Patents

Literature

30results about How to "Reduce the impact of settlement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

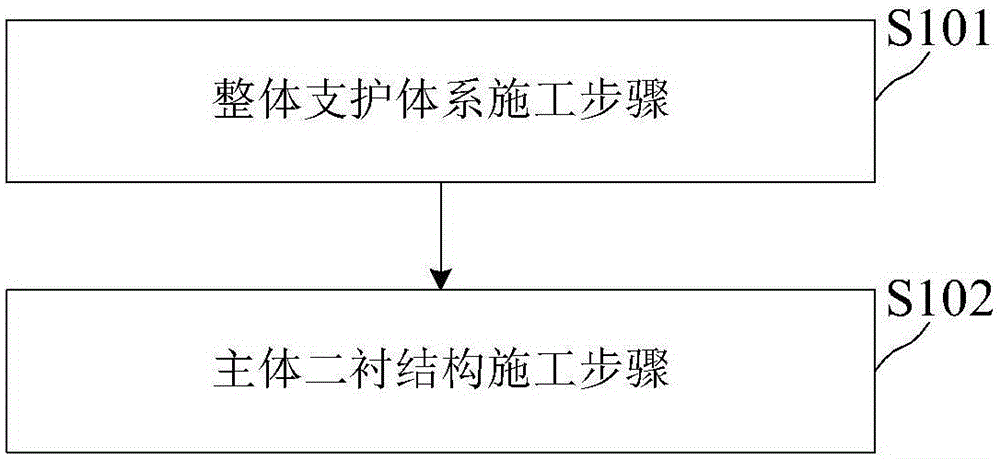

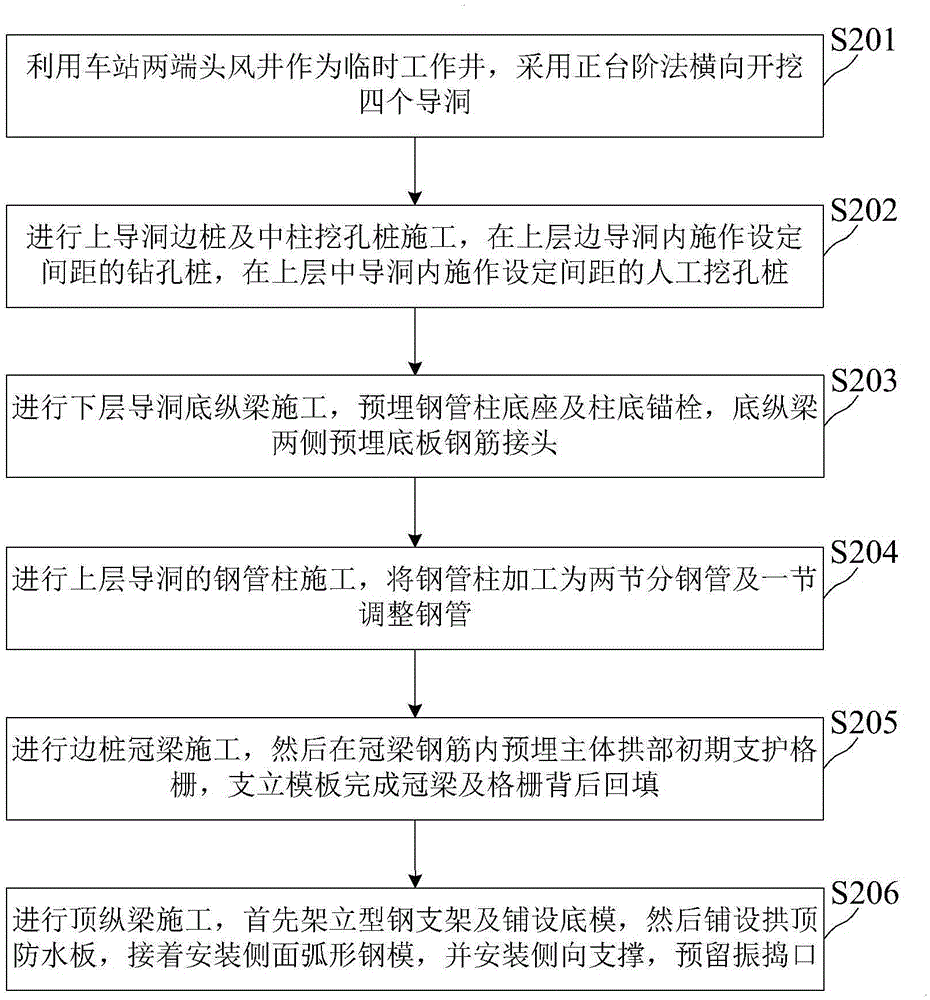

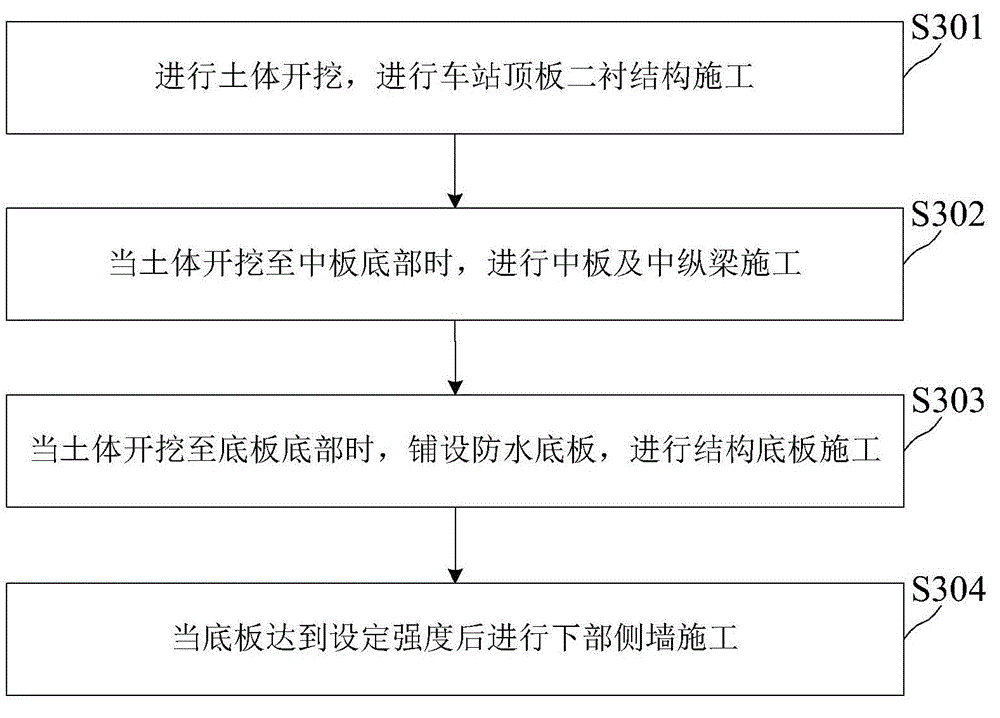

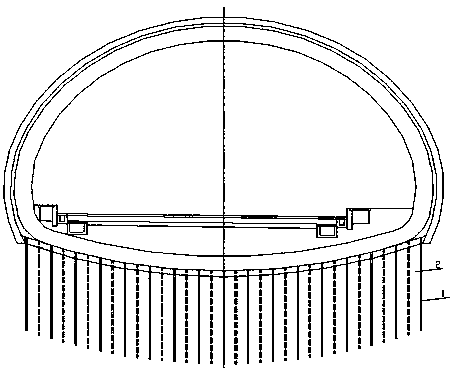

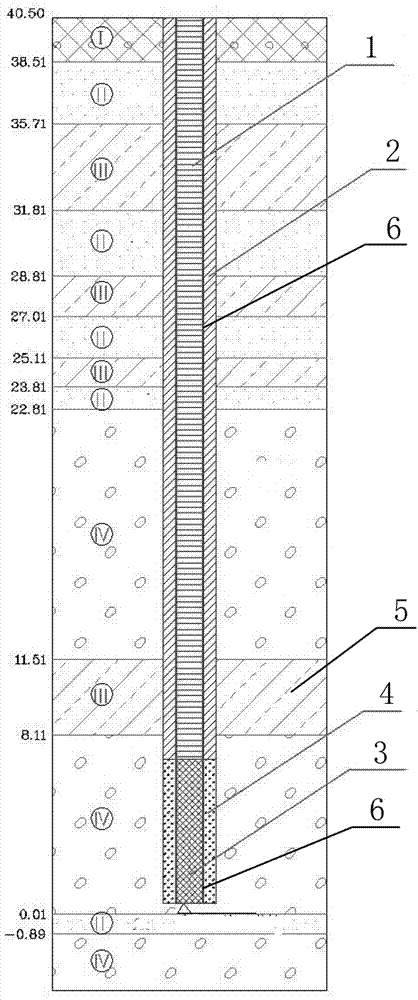

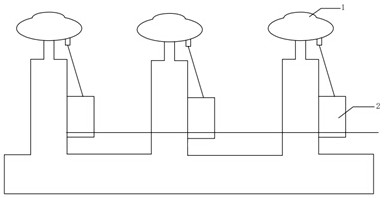

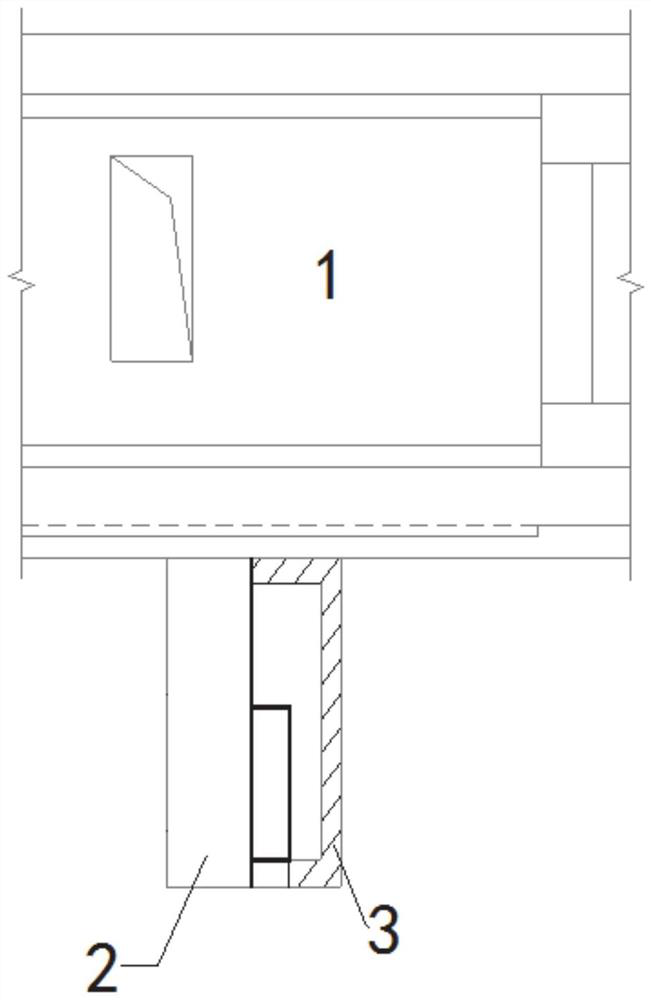

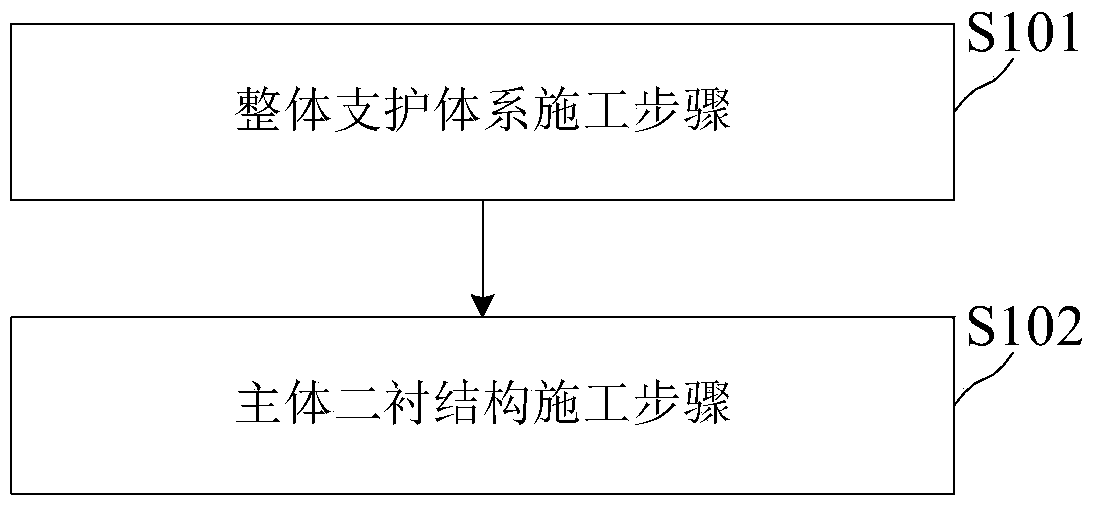

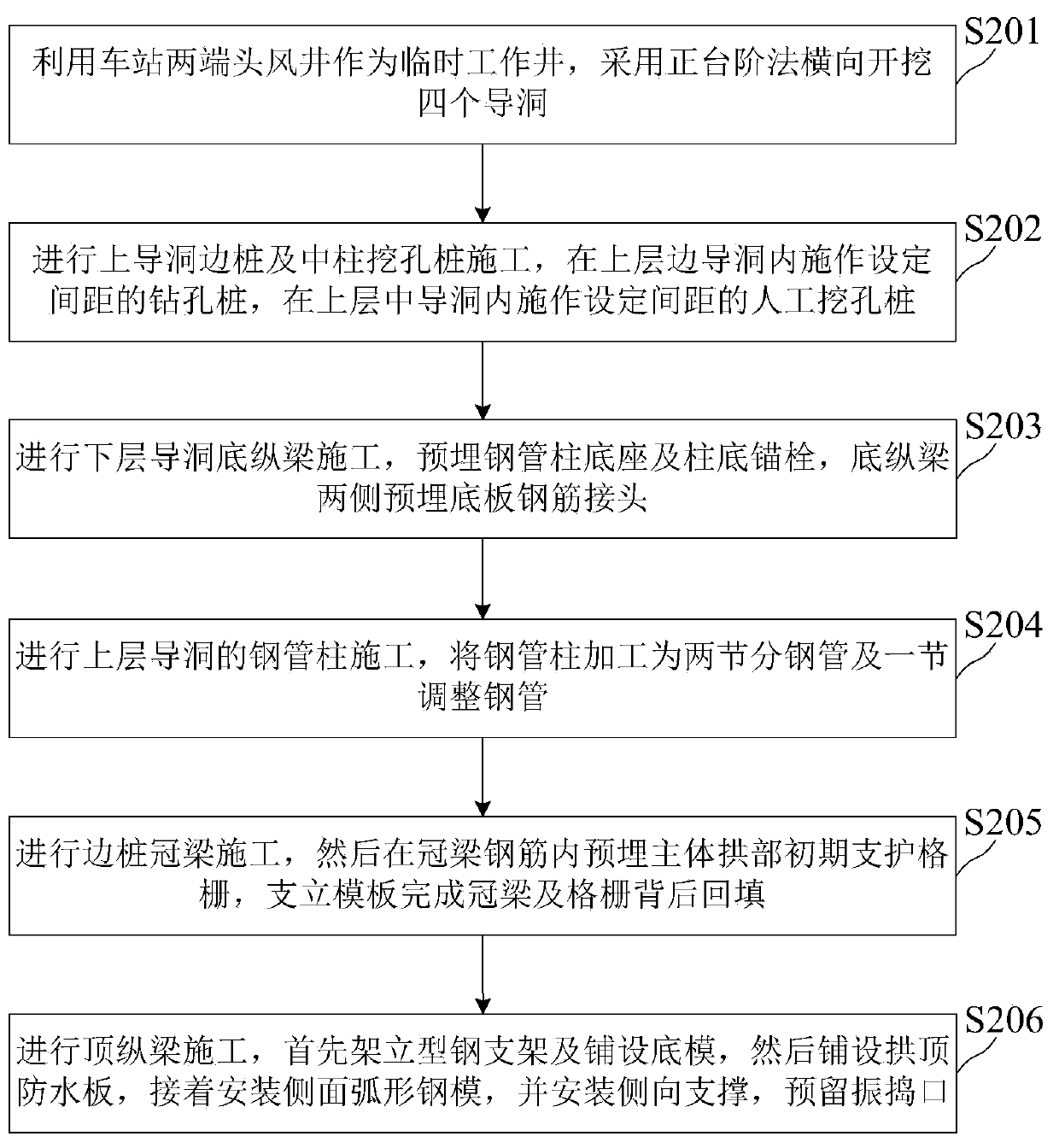

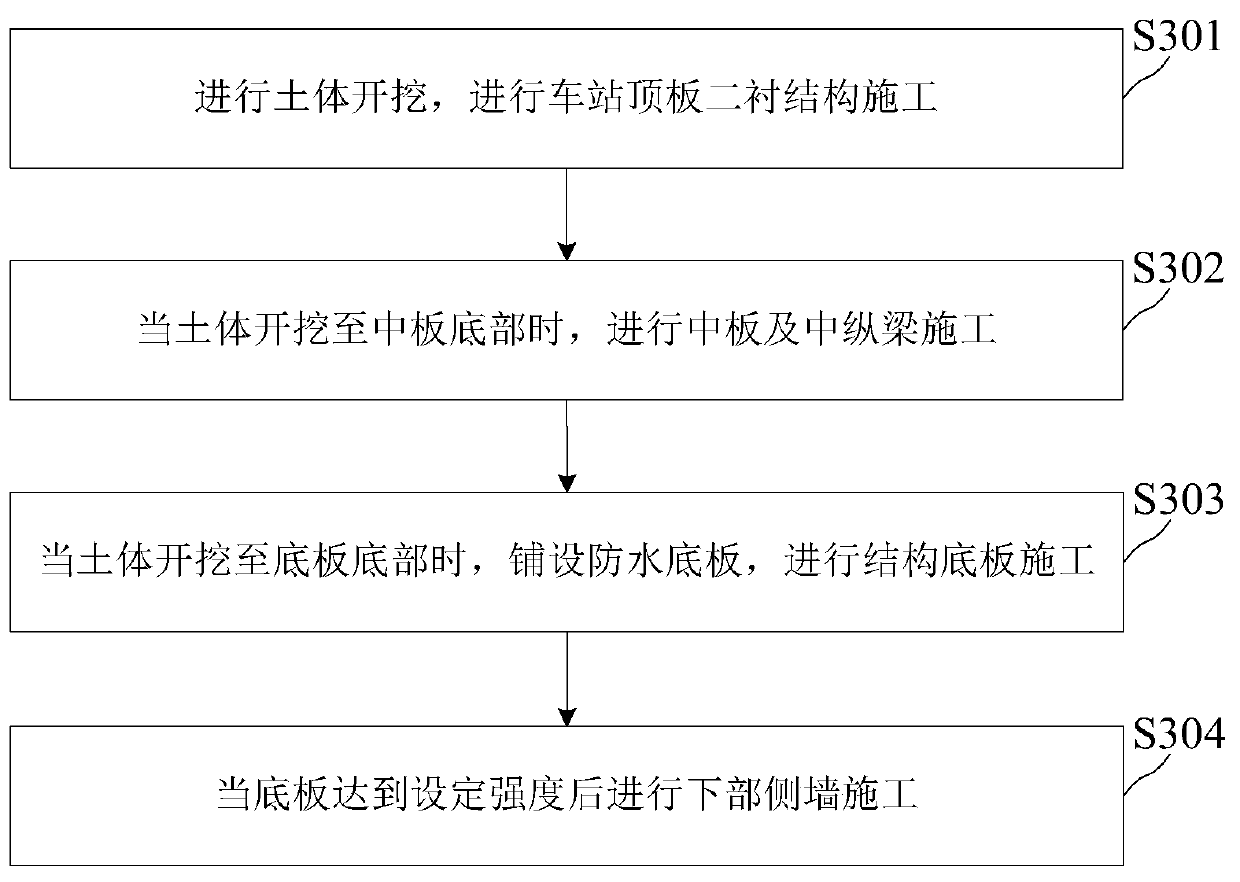

Mined metro station hole pile construction method

ActiveCN106703814AReduce the impact of settlementSave masonryUnderground chambersTunnel liningSupporting systemMetro station

