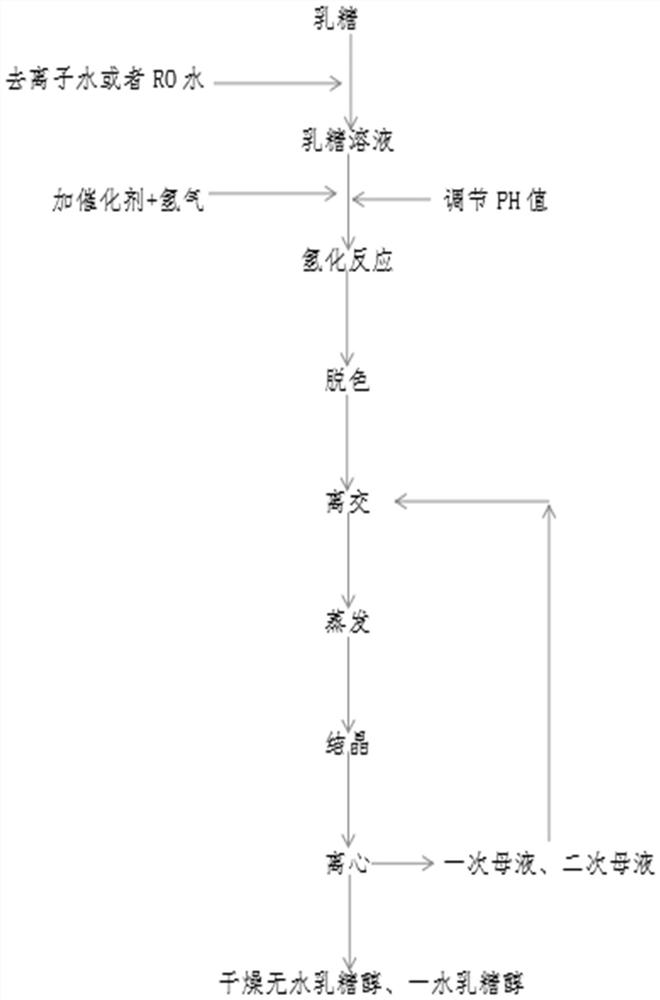

Production process of lactitol crystals

A production process, lactitol technology, applied in the field of lactitol production process crystals, can solve the problems of low lactitol content, inconsistent operation, difficult to increase yield, etc., achieve catalyst dosage optimization, process simplification, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Example 1: (Constant temperature evaporation and crystallization above 78°C without cooling down)

[0063] (1) if figure 1 As shown, 1800.0 kg of lactose was added to deionized water to form an aqueous solution of lactose with a mass percent concentration of 50.0% (that is, lactose refraction). The lactose content was 99.0%. Food-grade sodium carbonate was used to adjust the pH to 7.55, and 2% of lactose mass was added. Raney nickel catalyst, set the hydrogenation temperature at 110°C, the hydrogen pressure at 8.0-10MPa, react for 3.0h, and discharge the material into a settling tank to obtain lactose hydrogenation liquid; the discharge pipeline passes through a tank filled with RO water (the interior is a coil structure ) about 5 square meters, that is, the temperature of the hydrogenation solution is lowered, and the temperature of the RO water is also raised to above 70°C. That's it.

[0064] (2) The hydrogenated lactitol solution was settled in the first settling ...

Embodiment 2

[0077] Example 2 (evaporative crystallization at 77°C, crystallization tank at 79°C)

[0078]1) Add 1,800.0 kg of lactose into RO water (after heat exchange with lactulose hydrogenation solution, temperature 78° C.) to form an aqueous solution of lactose with a mass percent concentration of 56.0% (i.e. lactose refraction, concentration), with a lactose content of 98.5%. Use sodium carbonate aqueous solution (30%) to adjust the pH to 7.8, add a Raney nickel catalyst with a lactose mass of 3.2%, set the hydrogenation temperature to 115 ° C, and the hydrogen pressure to 8.8 MPa, react for 2.5 hours, and discharge the material to a settling tank to obtain lactose hydrogenation liquid;

[0079] (2) The lactitol hydrogenated solution was settled in the first settling tank for 2 hours, the upper layer hydrogenated solution was put into the second settling tank, and settled for 1.5 hours again to obtain the lactitol hydrogenated solution; the index of the lactitol solution is: lactito...

Embodiment 3

[0087] Example 3 (evaporative crystallization above 78°C)

[0088] (1) Add 1800.0 kg of lactose into RO water (after heat exchange with lactulose hydrogenation solution, temperature 75° C.) to prepare an aqueous solution of lactose with a mass percent concentration of 57.5% (i.e. lactose refraction), with a lactose content of 99.0%. Sodium carbonate aqueous solution (30%) adjusts the pH to 7.9, adds a Raney nickel catalyst with a lactose mass of 3.5%, sets the hydrogenation temperature to 110°C, and the hydrogen pressure to 8.0MPa, reacts for 2.5 hours, and discharges the material to a sinker to obtain a lactose hydrogenation solution .

[0089] (2) The lactitol hydrogenated solution was settled in the first settling tank for 2 hours, the upper layer hydrogenated solution was put into the second settling tank, and settled for 1.5 hours again to obtain the lactitol hydrogenated solution; the index of the lactitol solution is: lactitol purity 98.6% , lactitol refraction 57.0%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com