Drill kind electric tool

A technology of electric tools and working heads, which is applied in the direction of manufacturing tools, portable drilling rigs, portable mobile devices, etc., can solve the problems of unspecified drilling electric tools, etc., and achieve the effect of improving efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

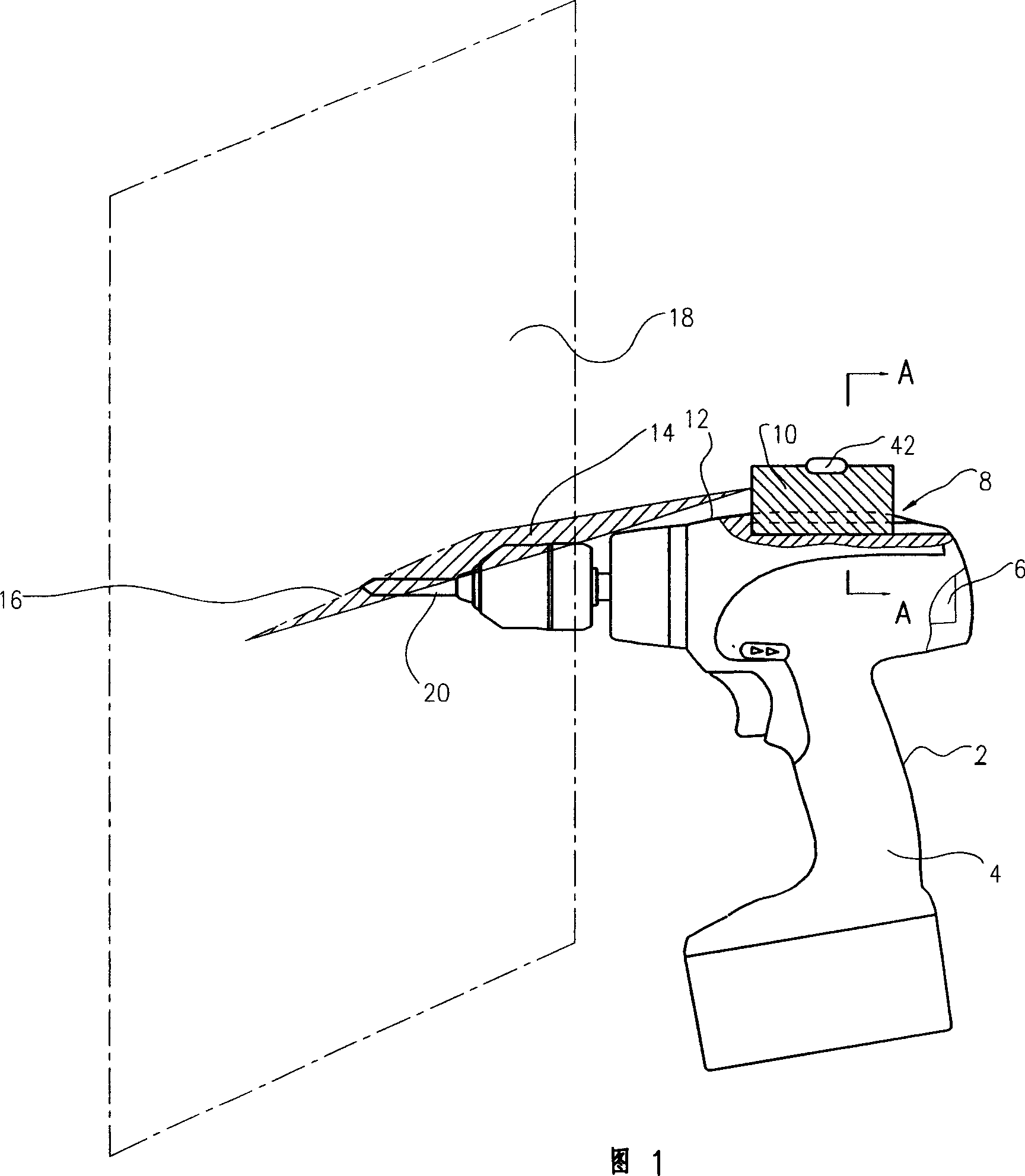

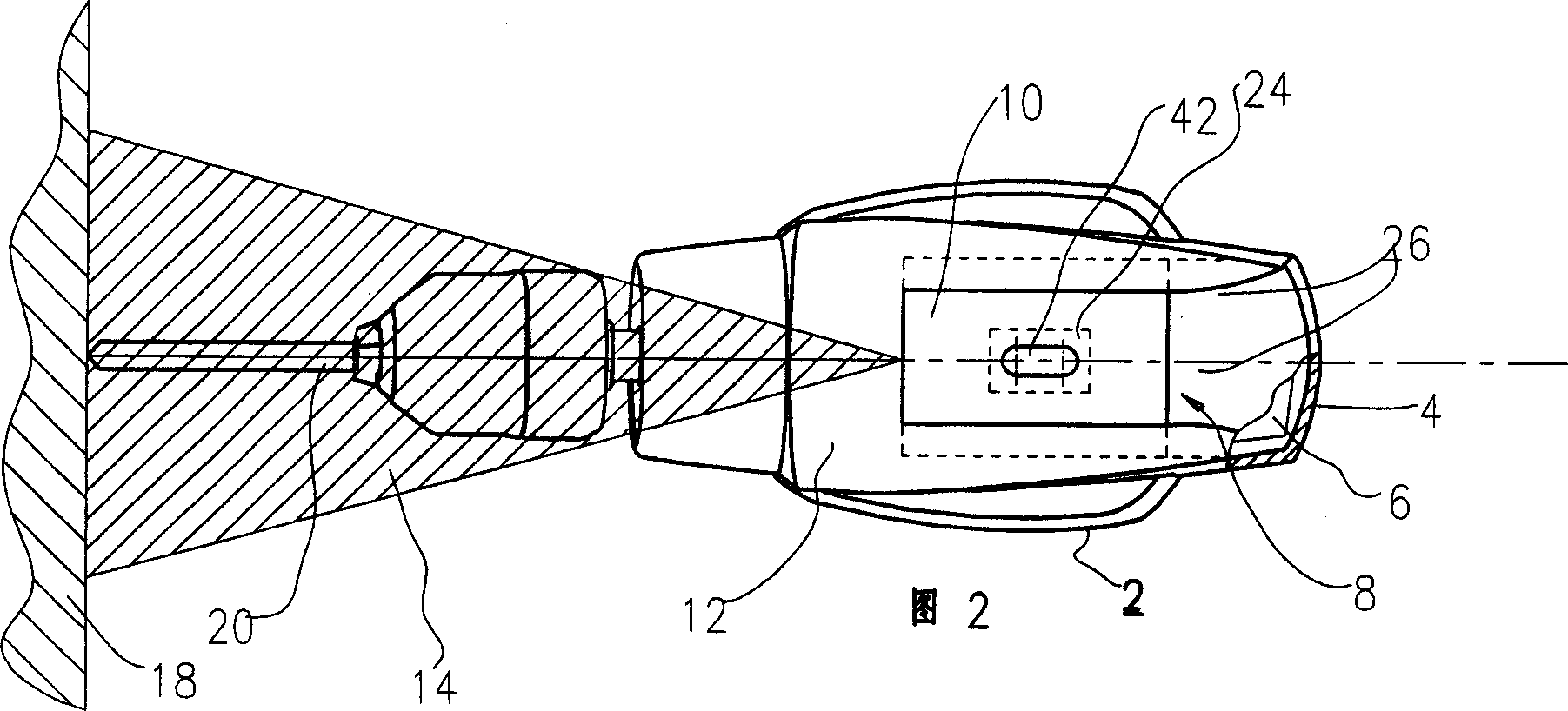

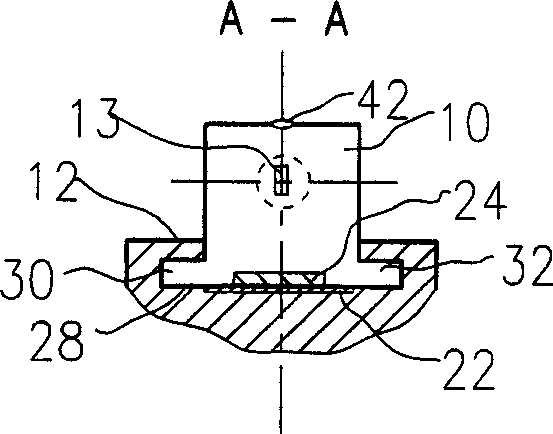

[0023] Please refer to Figure 1 to image 3 , an electric drill 2, comprising a housing 4, a motor 6 accommodated in the housing 4, a laser level 10 operable to emit a laser 14, a connecting device 8, the connecting device 8 connects the laser level 10 is connected to the housing 4 and the connection device 8 is arranged on the top shell 12 of the housing 4 .

[0024] A working head 20 is installed on the chuck at the front end of the drill, such as the traditionally used chuck of the current electric drill, the chuck can be keyless, or a chuck that requires a corresponding key.

[0025] When the laser level 10 is in the open state, when the laser tube (not marked) on the laser level is projected from the mouth 13 to guide the surface of the workpiece, a mark can be formed on the work surface. The marks formed are just aligned with the frontmost end of the working head 20, thus providing clear marks of alignment and instructions for the operator.

[0026] In a preferred embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com