Patents

Literature

30results about How to "Control posture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

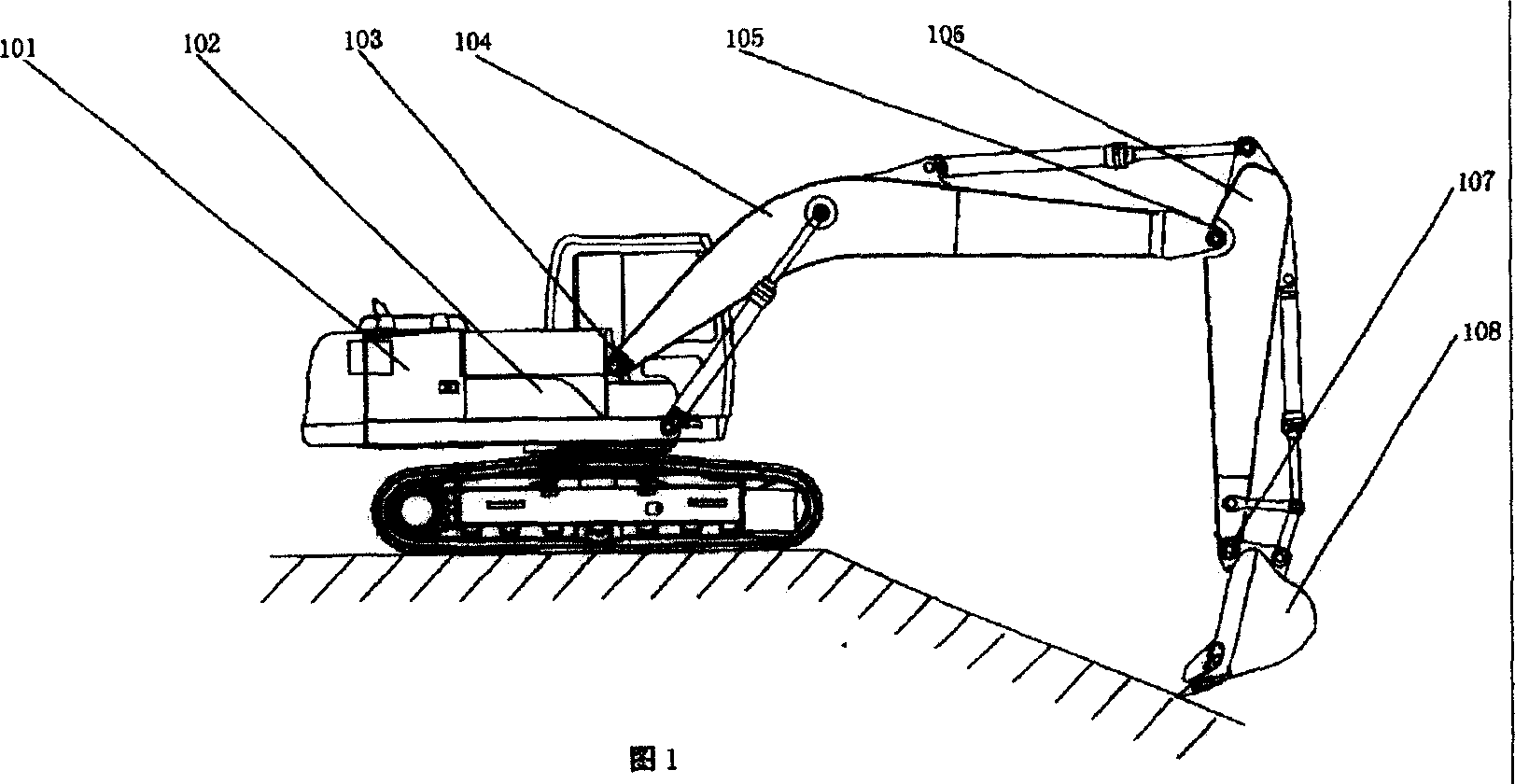

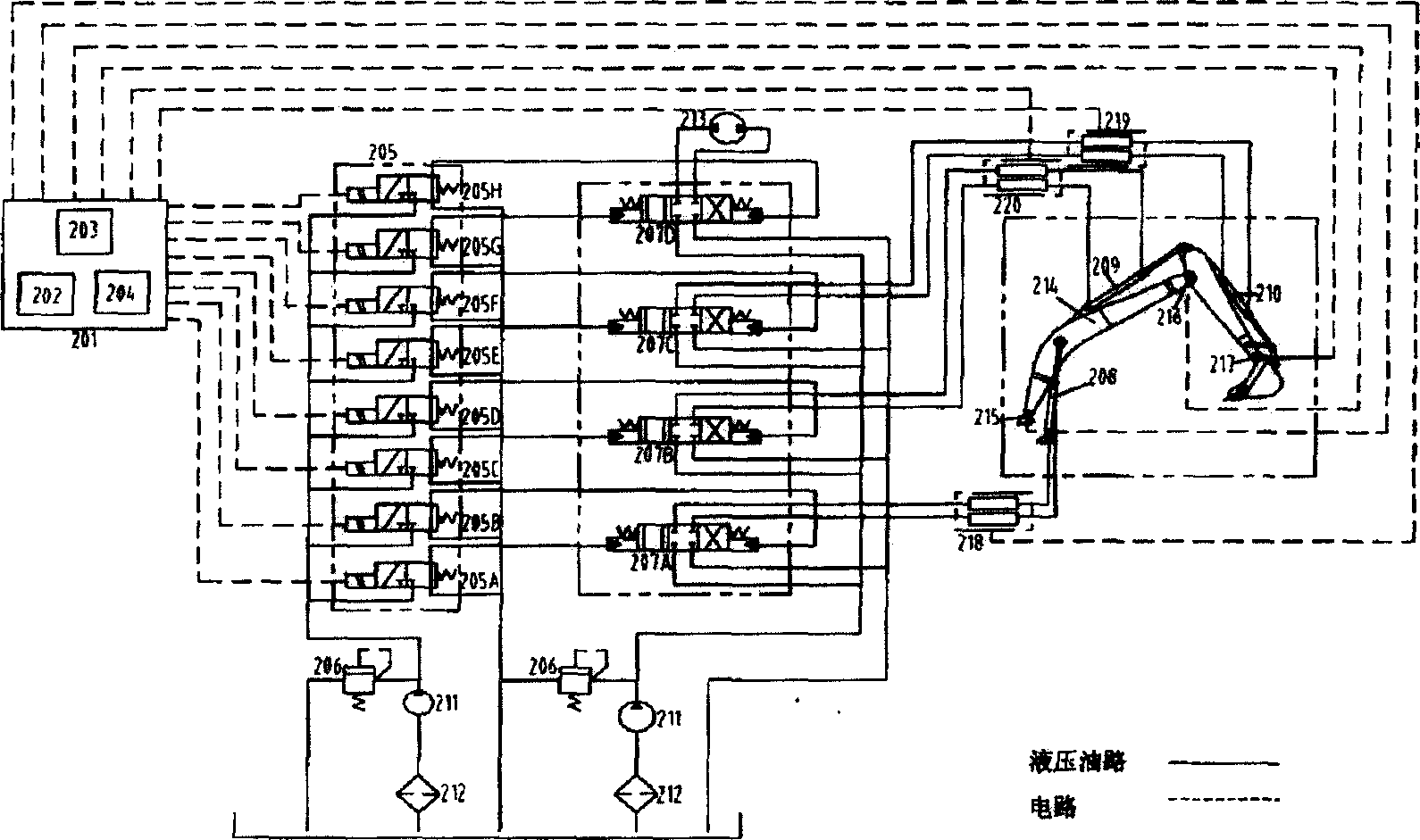

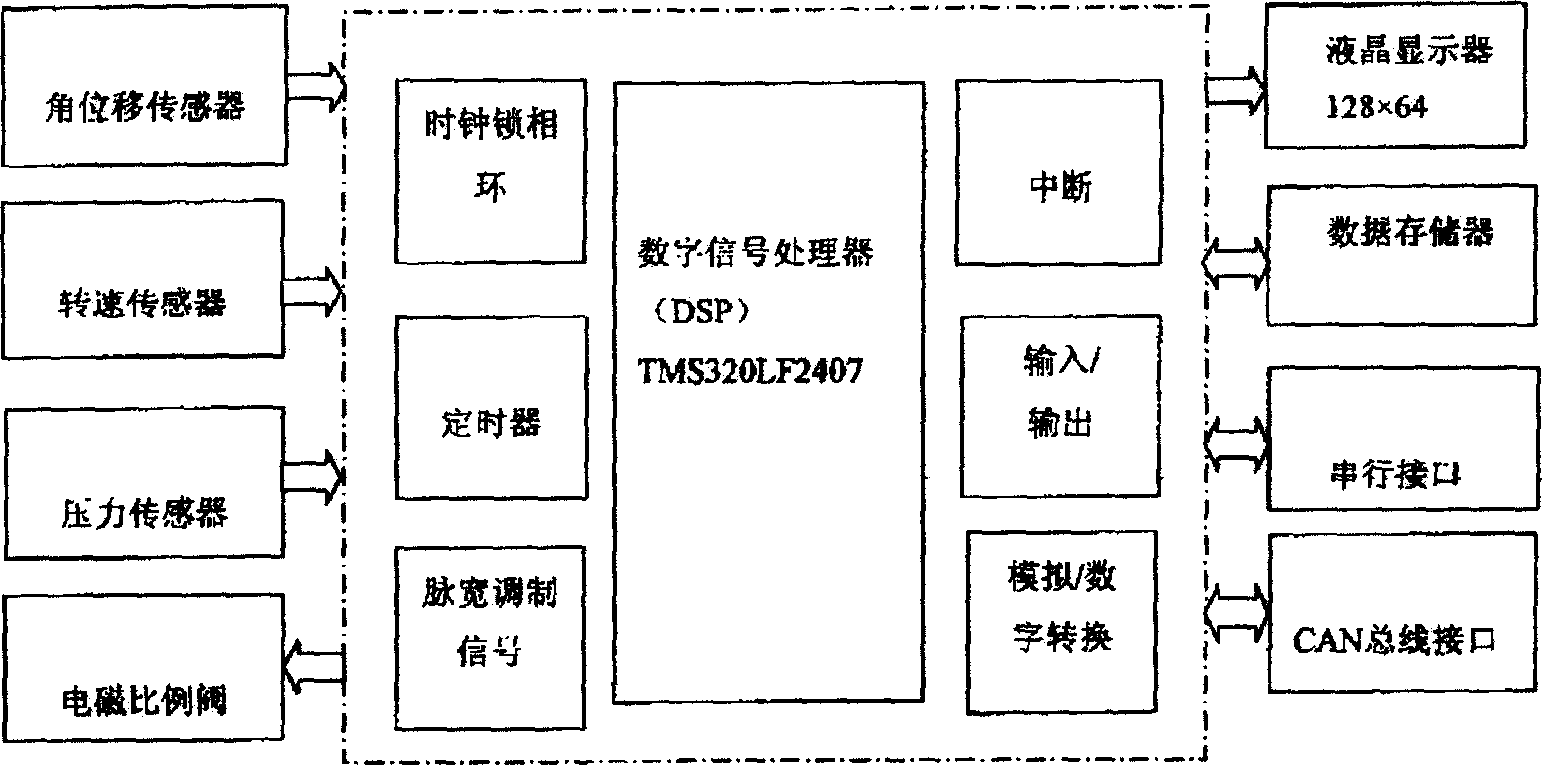

Path control system used for hydraulic digger operating device and its method

InactiveCN1651666ARealize automatic manipulationPrecise and stable positionSoil-shifting machines/dredgersPosition/direction controlHydraulic cylinderAutomatic control

The present invention relates to a track control system for hydraulic excavator working equipment and its method. Said system includes the following main components: DSP, moving arm angle detection mechanism, bucket arm angle detection mechanism, bucket angle detection mechanism, hydraulic cylinder, engine, working equipment and its driving cylinder and CAN bus. Said invention also provides the concrete steps of said control method. It can implement automatic control of hydraulic excavator working equipment, and can accurately and stably control the position and attitute of said hydraulic excavator working equipment so as to raise its working efficiency.

Owner:GUANGXI LIUGONG MASCH CO LTD

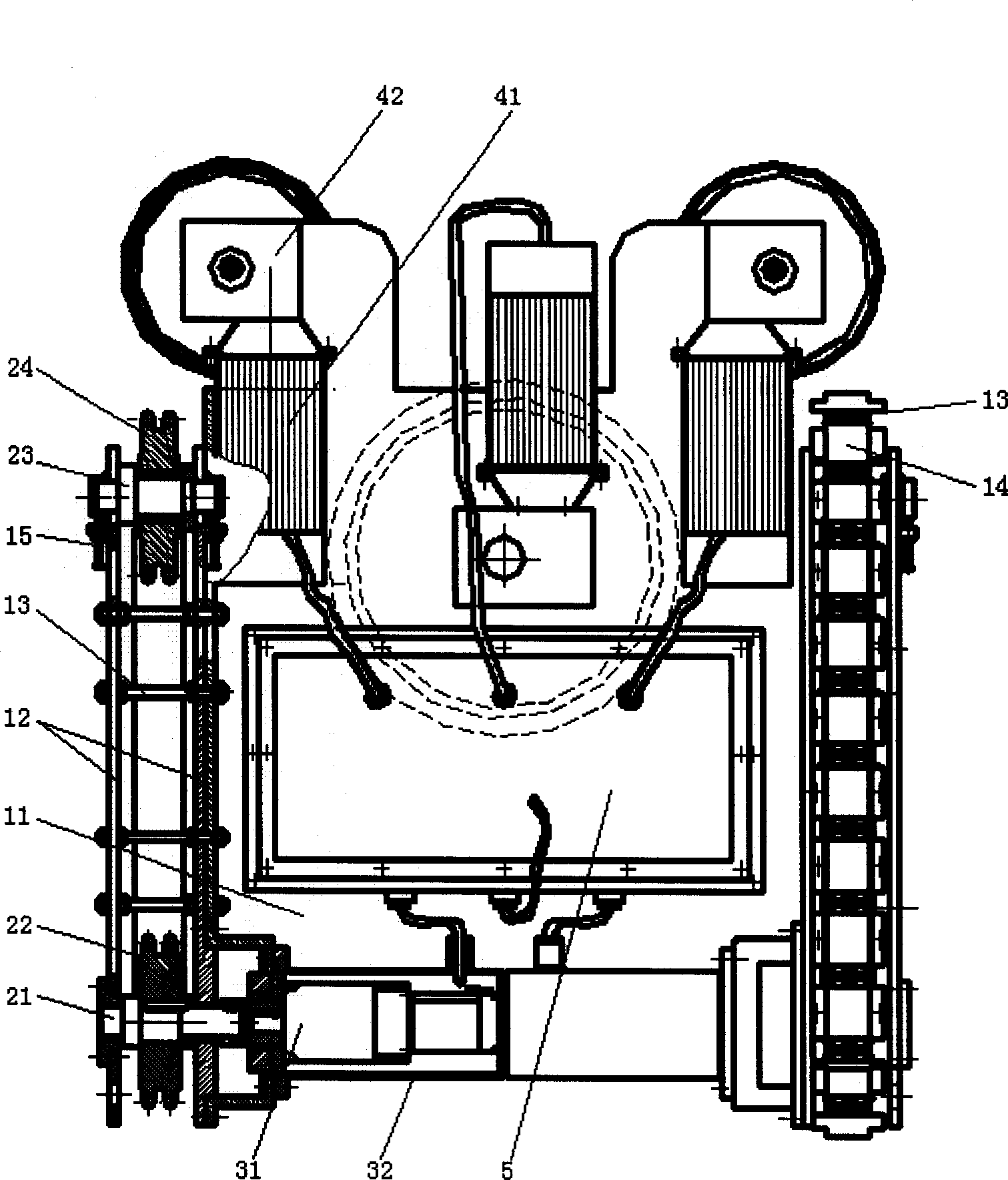

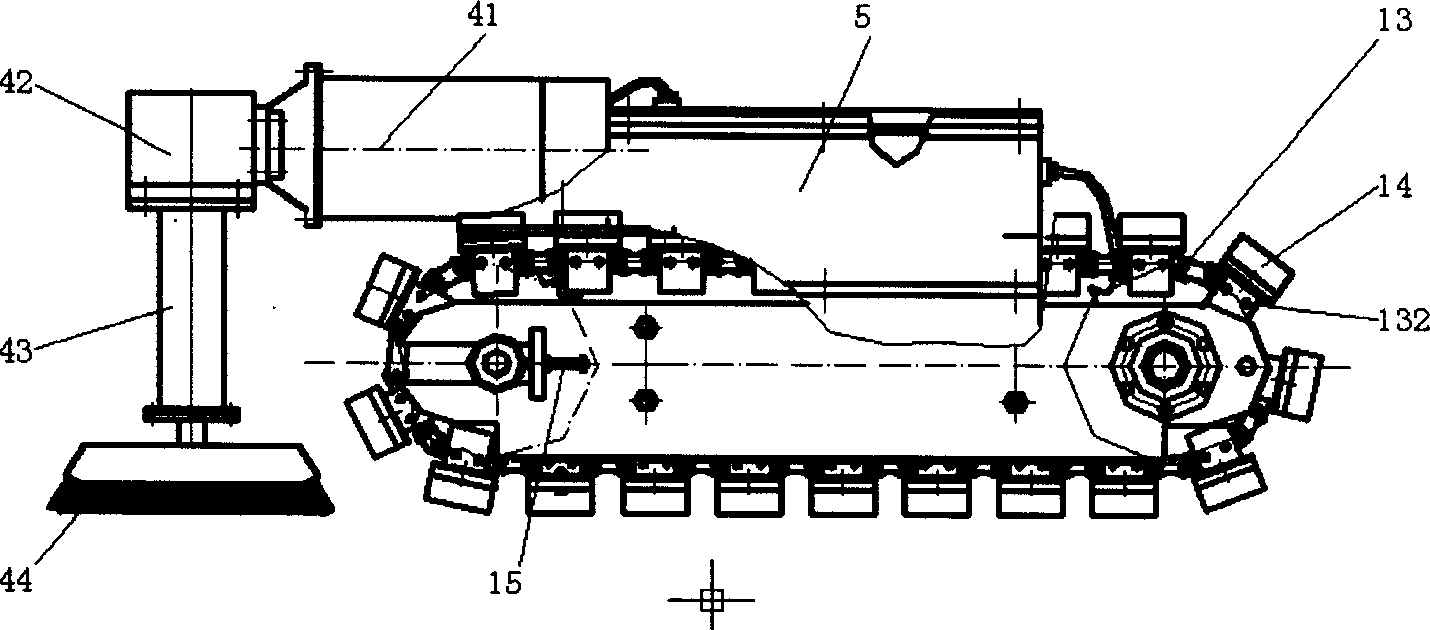

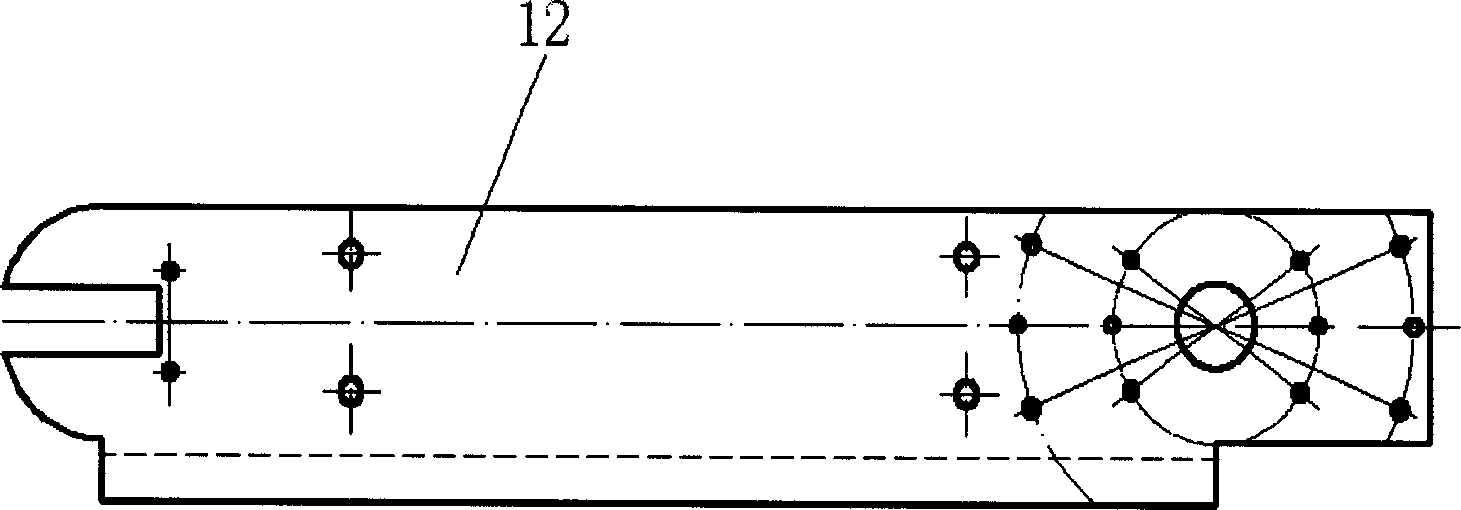

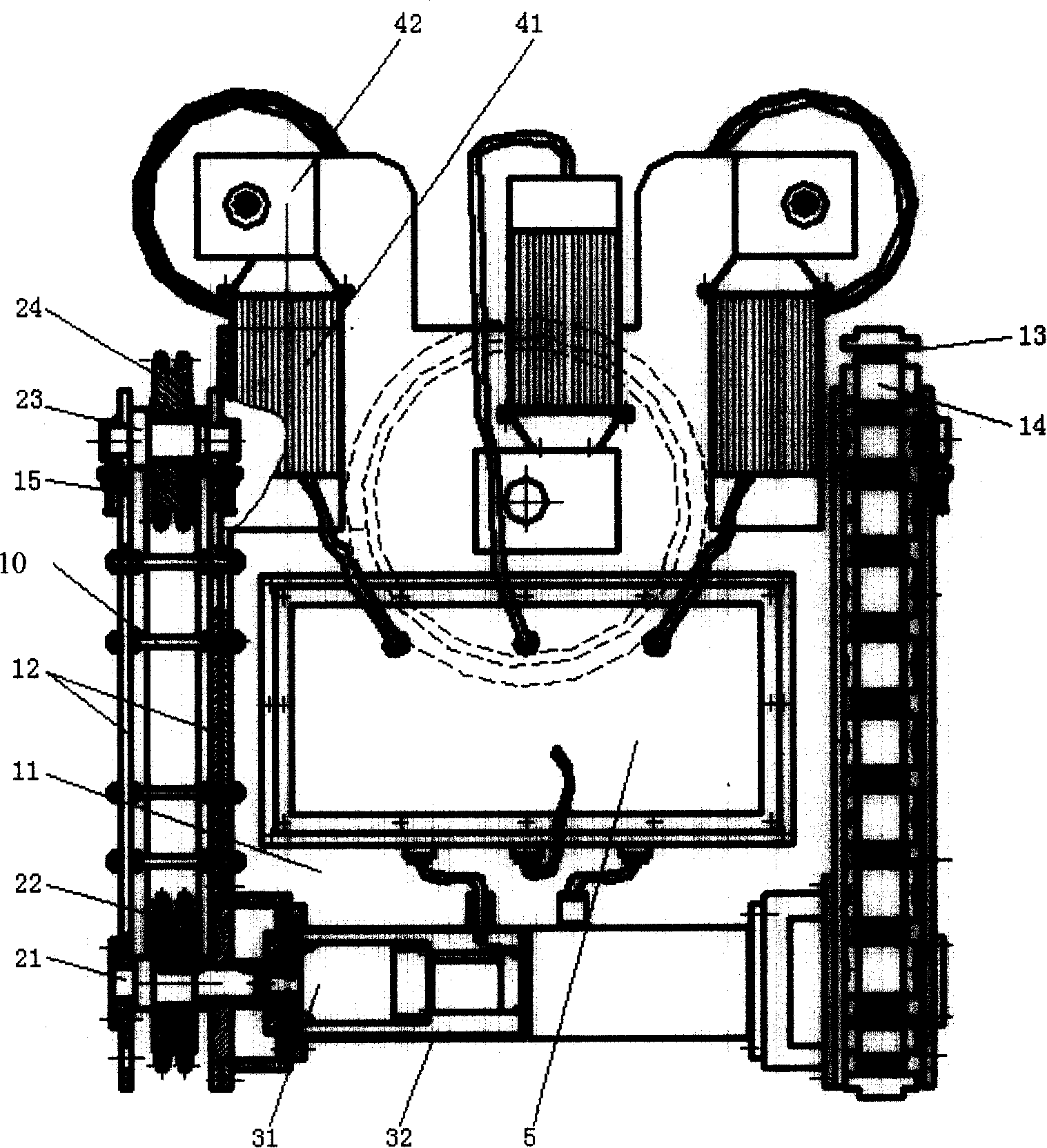

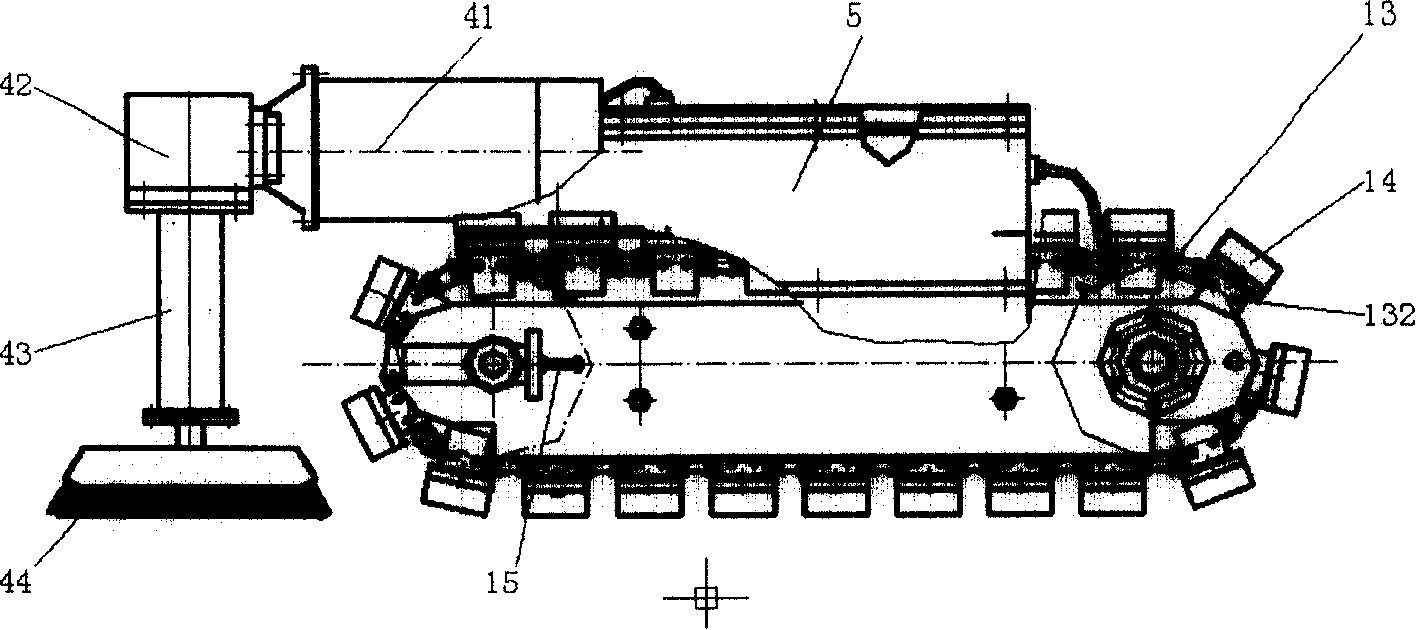

Permanent-magnet adsorption type double-track robot for ship hull surface cleaning and brushing

InactiveCN1789062AControl postureRealize autonomous operationVehiclesSurface cleaningMarine engineering

The permanent magnetic double crawler robot for washing hull surface has permanent magnets fixed onto its double crawler for adsorption onto hull surface and a remote control device to realize the overwater and underwater crawling and hull cleaning operation. The permanent magnetic double crawler robot is different from available hull surface cleaning machine (robot) in that it has adsorption and walking functions originated from the double crawler comprising driving chain wheel pair and permanent magnetic adsorption unit. The permanent magnetic double crawler robot is different from available wall-crawling crawler robot in that it has specific structure with two row of chain wheel pairs in each crawler resulting in improved smoothness and no crawler breaking fault and permanent magnetic adsorption unit suitable for hull surface operation. In addition, the robot is provided with three telescopic brush assemblies, etc. suitable for underwater operation.

