Control method of supercharged gas water heater and gas water heater

A technology of a gas water heater and a control method, which is applied to the control field of gas water heaters and pressurized gas water heaters, can solve the problems of affecting the hot water output speed of users' bathing experience, the gas water heater cannot be started normally, the gas water heater cannot work normally, etc. Intake pressure and stability, improve bathing experience, and improve user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

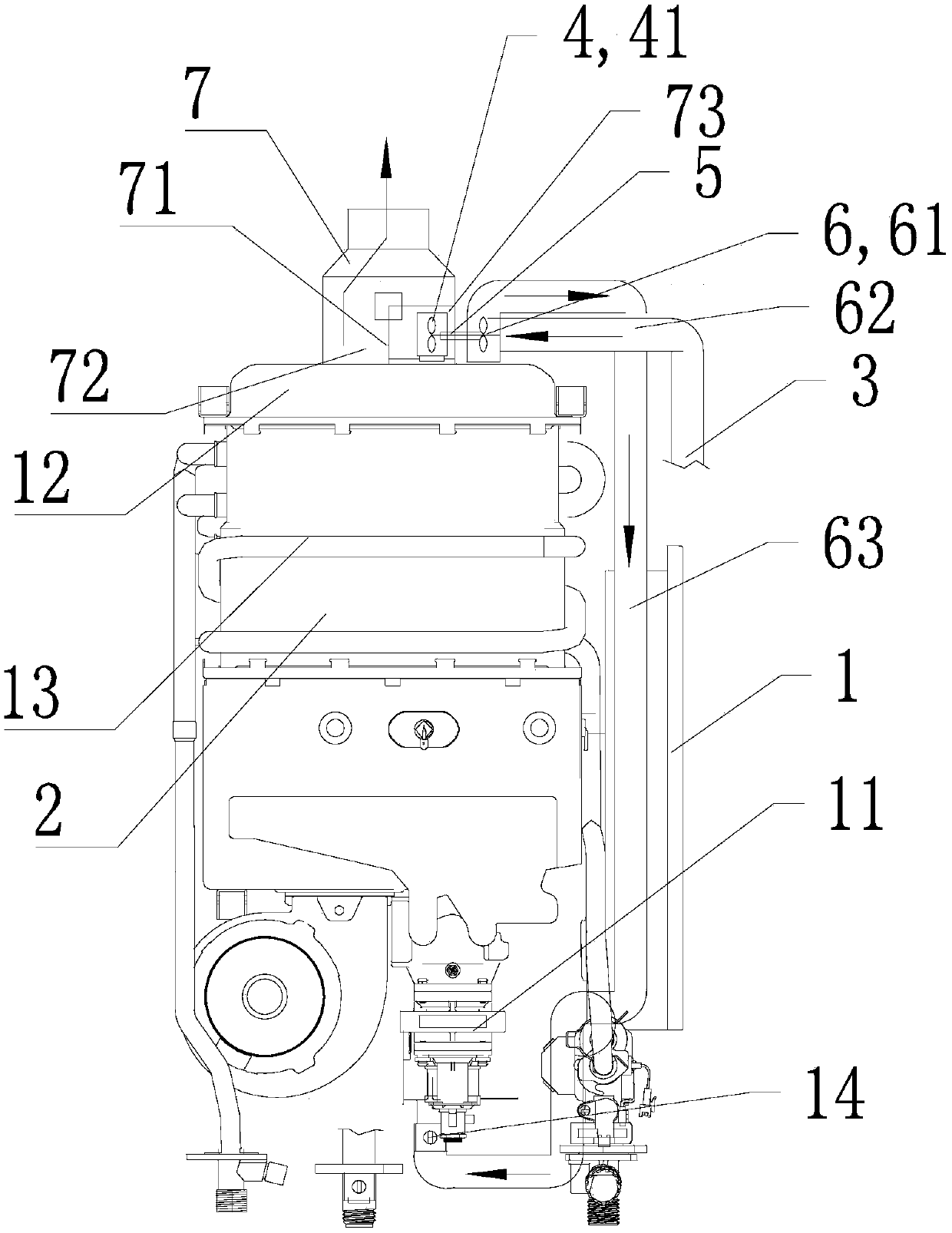

[0041] Such as figure 1 As shown, this embodiment provides a pressurized gas water heater, including a combustion chamber 2 and a gas intake pipeline 3, the gas intake pipeline 3 is connected to the combustion chamber 2, and the gas enters the combustion chamber 2 for combustion, and the combustion chamber 2 is provided with Exhaust gas discharge pipeline 7, a turbine device 4 is arranged in the exhaust gas discharge pipeline 7, a supercharging device 6 is arranged on the gas intake pipeline 3, the turbo device 4 is connected with the supercharging device 6, and the exhaust gas drives the turbine device 4 to rotate , drive the supercharging device 6 to pressurize the gas.