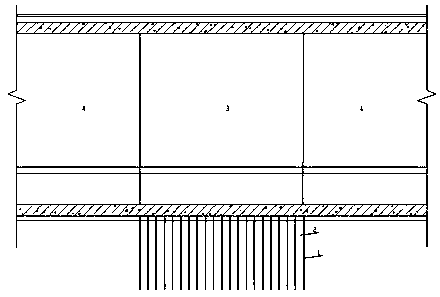

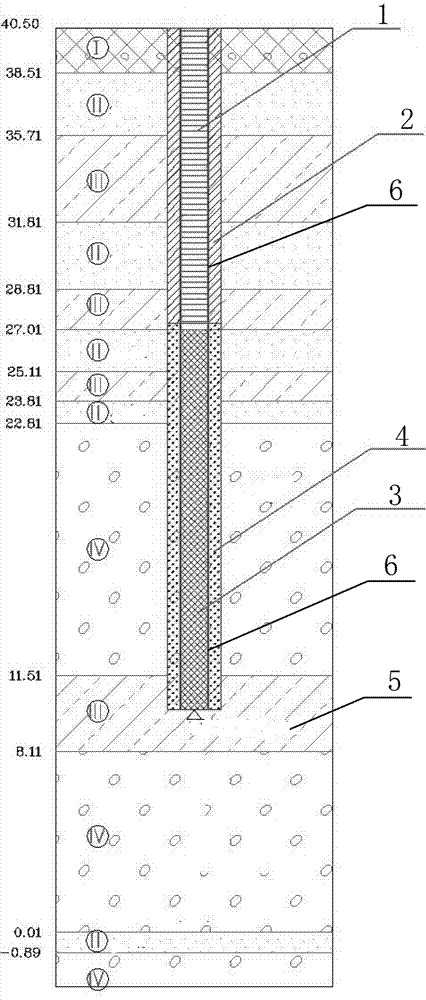

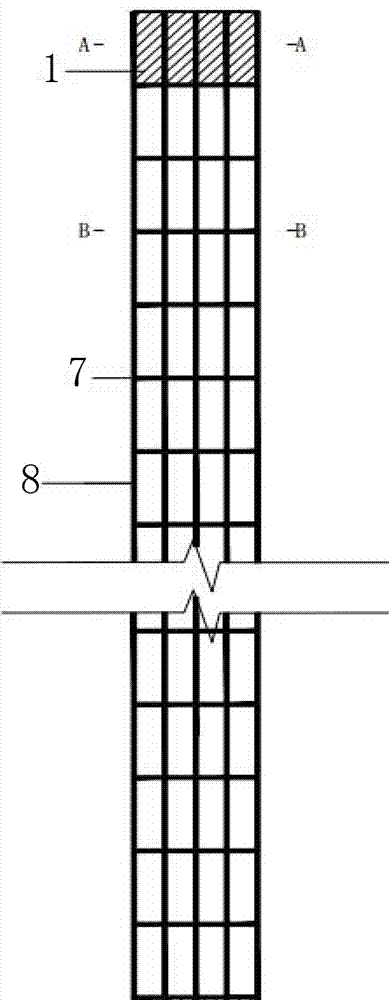

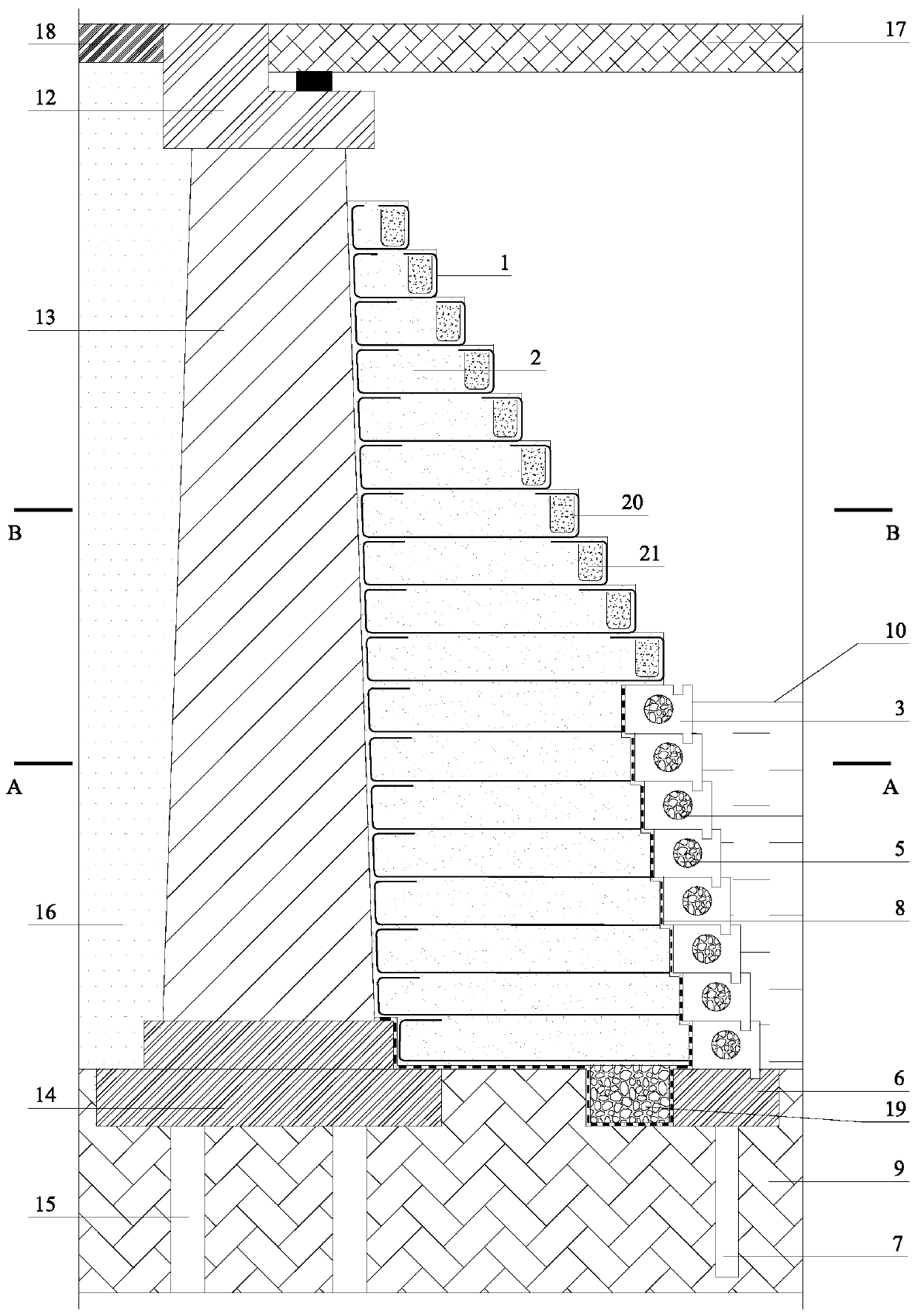

Provided is a mined metro station hole pile construction method. The method comprises the steps of whole support system construction and main body second lining construction; the whole support system construction step comprises the substeps that by utilizing air shafts at the two ends of the station as temporary working wells, four pilot tunnels are transversely dug through a positive step method; upper pilot tunnel side pile and middle column hole digging pile construction is conducted, bored piles are constructed inside an upper layer side pilot tunnel at intervals, and artificial hole digging piles are constructed inside an upper layer middle pilot tunnel at intervals; lower layer pilot tunnel bottom longitudinal beam construction is conducted; upper layer pilot tunnel steel pipe column construction is conducted; side pile crown beam construction is conducted; top longitudinal beam construction is conducted; top arch initial supporting structure construction is conducted; the main body second lining construction step comprises the substeps that soil body excavation is conducted, and station top plate second lining structure construction is conducted; when a soil body is dug to the bottom of a middle plate, middle plate and middle longitudinal beam construction is conducted; when a soil body is dug to the bottom of a base plate, the waterproof base plate is laid, and structure base plate construction is conducted; lower portion side wall construction is conducted when the base plate reaches the set intensity.

Owner:HONGRUN CONSTR GROUP STOCK

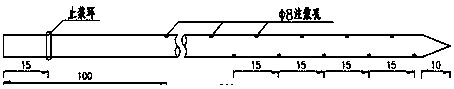

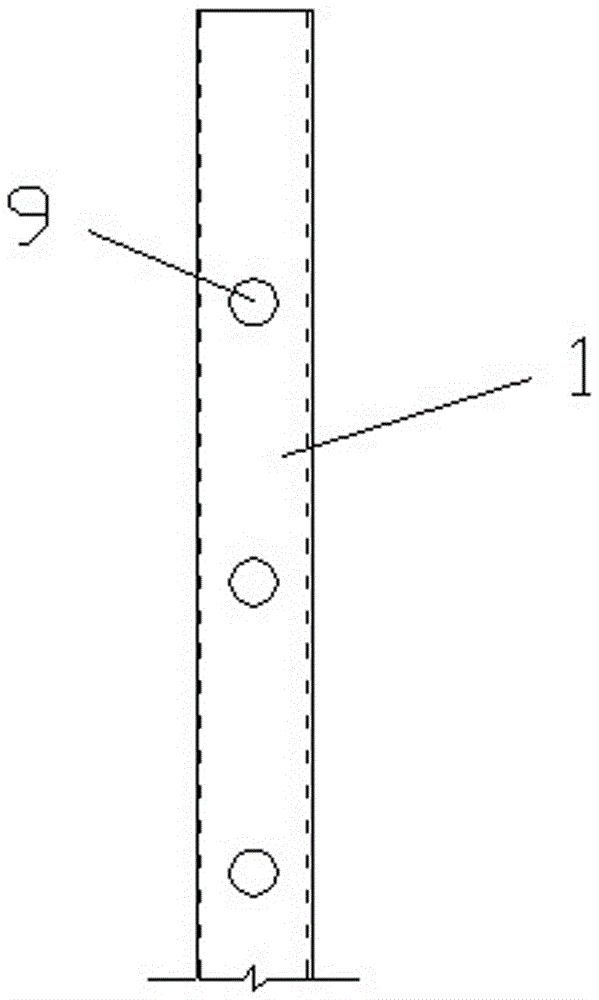

Processing method of weak surrounding rock of substrate of novel tunnel invert

InactiveCN108386198AReduce the impact of settlementGuarantee the quality of the projectUnderground chambersTunnel liningSoluble glassSlurry

The invention relates to a processing method of weak surrounding rock of a substrate of a novel tunnel invert and belongs to the technical field of construction engineering. The processing method comprises the following specific steps: 1) excavation and leveling of the tunnel invert: excavating the tunnel invert according to the size of a design drawing, and artificially leveling the excavated tunnel invert; 2) performing primary support on the invert; 3) drilling: vertically drilling the primary support surface of the invert by adopting a hand drill, mounting steel pipes of which the diameteris phi 50mm at an interval of 1m in a quincuncial shape, and drilling grouting holes in the pipe walls of the steel pipes in a quincuncial shape; 4) grouting: filling cement grout after the steel pipes are drilled, when the underground water of the substrate of the invert is larger, filling cement-soluble glass grout, and during construction, when the grouting pressure in each hole reaches the designed grouting pressure, finishing grouting; and 5) after construction of the cement grout of the steel pipes is completed, normally constructing the invert and filling the invert according to the requirements of the design drawing. The processing method provided by the invention reduces the influence of foundation settlement of the weak surrounding rock as much as possible and ensures the quality of the main structure of the tunnel, the engineering quality and the operation safety of the tunnel.