Owner:HARBIN ENG UNIV

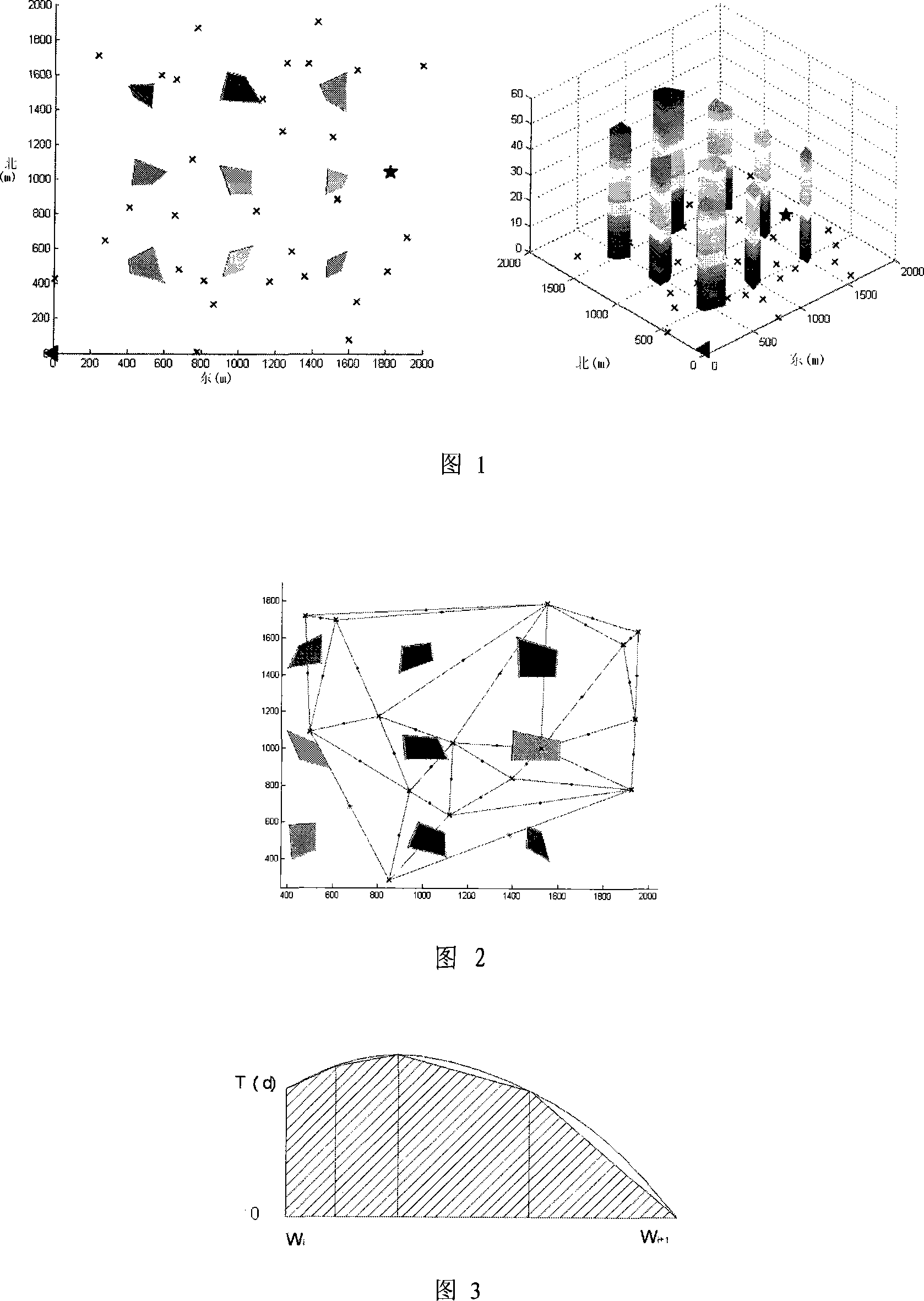

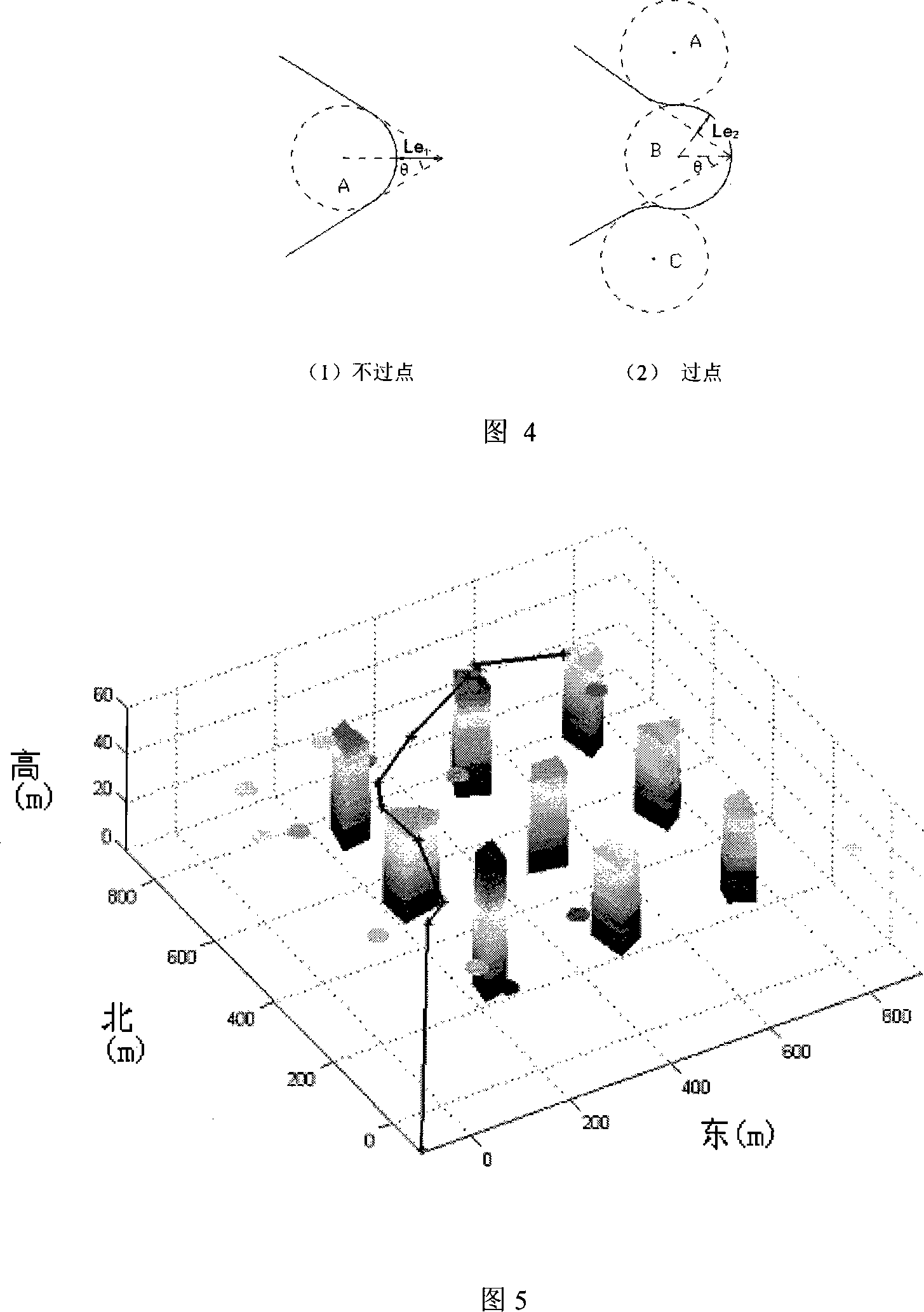

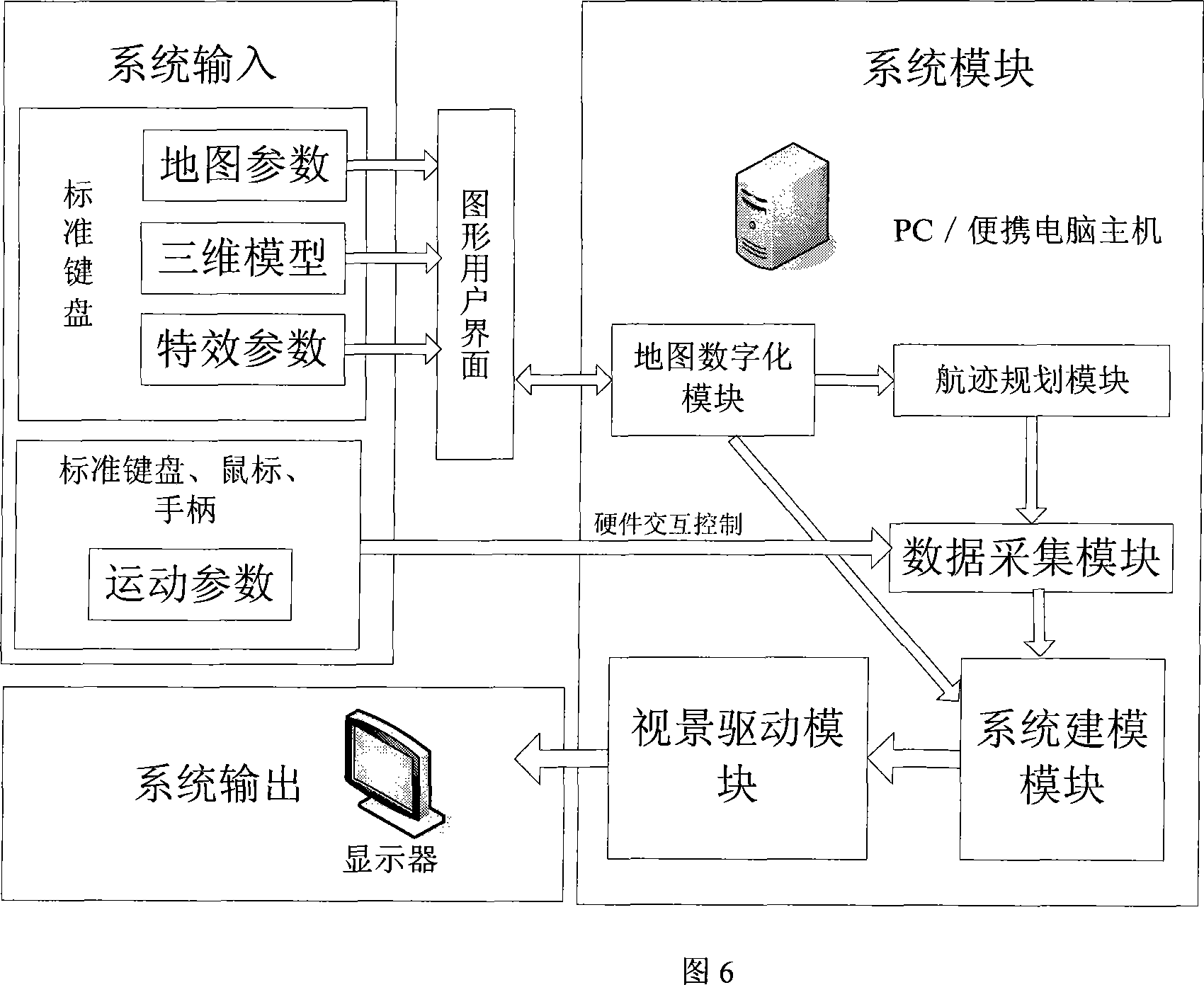

Minisize rudders three-dimensional track emulation method under city environment

The present invention relates to a method of the 3D track simulation for a miniature aircraft under urban surroundings and belongs to the field of the 3D real-time route navigation technology for a miniature aircraft. The following modules are set in a computer: a map digitalized module, which digitalizes the 3D model of urban surroundings including threat points, buildings, the departure and target points of a miniature aircraft that is inputted by the graphical user interface (GUI), map parameters and the coordinate of a candidate navigation point composed of the 3D model of urban surroundings and the map parameters; a flight path programming module, which inputs the data from the map digitalized module, calculates the overall route index that takes the flight resource consumption rate and the survival rate into consideration, figures out the most feasible route using network optimizing algorithm under the condition of taking barriers into consideration, and then smooths the bevel at turnings and generates a realtime flight orbit; a data-collecting module, which collects the coordinate values of the aircraft positions and postures outputted by the flight path programming module and forms a posture coordinate value including orthogonal coordinate variables X, Y and Z, a pitch angle h, a yawing angle p and a roll angle r. The present invention saves flight resources and improves flights simultaneously.

