Intelligent purification system for large-scale factory building welding smoke haze

A technology for purification systems and workshops, applied in air-conditioning systems, heating and ventilation control systems, heating and ventilation safety systems, etc., can solve the problems of difficulty in removing smoke and haze, direct discharge of smoke and dust into the atmosphere, and high operating costs, and achieve better energy-saving effects. Good, environmental protection effect, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

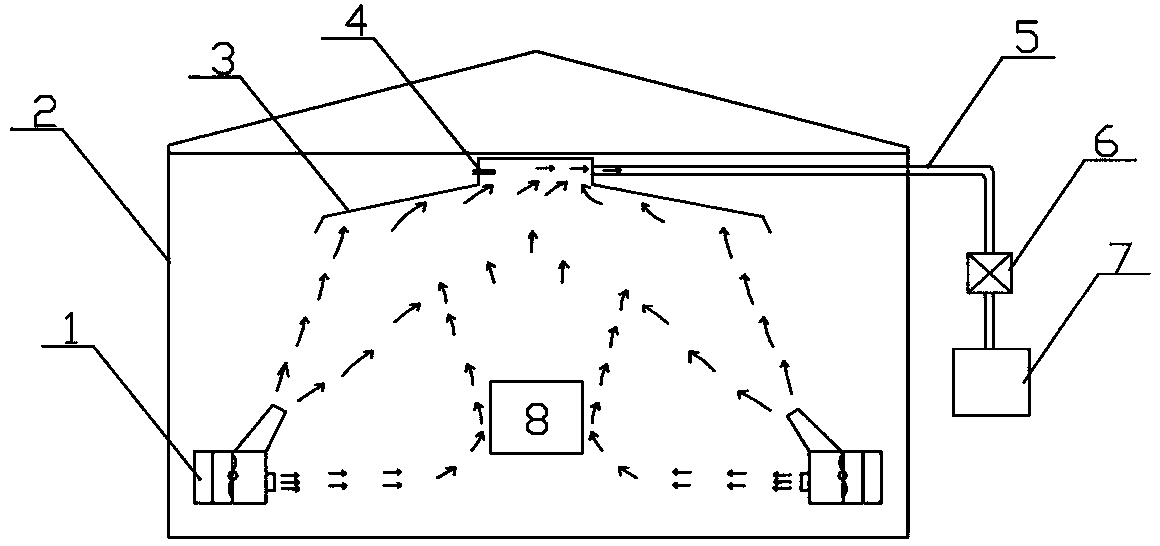

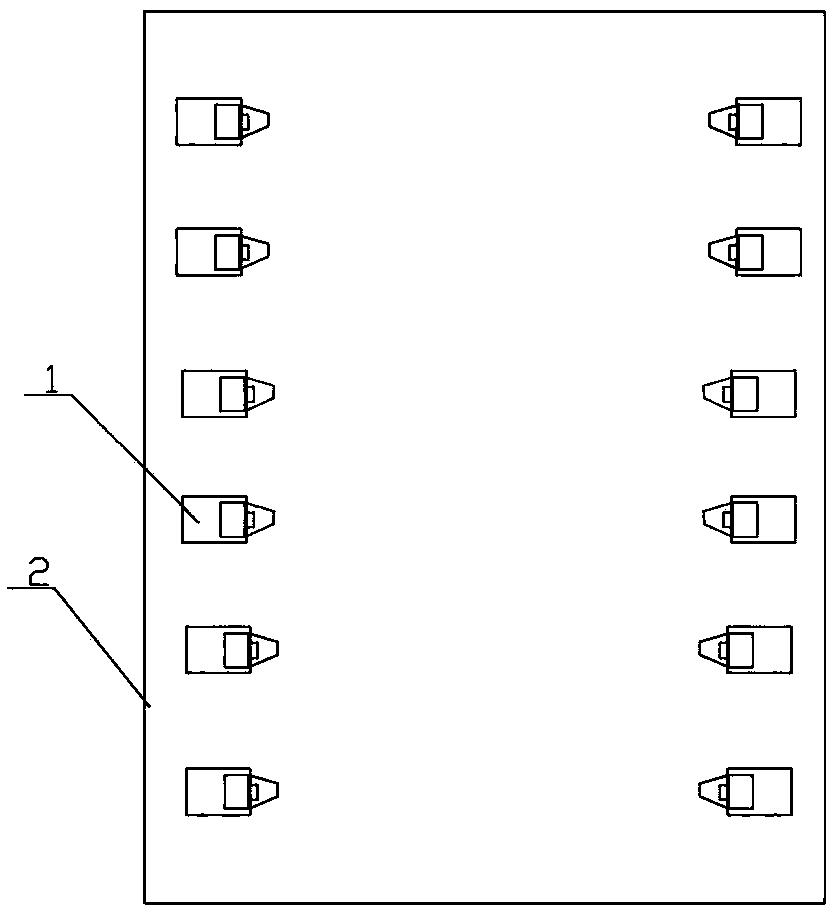

[0019] Such as figure 1 , figure 2 and image 3 As shown, the intelligent purification system for large-scale factory building welding smoke and haze of the present invention includes an air supply device 1 arranged in the factory building 2, and is characterized in that the described air supply device 1 is arranged around the lower part of the factory building, and a smoke exhaust device is provided on the top of the factory building. Cover 3 and the exhaust duct 5 communicated with the smoke exhaust hood 3, the exhaust duct 5 passes through the upper wall of the factory building and is connected with the induced draft fan 6 and the dust collector 7 provided outside the factory building. At least one smoke detection sensor 4 is arranged on the cover 3;

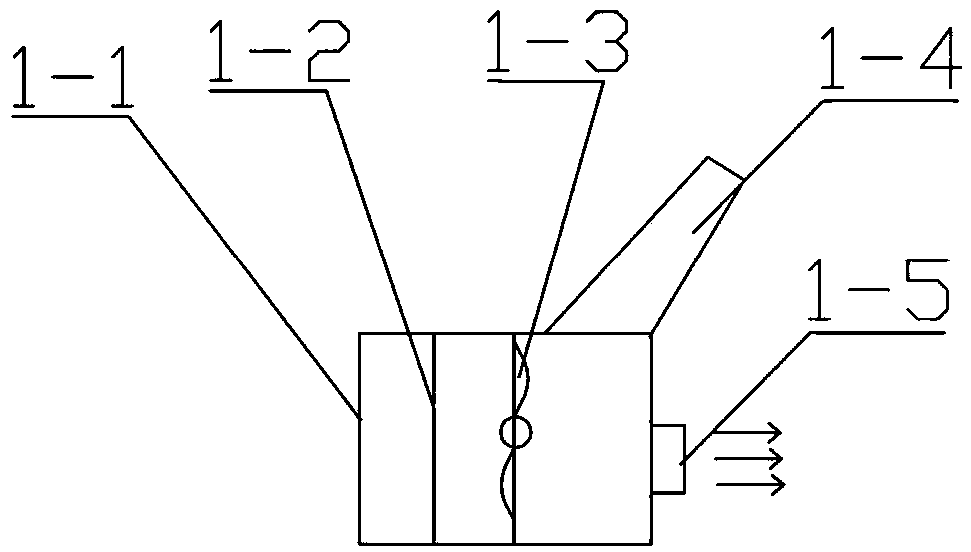

[0020] The air supply device consists of a casing 1-1, an intelligent motor arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com