Owner:SINOHYDRO BUREAU 14 CO LTD

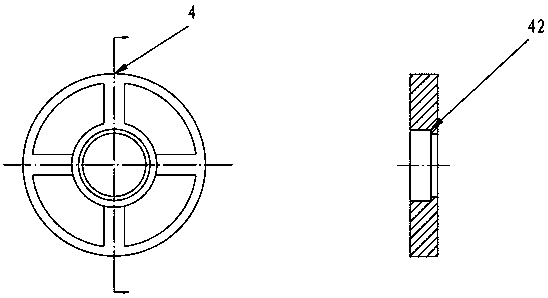

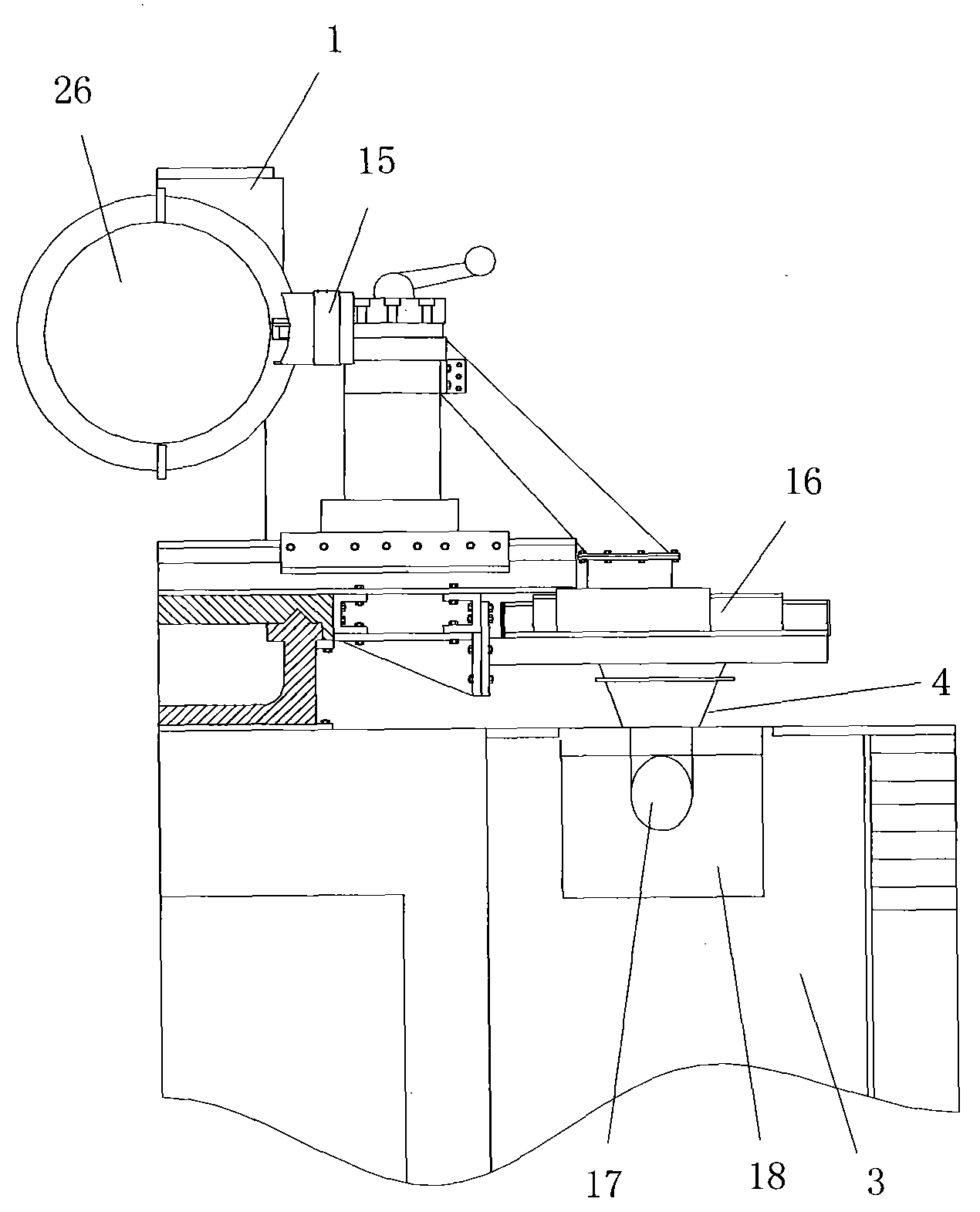

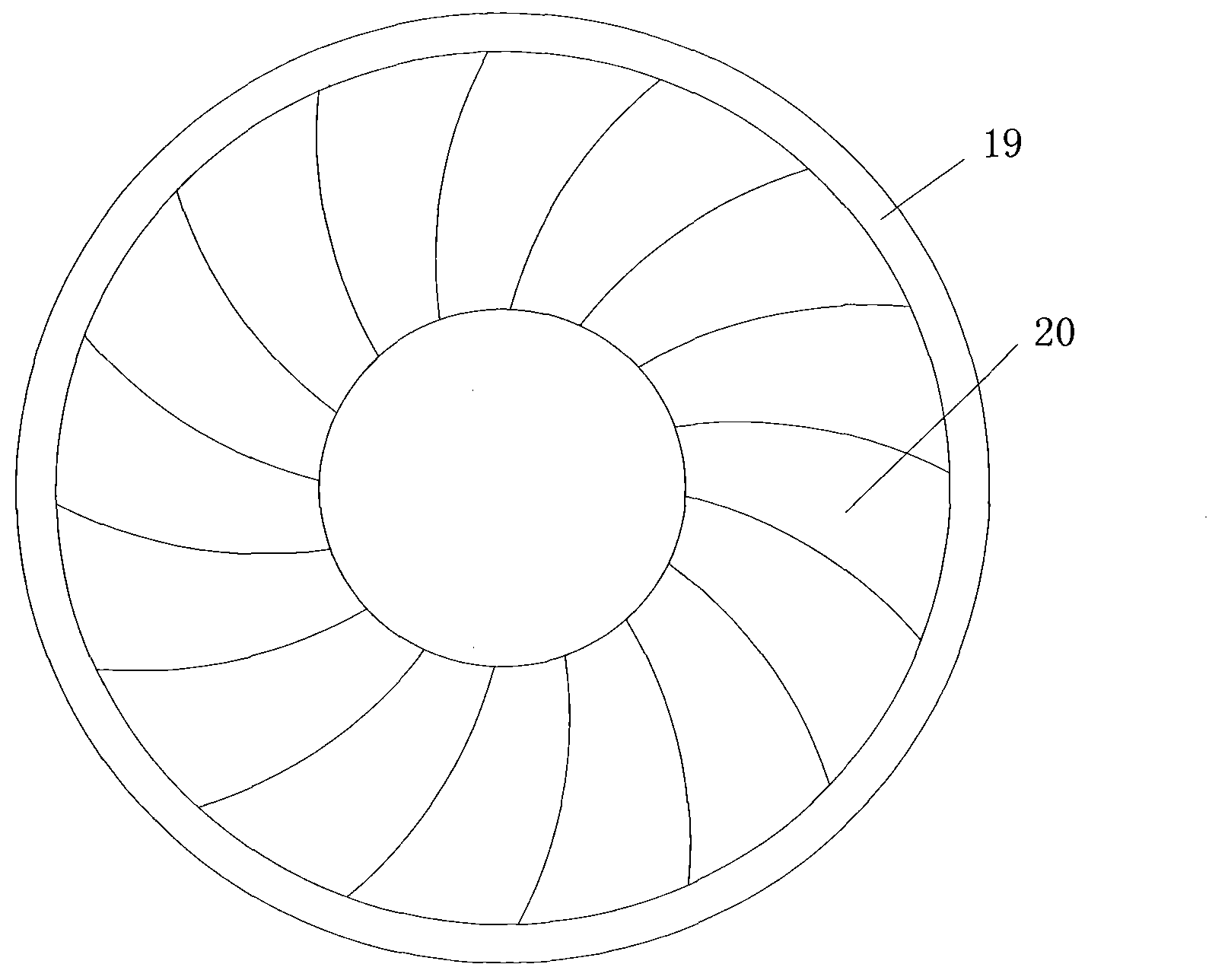

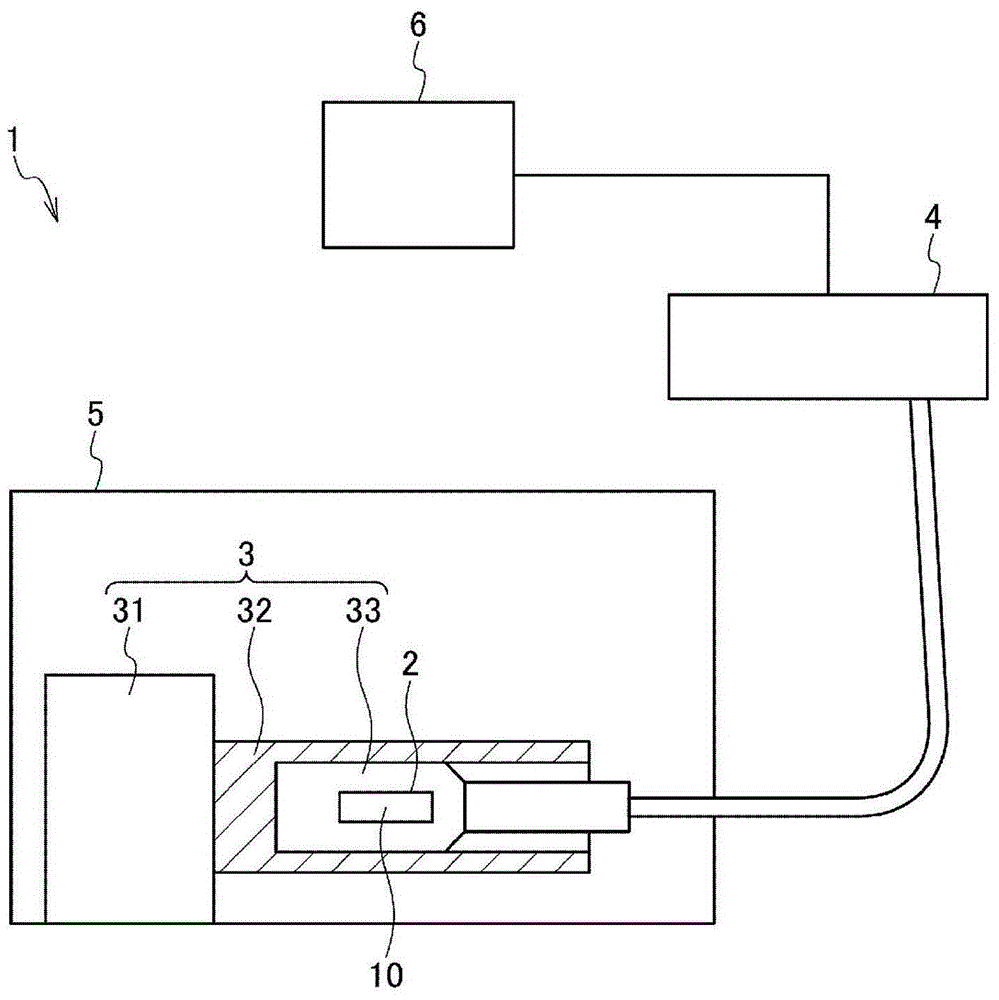

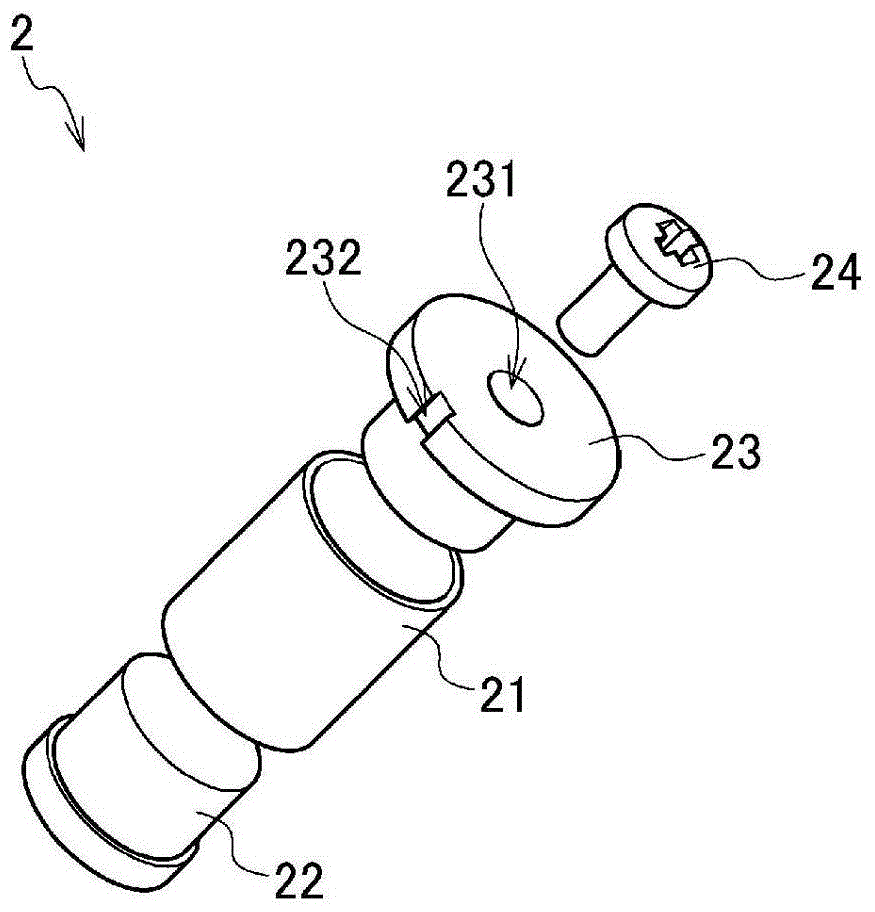

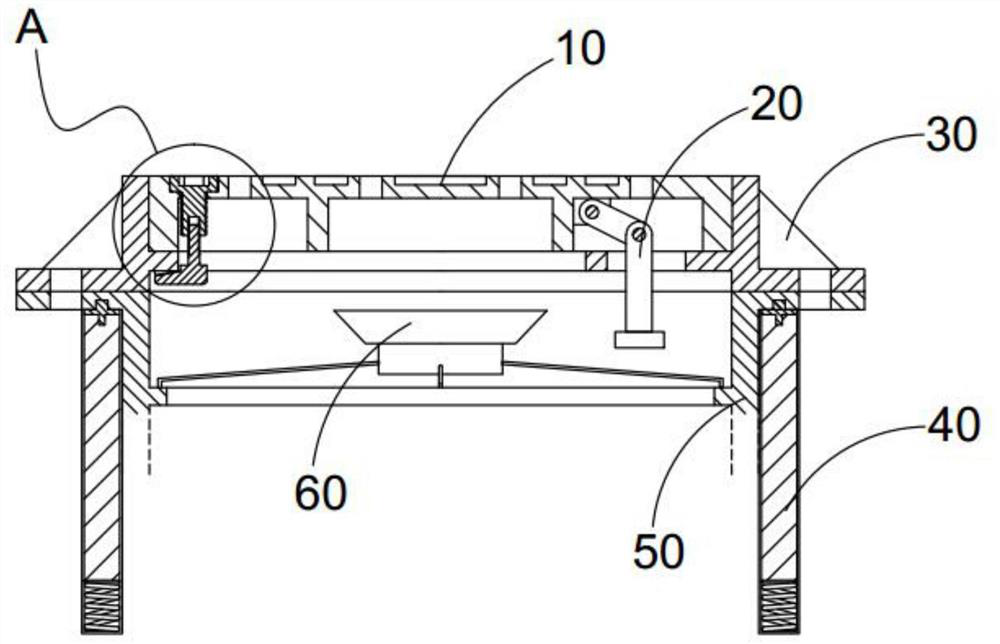

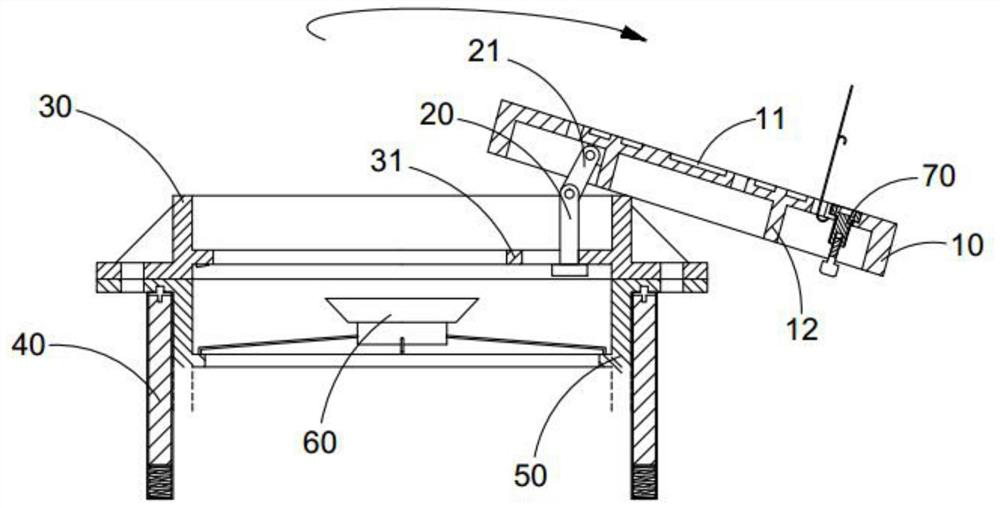

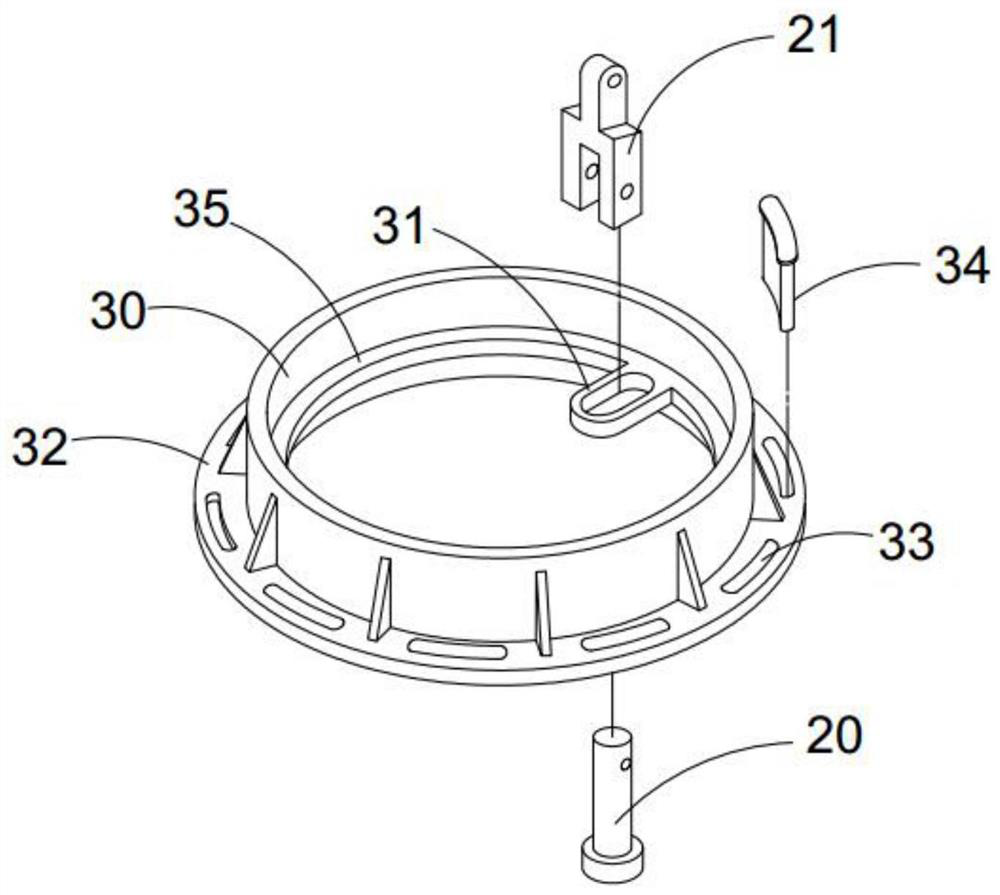

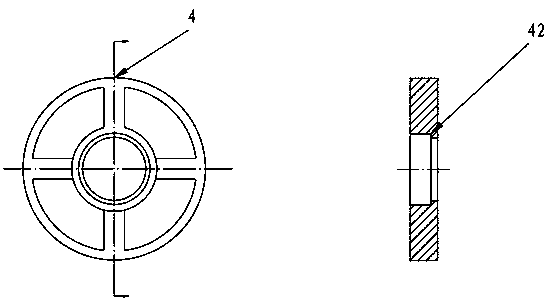

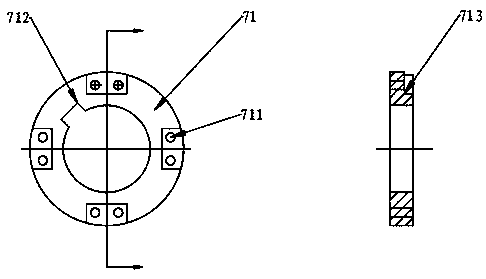

Simulation experiment device and method for secondary crushing and fluidization of submarine gas hydrate

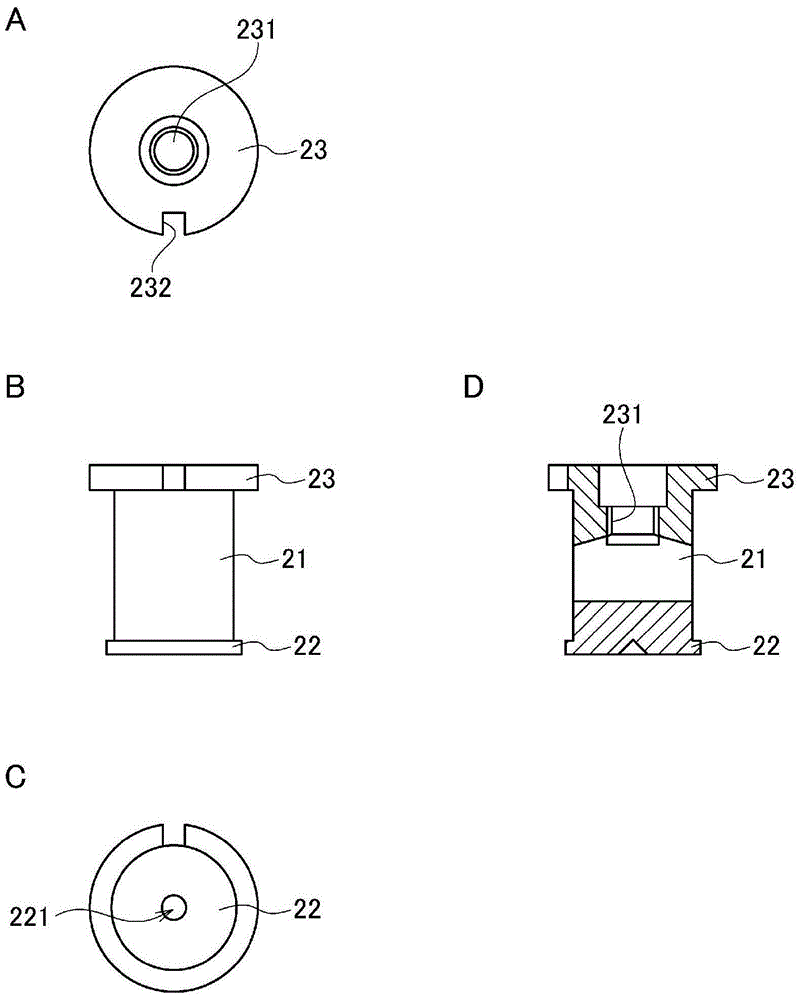

ActiveCN108468534AAdjustable positionIncrease the probability of collisionSurveyConstructionsControl systemEngineering

The invention provides a simulation experiment device and method for secondary crushing and fluidization of submarine gas hydrate. The simulation experiment device for the secondary crushing and fluidization comprises a secondary crushing pipeline, a rotating power assembly, a particle crushing knife tackle, a material falling assembly, a crushed particle recovery device and a control system, wherein the rotating power assembly comprises a motor and a rotating shaft, the particle crushing knife tackle is connected to the rotating shaft of the rotating power assembly through a flat key, the rotating power assembly is connected with a particle crushing pipeline through a bolt and a nut, the particle crushing pipeline is welded with a round-to-square flange plate and connected with the material falling assembly through a bolt and a nut, the crushed particle recovery device is placed on a crushing pipeline outlet, and the control system is connected with and controls the motor of the rotating power assembly and the material falling assembly. The crushing method adjusts the rotating speed of the rotating power assembly and the material falling speed of the material falling assembly through the control system, circulating water is pumped, non-premixed particles in a hopper is discharged down, and an outlet recovery device recovers crushed particles.

Owner:SOUTHWEST PETROLEUM UNIV

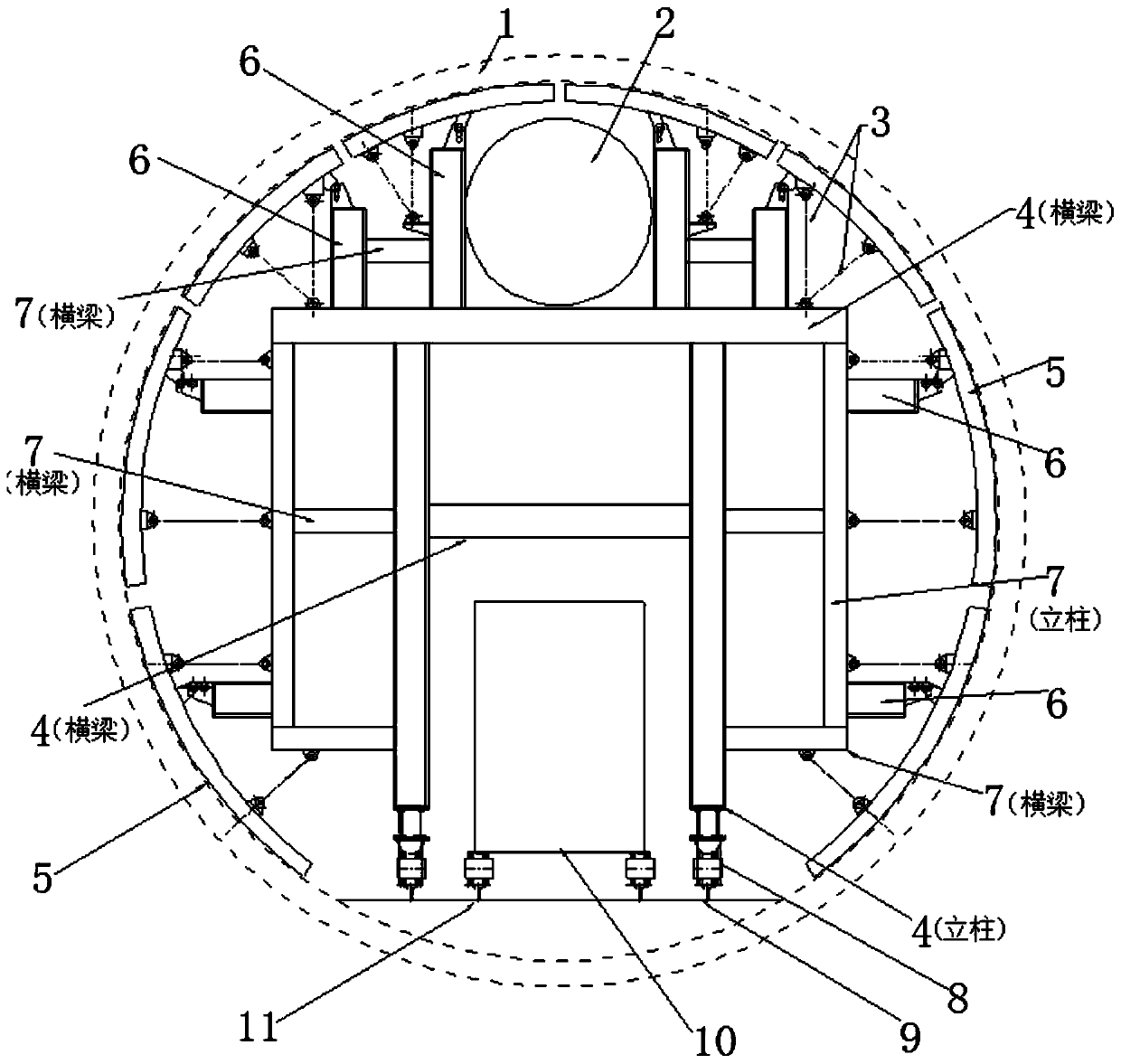

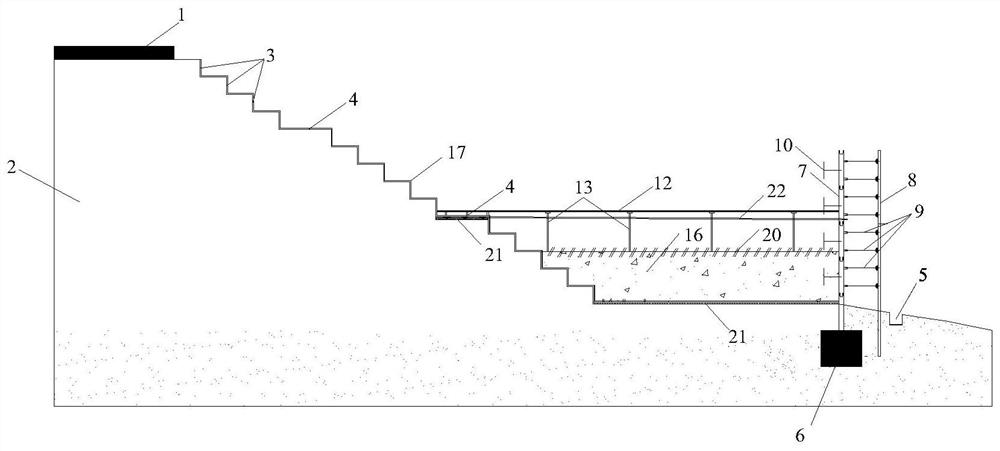

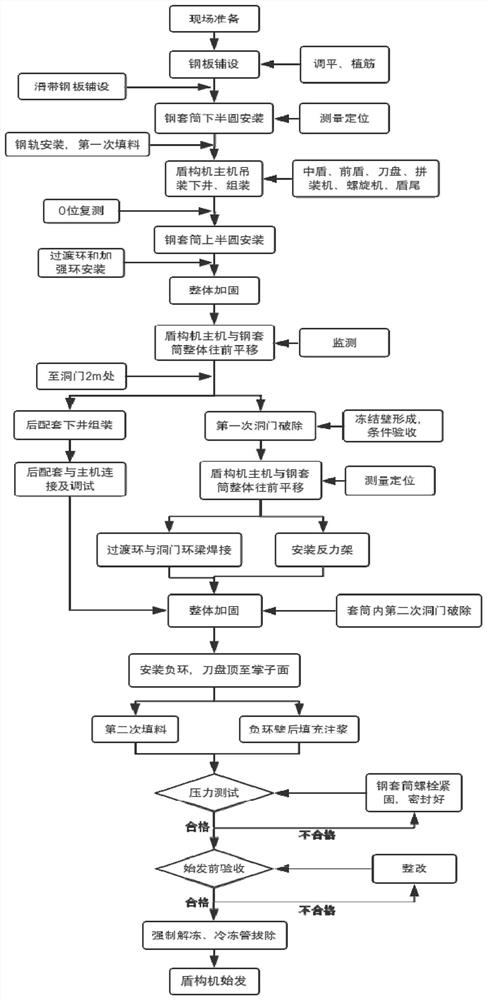

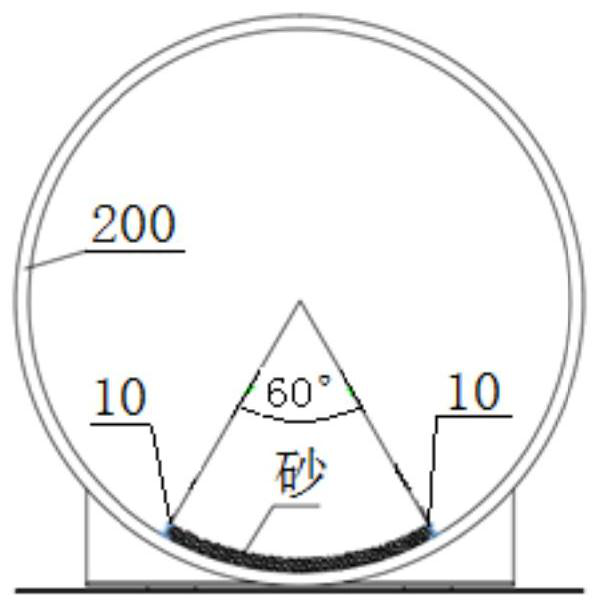

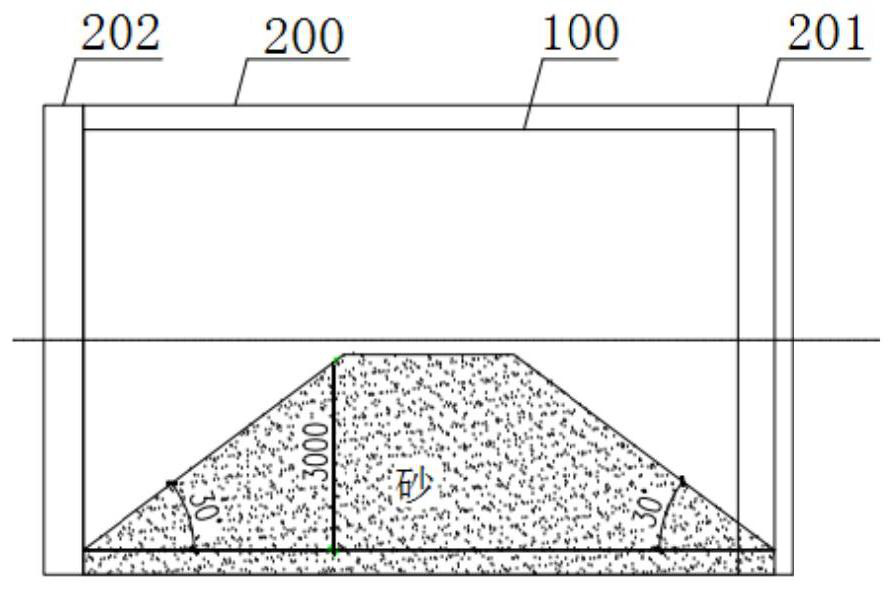

Construction method enabling shield tunneling machine to underneath pass through existing station to start