Owner:TSINGHUA UNIV

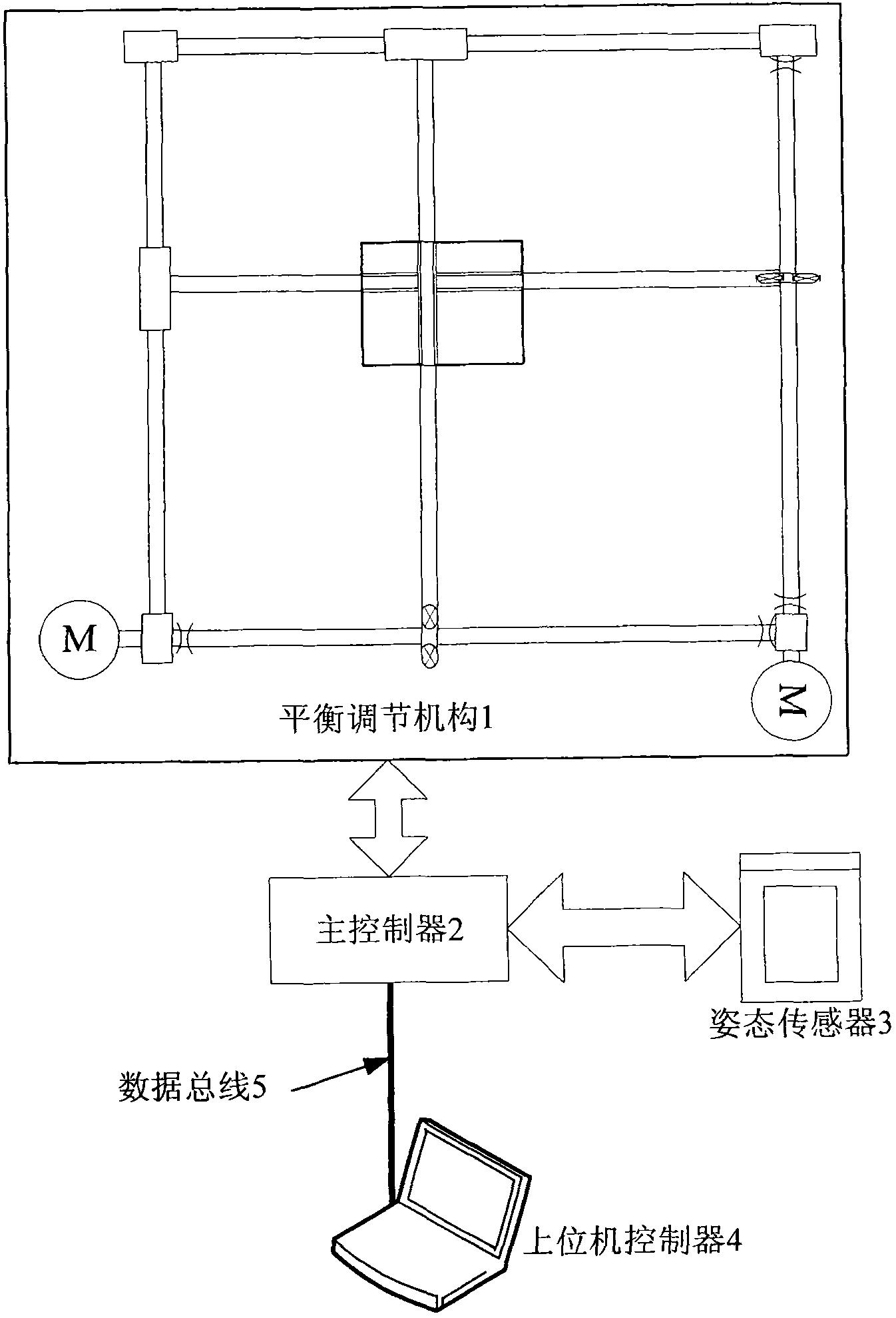

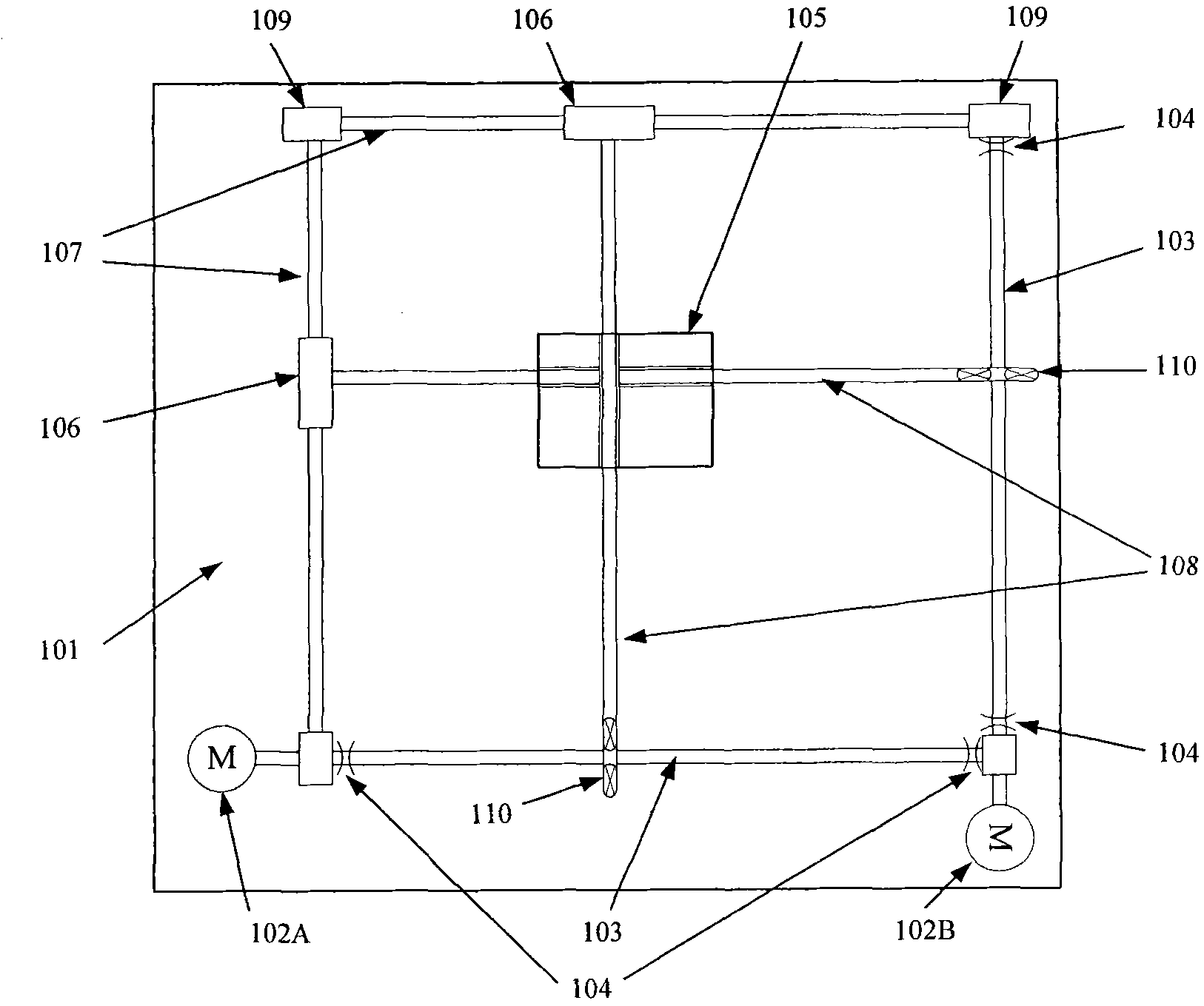

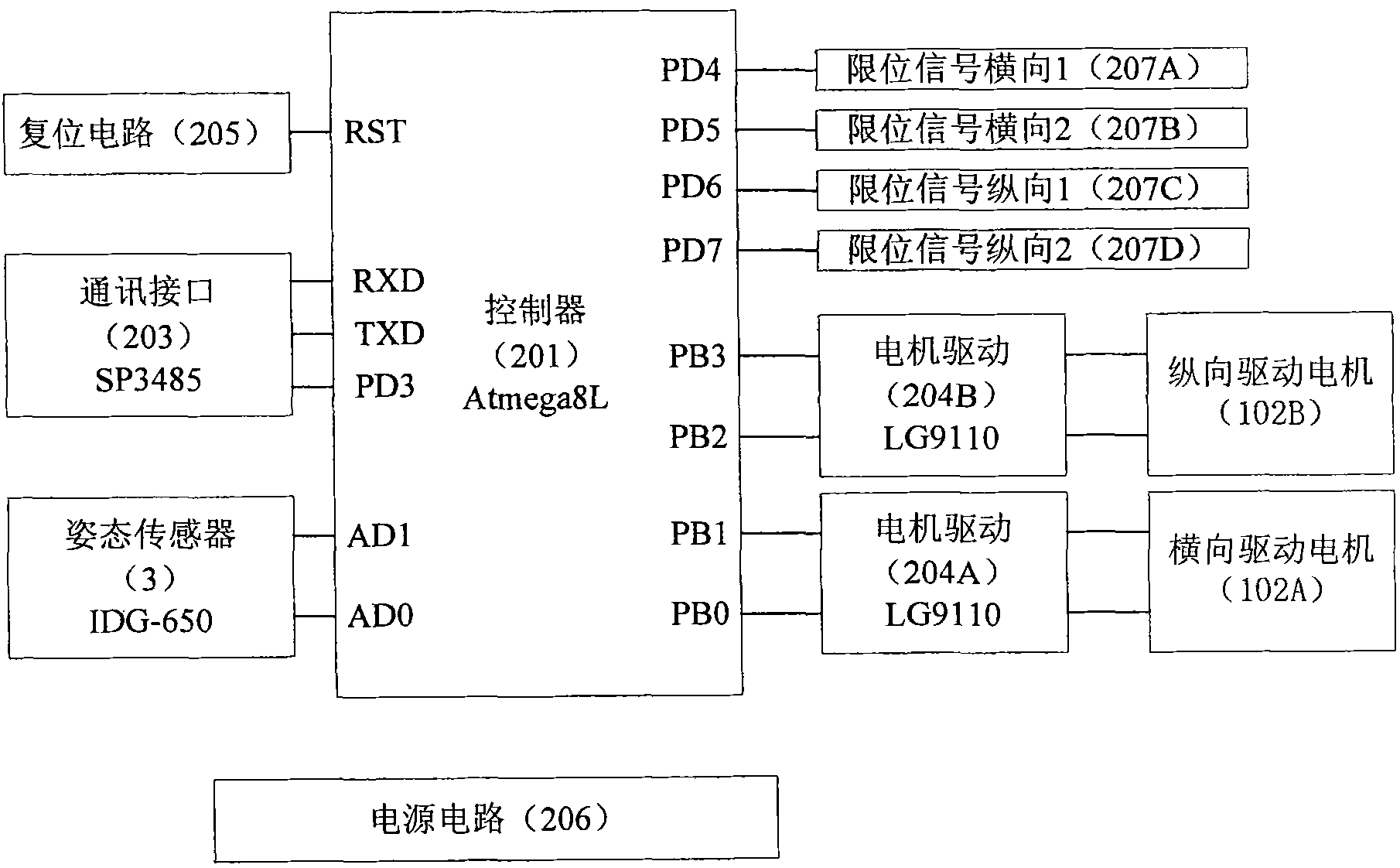

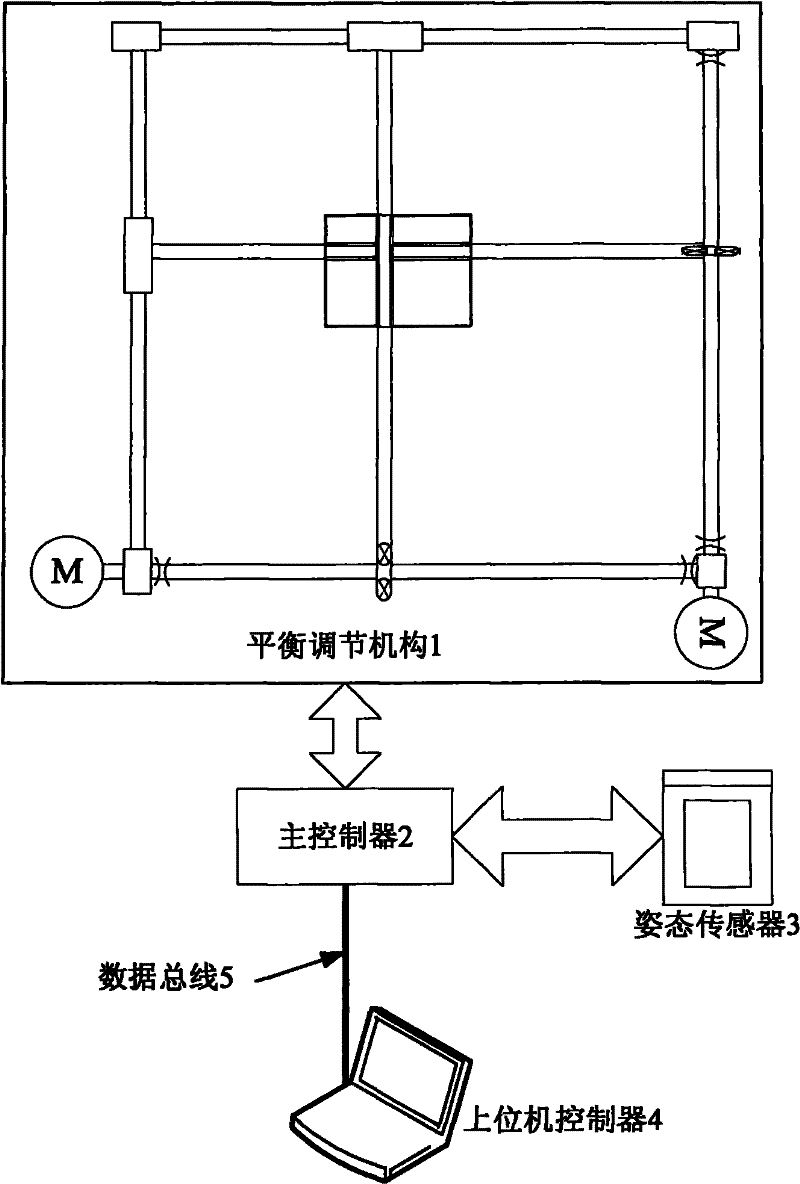

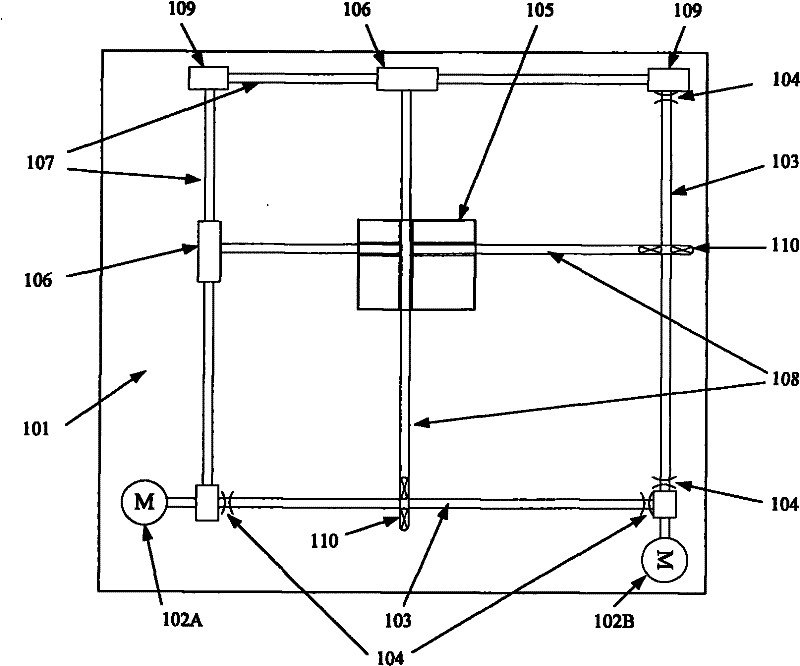

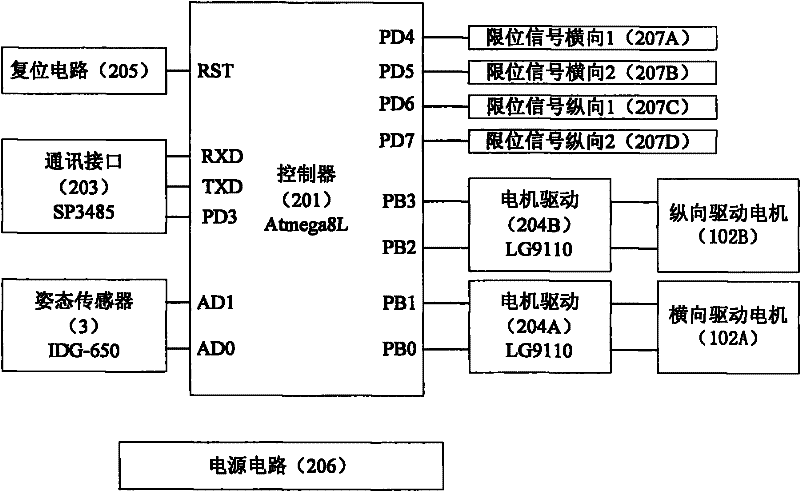

Inner system for controlling gestures of underwater robot

InactiveCN102012704AControl postureAttitude control is widely applicableAttitude controlUnderwater equipmentControl systemEngineering

The invention discloses an inner system for controlling the gestures of an underwater robot, comprising a main controller connected with an adjustment mechanism, a gesture sensor, and an upper computer controller, wherein the adjustment mechanism is a balance adjustment mechanism arranged inside the underwater robot, and comprises a gravity slider, a double-shaft drive motor, a worm, a guiderail, a slide bar, a limit switch and a mechanism platform; the double-shaft drive motor is connected with the worm to drive the worm to rotate bidirectionally; the worm drives the slide bar to perform planar movement through the transmission of a lead screw; one end of the slide bar is connected with the lead screw of the worm and penetrates the gravity slider, while the other end thereof is connected with the guiderail by a slider and drives the gravity slider to move in a plane so as to realize the gravity adjustment of the underwater robot and control the transverse swing and longitudinal incline gestures of the underwater robot. The control system for gestures can be widely applied to the gesture control of the underwater robot.

Owner:SHANGHAI UNIV

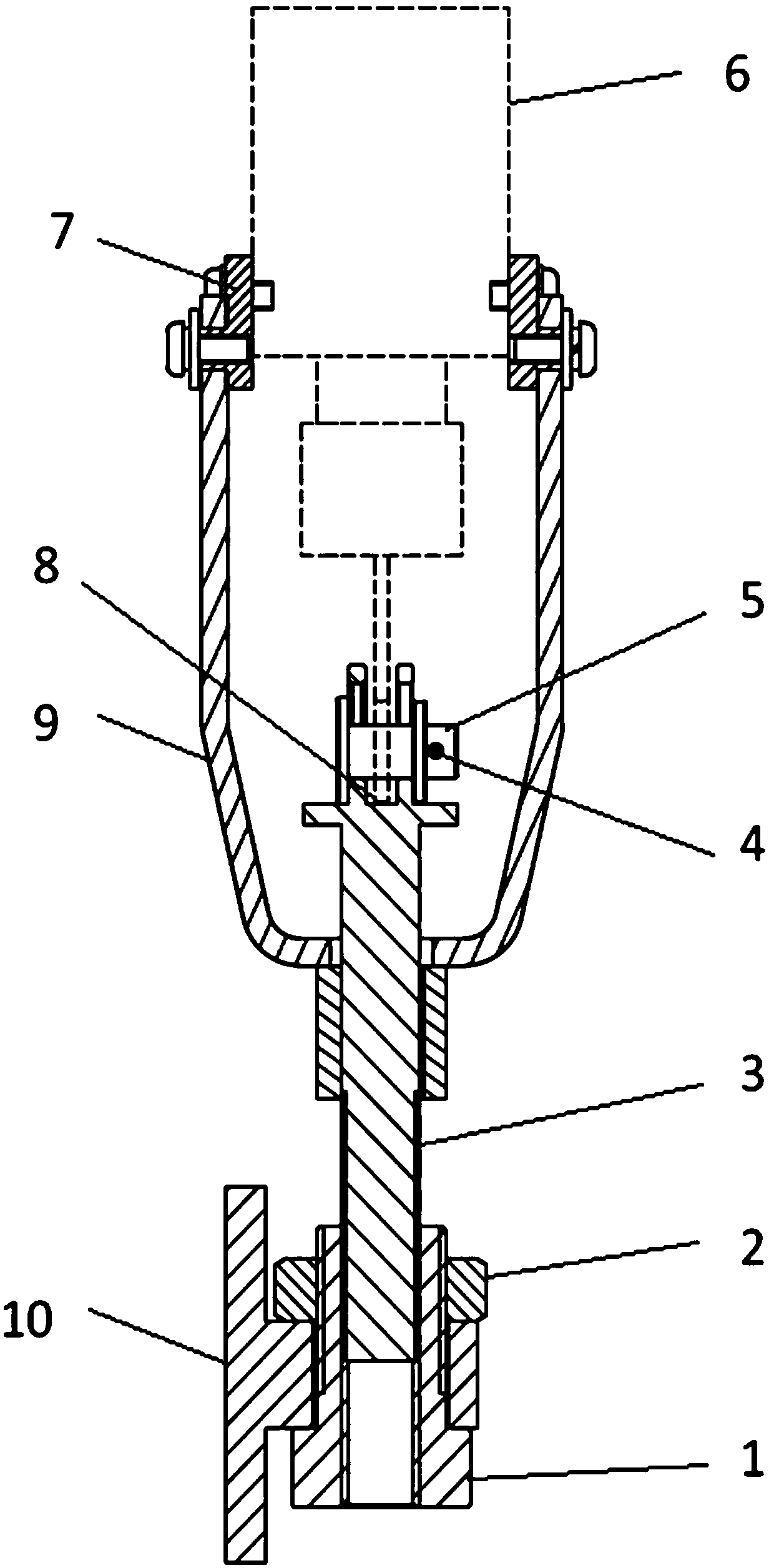

Missile hanger separation mechanism

ActiveCN105066796AImprove space occupancyEasy to install and maintainSelf-propelled projectilesCombustionActuator

The invention discloses a missile hanger separation mechanism. The missile hanger separation mechanism comprises a hanger, an explosive bolt, an actuator, a missile body and a location pin, wherein one end of the actuator is connected with the missile body through a second fastener, and the other end of the actuator is connected with the hanger through a first fastener; one end of the explosive bolt is connected with the missile body through a fourth fastener, and the other end of the explosive bolt is connected with the hanger through a third fastener; the hanger is fixed on the missile body through the location pin, and the contact surface of the missile body and the hanger is a separation surface; a U-shaped groove is formed in the upper end of the explosive bolt, and the central plane of the U-shaped groove is located on the separation surface; and a push rod and a combustion cavity are arranged on and formed in the actuator, the combustion cavity is filled with gunpowder, and the push rod carries out initial locking through a shear pin. The missile hanger separation mechanism disclosed by the invention is simple and convenient to install and maintain, high in action synchronization of initiating explosive devices, and capable of effectively controlling the posture of the hanger after flying away from the missile body, and guaranteeing no collision of the hanger with the missile body during the process of flying away from the missile body, thus improving the flying safety of a carrying aircraft and a missile.

Owner:JIANGXI HONGDU AVIATION IND GRP

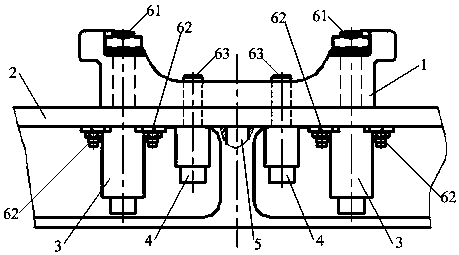

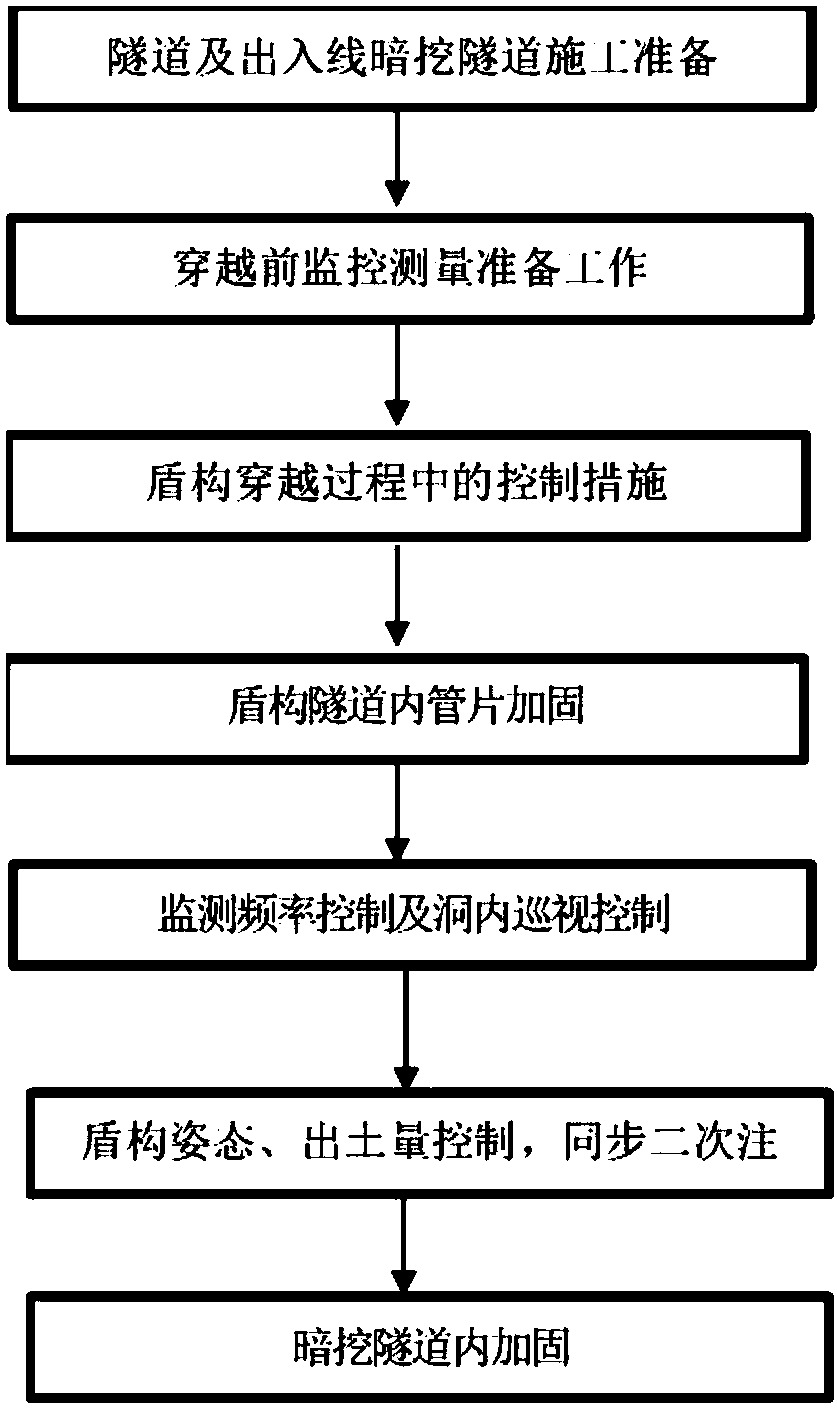

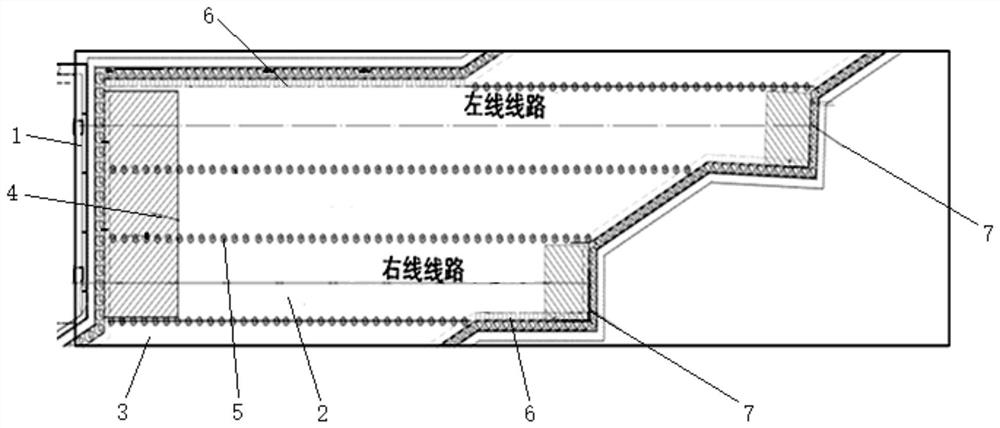

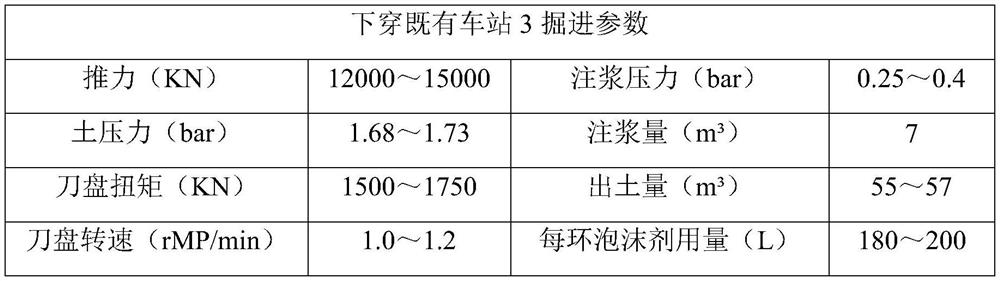

Construction method of shield close-range undercrossing underground excavated tunnel of composite stratum

InactiveCN108049876AThe method steps are simpleReasonable designUnderground chambersTunnel liningClose rangeControl measure

The invention relates to a construction method of a shield close-range undercrossing underground excavated tunnel of a composite stratum. The construction method comprises the steps of tunnel construction preparation; exit and entrance line underground excavated tunnel construction preparation; monitoring and measuring preparing work before crossing; control measures in the process of shield crossing; segment reinforcement in the shield tunnel; monitoring frequency control; and patrol control in a hole. The construction method has the beneficial effects that the method is simple in step, reasonable in design, easy and convenient to construct, low in input cost and high in implementation of actual engineering operation; through the construction method, the undercrossing tunneling efficiencycan be improved, and the posture of a shield tunneling machine is controlled, so that the possibility of tunnel accidents is reduced, and a favorable foundation for following successful crossing is laid; and the practical value is high, the using effect is good, compared with an existing construction method of undercrossing an underground excavated tunnel, the construction period is shortened, and the construction cost is greatly reduced.

Owner:ZHEJIANG UNIV CITY COLLEGE

Permanent-magnet adsorption type double-track robot for ship hull surface cleaning and brushing

InactiveCN100383007CControl postureRealize autonomous operationVehiclesSurface cleaningMarine engineering

The permanent magnetic double crawler robot for washing hull surface has permanent magnets fixed onto its double crawler for adsorption onto hull surface and a remote control device to realize the overwater and underwater crawling and hull cleaning operation. The permanent magnetic double crawler robot is different from available hull surface cleaning machine (robot) in that it has adsorption and walking functions originated from the double crawler comprising driving chain wheel pair and permanent magnetic adsorption unit. The permanent magnetic double crawler robot is different from available wall-crawling crawler robot in that it has specific structure with two row of chain wheel pairs in each crawler resulting in improved smoothness and no crawler breaking fault and permanent magnetic adsorption unit suitable for hull surface operation. In addition, the robot is provided with three telescopic brush assemblies, etc. suitable for underwater operation.

Owner:HARBIN ENG UNIV

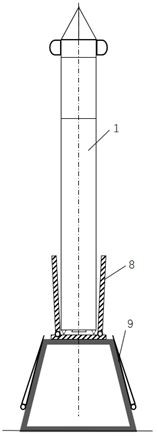

Conical top cover pull type recycling sub-orbital carrier rocket

InactiveCN114735248AStable recyclingPrecision landingCosmonautic vehiclesCosmonautic propulsion system apparatusStructural engineeringRocket

The invention discloses a cone top cover pull type recovery sub-orbital carrier rocket, which belongs to the technical field of spaceflight rockets, and comprises a primary rocket body, a cone top cover arranged at the upper end of the primary rocket body, and a recovery power device, a load is accommodated in the cone top cover; the power recovery device at least comprises a power recovery engine and a power recovery cover arranged on the outer side of the power recovery engine, an engine jet pipe is arranged on the power recovery engine, and the orientation of the engine jet pipe is fixedly arranged or can be adjusted to be downward or outward obliquely downward; the two recovery power devices are symmetrically arranged on the outer side face of the upper portion of the first-stage rocket body or the outer side face of the cone top cover on the two sides. According to the cone top cover pull type recovery suborbital carrier rocket, the technical problems that in the prior art, a landing point is uncontrollable and recovery is difficult are solved, the test environment of ground launching, flight and suborbital flight can be provided, and an environment test in a real state and test services of the environment test can be provided for research and development of aerospace products.

