Method for setting and controlling pulverized coal preparing system

A pulverized coal preparation and control method technology, applied in the field of control and regulation, can solve the problems of wasting manpower, increasing the failure rate of equipment, reducing the service life of equipment, etc., to reduce work intensity and difficulty, multi-parameter control interval, and save energy and resource effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

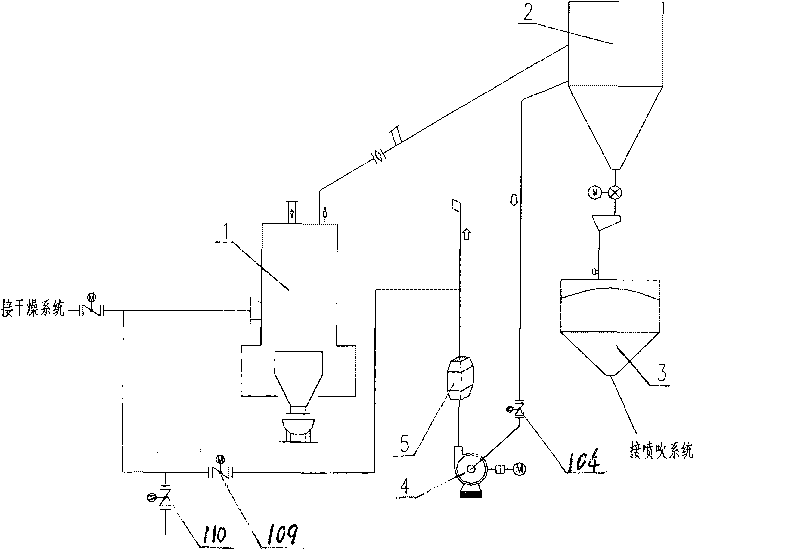

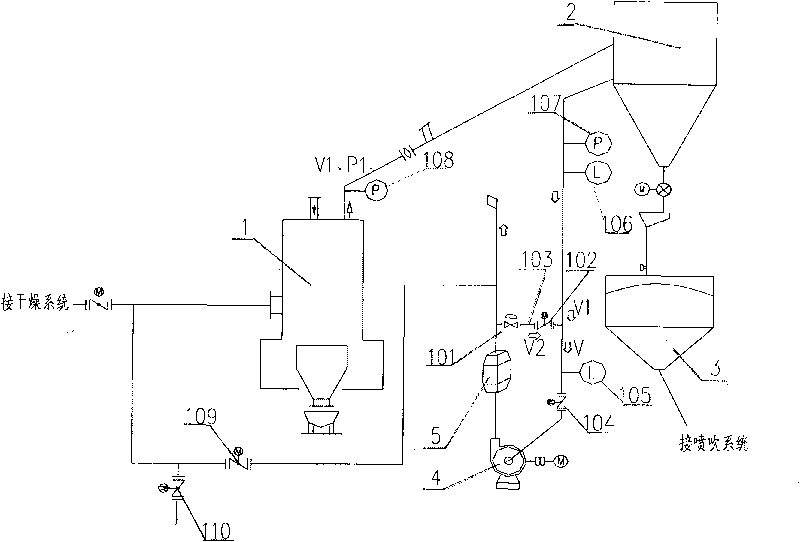

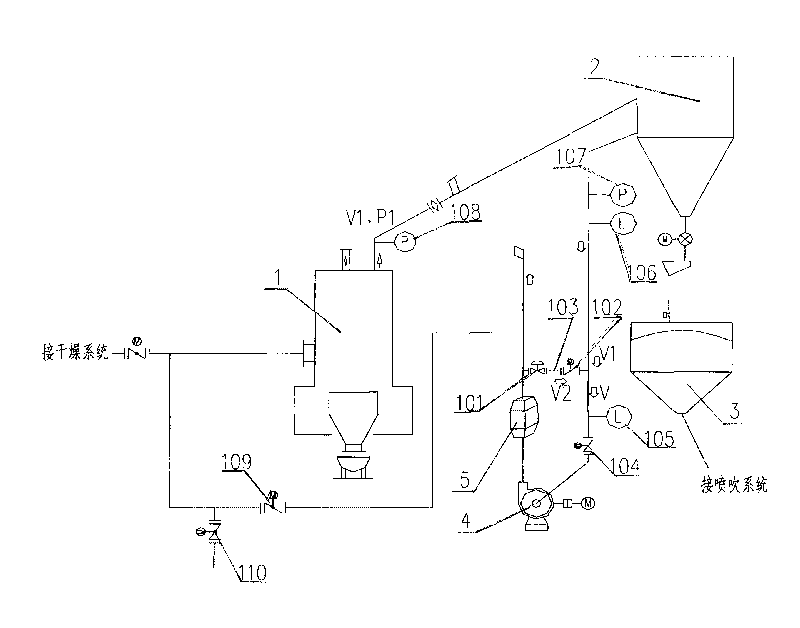

[0021] Attached below figure 2 The present invention will be further described with specific examples, but the present invention is not limited to the following specific methods.

[0022] The hot air of the drying system is connected to the coal mill 1, and the pulverized coal is sent to the pulverized coal collection device 2 through the pneumatic conveying pipeline, and the pulverized coal is collected in the pulverized coal bin 3, and the exhaust gas is discharged through the pulverized coal fan 4 and the muffler 5 .

[0023] The other branch of the hot air of the drying system is equipped with electric butterfly valves 109 and 110, which are connected to the discharge pipeline behind the muffler 5.

[0024] Fan inlet valve 104 is installed at the inlet of pulverized coal fan 4 .

[0025] A communication pipe 103, a flow control valve 101 and an electric control valve 102 are installed between the waste gas pipeline from the pulverized coal collection device 2 to the pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com