Control method of pressurizing gas water heater and gas water heater

A technology of a gas water heater and a control method, which is applied in the field of control of gas water heaters and pressurized gas water heaters, and can solve problems affecting the speed of hot water output, users' bathing experience, gas water heaters that cannot work normally, and gas water heaters that cannot start normally. The temperature of the water outlet and the stability of the water outlet improve the bathing experience and facilitate the effect of pressurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

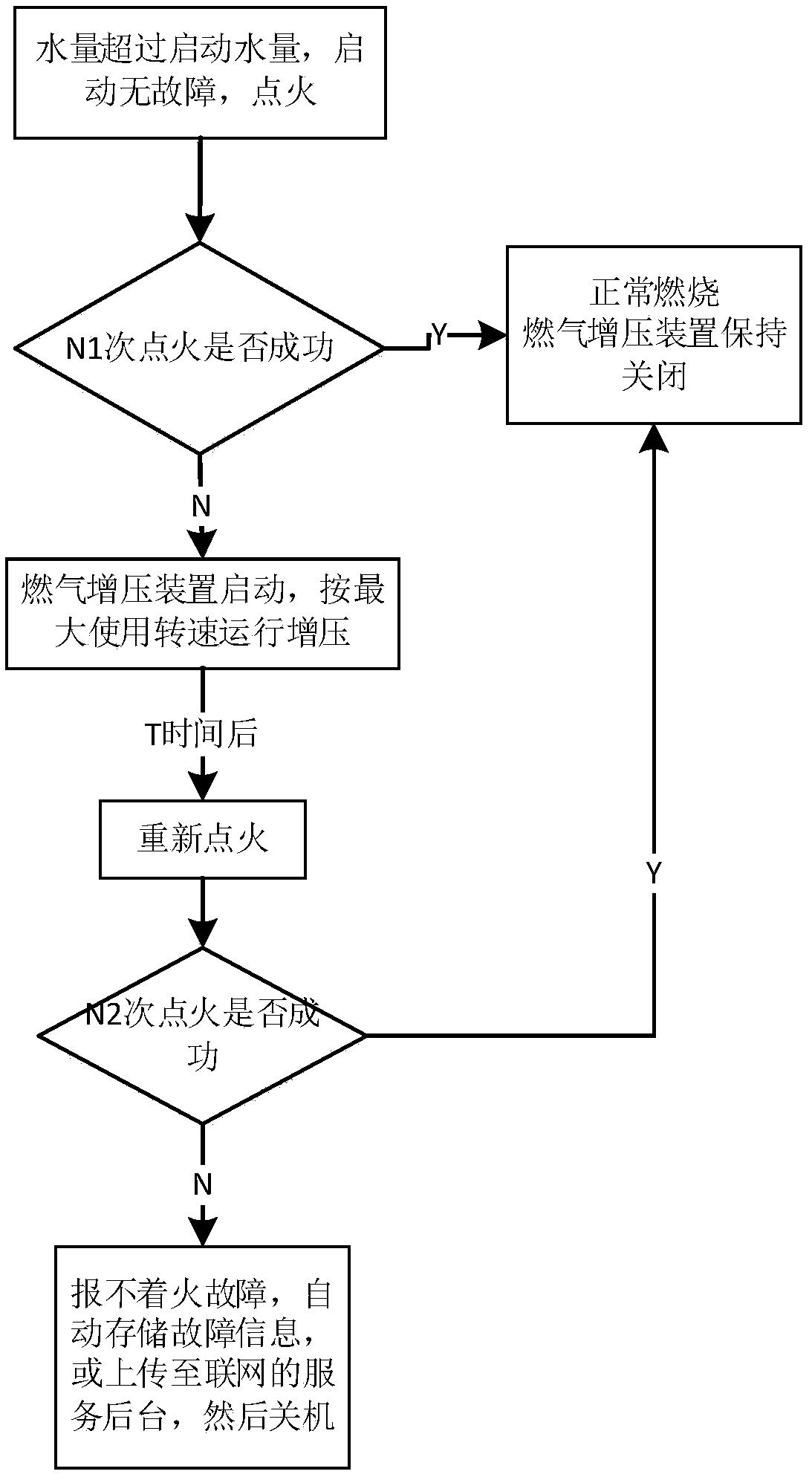

[0038] Such as figure 1 As shown, this embodiment provides a control method for a pressurized gas water heater. The gas water heater includes a gas booster device 4 arranged on the gas intake pipeline 3. After the gas water heater is started, the gas booster device 4 is controlled according to whether the ignition is successful. On / off, pressurization of gas on / off.