Owner:精易兴航(北京)科技创新有限公司

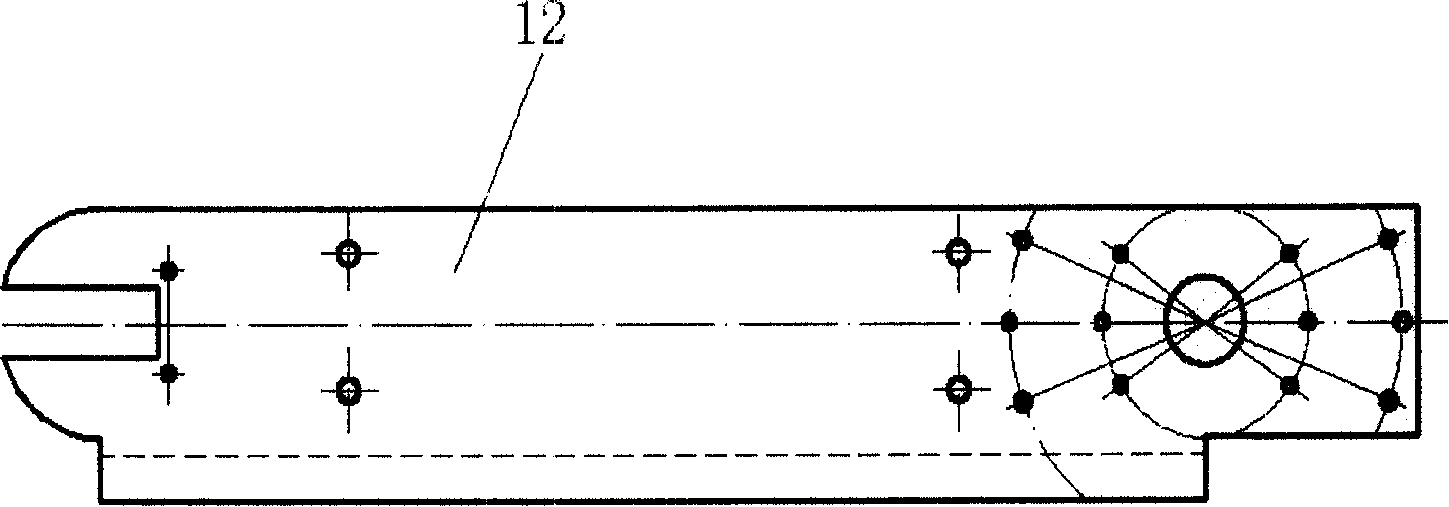

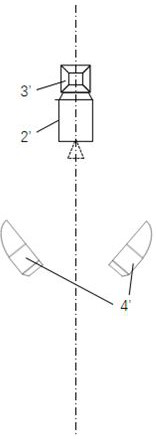

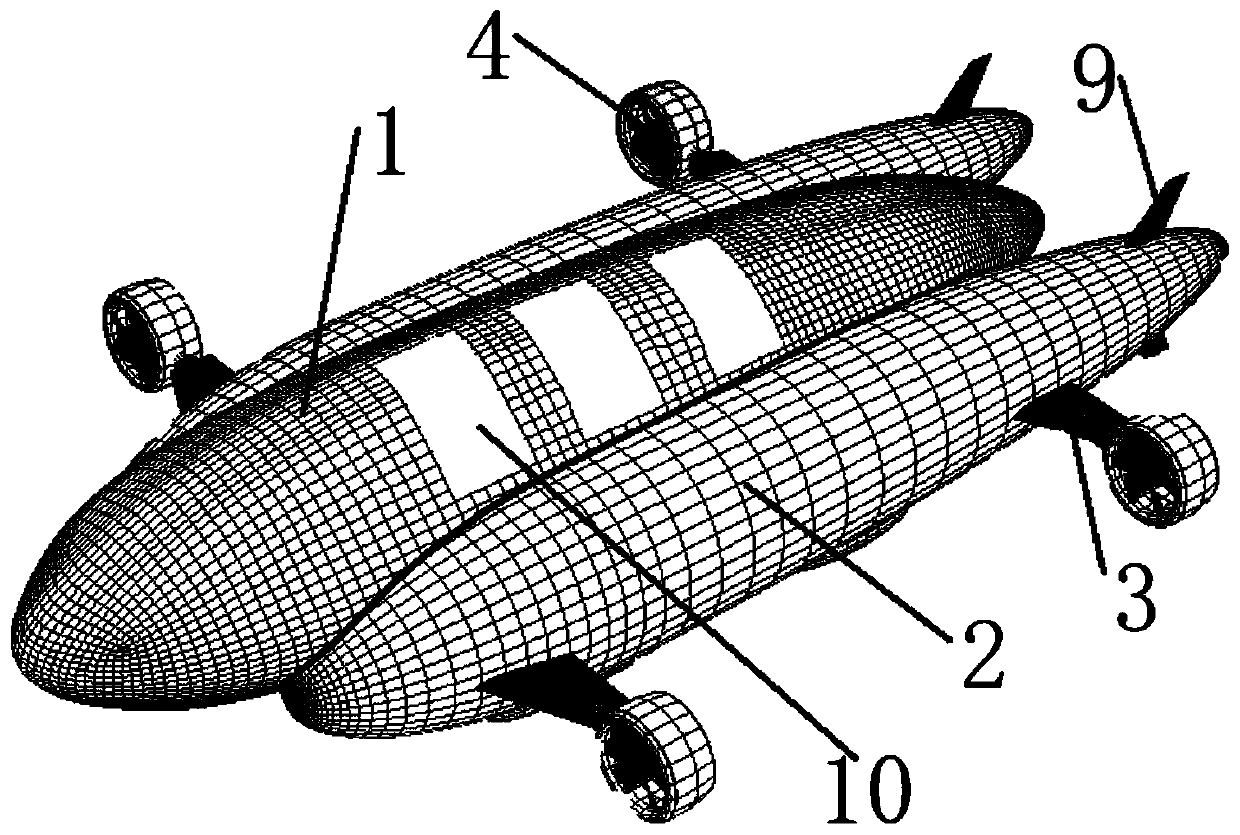

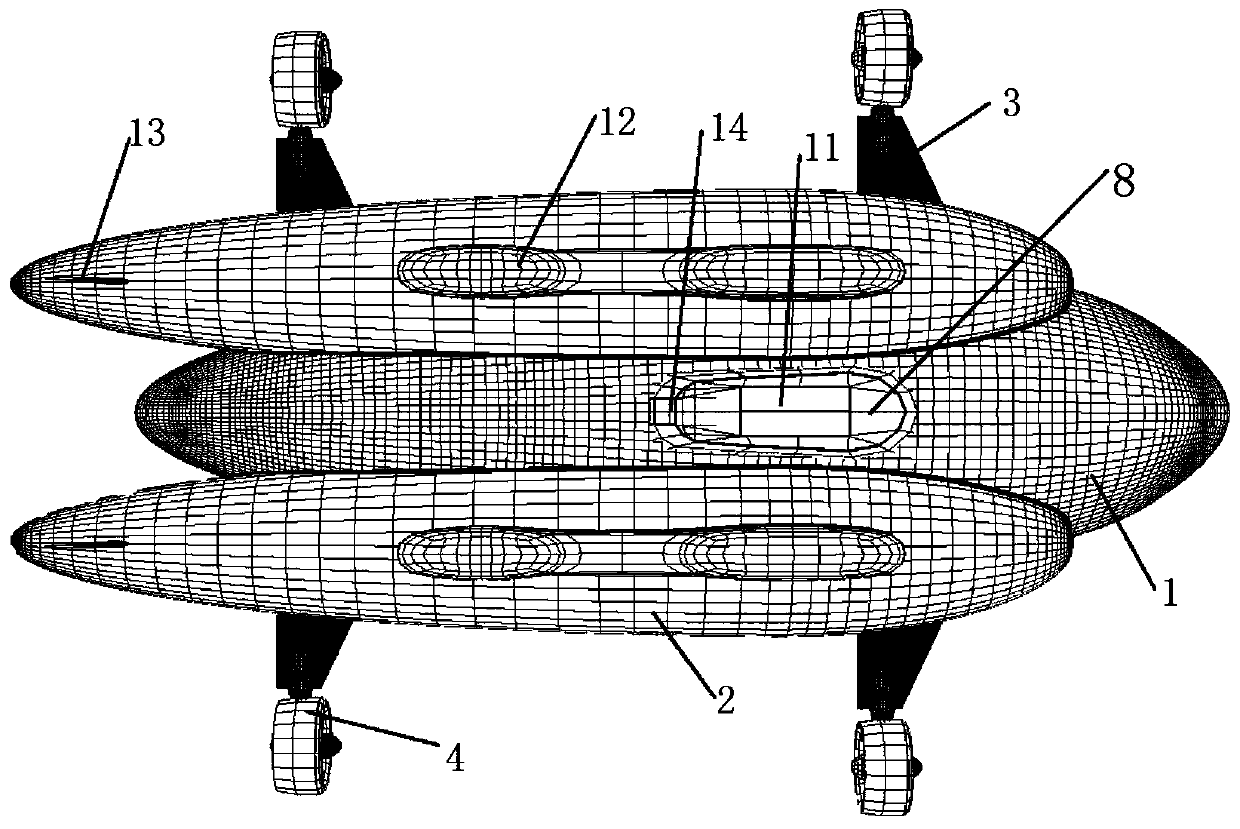

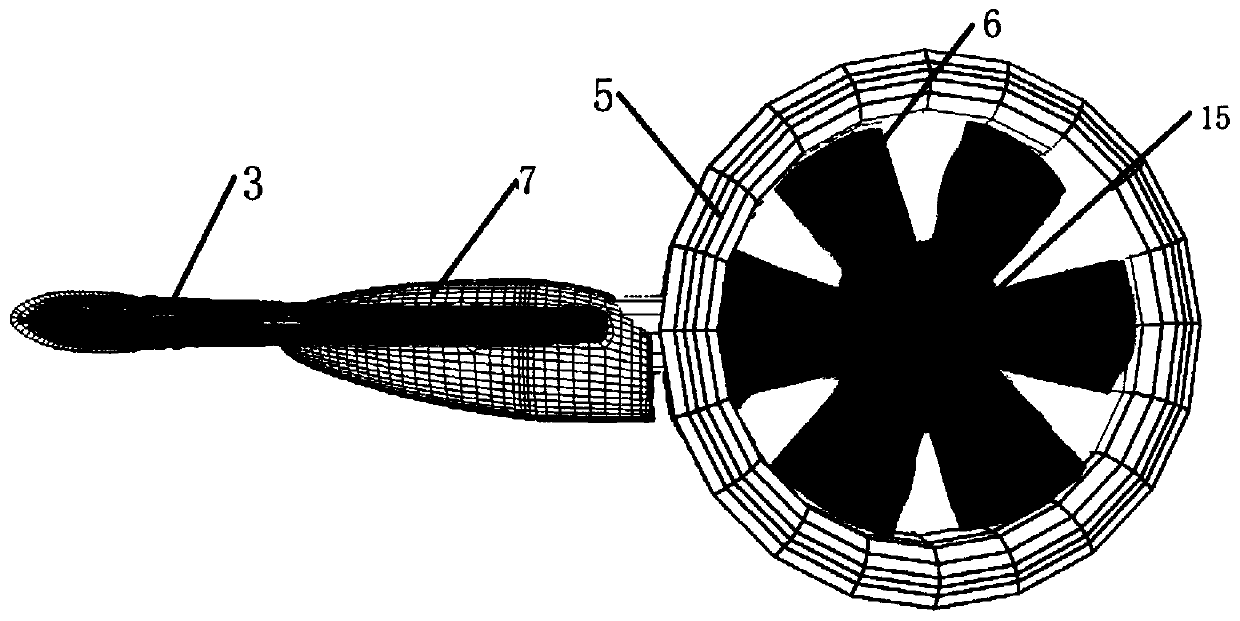

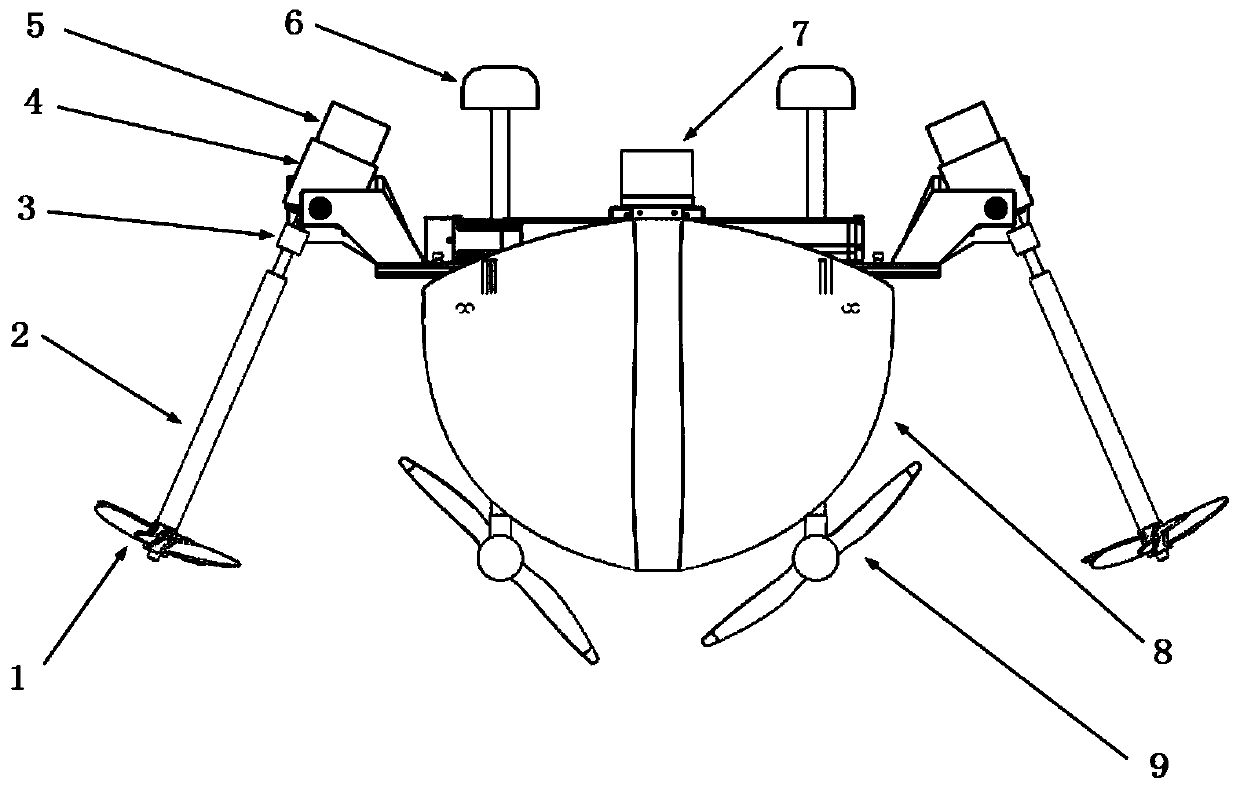

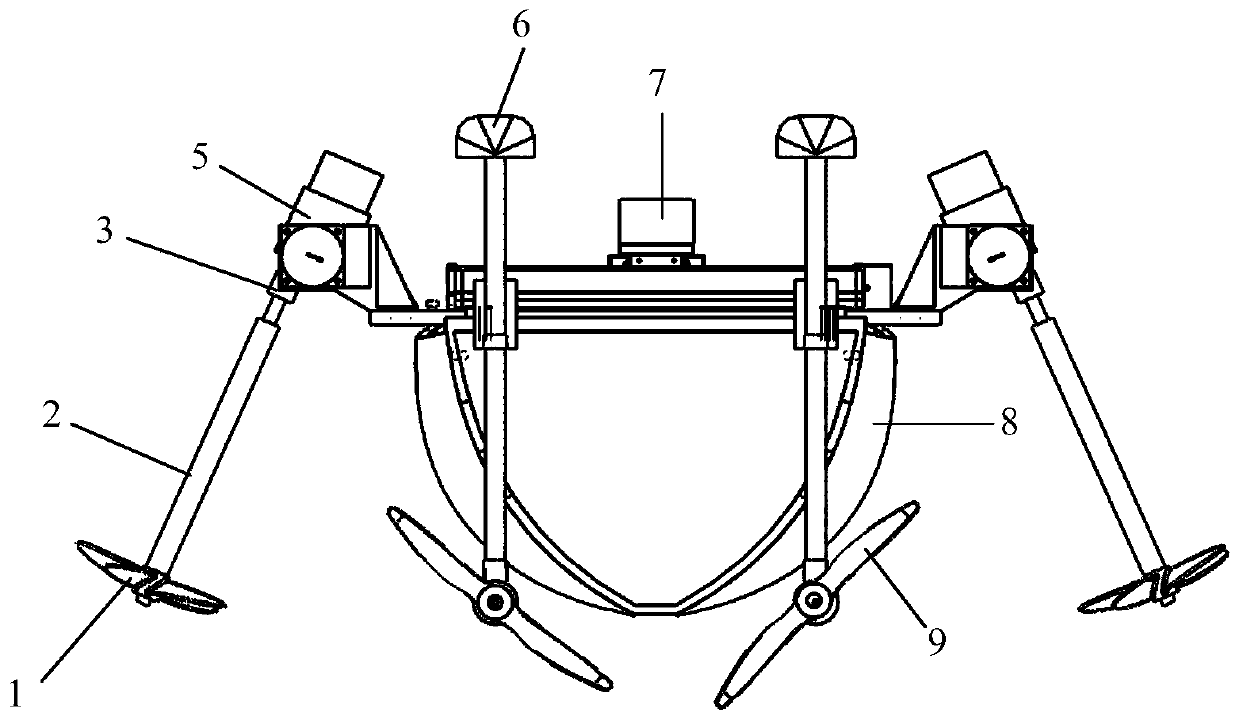

Four-vector ducted loading airship

PendingCN110979625AIncrease loading capacityIncreased aerodynamic liftBatteries circuit arrangementsElectric powerNacelleLevel flight

The invention discloses a four-vector ducted loading airship which is characterized in that the four-vector ducted load-carrying airship comprises a buoyancy air bag, the buoyancy air bag comprises amiddle air bag (1) and outer side air bags (2) which are symmetrically arranged with the middle air bag (1) as the main axis, and the middle air bag (1) and the outer side air bags (2) are arranged inparallel; wings (3) are symmetrically mounted at the front parts and the tail parts of the outer side air bags (2) respectively, and duct power devices (4) are mounted at wing tips of the wings (3);the loading airship further comprises a nacelle (8), an empennage, a solar cell array (10) and an internal mechanism or air cushion landing device (12); the solar cell array (10) is mounted at the upper part of the middle air bag (1); and the air cushion landing device (12) is mounted at the bottom of the buoyancy air bag. Pneumatic lifting and buoyancy are combined, the loading capacity of the airship is improved, and meanwhile, vertical take-off and landing, level flight hovering and maneuvering flight of the airship are controlled.

Owner:BEIHANG UNIV YUNNAN INNOVATION INST

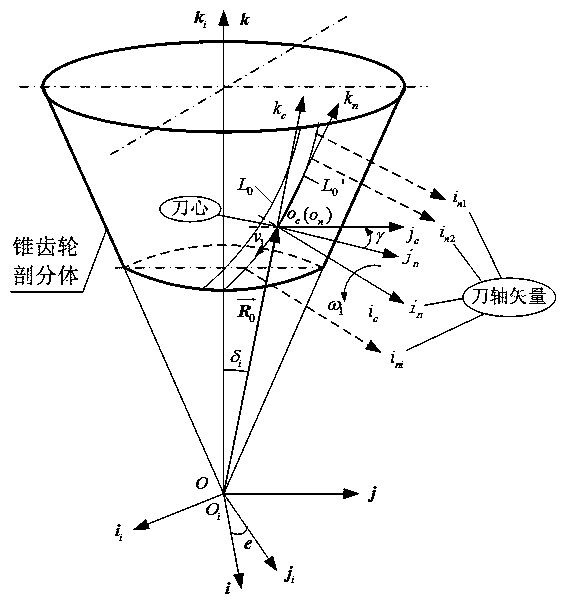

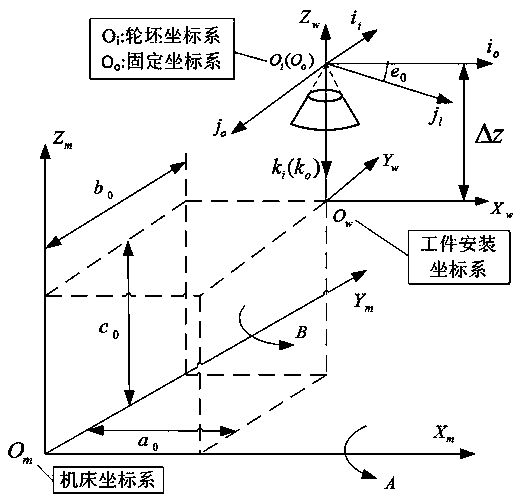

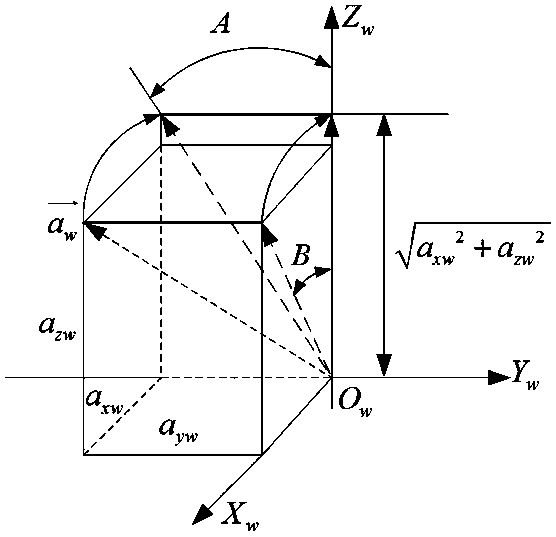

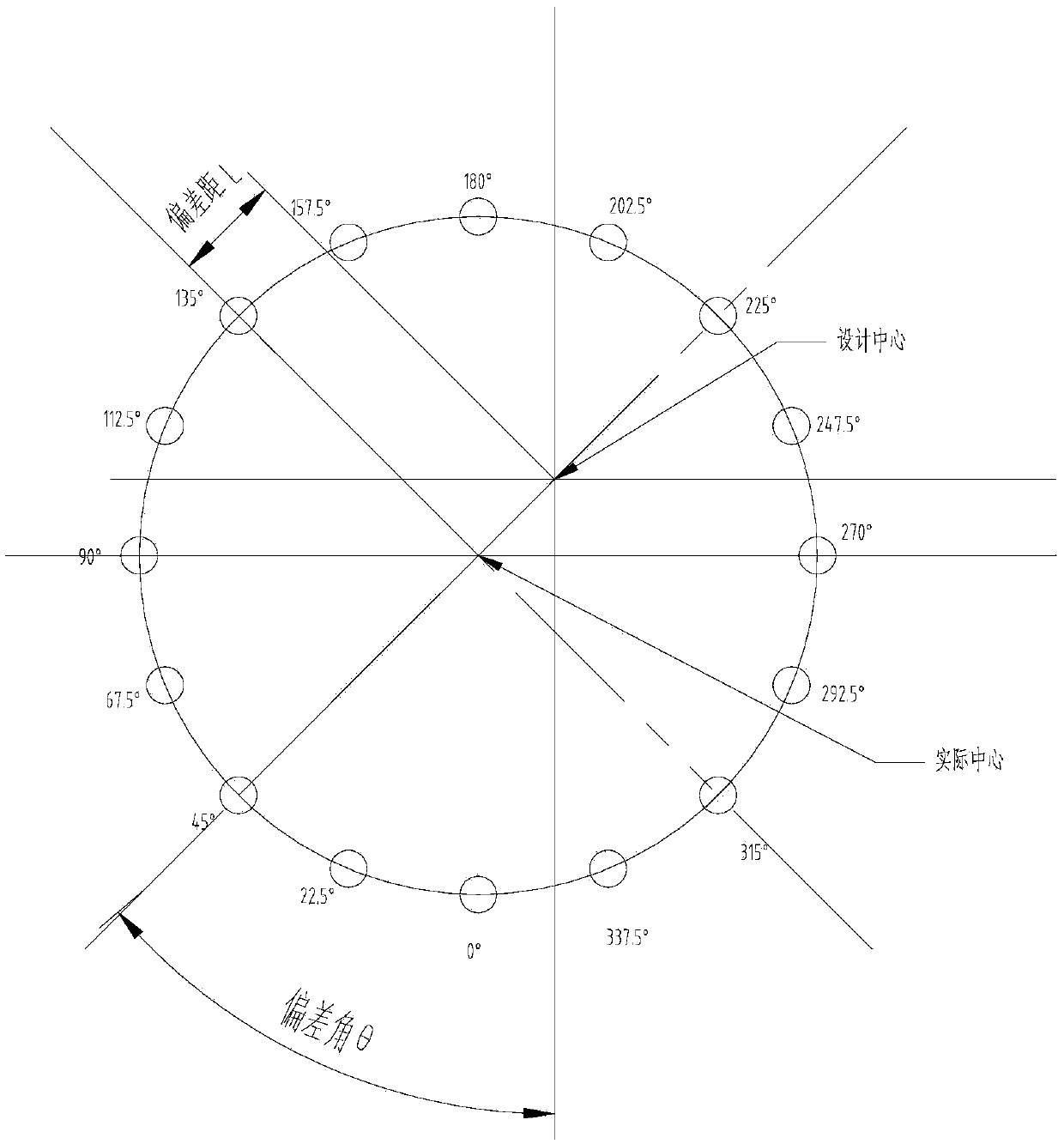

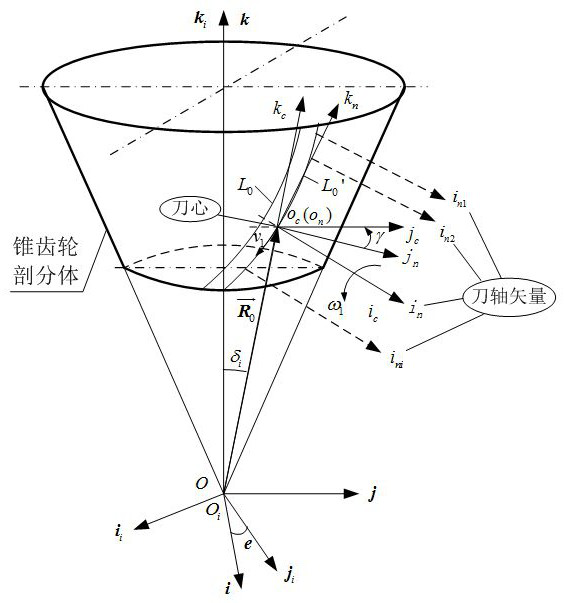

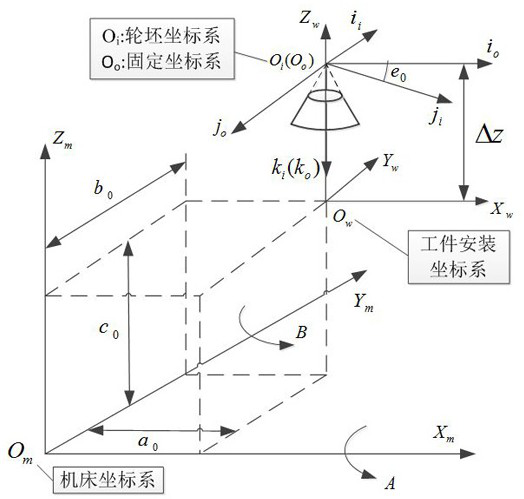

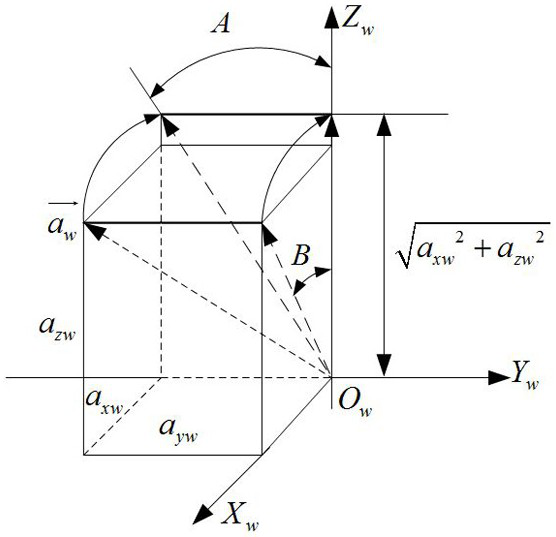

Method for calculating gear cutting movement trajectory of splitting type equal-base bevel gear wheel

ActiveCN109116803APrecise calculation of motion trajectoryControl postureNumerical controlNumerical controlGear wheel

Provided in the invention is a method for calculating the gear cutting movement trajectory of a splitting type equal-base bevel gear wheel. On the basis of the theory of the equal-base circular-curvebevel gear wheel, a splitting type gear cutting processing coordinate system is established according to characteristics of tooth surface forming and each instantaneous cutter position attitude of thetooth surface is analyzed; calculation and coordinate conversion are carried out by a cutter axis vector and a cutter core coordinate, so that a cutter position under a wheel blank coordinate systemis obtained. Each instantaneous cutter position during gear cutting processing is calculated by combining the structural layout of a general machine tool and an installation position relationship between a split wheel blank and a machine tool; and then post-processing is carried out to obtain an expression function of a machine tool motion coordinate during numerical control gear cutting is obtained. According to the invention, a problem that processing can not be carried out when the revolution center of the split type wheel blank of the equal-base bevel gear wheel falls beyond the general numerical control machine tool and thus is not overlapped with a certain revolution axis of the machine tool is solved.

