Heat dissipation device capable of dissipating heat in partitioned mode and mainboard with heat dissipation device

A technology of cooling device and motherboard, applied in the direction of digital processing power distribution, instruments, electrical digital data processing, etc., can solve problems such as reducing operating performance, affecting motherboard performance, central processing unit and electronic parts loss and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

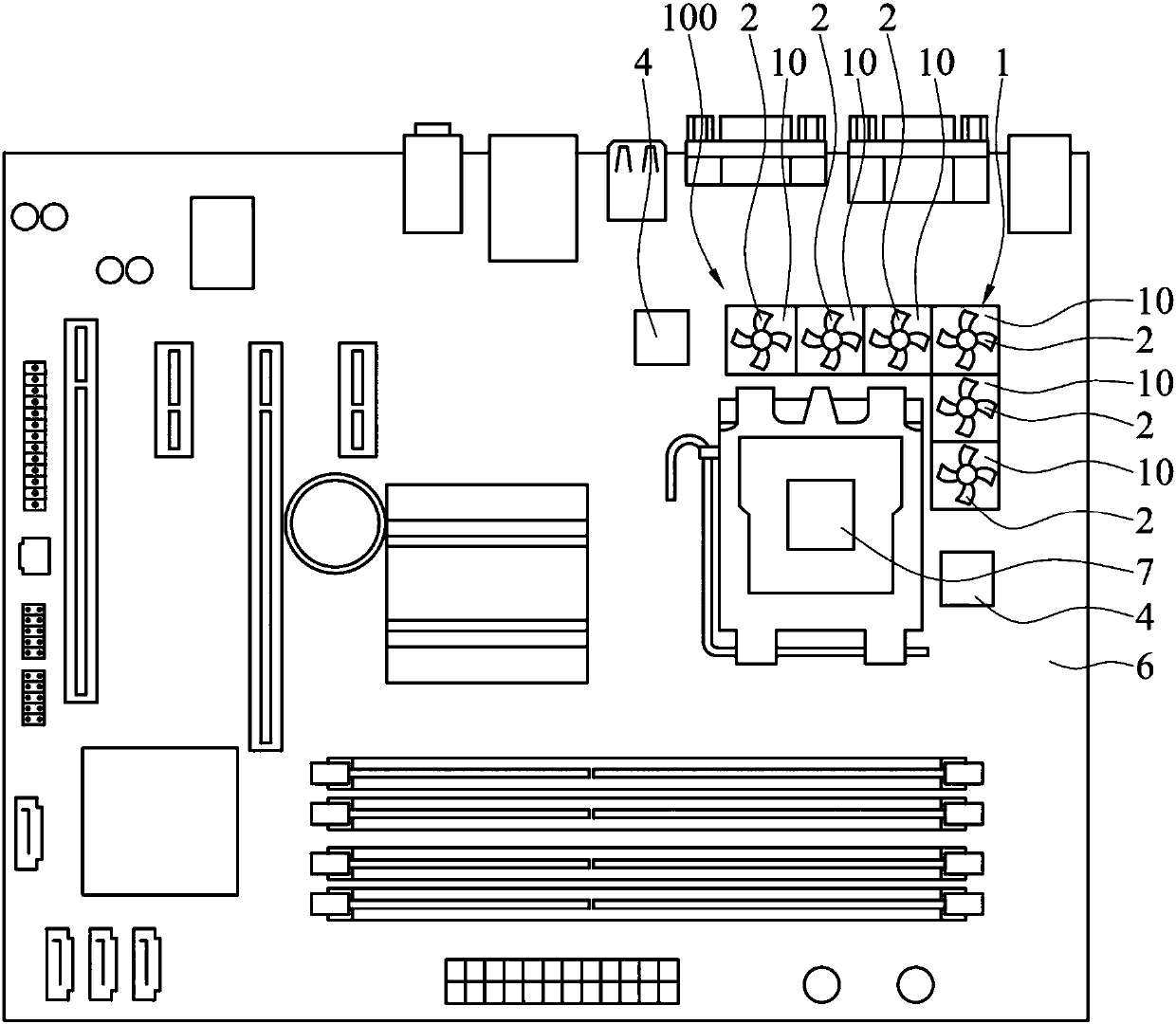

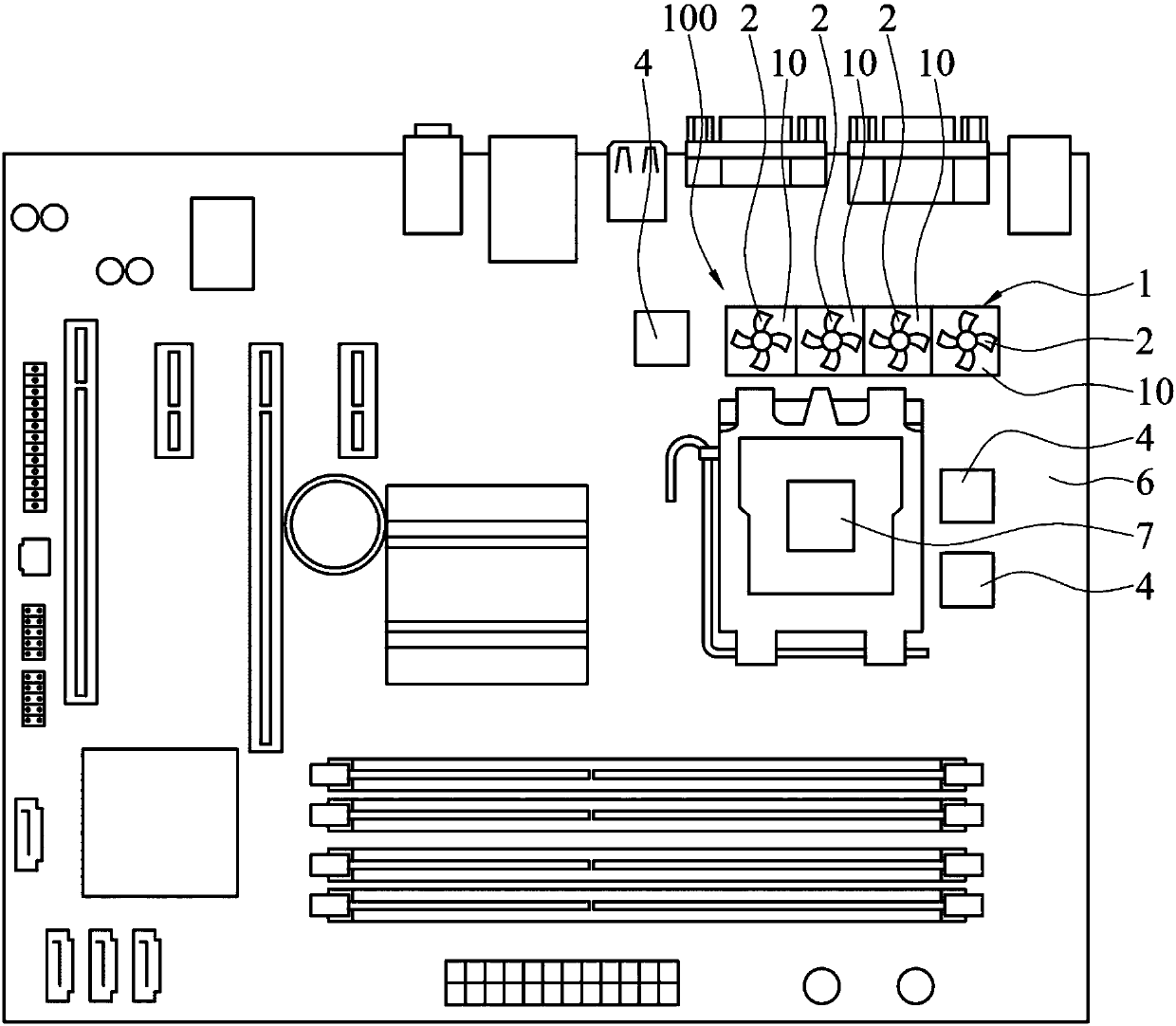

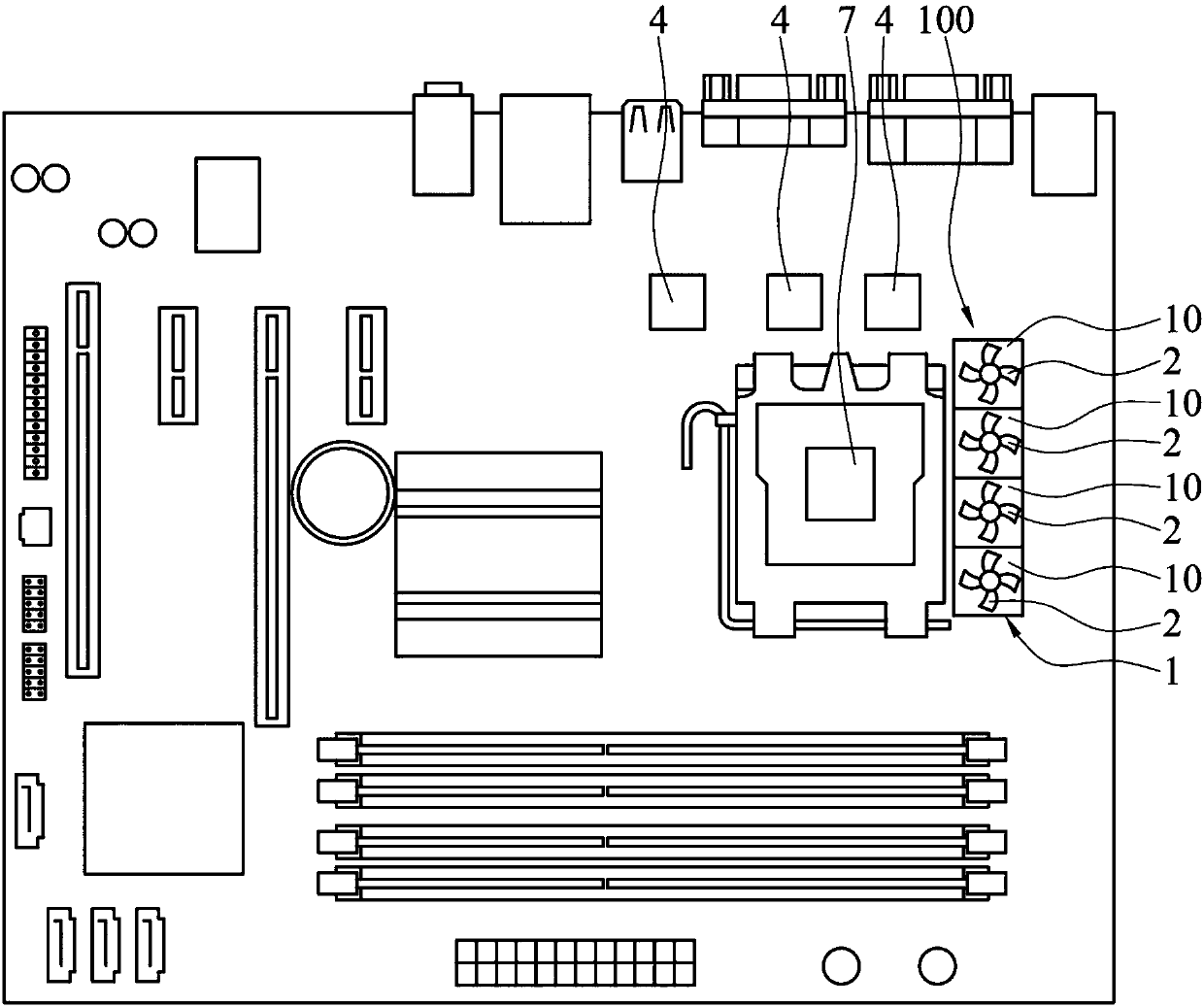

[0044] see Figure 1A to Figure 1C , are respectively schematic diagrams of an embodiment of the installation mode of the radiator of the present invention. The heat dissipation device 100 can be used to dissipate heat from a plurality of electronic components 4 . The heat dissipation device 100 includes a heat sink 1 , a plurality of fan modules 2 and a control circuit 3 . The heat sink 1 can conduct heat to each electronic component 4 . exist Figure 1A to Figure 1C In the shown embodiment, the upper surface of the heat sink 1 is divided into a plurality of heat dissipation areas 10, and each heat dissipation area 10 is used to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com