Patents

Literature

116results about How to "Control air volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Extractor hood

ActiveCN103328897AControl air volumeDomestic stoves or rangesLighting and heating apparatusAir volumeEngineering

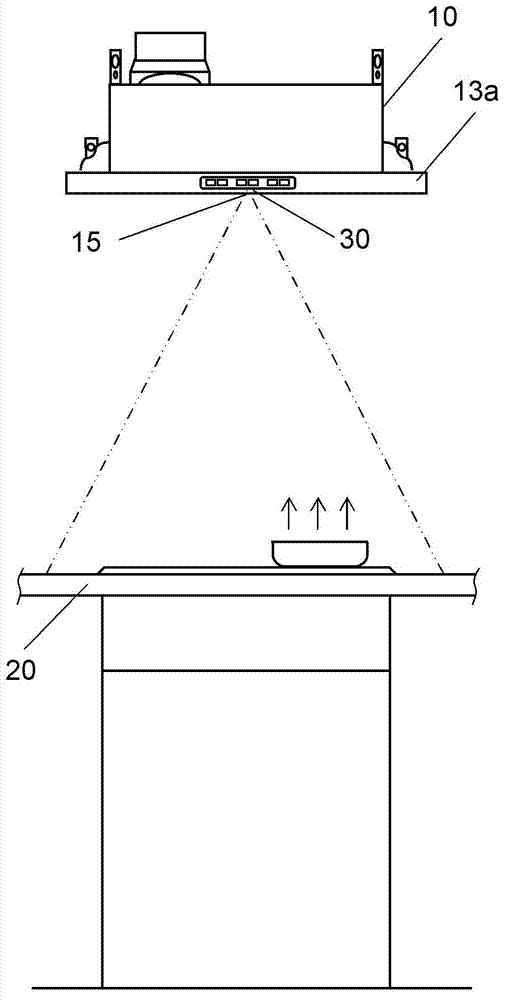

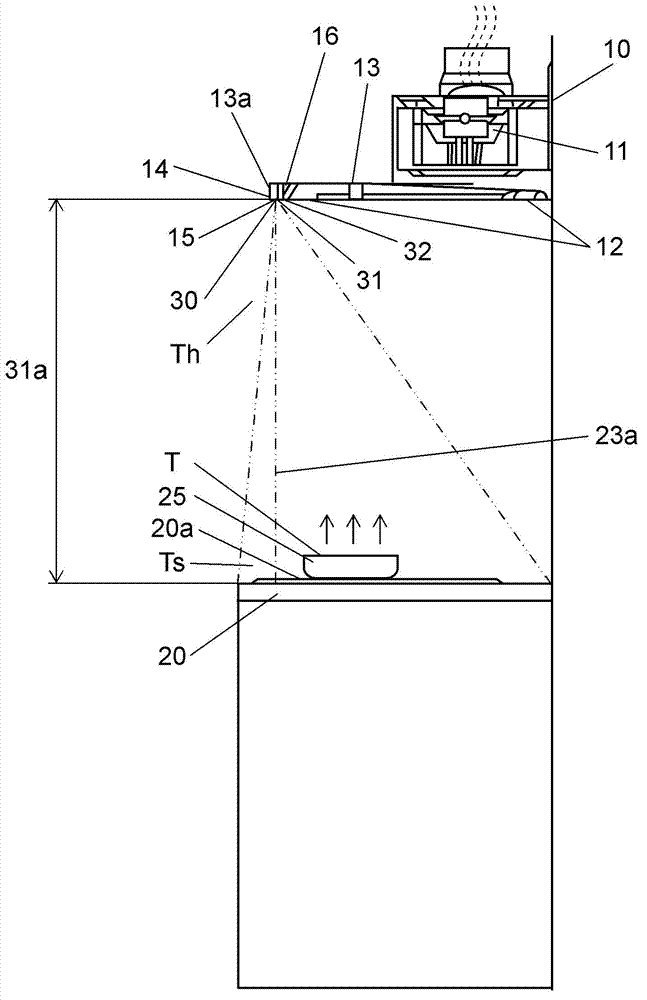

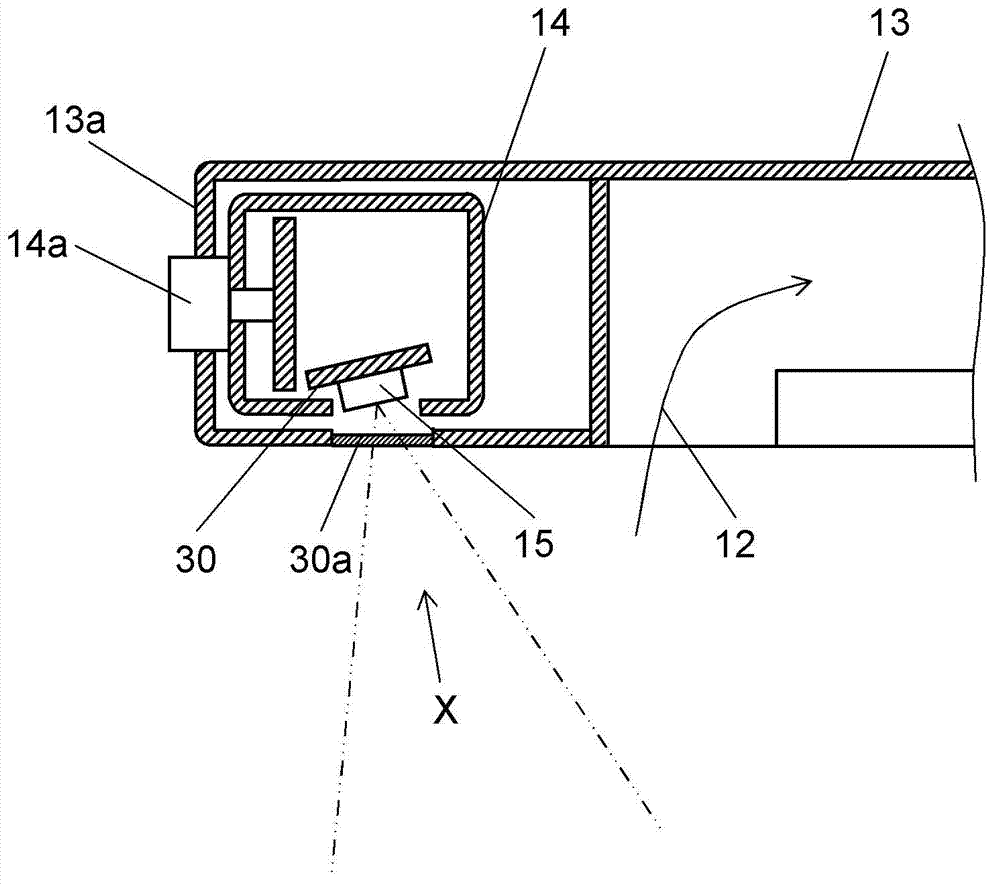

An extractor hood that alters the volume of air from a fan in accordance with the temperature of the food being cooked in a cooker, and that is provided with: an infrared sensor for detecting an average temperature from the temperature of the food being cooked and the ambient temperature of the food being cooked; a temperature sensor for detecting the ambient temperature of the cooker; a signal reception unit; and an air volume control unit. In the air volume control unit, the temperature of the food being cooked is calculated from the average temperature using the ambient temperature of the cooker as the ambient temperature of the food being cooked, and the volume of air from the fan is determined using a cooker signal and the temperature of the food being cooked.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

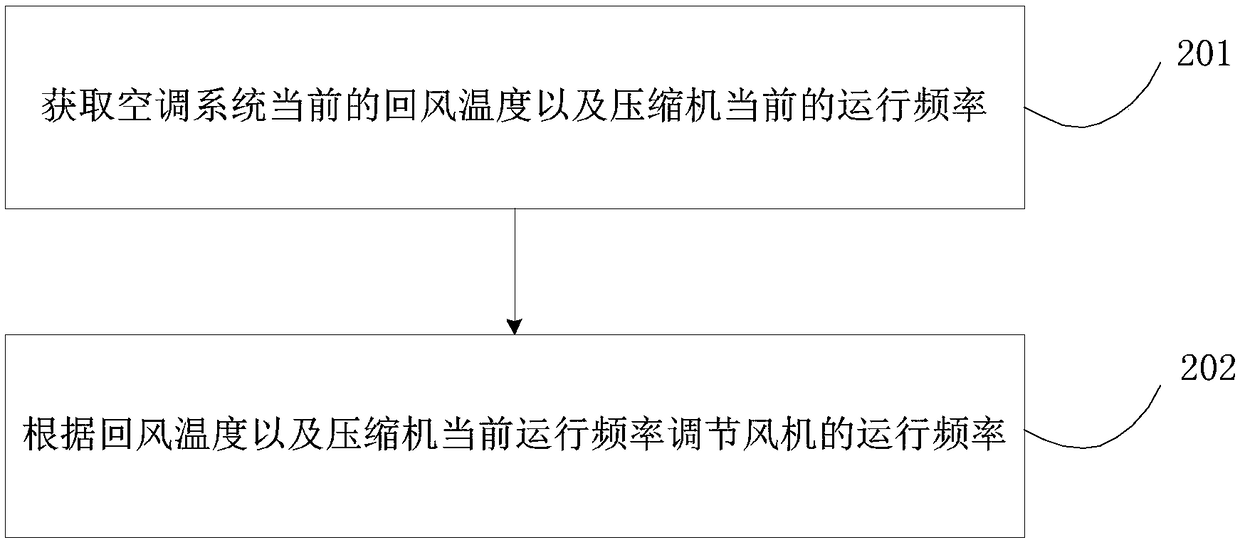

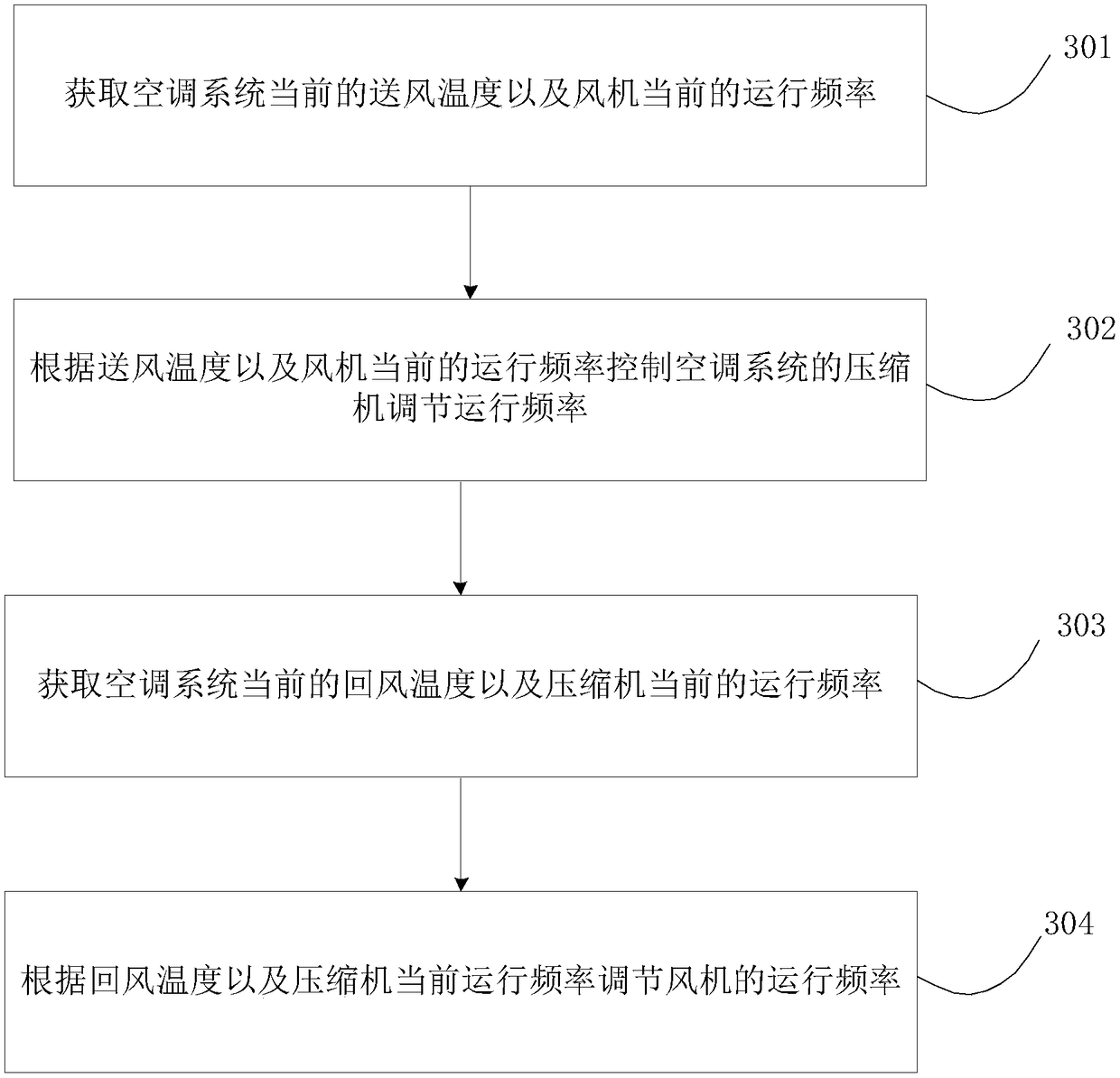

Air conditioning system control method and device

ActiveCN108375175AControl air volumeReasonable air volumeProgramme controlMechanical apparatusAir conditioningAir temperature

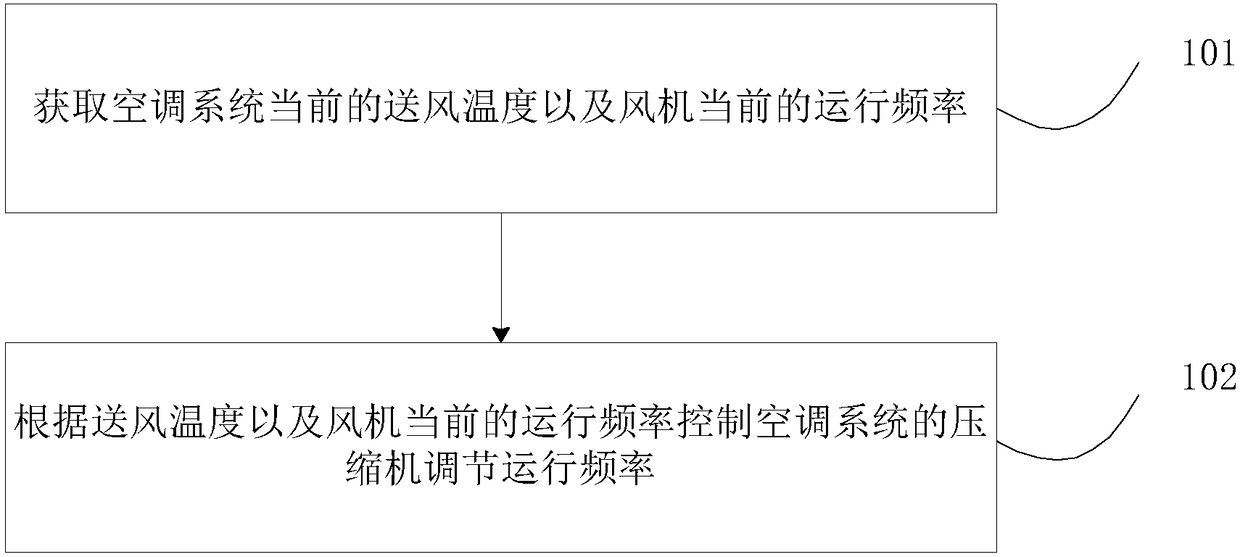

The invention discloses an air conditioning system control method and device in order to solve the problem of the related art that air supply quantity of the air conditioning system cannot be effectively controlled. The air conditioning system control method includes: acquiring current air supply temperature of the air conditioning system and current operating frequency of a fan, controlling a compressor of the air conditioning system to adjust operating frequency according to the air supply temperature and the current operating frequency of the fan; and / or, acquiring current return air temperature of the air conditioning system and current operating frequency of the compressor, and adjusting operating frequency of the fan according to the return air temperature and the current operating frequency of the compressor. The air conditioning system control method and device allows air supply quantity of an air conditioning system to be effectively controlled, thereby improving user experience.

Owner:GREE ELECTRIC APPLIANCES INC

Gas mixture ratio control apparatus and method implementing low-nitrogen combustion by oxygen-deficient CO2-rich gas

InactiveCN104501203AControl air volumeIndirect carbon-dioxide mitigationBlast-producing apparatusAir preheaterLow nitrogen

The invention provides a gas mixture ratio control apparatus and method implementing low-nitrogen combustion by oxygen-deficient CO2-rich gas. The apparatus comprises an air preheater, a mixed gas tank, a blower, a boiler flue gas reflow pipe, a fresh air pipe and a blower air pipe; one end of a flue gas incoming chamber of the air preheater is communicated with a flue gas outlet of a boiler and communicated with the mixed gas tank through the boiler flue gas reflow pipe; a fresh air outlet of the fresh air preheater is communicated with the mixed gas tank through the fresh air pipe; the mixed gas tank is communicated with an air inlet of the blower; the blower is communicated with a primary air chamber inlet of the boiler. The blower extracts boiler flue gas and fresh air through the boiler flue gas reflow pipe and the fresh air pipe, respectively; the boiler flue gas and the fresh air are mixed well in the mixed gas tank; mixed gas is blown into the boiler by the blower; various gases engage in oxidation-reduction reactions in a hearth of the boiler; thus, oxygen nitride is eliminated or largely decreased.