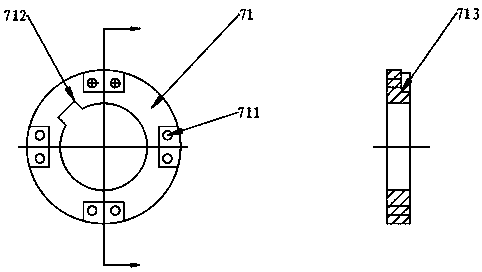

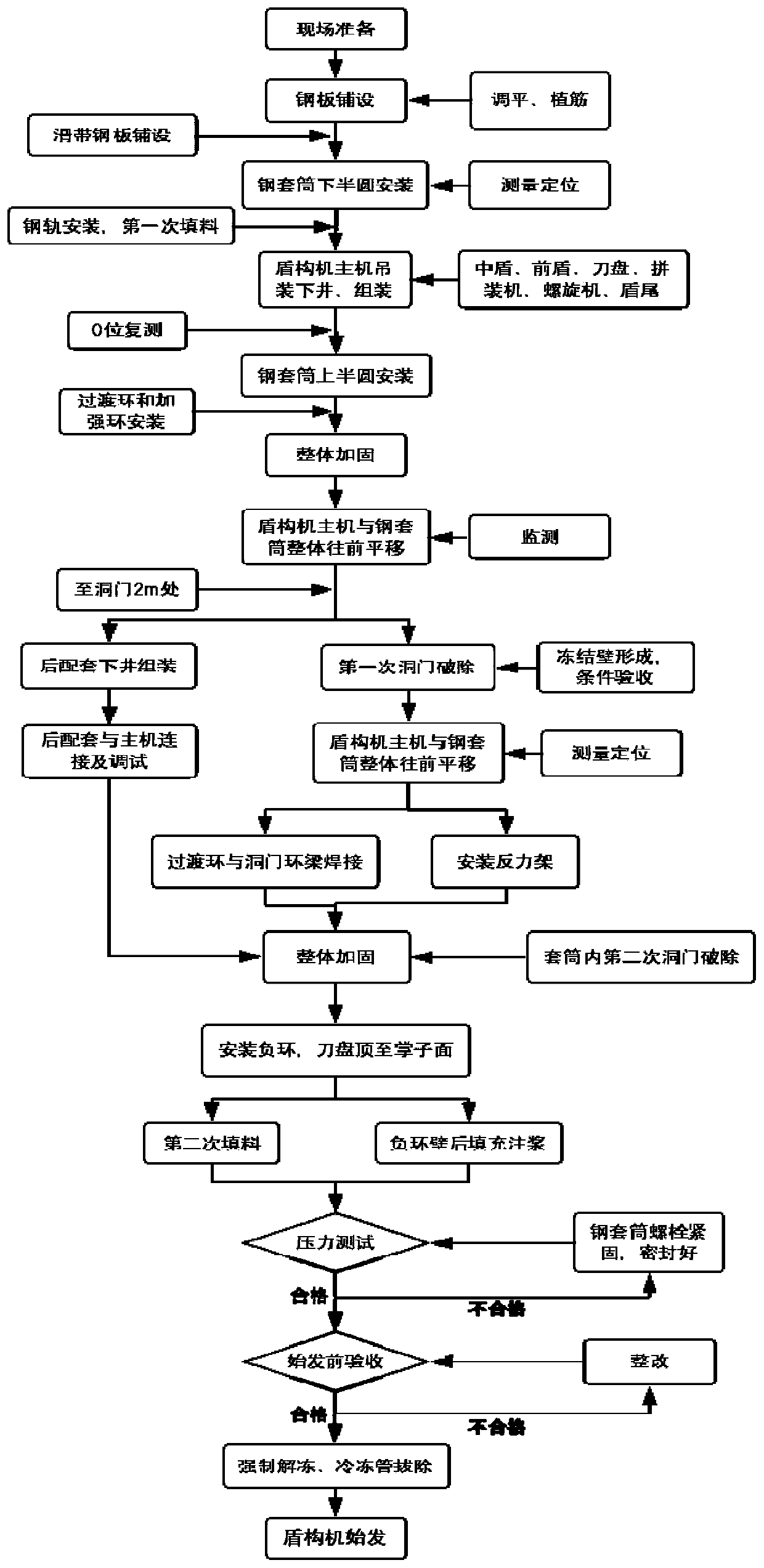

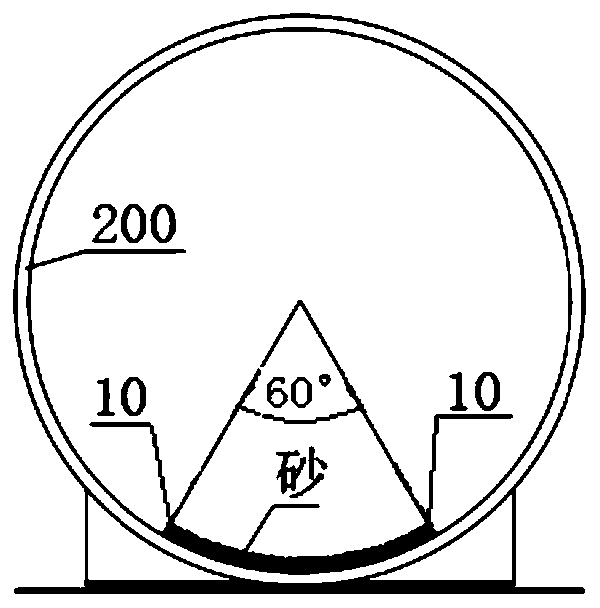

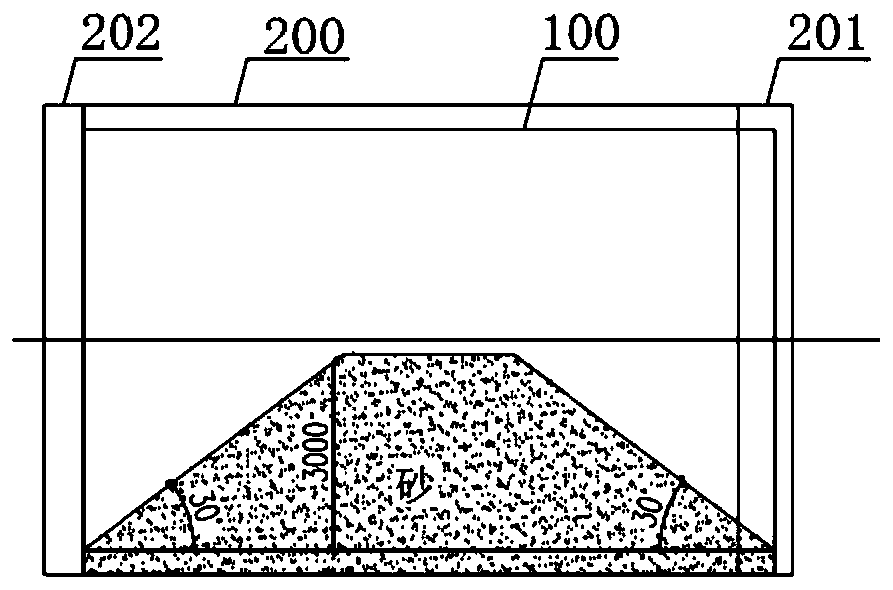

ActiveCN110924961AControl chisel construction safetyEnsure the safety of chiseling constructionUnderground chambersTunnel liningClassical mechanicsStructural engineering

The invention discloses a construction method enabling a shield tunneling machine to underneath pass through an existing station to start. A steel sleeve is adopted for construction, and the followingflow including bottom plate levelling and steel plate laying for an underneath passing channel, vertical freezing reinforcement for a tunnel door, installation for the lower half-circle of the steelsleeve, downhole installation for the shield tunneling machine, overall underneath passing and longitudinal movement of the steel sleeve, breaking for the tunnel door, installation for a negative ring, backfilling for the sleeve, pressure testing, pulling-out for a freezing pipe, sealing for a freezing hole, and starting of the shield tunneling machine. The steel sleeve comprises a main sleeve body, a transition ring, a reinforcing ring, a bottom frame and a counter-force frame, wherein the main sleeve body is formed by splicing four sections of sleeve bodies with the same length; and each sleeve body is composed of an upper half-circle sleeve body and a lower half-circle sleeve body. The transition ring is connected to the front end of the main barrel body; the reinforcing ring is connected to the rear end of the main barrel body; the bottom frame is also divided into four sections of bases; and the counter-force frame is connected to the rear end of the reinforcing ring. According tothe construction method, damage to a constructed station structure can be avoided, the construction risk and difficulty of starting driving of the shield tunneling machine and later-period detachmentfor the sealing device for the tunnel door are lowered, and the construction period is accelerated.

Owner:CCCC THIRD HARBOR ENG +2

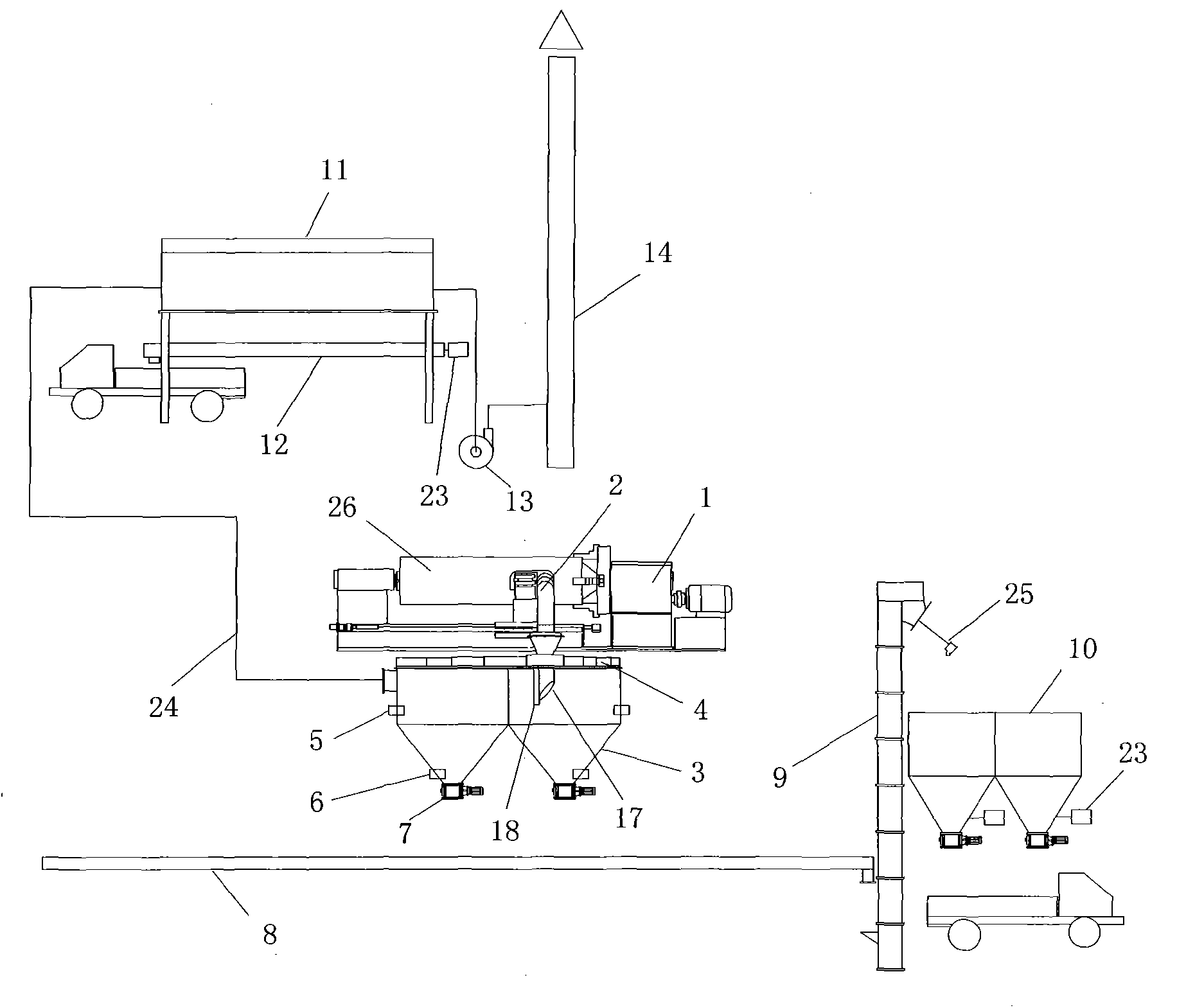

Cutting chipping gas-solid separation and dust collection treatment system

InactiveCN104338404AEasy to separateReduce the impact of settlementCombination devicesBaghouseMachine tool

The invention discloses a cutting chipping gas-solid separation and dust collection treatment system. The cutting chipping gas-solid separation and dust collection treatment system structurally comprises an induced air dust collection cover device arranged on a machine tool in a sliding manner; two settling bins are arranged in parallel under the induced air dust collection cover device; electric unloaders are arranged at the bottoms of the two settling chambers; an air outlet pipeline is arranged at one sides of the settling chambers; a scraper conveyor is arranged under the electric unloaders; an elevator is arranged at the discharge end of the scraper conveyor and connected with a storage bin; the air outlet pipeline is connected with a pulsing bag-type dust remover; a screw discharger is arranged under the pulsing bag-type dust remover; an air outlet of the pulsing bag-type dust remover is connected with an induced draft fan which is connected with a chimney. The cutting chipping gas-solid separation and dust collection treatment system is capable of overcoming the shortcomings in the prior art; as a result, the air pressure and air speed requirements of the system are reduced, the abrasion of particle recovering to the pipeline is reduced and the dust removal effect is good; besides, the labor intensity is reduced and the production efficiency is improved.

Owner:河北顺天电极有限公司

Subway foundation pit dewatering well with pressure reduction monitoring effect

PendingCN107165181AReduce the impact of settlementProtection securityExcavationsWater useWater filter

The invention discloses a subway foundation pit dewatering well with a pressure reduction monitoring effect. The subway foundation pit dewatering well comprises an upper water feeding layer and a lower water filtering layer, and a steel reinforcement cage is arranged in the well and penetrates through the water feeding layer and the water filtering layer from top to bottom; a steel pipe is arranged on the portion, inside the steel reinforcement cage, of the water feeding layer, and the steel reinforcement cage is externally filled with clay; a steel reinforcement water filtering pipe is arranged on the portion, inside the steel reinforcement cage, of the water filtering layer, and the steel reinforcement cage is externally provided with a double-layer nylon cloth and externally filled with a filtering material. According to the dewatering well device, not only is real-time monitoring on the underground water change condition achieved, but also a guarantee is provided for emergency measures of recharging water in the pit in the foundation pit excavating process, upheaval destruction in the foundation pit excavating process is avoided, therefore, settlement influences of the surrounding ground, traffic, buildings and the like are reduced, the safety of the ambient environment is guaranteed, and unnecessary losses are avoided.

Owner:CCCC TUNNEL ENG

Electrical characteristic measurement device

InactiveCN104919309AReduce the impact of settlementAccurate measurementBiological testingMaterial impedanceMeasurement deviceEngineering