Owner:HENAN UNIV OF SCI & TECH

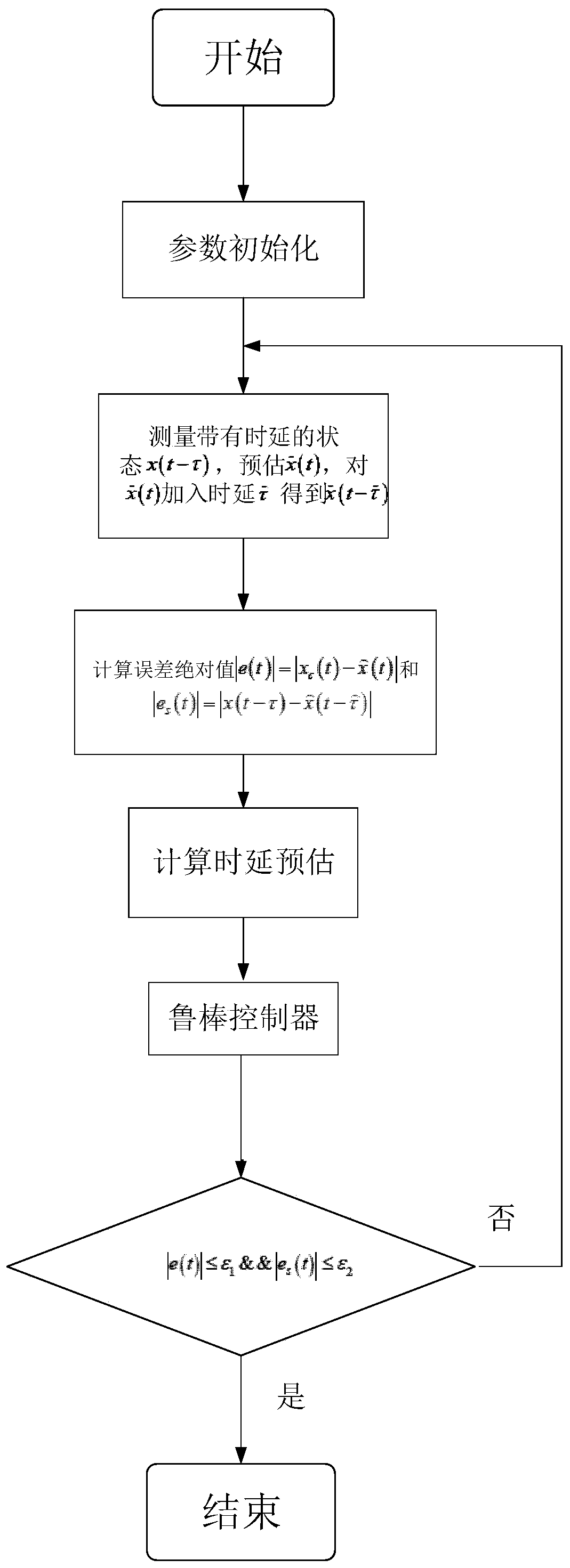

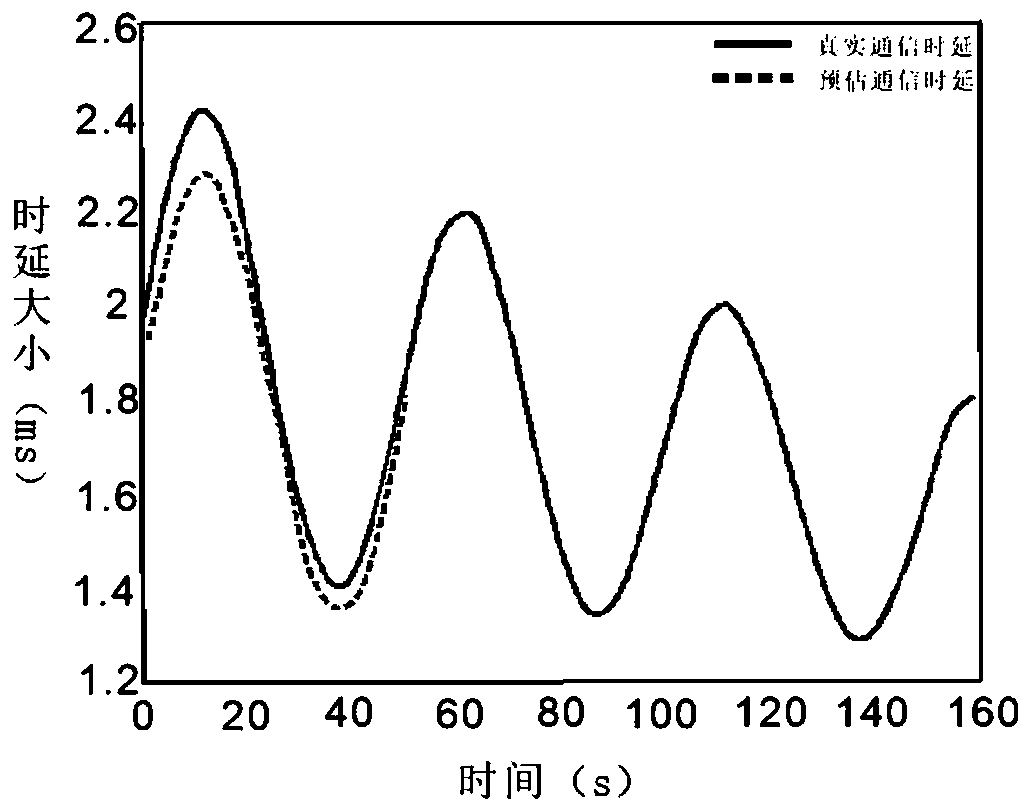

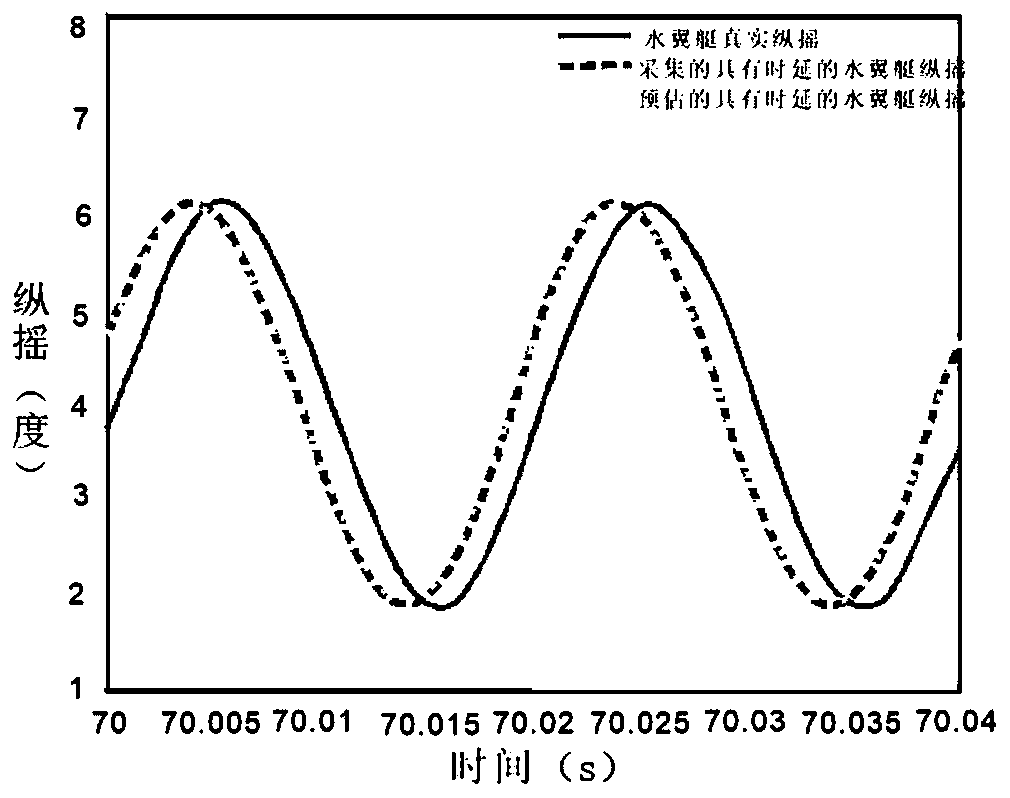

Longitudinal motion control method for hydrofoil boat

ActiveCN110837254AImprove real-time performanceImprove efficiencyPosition/course control in two dimensionsTime delaysSea waves

The invention discloses a longitudinal motion control method for a hydrofoil boat. The method comprises the steps of: establishing a state equation for a hydrofoil boat according to the longitudinal motion characteristics of the hydrofoil boat; and designing a robust controller, enabling the estimated time delay value to approach to a real time delay value by utilizing a robust estimation controlalgorithm, wherein the estimated hydrofoil boat state model approaches the real hydrofoil boat motion state, so that when the estimated hydrofoil boat motion state follows a given reference state, thereal state of the hydrofoil boat can still follow the given reference state in the presence of sensor network communication delay, and the hydrofoil boat motion state is stable. According to the method, the estimation control algorithm is adopted to research the estimation method of the communication time delay, the real-time performance of the system is improved, the system can rapidly control the attitude of the hydrofoil boat, and the efficiency is improved. Robust control is adopted, interference of sea waves on the hydrofoil boat is considered, the stability of the system is greatly improved, and adjustment of the posture of the system is facilitated to a large extent.

Owner:HARBIN ENG UNIV

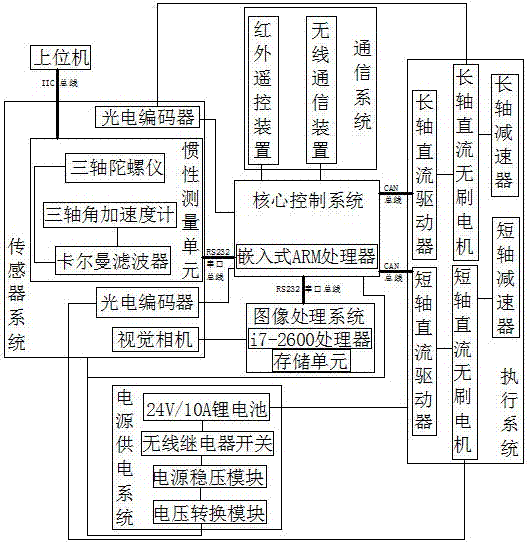

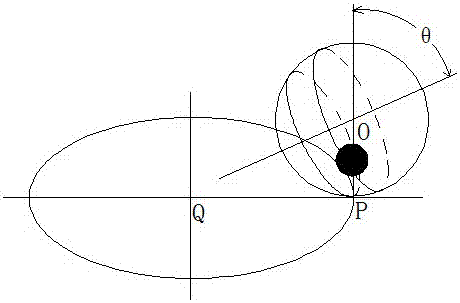

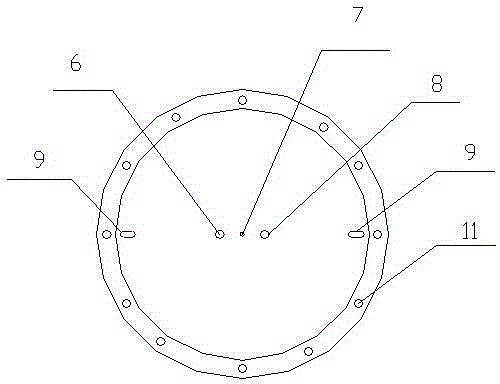

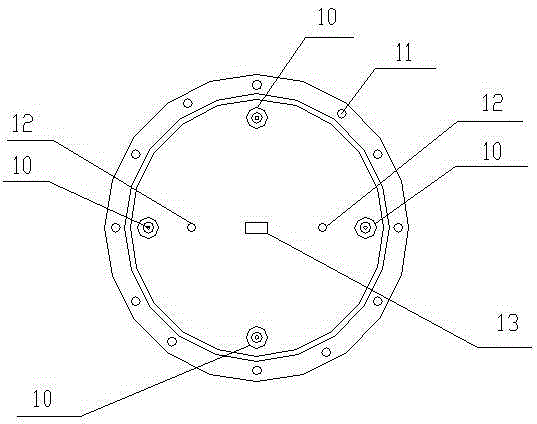

Motion control system of spherical robot having visual feedback and motion control method thereof

ActiveCN107272725AControl speedControl postureAttitude controlSpeed/accelaration control using electric meansVisual perceptionInertia

The invention discloses a motion control system of a spherical robot having visual feedback and a motion control method thereof. The motion control system comprises a spherical robot body, a control system which is installed on the spherical robot body and an upper computer which wirelessly communicates with the control system. The control system comprises a core control system, a performing system, a sensor system, an image processing system and a power supply system which are electrically connected with the core control system, and a communication system which performs wireless transmission with the core control system. The performing system, the sensor system, the communication system and the image processing system are electrically connected with the power supply system. According to the motion control system of the spherical robot having visual feedback and the motion control method thereof, the inertia measurement unit data are processed so that accurate acquisition of attitude information can be realized; and the speed and the attitude of the spherical robot can be controlled and rectilinear motion and arc turning motion of the robot can be realized.

Owner:广州一衍信息科技有限公司

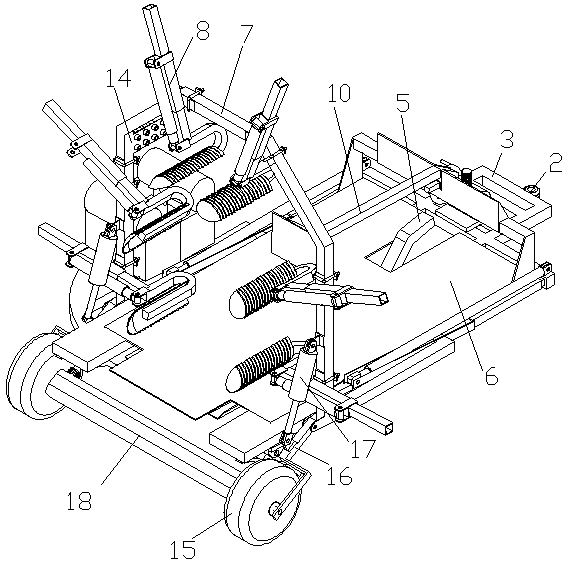

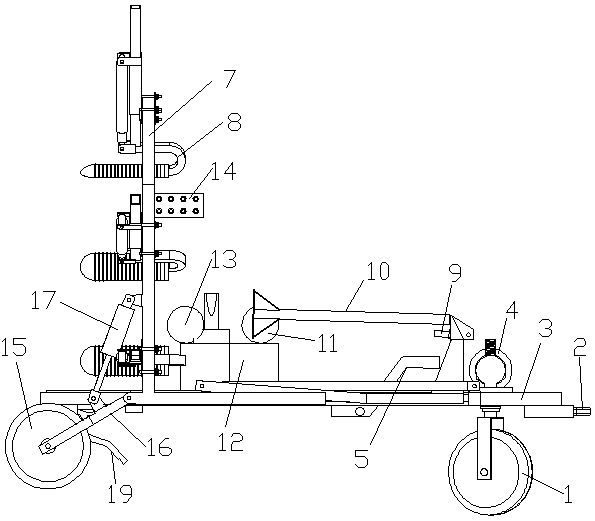

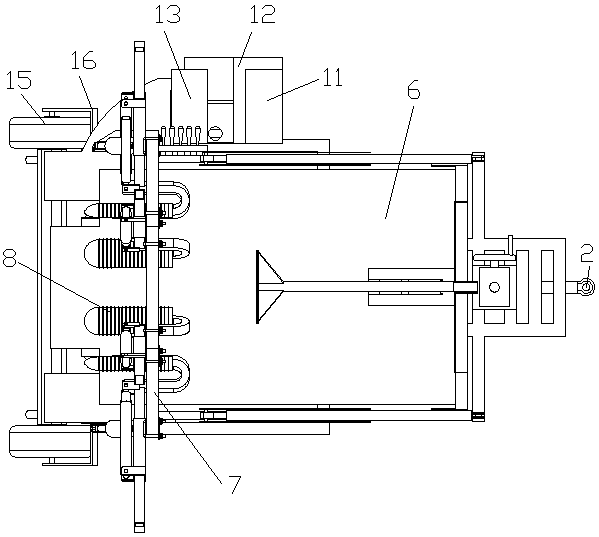

Bale filling machine

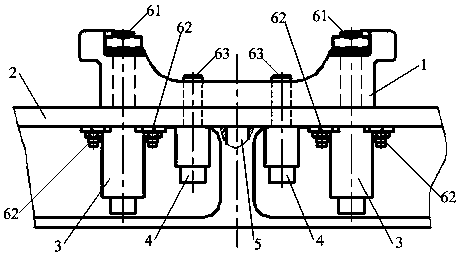

PendingCN111572837AControl postureEffective control postureIndividual articlesHydraulic cylinderVehicle frame

The invention discloses a bale filling machine which comprises a frame, a drawing head, a front wheel and rear wheels. The frame is provided with a hand rocking lifter, a pushing tray mechanism, a portal frame, a hydraulic oil tank, a hydraulic pump and a power mechanism. The frame is provided with a guide rail for the pushing tray mechanism to slide. A trigger is arranged in the pushing tray mechanism. The portal frame is arranged behind the pushing tray mechanism. The portal frame is provided with a bag opening mechanism and a hydraulic hand control valve assembly. The hydraulic hand controlvalve assembly is connected with a hydraulic system. The rear wheels are composed of a left rear wheel and a right rear wheel. The left rear wheel and the right rear wheel are connected through a rear wheel shaft. The rear wheel shaft is provided with a rear wheel shaft sleeve in a sleeving manner. The two rear wheels are fixedly connected through a rear wheel support and the frame. Portal frameinclining hydraulic cylinders are arranged on the rear sides of stand columns on the two sides of the portal frame correspondingly. Piston ends of the portal frame inclining hydraulic cylinders are connected with the rear wheel support in a hinged manner. The other ends of the portal frame inclining hydraulic cylinder are hinged to the stand columns on the two sides of the portal frame. Portal frame inclining limiters are arranged at the left end and the right end of the rear wheel shaft sleeve correspondingly.

Owner:HENAN AGRICULTURAL UNIVERSITY

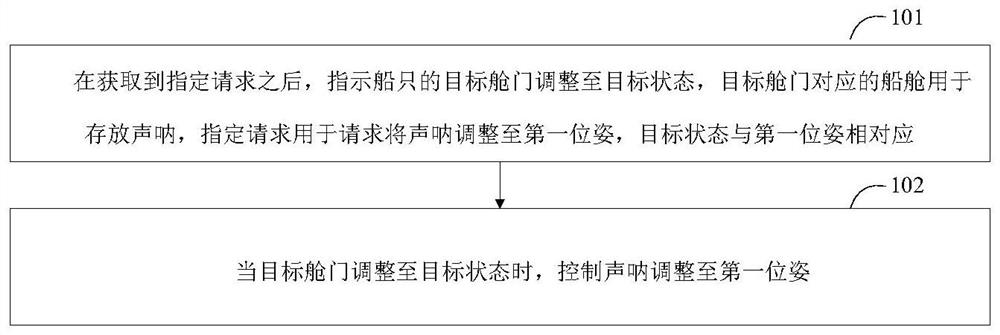

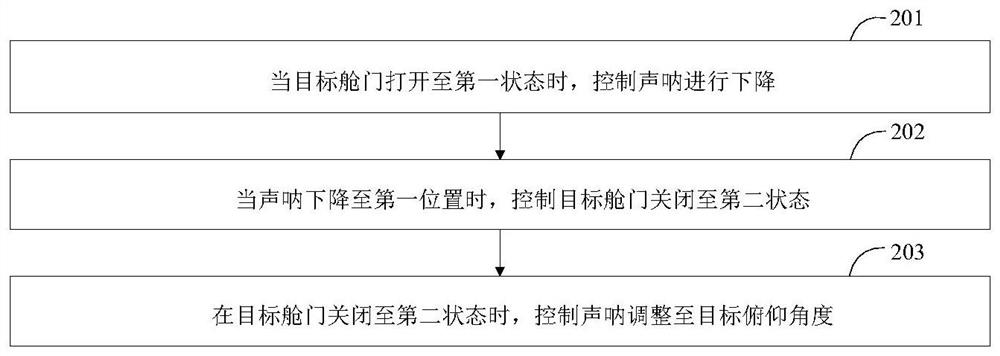

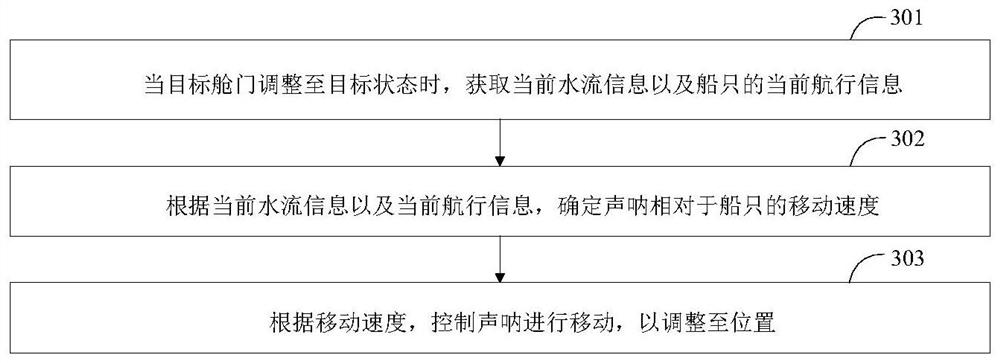

Method and device for controlling sonar and control equipment

PendingCN114646965AControl positionControl postureVessel partsAcoustic wave reradiationSonarMarine engineering

The method for controlling the sonar is applied to a control device, the control device is loaded on a ship, and the method comprises the steps that after a specified request is obtained, a target cabin door of the ship is indicated to be adjusted to a target state, a cabin corresponding to the target cabin door is used for storing the sonar, and the specified request is used for requesting to adjust the sonar to a first pose; the target state corresponds to the first pose; and when the target cabin door is adjusted to the target state, controlling the sonar to be adjusted to the first pose. By means of the method, the problems that the sonar cannot be effectively controlled on ships such as an unmanned ship, the sonar can only be kept in the using state of stretching out of the ship all the time after being installed on the ship, and the execution efficiency and navigation of the ship are affected can be solved.