Owner:深圳市山水乐环保科技有限公司

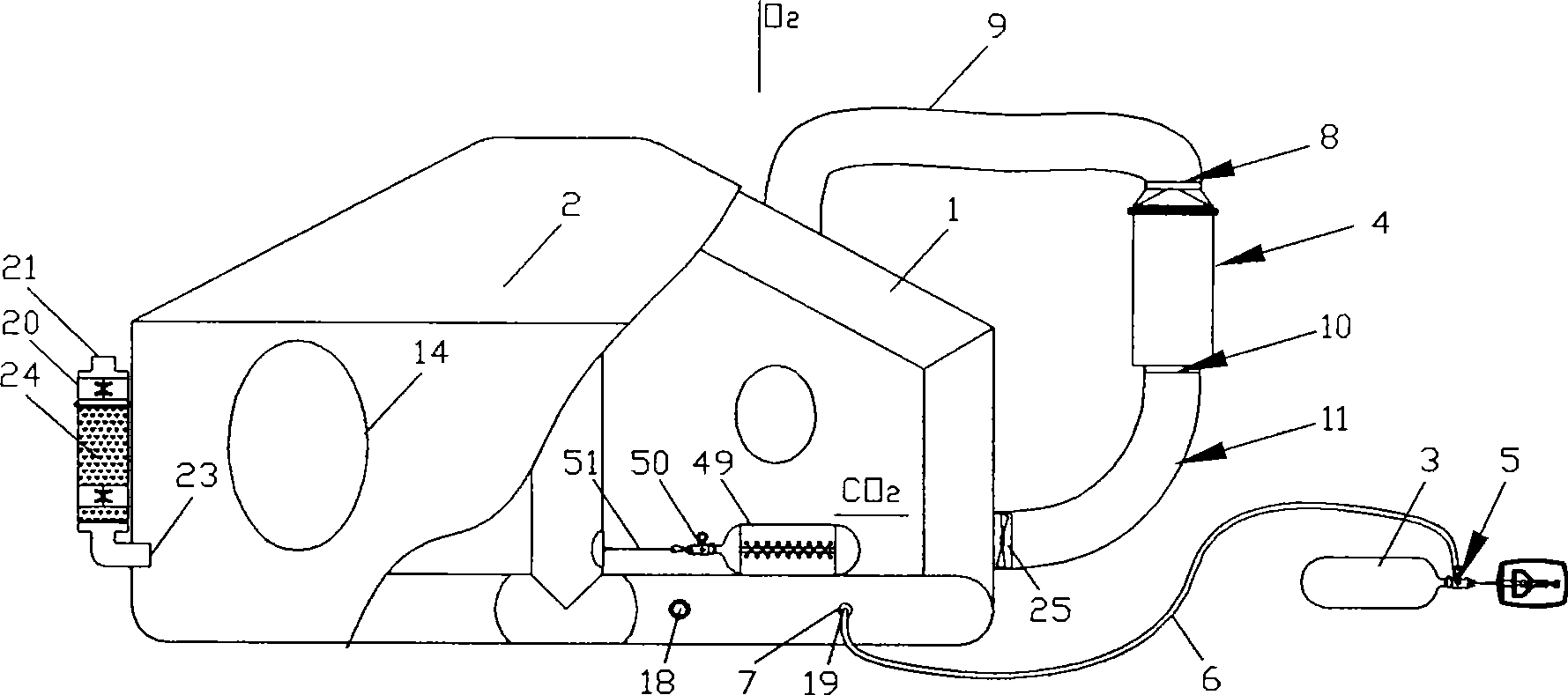

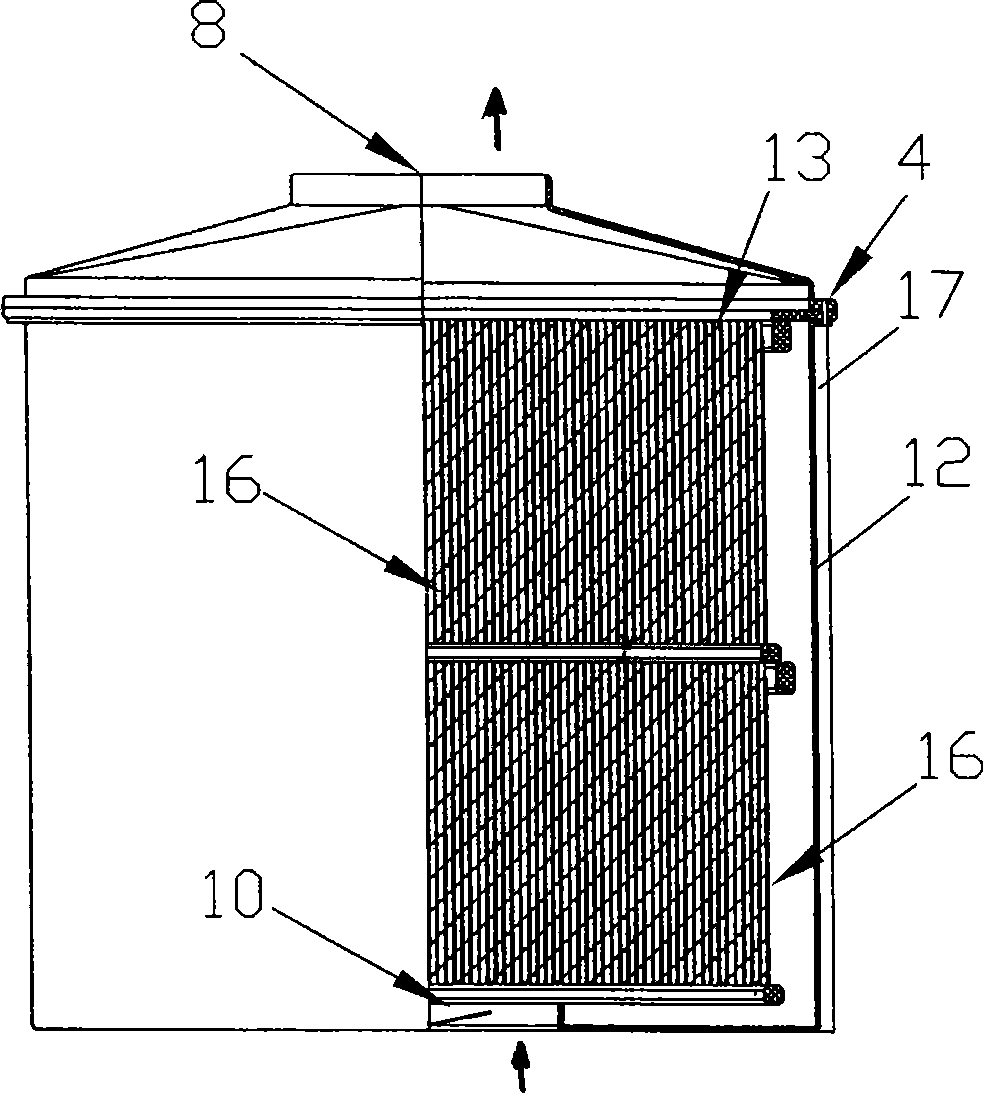

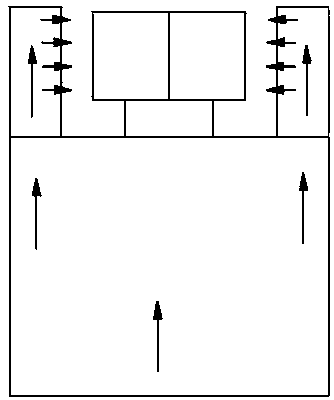

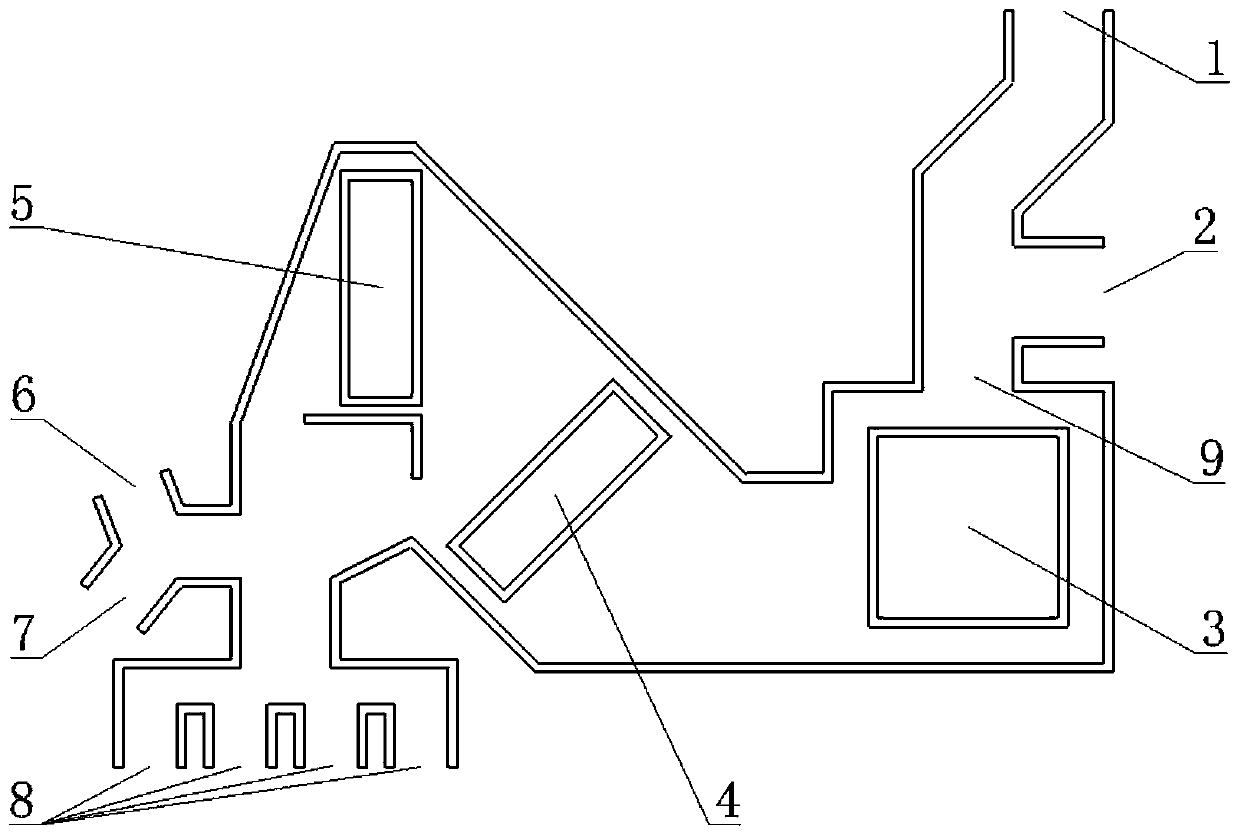

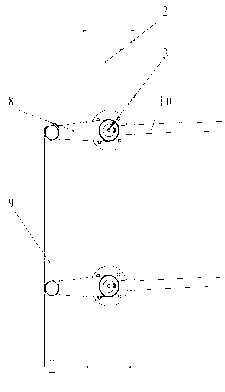

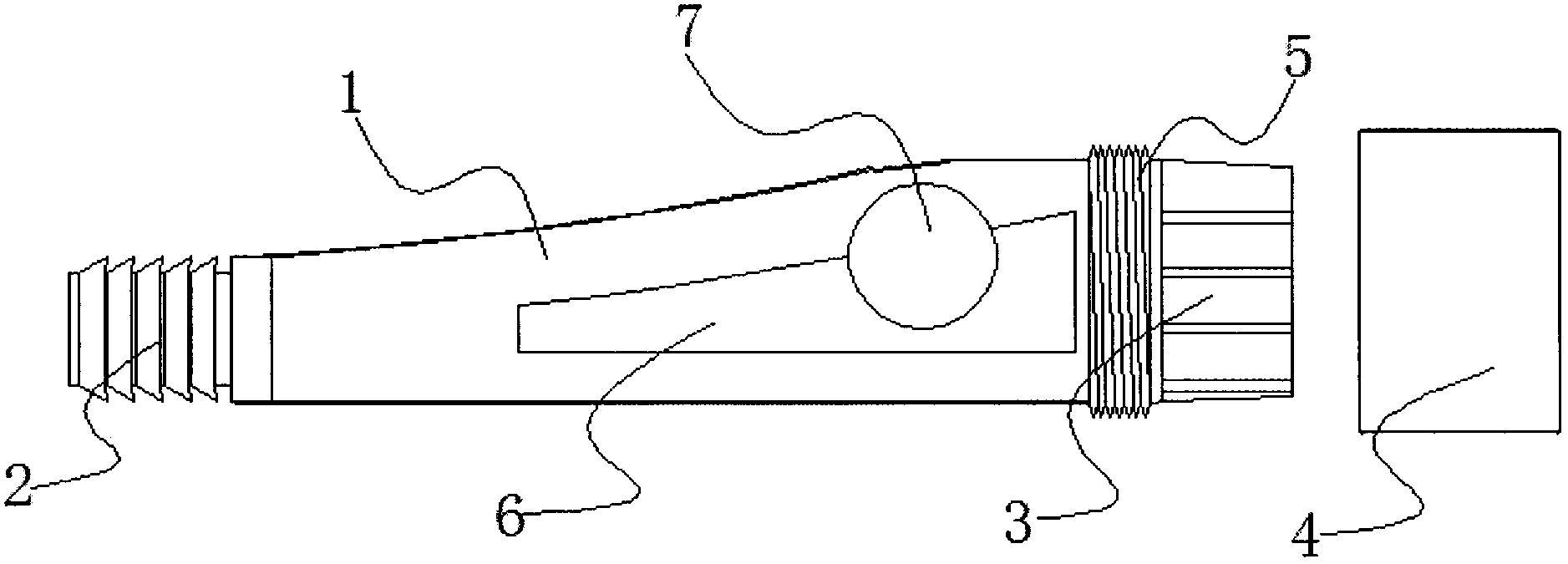

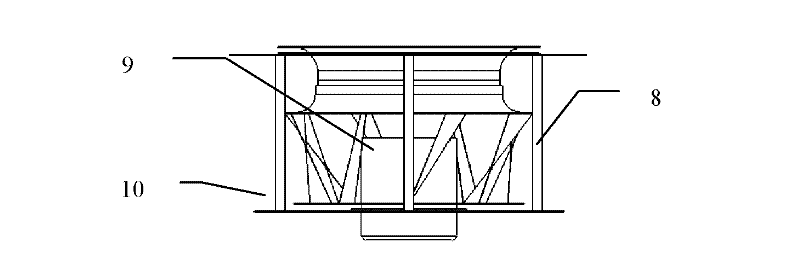

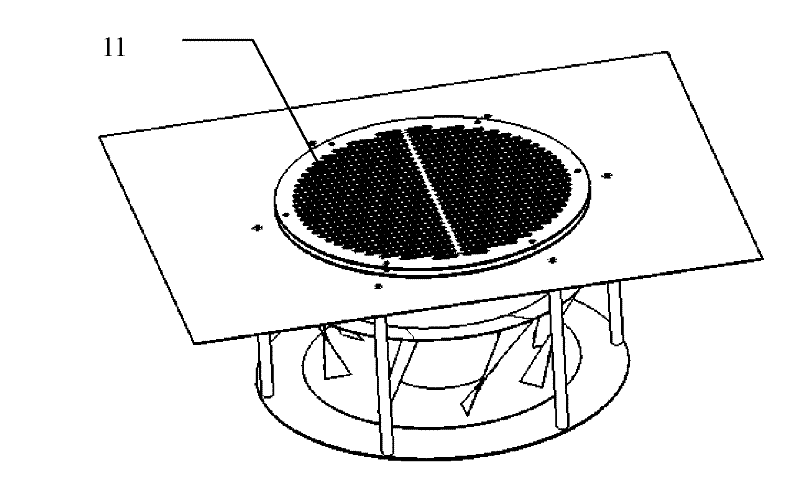

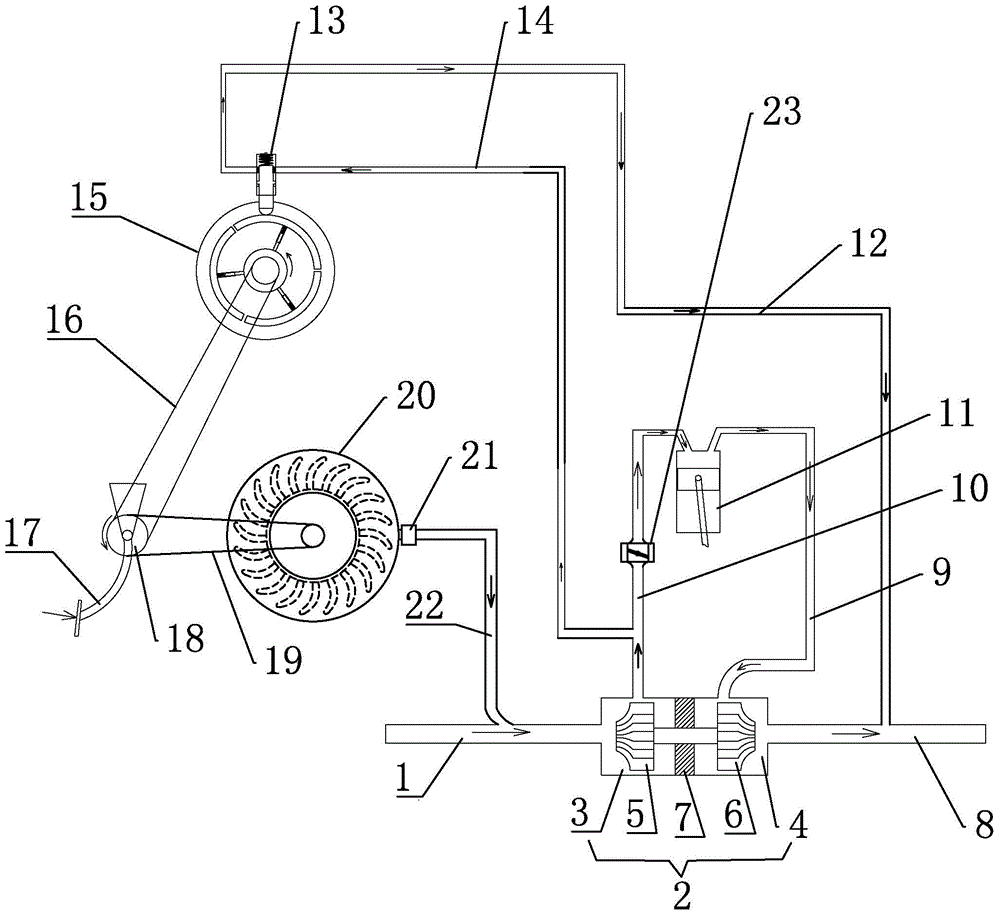

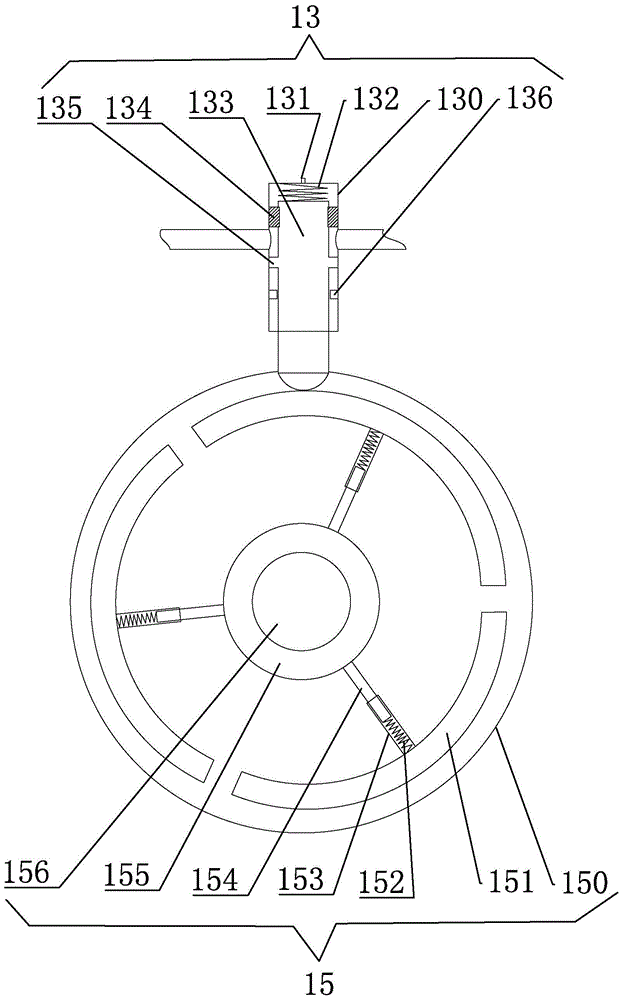

Isolation type refuge warehouse

The invention belongs to the field of refuge and lifesaving equipment in the underground mining industry, and in particular relates to an isolated refuge cabin for a mine, which comprises a supporting air bag (1), a wall body (2) assembled outside the supporting air bag (1), a respiration supply body (4) and an air charging device (3). An air charging outlet (5) of the air charging device (3) is connected with an air charging inlet (7) of the supporting air bag (1) through an air delivery pipe (6); an air suction opening (8) of the respiration supply body (4) is communicated with an inner cavity of the wall body (2) through an air suction pipe (9); an air outlet (10) of the respiration supply body (4) is communicated with the lower part of the inner cavity of the wall body (2) through an air discharging pipe (11); the respiration supply body (4) comprises a shell (12) and an oxygen preparation agent (13) filled in the shell (12); and the wall body (2) is provided with an escape door (14 ). The operation is secure and convenient. The isolated refuge cabin has safe and convenient operation, and can effectively isolate the external environment of the stricken area when the disaster occurs in the mine, and the refuge chamber satisfies the corresponding living conditions for human body.

Owner:SHANGHAI PENGYAN MINING SAFETY EQUIP MFG

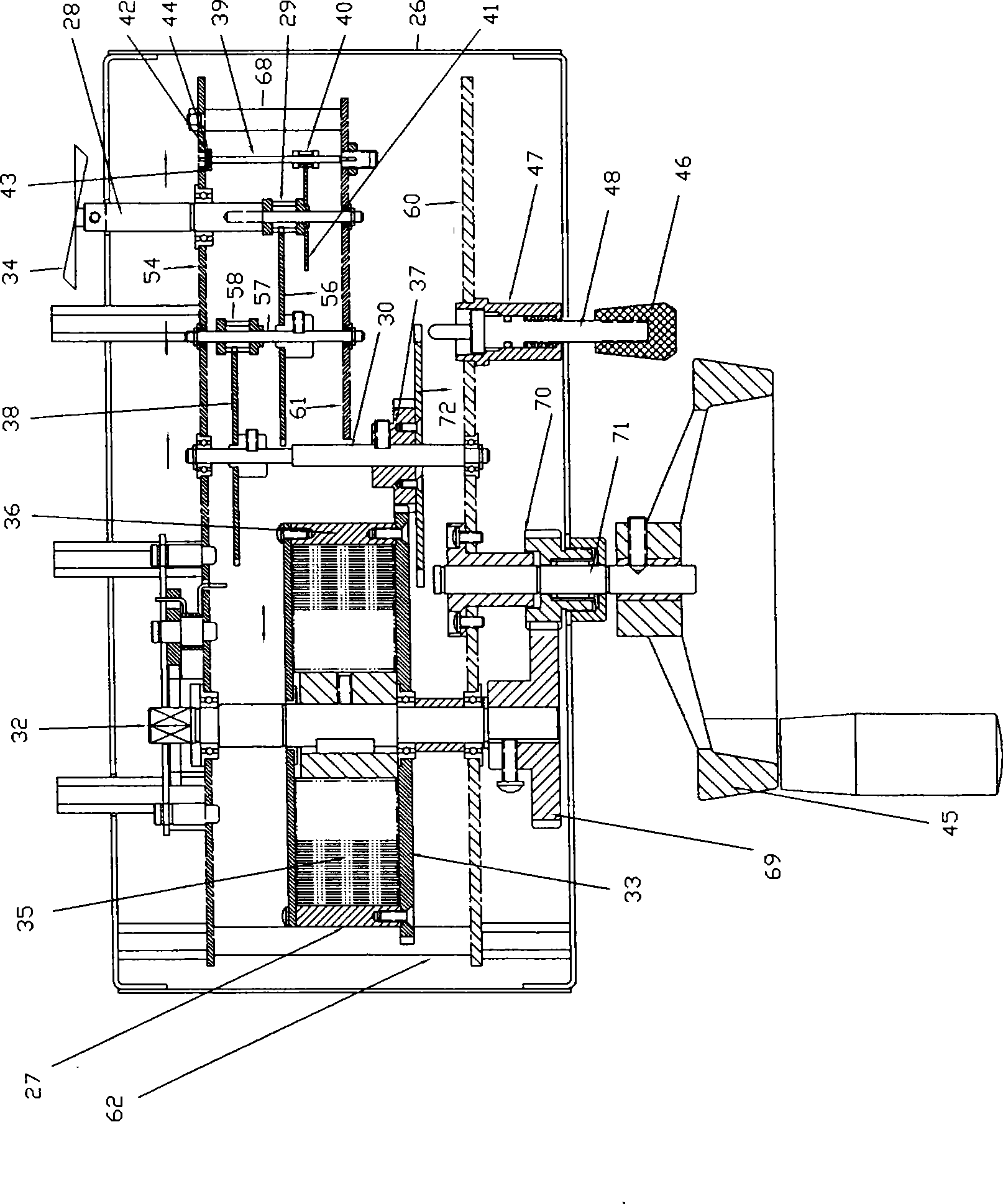

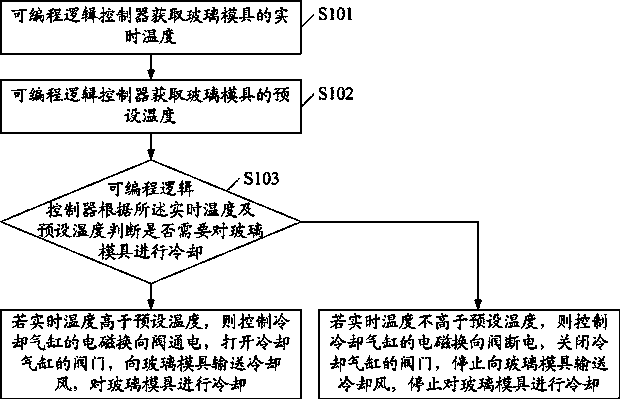

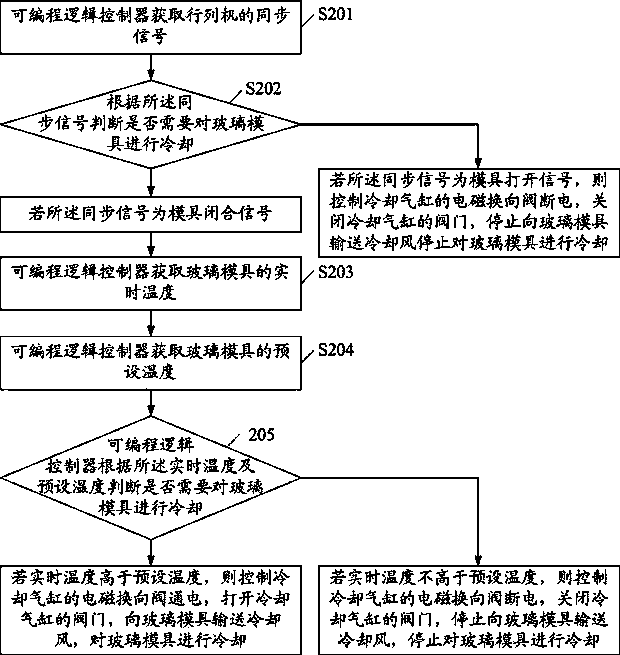

Method and device for automatically carrying out thermoregulation control on molding mould of I.S. machine

InactiveCN104176910ARealize automatic adjustmentStable molding temperatureGlass blowing apparatusProgramme control in sequence/logic controllersDirectional ValveMaterials science

The invention discloses a method for automatically carrying out thermoregulation control on a molding mould of an I.S. machine. The method comprises the following steps: A, obtaining a real-time temperature of a glass mould; B, obtaining a preset temperature of the glass mould; C, judging whether to cool the glass mould or not according to the real-time temperature and the preset temperature, if the real-time temperature is higher than the preset temperature, controlling a solenoid directional valve of a cooling gas cylinder to switch on, opening a valve of the cooling gas cylinder, and cooling the glass mould, if the real-time temperature is not higher than the preset temperature, controlling the solenoid direction valve of the cooling gas cylinder to switch off, closing the valve of the cooling gas cylinder and stopping cooling of the glass mould. The invention further discloses a device for automatically carrying out thermoregulation control on the molding mould of the I.S. machine. According to the invention, the on-off of the solenoid direction valve of the cooling gas cylinder, the opening-closing of the valve and the opening of the glass mould are guaranteed to be synchronous, so that the air quantity of the cooling air output to the glass mould by the cooling gas cylinder is effectively controlled, the automatic regulation on the temperature of the glass mould is realized, and the quality of glass products is improved.