Owner:SONY CORP

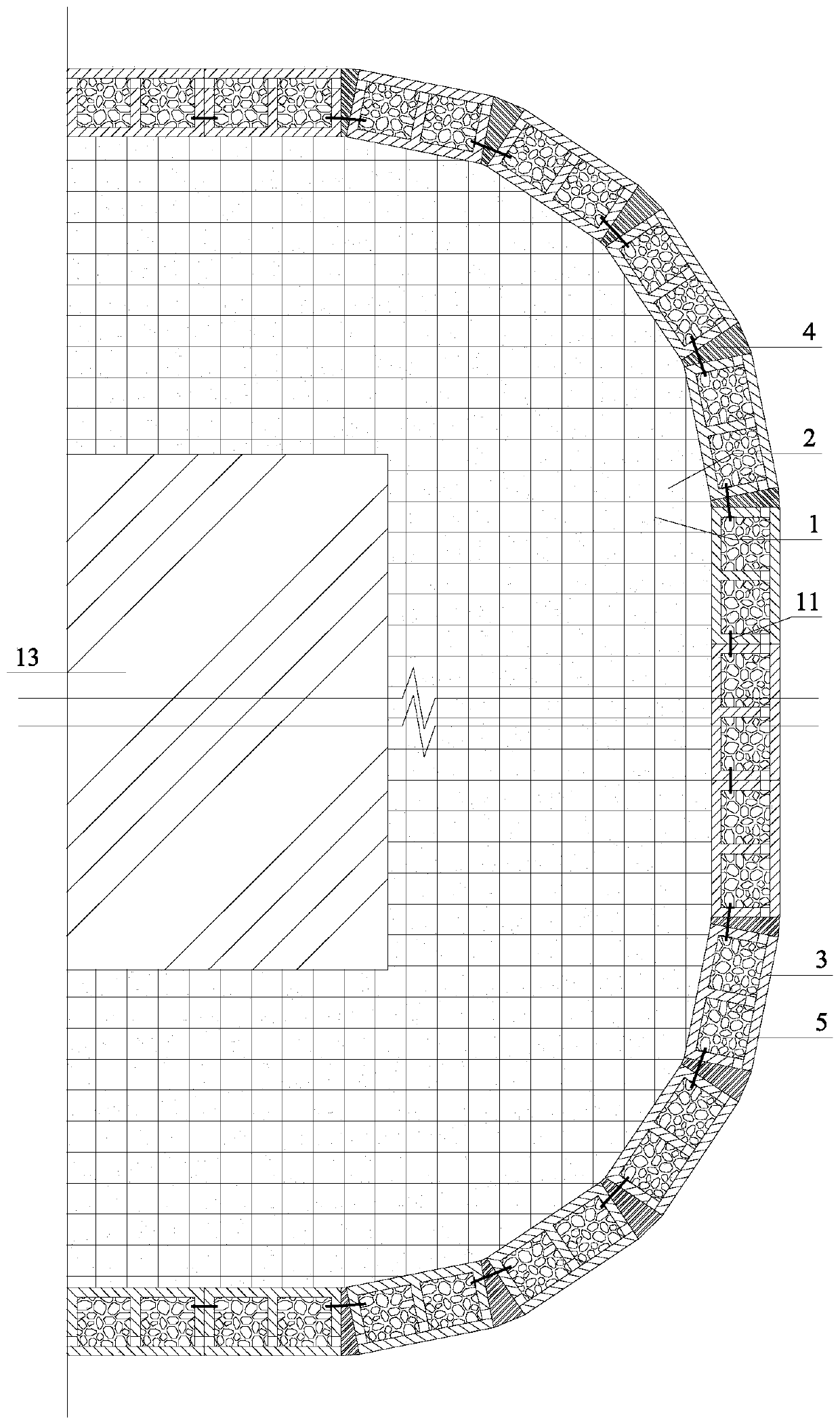

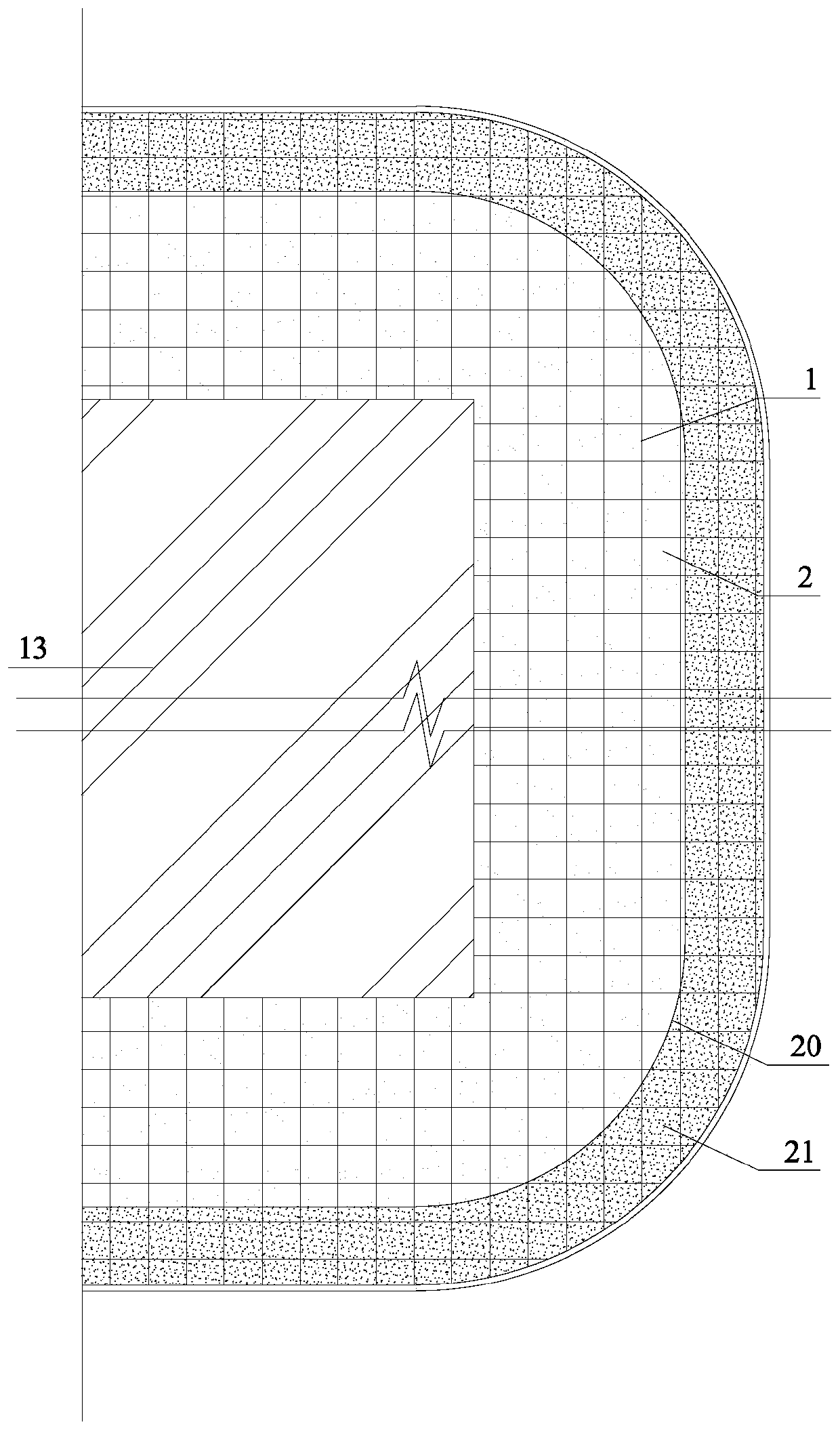

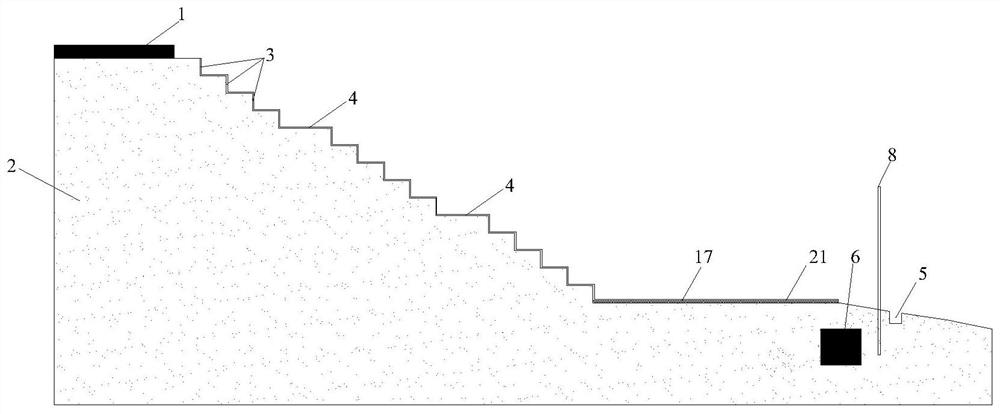

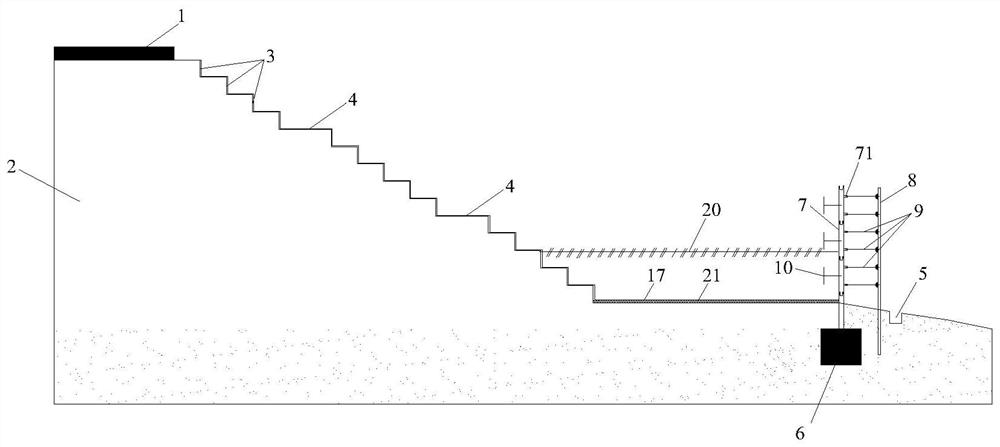

Ecological protection construction method of stepped 3D stiffened bridge abutment conical slope

InactiveCN111305152AImprove stabilityDissipate impact loadCoastlines protectionBridge structural detailsEnvironmental resource managementEngineering

The invention relates to an ecological protection construction method of a stepped 3D stiffened bridge abutment conical slope. The construction method mainly comprises the construction steps of construction of a foundation A, construction of a drainage blanket, construction of a first-storey stepped component, construction of first-storey backfill soil, protection construction of the conical slopebelow the maximum water level, and protection construction of the conical slope above the maximum water level. Through the construction method, after completion of the foundation A and the drainage blanket, the first-storey stepped component and a corner component are mounted on the foundation; the first-storey backfill soil is laid, and the backwater ends of geogrids are reversely enveloped; referring to the above steps, protection construction is conducted on the portion, below the maximum water level, of the conical slope; further layered construction is conducted on the portion, above themaximum water level, of the conical slope, the two ends of each geogrid are reversely enveloped, and an isolation zone is isolated at the end facing water. The ecological protection construction method of the conical slope has the advantages that construction is fast and convenient, the stability is high, the waterproof performance is good, the ecological effect is high, the occupied area is small, the comprehensive benefits are prominent, and the defects existing in signal ecological protection and engineering protection are overcome.

Owner:杭州昂创科技有限公司

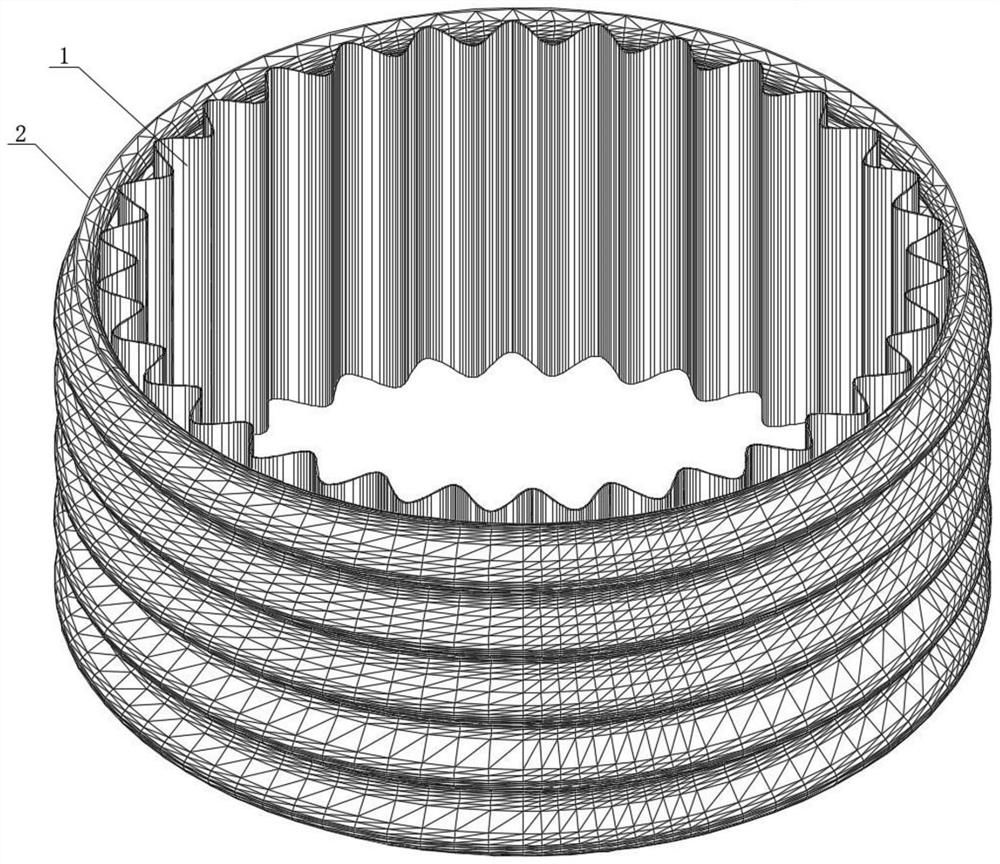

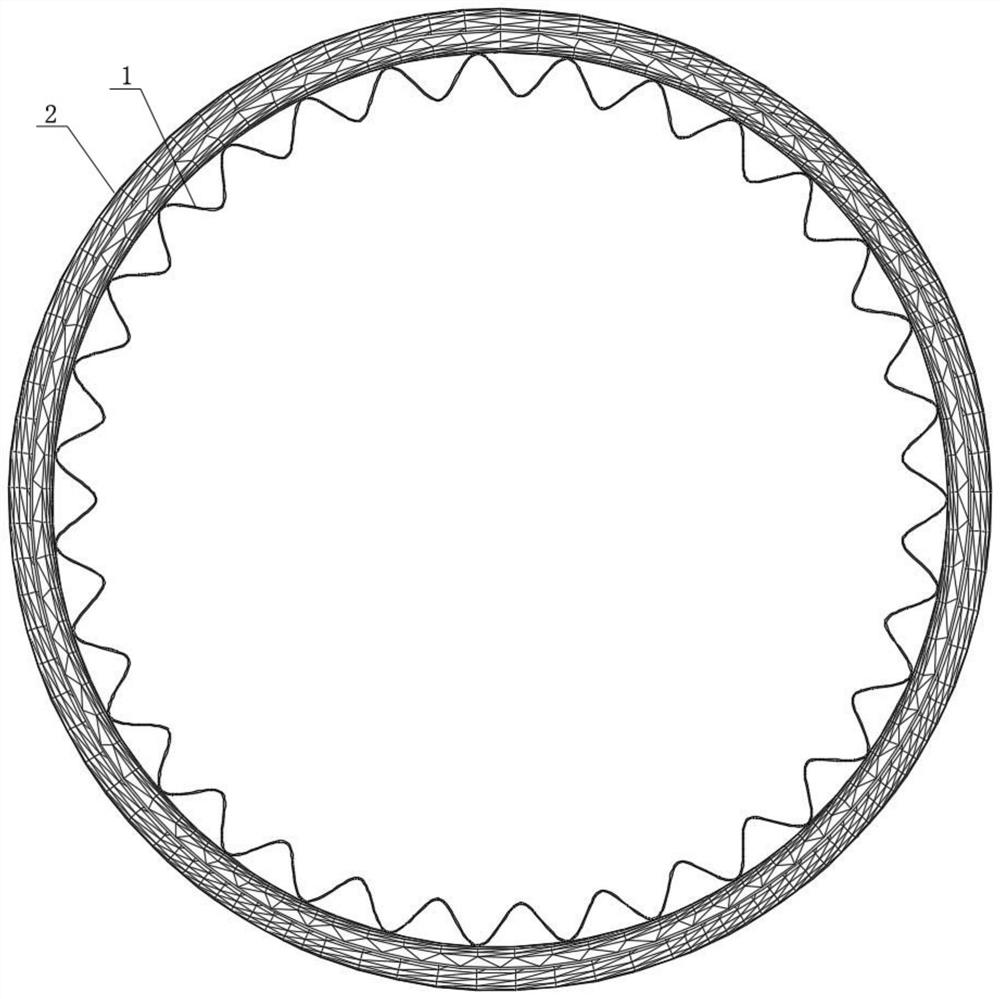

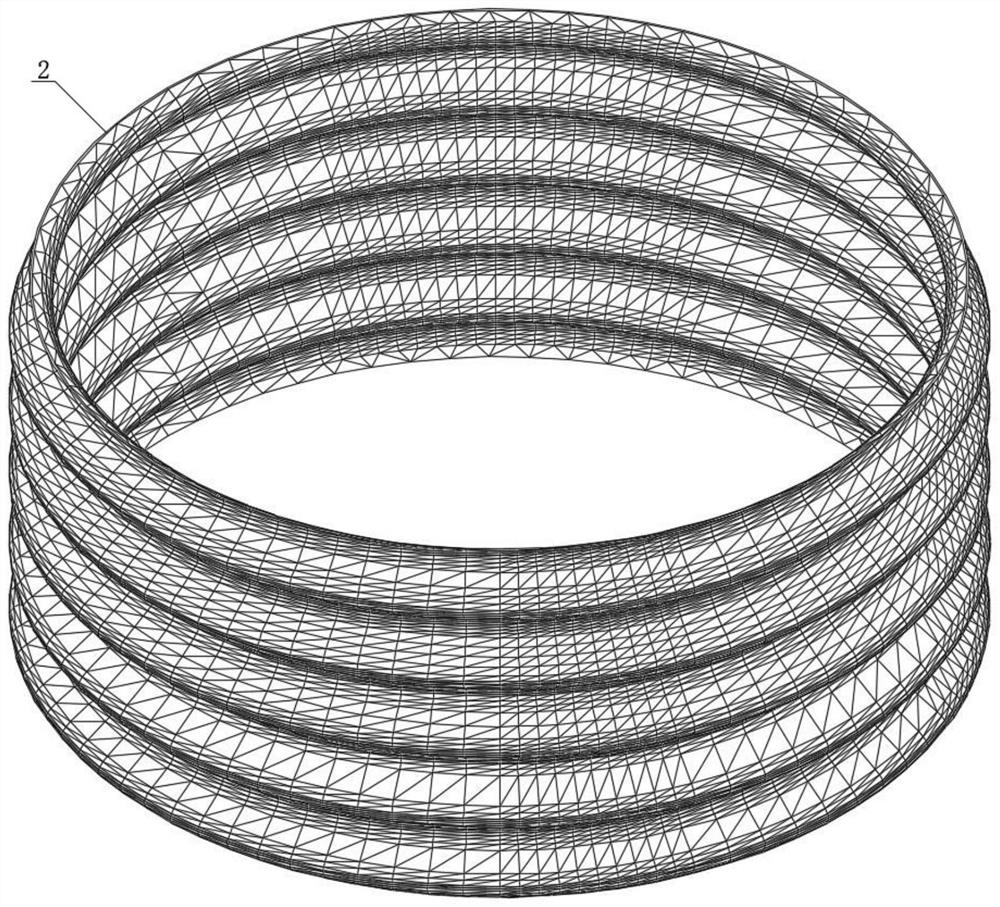

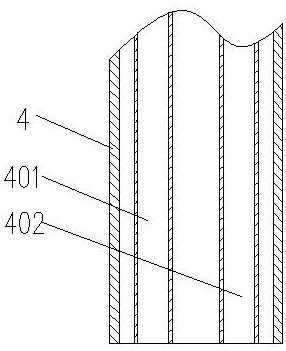

Corrugated pipe culvert structure

PendingCN111794136AEasy assembly and constructionReduction and Exemption Construction Auxiliary Rib Positioning MeasuresGround-workArchitectural engineeringCulvert

The invention discloses a corrugated pipe culvert structure. The corrugated pipe culvert is formed by sequentially connecting at least two layers of corrugated pipes in a sleeved mode. In the at leasttwo layers of corrugated pipes, the stripe directions of at least two adjacent layers of corrugated pipes are different, the stripe directions of the corrugated pipes take convex points on the outersides of the corrugated pipe bodies as wave crests and take convex points on the inner sides of the pipe bodies as wave troughs, and the wrinkle stripes formed between the wave crests and the wave troughs are extensible, and the extension direction is called as the stripe direction. According to the invention, a multi-layer corrugated pipe structure design is adopted; the stripe directions of theadjacent corrugated pipes are different; the formed pipe body is rigid in the circumferential direction and the axial direction; the characteristic of weak transverse stability of the one-way steel corrugated pipe culvert is overcome; the overall anti-pressure ability of the corrugated pipe culvert is improved; the characteristic that all layers of steel corrugated pipes are flexible in one direction and easy to construct and assemble can be brought into play during construction; a large number of construction auxiliary rib positioning measures can be omitted, excessive development of plastichinges in the construction process can also be omitted, the implementation progress is fast, and a two-way rigid steel corrugated pipe whole is formed after construction is completed.