Owner:ZHUHAI YUNZHOU INTELLIGENCE TECH COMPANY

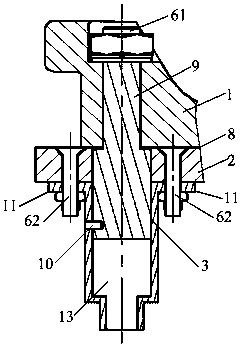

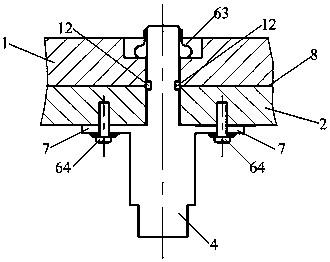

A passive pull-off mechanism for a shedding plug

ActiveCN106972318BSimple structureEasy to installCoupling device detailsEngineeringMechanical engineering

Owner:BEIJING MECHANICAL EQUIP INST

A missile hanging separation mechanism

ActiveCN105066796BImprove space occupancyEasy to install and maintainSelf-propelled projectilesCombustionActuator

The invention discloses a missile hanger separation mechanism. The missile hanger separation mechanism comprises a hanger, an explosive bolt, an actuator, a missile body and a location pin, wherein one end of the actuator is connected with the missile body through a second fastener, and the other end of the actuator is connected with the hanger through a first fastener; one end of the explosive bolt is connected with the missile body through a fourth fastener, and the other end of the explosive bolt is connected with the hanger through a third fastener; the hanger is fixed on the missile body through the location pin, and the contact surface of the missile body and the hanger is a separation surface; a U-shaped groove is formed in the upper end of the explosive bolt, and the central plane of the U-shaped groove is located on the separation surface; and a push rod and a combustion cavity are arranged on and formed in the actuator, the combustion cavity is filled with gunpowder, and the push rod carries out initial locking through a shear pin. The missile hanger separation mechanism disclosed by the invention is simple and convenient to install and maintain, high in action synchronization of initiating explosive devices, and capable of effectively controlling the posture of the hanger after flying away from the missile body, and guaranteeing no collision of the hanger with the missile body during the process of flying away from the missile body, thus improving the flying safety of a carrying aircraft and a missile.

Owner:JIANGXI HONGDU AVIATION IND GRP

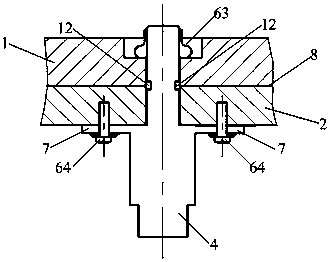

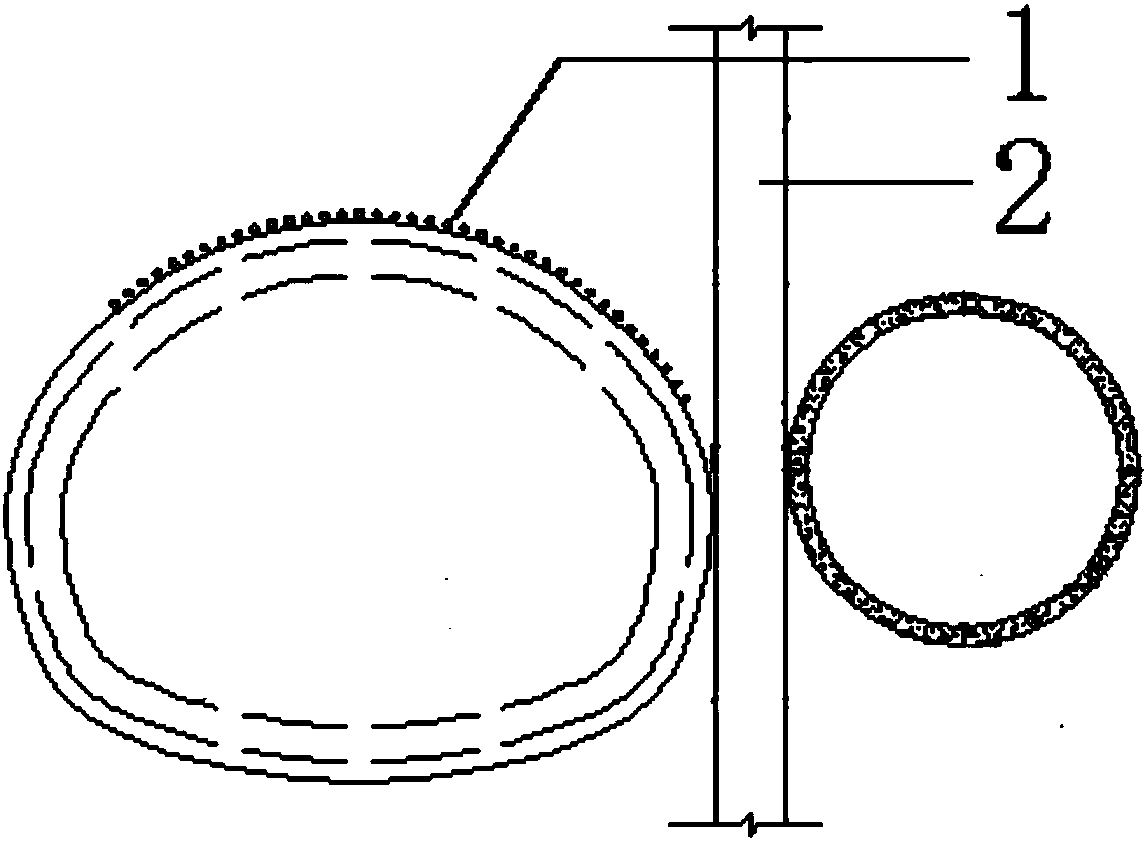

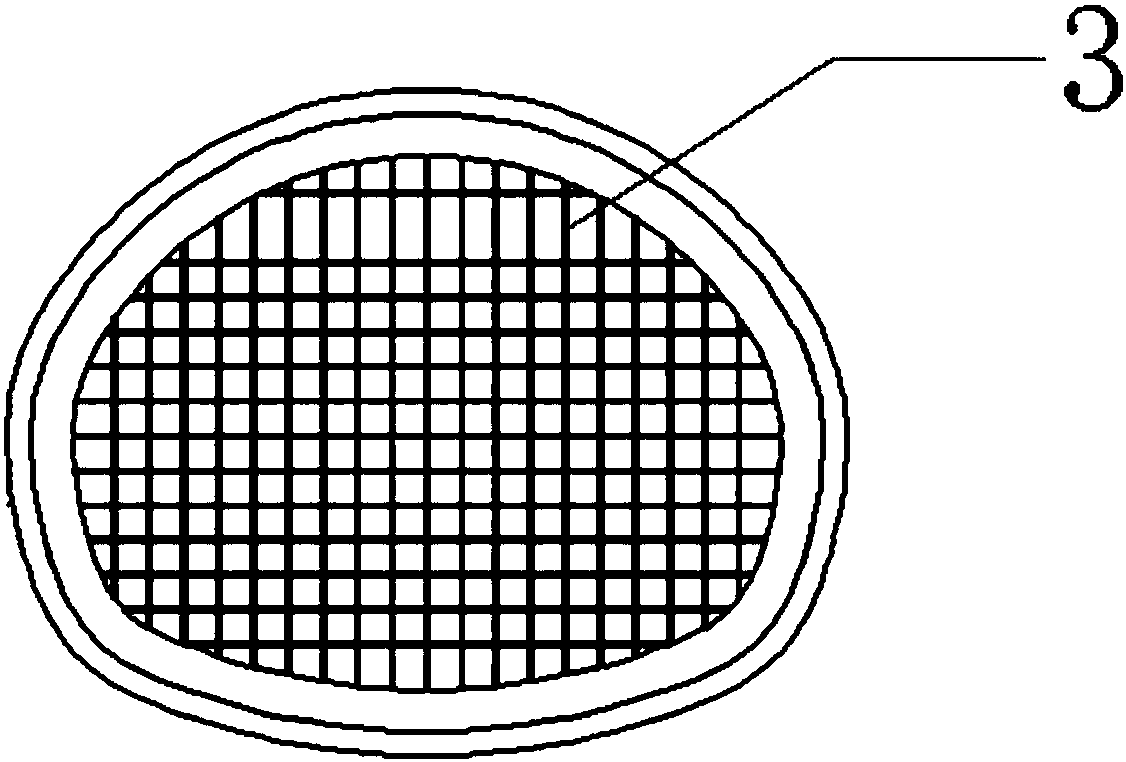

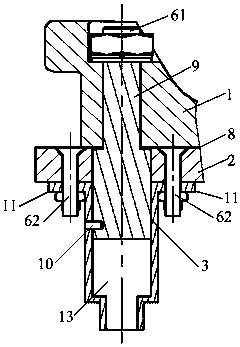

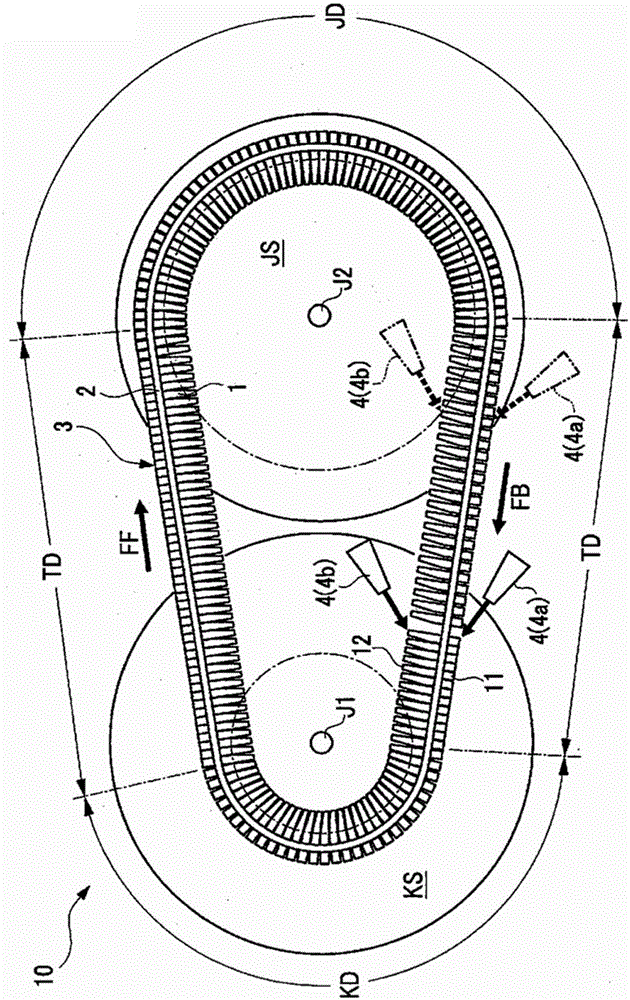

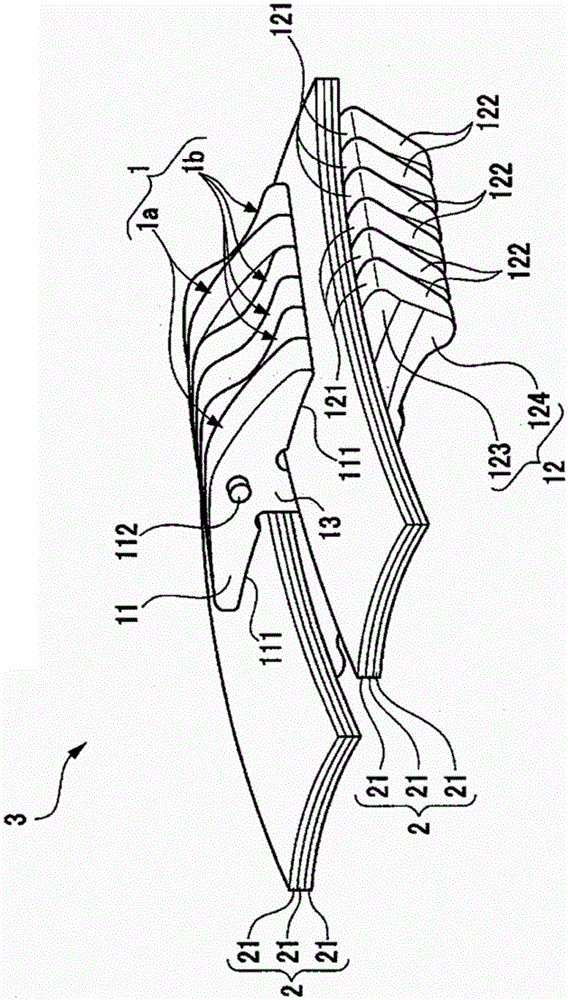

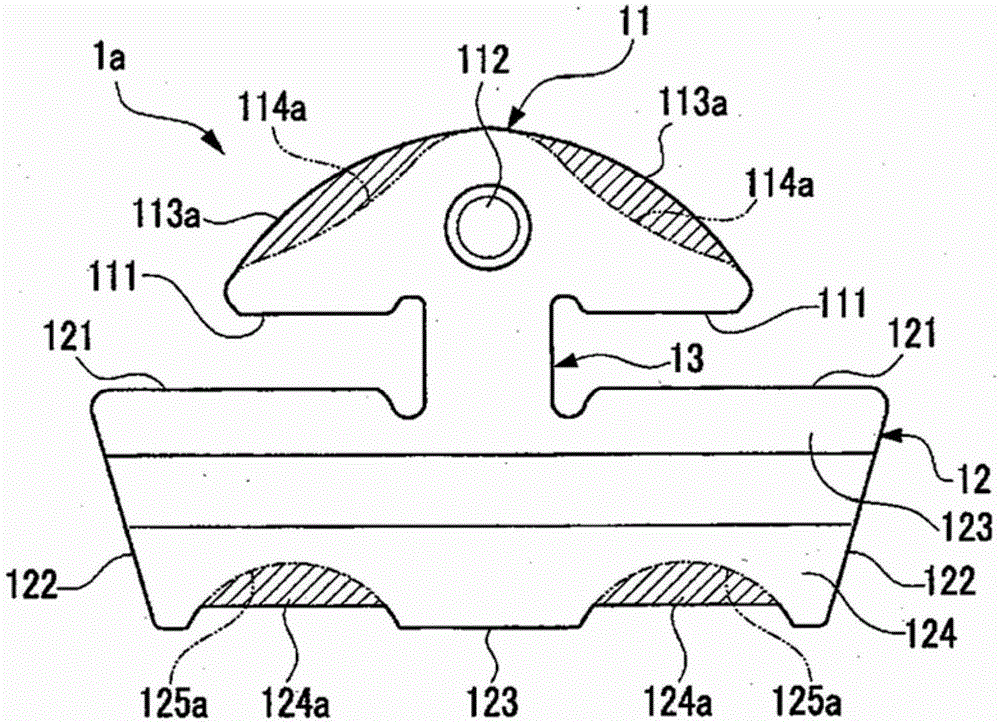

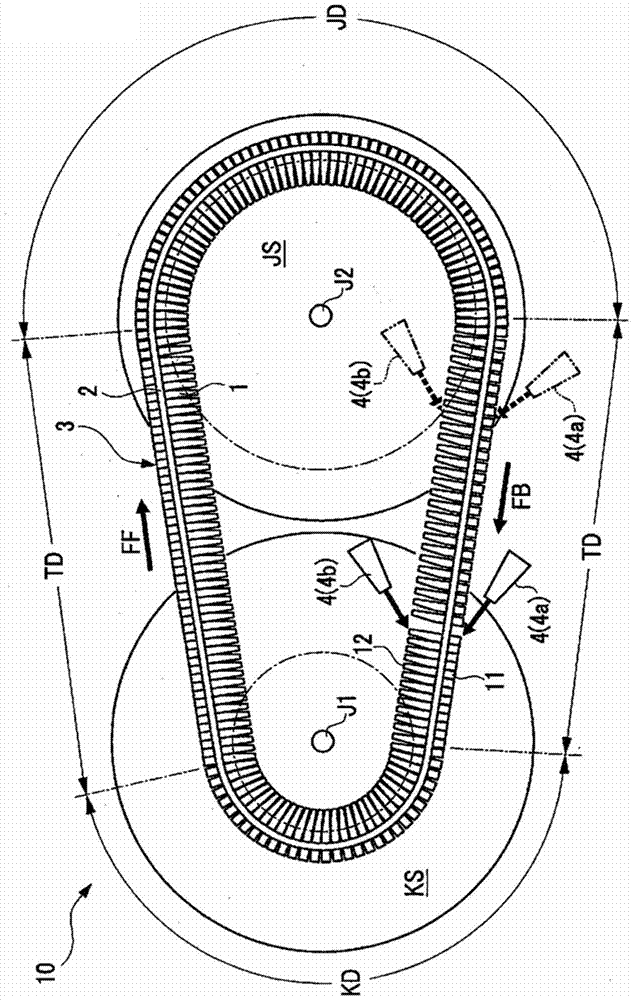

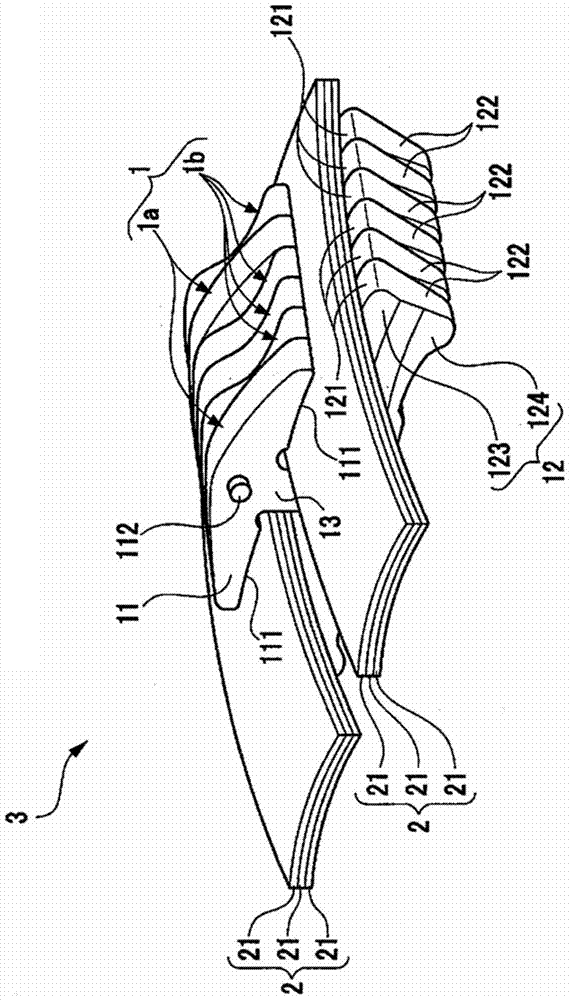

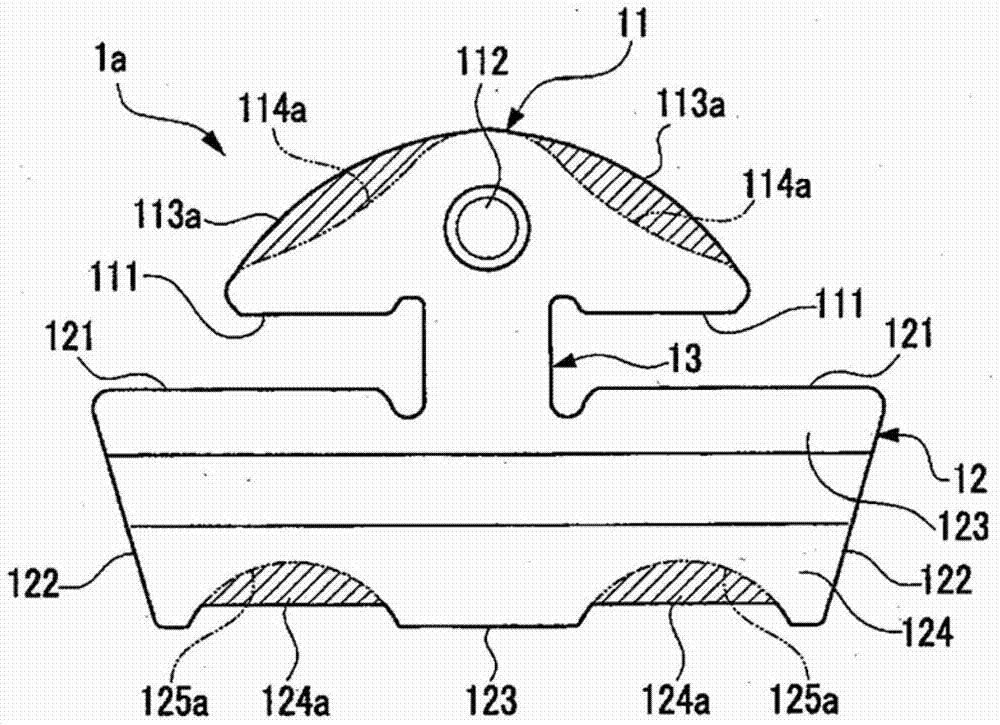

Continuously variable transmission

ActiveCN105209788AImprove transfer efficiencyControl postureV-beltsGearingElectrical and Electronics engineeringFlange

This continuously variable transmission (10) is obtained by winding, around a drive sheave (KS) and a driven sheave (JS), a continuously variable transmission belt (3) in which a plurality of metal elements (1) are stacked and supported on an endless ring (2). In at least one of the metal elements (1), flange parts (113a, 124a) are formed on a head part (11) positioned at an outer peripheral side of the endless ring (2) and a trunk part (12) positioned at an inner peripheral side of the endless ring (2). The continuously variable transmission (10) is provided with a fluid supply device (4) which, during movement of the continuously variable transmission belt (3) from the driven sheave (JS) to the drive sheave (KS), sprays lubricating oil (4aw, 4bw) in a movement direction (the direction of arrow FB) of the continuously variable transmission belt (3), towards the flange parts (113a, 124a).

Owner:TOYOTA JIDOSHA KK

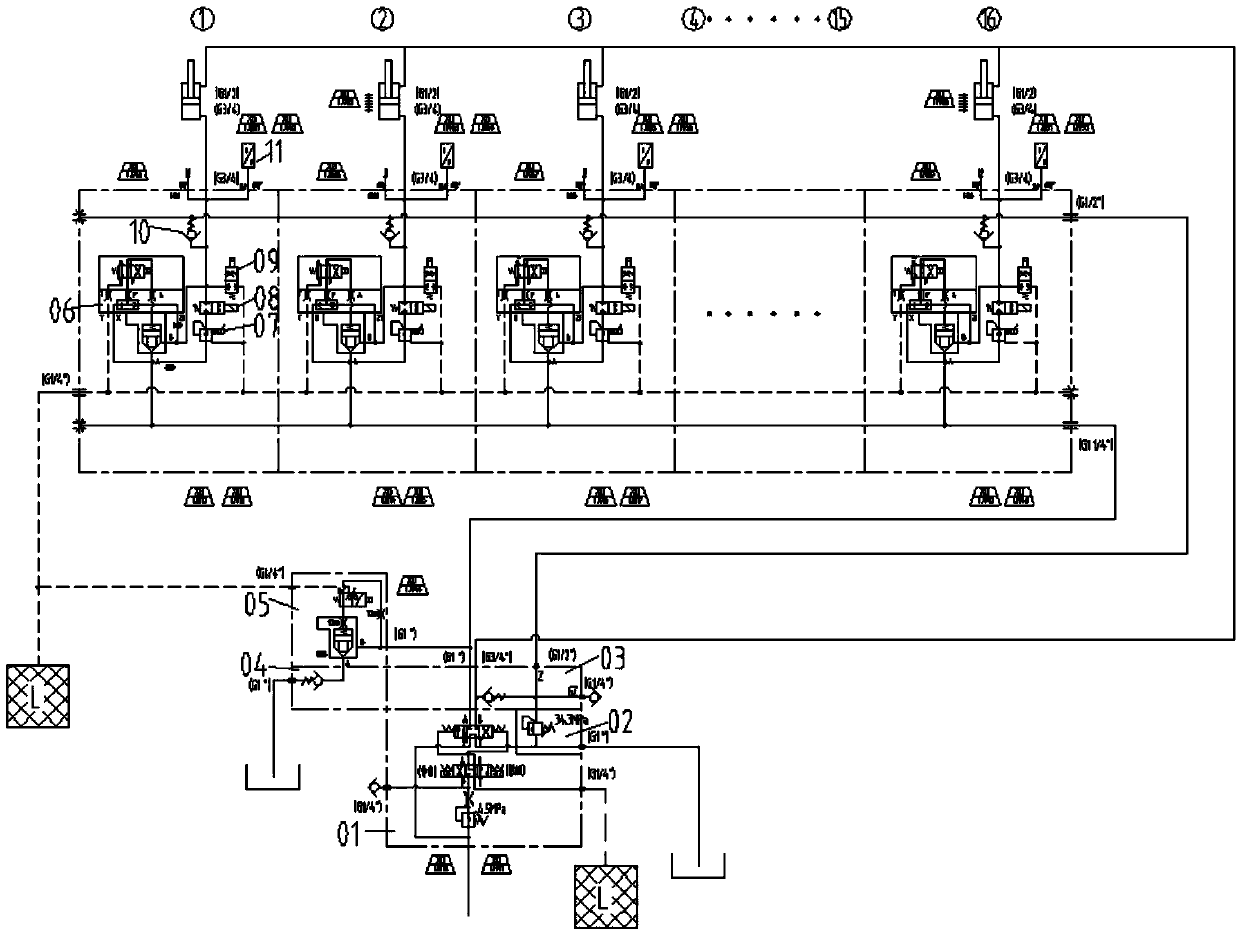

Shield machine automatic arbitrary group propulsion control system

The invention discloses an automatic and random grouping push control system of a shield tunneling machine. The automatic and random grouping push control system comprises a push oil cylinder reverse control device set and a plurality of push oil cylinder thrust control device sets, the signal control ends of the push oil cylinder thrust control device sets and the signal control end of the push oil cylinder reverse control device set are connected with an upper computer of the shield tunneling machine, and the upper computer sends signals to the push oil cylinder thrust control device sets and the push oil cylinder reverse control device set to adjust the push posture of the shield tunneling machine in real time by adjusting the maximum thrust of an oil cylinder. The shield tunneling machine can advance precisely along designed tracks, construction quality can be improved, and construction efficiency can be improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD +1

