Construction method enabling shield tunneling machine to underneath pass through existing station to start

A technology with existing stations and construction methods, which is applied to earth drilling, underground chambers, shaft equipment, etc., and can solve the problems of existing stations such as daily operation and passenger impact, leakage, and soil disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with accompanying drawing.

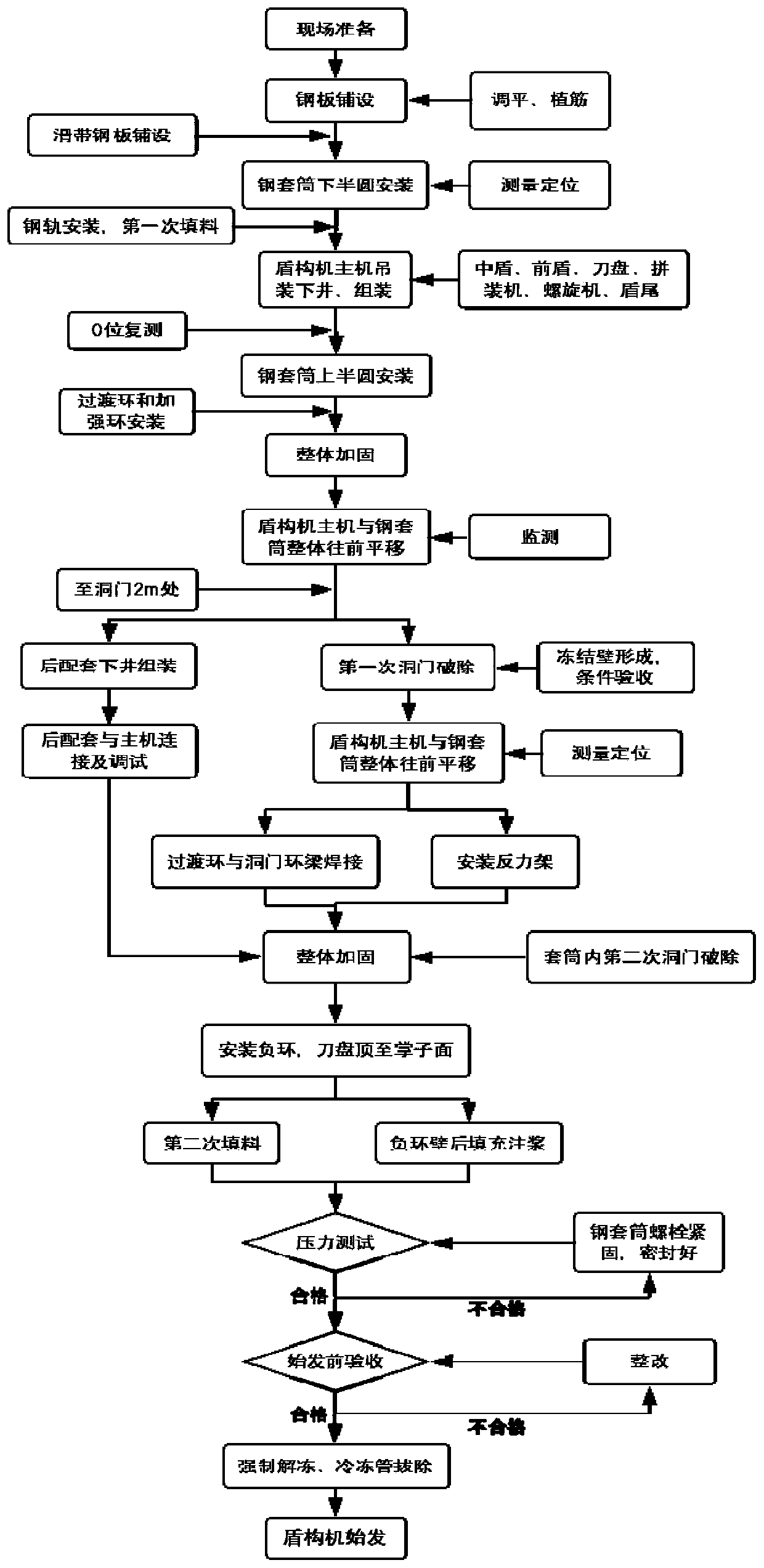

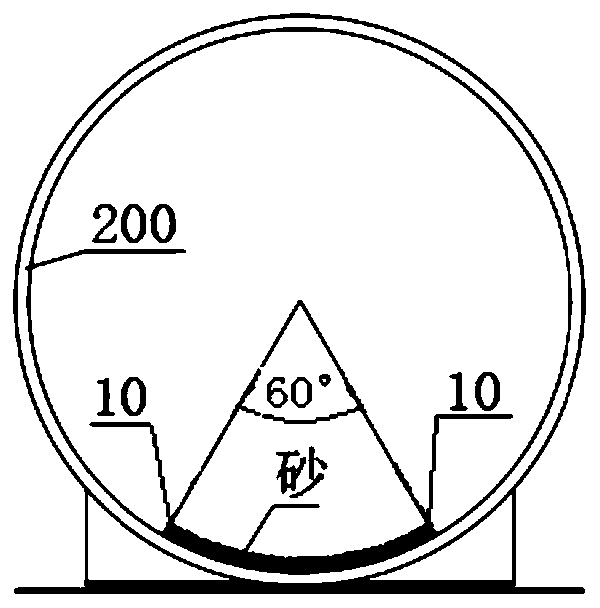

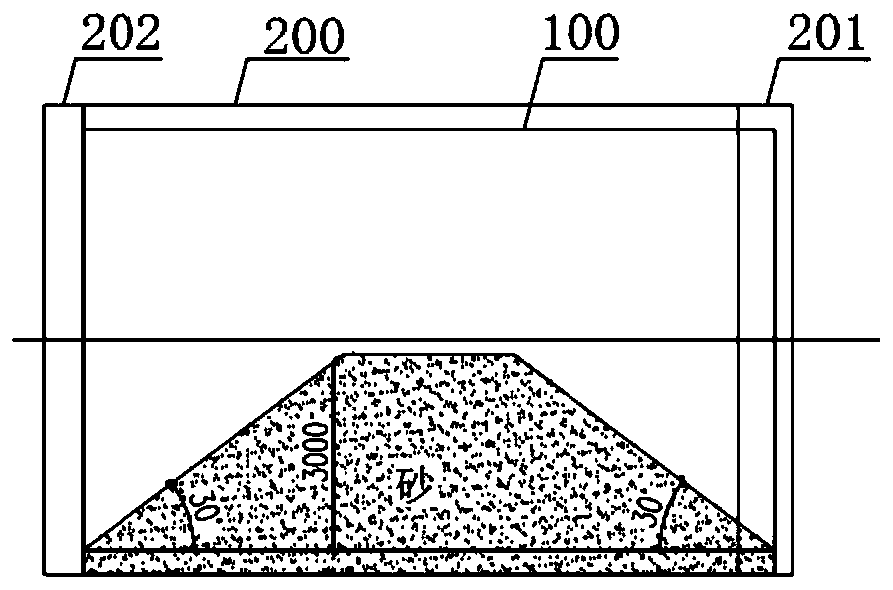

[0052] see Figure 1 to Figure 7 , the shield tunneling machine of the present invention passes through the existing station originating construction method, adopts steel sleeve construction and includes the following processes: leveling the bottom plate of the passageway under the tunnel and laying steel plates, reinforcing the ends, installing the lower semicircle of the steel sleeve, and shield tunneling Downhole installation of the machine, overall vertical movement of the steel sleeve and the shield machine, removal of the door, installation of negative ring segments, backfilling of the steel sleeve, pressure test, removal of the frozen pipe and sealing of the frozen hole, and the start of the shield machine.

[0053] The steel sleeve consists of the first to fourth main cylinders of the same length spliced from front to back, a transition ring connected to the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com