Owner:CHINA SOUTHWEST ARCHITECTURAL DESIGN & RES INST CORP LTD

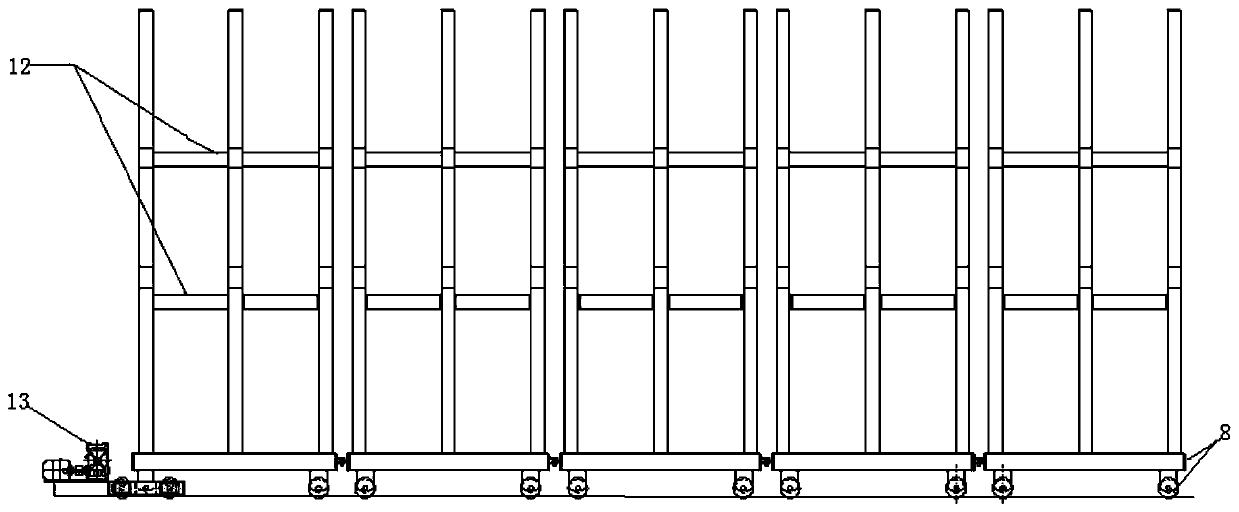

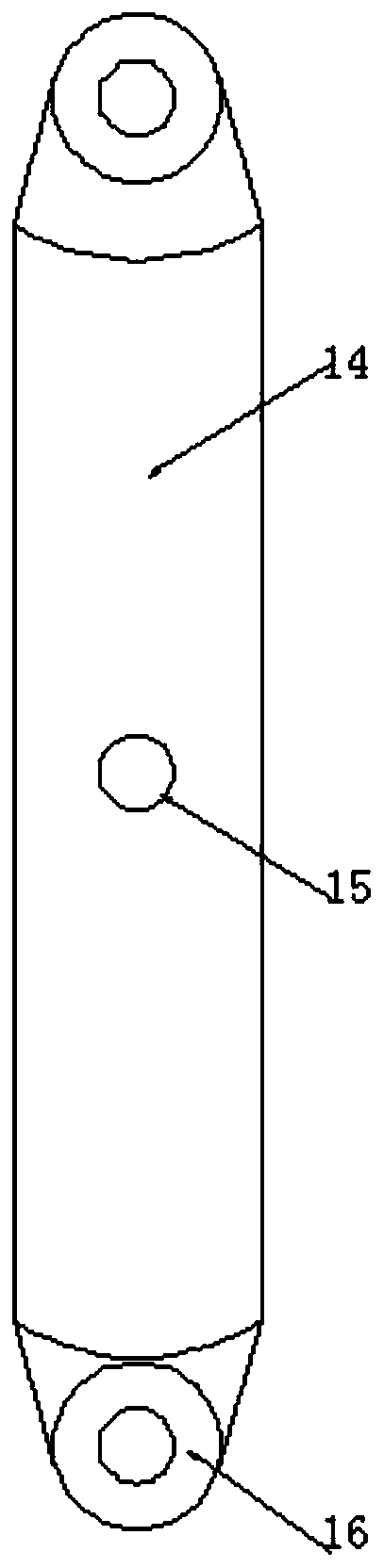

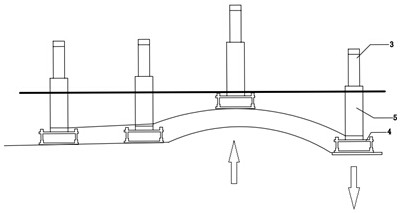

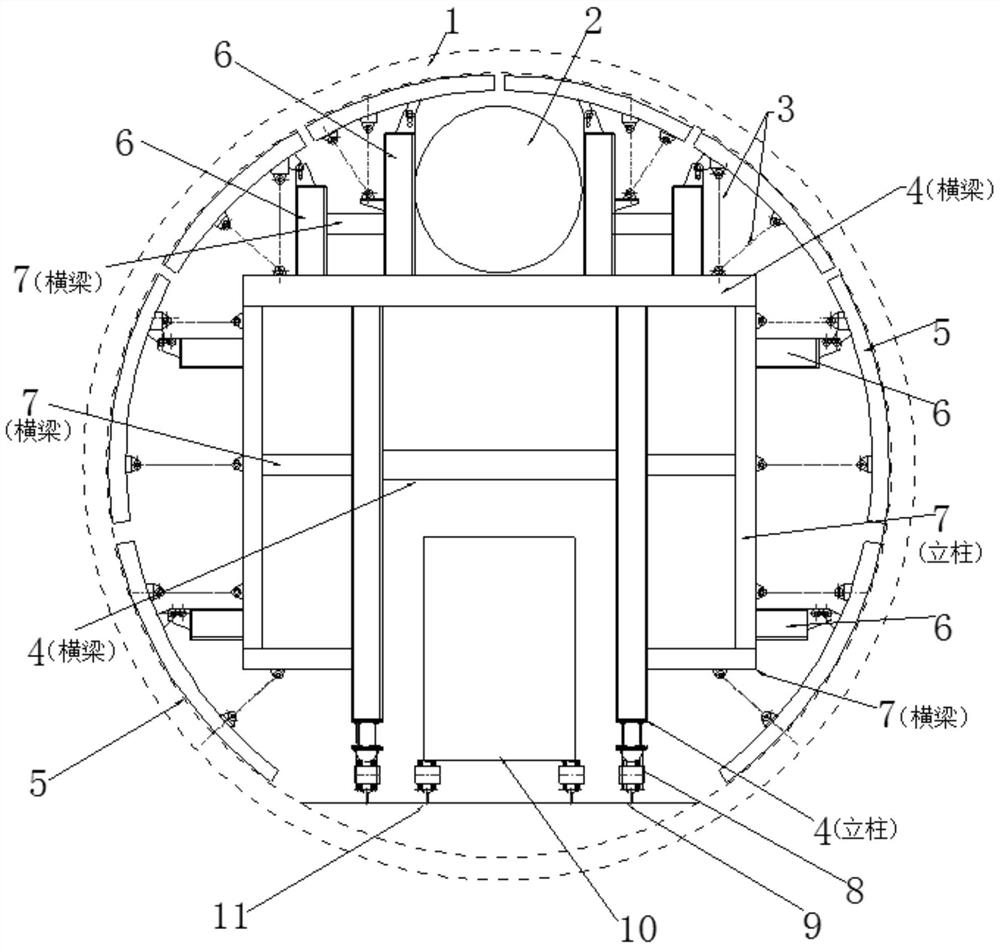

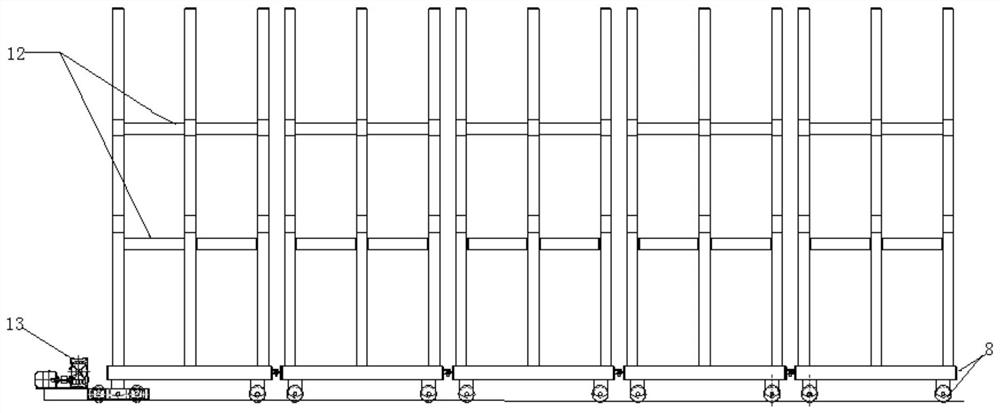

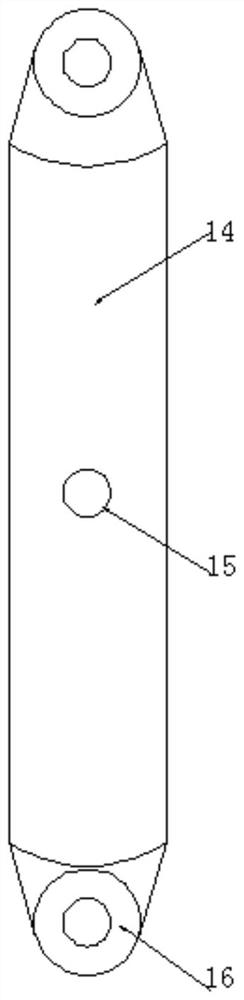

Shield tunnel internal supporting trolley system under small spacing, shallow soil covering and small radius conditions

ActiveCN111236990AReduce the impact of settlementReduce construction riskUnderground chambersTunnel liningVehicle frameGeotechnical engineering

The invention discloses a shield tunnel internal supporting trolley system under small spacing, shallow soil covering and small radius conditions. The shield tunnel internal supporting trolley systemcomprises a trolley track, a muck vehicle track, a trolley and a muck vehicle, wherein the trolley track and the muck vehicle track are arranged at the bottom of a tunnel, the trolley is matched withthe trolley track, and the muck vehicle is matched with the muck vehicle track; the trolley track adopts an original track on which a shield trolley walks; and the trolley comprises a frame, a walkingmechanism and a supporting mechanism, the upper portion of the frame can contain a ventilation pipeline, the lower portion of the frame stretches across the muck vehicle and does not interfere with the muck vehicle, the supporting mechanism comprises arc-shaped plate supports, sliding hinge pieces and telescopic jacking pieces, the arc-shaped plate supports are distributed on the upper portion and the two sides of the tunnel, gaps exist between the adjacent arc-shaped plate supports, the arc-shaped plate supports are slidably hinged to the frame through the sliding hinge parts, the arc-shapedplate supports are telescopically connected with the frame through the telescopic jacking pieces, and when the telescopic jacking pieces drive the arc-shaped plate supports to be ejected out and retracted back, the sliding hinge parts play a role in guiding and limiting. According to the system, duct pieces are prevented from being damaged, advancing spaces of the ventilation pipeline and muck isreserved, and the influence on the first-departure line tunnel is reduced to the minimum.

Owner:CHINA RAILWAY 11TH BUREAU GRP +1

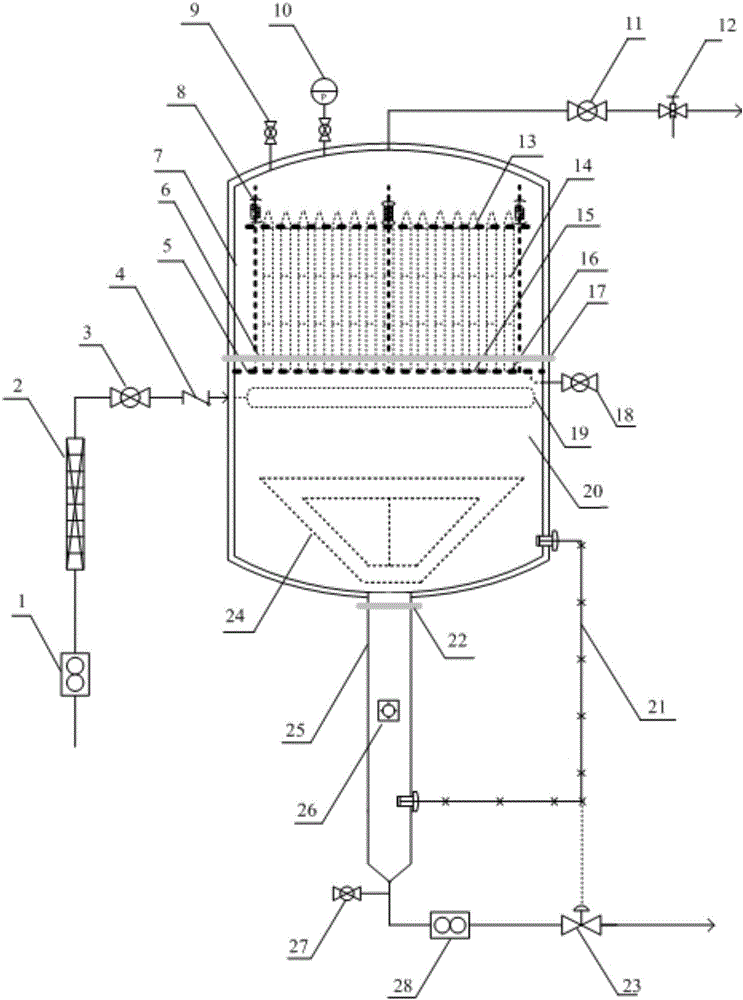

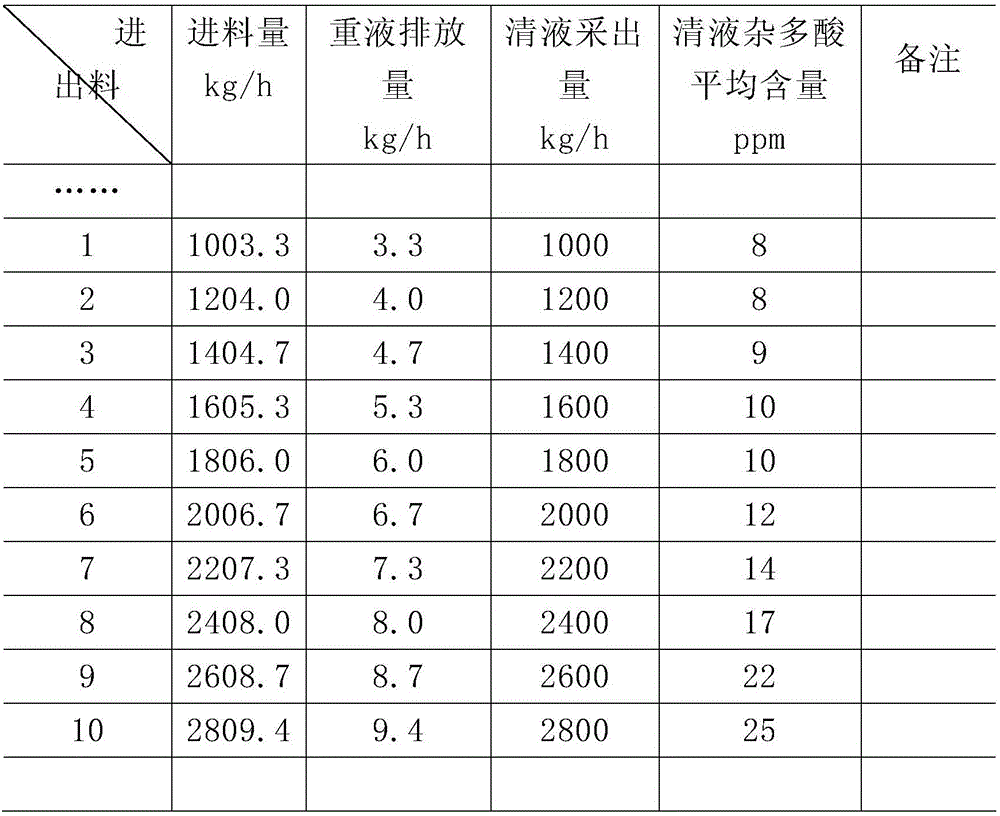

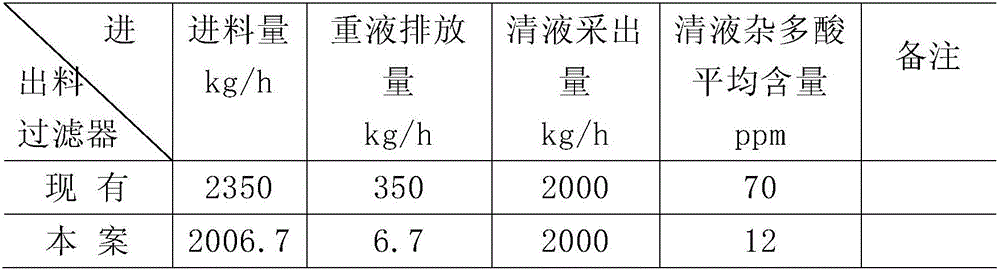

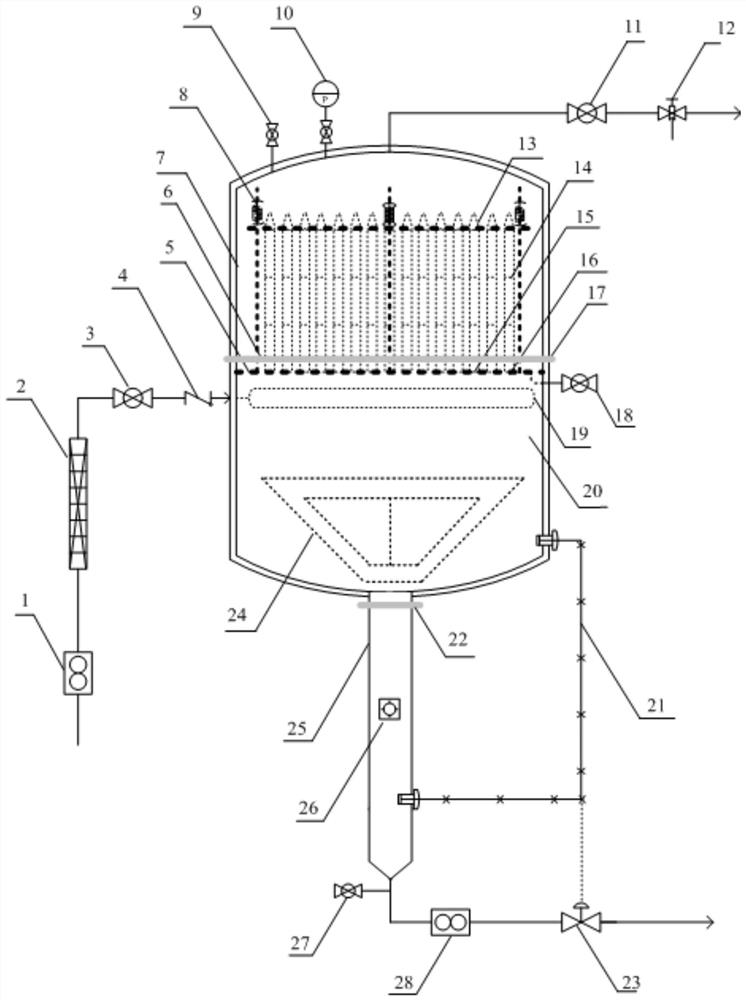

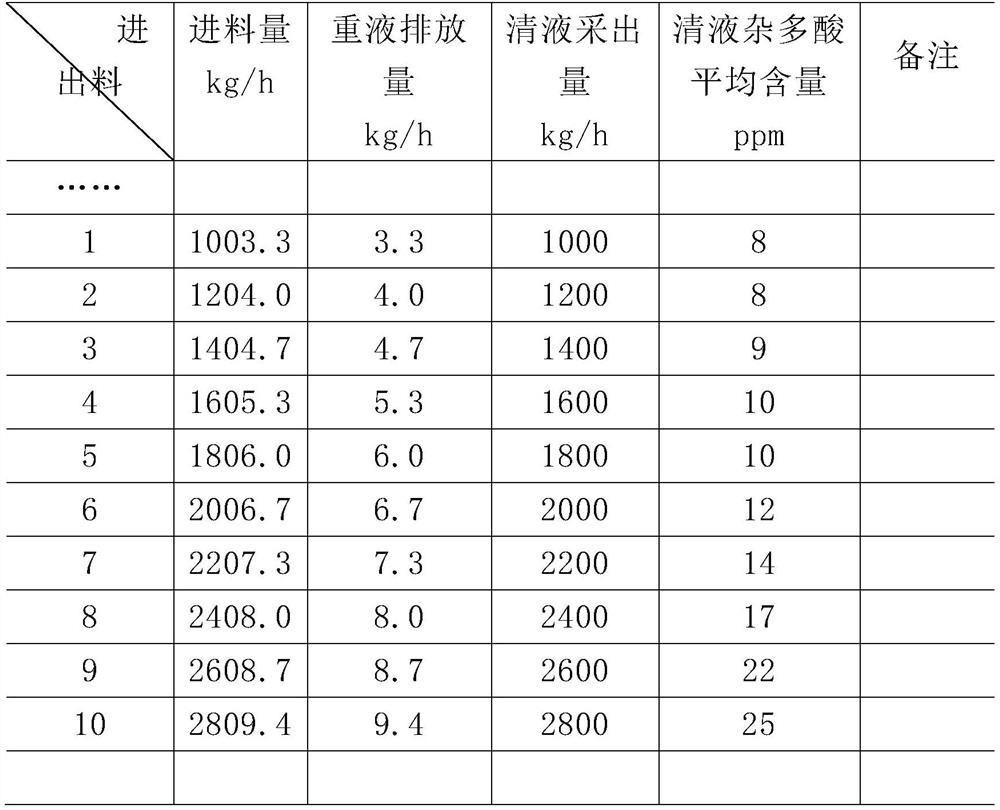

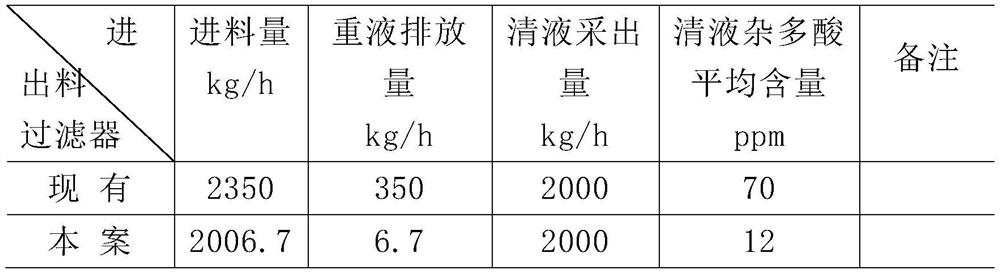

Filtering equipment for realizing separation of catalyst in production of polytetramethylene ether glycol

ActiveCN106669279AReduce the impact of settlementReduce settlementFiltration circuitsEtherEngineering

The invention belongs to the technical field of chemical production equipment and relates to filtering equipment for realizing separation of a catalyst in production of polytetramethylene ether glycol. The filtering equipment comprises an upper barrel body and a lower barrel body which are in sealed connection, wherein a pipe plate is fixedly connected with an inner wall of the lower barrel body; the upper surface of the pipe plate is fixedly connected with a filter element; a first polytetrafluoroethylene gasket is arranged between the filter element and the pipe plate; a pressing plate is arranged at the upper part of the filter element; a plurality of screw rods which vertically and upward extend are fixed on the pipe plate; upper ends of the screw rods penetrate through corresponding through holes in the pressing plate, and springs sleeve the upper ends of the screw rods; the lower ends of the springs are tightly pressed on the upper surface of the pressing plate; and the upper ends of the springs jack against the bottom surfaces of nuts on the screw rods. When the filtering equipment works, the filtering equipment works stably, and the utilization efficiency of the filter element is greatly improved.

Owner:无锡玖和隆工程科技有限公司

Inspection well for pipeline engineering and cover structure

ActiveCN111894039AAvoid crackingExtended service lifeArtificial islandsTraffic signalsStructural engineeringRoad surface

The invention discloses an inspection well for pipeline engineering and a cover structure, and belongs to the technical field of road safety. The inspection well comprises an inspection well body; aninspection well supporting assembly is attached to the well wall of the inspection well body, the inspection well supporting assembly comprises a supporting box body, the upper portion of the supporting box body is arranged in a penetrating mode, and a second assembling cover plate capable of moving up and down is arranged in the supporting box body; at least three supporting springs are arrangedbelow the second assembling cover plate, a through opening in the upper portion of the supporting box body is covered with a first assembling cover plate matched with the through opening in the upperportion of the supporting box body in shape, and the space between the first assembling cover plate and the second assembling cover plate is filled with a second filling piece, a first filling piece and a third filling piece. According to the inspection well, the influence of uneven placement of an inspection well cover caused by pavement settlement is reduced, and noise generated when a vehicle passes through the inspection well cover placed on the inspection well is low. According to the cover structure, the well cover is prevented from being abnormally opened or lost, the anti-theft and warning functions are achieved, and the well mouth vacancy under the condition that the well cover is washed away is avoided.

Owner:温州好惠报企业管理有限公司

Preparation method of raw material for producing titanium dioxide of decorative base paper

ActiveCN107500346AUnchanged stabilityImprove acid hydrolysis rateTitanium and titanyl sulfatesIron powderSulfate

The invention provides a preparation method of a raw material for producing titanium dioxide of decorative base paper, and belongs to the technical field of titanium dioxide of decorative base paper. The method comprises the following steps: A, selecting titanium ore of which the residue on sieve is 10.0-20.0% under 325 meshes and the residue on sieve is 0 under 200 meshes, the water content is not greater than 0.5%, TiO2 is not less than 45%, Fe2O3 is not greater than 8%, and the temperature is not greater than 40 DEG C; selecting sulfuric acid on the concentration of 30-55% and under the temperature of being not greater than 40 DEG C; mixing sulfuric acid and titanium ore; cooling to obtain a titanium ore pre-mixed material; B, feeding the titanium ore pre-mixed material into a reaction tank; stirring; adding sulfuric acid on the concentration of 98%; reacting; then curing; C, cooling the cured material; adding dilute sulphuric acid; then adding sand filtering water to dissolve; D, adding zero-valent iron powder to the dissolved liquid to react; E, precipitating the liquid obtained in the reaction in step D; collecting supernate; filtering to obtain titanous sulfate containing not greater than 30mg / L of filtrate solid content. The method is stable to operate, high in acidolysis rate, stable in quality index, and stable in quality of titanium dioxide prepared by the sulfuric acid method.

