Gasoline supercharged engine exhaust gas recirculation system device

A technology of supercharged engine and recirculation system, which is applied in the direction of exhaust gas recirculation, engine components, machine/engine, etc., which can solve the problem that the working condition range of the EGR system becomes smaller, the adjustment response time of the EGR valve is long, and it is disadvantageous to accurately control the amount of exhaust gas circulation. and other problems to achieve the effect of short adjustment response time, small size and short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

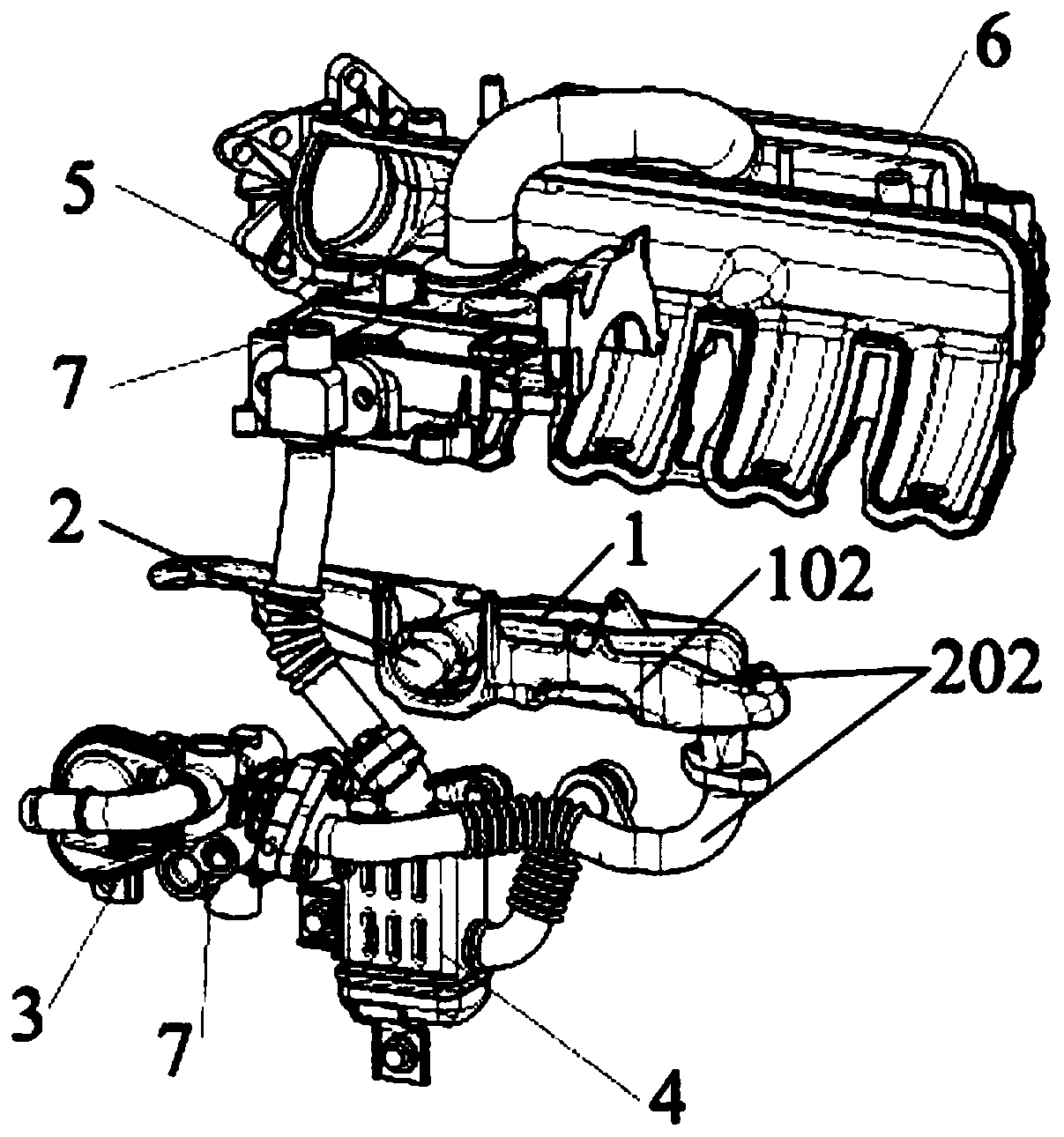

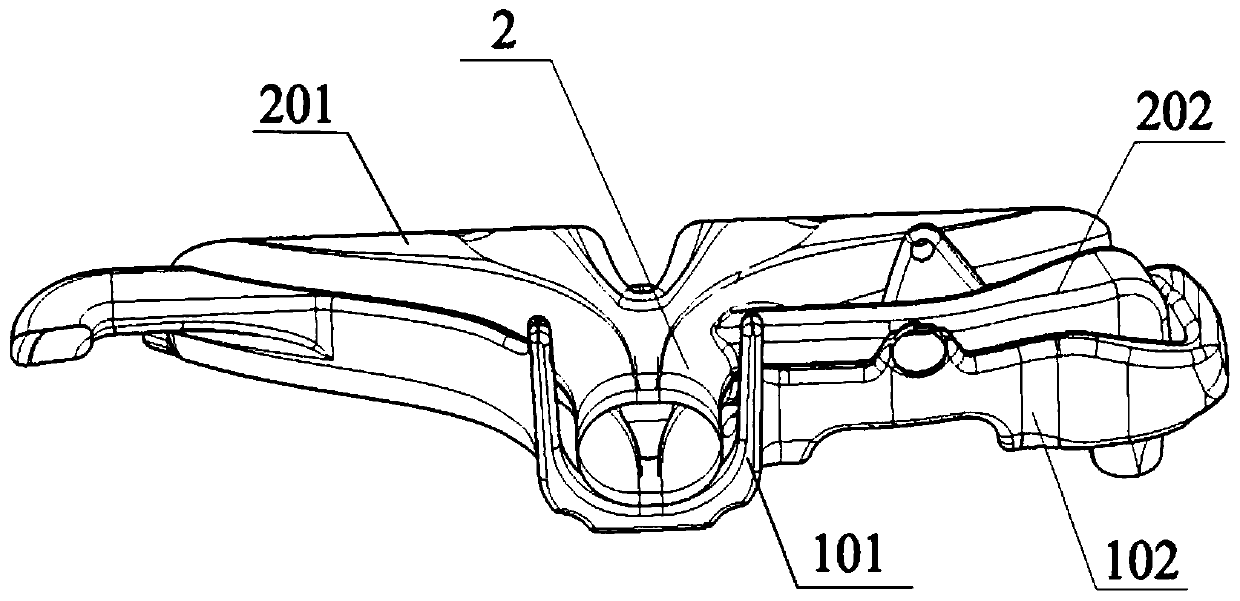

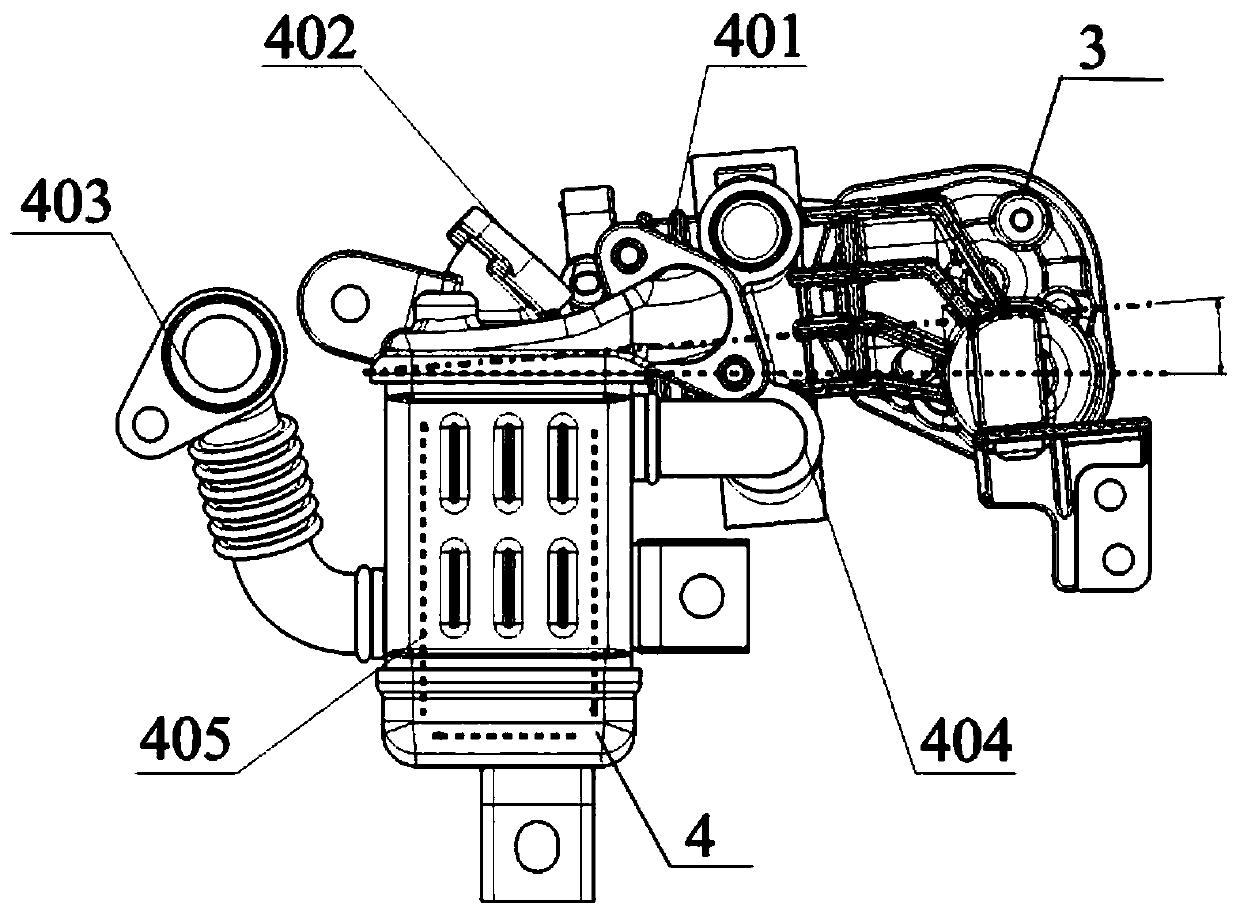

[0029] Such as Figure 1-7 As shown, a gasoline supercharged engine exhaust gas recirculation system device includes a cylinder head 1, the exhaust side of the cylinder head 1 is provided with an exhaust manifold 2, and the intake side is provided with an intake manifold 6, and the exhaust manifold 2 is connected to the The supercharging system is connected, and the exhaust main pipe 2 is bypassed by an EGR intake pipe 202, and the other end of the EGR intake pipe 202 is connected to the EGR valve, the EGR cooler and the intake main pipe 6 in sequence; the exhaust main pipe 2 is connected to the cylinder head 1 side simultaneously. An exhaust manifold 201, the cylinder head 1 is also provided with an exhaust side water jacket 101, the cross section of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com