[0042] In this embodiment, the gas water heater with pressurization function includes a heat exchange device 13, a combustion chamber 2, and a gas intake pipeline 3, the gas intake pipeline 3 is connected to the combustion chamber 2, and the gas enters the combustion chamber 2 and burns as a heat exchange d...

Embodiment 2

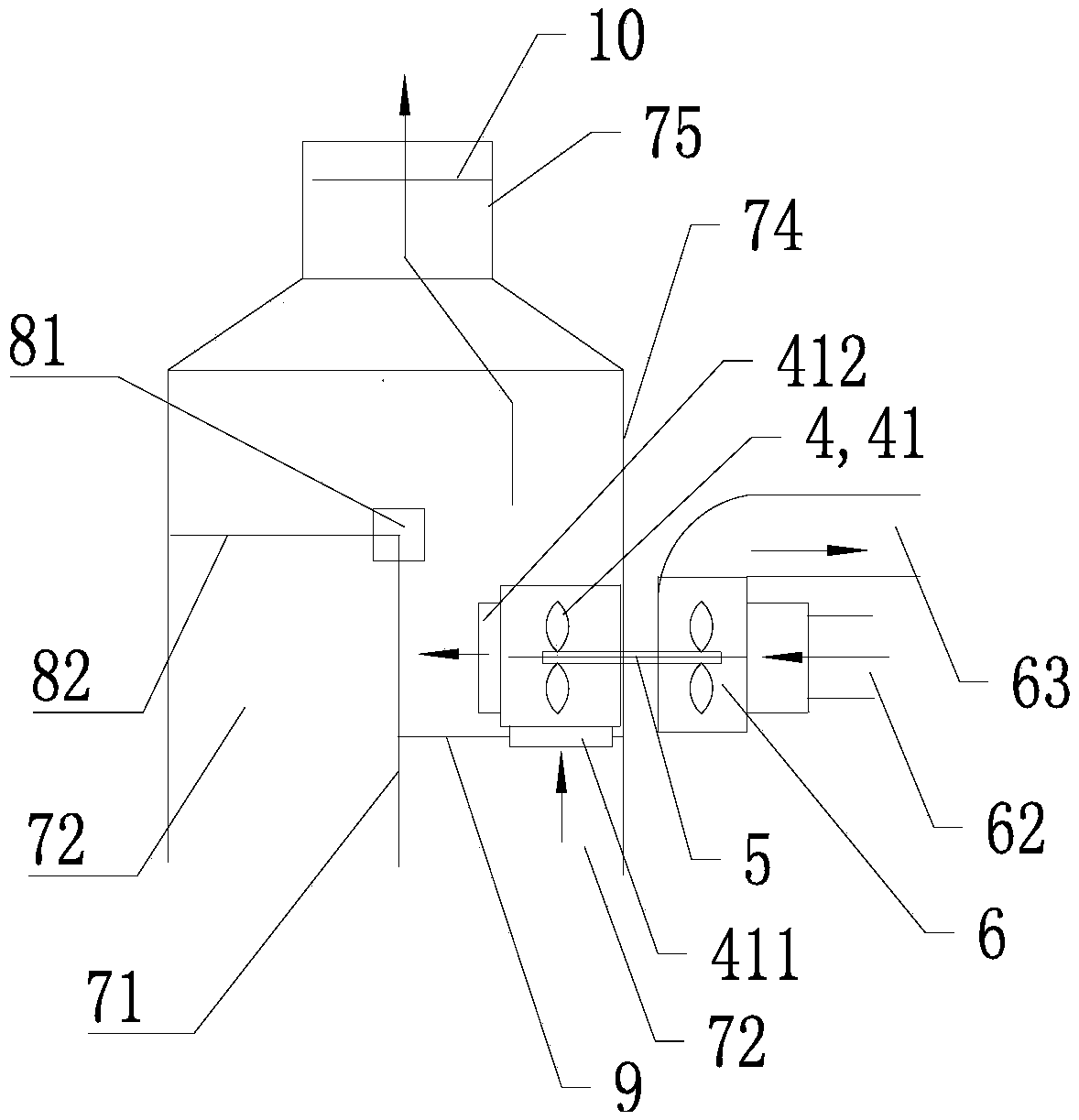

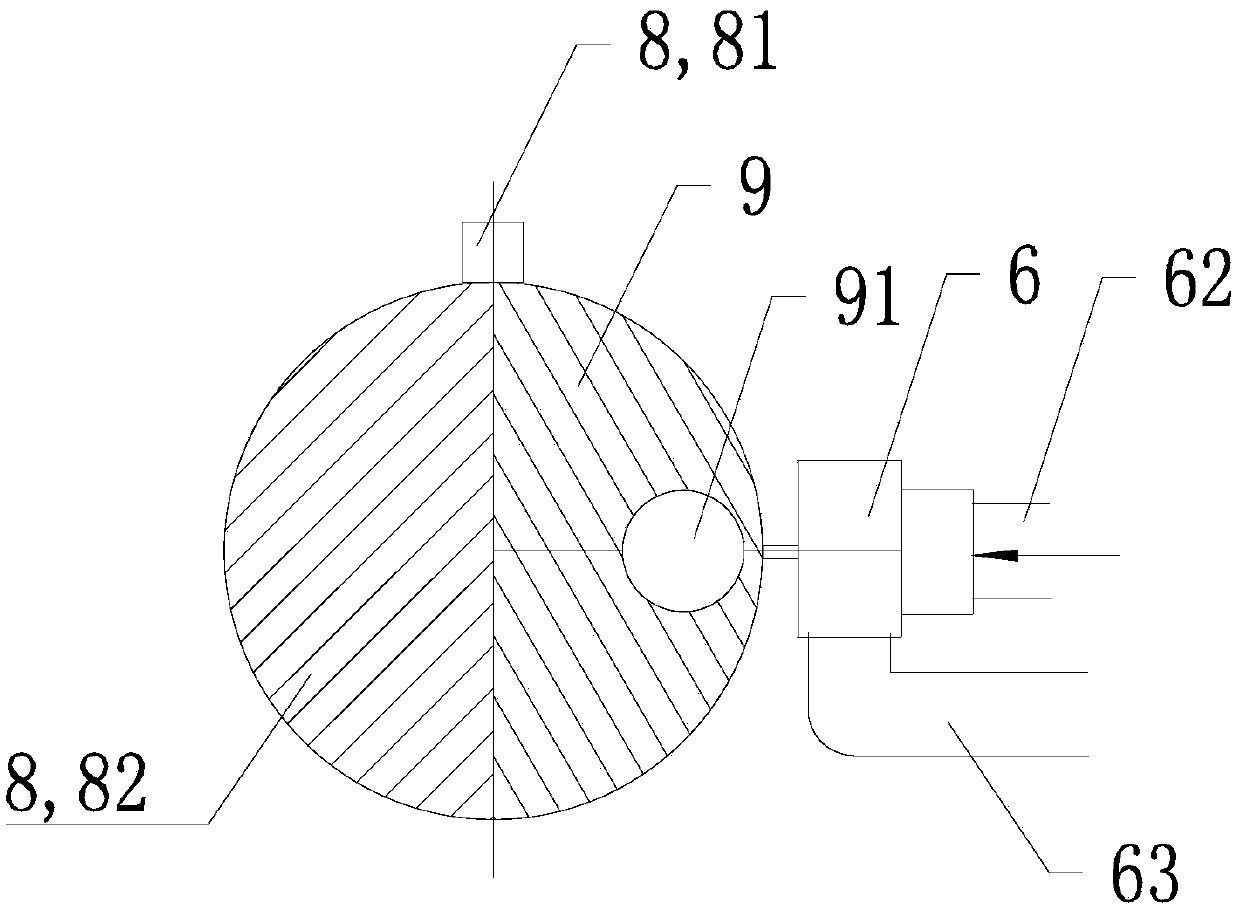

[0073] Such as figure 2 with image 3 As shown, this embodiment is a further solution of Embodiment 1. The turbine device 4 of this embodiment is located in the second discharge chamber 73. The turbine device 4 includes a turbine 41, and an exhaust gas inlet 411 and an exhaust gas outlet 412 are also arranged on it; The side of the turbine device 4 close to the combustion chamber 2 is also provided with a blocking partition 9, the blocking partition 9 and the partition 71 are arranged at a certain angle, and the edge is fixed to the inner wall of the second discharge chamber 73; the blocking partition 9 An opening 91 is provided on the top, and the opening 91 is set correspondingly to the waste gas inlet 411 of the turbine device 4 . In this way, the exhaust gas can be blocked and concentrated to the opening 91 and then enter the turbine device 4, and the exhaust gas passing through the chamber can be utilized to the greatest extent, which is beneficial to control the operat...

Embodiment 3

[0076] Such as Figure 4 As shown, this embodiment is a further limitation of Embodiment 1 or Embodiment 2, and provides a control method for a pressurized gas water heater. The gas water heater includes a combustion chamber 2 and a gas inlet pipeline 3 communicating with it. An exhaust gas discharge pipeline 7 is provided, a turbine device 4 is arranged in the exhaust gas discharge pipeline 7, a booster device 6 and a gas pressure detection device 14 are arranged on the gas intake pipeline 3, and the turbine device 4 and the booster device 6 Connection; the gas water heater controls the exhaust gas flow direction according to the gas pressure value detected by the gas pressure detection device 14, drives / closes the supercharging device 6 through the turbine device 4, and performs / stops supercharging the gas. In this way, the energy of the exhaust gas can be used again to increase the pressure of the intake gas and ensure the stability of the gas intake pressure. It is suitabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com