Gas-liquid mixing device

A gas-liquid mixing and mixing chamber technology, which is applied in the fields of hydrocarbon oil cracking, petroleum industry, chemical instruments and methods, etc. Thermal efficiency, saving investment, easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

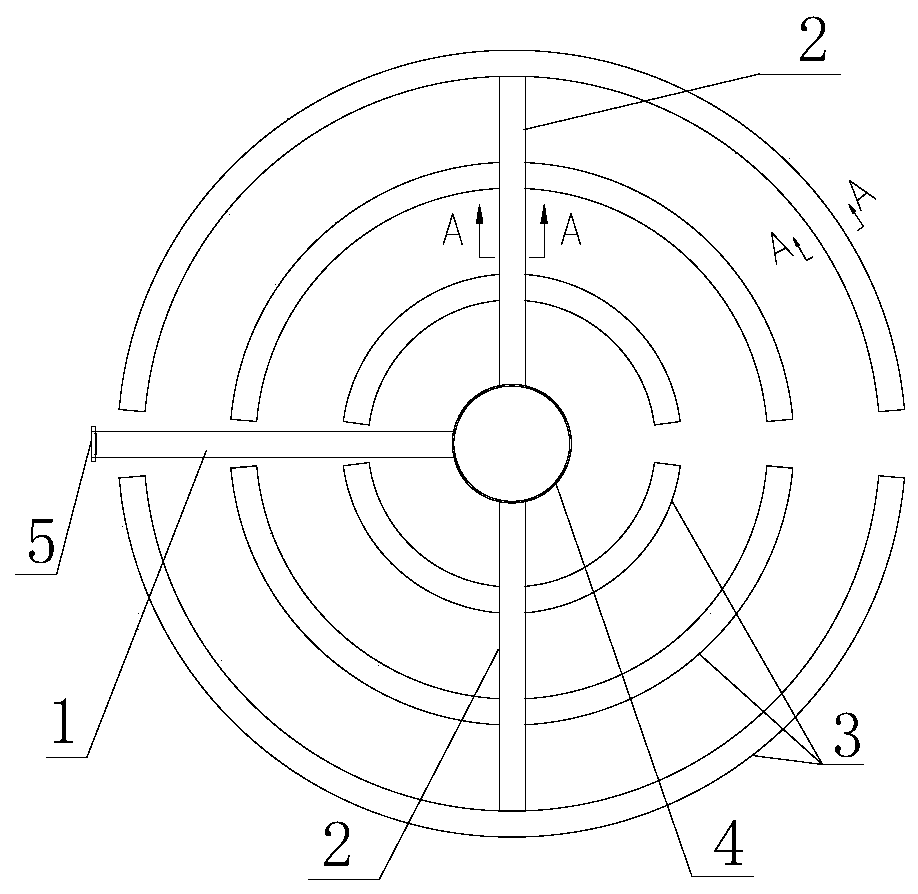

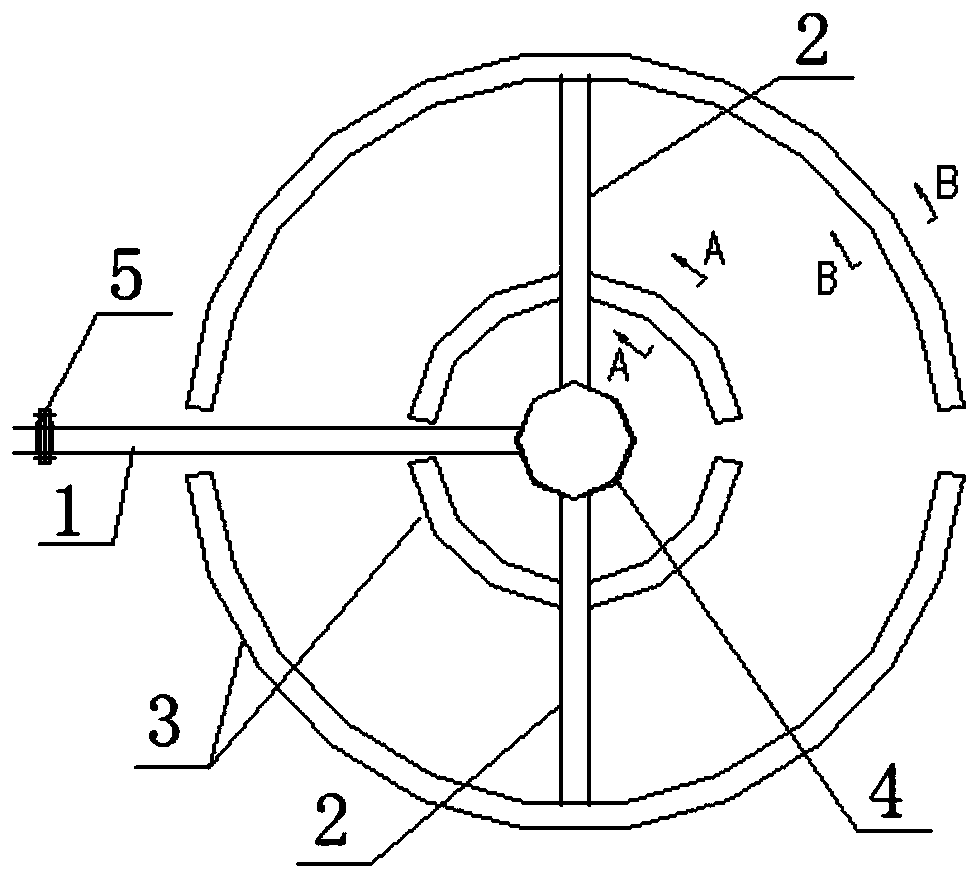

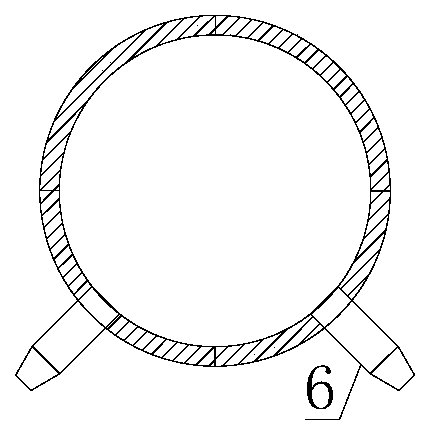

[0037] Such as Figure 1~5 As shown, the cold hydrogen distributor of the present invention includes an inlet pipe 1, a distribution ring pipe 3, a distribution straight pipe 2, a nozzle 6 and a mixing chamber 4, and the inlet pipe 1, the distribution ring pipe 3, the distribution straight pipe 2 and the mixing chamber 4 are all Located in the same plane; the distribution ring pipe 3 is in the shape of a semicircular arc with both ends closed, and is distributed concentrically with the mixing chamber 4 as the center; the mixing chamber 4 is a cylindrical body with an open upper end and a closed bottom; the distribution straight pipe 2 and the distribution The ring pipe 3 intersects and runs through, one end of the distribution straight pipe 2 communicates with the side wall of the mixing chamber 4, and the other end communicates with the distribution ring pipe 3; the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com