Owner:FOSHAN HUAXING GLASS

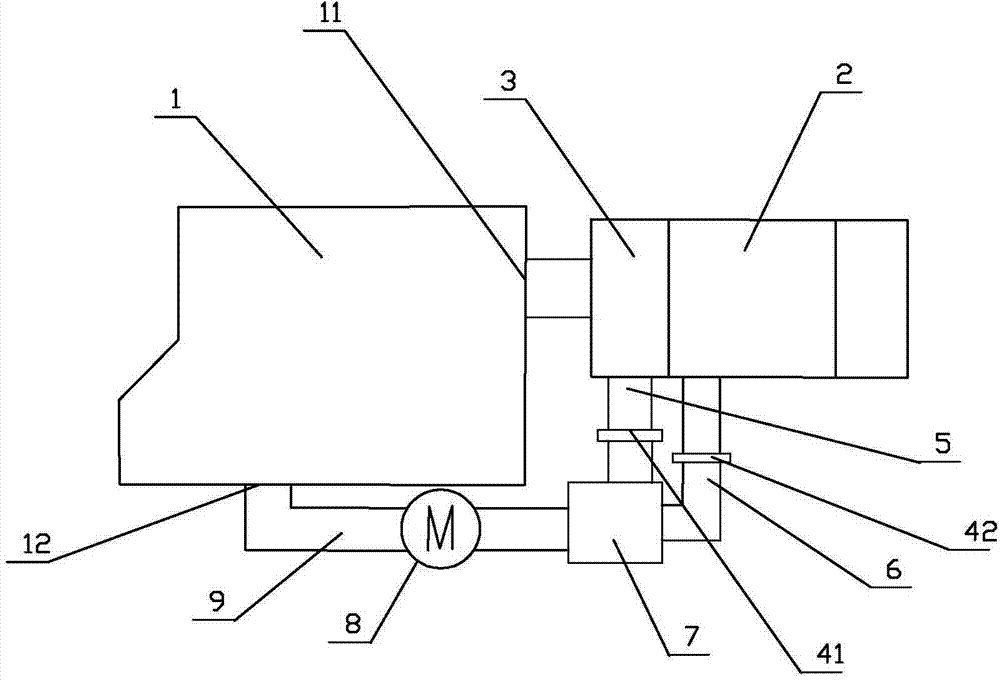

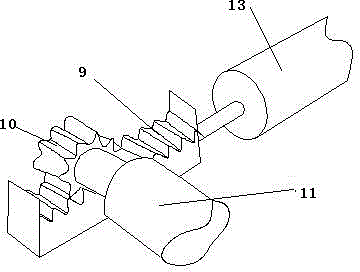

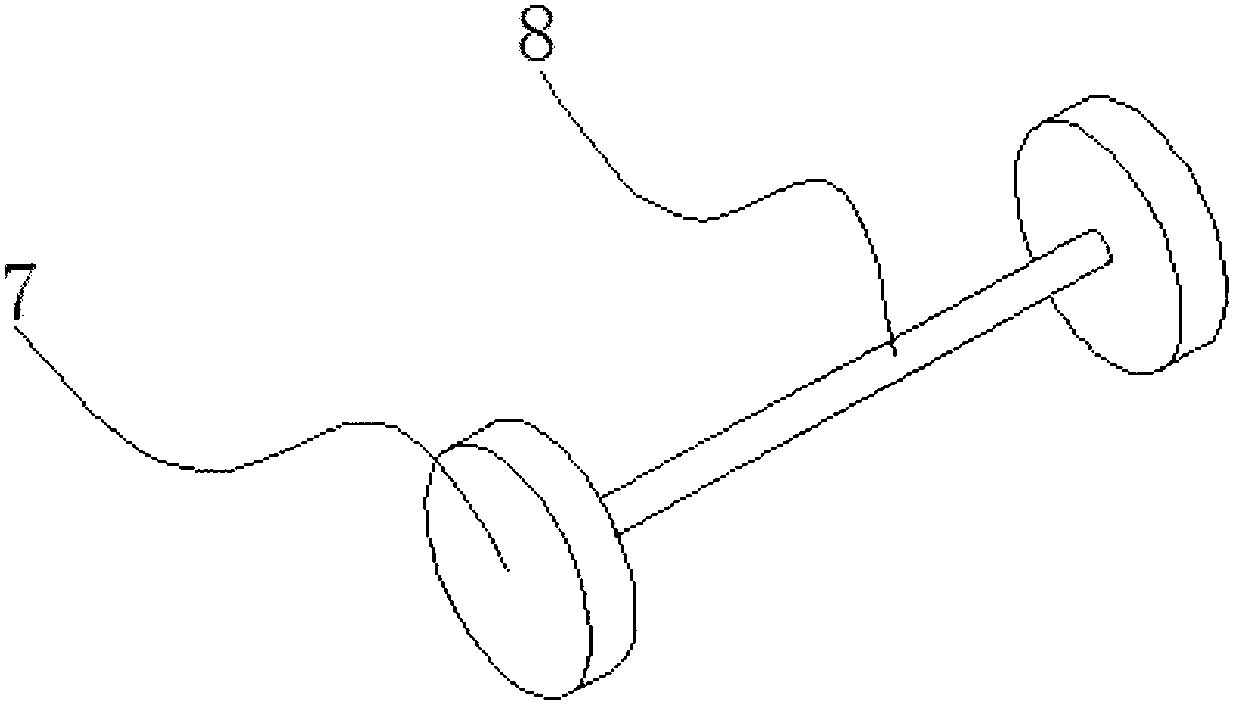

Split type intelligent plunger with pulley mechanism

InactiveCN109723408AReal-time control of motion speedAvoid damageFlexible member pumpsFluid removalDual mechanismButterfly valve

The invention relates to the field of gas well drainage and gas production, in particular to a split type intelligent plunger with a pulley mechanism. The split type intelligent plunger with pulley mechanism is characterized in that the intelligent plunger comprises a plunger body, a pulley mechanism at the lower end of the plunger body, a plunger sleeve, a spring slip arranged in the plunger sleeve, an open butterfly valve with a locking device, an upper buffer, a lower buffer, a self-adaptive valve mechanism arranged in the lower buffer and a pressure sensor, a temperature sensor, a speed sensor and a microprocessor control attached to the plunger body and the plunger sleeve; the speed of the plunger body and the plunger sleeve in the ascending or descending process is controlled by controlling the action of the pulley mechanism. Compared with the prior art, the split type intelligent plunger with pulley mechanism has the advantages that the defect that the speed of the plunger usedfor draining water in the prior continuous production operation without closing the well is not controllable is solved, and the problem that an underground or wellhead accident is caused due to serious collision between the plunger body and the plunger sleeve in the a ascending or descending process is effectively avoided.

Owner:SOUTHWEST PETROLEUM UNIV

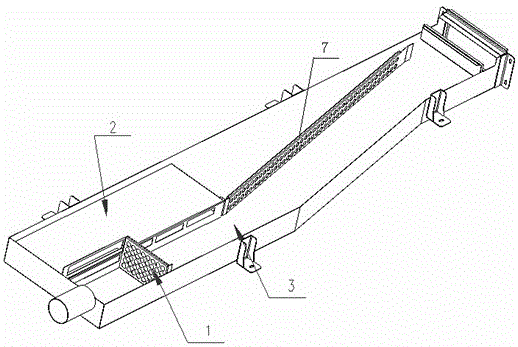

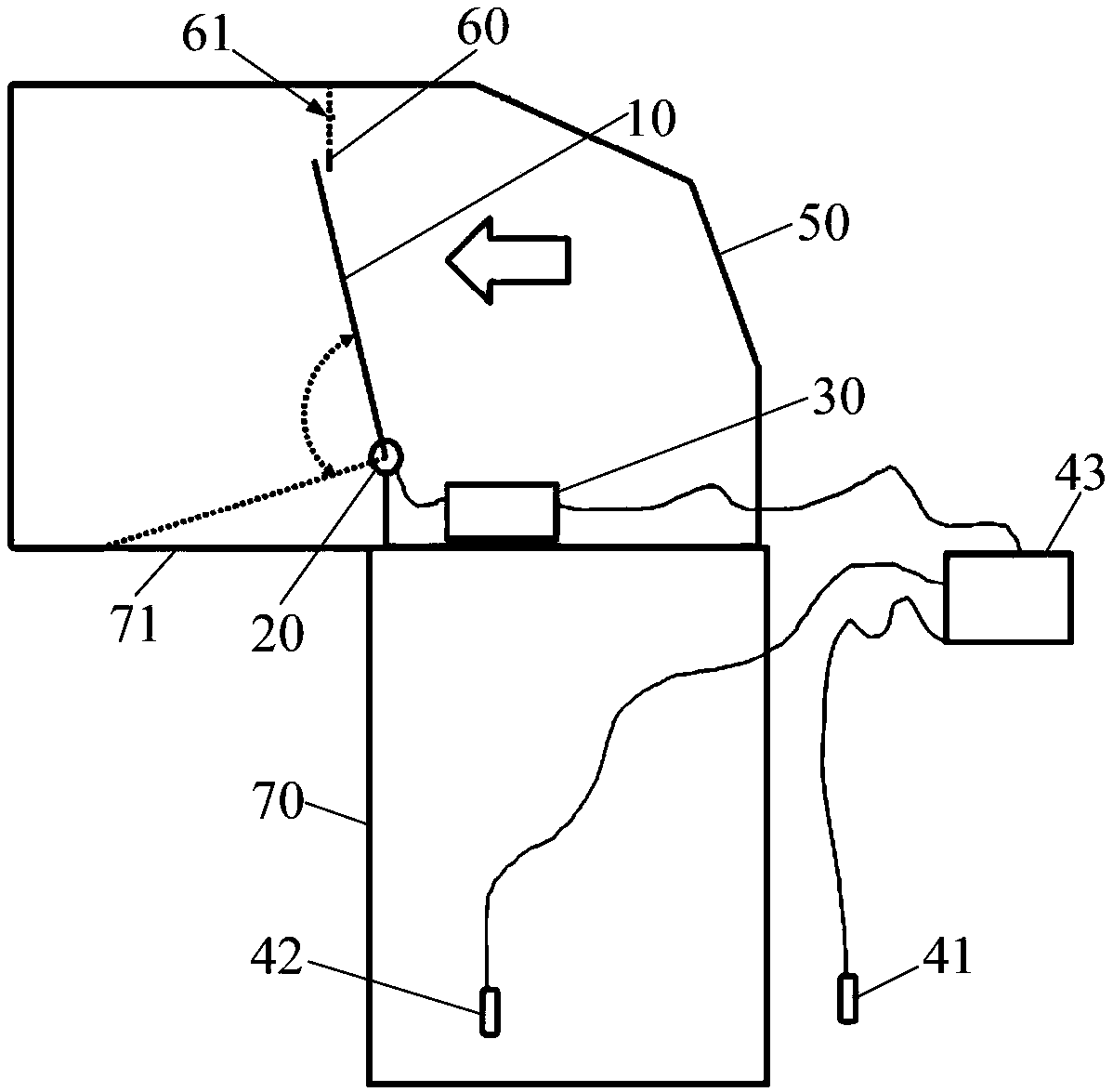

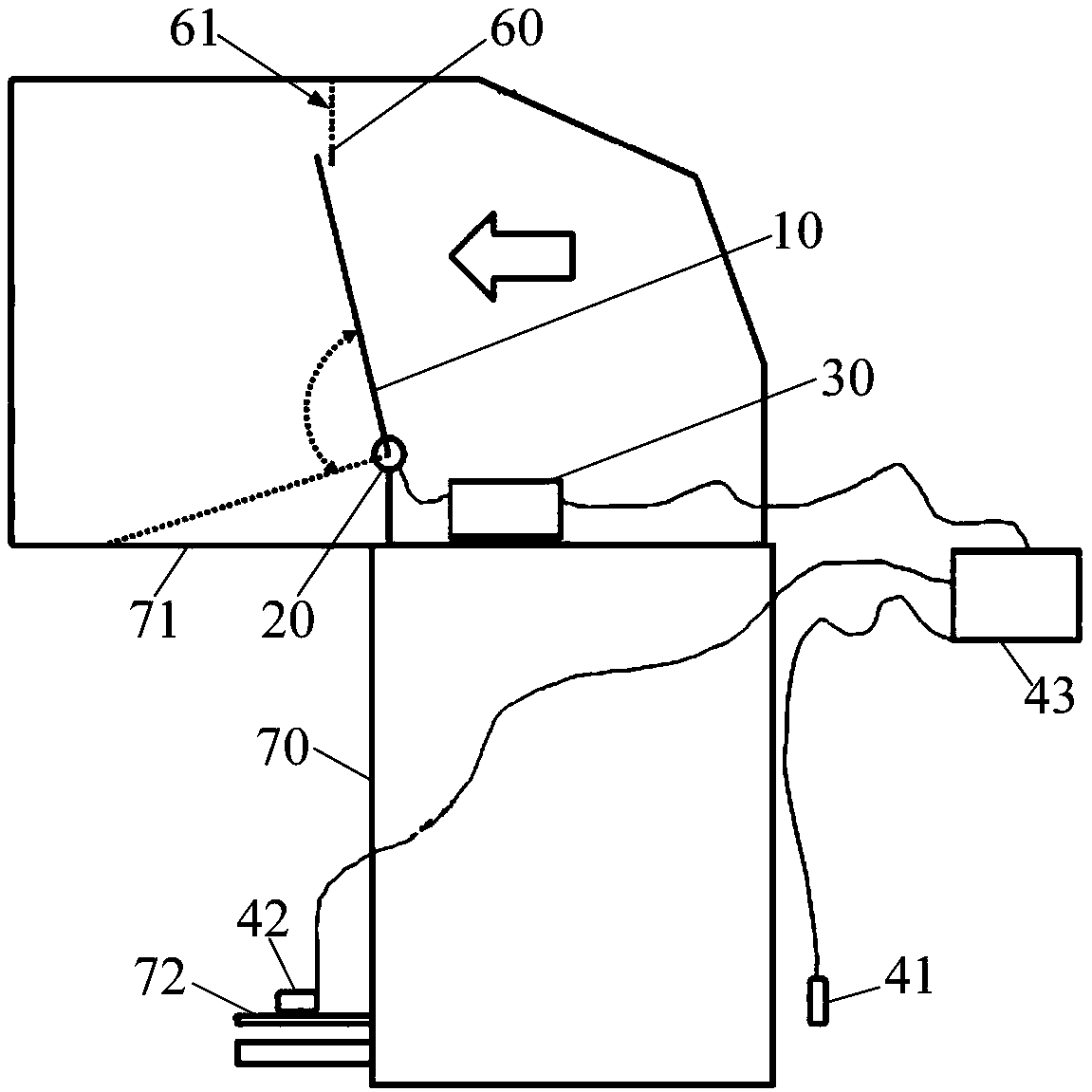

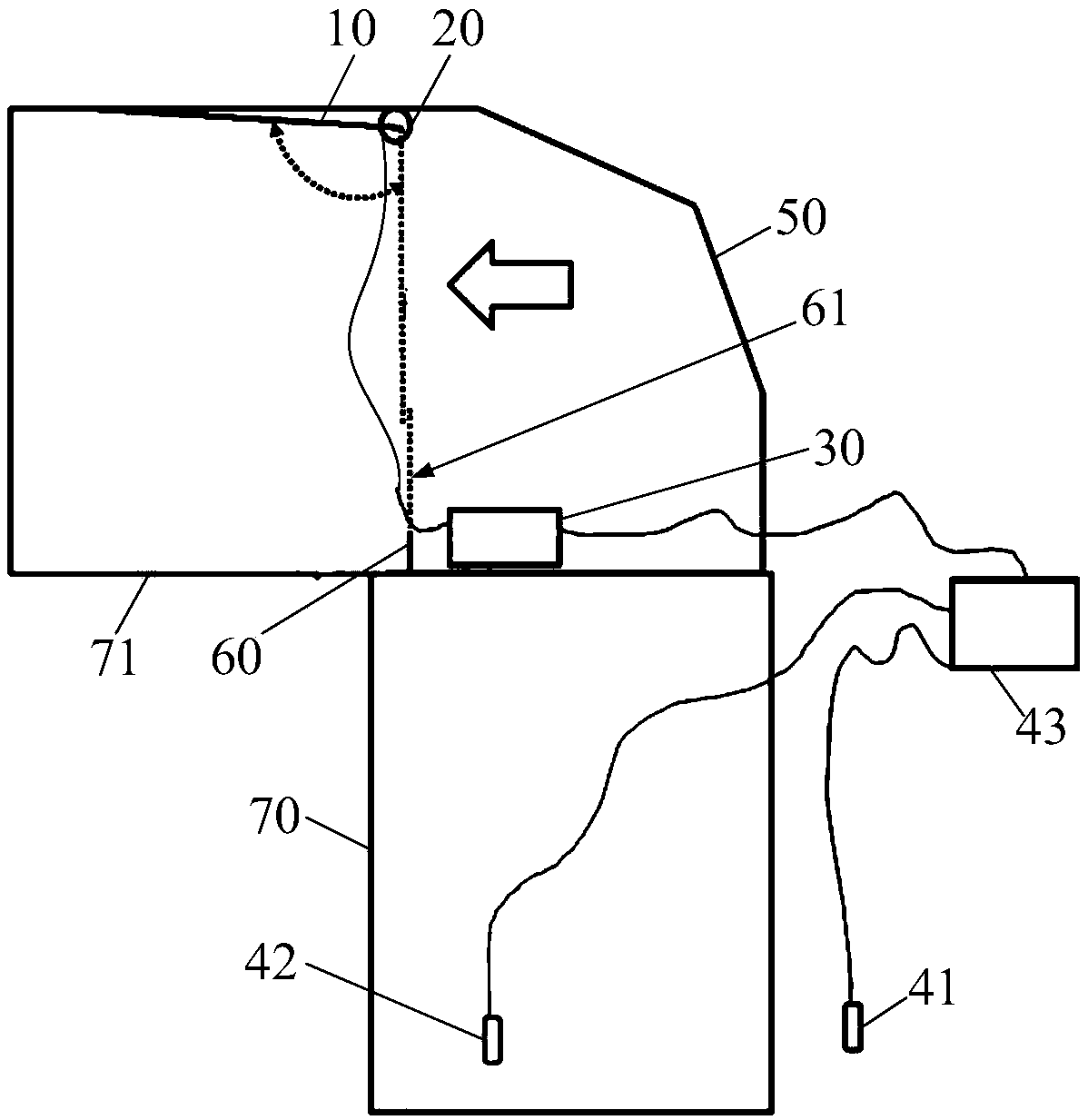

Induced draft channel structure of rail traffic vehicle cab

ActiveCN106004896AInhibition of dynamic pressureControl air volumeLocomotivesEngineeringAir conditioning

The invention relates to an induced draft channel structure of a rail traffic vehicle cab. The induced draft channel structure comprises a main air duct body, wherein an air inlet is formed in one end of the main air duct body, an air outlet is formed in the other end of the main air duct body, the air inlet is communicated with an air source treated by an air conditioning unit in a passenger carriage air duct, and the air outlet is connected with a cab ventilation unit through a pipeline; and the induced draft channel structure is characterized in that a guide plate is arranged in the main air duct, the guide plate allows a guide passage to be formed between the air inlet and the air outlet, the end of the guide passage, adjacent to the air outlet, is provided with a resistance plate perpendicular to the flowing direction of the wind, and one side of the resistance plate is provided with a static pressure cavity. The induced draft channel structure can effectively suppress the action of the dynamic pressure of the passenger carriage air conditioning unit and control the air volume sent into a cab.

