Production method of liquid crystal glass substrate

A technology for liquid crystal glass substrates and production methods, applied in glass furnace equipment, glass manufacturing equipment, glass cutting devices, etc., can solve the problems of low production efficiency, high defective rate, poor quality of glass substrates, etc., and achieve high production efficiency , high yield, high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

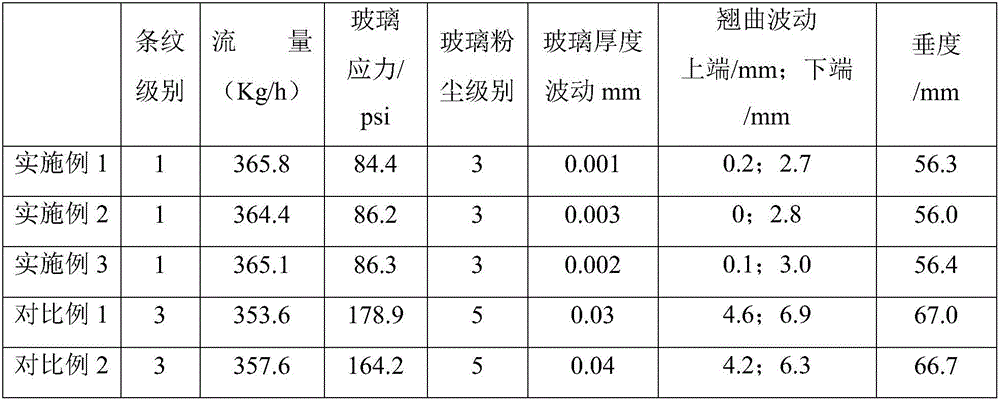

Embodiment 1

[0042] (1), prepare the glass substrate raw material according to the following weight percentage: 56% by weight of SiO 2 , 7% by weight of B 2 o 3 , 14 wt% Al 2 o 3 , 0.01% by weight of BaO, 3% by weight of CaO, 0.5% by weight of SrO and 0.1% by weight of clarifier SnO 2 ;

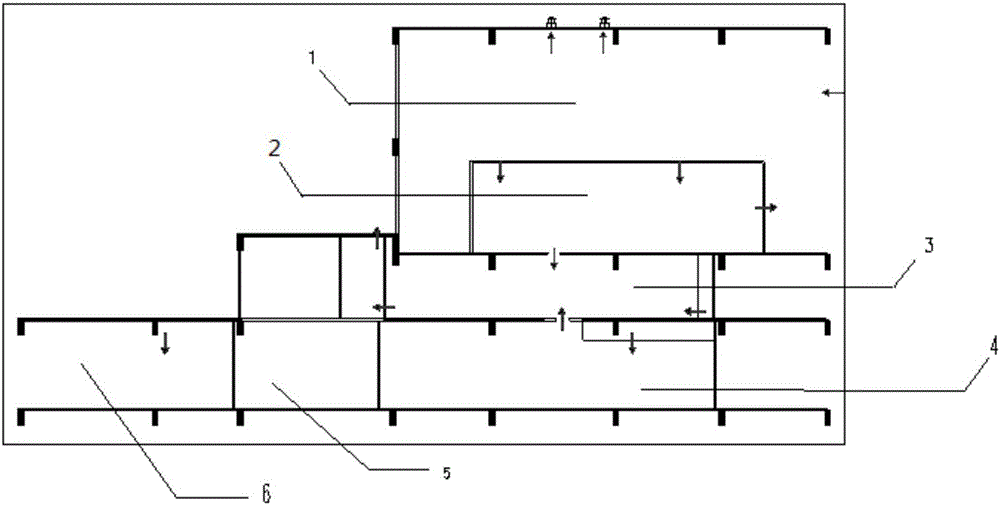

[0043] (2), set pressure sensors independently in the pool furnace area (1), platinum area (2), forming area (3), hot cutting area (4), hot cutting peripheral area (5) and half-wrapped area (6) , static pressure box, exhaust fan or adjustable air valve, detect the pressure through the pressure sensor and control the static pressure box, exhaust fan or adjustable air valve through the controller, or adjust the total air supply volume and total exhaust air volume of each area (1) operating environment pressure higher than atmospheric pressure 4Pa, platinum area (2) operating environment pressure higher than atmospheric pressure 14Pa, molding area (3) operating environment pressure higher than atmospher...

Embodiment 2

[0046] (1), prepare the glass substrate raw material according to the following weight percentage: SiO of 64% by weight 2 , 11% by weight of B 2 o 3 , 18 wt% Al 2 o 3 , 10% by weight of BaO, 8% by weight of CaO, 8% by weight of SrO, 0.5% by weight of ZnO, 4% by weight of MgO, 0.5% by weight of ZrO 2 and 1% by weight of clarifier SnO 2 ;

[0047] (2), set pressure sensors independently in the pool furnace area (1), platinum area (2), forming area (3), hot cutting area (4), hot cutting peripheral area (5) and half-wrapped area (6) , static pressure box, exhaust fan or adjustable air valve, the pressure is detected by the pressure sensor and the static pressure box, exhaust fan or adjustable air valve is controlled by the controller, and at the same time combined with the total air supply and exhaust air volume control of the adjustment area The pool furnace area (1) operating environment pressure is 6Pa higher than atmospheric pressure, platinum area (2) operating environm...

Embodiment 3

[0050] (1), prepare the glass substrate raw material according to the following weight percentage: 60% by weight of SiO 2 , 9% by weight of B 2 o 3 , 16 wt% Al 2 o 3 , 5% by weight of BaO, 5% by weight of CaO, 4% by weight of SrO, 0.25% by weight of ZnO, 2% by weight of MgO, 0.25% by weight of ZrO 2 and 0.5 wt% clarifier SnO 2 ;

[0051] (2), set pressure sensors independently in the pool furnace area (1), platinum area (2), forming area (3), hot cutting area (4), hot cutting peripheral area (5) and half-wrapped area (6) , static pressure box, exhaust fan or adjustable air valve, detect the pressure through the pressure sensor and control the static pressure box, exhaust fan or adjustable air valve through the controller, or control the total air supply volume and the total exhaust air volume Control the operating environment pressure of the pool furnace area (1) to be 5Pa higher than atmospheric pressure, the operating environment pressure of platinum area (2) to be 15P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com