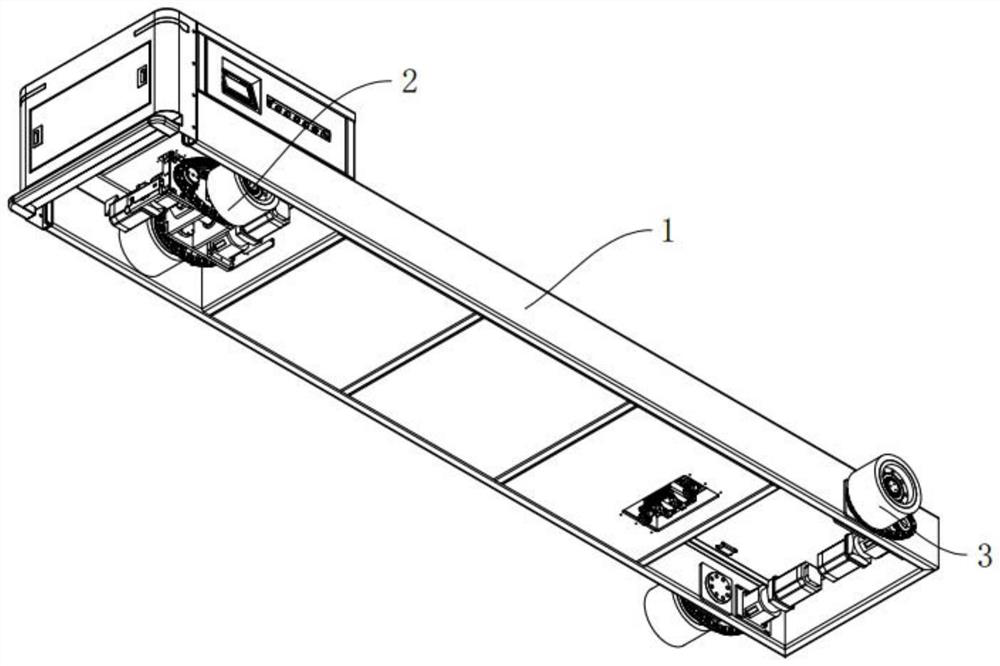

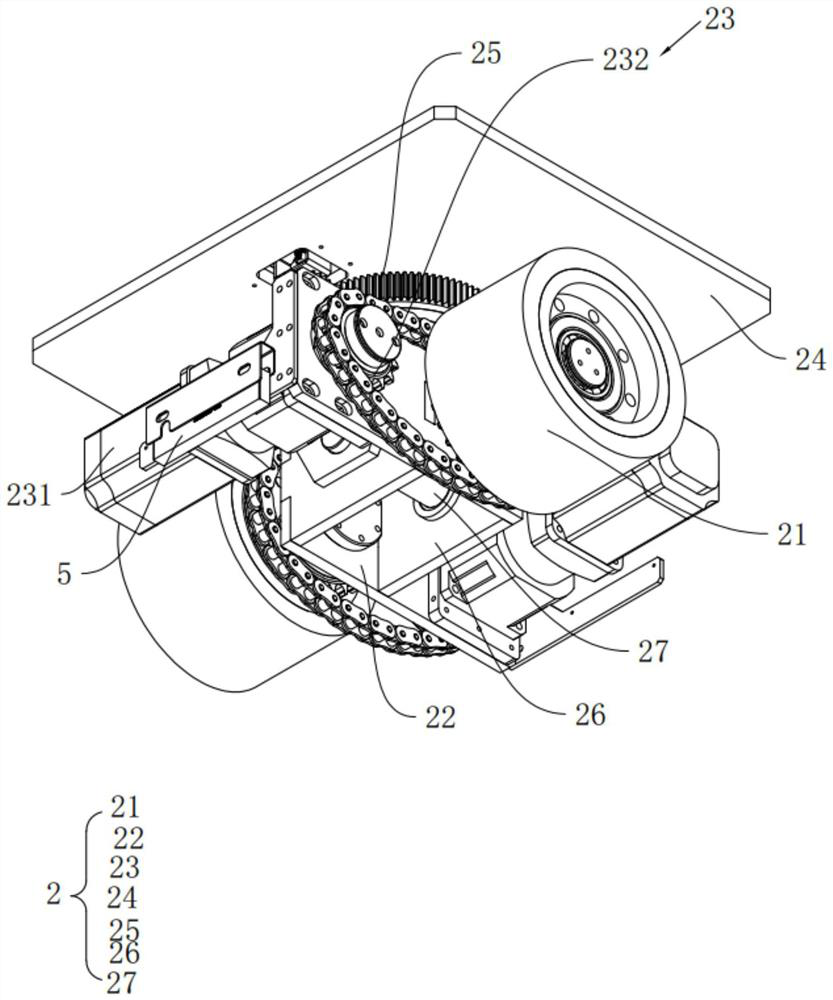

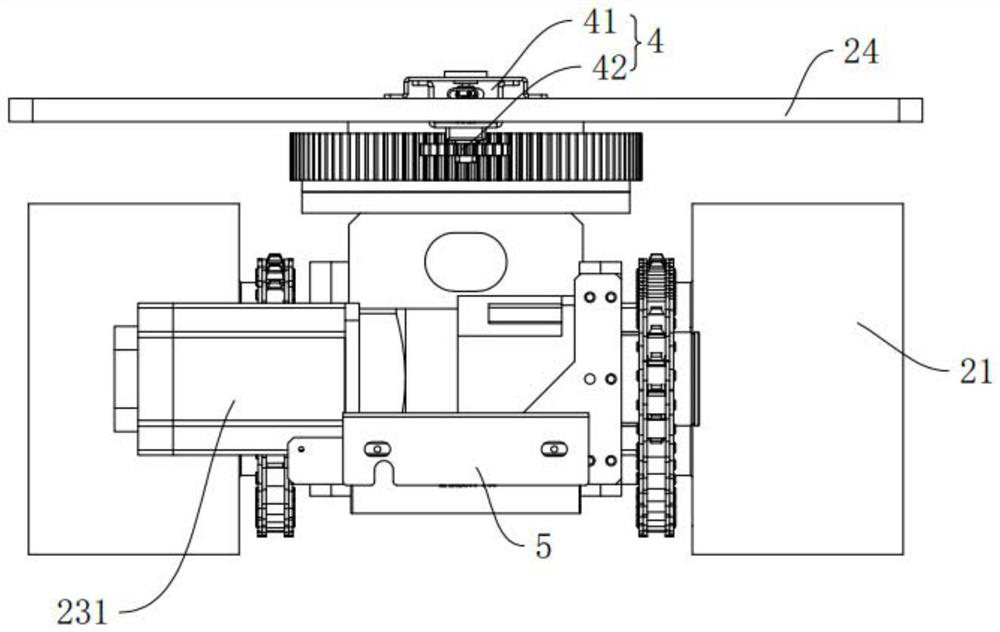

Long-distance chassis mechanism and AGV

PendingCN114228821AControl the walking routeControl postureSteering linkagesMechanical steering gearsControl theoryRolling chassis

The invention relates to a long-distance chassis mechanism and an AGV. The long-distance chassis mechanism comprises a chassis body. The front driving assembly is arranged at the front end of the chassis body and is suitable for driving the chassis body to move and turn; the at least two rear driving assemblies are arranged at the rear end of the chassis body and are symmetrically arranged relative to the chassis body; and the turning detection assembly is arranged at the front driving assembly and is suitable for detecting the turning angle of the front driving assembly, transmitting signals to the two rear driving assemblies and controlling the speed of the rear driving assemblies, and the effect of accurately controlling the walking route and posture of the AGV during turning is achieved.

Owner:HUAXIAO PRECISION SUZHOU

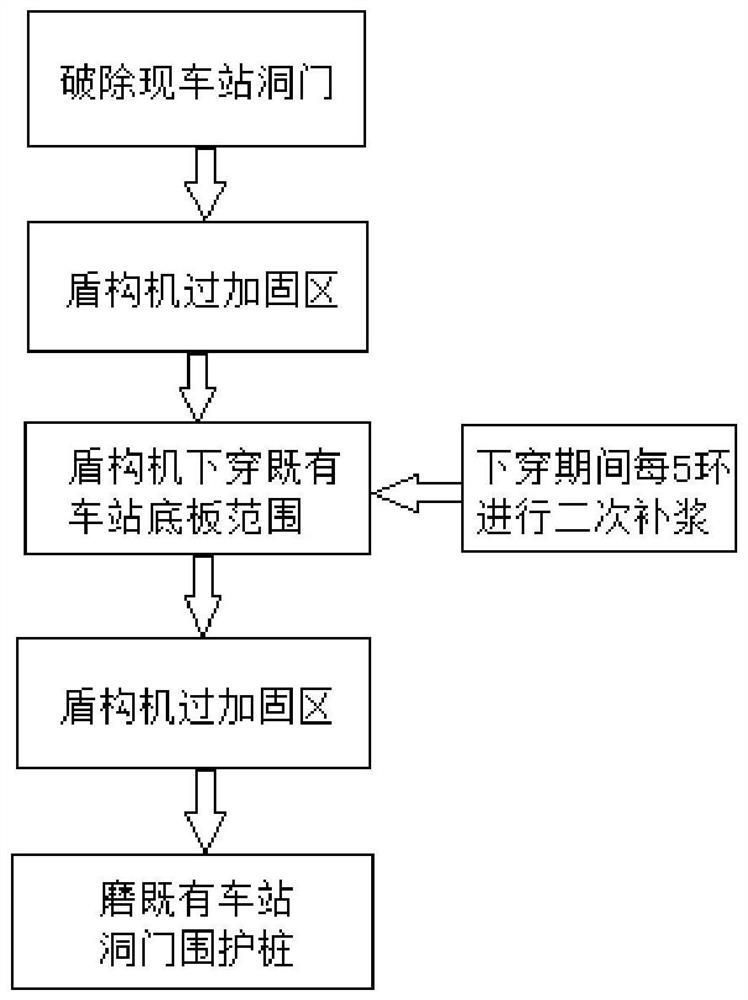

A Construction Method for Shield Tunneling Under the Existing Station in Powder Soil Stratum

ActiveCN110130909BReduce the impact of disturbanceControl postureUnderground chambersTunnel liningGround subsidenceStructural engineering

The invention discloses a construction method for shield tunneling under an existing station in a silt layer, which comprises the following steps: step 1: removing the portal (1) of the existing station (2); step 2: removing the existing station ( 3) and the existing station (2) for reinforcement; step 3: the shield machine passes through the reinforcement area of the starting end of the existing station (3); step 4: the shield machine passes under the floor of the existing station (3) range, and carry out synchronous grouting and secondary grouting during the underpass; step 5: the shield machine passes through the existing station (3) and exits the end area of the existing station; step 6: the shield machine exits the existing station (3) ) and grind the retaining piles of the existing station (3). The invention can reduce the impact of disturbance on the silt layer soil during the tunneling process of the shield machine, effectively control the attitude of the shield machine, reduce the impact of ground subsidence, reduce construction risks, and speed up the construction period.

Owner:中建八局轨道交通建设有限公司

CVT

This continuously variable transmission (10) is obtained by winding, around a drive sheave (KS) and a driven sheave (JS), a continuously variable transmission belt (3) in which a plurality of metal elements (1) are stacked and supported on an endless ring (2). In at least one of the metal elements (1), flange parts (113a, 124a) are formed on a head part (11) positioned at an outer peripheral side of the endless ring (2) and a trunk part (12) positioned at an inner peripheral side of the endless ring (2). The continuously variable transmission (10) is provided with a fluid supply device (4) which, during movement of the continuously variable transmission belt (3) from the driven sheave (JS) to the drive sheave (KS), sprayed lubricating oil (4aw, 4bw) in a movement direction (the direction of arrow FB) of the continuously variable transmission belt (3), towards the flange parts (113a, 124a).

Owner:TOYOTA JIDOSHA KK

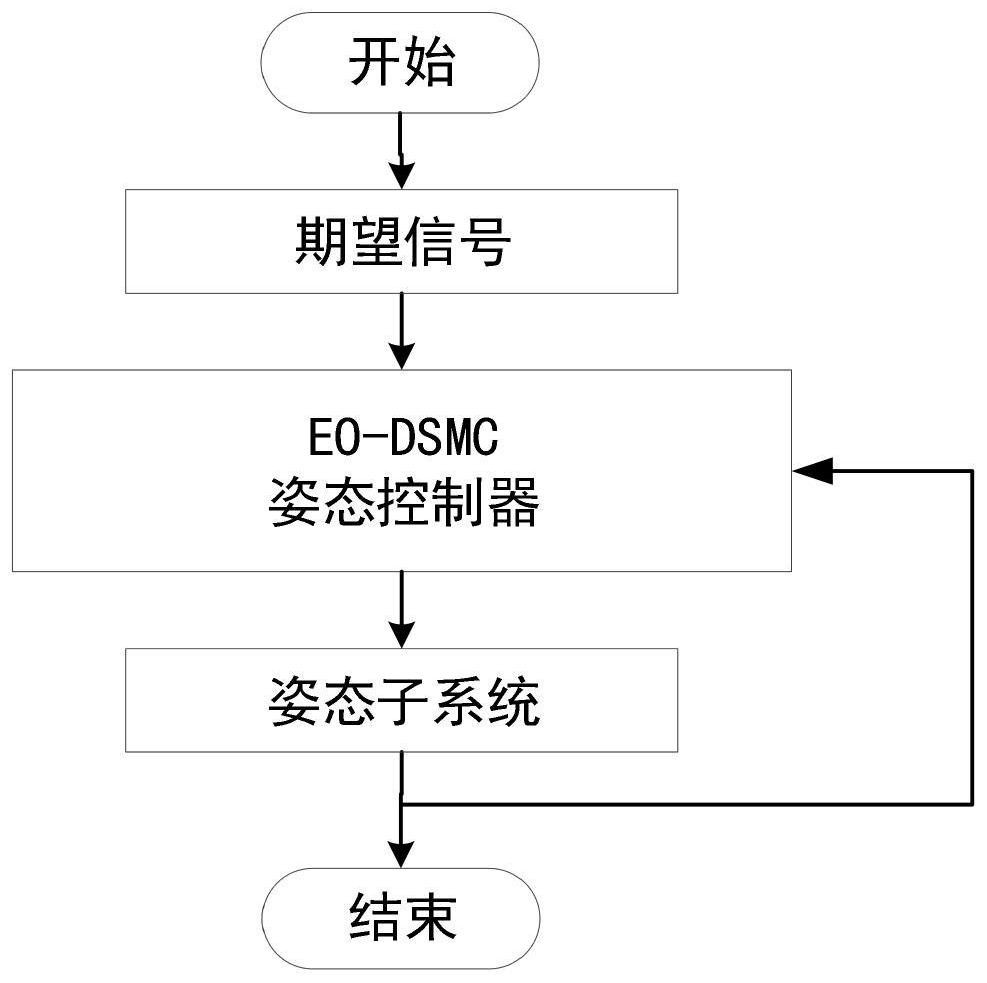

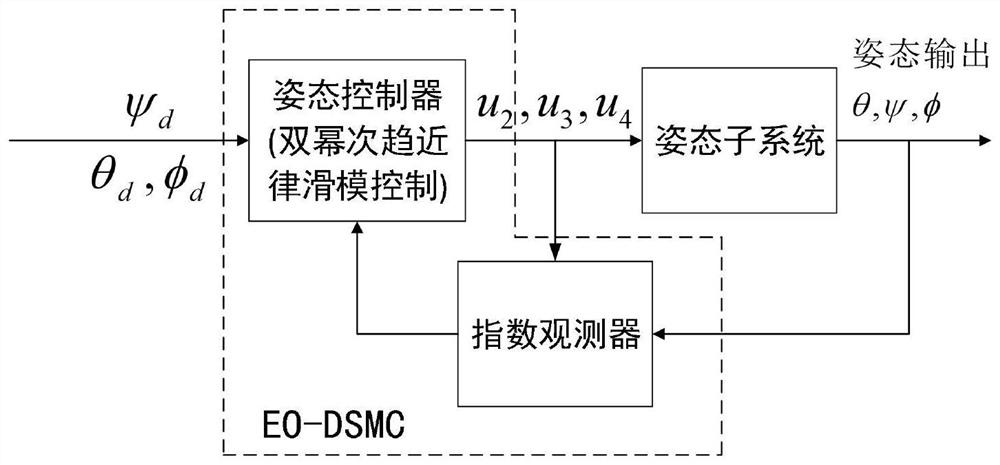

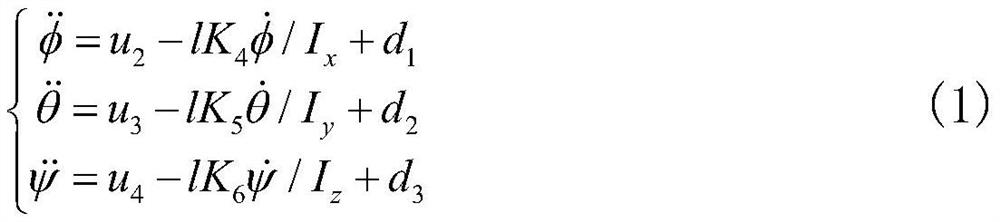

Design method of attitude subsystem controller for attitude angle control input saturation

ActiveCN113110551AControl postureReduce buffetingSustainable transportationAttitude controlLoop controlSimulation

A design method of an attitude subsystem controller for attitude angle control input saturation is provided, a double-power reaching law sliding mode controller based on an index observer is designed in combination with the index observer and a double-power reaching rate sliding mode control method for a quadrotor unmanned aerial vehicle attitude subsystem; a more accurate attitude angle of the four-rotor unmanned aerial vehicle can be obtained through the designed controller, and the attitude of the unmanned aerial vehicle can be better controlled; an expected attitude angle is given and input into the double-power approaching rate sliding mode controller based on the index observer, interference signals observed by the index observer in the controller are input into the attitude subsystem for interference compensation, and a new attitude angle can be obtained through the attitude subsystem. A new attitude angle signal is input into the designed controller again, closed-loop control is formed, and real-time updating is carried out. The problem of attitude angle control input saturation can be solved, the buffeting defect caused by sliding mode control is weakened to a certain extent, and the control precision and stability of the system can be improved.

Owner:XIAN UNIV OF TECH

Inner controlling system for gestures of underwater robot

InactiveCN102012704BControl postureAttitude control is widely applicableAttitude controlUnderwater equipmentControl systemClassical mechanics

The invention discloses an inner system for controlling the gestures of an underwater robot, comprising a main controller connected with an adjustment mechanism, a gesture sensor, and an upper computer controller, wherein the adjustment mechanism is a balance adjustment mechanism arranged inside the underwater robot, and comprises a gravity slider, a double-shaft drive motor, a worm, a guiderail,a slide bar, a limit switch and a mechanism platform; the double-shaft drive motor is connected with the worm to drive the worm to rotate bidirectionally; the worm drives the slide bar to perform planar movement through the transmission of a lead screw; one end of the slide bar is connected with the lead screw of the worm and penetrates the gravity slider, while the other end thereof is connectedwith the guiderail by a slider and drives the gravity slider to move in a plane so as to realize the gravity adjustment of the underwater robot and control the transverse swing and longitudinal incline gestures of the underwater robot. The control system for gestures can be widely applied to the gesture control of the underwater robot.

Owner:SHANGHAI UNIV

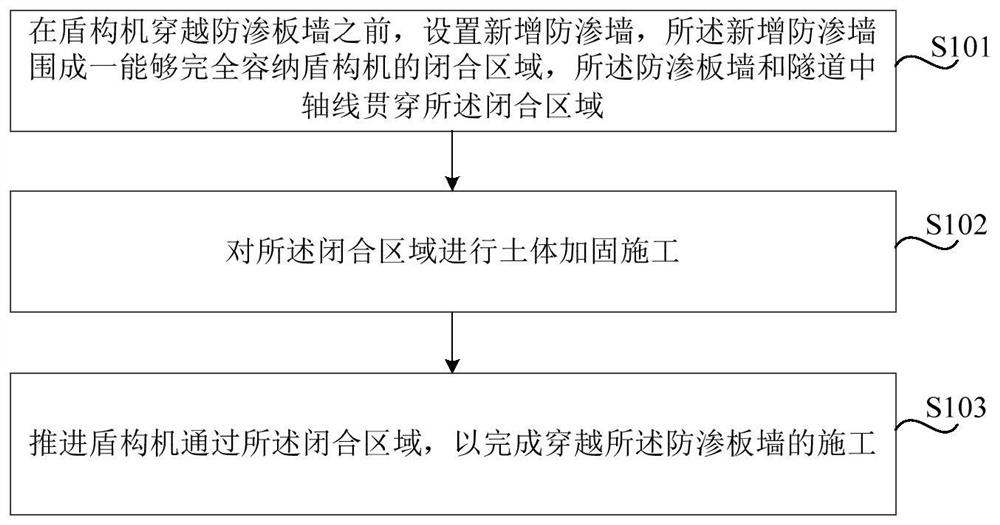

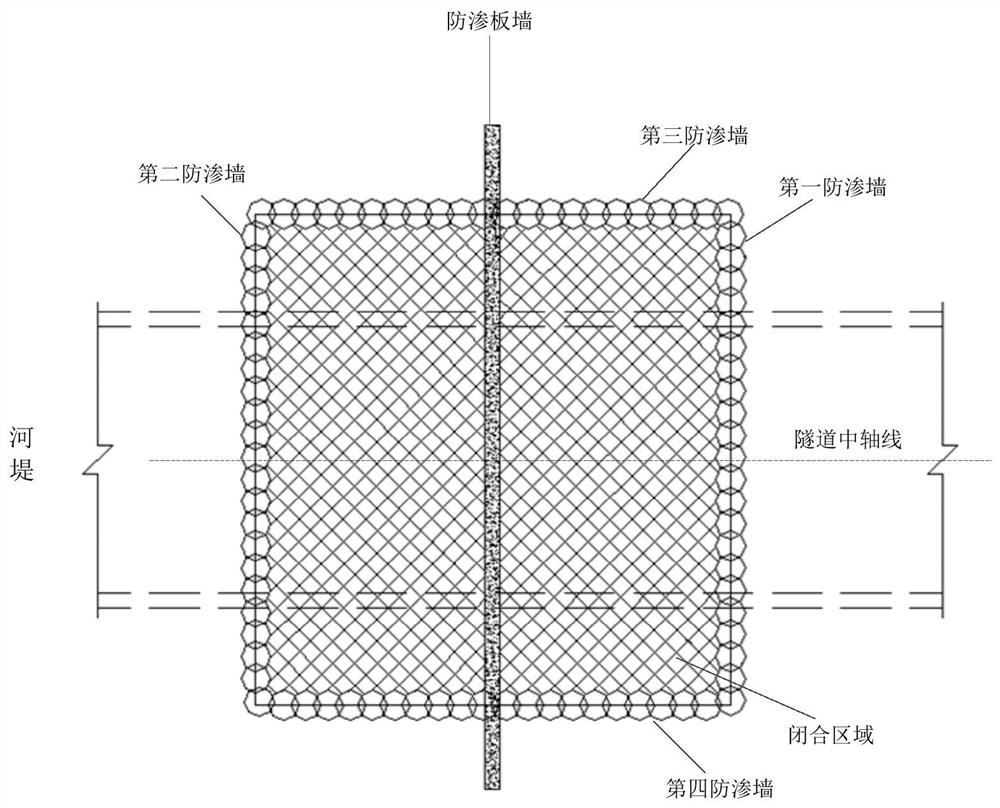

Construction method of crossing anti-seepage slab wall in shield section construction

ActiveCN108999218BImprove anti-seepage performanceControl postureProtective foundationTunnelsArchitectural engineeringStructural engineering

The embodiment of the invention provides a construction method for crossing an impermeable plate wall during construction of a shield section. The construction method comprises the following steps that newly-additionally-arranged impermeable walls are arranged before a shield machine crosses the impermeable plate wall, a closed area capable of completely accommodating the shield machine is definedby the newly-additionally-arranged impermeable walls in a surrounding mode, andthe central axisof the impermeable plate wall and thecentral axis of a tunnel penetrate through the closed area; soil reinforcement construction is carried out on the closed area; and the shield machine is pushed to pass through the closed area so as to complete the construction for crossing the impermeable plate wall.According to the provided method, the impermeability of the impermeable plate wall can be improved, and the posture of the shield machine is controlled, so that damage to the impermeable plate wall is reduced, and the flood control effect of a river bank is improved.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