Owner:CRRC NANJING PUZHEN CO LTD

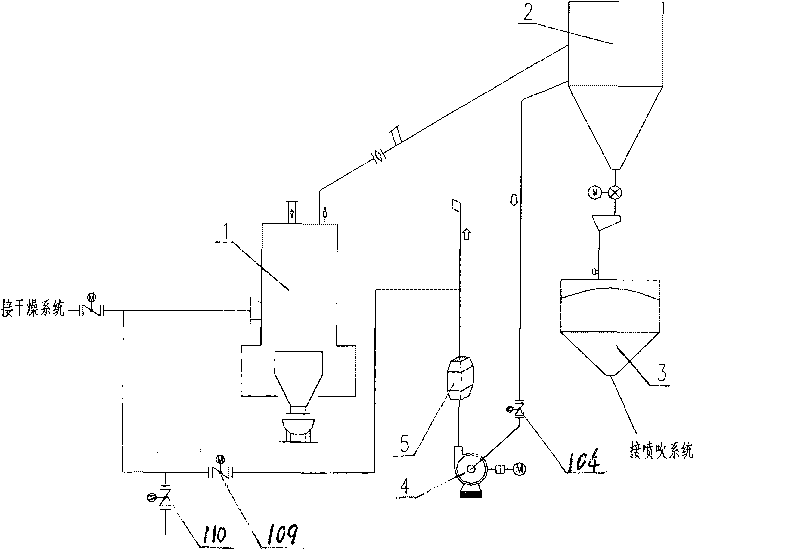

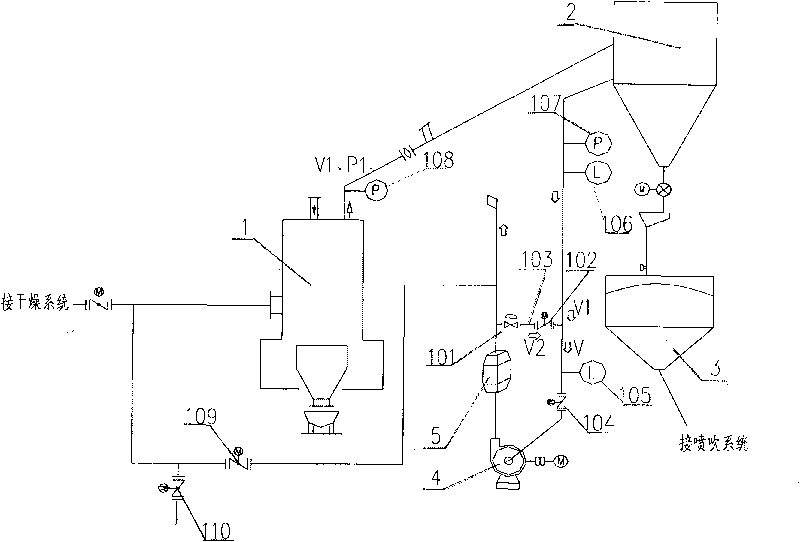

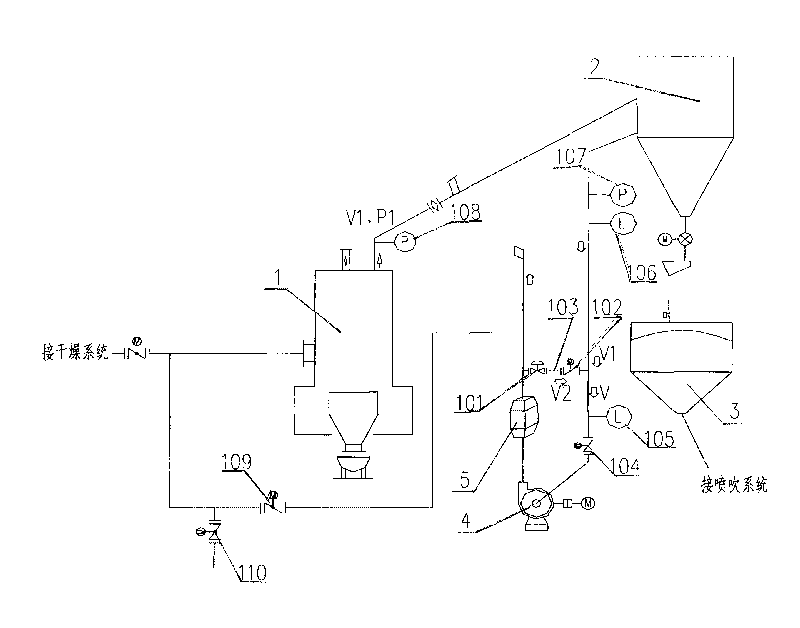

Method for setting and controlling pulverized coal preparing system

The invention discloses a method for setting and controlling a pulverized coal preparing system, belonging to the field of the controlling and adjusting technology. One branch of hot air of a drying system is connected to a coal pulverizer; the produced pulverized coal is fed into a pulverized coal collecting system through a pneumatic conveying pipe and is collected in a pulverized coal bunker; waste gas is discharged through a pulverized coal fan and a muffler; the other branch of hot air of the drying system is provided with an electric butterfly valve; the electric butterfly valve is connected with a waste gas exhaust pipe which is arranged at the rear of the muffler; and the a pulverized coal fan entrance valve is arranged on the entrance of the pulverized coal fan. The invention is characterized in that the waste gas exhaust pipe which is arranged at the rear of the muffler is communicated with a pulverized coal fan entrance pipe through a communicating pipe and an electric adjusting valve is arranged on the communicating pipe to adjust and control the air quality on the exist of the coal pulverizer and stabilize the negative pressure on the exist of the pulverizer so as to ensure than the pulverized coal fan operates under constant operating mode. The invention can improve the operating stability of the pulverized coal preparing system and can accurately select the type of the pulverized coal fan so as to appropriately reduce the capacity of the pulverized coal fan and save the energy and the resource.

Owner:CISDI ENG CO LTD

Anti-virus type automobile air conditioning system

PendingCN111231629AEfficient captureEfficient killingAir-treating devicesProcess engineeringEngineering

The invention discloses an anti-virus type automobile air conditioning system. The system comprises an air conditioning duct and a draught fan, an evaporator and a warm air heat exchanger which are arranged in the air conditioning duct. An outer circulation air inlet, an inner circulation air inlet, a windshield air outlet, a lower air outlet and a working air outlet are formed in the air conditioning duct. The system further comprises an anti-virus filter element, the anti-virus filter element is installed at the position of the inner circulation air inlet, the anti-virus filter element comprises a rough filtration and supporting layer, a fine filtration layer, a refined filtration layer and a virus and fine particle trapping layer, and the rough filtration and supporting layer, the finefiltration layer, the refined filtration layer and the virus and fine particle trapping layer are fixed in a layered mode from top to bottom and form a whole. The air purifier can effectively captureand kill harmful components such as viruses and bacteria, and meanwhile it is ensured that the existing filtering capacity is not reduced.

Owner:开沃新能源汽车集团股份有限公司

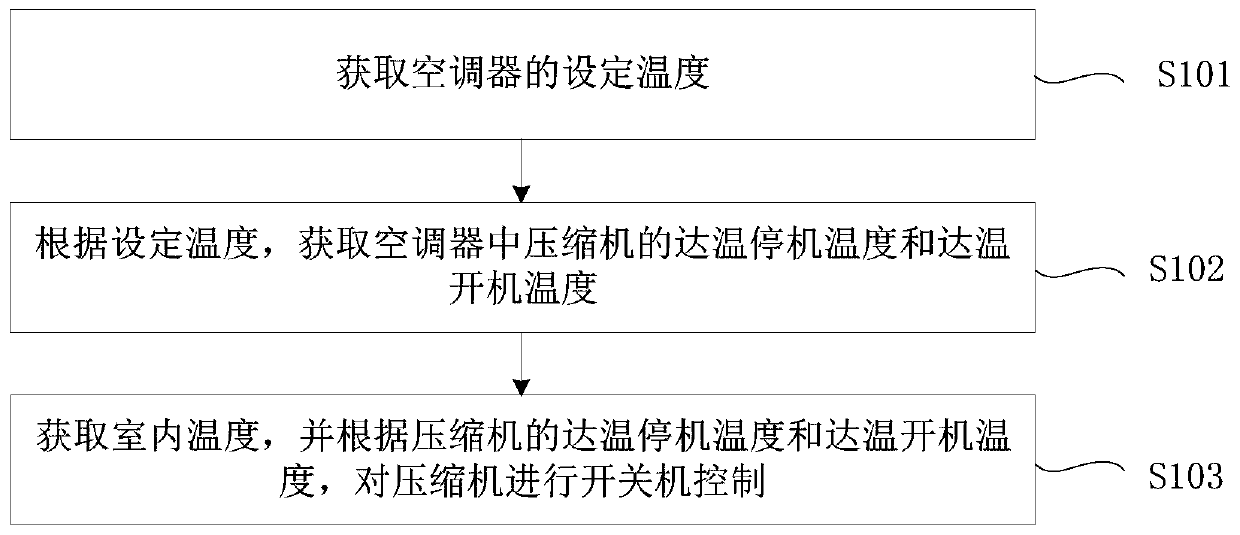

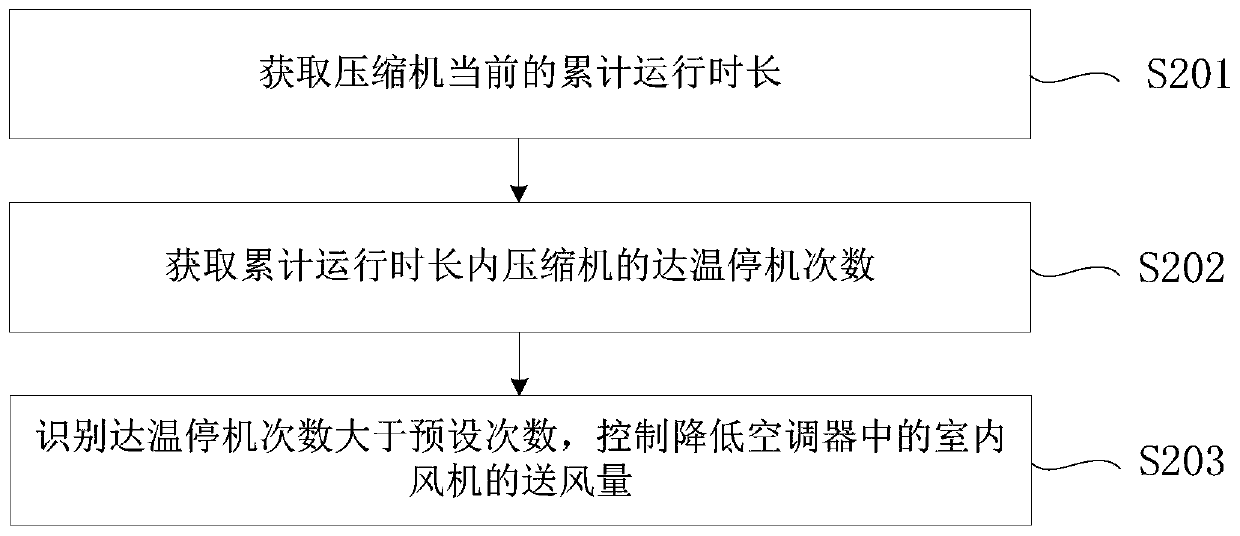

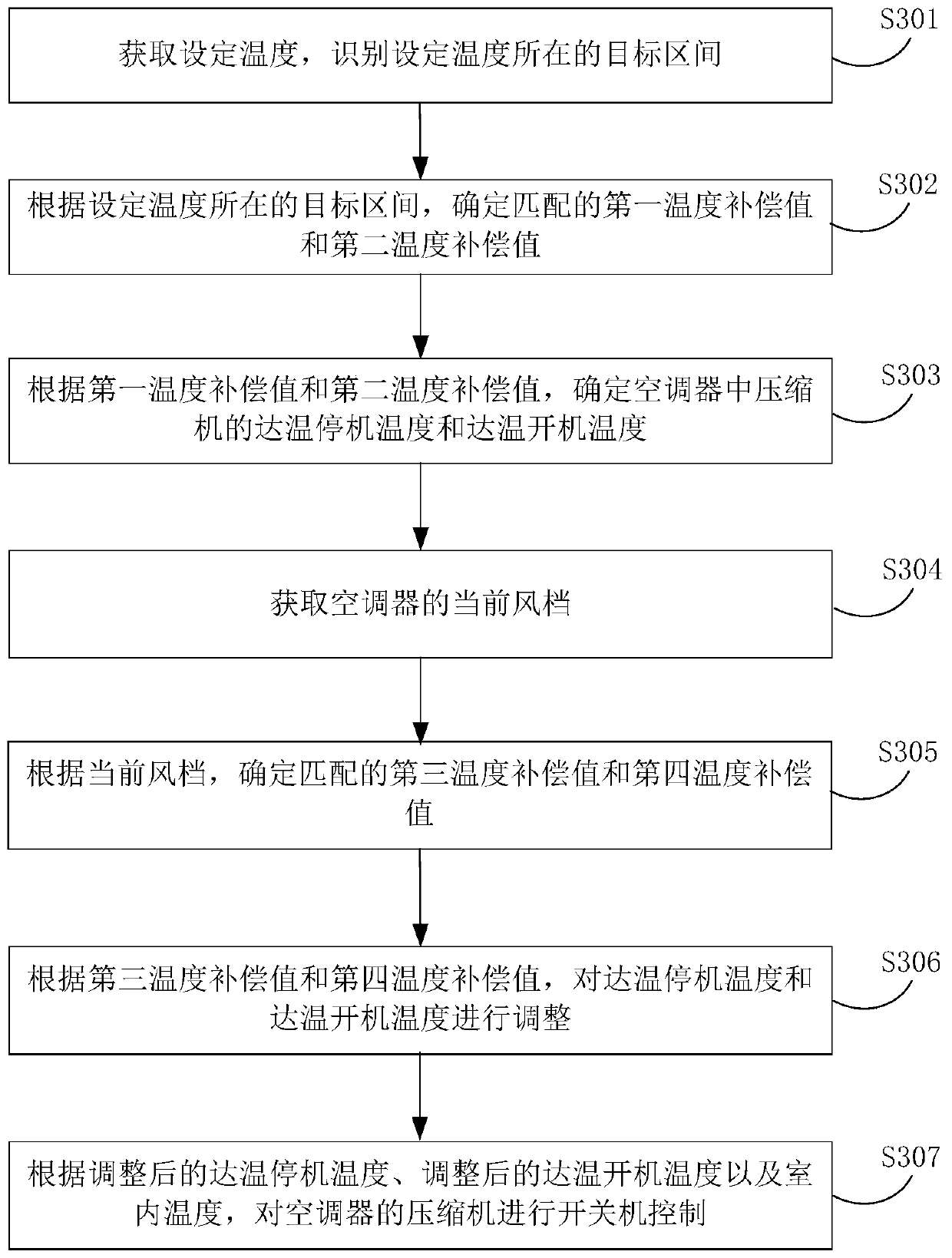

Air conditioner control method and device, air conditioner and electronic equipment

ActiveCN110285551AOvercome the problem of frequent start and stopControl air volumeMechanical apparatusSpace heating and ventilation safety systemsEngineeringElectronic equipment

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

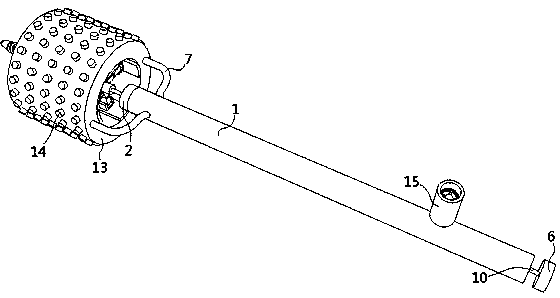

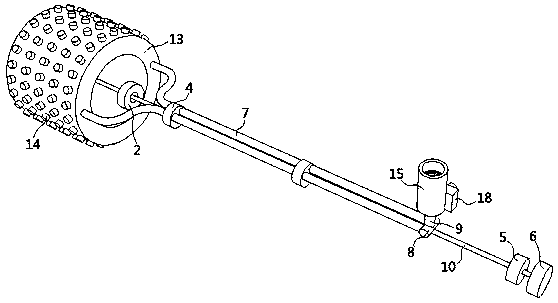

Biological balloon dilatation catheter

PendingCN108853694AReduce the degree of deformationProtection securityBalloon catheterSurgeryBalloon dilatation catheterBlood vessel

The invention discloses a biological balloon dilatation catheter and relates to the technical field of catheter. The biological balloon dilatation catheter disclosed by the invention comprises a firstcatheter body, a handle, a third catheter body, a fourth catheter body and a first fixed plate, wherein a group of second blocking plates and a third blocking plate are sequentially fixed to an innerwall of the first catheter body from left to right, a fifth catheter body and a fourth blocking plate are sequentially fixed to an inner wall of the fourth catheter body from top to bottom, and one end of the third catheter body penetrates through one surface of the fourth blocking plate and extends into the fourth catheter body. According to the biological balloon dilatation catheter disclosed by the invention, a steel wire is pulled to drive a first supporting rod to slide in an air bag, so that a second fixed plate is driven to rotate, the second fixed plate and a fourth fixed plate are matched, supporting plates are opened, the air bag is supported by the plurality of the supporting plates, and a blocked part can be better opened by the air bag; furthermore, a deformation degree of the air bag is protected to be smaller, and no secondary damage is generated to blood vessels; meanwhile, blood circulation cannot be blocked in a treating process, and safety of patients is protected.