Owner:HEBEI MILSON TITANIUM DIOXIDE

Construction method for continuous underneath passing of large-diameter water delivery pipeline in shield section

ActiveCN114737979AReduced settling deformation tendencyReduce the impact of settlementPipe laying and repairUnderground chambersArchitectural engineeringStructural engineering

The invention provides a construction method for continuously and downwards penetrating a large-diameter water conveying pipeline in a shield interval. The construction method is mainly used for construction of continuous downward penetration of at least two large-diameter water delivery pipelines in a large-diameter shield section, and the downward penetration area is provided with an overhaul well of the water delivery pipelines. The construction method sequentially comprises the processes of reinforcement of a shield section left and right line underneath penetrating water conveying line range and a water conveying pipe overhaul well, reinforcement of a pipe shed vertical shaft construction range, pipe shed vertical shaft construction, monitoring point burying, shield trial tunneling and radial grouting reinforcement in the shield underneath penetrating process. The construction method is high in universality, orderly in procedure connection and small in cross operation influence, the related problem that a large-diameter water conveying pipeline continuously and downwards penetrates through the shield section is solved, the construction method can be widely applied to construction of downwards penetrating through other buildings (structures) in the shield section, the construction quality of the shield section tunnel is guaranteed, and the construction period is shortened. And breakage of the large-diameter water delivery pipeline is avoided.

Owner:CHINA RAILWAY 11TH BUREAU GRP +1

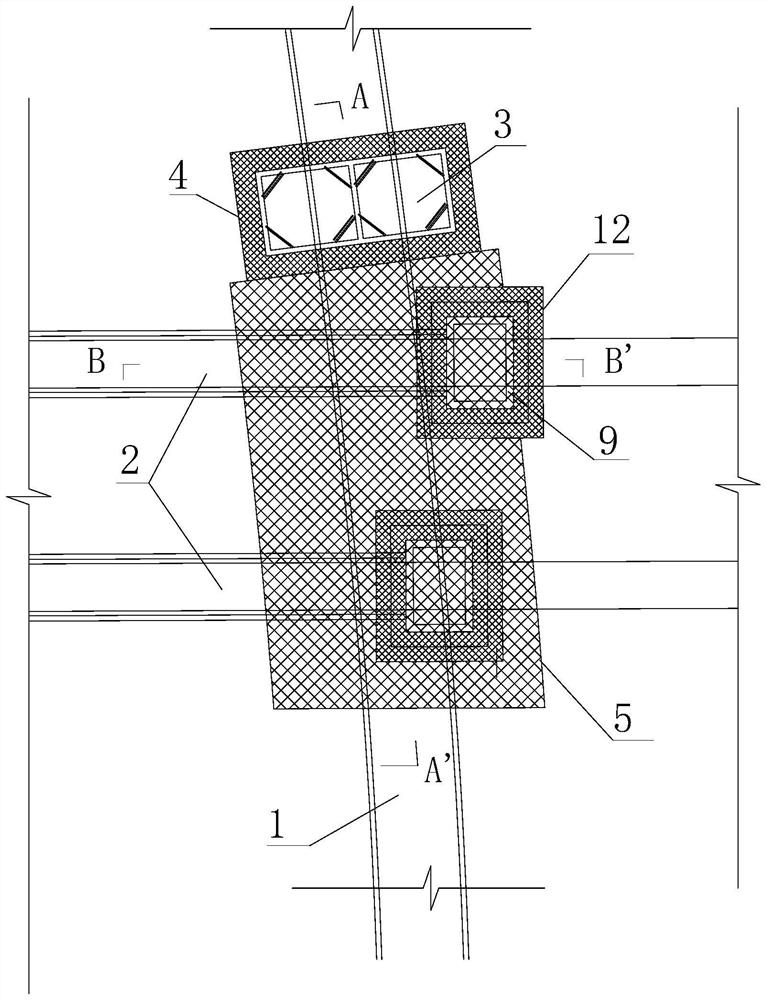

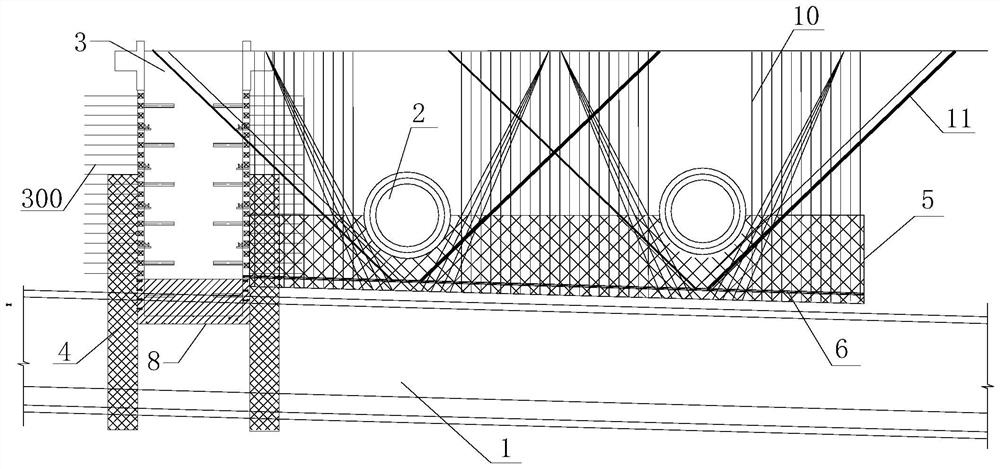

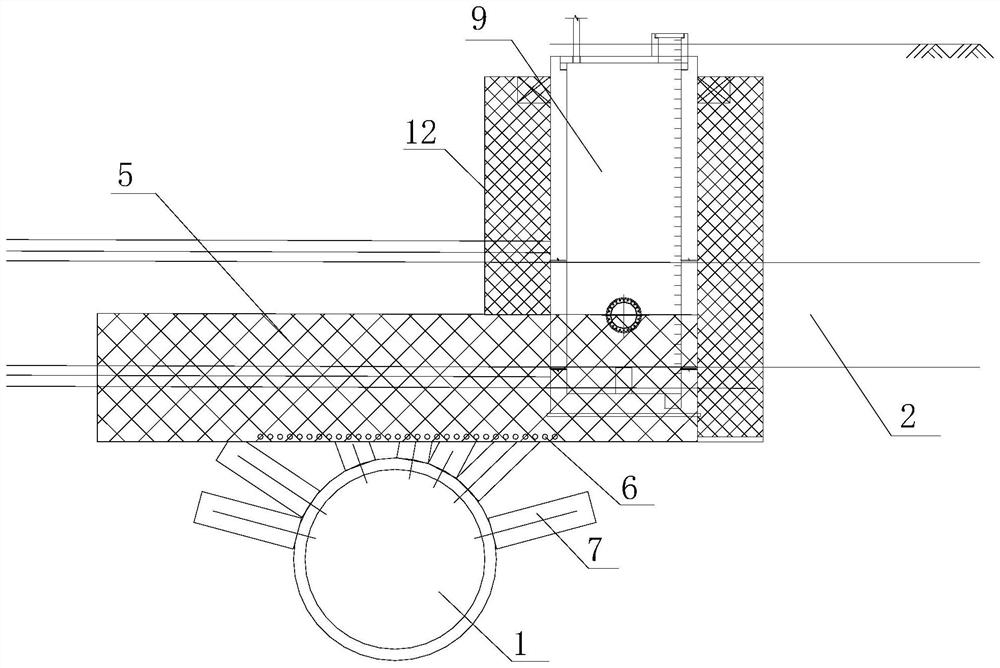

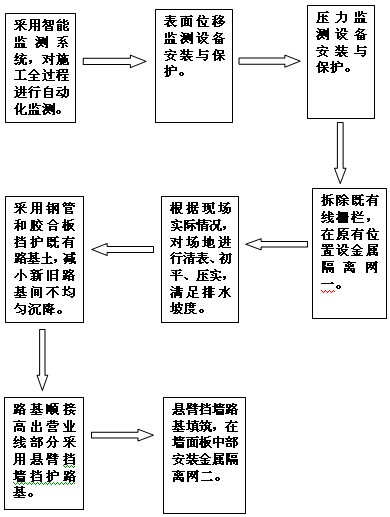

Retaining wall type high-speed railway subgrade coordinated settlement control construction method based on intelligent monitoring of adjacent existing lines

ActiveCN113718560AReduce the impactReduce differential settlementArtificial islandsFoundation testingArchitectural engineeringMonitoring system

The invention discloses an adjacent existing line retaining wall type high-speed rail roadbed coordinated settlement control construction method based on intelligent monitoring, and relates to the technical field of constructional engineering.The overall construction sequence is as follows: firstly, intelligent monitoring instruments and equipment are laid to conduct automatic detection on a whole construction railway section, then a first metal separation net is constructed, and then a site is primarily leveled; and high-pressure jet grouting pile and isolation pile construction is carried out, foundation pit excavation and supporting are carried out after pile arrangement is completed, a retaining wall type roadbed construction stage is entered, and cantilever retaining wall roadbed filling is carried out. The construction method is simple, the influence on settlement of the adjacent existing lines in the construction process can be effectively reduced, the safety and comfort of the operation railway are guaranteed, the construction quality is high, differential settlement of the transition section of the new roadbed and the old roadbed is greatly reduced, an intelligent monitoring system is adopted for settlement and displacement monitoring in the whole construction railway section construction period, the deformation condition of the existing structure in the construction period is mastered in time, deformation overrun is controlled and treated in time, and the operation safety of a business line is ensured.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

A Freezing Method for Repairing Holes in Underpasses of Tunnels

ActiveCN110847151BReduce distortionFreeze effectiveSoil preservationArchitectural engineeringMechanical engineering

Owner:合肥九州龙腾科技成果转化有限公司

The construction method of the station guide tunnel and underground excavation of the existing operating station under zero distance

ActiveCN111946353BIncrease speedImprove efficiencyUnderground chambersTunnel liningArchitectural engineeringSafety risk

The invention discloses a station guide tunnel and underground digging station construction method that passes through the existing operating station at zero distance, solves the problems of slow construction speed and high safety risk in the prior art, improves the efficiency of guide tunnel construction, and shortens the construction time of newly built stations The beneficial effect of avoiding the excessive settlement and deformation of the structure of the existing operation station is to avoid the beneficial effect of the construction period. The specific plan is as follows: the construction method of the station guide tunnel passing through the existing operation station at zero distance, including the use of pipe jacking machines to carry out the operation of the guide tunnel. It includes the following contents: use the underground excavation of the cross passage as the pipe jacking work shaft; after the hole is cut out, the pipe jacking machine jacking operation is carried out in the cross passage; while the pipe jacking machine is jacking, the pipe joints and segments are assembled Form the secondary lining structure of the pilot hole.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

A raw material preparation method for the production of decorative base paper titanium dioxide

ActiveCN107500346BUnchanged stabilityImprove acid hydrolysis rateTitanium and titanyl sulfatesIron powderSulfate

The invention provides a preparation method of a raw material for producing titanium dioxide of decorative base paper, and belongs to the technical field of titanium dioxide of decorative base paper. The method comprises the following steps: A, selecting titanium ore of which the residue on sieve is 10.0-20.0% under 325 meshes and the residue on sieve is 0 under 200 meshes, the water content is not greater than 0.5%, TiO2 is not less than 45%, Fe2O3 is not greater than 8%, and the temperature is not greater than 40 DEG C; selecting sulfuric acid on the concentration of 30-55% and under the temperature of being not greater than 40 DEG C; mixing sulfuric acid and titanium ore; cooling to obtain a titanium ore pre-mixed material; B, feeding the titanium ore pre-mixed material into a reaction tank; stirring; adding sulfuric acid on the concentration of 98%; reacting; then curing; C, cooling the cured material; adding dilute sulphuric acid; then adding sand filtering water to dissolve; D, adding zero-valent iron powder to the dissolved liquid to react; E, precipitating the liquid obtained in the reaction in step D; collecting supernate; filtering to obtain titanous sulfate containing not greater than 30mg / L of filtrate solid content. The method is stable to operate, high in acidolysis rate, stable in quality index, and stable in quality of titanium dioxide prepared by the sulfuric acid method.

Owner:HEBEI MILSON TITANIUM DIOXIDE

Construction method of excavating hole piles in subway stations

ActiveCN106703814BReduce the impact of settlementSave masonryUnderground chambersTunnel liningMetro stationSupporting system

Provided is a mined metro station hole pile construction method. The method comprises the steps of whole support system construction and main body second lining construction; the whole support system construction step comprises the substeps that by utilizing air shafts at the two ends of the station as temporary working wells, four pilot tunnels are transversely dug through a positive step method; upper pilot tunnel side pile and middle column hole digging pile construction is conducted, bored piles are constructed inside an upper layer side pilot tunnel at intervals, and artificial hole digging piles are constructed inside an upper layer middle pilot tunnel at intervals; lower layer pilot tunnel bottom longitudinal beam construction is conducted; upper layer pilot tunnel steel pipe column construction is conducted; side pile crown beam construction is conducted; top longitudinal beam construction is conducted; top arch initial supporting structure construction is conducted; the main body second lining construction step comprises the substeps that soil body excavation is conducted, and station top plate second lining structure construction is conducted; when a soil body is dug to the bottom of a middle plate, middle plate and middle longitudinal beam construction is conducted; when a soil body is dug to the bottom of a base plate, the waterproof base plate is laid, and structure base plate construction is conducted; lower portion side wall construction is conducted when the base plate reaches the set intensity.

Owner:HONGRUN CONSTR GROUP STOCK

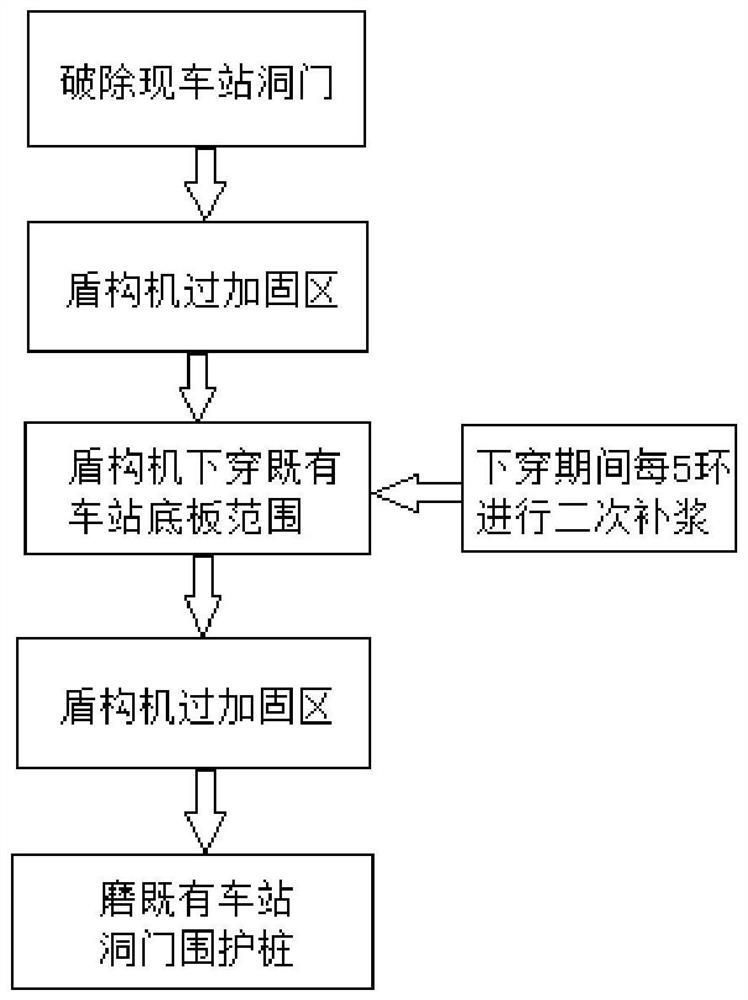

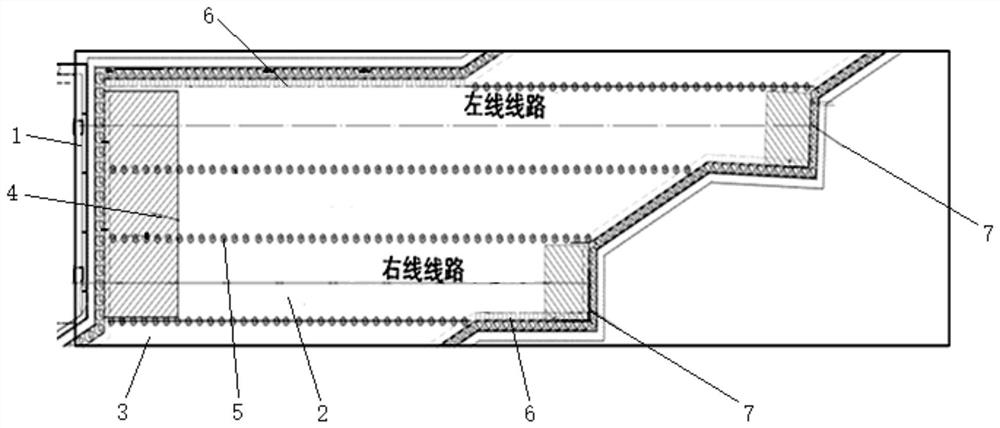

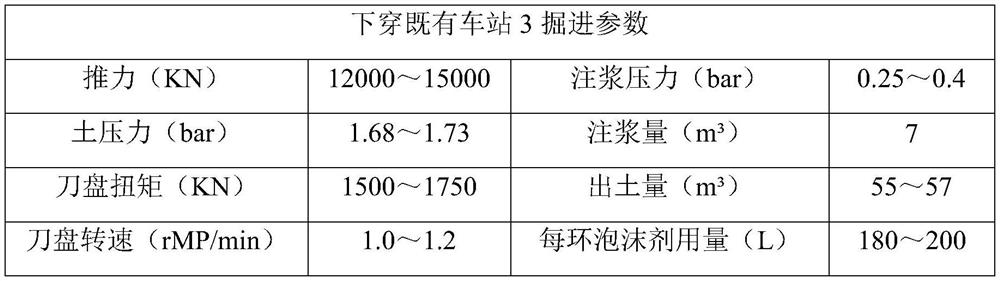

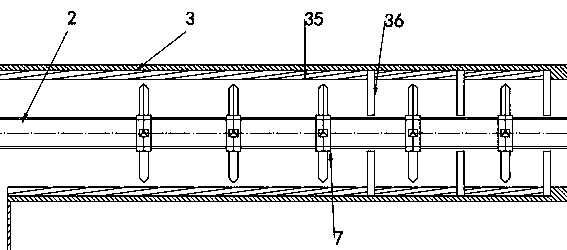

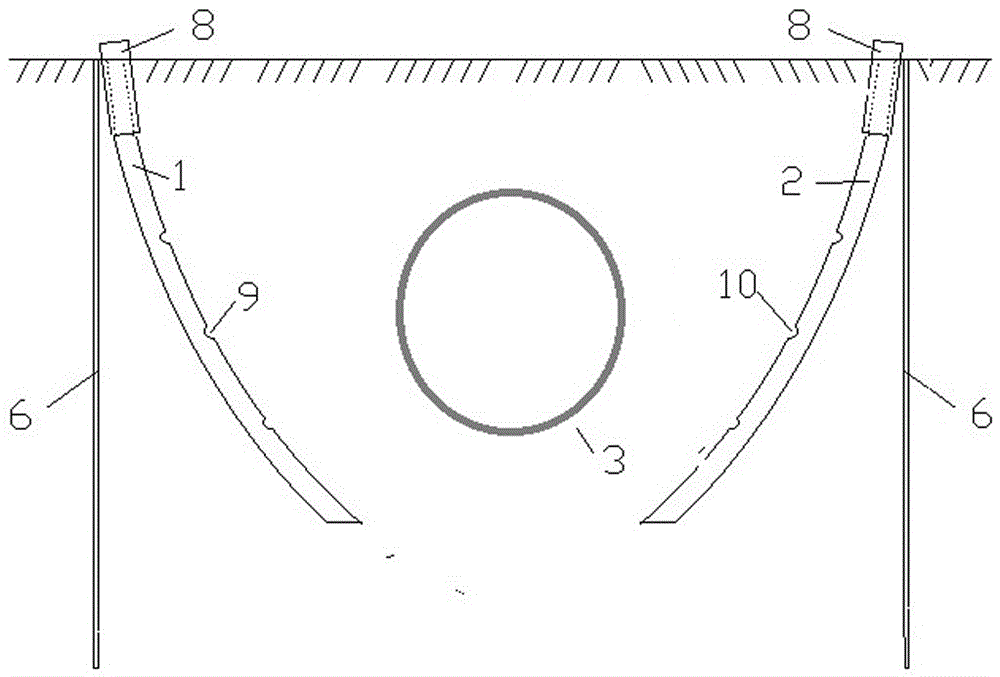

A Construction Method for Shield Tunneling Under the Existing Station in Powder Soil Stratum

ActiveCN110130909BReduce the impact of disturbanceControl postureUnderground chambersTunnel liningGround subsidenceStructural engineering

The invention discloses a construction method for shield tunneling under an existing station in a silt layer, which comprises the following steps: step 1: removing the portal (1) of the existing station (2); step 2: removing the existing station ( 3) and the existing station (2) for reinforcement; step 3: the shield machine passes through the reinforcement area of the starting end of the existing station (3); step 4: the shield machine passes under the floor of the existing station (3) range, and carry out synchronous grouting and secondary grouting during the underpass; step 5: the shield machine passes through the existing station (3) and exits the end area of the existing station; step 6: the shield machine exits the existing station (3) ) and grind the retaining piles of the existing station (3). The invention can reduce the impact of disturbance on the silt layer soil during the tunneling process of the shield machine, effectively control the attitude of the shield machine, reduce the impact of ground subsidence, reduce construction risks, and speed up the construction period.