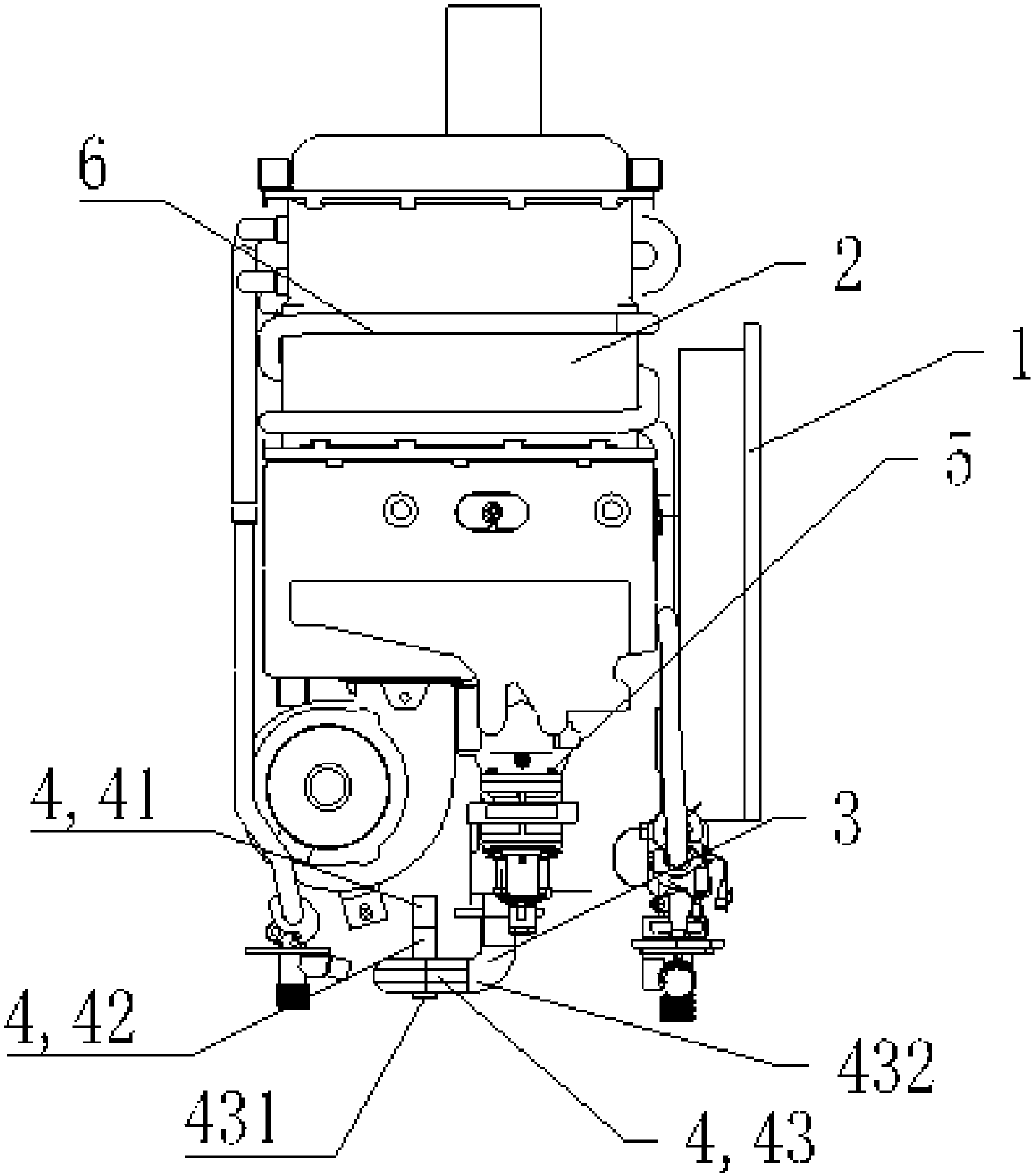

[0039] In this embodiment, the gas water heater with supercharging function includes a heat exchange device, a combustion chamber 2, and a gas intake pipeline 3. The heat source, the water in the heat exchange device flows out from the water outlet after heat exchange, and is used for bathing by users.

[0040] The gas intake pipeline 3 is provided with a gas booster 4, which can boost the gas. The gas pressurizing device 4 may include various types, and it only needs to be able to pressurize the gas in the gas intake pipeline 3 . For example, the motor 41 may drive a supercharging device, or may be a turbocha...