Owner:杭州耕鑫生物科技有限公司

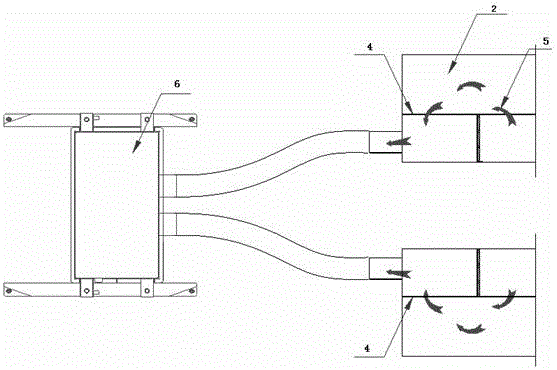

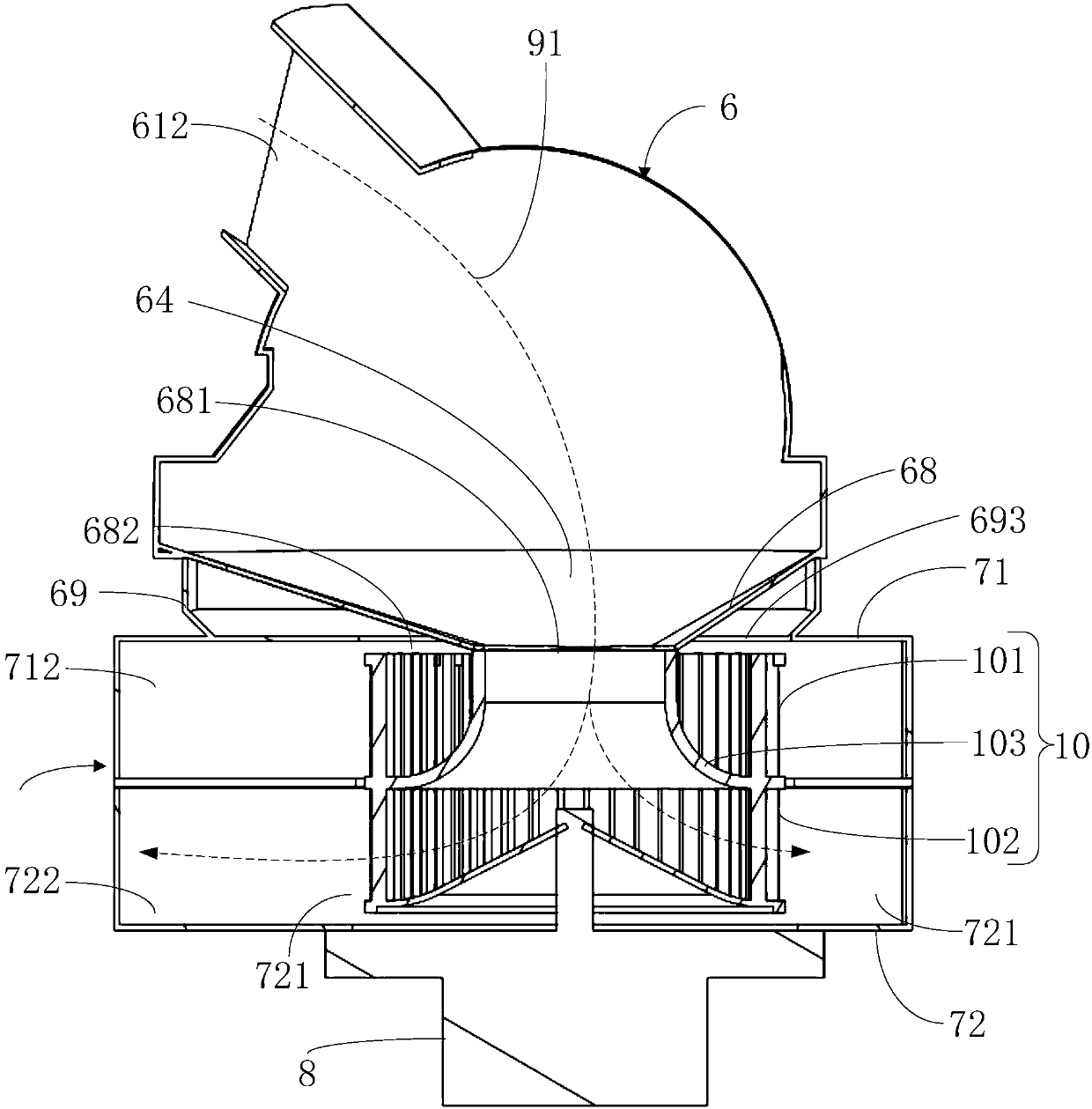

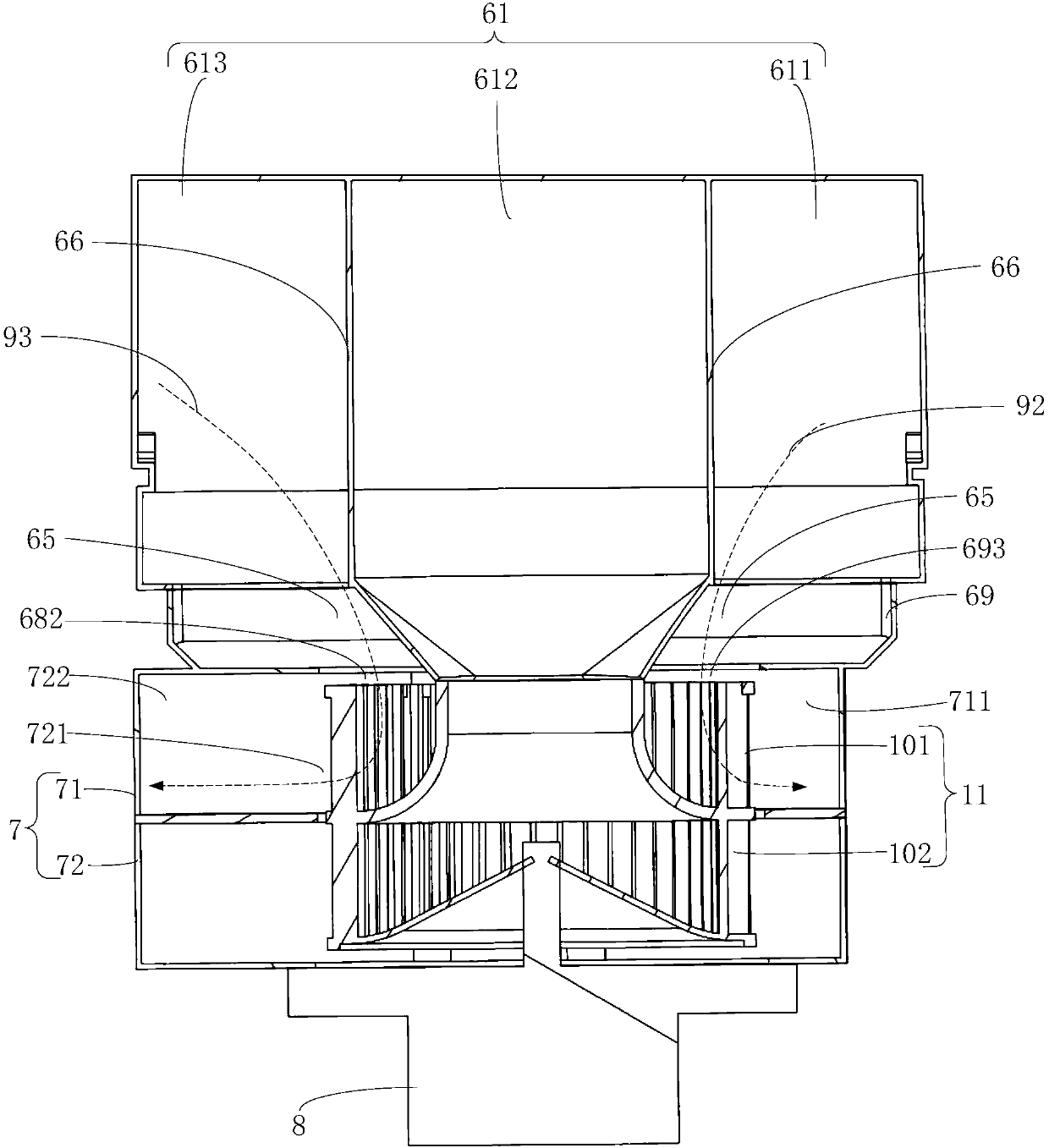

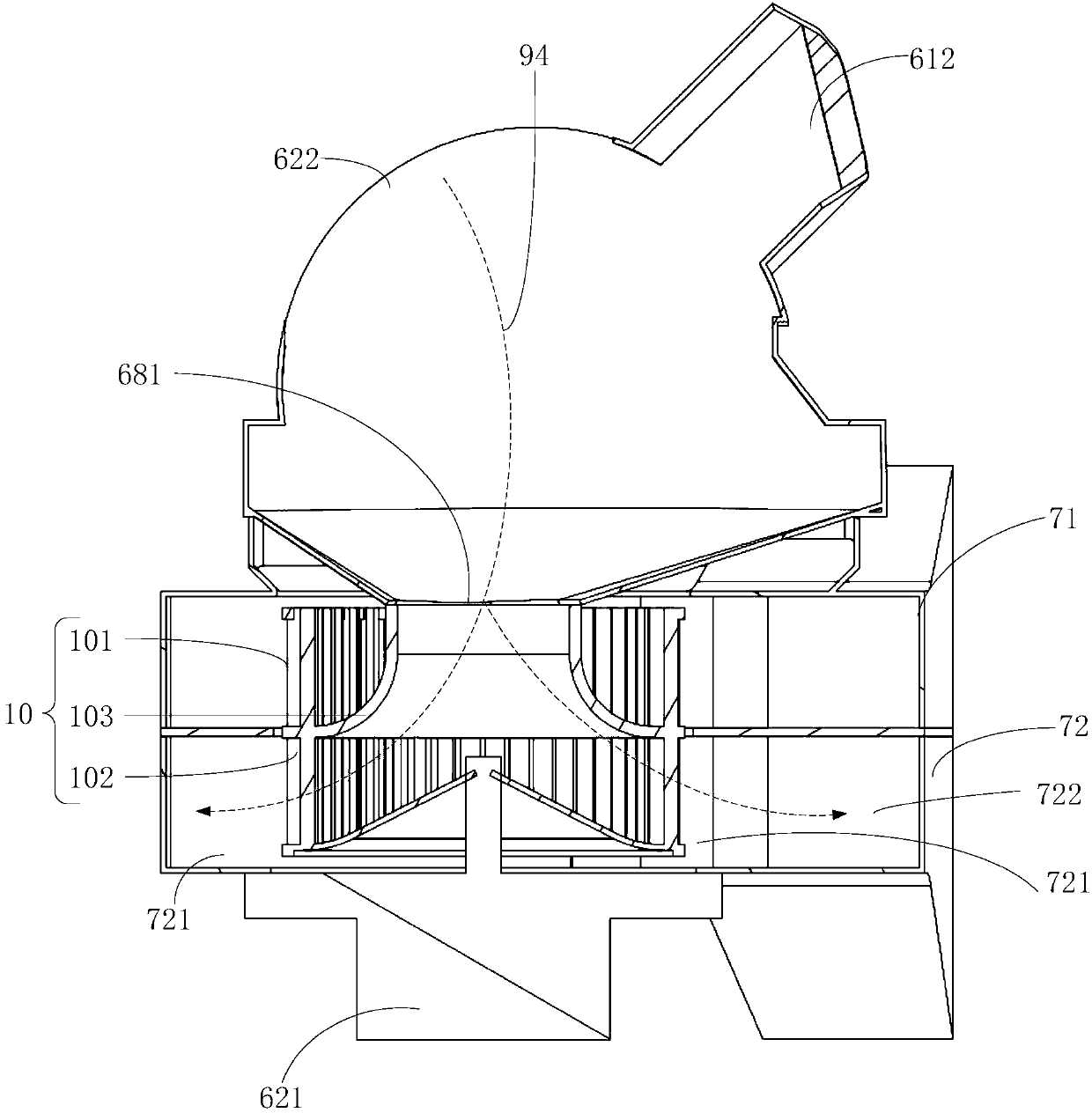

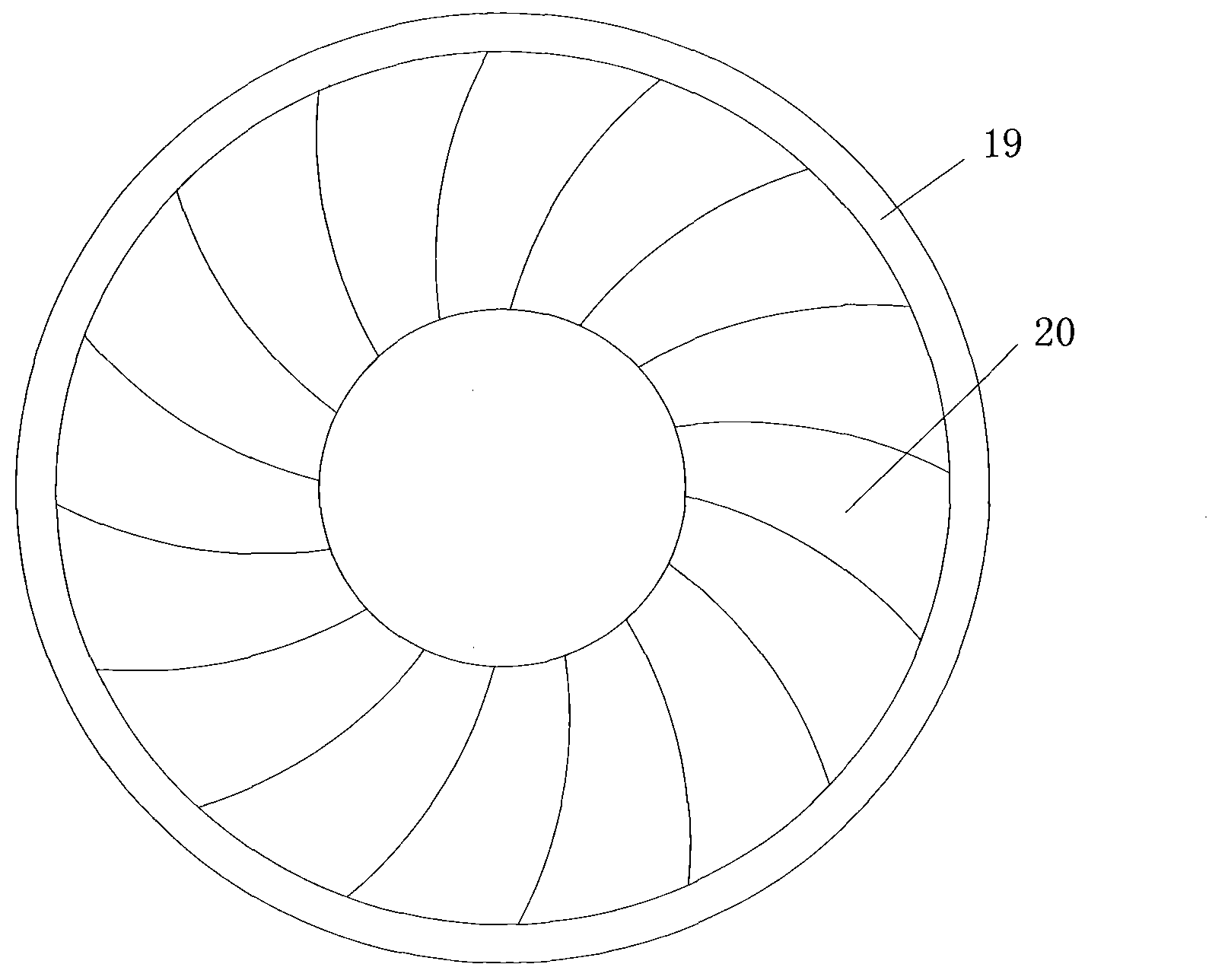

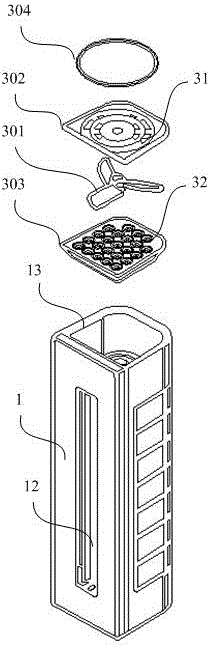

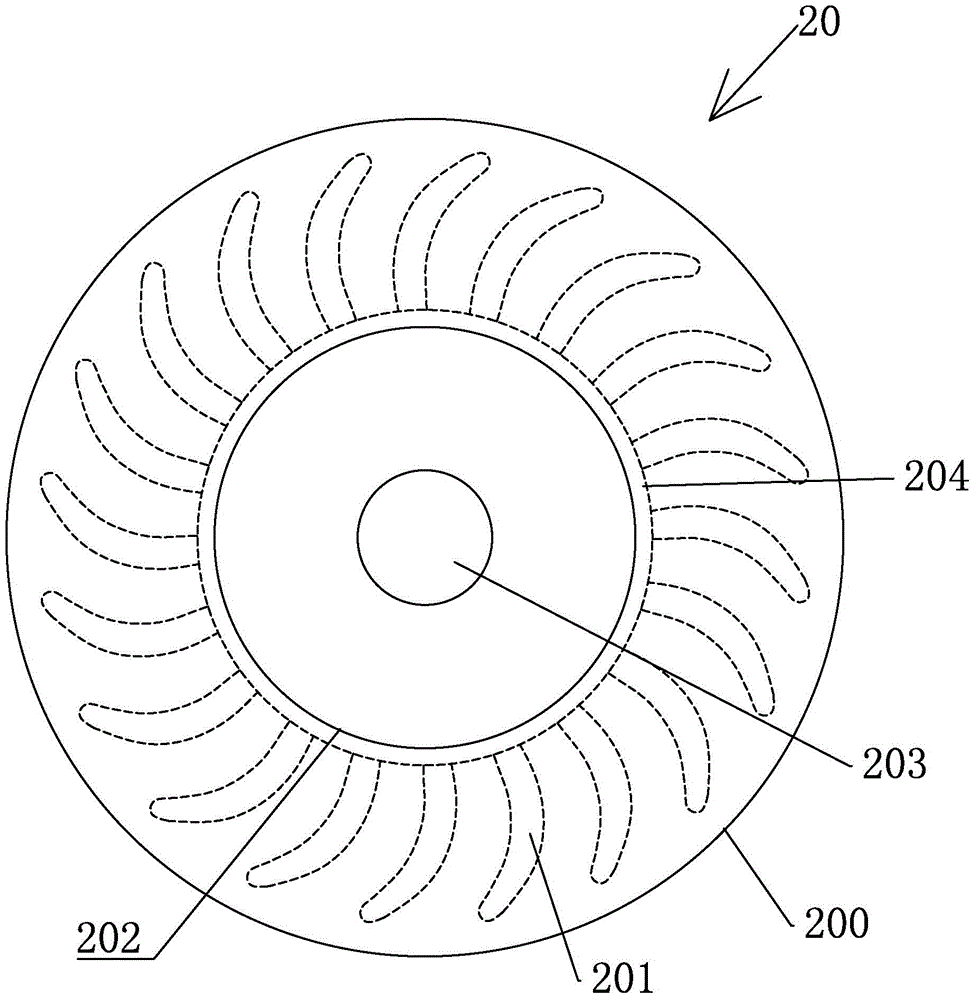

Fan and air conditioning unit

ActiveCN110273845AControl the air volumeControl air volumePump componentsVehicle heating/cooling devicesInterior spaceImpeller

The invention discloses a fan and an air conditioning unit. The fan comprises a volute, an air supply part and an air inlet part. The volute comprises a first volute body and a second volute body which are mutually isolated; the first volute body is provided with an air inlet; the air supply part comprises an impeller and a first isolating piece at least partially sleeved with the impeller; at least one part of the impeller is arranged in the first volute; the other part of the impeller is arranged in the second volute; the first isolating piece can enable fluid flowing into the air supply part to blow towards the impeller in two parts; the air inlet part comprises a second isolating piece; the second isolating piece is arranged in the air inlet part, and the air inlet part can be devided into two or more first cavities and second cavities which are mutually isolated; the first cavity communicates with inner space of the first isolating piece; and the second cavity communicates with outer space of the first isolating piece.

Owner:HANGZHOU SANHUA RES INST CO LTD

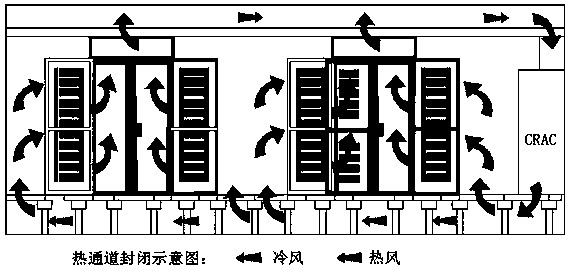

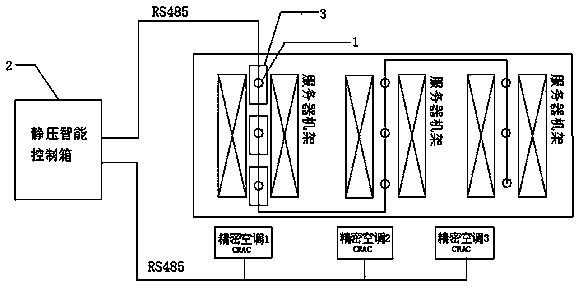

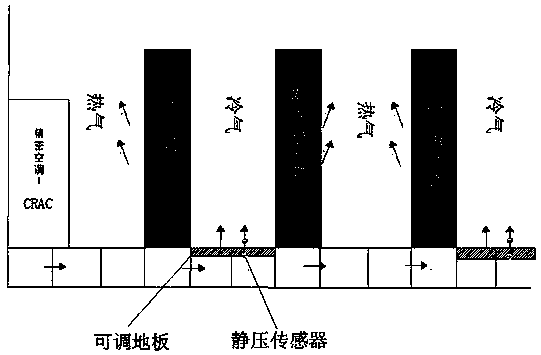

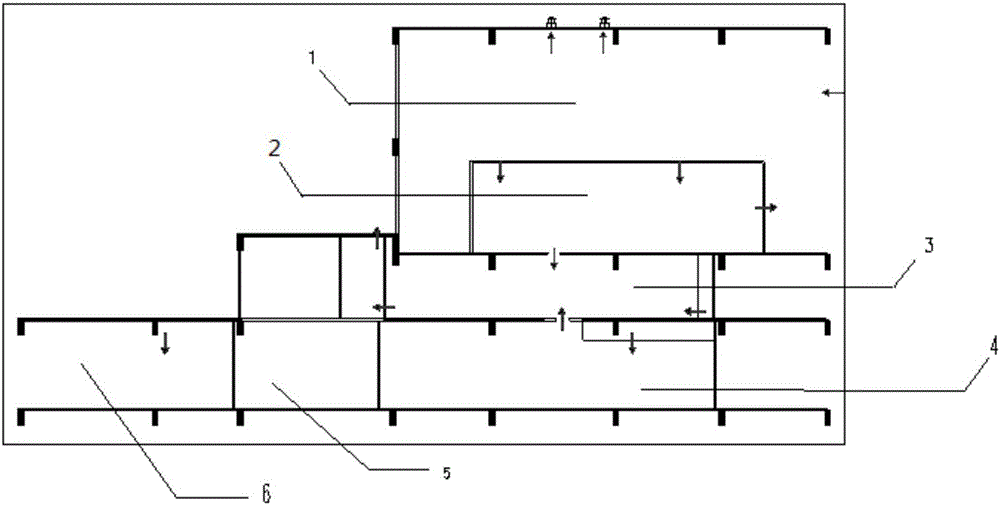

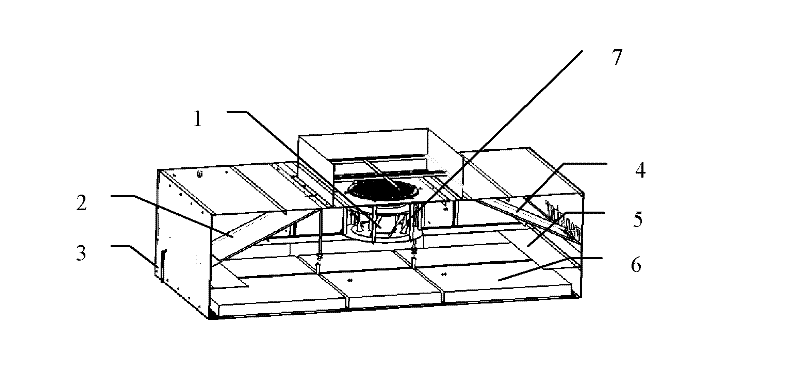

Device for controlling uniform air supply of static pressure box of data center and implementation method thereof

ActiveCN107655083APrecisely adjustable air supply size areaAdjust the size of the air supply areaDucting arrangementsMechanical apparatusIt equipmentControl data

The invention discloses a device for controlling uniform air supply of a static pressure box of a data center and an implementation method thereof. The device comprises static pressure sensors, a static pressure intelligent control box and accurate adjustable air supply floors; static pressure sensors are used for detecting current static pressure values of air supply openings in real time; the static pressure intelligent control box is used for receiving and calculating the static pressure values of the air supply openings detected by the static pressure sensors; the accurate adjustable air supply floors are used for receiving an instruction to adjust the air supply size and area of the air supply floors; and the static pressure intelligent control box comprises a main controller, an RS485 communication module, a human-computer interaction HMI and a power supply, and the main controller is used for adjusting and controlling the areas of the air supply openings in the accurate adjustable air supply floors. According to the device and the method, the rotating speed of blowers can be adjusted and the areas of the air supply openings can be controlled according to the static pressurevalues of the air supply openings of the air supply floors in a machine room so that that the uniformity of the air supply amount and the static pressure of each air supply opening can be guaranteed,and IT equipment in the machine room can be cooled rapidly.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

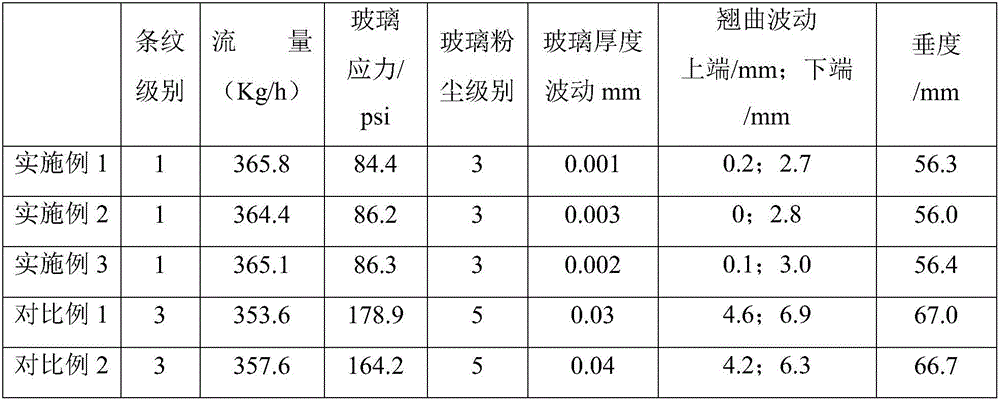

Production method of liquid crystal glass substrate

ActiveCN105948460AImprove yieldImprove qualityGlass furnace apparatusGlass severing apparatusWork in processAtmospheric pressure

The invention discloses a production method of a liquid crystal glass substrate. The method includes the steps that 1, raw materials are sent to a pool furnace area for melting; 2, molten glass liquid is sent to a platinum area for purification; 3, the purified glass liquid is sent to a forming area for curing; 4, a glass plate is sent to a hot-cutting area for cutting and then transported by a hot-cutting peripheral area into a half-packaging area, packaging of the liquid crystal glass substrate is completed after check is conducted, and a semi-finished product of the liquid crystal glass substrate is obtained; the environmental pressure of the pool furnace area is controlled to be 4-6 Pa higher than the atmospheric pressure, the environmental pressure of the platinum area is controlled to be14-16 Pa higher than the atmospheric pressure, the environmental pressure of the forming area is controlled to be 10.5-12.5 Pa higher than the atmospheric pressure, the environmental pressure of the hot-cutting area is controlled to be 14-16 Pa higher than the atmospheric pressure, the environmental pressure of the hot-cutting peripheral area is controlled to be 11-13 Pa higher than the atmospheric pressure, and the environmental pressure of the half-packaging area is controlled to be 6-8 Pa higher than the atmospheric pressure. By means of the production method of the liquid crystal glass substrate, quality of the liquid crystal glass substrate can be remarkably improved.