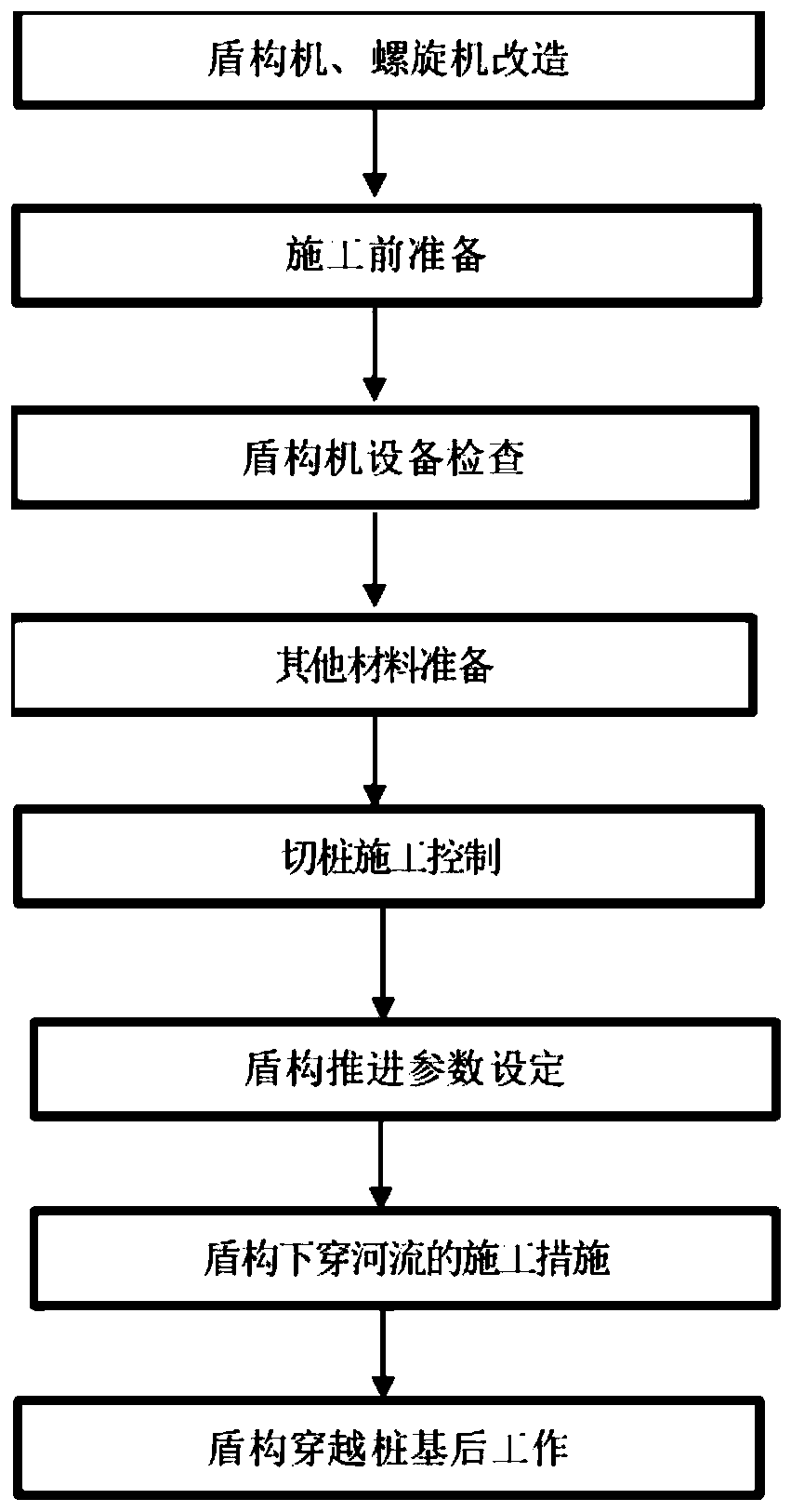

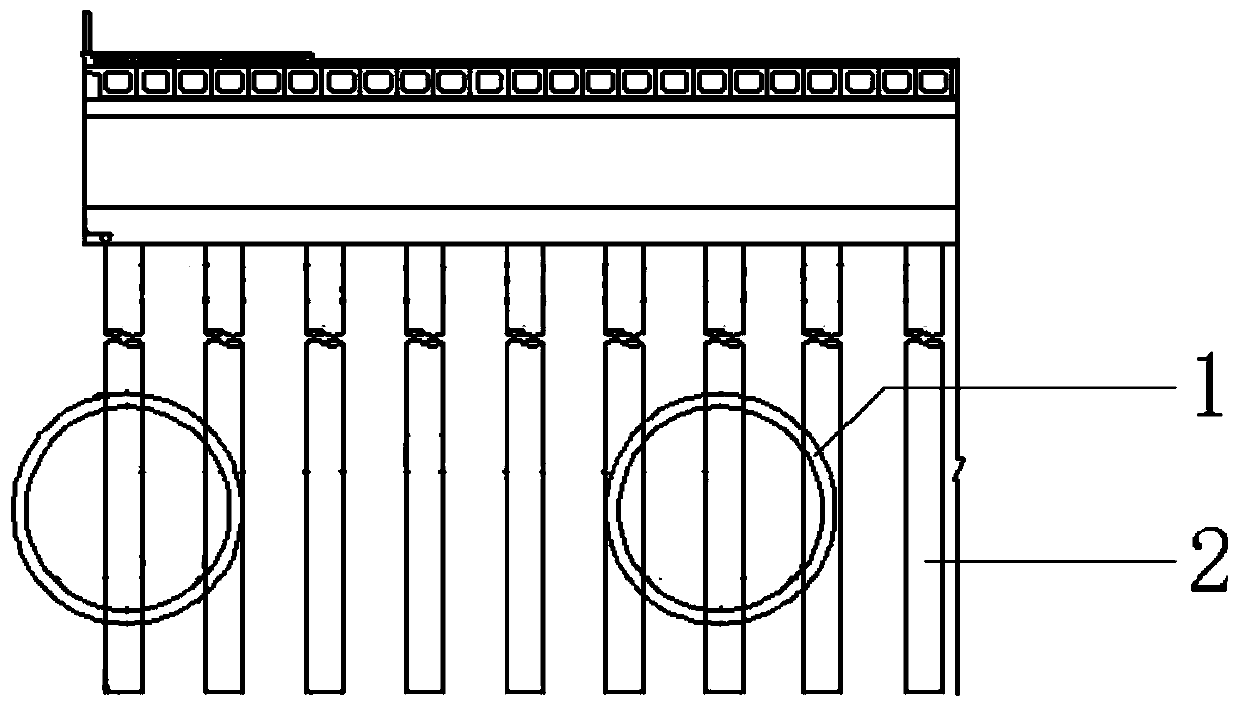

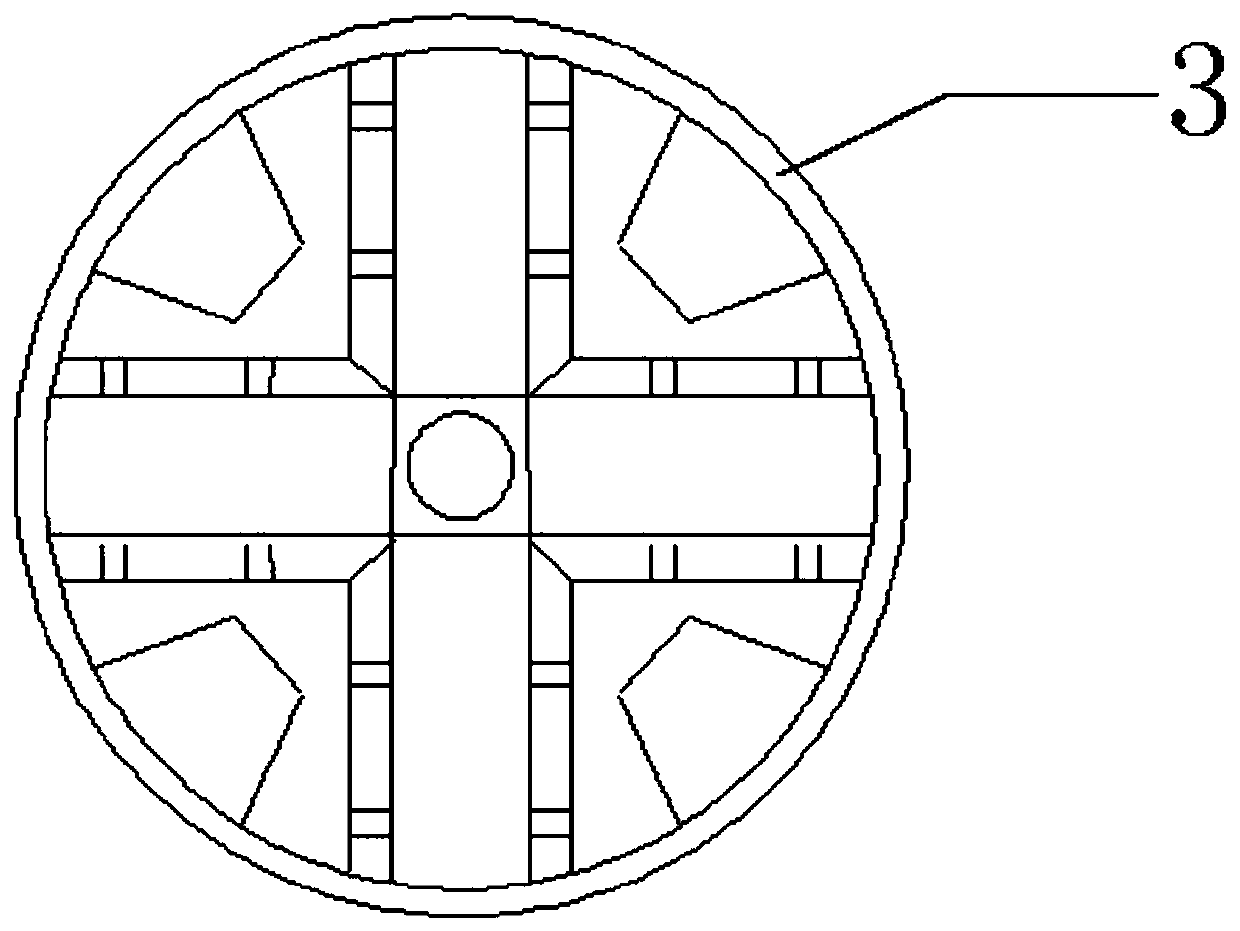

A construction method for silt soil layer shield cutting piles to cross the river

ActiveCN108049878BThe method steps are simpleReasonable designUnderground chambersTunnel liningMaterials preparationArchitectural engineering

The invention relates to a construction method for crossing rivers with shield tunneling piles in powder soil stratum, including: material preparation; specific measures for pile foundation cutting by shield tunneling: pile cutting construction control, monitoring control, construction control for crossing rivers, and construction of unknown obstacles Measures, pipeline protection measures; shield propulsion parameter setting; construction measures for crossing the river; control technology after the shield passes through the pile foundation; monitoring frequency control; inspection control in the cave. The beneficial effects of the present invention are: the method is simple in steps, reasonable in design, simple and convenient in construction, low in investment cost, and strong in practical engineering operations; the method of the present invention can improve the efficiency of tunneling under the tunnel, and control the attitude of the shield machine, thereby It reduces the possibility of accidents in the tunnel and lays a favorable foundation for the subsequent successful crossing; it has high practical value and good use effect. Compared with the existing tunnel construction method of underpassing, it shortens the construction period and greatly reduces the construction cost.

Owner:ZHEJIANG UNIV CITY COLLEGE

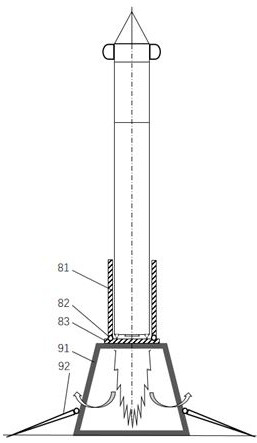

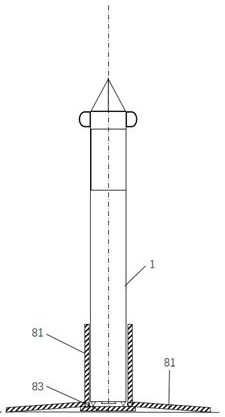

Sleeve cover type spaceflight rocket

InactiveCN114739238APrecision landingControl postureSelf-propelled projectilesStructural engineeringRocket

The invention discloses a cover type spaceflight rocket, which relates to the technical field of spaceflight rockets, and comprises a first-stage rocket body, a cone top cover arranged at the upper end of the first-stage rocket body, and a power recovery device, the conic top sleeve cover sequentially comprises a conic top cover and a sliding rail cylinder cover from top to bottom; the cone top cover sequentially comprises a scalloped segment part and a shell section from top to bottom; the sliding rail cylinder cover comprises a sleeve, a sliding rail and a load support. The upper portion of the sleeve is connected with the lower portion of the shell section, the lower portion of the sleeve is connected with the load support, and the sliding rail is arranged on the inner side face of the sleeve. The cone top cover, the sleeve and the load support jointly define a space which can be opened and closed and is used for containing a load, and at least one part of the load is slidably connected with the sliding rail in a matched mode. The cone top sleeve cover and the first-stage rocket body are integrally recycled, and a pull type recycling mode is adopted, so that stable and accurate landing is ensured; the device can be applied to tests of ground launch, flight and sub-orbit flight.

Owner:精易兴航(北京)科技创新有限公司

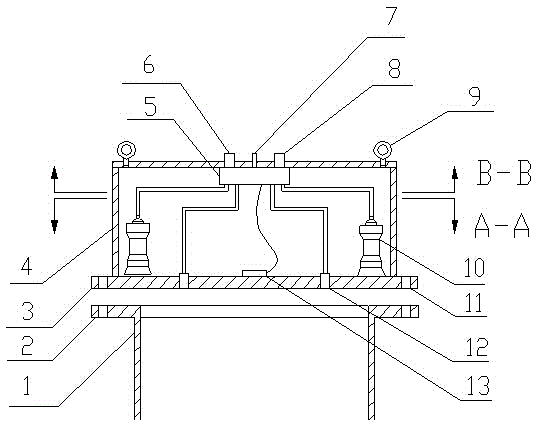

Vibrating Suction Bucket Foundation Leveling Device

ActiveCN104652502BControl postureWeaken frictional resistanceFoundation engineeringPositive pressureSolenoid valve

The invention discloses a vibrating type leveling device for suction bucket foundation. A bucket cover is covered on a bottom plate, a plurality of vibrating mechanisms are uniformly distributed at the same periphery of the bottom plate which is positioned in the bucket cover; two bottom plate negative-pressure openings are formed in the bottom plate in the vibrating mechanisms; a two-way angle sensor is mounted on the center of the bottom plate; a positive pressure opening, a wire outlet and a bucket cover negative pressure opening are formed in an upper surface of the bucket cover, the positive pressure opening is connected with a plurality of solenoid valve input openings in a solenoid valve control module respectively, a plurality of solenoid valve output openings are connected to pneumatic connectors of the respective vibrating mechanisms respectively; the bucket cover negative pressure opening is connected with the two bottom plate negative-pressure openings through the solenoid valve control module; a signal wire of the two-way angle sensor and a control wire of each solenoid valve are connected to a programmable logic controller through the wire outlet in the bucket cover. The vibrating type leveling device not only can control the gesture of the bucket foundation, but also can weaken friction resistance between the bucket foundation and a soil body, improves penetration depth, and can detect the inclination degree of the bucket foundation in real time and can control the penetration gesture of the bucket foundation.

Owner:ZHEJIANG UNIV +1

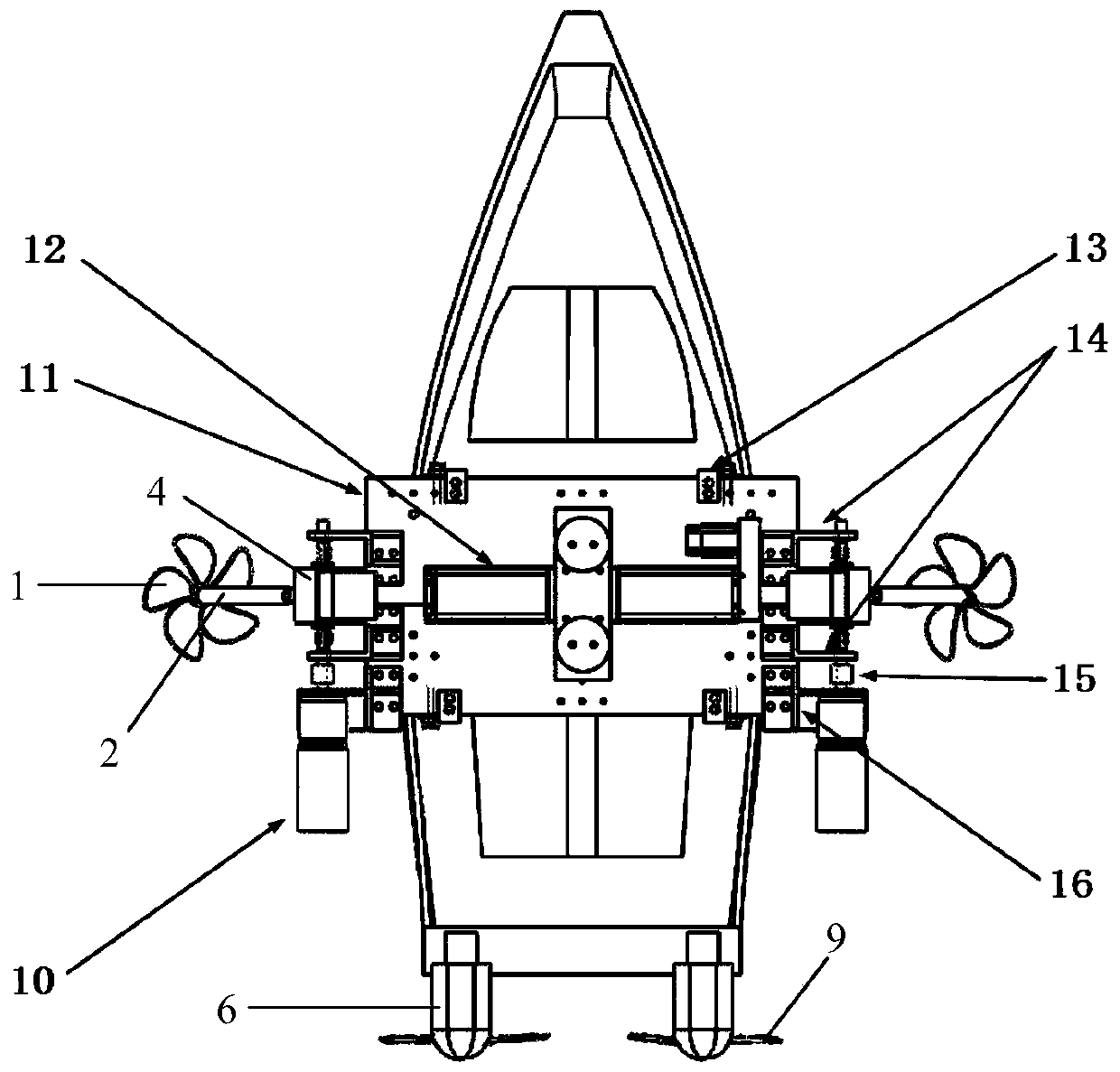

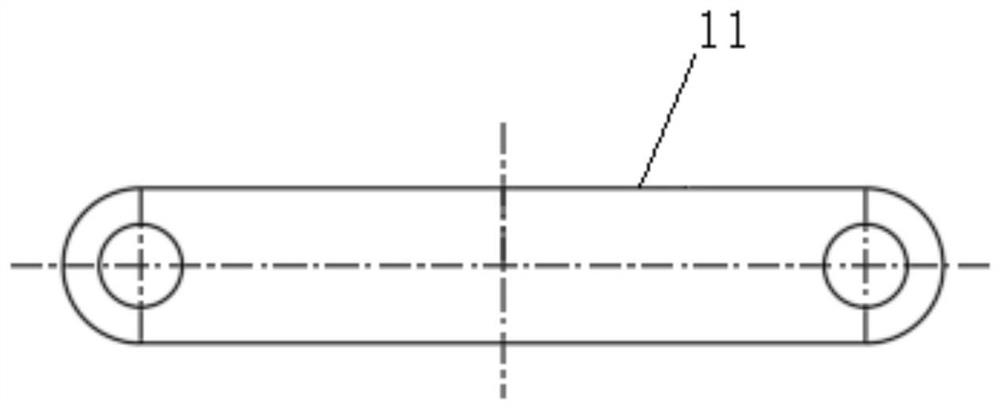

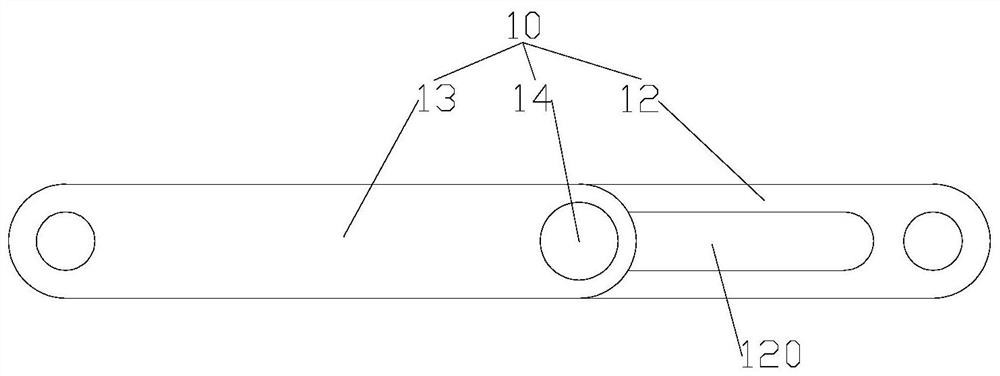

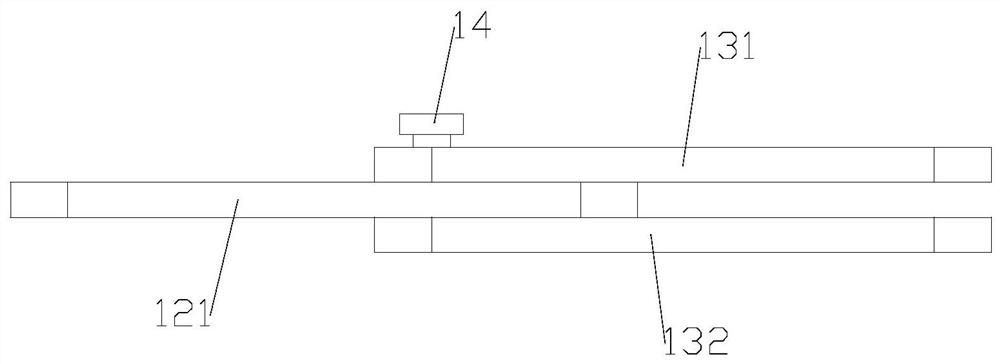

Combined ship anti-rolling device based on two-dimensional vector thruster and moving heavy objects

ActiveCN108313232BControl postureControl reaction speedVessel movement reduction by mass displacementPropulsive elementsCouplingElectric machinery

The invention discloses a combined ship stabilizer based on a two-dimensional vector propeller and moving a heavy object, and relates to the ship stabilizer. Rolling propellers are connected with direct-current power motor shaft couplings through propeller swing rods, the direct-current power motor shaft couplings are connected with power motors through power motor brackets, and the power motor brackets are connected with swing motors through the direct-current power motor shaft couplings. The power motor brackets are installed on direct-current motor supporting platforms, rear power propellerbrackets are connected with front-back moving ship propellers, and guide rail heavy objects are installed on guide rails. The guide rails are installed on a profile platform, the direct-current motorsupporting platforms are installed on the left and right sides of the guide rails, and the front-back moving ship propellers which are used for a hull moving forth and back are installed on the two sides of the rear part of the swing motor. The profile platform is installed in close proximity to the direct-current motor supporting platforms on both sides, swing motor shaft couplings are connectedwith the swing motors, the swing motors are arranged on swing motor supporting platforms, and connecting pieces between the hull and a profile plate are arranged on the profile platform.

Owner:XIAMEN UNIV

Shield escape method

ActiveCN112127901AGet out of trouble quicklyIncrease the excavation diameterHydro energy generationTunnelsSocial benefitsClassical mechanics

The invention discloses a shield escape method. The method is characterized by comprising the following steps of S10, modifying an excavation cutter set of a shield tunneling machine to expand the excavation diameter of the shield tunneling machine; S20, correspondingly replacing a plurality of groups of hinged oil cylinders between the shield middle and the shield tail with connecting protectioncomponents with rigid structures; and S30, adding a plurality of groups of auxiliary oil cylinders connected with the shield middle and the shield tail correspondingly between the shield middle and the shield tail. Compared with the prior art, the shield escape method is ingenious in thought, convenient and efficient, the problems that during existing shield construction, due to the fact that theshield tunneling machine generates large thrust under the special working condition, the operation efficiency is low, or even tunneling is difficult are effectively solved, the problems are solved with cooperation of the method in multiple aspects, normal tunneling can be recovered within multiple rings, and therefore, the working efficiency is improved, smooth and safe construction is guaranteed,a method reference is provided for the condition that it is difficult for the shield tunneling machine to tunnel due to large thrust in the future, and high universality, good social benefits and good popularization and application prospects are achieved.

Owner:CCFEB CIVIL ENG

A method for calculating the tooth-cutting motion trajectory of a split equal-base bevel gear

ActiveCN109116803BPrecise calculation of motion trajectoryControl postureNumerical controlNumerical controlGear wheel

Provided in the invention is a method for calculating the gear cutting movement trajectory of a splitting type equal-base bevel gear wheel. On the basis of the theory of the equal-base circular-curvebevel gear wheel, a splitting type gear cutting processing coordinate system is established according to characteristics of tooth surface forming and each instantaneous cutter position attitude of thetooth surface is analyzed; calculation and coordinate conversion are carried out by a cutter axis vector and a cutter core coordinate, so that a cutter position under a wheel blank coordinate systemis obtained. Each instantaneous cutter position during gear cutting processing is calculated by combining the structural layout of a general machine tool and an installation position relationship between a split wheel blank and a machine tool; and then post-processing is carried out to obtain an expression function of a machine tool motion coordinate during numerical control gear cutting is obtained. According to the invention, a problem that processing can not be carried out when the revolution center of the split type wheel blank of the equal-base bevel gear wheel falls beyond the general numerical control machine tool and thus is not overlapped with a certain revolution axis of the machine tool is solved.

Owner:HENAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com