Embodiment 2

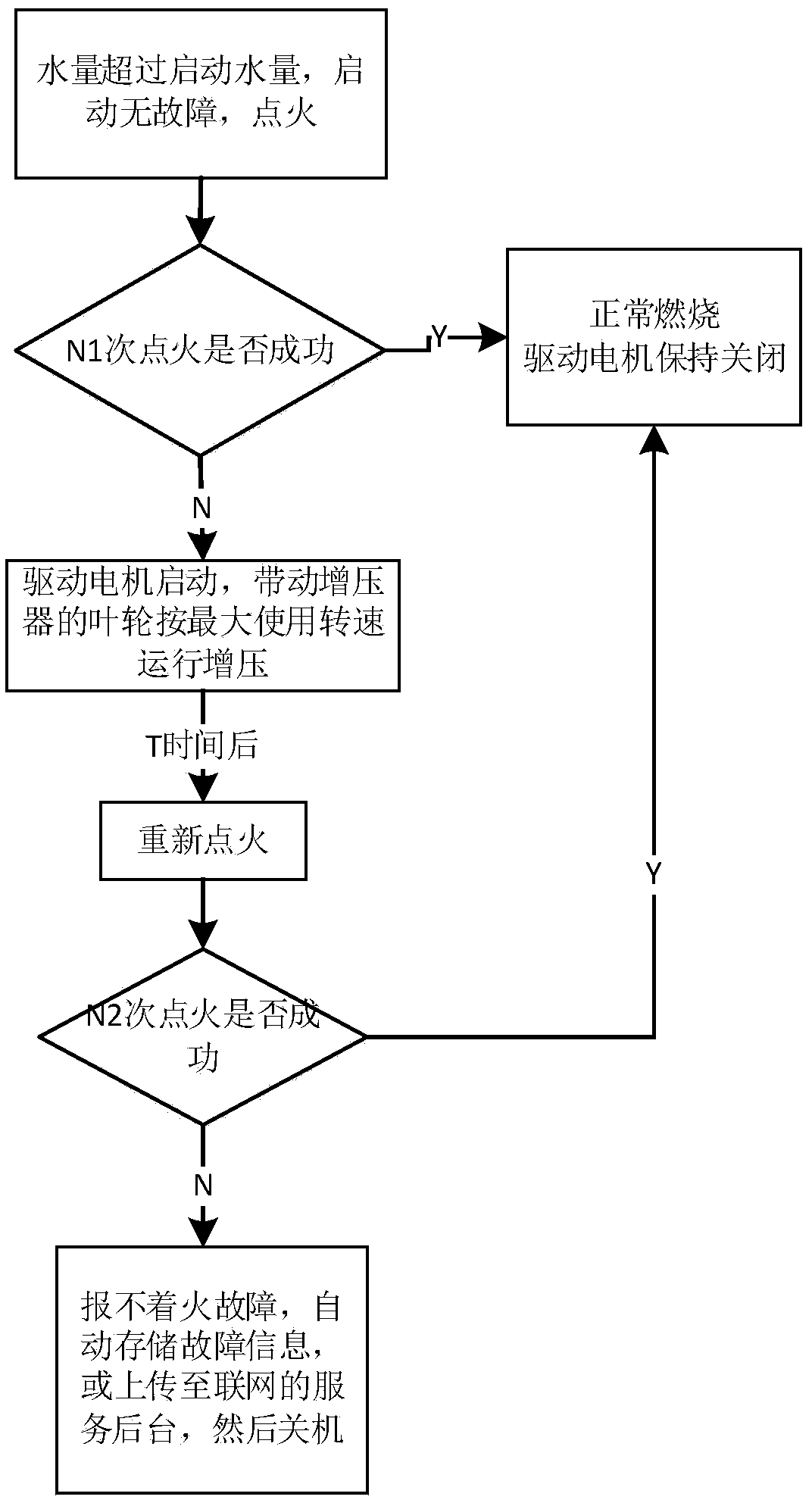

[0060] This embodiment is a further limitation of Embodiment 1. The pressurized gas water heater of this embodiment includes a control device 1, a heat exchange device, a combustion chamber 2 and a gas intake pipeline 3, and the gas intake pipeline 3 is connected to the combustion chamber 2. Gas enters the combustion chamber 2 and burns to provide a heat source for the heat exchange device. The gas intake pipeline 3 is provided with an electrically driven gas booster 4 , and the electrically driven gas booster 4 is electrically connected to the control device 1 .

[0061] In this solution, the electric-driven gas booster device 4 is adopted, and the control device 1 can conveniently control the opening, closing, driving parameters, etc. of the electric-driven gas booster device 4, control the boosting effect on the gas, and keep the gas pressure at a relative Within a stable pressure range, the gas water heater can be guaranteed to burn efficiently.

[0062] In a further solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com