Owner:ZHENGZHOU XUFEI OPTOELECTRONICS TECH +1

Manually-operated louver valve

The invention discloses a manually-operated louver valve, which comprises a flange, a casing, rotation shafts, hollow shafts, blades, a high temperature wear resistant rubber, cranks, a connecting rod, and handles, wherein the flange is connected with the casing; the rotation shafts are placed in the casing; the blades are fixedly connected with the hollow shafts; the rotation shafts are sleeved with the hollow shafts, and the two are in bolted connection; the high temperature wear resistant rubber is mounted at edges of the blades and the two are in bolted connection; the handles are connected with the external of the casing, and are connected with the rotation shafts through the cranks and the connecting rod. The valve can effectively control the blowing rate in various severe environments, effectively guarantees the sealing property particularly through the high temperature wear resistant rubber, can better control the leakage rate of the valve to a smallest level, and can allow exhaust gases to be better recycled and reused in a cogeneration.

Owner:JIANGSU XINLIAN HYDRAULIC MECHANICAL & ELECTRICALCO

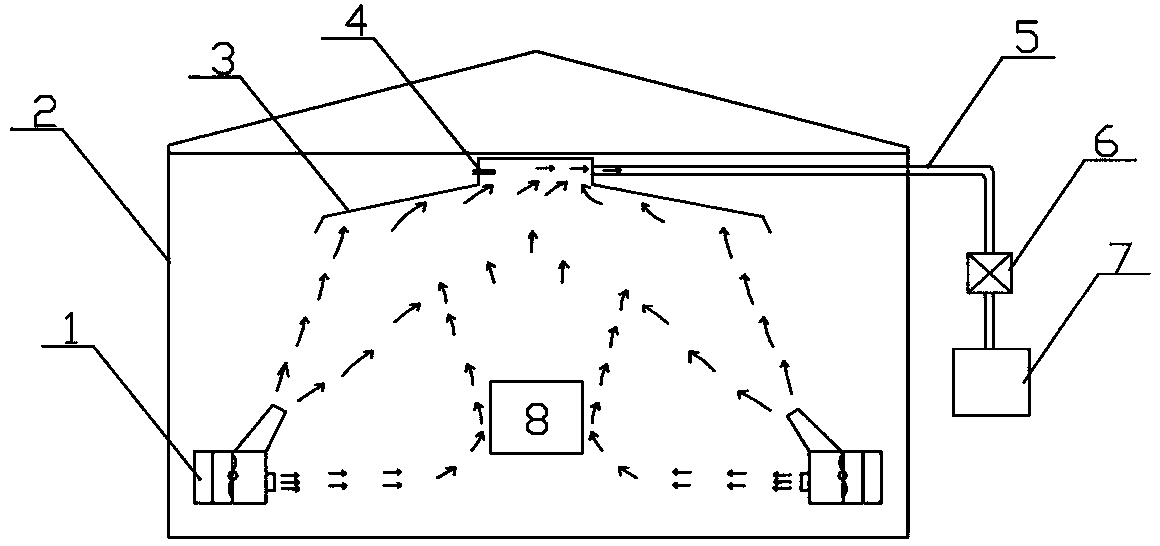

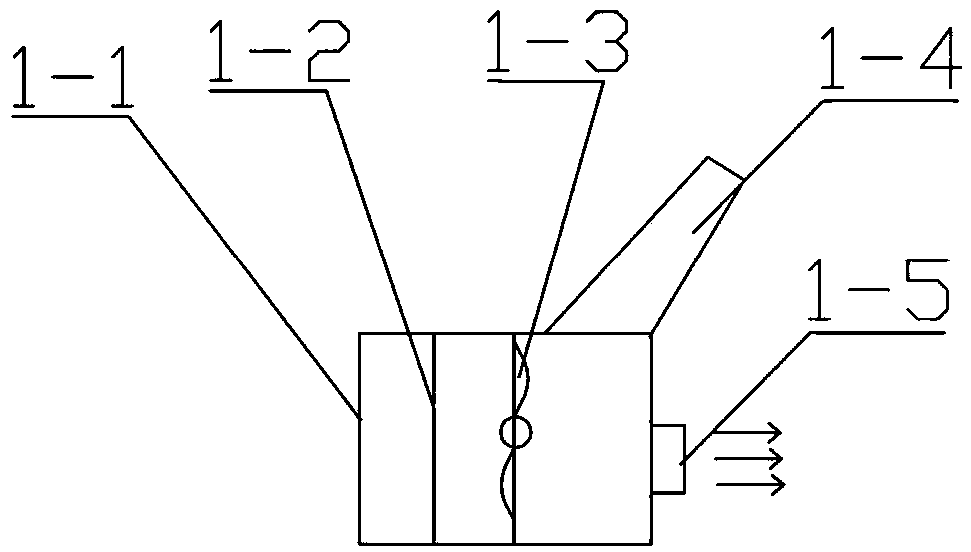

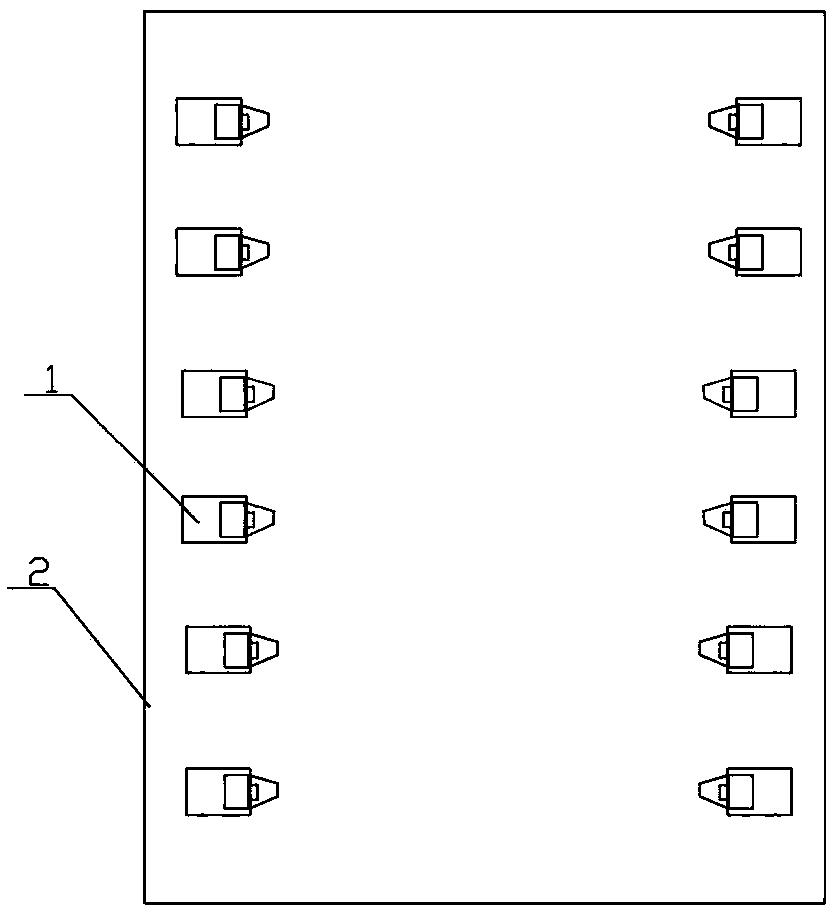

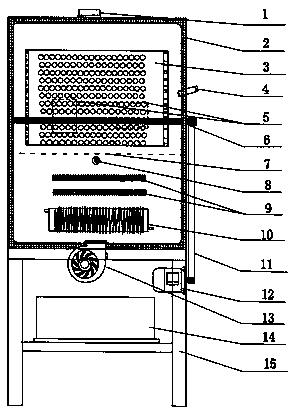

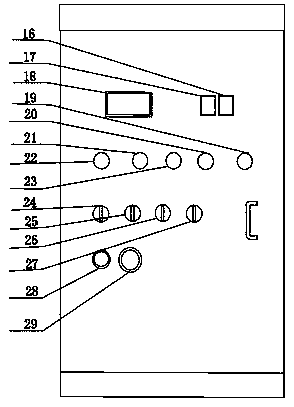

Intelligent purification system for large-scale factory building welding smoke haze

ActiveCN103776108ASimple structureEasy maintenanceSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringSmoke

The invention relates to an intelligent purification system for large-scale factory building welding smoke haze. The intelligent purification system comprises an air supply device arranged in a factory building. The intelligent purification system is characterized in that the air supply device is arranged on the periphery of the lower portion of the factory building, an exhaust hood and an exhaust duct communicated with the exhaust hood are arranged at the top of the factory building, the exhaust duct penetrates a wall on the upper portion of the factory building and is connected with an induced draft fan and a dust collector, the induced draft fan and the dust collector are arranged outside the factory building, at least one smoke haze detection sensor is arranged on the exhaust hood, the air supply device comprises a shell, an intelligent motor, a fan, a filter, a jet air supply outlet A and a horizontal air supply outlet B, the intelligent motor is arranged in the shell, the jet air supply outlet A is formed in the upper portion of the shell, and the horizontal air supply outlet B is formed in the side of the shell. The intelligent purification system is simple in structure, convenient to maintain, fine in exhaust, ventilation and purification effects and fine in energy-saving effect and makes a contribution to developing the economy, protecting environments and treating haze Pm2.5, and the intelligent motor can control air supply and exhaust quantity according to practical situations.

Owner:鞍山徕亚机械设备有限公司

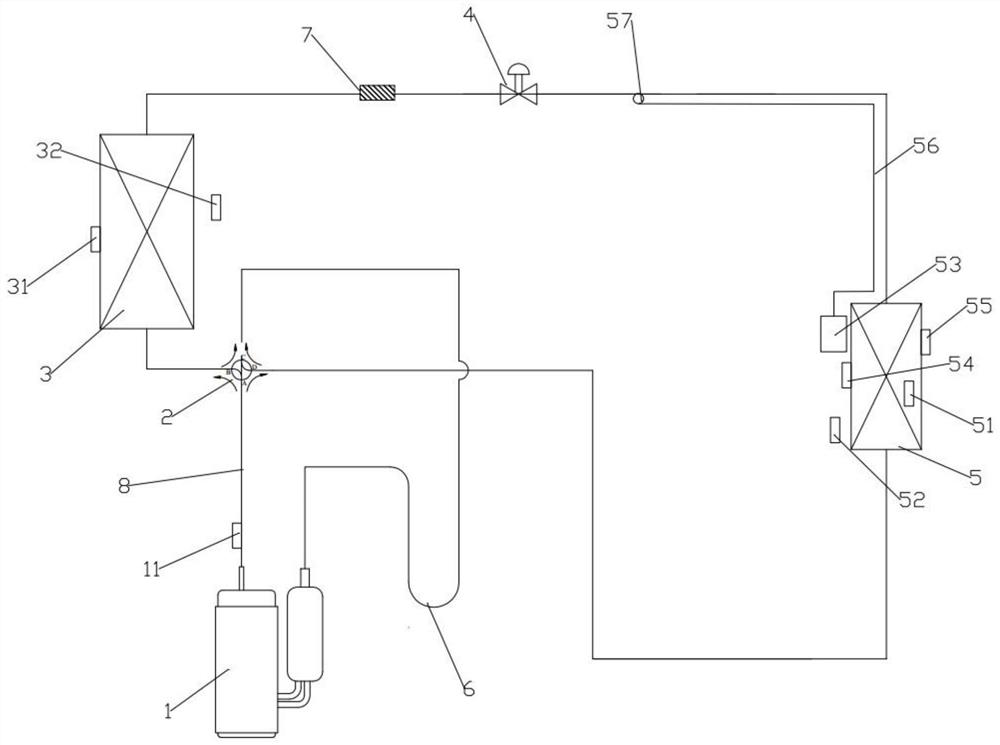

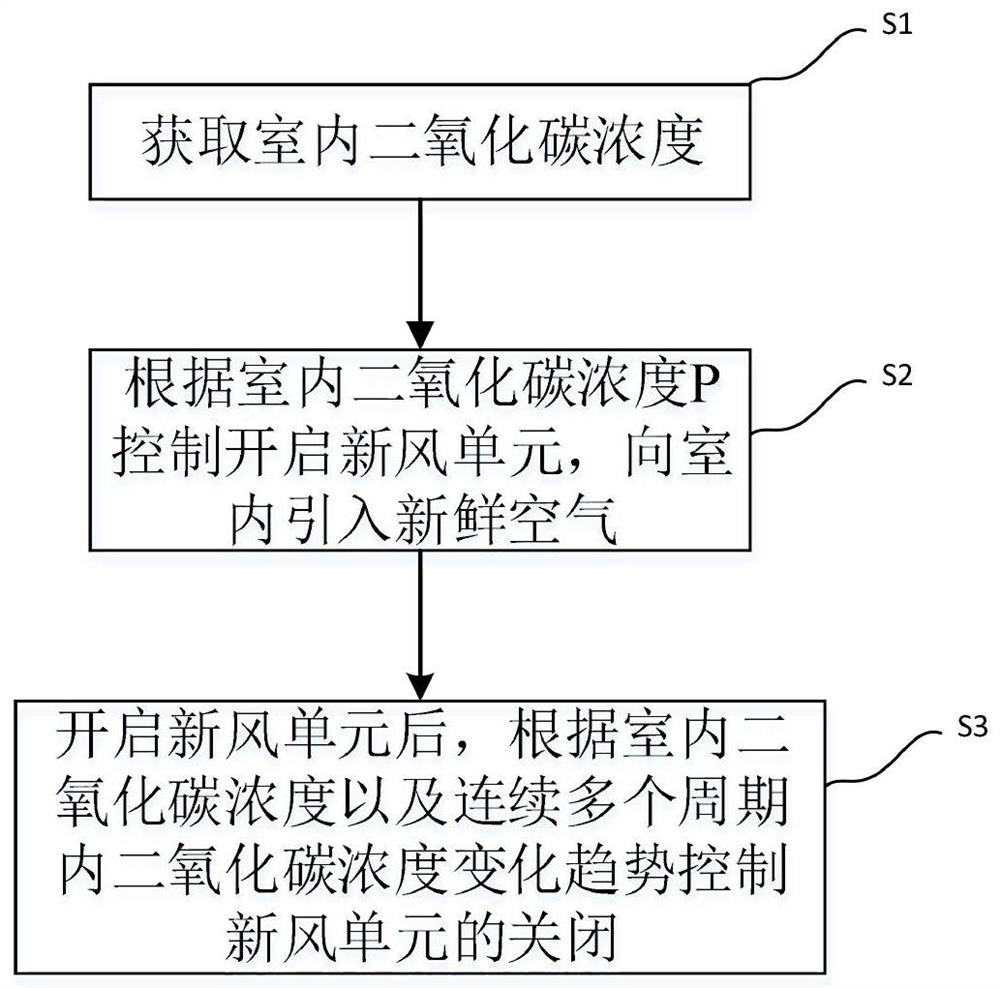

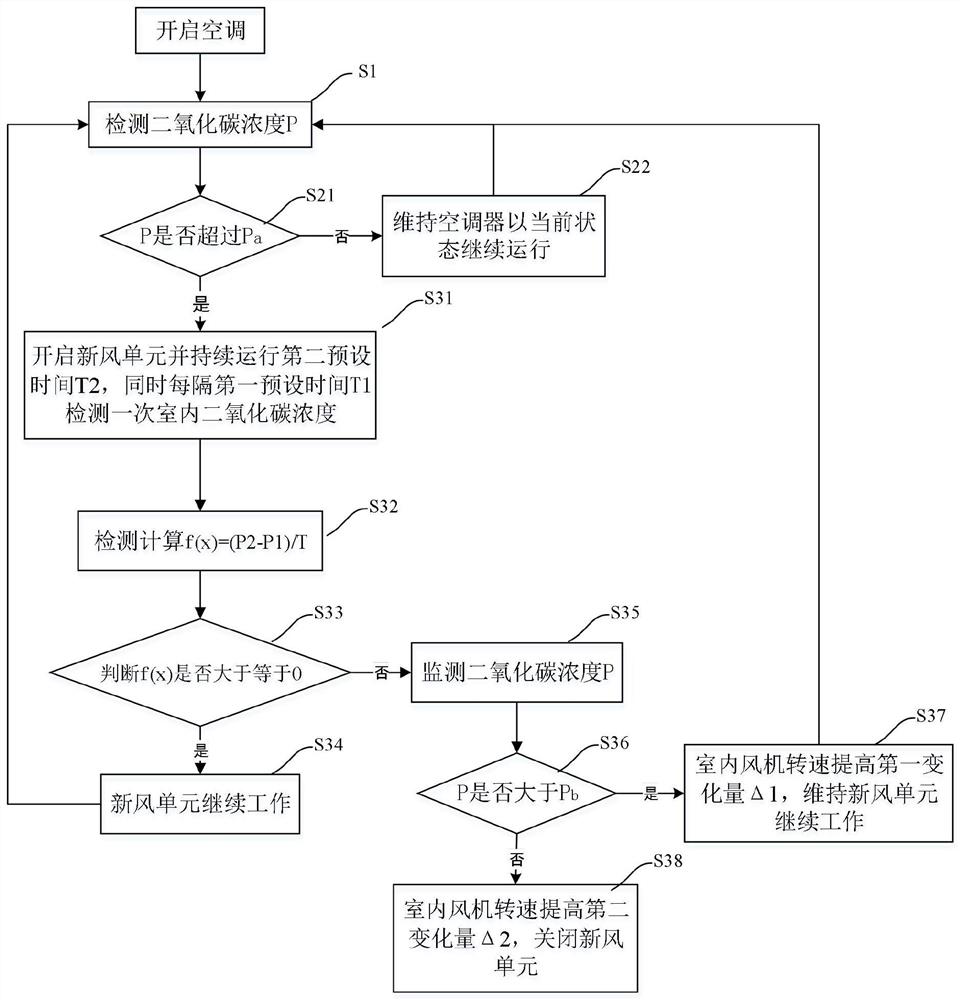

Ventilation system control method and device and air conditioner

ActiveCN111780335AEnsure data accuracy and stabilityImprove indoor air qualityMechanical apparatusSpace heating and ventilation safety systemsProcess engineeringIndoor air

The invention provides a ventilation system control method and device and an air conditioner. The method comprises the steps that the indoor carbon dioxide concentration is obtained; a ventilation unit is controlled to be started according to the indoor carbon dioxide concentration, and fresh air is introduced an indoor; after the ventilation is started, the ventilation unit is controlled to be closed according to the indoor carbon dioxide concentration and the carbon dioxide concentration change trend; and the carbon dioxide concentration change trend is obtained by detecting a first-order derivative f (x) of the carbon dioxide concentration. By arranging a carbon dioxide concentration sensor and the ventilation unit, the indoor carbon dioxide concentration is detected in real time, the first-order derivative of the carbon dioxide concentration is accurately calculated, the indoor carbon dioxide concentration change can be accurately and reliably fed back in real time, the ventilationunit is accurately regulated and controlled to introduce outdoor fresh air into the indoor, and the ventilation unit is controlled to be opened and closed; erroneous judgment caused by abnormal signals is avoided, the data accuracy and stability are effectively guaranteed, and the indoor air quality is improved.

Owner:NINGBO AUX ELECTRIC +1

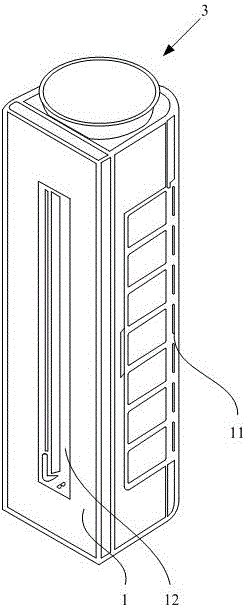

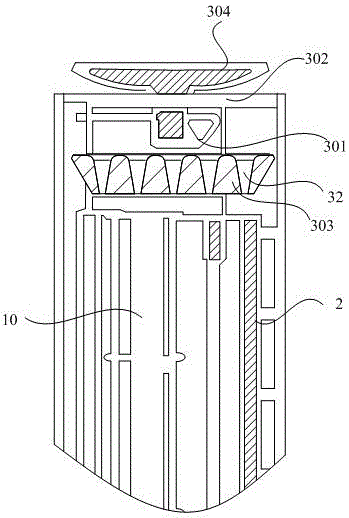

Air inducing type cabinet air conditioner and air mixing method

ActiveCN106287946ARealize controllable operationIncrease wind speedDucting arrangementsLighting and heating apparatusEngineeringMixing effect

The invention discloses an air inducing type cabinet air conditioner and an air mixing method. The air inducing type cabinet air conditioner comprises a shell and an evaporator, wherein an air inlet and an air outlet are arranged on the shell; the air inducing type cabinet air conditioner further comprises an air inducing component; the air inducing component comprises an air duct and a fan; an air inlet port is arranged on the air duct; an air inducing port is arranged on the shell; the fan is arranged between the air inducing port and the air inlet port; air outlet nozzles are arranged on the air duct; and the air outlet nozzles are located in the shell and face to the air outlet. The air mixing effect and the air mixing ability of the air inducing type cabinet air conditioner are improved, and the integral appearance effect of the air inducing type cabinet air conditioner is optimized.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

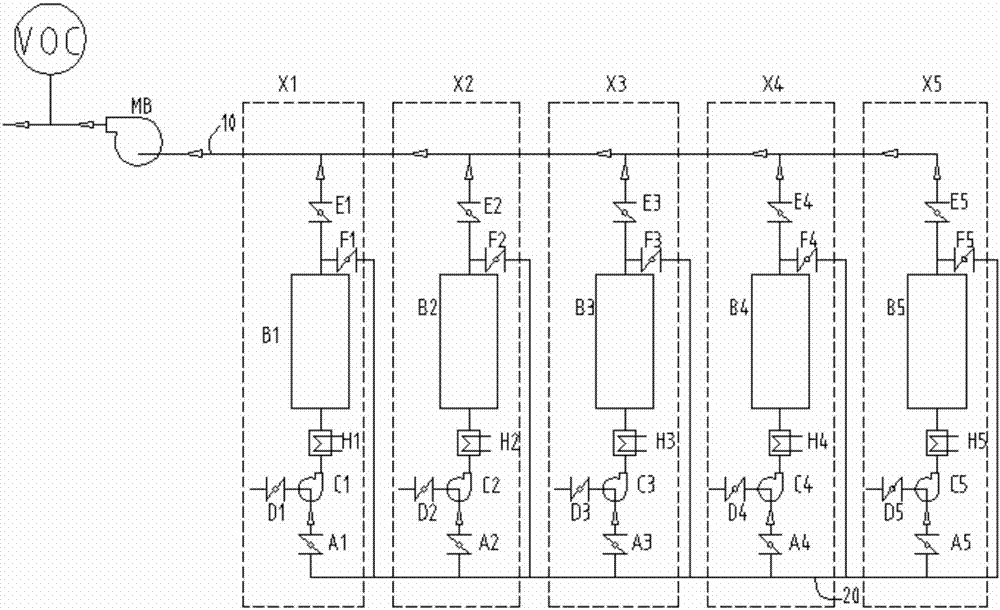

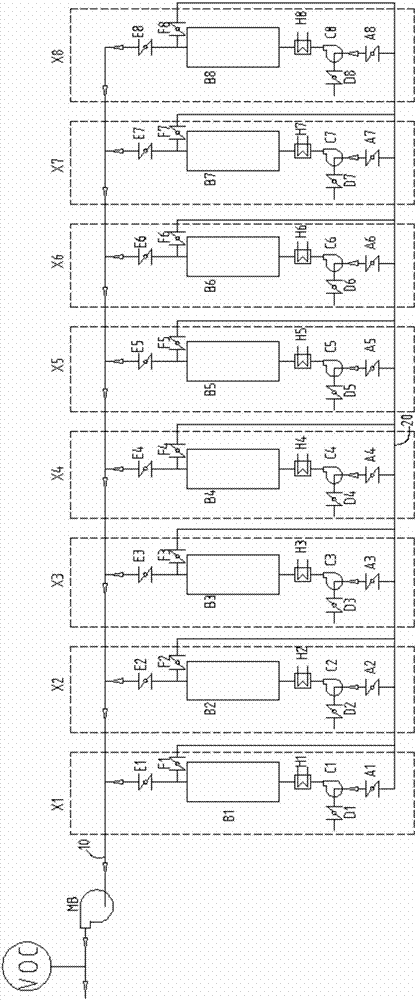

Air circulation system for printing machine

The invention discloses an air circulation system for a printing machine. The air circulation system comprises n printing color cells which are arranged in parallel, wherein n is larger than or equal to 2. Each printing color cell comprises a printing drying channel, a color set air supply draught fan, an exhaust valve and an air return valve, wherein an inlet of the printing drying channel communicates with an outlet of the color cell air supply draught fan. An outlet of the printing drying channel of each printing color cell communicates with a main exhaust pipe through the corresponding exhaust valve, and the outlet of the printing drying channel of each printing color cell communicates with a main air return pipe through the corresponding air return valve. An inlet of the color cell air supply draught fan of each printing color cell communicates with the main air return pipe, and an outlet of the main exhaust pipe communicates with an inlet of a main exhaust draught fan. An outlet of the main exhaust draught fan is led to a waste gas treatment device, and a certain number of exhaust valves are opened for controlling the air extracting amount of the main exhaust draught fan. By means of the air circulation system for the printing machine, waste gas of the printing color cells large in ink feeding amount can be directly discharged, waste gas of the printing color cells small in ink feeding amount enters the main air return pipe to be cycled, the waste gas treatment efficiency is improved, and the waste gas treatment cost is reduced.