Owner:中建八局轨道交通建设有限公司

A simulation experiment device and method for secondary crushing and fluidization of subsea natural gas hydrate

ActiveCN108468534BReduce the impact of settlementGuaranteed Particle ConcentrationSurveyConstructionsRotational axisControl system

The invention provides a simulation experiment device and method for secondary crushing and fluidization of submarine gas hydrate. The simulation experiment device for the secondary crushing and fluidization comprises a secondary crushing pipeline, a rotating power assembly, a particle crushing knife tackle, a material falling assembly, a crushed particle recovery device and a control system, wherein the rotating power assembly comprises a motor and a rotating shaft, the particle crushing knife tackle is connected to the rotating shaft of the rotating power assembly through a flat key, the rotating power assembly is connected with a particle crushing pipeline through a bolt and a nut, the particle crushing pipeline is welded with a round-to-square flange plate and connected with the material falling assembly through a bolt and a nut, the crushed particle recovery device is placed on a crushing pipeline outlet, and the control system is connected with and controls the motor of the rotating power assembly and the material falling assembly. The crushing method adjusts the rotating speed of the rotating power assembly and the material falling speed of the material falling assembly through the control system, circulating water is pumped, non-premixed particles in a hopper is discharged down, and an outlet recovery device recovers crushed particles.

Owner:SOUTHWEST PETROLEUM UNIV

Construction method of widening high-fill subgrade with foam light soil

ActiveCN110042716BReduce vertical additional stressReduce the impact of settlementRoadwaysExcavationsSupport removalPre stress

The invention relates to a construction method for widening a high-fill roadbed with foam light soil, which is characterized in that the original old roadbed is first cut into a stepped shape, and a concrete baffle is arranged on the periphery of the widened side of the roadbed as a formwork for pouring foam light soil. The reinforcement mesh is laid horizontally at the position of the large platform to connect with the baffle, and prestressed anchor rods are added to anchor on the baffle, and the pouring construction of foam light soil is carried out by layering, partitioning and segmenting, and finally the baffle is removed and the hanging type is installed. Geotechnical bag: The construction method includes original subgrade construction, baffle installation, lightweight foam soil pouring, steel mesh and drainage pipe installation, anchor cable construction, lightweight foam soil pouring, steel support removal and installation of hanging geotechnical bags. According to the invention, baffles and pre-embedded section steel are provided on the widened side of high filling to form a stable support structure, which can effectively improve the stability of the baffle, and the section steel after construction can be recycled and used, reducing material loss and engineering cost.

Owner:杭州悦为科技有限公司

A construction method for the shield machine to go under the existing station and start

ActiveCN110924961BControl chisel construction safetyEnsure the safety of chiseling constructionUnderground chambersTunnel liningStructural engineeringShield tunneling

The invention discloses a construction method enabling a shield tunneling machine to underneath pass through an existing station to start. A steel sleeve is adopted for construction, and the followingflow including bottom plate levelling and steel plate laying for an underneath passing channel, vertical freezing reinforcement for a tunnel door, installation for the lower half-circle of the steelsleeve, downhole installation for the shield tunneling machine, overall underneath passing and longitudinal movement of the steel sleeve, breaking for the tunnel door, installation for a negative ring, backfilling for the sleeve, pressure testing, pulling-out for a freezing pipe, sealing for a freezing hole, and starting of the shield tunneling machine. The steel sleeve comprises a main sleeve body, a transition ring, a reinforcing ring, a bottom frame and a counter-force frame, wherein the main sleeve body is formed by splicing four sections of sleeve bodies with the same length; and each sleeve body is composed of an upper half-circle sleeve body and a lower half-circle sleeve body. The transition ring is connected to the front end of the main barrel body; the reinforcing ring is connected to the rear end of the main barrel body; the bottom frame is also divided into four sections of bases; and the counter-force frame is connected to the rear end of the reinforcing ring. According tothe construction method, damage to a constructed station structure can be avoided, the construction risk and difficulty of starting driving of the shield tunneling machine and later-period detachmentfor the sealing device for the tunnel door are lowered, and the construction period is accelerated.

Owner:CCCC THIRD HARBOR ENG +2

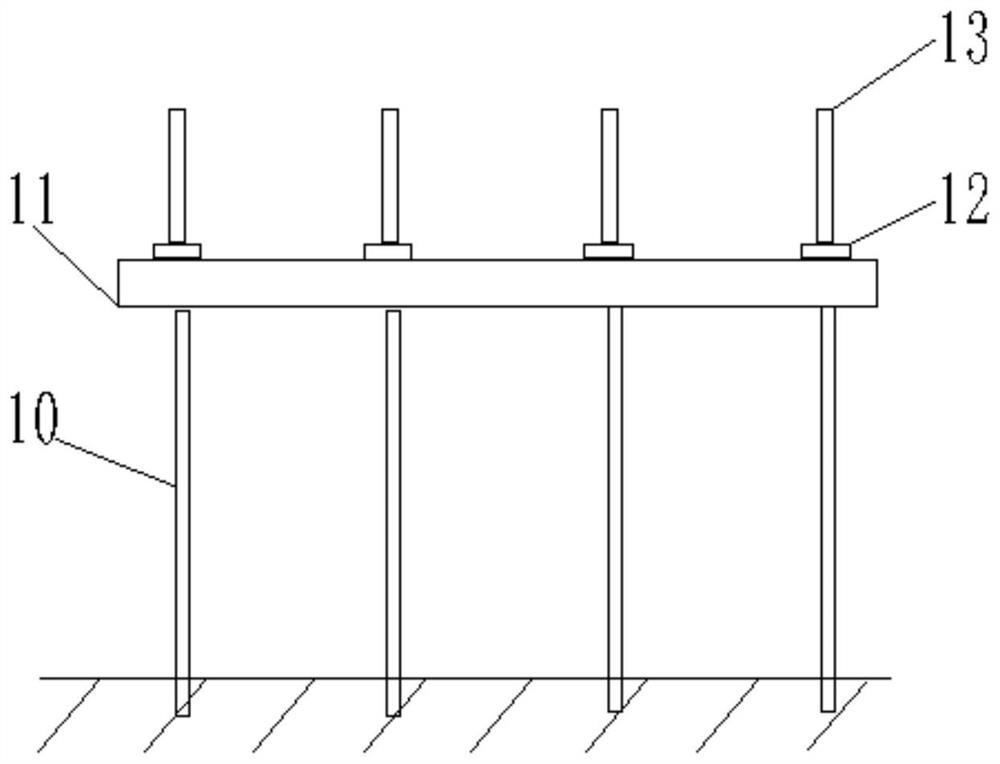

Installation process of hybrid bracket

ActiveCN109024655BReduce lossImprove construction efficiencyFoundation engineeringShoresArchitectural engineeringPipe

The invention discloses a mounting process of mixed brackets. The mounting process of the mixed brackets comprises the following steps: (1) floor brackets are mounted on the ground; the lower ends ofthe floor brackets extend underground; the floor brackets are pressed down; and the floor brackets are distributed around a lower-layer bridge; (2) longitudinal support beams are mounted at the tops of the lower-layer bridge and the floor brackets, and are arranged in the longitudinal direction of the bridge; (3) transverse support beams are mounted on the floor brackets and the longitudinal support beams; and (4) the floor brackets are mounted on the transverse support beams. The mounting process of the mixed brackets is balanced in load, stable in structure and firm in installation, adopts an assembled structure, performs the machining in the later period and the assembly in the previous period to reduce the scene assembly and disassembly workload, improves the bracket construction efficiency, reduces the transfer material loss, adopts large-diameter steel pipe piles to reduce the pile foundation stress to achieve enough safety stock, and prepresses the steel pipe piles beforehand toreduce the settlement influence of the steel pipe piles.

Owner:CHINA COMM 2ND NAVIGATIONAL BUREAU 2ND ENG

Filtration equipment to realize catalyst separation in polytetramethylene enigmatic glycol production

ActiveCN106669279BReduce the impact of settlementReduce settlementFiltration circuitsPtru catalystMeth-

The invention belongs to the technical field of chemical production equipment, and relates to a filtering device for realizing the separation of catalysts in the production of polytetramethylene enigmatic glycol, comprising an upper cylinder body and a lower cylinder body sealed and connected, and a tube plate fixedly connected to the inner wall of the lower cylinder body , the upper surface of the tube plate is fixedly connected to the filter element, the first polytetrafluoroethylene gasket is set between the filter element and the tube plate, the upper part of the filter element is set with a pressure plate, and several vertically extending screws are fixed on the tube plate, and the upper ends of the screws correspond to the pressure plate Through the through hole of the screw rod, a spring is sleeved on the upper end of the screw rod, the lower end of the spring is pressed against the upper surface of the pressure plate, and the upper end of the spring is pressed against the bottom surface of the nut on the screw rod. When the filtering device works, it runs stably, which greatly improves the use efficiency of the filter element.

Owner:无锡玖和隆工程科技有限公司

Internal support trolley system of shield tunnel under the condition of small spacing, shallow covering soil and small radius

ActiveCN111236990BReduce the impact of settlementReduce construction riskUnderground chambersTunnel liningVehicle frameShield tunneling

The invention discloses an internal supporting trolley system of a shield tunnel under the condition of small spacing, shallow covering soil and small radius. The track of the trolley adopts the original track of the shield trolley; the trolley includes a frame, a running mechanism and a supporting mechanism. The upper part of the frame can accommodate the ventilation duct, and the lower part spans the muck truck without interfering with it. The support mechanism includes arc braces, sliding hinges and telescopic top pieces. The arc braces are distributed on the upper part and both sides of the tunnel with gaps between them. The arc braces are slidably hinged to the vehicle frame through sliding hinges. 1. Through the telescopic connection between the telescopic top piece and the vehicle frame, when the telescopic top piece drives the arc-shaped plank to push out and retract, the sliding hinge plays the role of guiding and limiting. This system avoids segment damage, leaves space for ventilation ducts and muck to travel, and minimizes the impact on the starting line tunnel.

Owner:CHINA RAILWAY 11TH BUREAU GRP +1

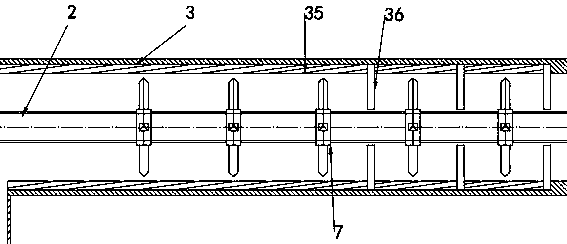

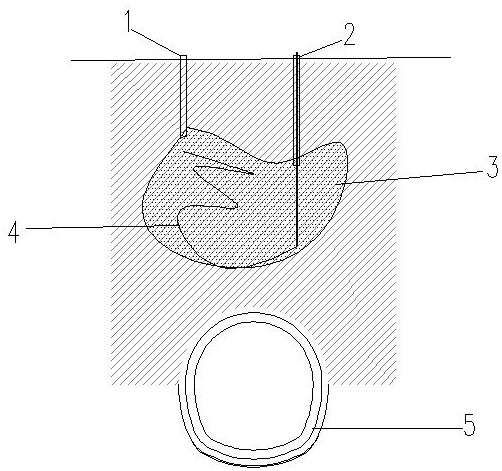

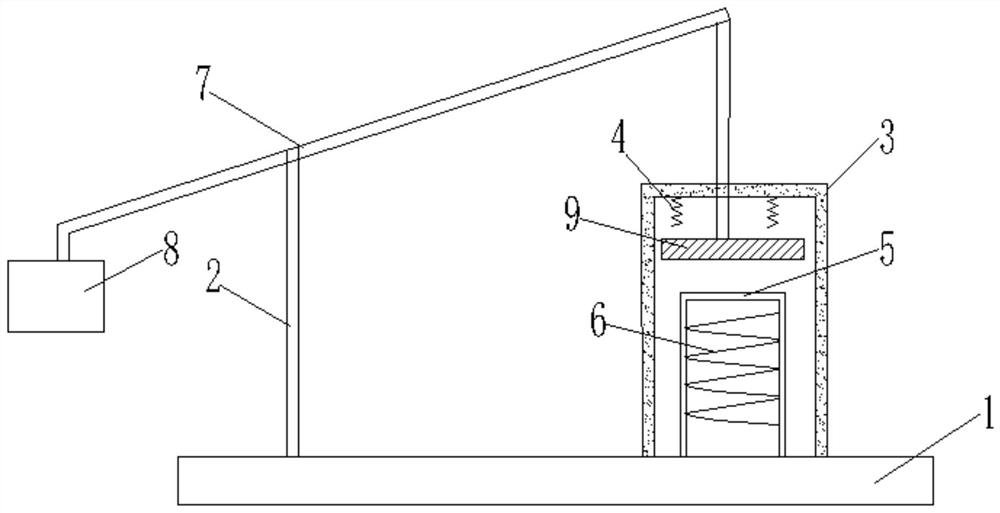

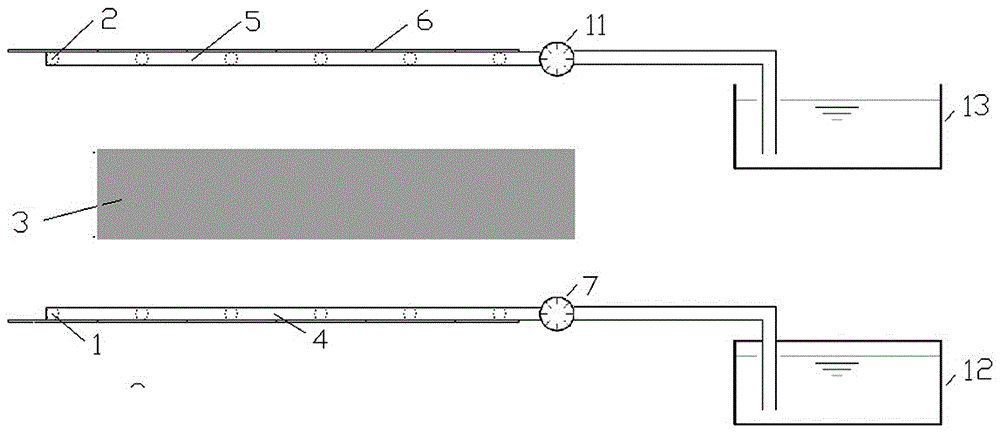

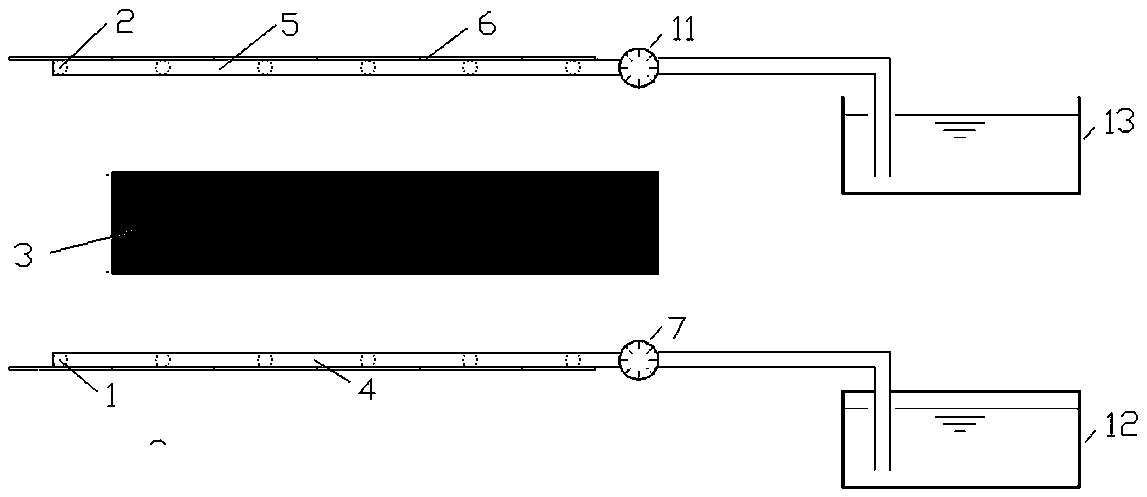

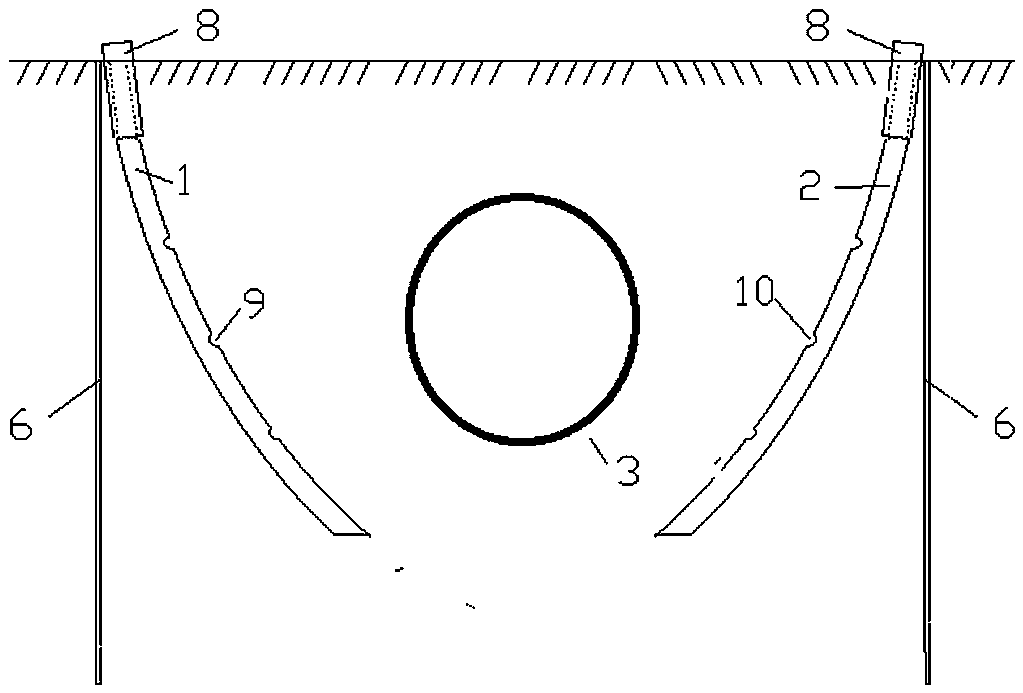

Silica sol reinforcing device for preventing shield tunneling machine from sinking in liquefiable sand and method thereof

ActiveCN106703007AReduce the impact of settlementPrevent liquefaction and sinkingSoil preservationEngineeringShield tunneling

The invention discloses a silica sol reinforcing device for preventing a shield tunneling machine from sinking in liquefiable sand. The device comprises a bending pipe jacking system, a silica sol injection system, a water pumping system and water separation plates; the bending pipe jacking system includes bending pipes perforated in the side edges; two rows of bending pipes are inserted in a foundation on two sides of an area where a shield tunnel is to be built; the silica sol injection system includes a silica sol solution injection main pipe, a first water pump and a silica sol storage container connected in sequence; the water pumping system includes a water pumping main pipe, a second water pump and a liquid storage pool connected in sequence; two rows of water separation plates are inserted in the foundation on two sides of the area to be built with the shield tunnel; a silica sol solution injection bending pipe is connected with the silica sol solution injection main pipe; and a water pumping bending pipe is connected with the water pumping main pipe. The device reinforces the liquefiable sand around the shield tunnel to be built through silica sol solution, is fast in permeation speed of the silica sol solution in the reinforcing process, is low in cost, is low in turbulence on surrounding environments, and can prevent vibration liquefication of the soil in the shield tunneling process to cause sinking of the shield tunneling machine after reinforcement.

Owner:枫荣(上海)文化传媒有限公司

A gas-solid separation and dust collection system for cutting debris

InactiveCN104338404BEasy to separateReduce the impact of settlementCombination devicesBaghouseMachine tool

Owner:河北顺天电极有限公司

Silica sol reinforcement device and method for preventing shield machine from sinking in liquefiable sand

InactiveCN106703007BReduce the impact of settlementPrevent liquefaction and sinkingSoil preservationEngineeringShield tunneling

Owner:枫荣(上海)文化传媒有限公司

Communication pipeline man hand hole downhole operation construction method

InactiveCN110984228AHigh construction strength and stabilityEnsure safetyArtificial islandsUnderwater structuresToxic gasBrick

The invention discloses a communication pipeline man hand hole downhole operation construction method. The method includes the following steps that the construction axis, the position and the elevation of a man hand hole are retested; the influence quantity of the settling volume on all part structures of the man hand hole is estimated; bricks are checked and maintained; the man hand hole is dug,the hole is broached, accumulated water is drained, and an envelop structure is constructed; a ventilating cloth curtain is arranged; toxic gas is subjected to segmented sampling detection; and the strength of the envelop structure, the downhole oxygen quantity and the harmful gas residual quantity are regularly detected. According to the method, the structures of the man hand hole are correspondingly subjected to design treatment according to the estimated settling volume in order to reduce the influences of the settling volume, it can be guaranteed that the construction strength stability ofthe man hand hole is high, by means of the ventilating cloth curtain, gas in the man hand hole can be exhausted through natural wind in a circulating manner, and the downhole operation safety of construction staff is guaranteed.

Owner:上海肯汀通讯科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com