Sleeve cover type spaceflight rocket

A shroud and rocket technology, which is applied in the field of aerospace rockets, can solve the problems of high rocket launch costs, and achieve the effects of easy control, cost saving, and reduced launch costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

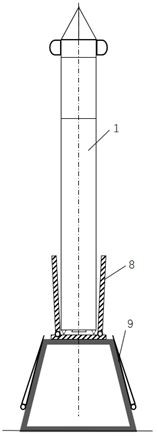

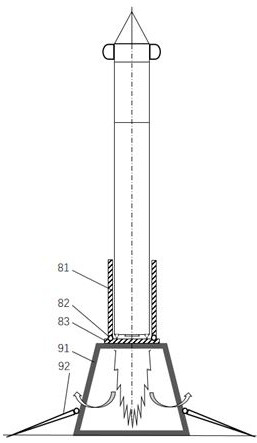

[0049] Example 1: Three "non-swing" recovery power engine solutions

[0050] Three recovery power engines are fixedly installed on the outer side of the shell section (or sleeve) of the conical top cover. The thrust of the recovery power engine is preferably 5t, and the engine and the arrow body are fixedly installed at an angle of 30° (the engine nozzles are oriented outwardly and obliquely). below), the recovery power engine and its engine nozzle do not swing, only the recovery thrust is adjusted. The rocket separation force is provided by two reverse thrust rockets symmetrically installed on the outer edge of the bottom of the first-stage rocket body. (1) Recovery power thrust function: During the ascent of the rocket, the recovery power engine starts and provides positive thrust to accelerate the rocket ascent. During the recovery process of the rocket, the recovery power engine starts to provide reverse thrust, and the rocket decelerates and descends. (2) The attitude c...

Embodiment 2

[0051] Example 2: Four "non-swing" recovery power engine solutions

[0052]Four "non-swing (that is, fixed)" recovery power engines are installed evenly around the circumference to provide rocket boost and recovery power thrust; the rocket separation force is provided by two reverse thrust rockets symmetrically installed on the outer edge of the bottom of the first-stage rocket body. Its working mechanism: (1) Attitude control function of recovery power: the thrust adjustment of two symmetrical recovery power engines controls the pitch attitude of the rocket, and the thrust adjustment of the other two recovery power engines controls the yaw attitude of the rocket (through the "pneumatic attitude control system"). control the roll attitude of the rocket). (2) Recovery power thrust function: During the ascent of the rocket, the recovery power engine starts and provides positive thrust to accelerate the rocket ascent. During the recovery process of the rocket, the recovery power...

Embodiment 3

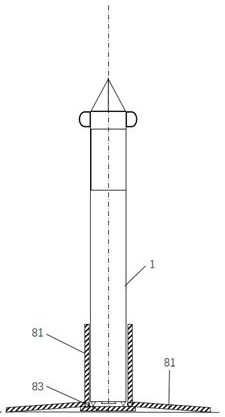

[0053] Example 3: Four "circumferential pendulum" recovery power engine scheme

[0054] Four "one-way swing" (circumferential) recovery power engines are installed evenly around the circumference to provide rocket boost, recovery power and attitude control thrust; the rocket separation force is provided by two reverse thrust rockets symmetrically installed on the outer edge of the bottom of the first-stage rocket body. Among them, the "circumferential direction" is relative to the overall columnar launch vehicle, which refers to, see Figure 2B , the engine nozzle can rotate in the direction perpendicular to the plane of the drawing with the swing mechanism as the axis. Its working mechanism: (1) Recovery power thrust function: During the rocket ascent, the recovery power engine starts, provides positive thrust, and accelerates the rocket ascent. During the recovery process of the rocket, the recovery power engine starts to provide reverse thrust, and the rocket decelerates a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com