Owner:广州黑马科技有限公司

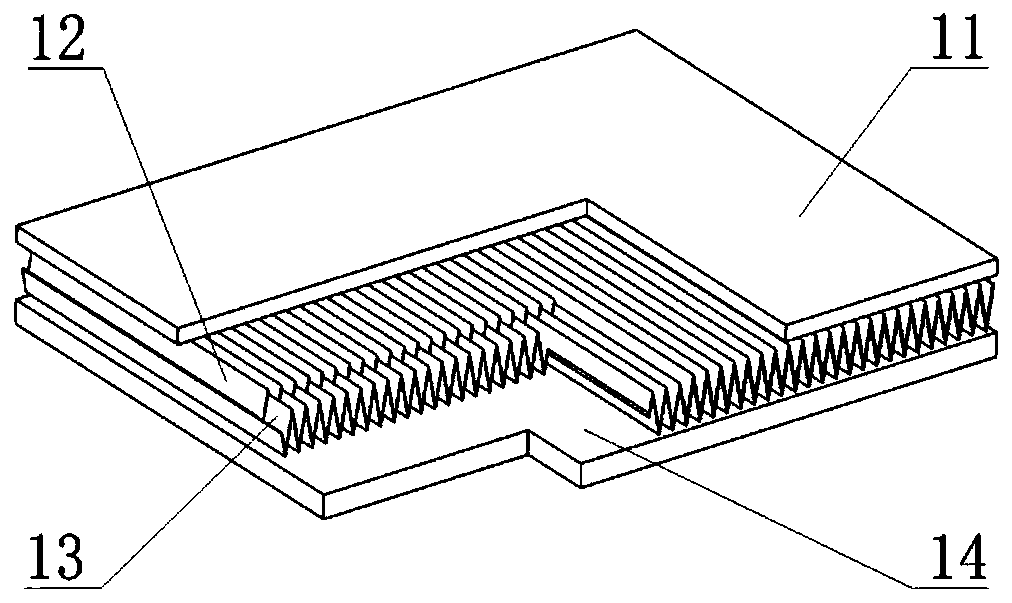

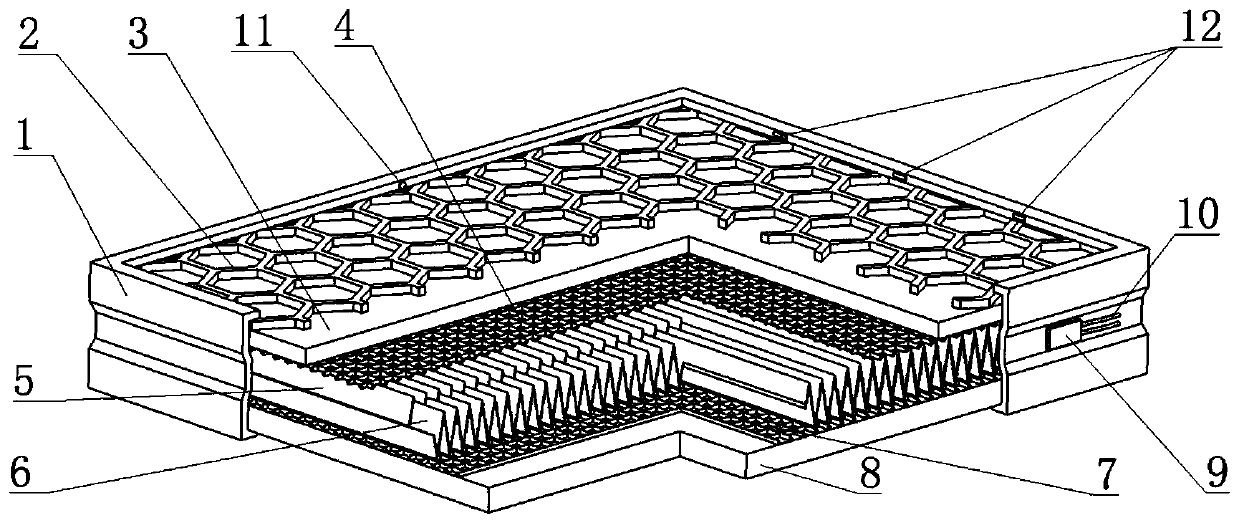

Anti-virus type automobile air conditioner filter

InactiveCN111228951AEfficient captureEfficient killingCombination devicesAir-treating devicesVirus typeViral type

The invention discloses an anti-virus type automobile air conditioner filter, the anti-virus type automobile air conditioner filter comprises a pre-filtering supporting layer, a rough filtering layer,an active electrostatic adsorption positive electrode layer, a fine filtering layer, a passive electrostatic adsorption layer, an active electrostatic adsorption negative electrode layer and a micropore trapping layer, which are fixed in a layered mode from top to bottom and form a filter body. The filter body is fixed in a sealed supporting frame, a plurality of ultraviolet sterilizing lamps arefixed on the inner wall of the sealed supporting frame, and the ultraviolet sterilizing lamps are arranged on the upper side and the lower side of the filter body; wherein a wire harness, a sensor, the ultraviolet disinfection lamp, the active electrostatic adsorption positive electrode layer, the passive electrostatic adsorption layer and the active electrostatic adsorption negative electrode layer are correspondingly connected with a controller, and the wire harness is in two-way communication with a whole vehicle CAN network. The anti-virus type automobile air conditioner filter is used for filtering, collecting, killing and removing viruses and removing part of organic matter, smell, bacteria, particles and the like, and therefore the air quality is improved in an auxiliary mode.

Owner:开沃新能源汽车集团股份有限公司

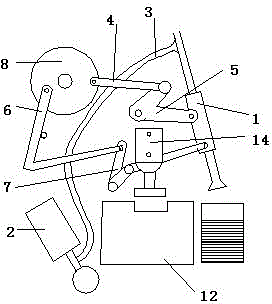

Feeding device for stamping bottle cap

The invention relates to a feeding device for stamping a bottle cap. A vacuum material suction rod is connected with a vacuum pump through a vacuum pipe; a suction head is arranged on the vacuum material suction rod; a lifting connection rod mechanism and a steering connection rod mechanism are hinged to two corresponding edges of a rotating disk respectively; the lifting connection rod mechanism comprises a first pushing rod and an L-shaped pulling rod; the first pushing rod is hinged to the rotating disk; the middle of the L-shaped pulling rod is hinged to a machine frame; the two ends of the L-shaped pulling rod are hinged to the first pushing rod and the vacuum material suction rod respectively; a second pushing rod is hinged to the rotating disk; a hinged point is arranged in the middle of a lever type swinging rod, and the two ends of the lever type swinging rod are hinged to the second pushing rod and the vacuum material suction rod respectively; a stamping workbench is arranged below a vacuum material suction device; a bottle cap groove is formed in the stamping workbench; a first cylinder is arranged right above the bottle cap groove; a compressing block is arranged on a piston rod of the first cylinder. According to the feeding device, the problem of existence of potential safety hazards or high equipment cost in the separation transmission process of a base plate is mainly solved.

Owner:重庆瑶红食品有限公司

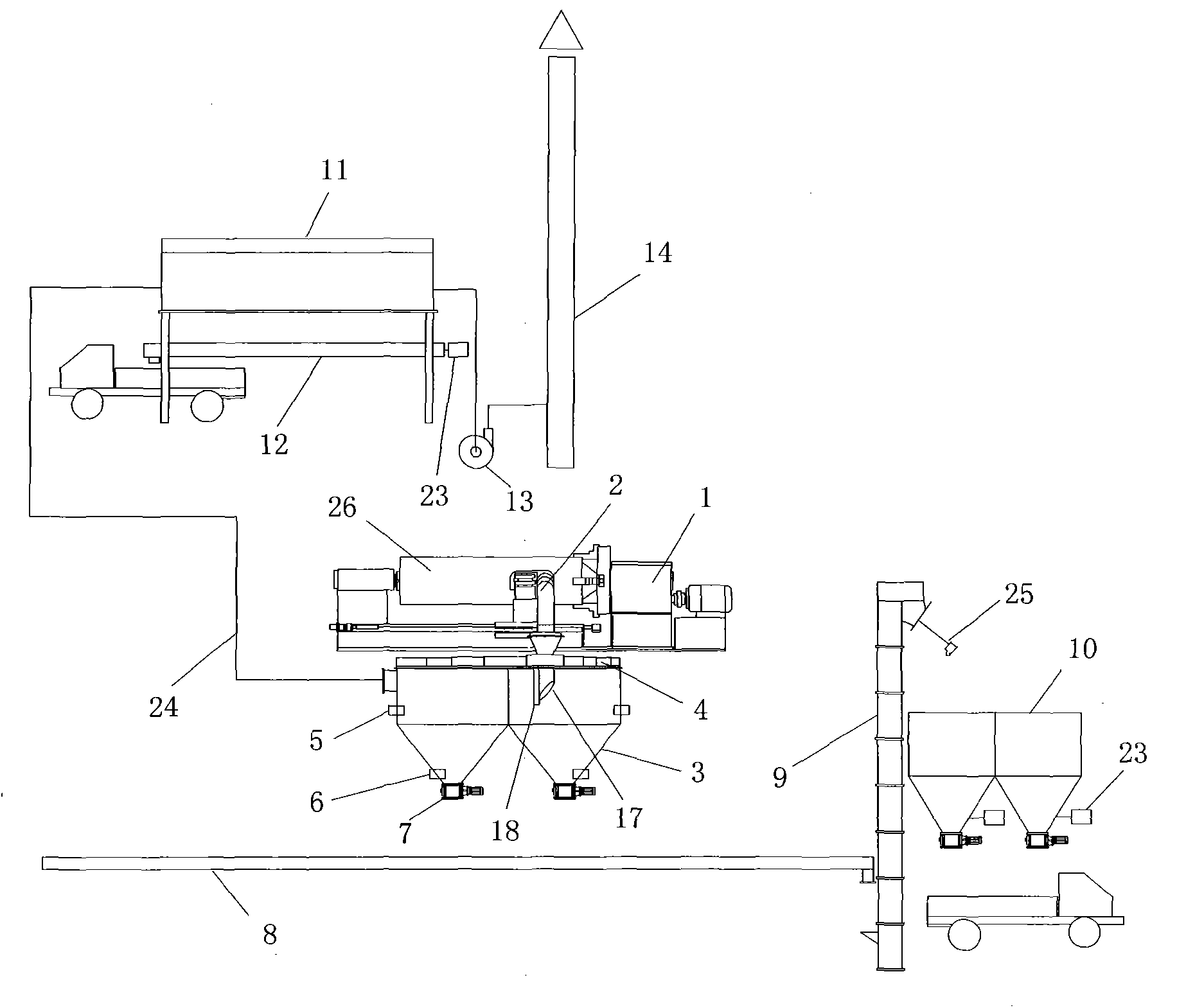

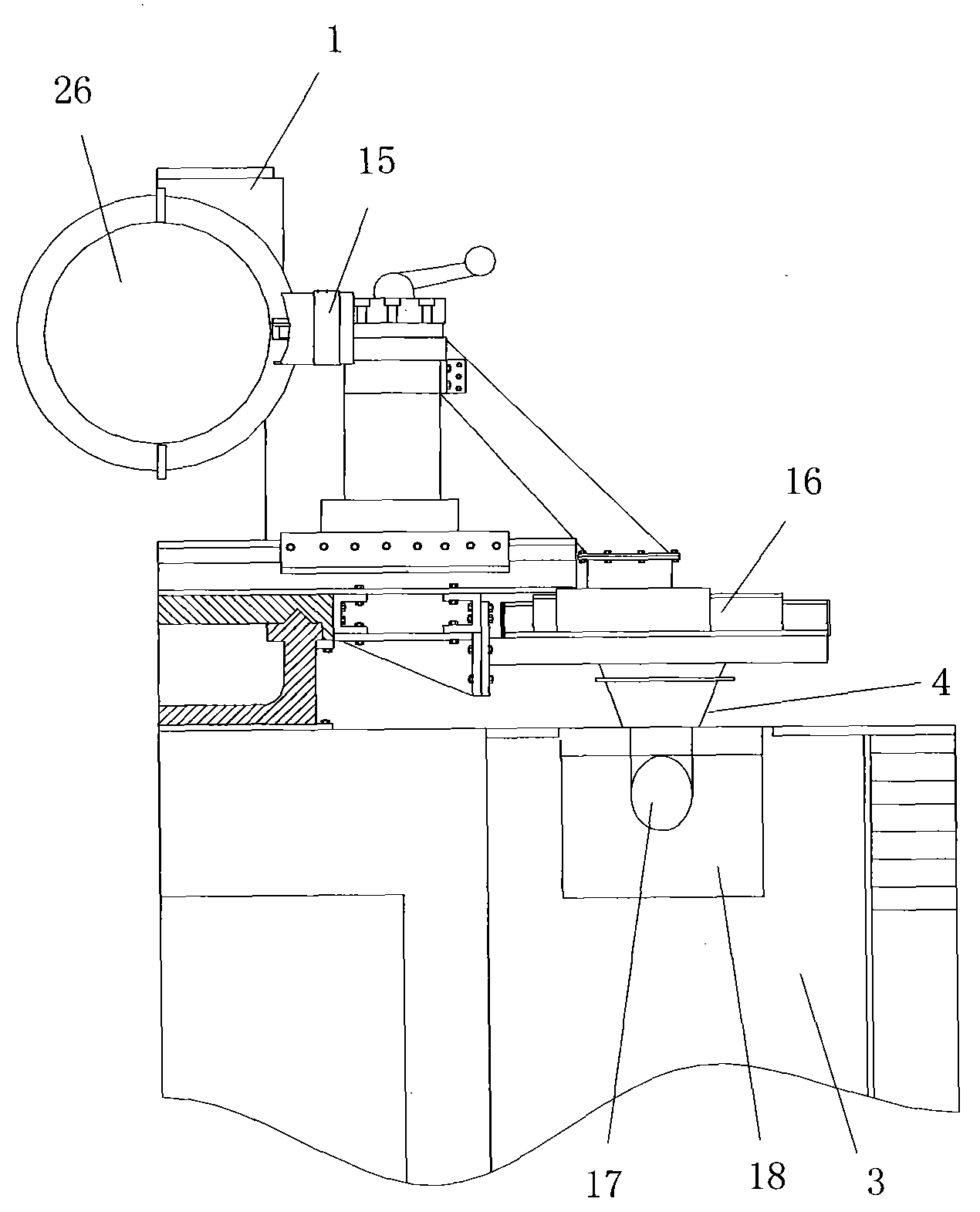

Cutting chipping gas-solid separation and dust collection treatment system

InactiveCN104338404AEasy to separateReduce the impact of settlementCombination devicesBaghouseMachine tool

The invention discloses a cutting chipping gas-solid separation and dust collection treatment system. The cutting chipping gas-solid separation and dust collection treatment system structurally comprises an induced air dust collection cover device arranged on a machine tool in a sliding manner; two settling bins are arranged in parallel under the induced air dust collection cover device; electric unloaders are arranged at the bottoms of the two settling chambers; an air outlet pipeline is arranged at one sides of the settling chambers; a scraper conveyor is arranged under the electric unloaders; an elevator is arranged at the discharge end of the scraper conveyor and connected with a storage bin; the air outlet pipeline is connected with a pulsing bag-type dust remover; a screw discharger is arranged under the pulsing bag-type dust remover; an air outlet of the pulsing bag-type dust remover is connected with an induced draft fan which is connected with a chimney. The cutting chipping gas-solid separation and dust collection treatment system is capable of overcoming the shortcomings in the prior art; as a result, the air pressure and air speed requirements of the system are reduced, the abrasion of particle recovering to the pipeline is reduced and the dust removal effect is good; besides, the labor intensity is reduced and the production efficiency is improved.

Owner:河北顺天电极有限公司

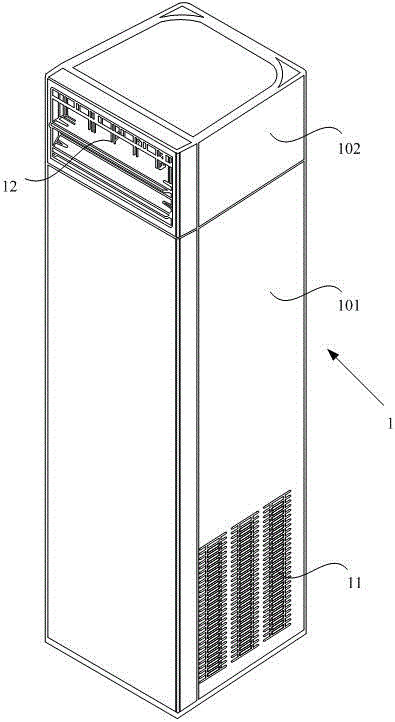

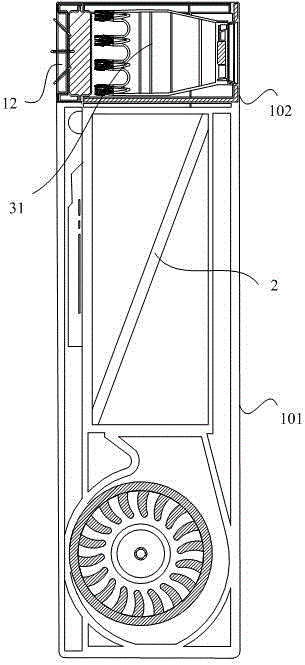

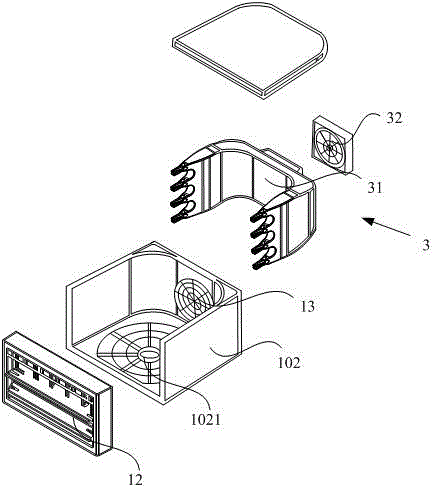

Vertical air conditioner and air mixing method

InactiveCN106225059ARealize controllable operationGood lookingDucting arrangementsMechanical apparatusMixing effectWaste management

The invention discloses a vertical air conditioner and an air mixing method. The vertical air conditioner comprises a shell and an evaporator; an air inlet and an air outlet are formed in the shell; an air outlet cavity is formed between the evaporator and the air outlet; an air guide module is arranged at the top of the shell, and is provided with an air guide inlet and an air guide outlet; a fan is arranged between the air guide inlet and the air guide outlet; and the air guide outlet is communicated with the air outlet cavity. The vertical air conditioner realizes improvement of air mixing effect and air mixing capacity, and optimizes overall appearance effect.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Blow pipe handle of air compressor

ActiveCN103909076ASimple structureEasy to usePositive displacement pump componentsCleaning using gasesGas compressorEngineering

The invention discloses a blow pipe handle of an air compressor. The blow pipe handle of the air compressor comprises a handle connected between a rubber hose and a blow pipe, a connector connected with the blow pipe is formed in one end of the handle, a fastening piece and a barrel in sleeve fit with the fastening piece are mounted at the other end of the handle, a circle of external thread matched with an internal thread of the sleeve is formed in the front end of the fastening piece, each of two sides of the handle is longitudinally opened with an adjusting groove, an adjusting shaft is mounted in the adjusting groove, the height of the adjusting shaft is matched with the outer diameter of the handle, and an adjusting button is mounted at each of two ends of the adjusting shaft. The blow pipe handle of the air compressor is simple in structure, convenient to use, capable of effectively controlling the air output, and capable of being regulated according to the practical situation of the sundries in blowing.

Owner:JINLING INST OF TECH

Multi-split air conditioner system, and air valve device and outdoor unit of multi-split air conditioner system

ActiveCN109163386AControl air volumeAdjustable air supply areaMechanical apparatusSpace heating and ventilation safety systemsAir volumeControl system

The invention provides a multi-split air conditioner system, and an air valve device and an outdoor unit of the multi-split air conditioner system. The air valve device comprises an air valve, an executer and a controller. The air valve can be arranged at the position of an air supply port of an outdoor draught fan of the multi-split air conditioner system and is used for adjusting the air supplyarea of the air supply port. The executer is connected with the air valve and used for controlling the air valve to be switched between the opening position and the closing position, and accordingly the air supply area of the air supply port can be adjusted. The controller is connected with the executer, is independent of a control system of the multi-split air conditioner system and is used for controlling the action of the executer. The air valve device can control the air volume of the outdoor draught fan, and the situation that under the low-temperature refrigeration work condition, due tothe too high air volume of the outdoor draught fan, the high pressure is relatively low, and consequently the system cannot normally run is avoided; and the actions of the air valve are controlled tobe conducted and not to be conducted through the executer, the actions of the executer are controlled through the controller, the controller is independent of the control system of the multi-split air conditioner system, accordingly, compatibility for existing systems is good, and system software upgrading is not needed.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

Microwave and electric heating combination-type coffee roasting device

ActiveCN108851132AImprove qualityReduce energy consumptionFood processingFood treatmentMicrowaveMoisture sensor

The invention relates to a microwave and electric heating combination-type coffee roasting device and belongs to the field of processing of agricultural products. The device comprises a microwave device, a monitoring device, a transmission device, an electric heating device and a control device; the microwave device is used for generating microwaves to conduct microwave heating on materials; the monitoring device comprises a temperature and humidity sensor, an infrared temperature measurement sensor and a temperature sensor; the temperature and humidity sensor is used for monitoring the temperature and humidity of discharged air, the infrared temperature measurement sensor is used for monitoring the temperature of the surfaces of the materials, and the temperature sensor is used for monitoring the temperature of an electric heating tube; the control device is used for controlling the microwave device, the transmission device and the electric heating device according to temperature andhumidity information of the discharged air, temperature information of the surfaces of the materials and the temperature of the electric heating tube which are monitored by the monitoring device. According to the device, a microwave heating mode is used for roasting green coffee beans, the preheating process is not needed during microwave heating, the quality of roasted coffee is improved, the roasting time is shortened, the roasting efficiency is improved, the production cost is lowered, and the device saves energy and is environmentally friendly.

Owner:KUNMING UNIV OF SCI & TECH

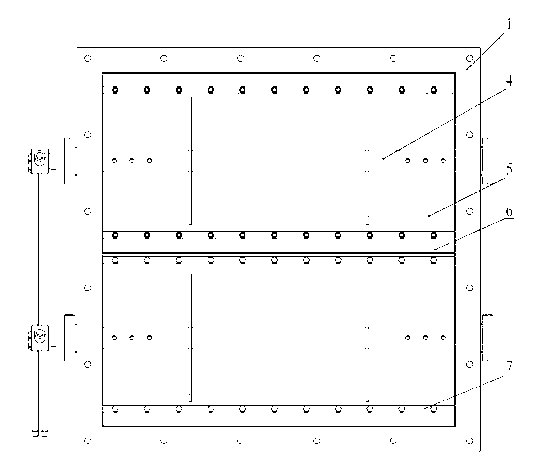

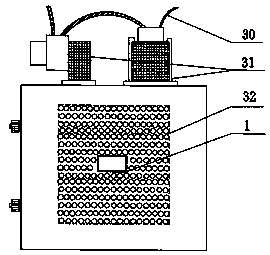

Vertical laminar flow system of microenvironment

InactiveCN102254790AEasy to controlControl air volumeSemiconductor/solid-state device manufacturingAir volumeKeel

The invention discloses a vertical laminar flow system of a microenvironment. The vertical laminar flow system comprises a chamber with a cuboidal shape, a fan module, a deflector, a flow equalization device, a filter module and a keel, wherein at least one fan is arranged in the fan module; the fan module is arranged in the chamber; the deflector is arranged in the chamber; the flow equalization device is arranged below the fan module and the deflector in the chamber; and the filter module and the keel are arranged on an inner ground surface in the chamber. The vertical laminar flow system of the microenvironment uniformly controls the air volume of an air inlet of a vertical laminar flow of the whole area by the fan module, and performs flow field optimization on the inner chamber by the coaction of the deflector and the flow equalization device to blow an air flow in the chamber uniformly and consistently into a lower-layer space by the air inlet surface of the filter module to obtain a flow field with relatively higher consistency, thereby making the cleanness of a local microenvironment meet requirements.

Owner:BEIJING SEVENSTAR ELECTRONICS CO LTD

Mower using exhaust gas turbocharging auxiliary device

The invention relates to a lawn mower adopting an exhaust gas turbocharging auxiliary device. The device includes a gas outlet pipe sealed and communicated with a rear intake pipe and a gas introduction pipe sealed and communicated with an exhaust pipe. There is a flow control device sealingly connected between the adjacent ends of the tubes. The flow control device is controlled by the accelerator pedal on one side. When the accelerator pedal is released, the flow control device is suitable for introducing an appropriate amount of gas from the gas outlet pipe to the gas inlet pipe; loosen the accelerator pedal When pedaling, the compressed gas in the rear intake pipe is directly introduced into the exhaust pipe through the pipeline and the flow control device, and the flow control device adjusts the amount of gas introduced according to the speed of the accelerator pedal; The speed sends a proper amount of outside air into the front intake pipe; the power of the engine is immediately weakened with the relaxation of the accelerator pedal, reducing the time lag of the turbo.

Owner:朱海燕

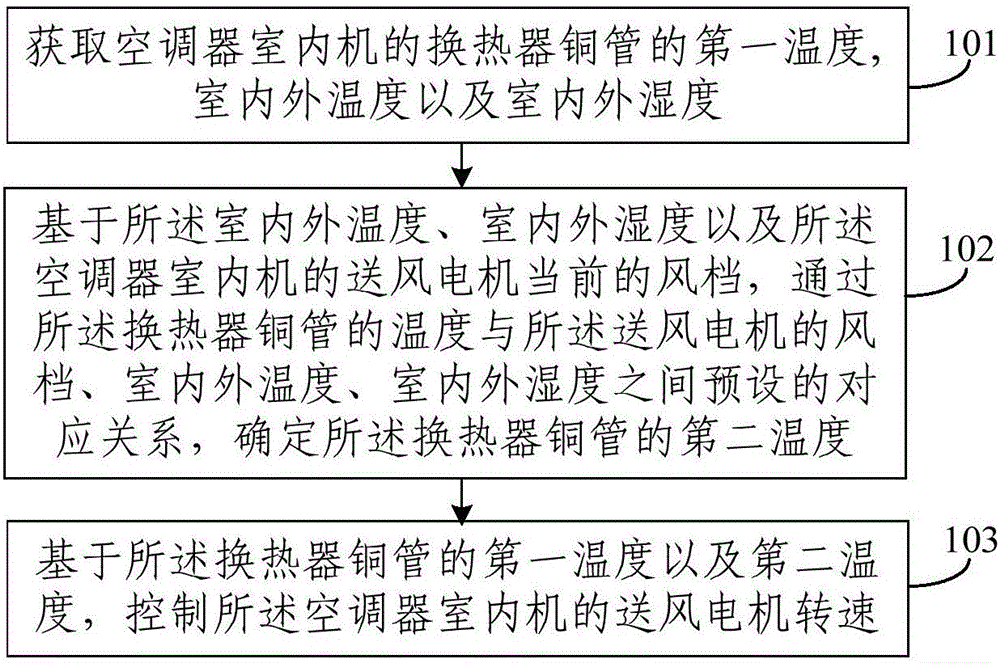

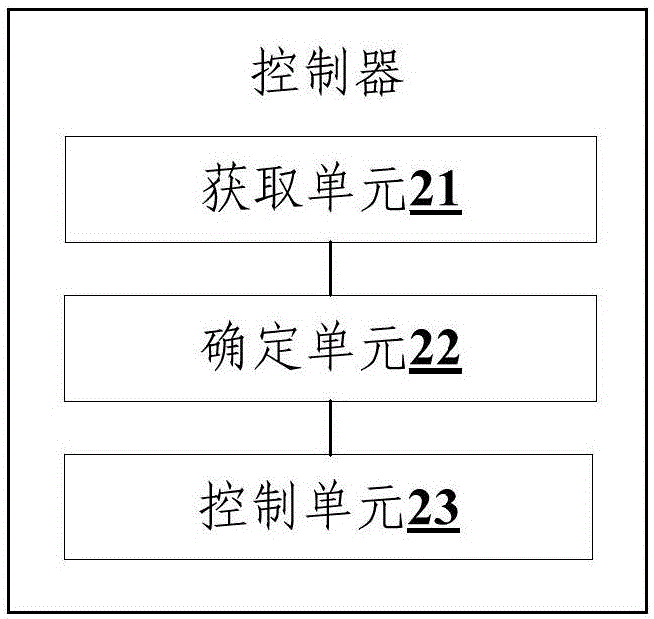

Rotating speed control method of air supply motor, controller and air conditioner

ActiveCN106440260AControl air volumeAir volume automatic adjustmentMechanical apparatusSpace heating and ventilation safety systemsAir volumeEngineering

The invention discloses a rotating speed control method of an air supply motor, a controller and an air conditioner. The method comprises the following steps: a first temperature of a heat exchanger copper pipe of an air conditioner indoor unit, an indoor / outdoor door temperature and an indoor / outdoor humidity are obtained; based on the indoor / outdoor temperature, the indoor / outdoor humidity and a present air level of the air supply motor of the air conditioner indoor unit, a second temperature of the heat exchanger copper pipe is determined through a preset corresponding relation among the temperature of the heat exchanger copper pipe, the air level of the air supply motor, the indoor / outdoor temperature and the indoor / outdoor humidity; and the rotating speed of the air supply motor of the air conditioner indoor unit is controlled based on the first temperature and the second temperature of the heat exchanger copper pipe. As the temperatures of the heat exchanger copper pipe corresponding to the indoor / outdoor temperature and humidity are determined, and the rotating speed of the air supply motor is controlled based on the temperatures and actual temperature of the heat exchanger copper pipe, the method can simply realize control of air volume of the air conditioner in a wider static pressure range, guarantees the air conditioner to automatically adjust the air volume under different mounting environments, and improves the room comfort.

Owner:HEFEI MIDEA HEATING & VENTILATING EQUIP +1

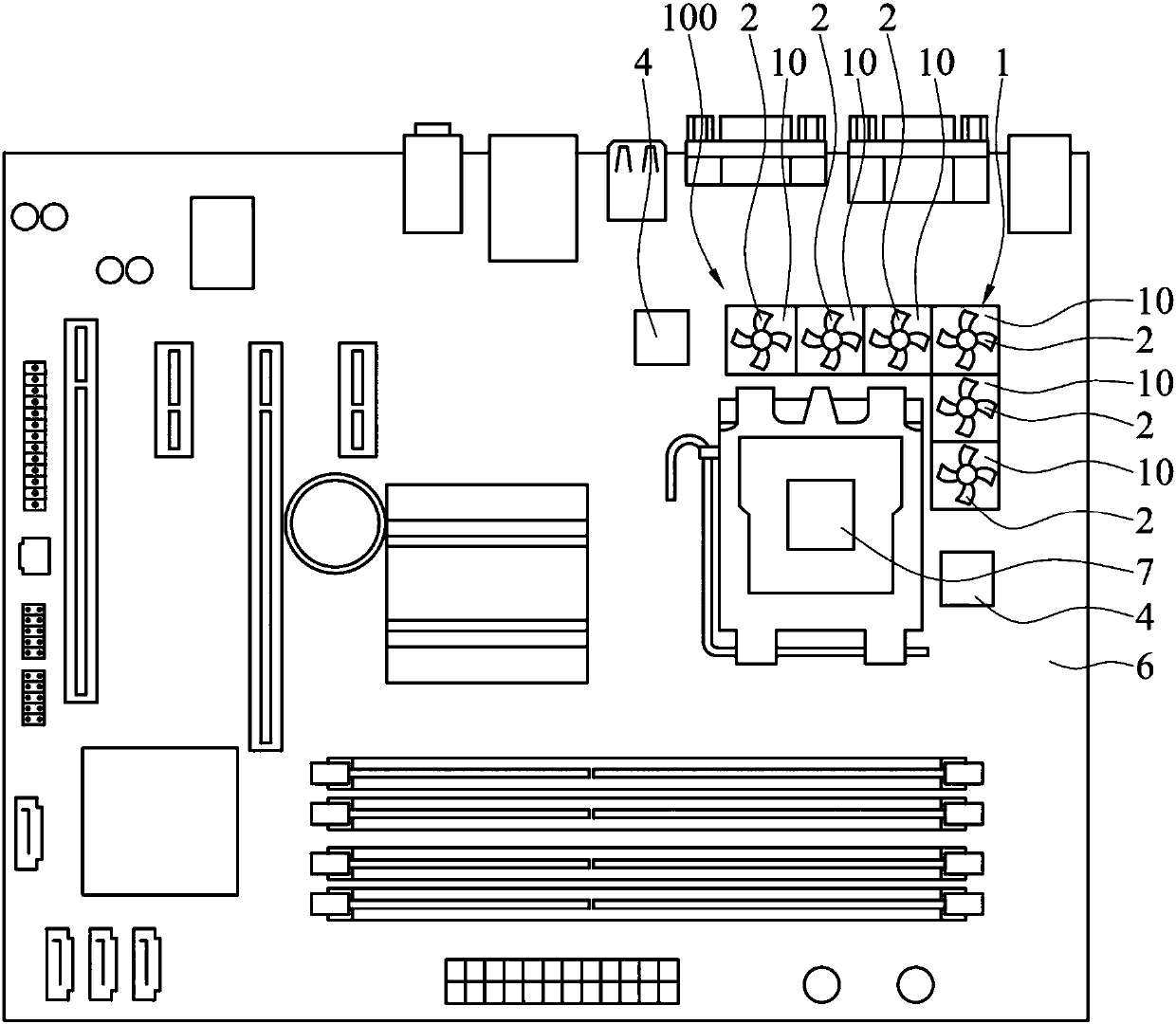

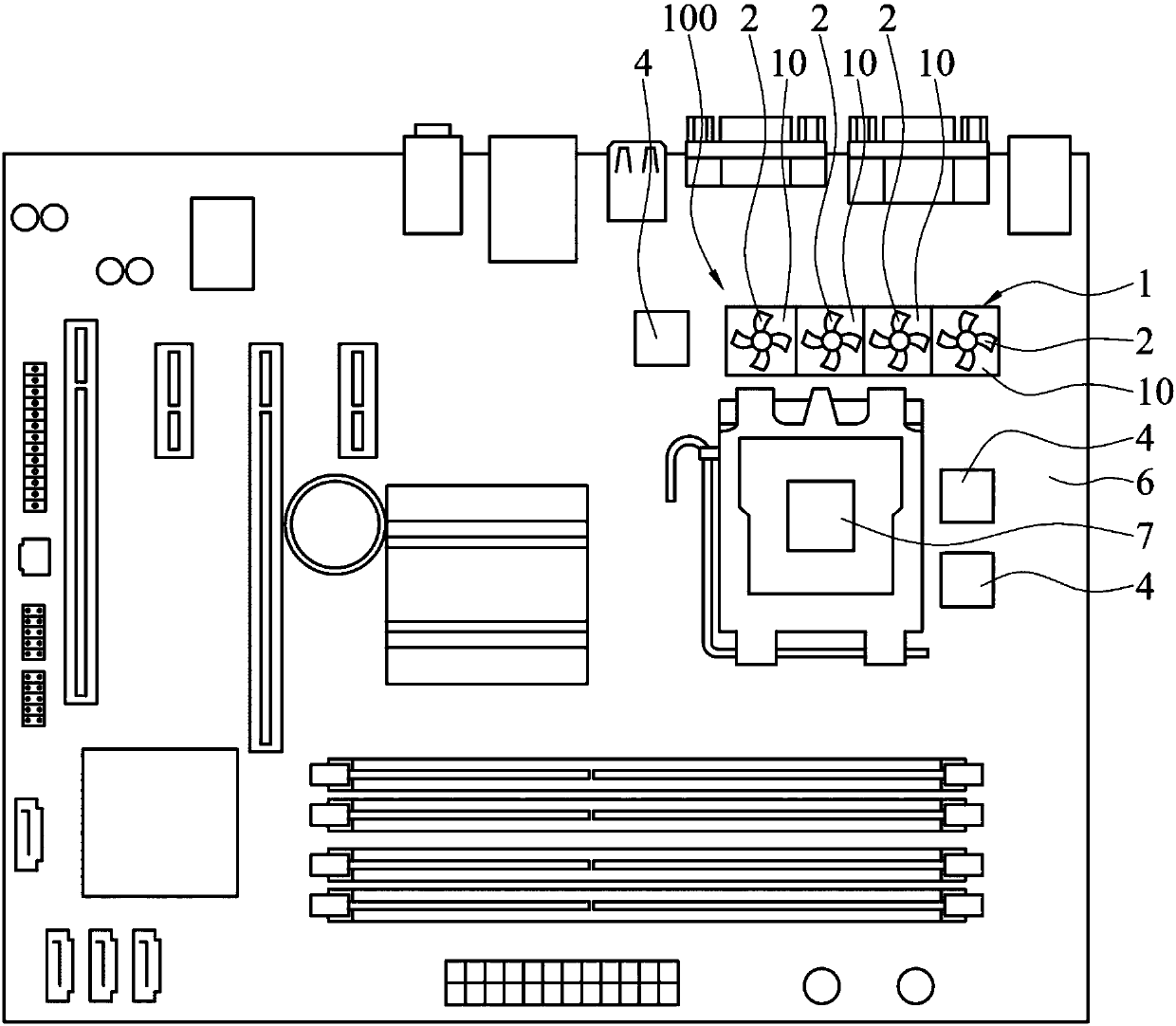

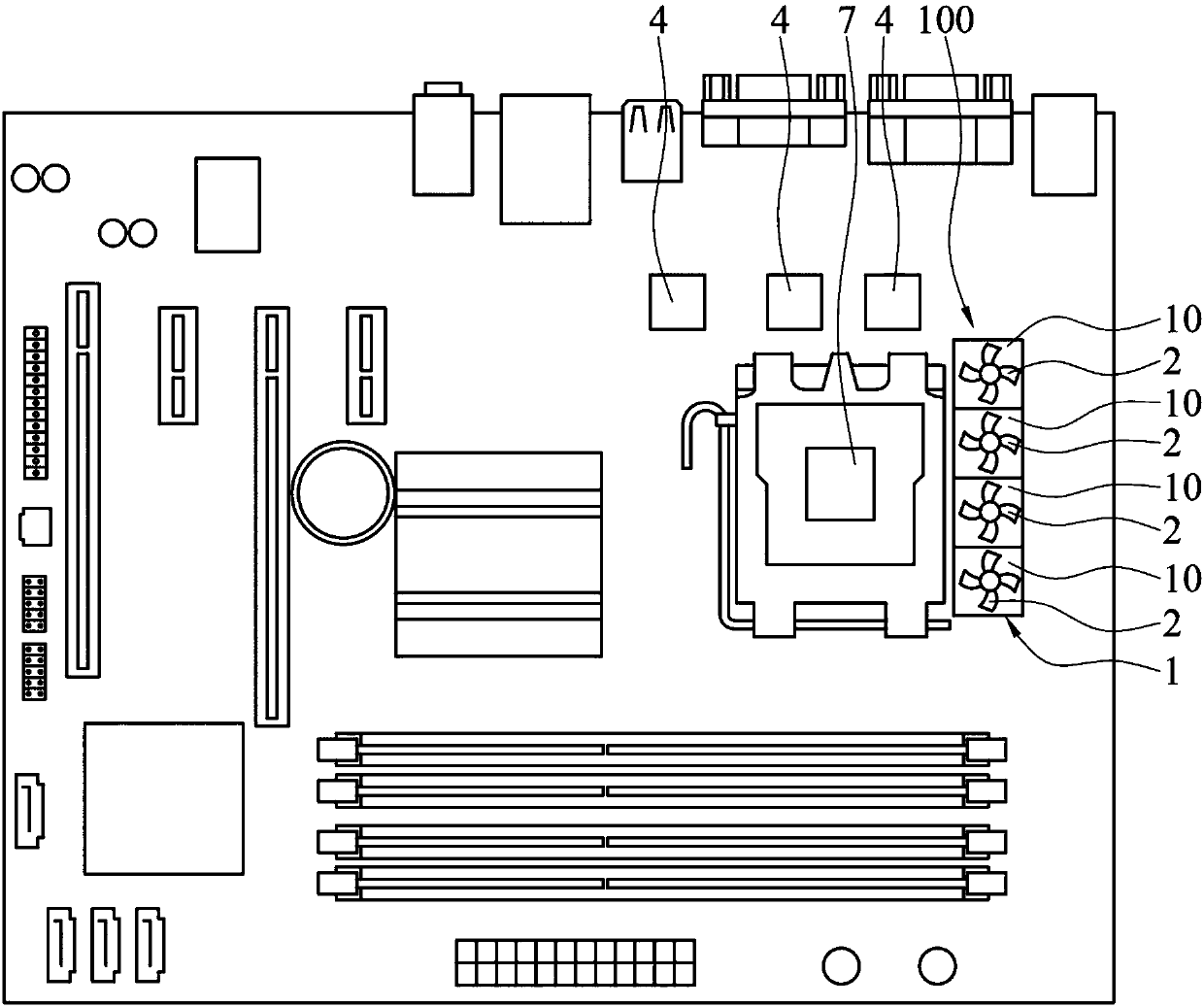

Heat dissipation device capable of dissipating heat in partitioned mode and mainboard with heat dissipation device

PendingCN109960382AAchieve stabilityControl air volumeDigital processing power distributionHeat spreaderControl circuit

The invention discloses a heat dissipation device capable of achieving partition heat dissipation and a mainboard with the heat dissipation device, and the heat dissipation device capable of achievingpartition heat dissipation is used for conducting heat dissipation on a plurality of electronic parts and comprises a heat dissipation device, a plurality of fan modules and a control circuit. The radiator is provided with a plurality of radiating areas, and each radiating area is used for conducting heat on at least one electronic part. The plurality of fan modules are arranged on the radiator,and each radiating area is at least correspondingly provided with one fan module. The control circuit is in signal connection with the electronic part and the fan module and detects the operation state of the electronic part, and at least one fan module in the heat dissipation area is controlled to act correspondingly to the operation state of the electronic part. The invention also provides a mainboard with the heat dissipation device.

Owner:GIGA BYTE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com